NISSAN ALMERA TINO 2001 Service Repair Manual

ALMERA TINO 2001

NISSAN

NISSAN

https://www.carmanualsonline.info/img/5/57352/w960_57352-0.png

NISSAN ALMERA TINO 2001 Service Repair Manual

Trending: air suspension, BT-22, maintenance, jacking points, fuel tank removal, fuel filter, warning light

Page 1