NISSAN ALMERA TINO 2001 Service Repair Manual

ALMERA TINO 2001

NISSAN

NISSAN

https://www.carmanualsonline.info/img/5/57352/w960_57352-0.png

NISSAN ALMERA TINO 2001 Service Repair Manual

Trending: driver seat adjustment, battery replacement, service schedule, keyless entry, alternator, differential, open hood

Page 1481 of 3051

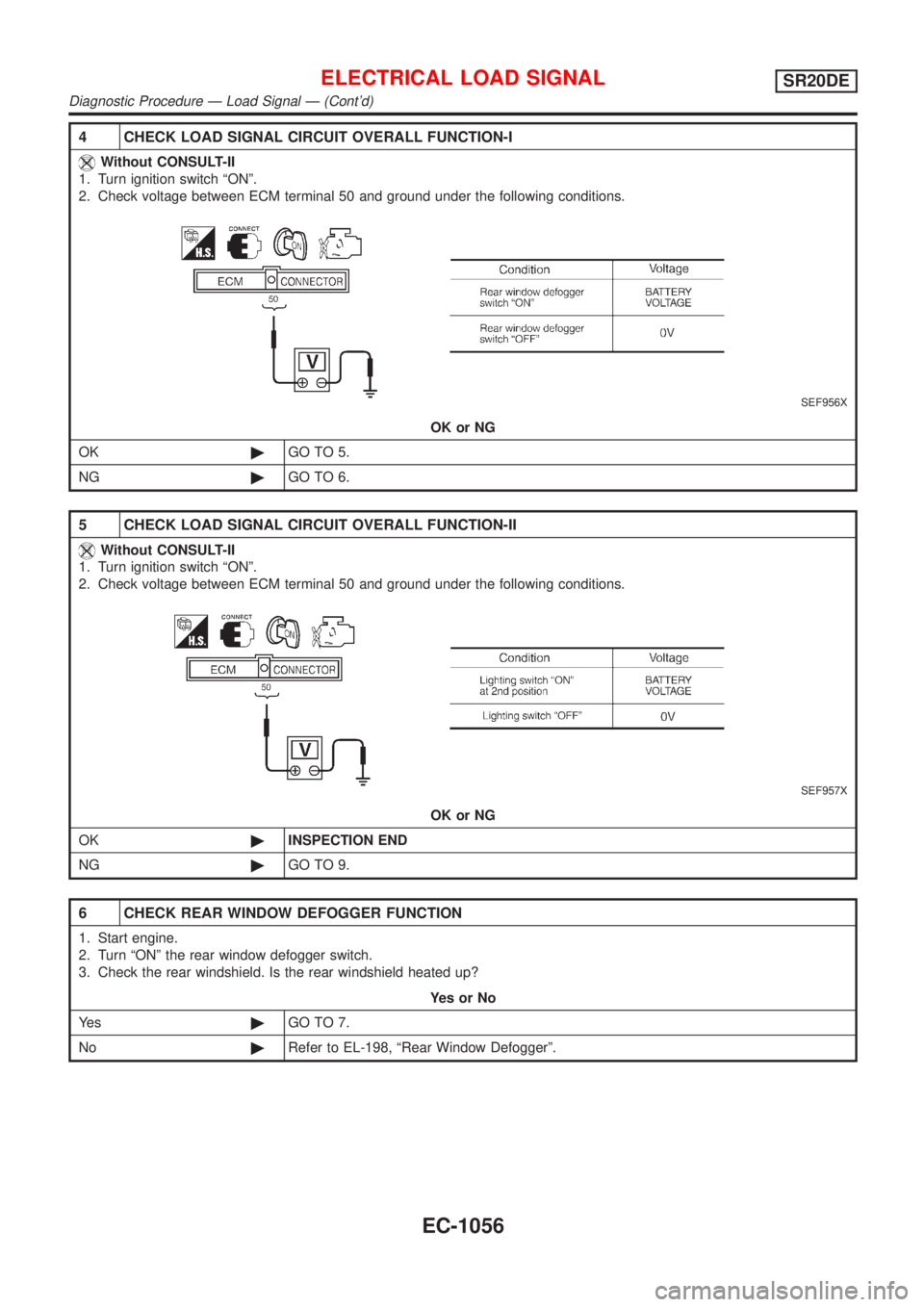

4 CHEC KLOA DSIGNA LCIRCUI TOVERAL LFUNCTION-I

Withou tCONSU LT -II

SEF956X

5 CHEC KLOA DSIGNA LCIRCUI TOVERAL LFUNCTION-II

Withou tCONSU LT -II

SEF957X

6 CHEC KREA RWINDO WDEFOGGE RFUNCTION

Diagnostic Procedure Ð Load Signal Ð (Cont'd)

Page 1482 of 3051

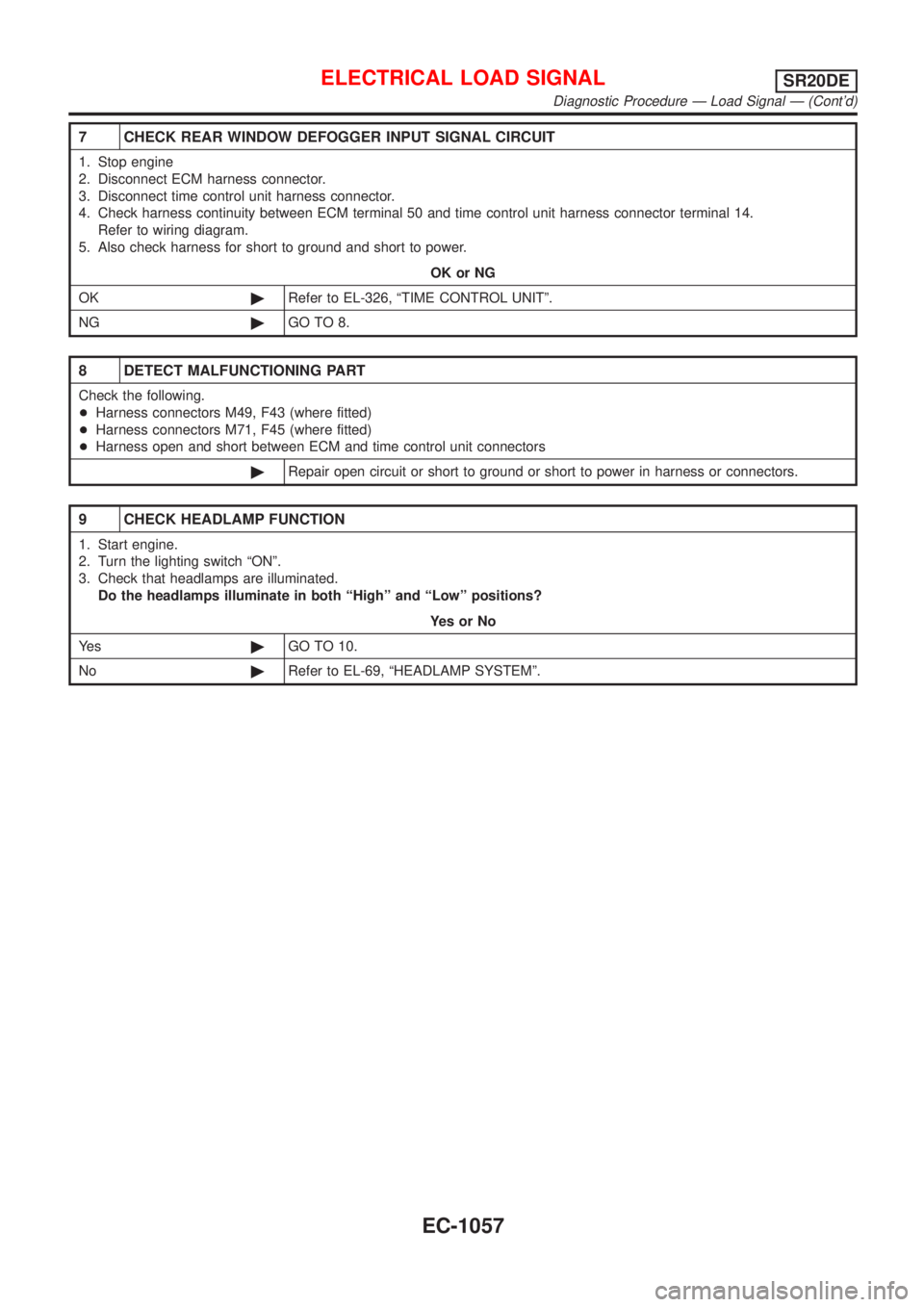

7 CHEC KREA RWINDO WDEFOGGE RINPU TSIGNA LCIRCUIT

8 DETEC TMALFUNCTIONIN GPART

9 CHEC KHEADLAM PFUNCTION

Diagnostic Procedure Ð Load Signal Ð (Cont'd)

Page 1483 of 3051

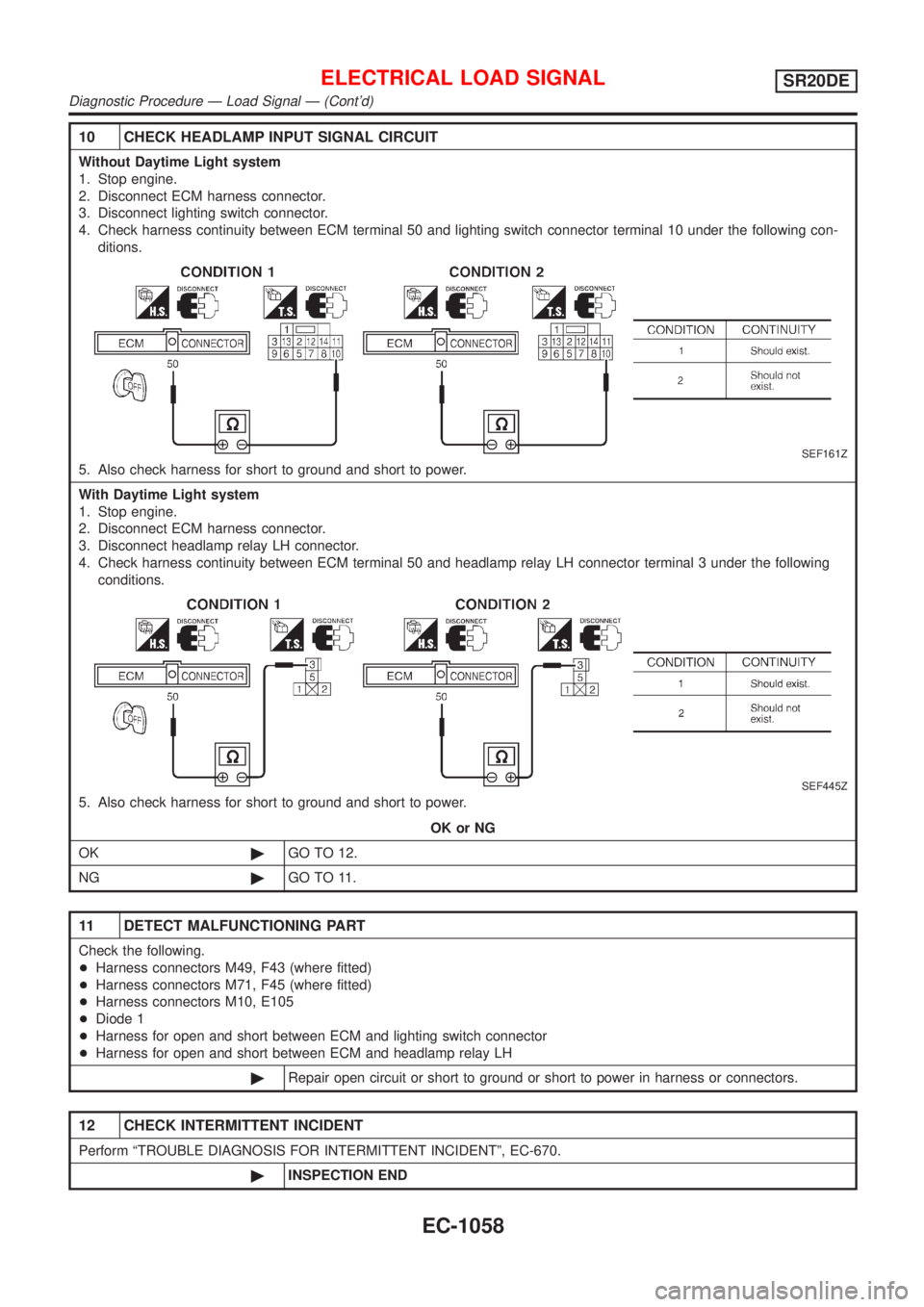

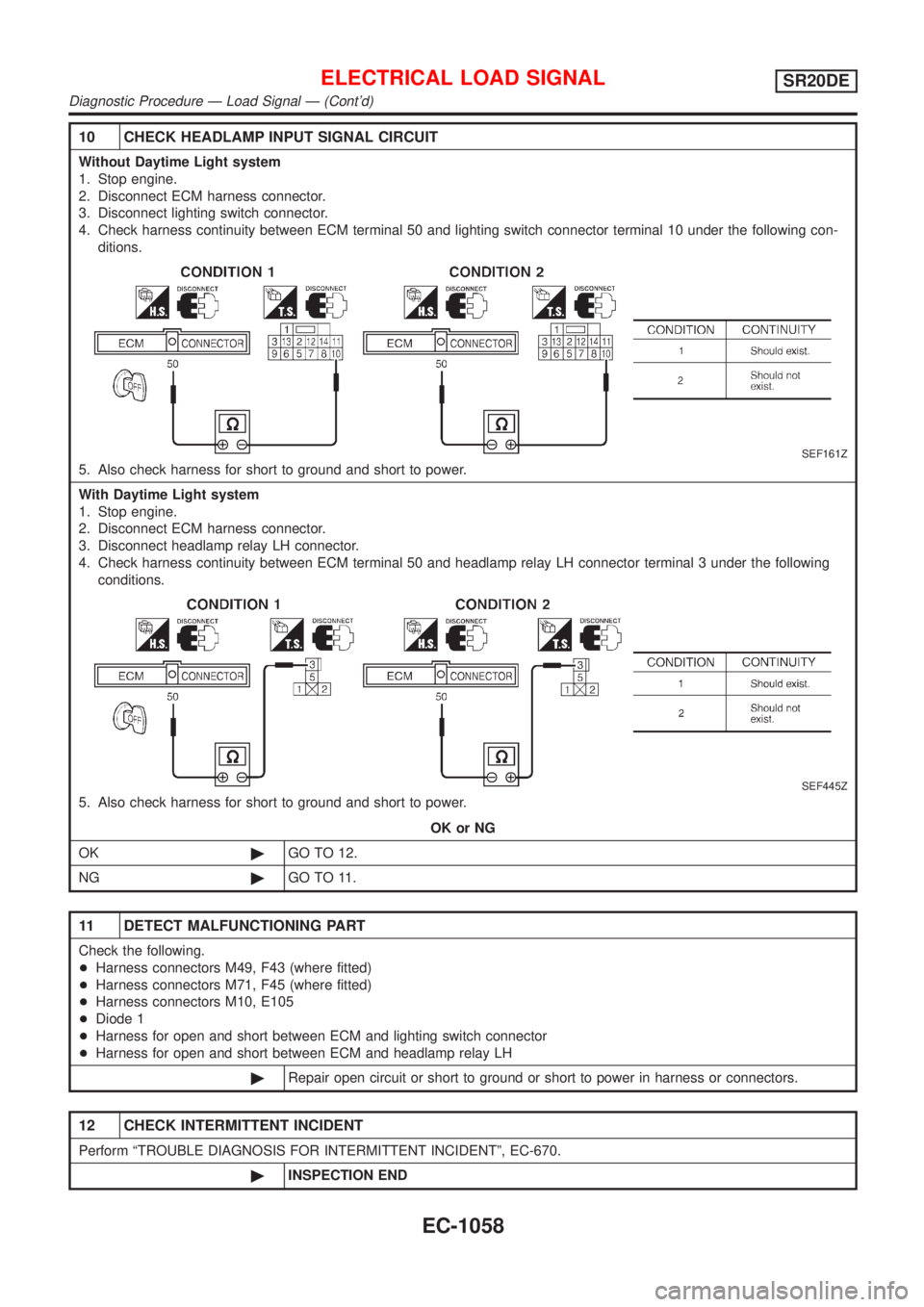

10 CHECK HEADLAMP INPUT SIGNAL CIRCUIT

Without Daytime Light system

1. Stop engine.

2. Disconnect ECM harness connector.

3. Disconnect lighting switch connector.

4. Check harness continuity between ECM terminal 50 and lighting switch connector terminal 10 under the following con-

ditions.

SEF161Z

5. Also check harness for short to ground and short to power.

With Daytime Light system

1. Stop engine.

2. Disconnect ECM harness connector.

3. Disconnect headlamp relay LH connector.

4. Check harness continuity between ECM terminal 50 and headlamp relay LH connector terminal 3 under the following

conditions.

SEF445Z

5. Also check harness for short to ground and short to power.

OK or NG

OK©GO TO 12.

NG©GO TO 11.

11 DETECT MALFUNCTIONING PART

Check the following.

+Harness connectors M49, F43 (where fitted)

+Harness connectors M71, F45 (where fitted)

+Harness connectors M10, E105

+Diode 1

+Harness for open and short between ECM and lighting switch connector

+Harness for open and short between ECM and headlamp relay LH

©Repair open circuit or short to ground or short to power in harness or connectors.

12 CHECK INTERMITTENT INCIDENT

Perform ªTROUBLE DIAGNOSIS FOR INTERMITTENT INCIDENTº, EC-670.

©INSPECTION END

ELECTRICAL LOAD SIGNALSR20DE

Diagnostic Procedure Ð Load Signal Ð (Cont'd)

EC-1058

Page 1484 of 3051

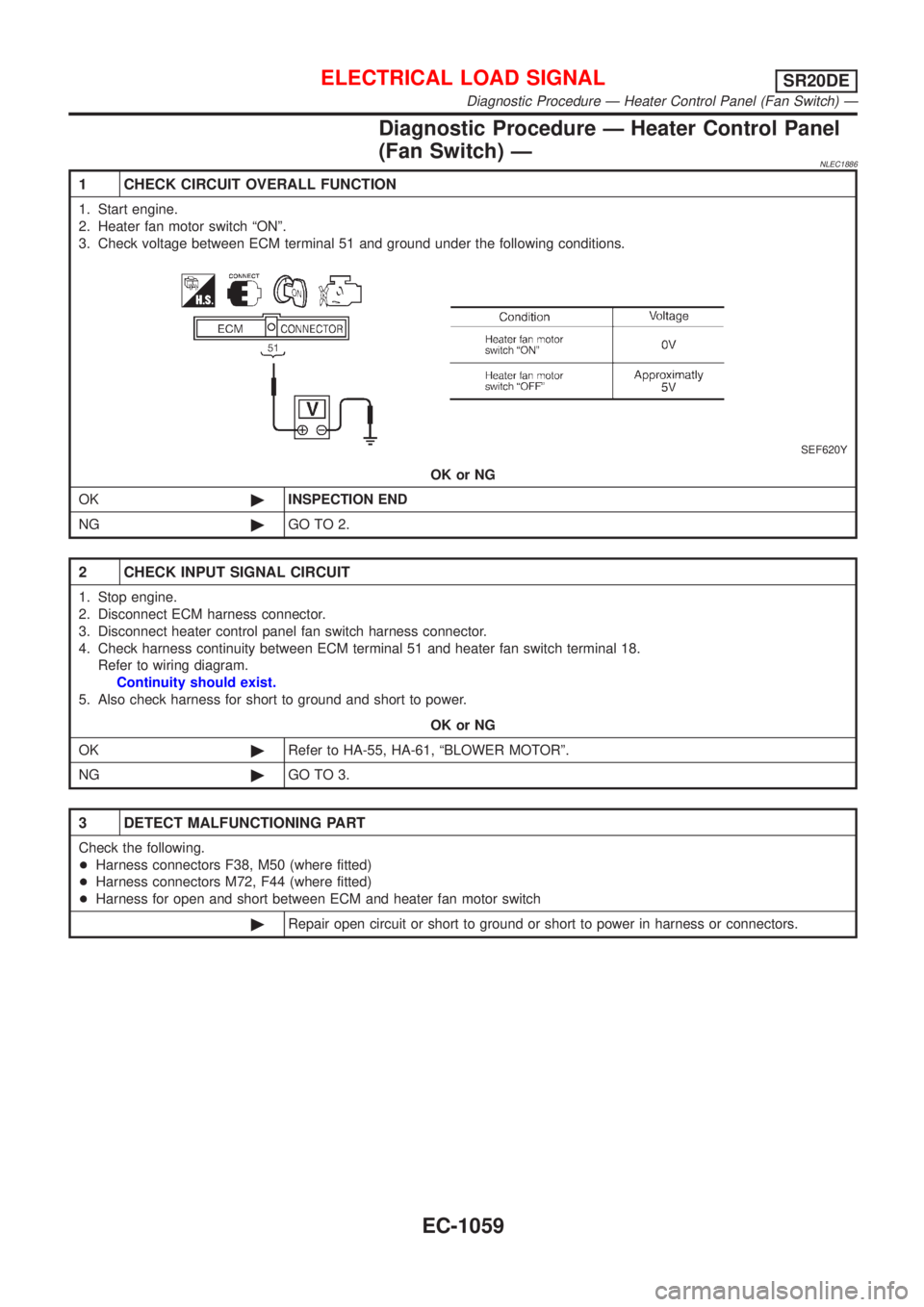

DiagnosticProcedur eÐ Heate rContro lPanel

1 CHEC KCIRCUI TOVERAL LFUNCTION

SEF620Y

2 CHEC KINPU TSIGNA LCIRCUIT

3 DETEC TMALFUNCTIONIN GPART

Diagnostic Procedure Ð Heater Control Panel (Fan Switch) Ð

Page 1485 of 3051

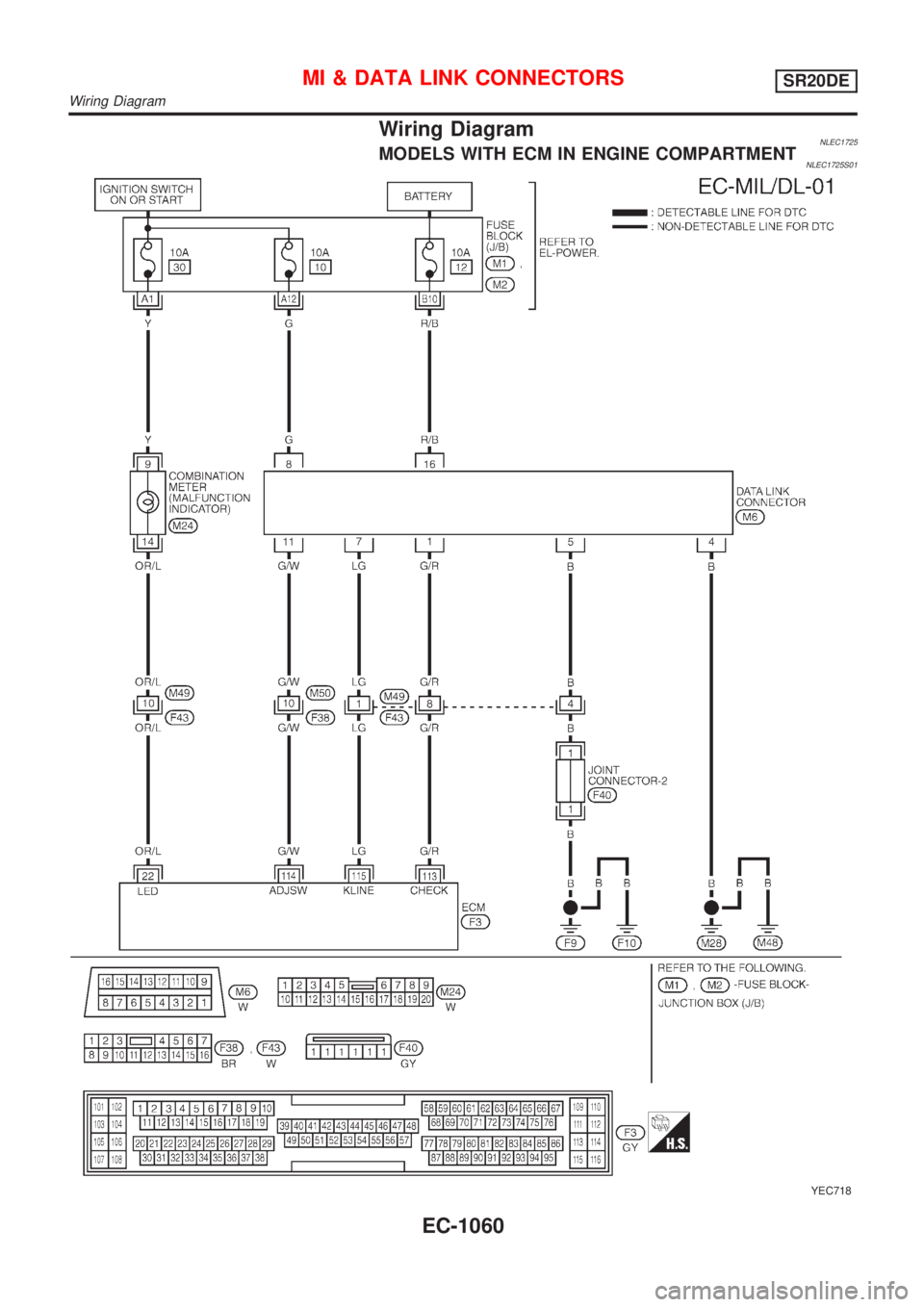

Wiring DiagramNLEC1725MODELS WITH ECM IN ENGINE COMPARTMENTNLEC1725S01

YEC718

MI & DATA LINK CONNECTORSSR20DE

Wiring Diagram

EC-1060

Page 1486 of 3051

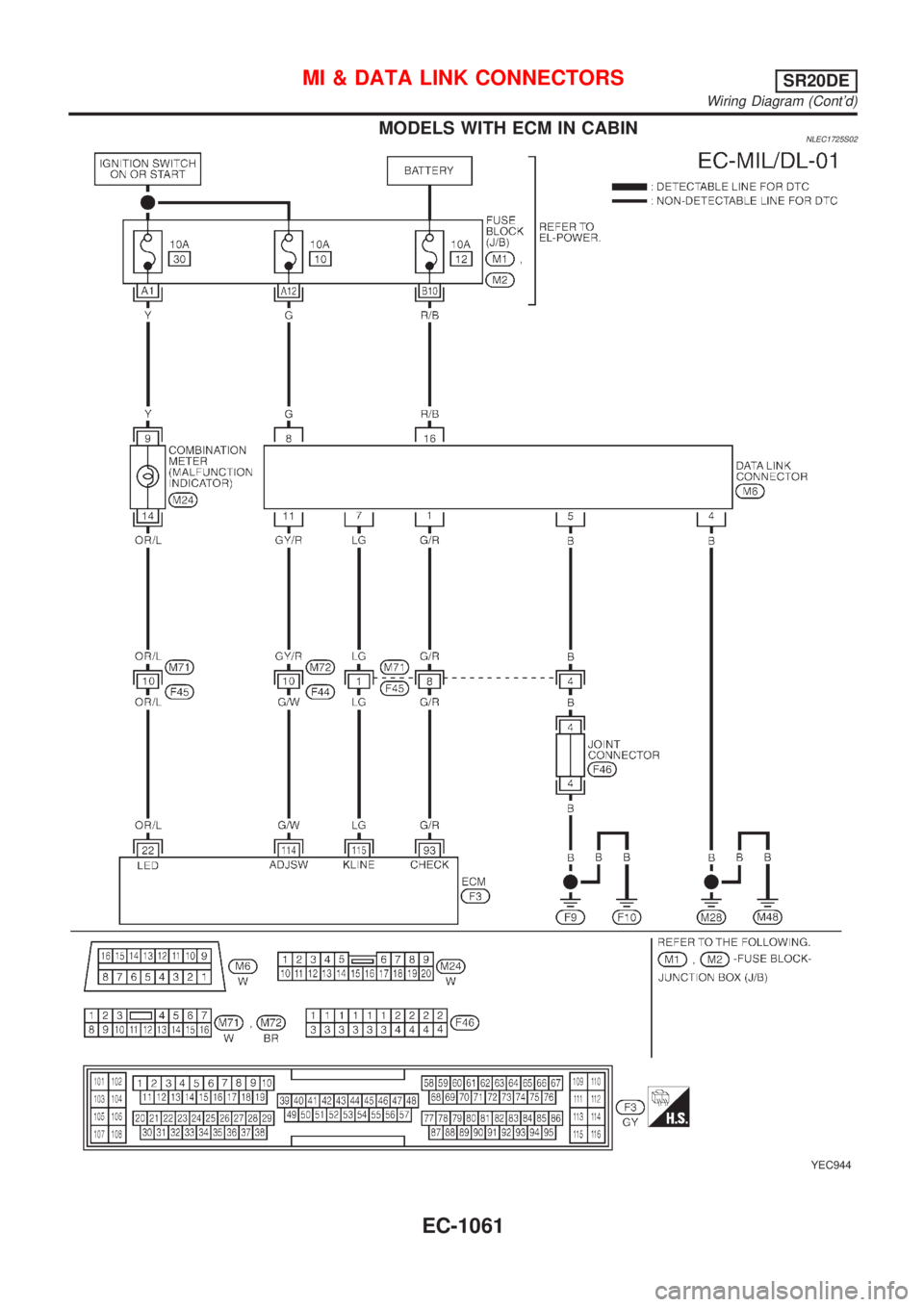

MODELS WITH ECM IN CABINNLEC1725S02

YEC944

MI & DATA LINK CONNECTORSSR20DE

Wiring Diagram (Cont'd)

EC-1061

Page 1487 of 3051

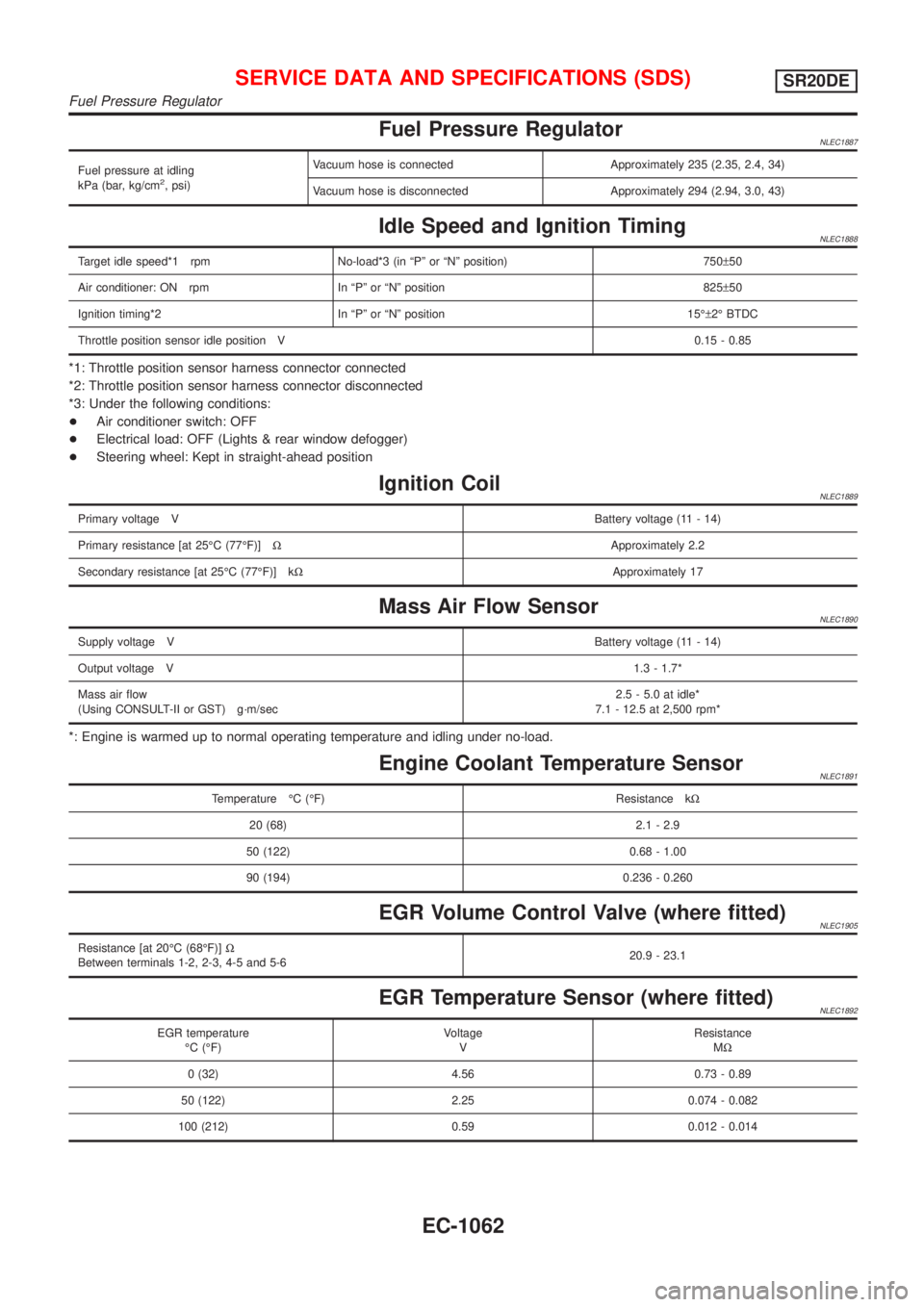

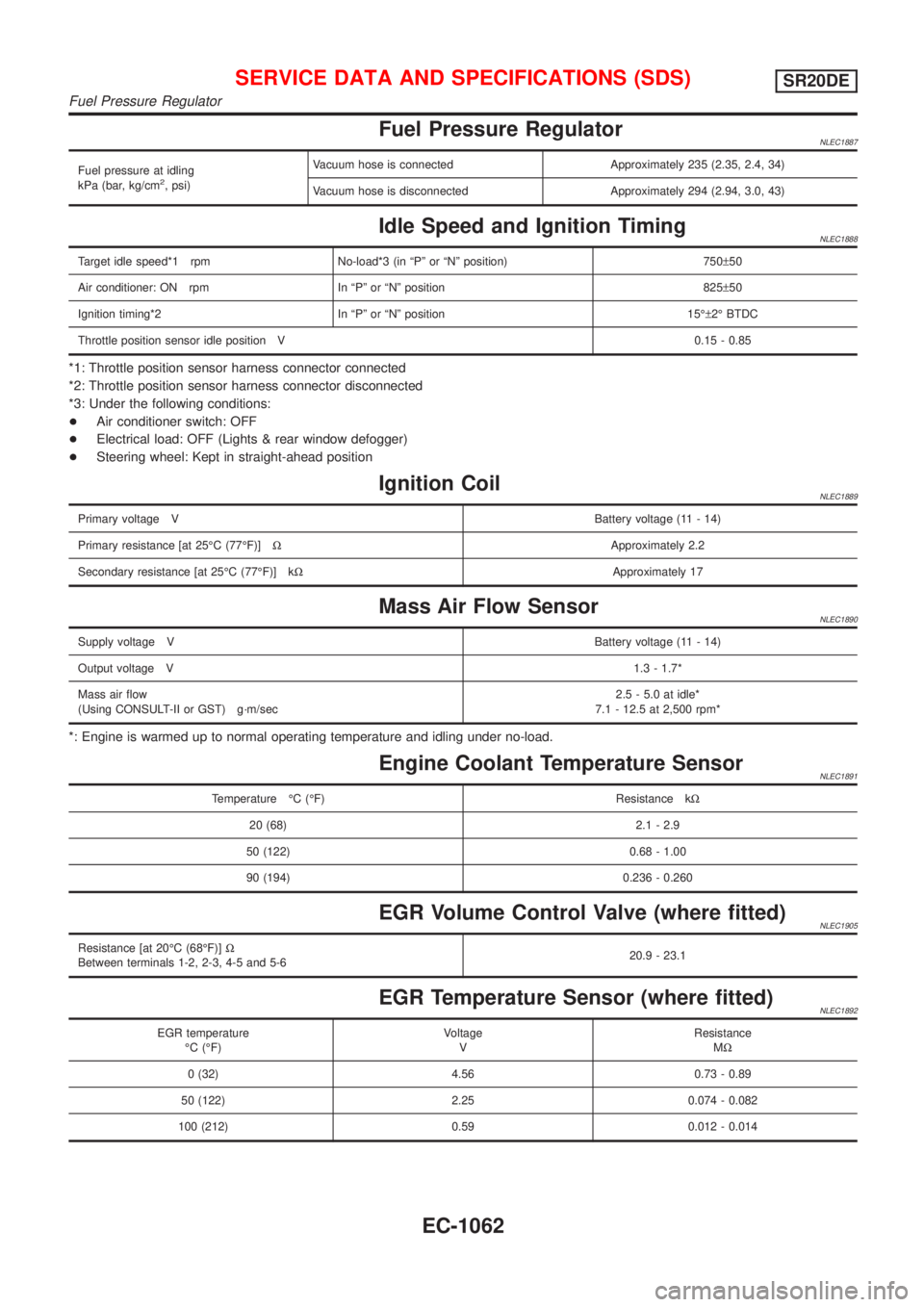

Fuel Pressure RegulatorNLEC1887

Fuel pressure at idling

kPa (bar, kg/cm2, psi)Vacuum hose is connected Approximately 235 (2.35, 2.4, 34)

Vacuum hose is disconnected Approximately 294 (2.94, 3.0, 43)

Idle Speed and Ignition TimingNLEC1888

Target idle speed*1 rpm No-load*3 (in ªPº or ªNº position) 750±50

Air conditioner: ON rpm In ªPº or ªNº position 825±50

Ignition timing*2 In ªPº or ªNº position 15ɱ2É BTDC

Throttle position sensor idle position V0.15 - 0.85

*1: Throttle position sensor harness connector connected

*2: Throttle position sensor harness connector disconnected

*3: Under the following conditions:

+Air conditioner switch: OFF

+Electrical load: OFF (Lights & rear window defogger)

+Steering wheel: Kept in straight-ahead position

Ignition CoilNLEC1889

Primary voltage VBattery voltage (11 - 14)

Primary resistance [at 25ÉC (77ÉF)]WApproximately 2.2

Secondary resistance [at 25ÉC (77ÉF)] kWApproximately 17

Mass Air Flow SensorNLEC1890

Supply voltage VBattery voltage (11 - 14)

Output voltage V1.3 - 1.7*

Mass air flow

(Using CONSULT-II or GST) g´m/sec2.5 - 5.0 at idle*

7.1 - 12.5 at 2,500 rpm*

*: Engine is warmed up to normal operating temperature and idling under no-load.

Engine Coolant Temperature SensorNLEC1891

Temperature ÉC (ÉF) Resistance kW

20 (68) 2.1 - 2.9

50 (122) 0.68 - 1.00

90 (194) 0.236 - 0.260

EGR Volume Control Valve (where fitted)NLEC1905

Resistance [at 20ÉC (68ÉF)]W

Between terminals 1-2, 2-3, 4-5 and 5-620.9 - 23.1

EGR Temperature Sensor (where fitted)NLEC1892

EGR temperature

ÉC (ÉF)Voltage

VResistance

MW

0 (32) 4.56 0.73 - 0.89

50 (122) 2.25 0.074 - 0.082

100 (212) 0.59 0.012 - 0.014

SERVICE DATA AND SPECIFICATIONS (SDS)SR20DE

Fuel Pressure Regulator

EC-1062

Page 1488 of 3051

![NISSAN ALMERA TINO 2001 Service Repair Manual Fuel PumpNLEC1893

Resistance [at 25ÉC (77ÉF)]W0.2 - 5.0

IACV-AAC ValveNLEC1894

Resistance [at 20ÉC (68ÉF)]W20±24

InjectorNLEC1895

Resistance [at 20ÉC (68ÉF)]W13.1 ± 16.0

ResistorNLEC1896

Resis NISSAN ALMERA TINO 2001 Service Repair Manual Fuel PumpNLEC1893

Resistance [at 25ÉC (77ÉF)]W0.2 - 5.0

IACV-AAC ValveNLEC1894

Resistance [at 20ÉC (68ÉF)]W20±24

InjectorNLEC1895

Resistance [at 20ÉC (68ÉF)]W13.1 ± 16.0

ResistorNLEC1896

Resis](/img/5/57352/w960_57352-1487.png)

Fuel PumpNLEC1893

Resistance [at 25ÉC (77ÉF)]W0.2 - 5.0

IACV-AAC ValveNLEC1894

Resistance [at 20ÉC (68ÉF)]W20±24

InjectorNLEC1895

Resistance [at 20ÉC (68ÉF)]W13.1 ± 16.0

ResistorNLEC1896

Resistance [at 25ÉC (77ÉF)] kWApproximately 5

Throttle Position SensorNLEC1897

Throttle valve conditionsVoltage (at normal operating temperature, engine off, ignition switch ON,

throttle opener disengaged)

Completely closed (a)0.15 - 0.85V

Partially openBetween (a) and (b)

Completely open (b)3.5 - 4.7V

Heated Oxygen Sensor 1 (Front) HeaterNLEC1898

Resistance [at 25ÉC (77ÉF)]W2.3 - 4.3

Intake Air Temperature SensorNLEC1900

Temperature ÉC (ÉF) Resistance kW

20 (68) 2.1 - 2.9

80 (176) 0.27 - 0.38

EVAP Canister Purge Volume Control ValveNLEC1901

Resistance [at 20ÉC (68ÉF)]W31-35

Heated Oxygen Sensor 2 (Rear) HeaterNLEC1902

Resistance [at 25ÉC (77ÉF)]W2.3 - 4.3

Crankshaft Position Sensor (OBD)NLEC1903

Resistance [at 20ÉC (68ÉF)]W166 - 204

SERVICE DATA AND SPECIFICATIONS (SDS)SR20DE

Fuel Pump

EC-1063

Page 1489 of 3051

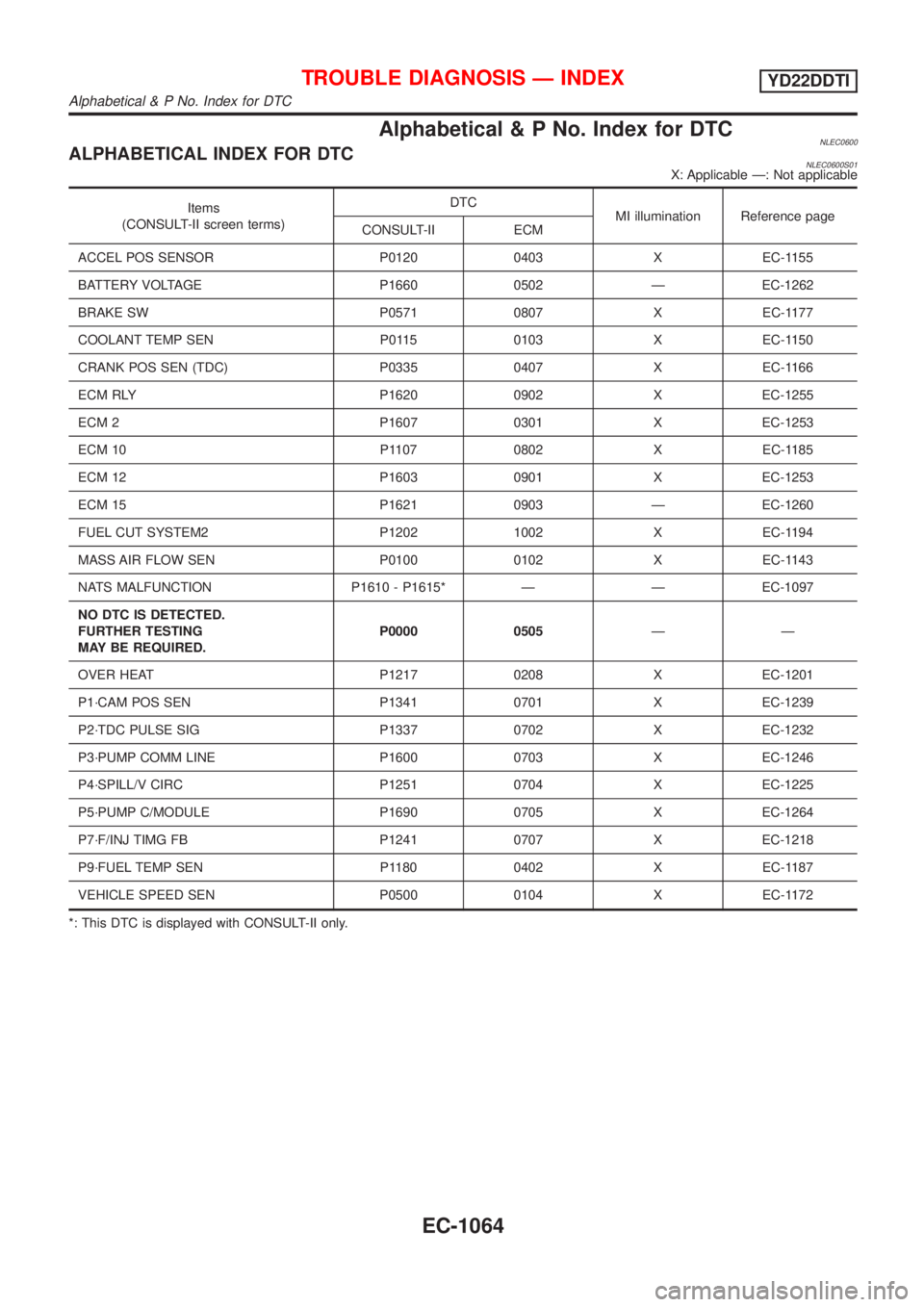

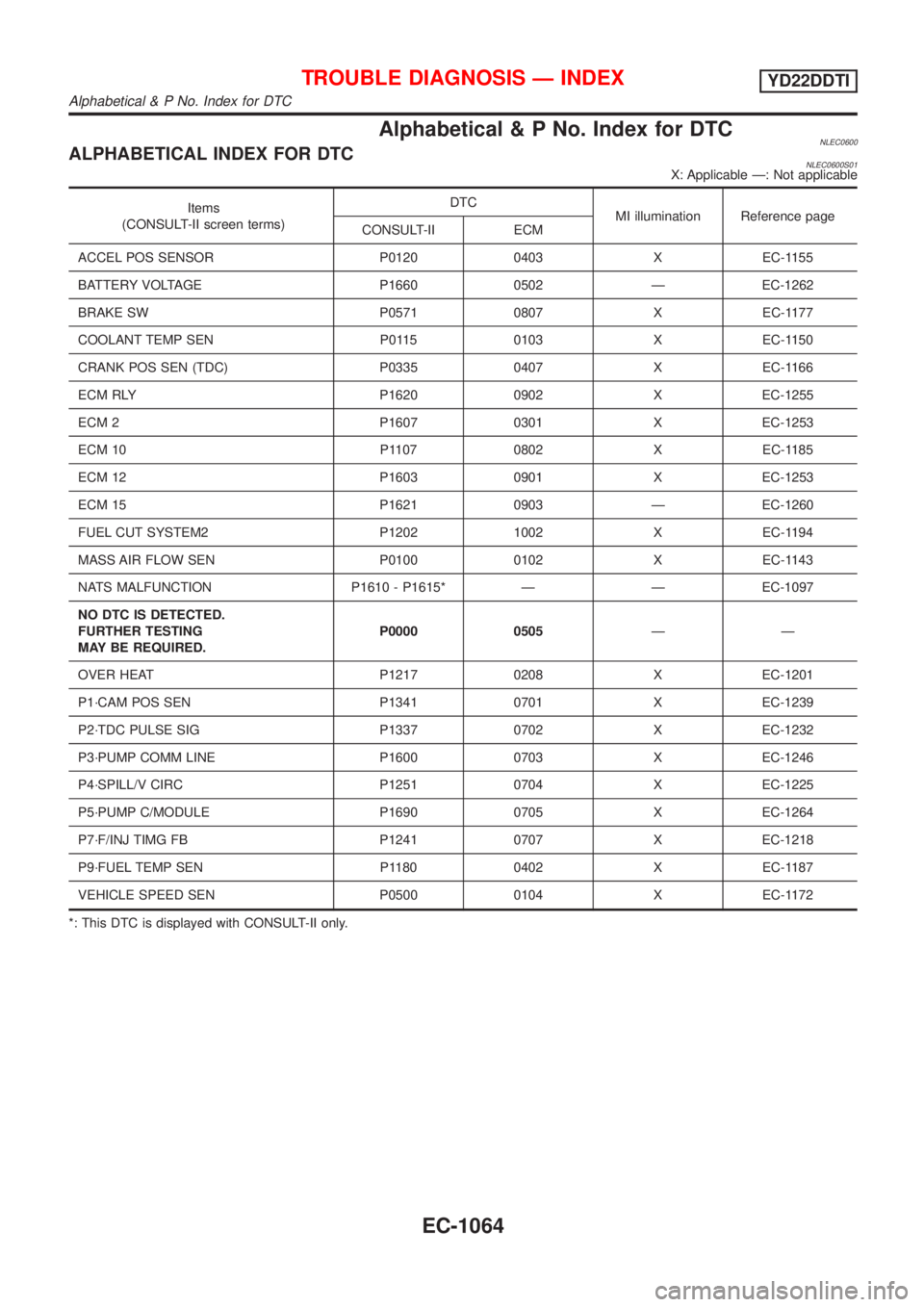

Alphabetical & P No. Index for DTCNLEC0600ALPHABETICAL INDEX FOR DTCNLEC0600S01X: Applicable Ð: Not applicable

Items

(CONSULT-II screen terms)DTC

MI illumination Reference page

CONSULT-II ECM

ACCEL POS SENSOR P0120 0403 X EC-1155

BATTERY VOLTAGE P1660 0502 Ð EC-1262

BRAKE SW P0571 0807 X EC-1177

COOLANT TEMP SEN P0115 0103 X EC-1150

CRANK POS SEN (TDC) P0335 0407 X EC-1166

ECM RLY P1620 0902 X EC-1255

ECM 2 P1607 0301 X EC-1253

ECM 10 P1107 0802 X EC-1185

ECM 12 P1603 0901 X EC-1253

ECM 15 P1621 0903 Ð EC-1260

FUEL CUT SYSTEM2 P1202 1002 X EC-1194

MASS AIR FLOW SEN P0100 0102 X EC-1143

NATS MALFUNCTION P1610 - P1615* Ð Ð EC-1097

NO DTC IS DETECTED.

FURTHER TESTING

MAY BE REQUIRED.P0000 0505ÐÐ

OVER HEAT P1217 0208 X EC-1201

P1´CAM POS SEN P1341 0701 X EC-1239

P2´TDC PULSE SIG P1337 0702 X EC-1232

P3´PUMP COMM LINE P1600 0703 X EC-1246

P4´SPILL/V CIRC P1251 0704 X EC-1225

P5´PUMP C/MODULE P1690 0705 X EC-1264

P7´F/INJ TIMG FB P1241 0707 X EC-1218

P9´FUEL TEMP SEN P1180 0402 X EC-1187

VEHICLE SPEED SEN P0500 0104 X EC-1172

*: This DTC is displayed with CONSULT-II only.

TROUBLE DIAGNOSIS Ð INDEXYD22DDTI

Alphabetical & P No. Index for DTC

EC-1064

Page 1490 of 3051

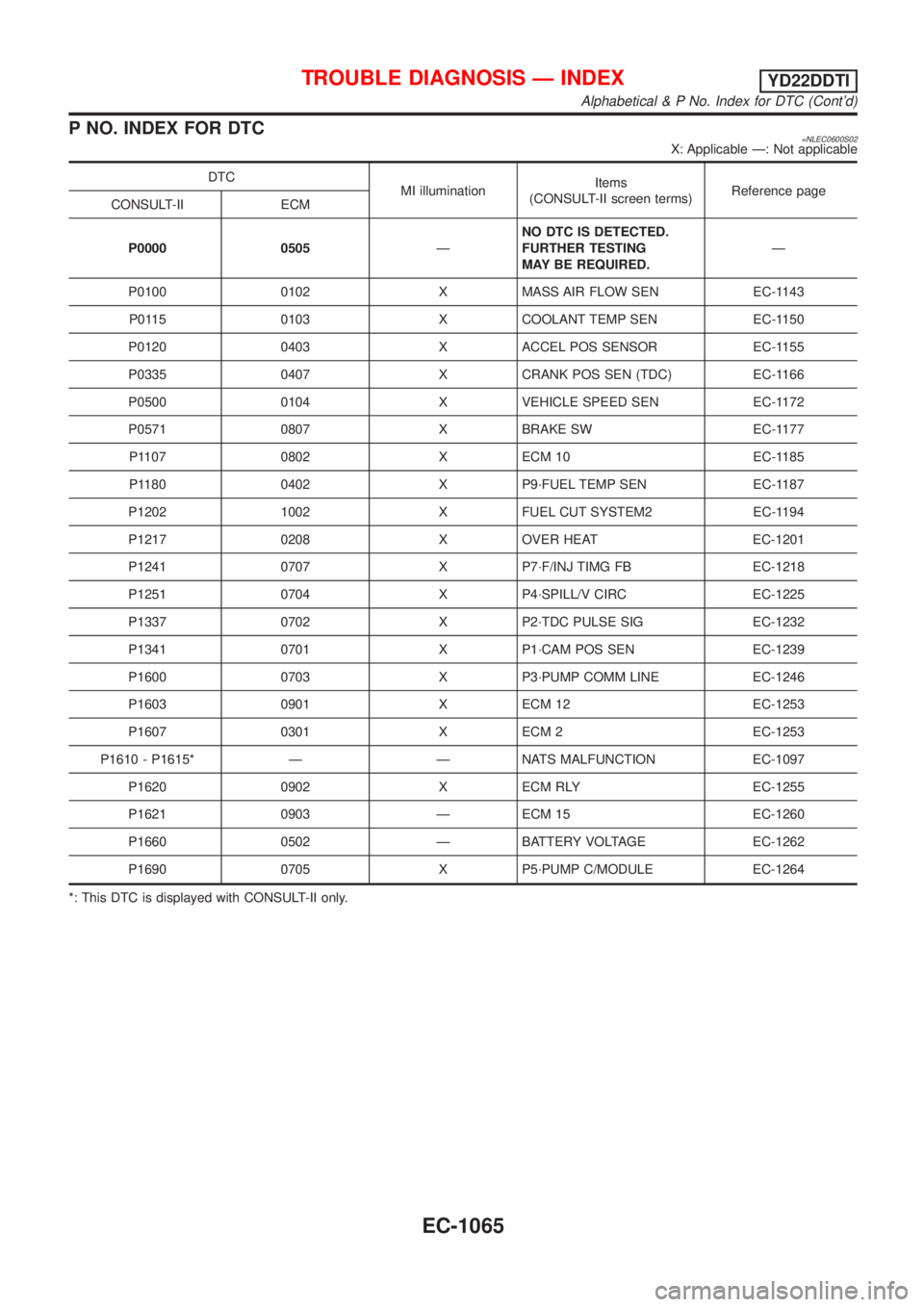

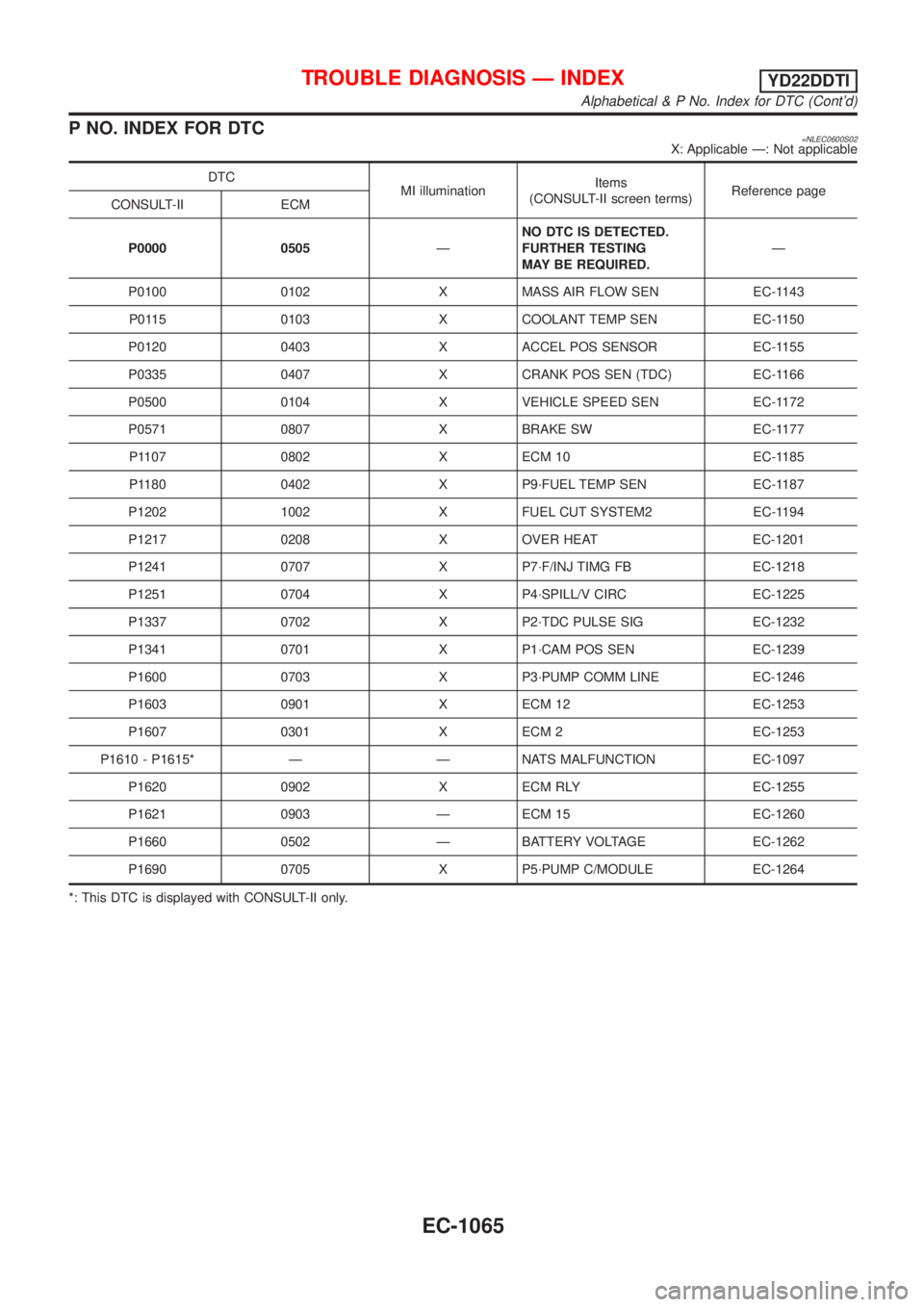

P NO. INDEX FOR DTC=NLEC0600S02X: Applicable Ð: Not applicable

DTC

MI illuminationItems

(CONSULT-II screen terms)Reference page

CONSULT-II ECM

P0000 0505ÐNO DTC IS DETECTED.

FURTHER TESTING

MAY BE REQUIRED.Ð

P0100 0102 X MASS AIR FLOW SEN EC-1143

P0115 0103 X COOLANT TEMP SEN EC-1150

P0120 0403 X ACCEL POS SENSOR EC-1155

P0335 0407 X CRANK POS SEN (TDC) EC-1166

P0500 0104 X VEHICLE SPEED SEN EC-1172

P0571 0807 X BRAKE SW EC-1177

P1107 0802 X ECM 10 EC-1185

P1180 0402 X P9´FUEL TEMP SEN EC-1187

P1202 1002 X FUEL CUT SYSTEM2 EC-1194

P1217 0208 X OVER HEAT EC-1201

P1241 0707 X P7´F/INJ TIMG FB EC-1218

P1251 0704 X P4´SPILL/V CIRC EC-1225

P1337 0702 X P2´TDC PULSE SIG EC-1232

P1341 0701 X P1´CAM POS SEN EC-1239

P1600 0703 X P3´PUMP COMM LINE EC-1246

P1603 0901 X ECM 12 EC-1253

P1607 0301 X ECM 2 EC-1253

P1610 - P1615* Ð Ð NATS MALFUNCTION EC-1097

P1620 0902 X ECM RLY EC-1255

P1621 0903 Ð ECM 15 EC-1260

P1660 0502 Ð BATTERY VOLTAGE EC-1262

P1690 0705 X P5´PUMP C/MODULE EC-1264

*: This DTC is displayed with CONSULT-II only.

TROUBLE DIAGNOSIS Ð INDEXYD22DDTI

Alphabetical & P No. Index for DTC (Cont'd)

EC-1065

Trending: clutch, navigation, airbag off, BT-1, steering, differential, stop start

![NISSAN ALMERA TINO 2001 Service Repair Manual Fuel PumpNLEC1893

Resistance [at 25ÉC (77ÉF)]W0.2 - 5.0

IACV-AAC ValveNLEC1894

Resistance [at 20ÉC (68ÉF)]W20±24

InjectorNLEC1895

Resistance [at 20ÉC (68ÉF)]W13.1 ± 16.0

ResistorNLEC1896

Resis NISSAN ALMERA TINO 2001 Service Repair Manual Fuel PumpNLEC1893

Resistance [at 25ÉC (77ÉF)]W0.2 - 5.0

IACV-AAC ValveNLEC1894

Resistance [at 20ÉC (68ÉF)]W20±24

InjectorNLEC1895

Resistance [at 20ÉC (68ÉF)]W13.1 ± 16.0

ResistorNLEC1896

Resis](/img/5/57352/w960_57352-1487.png)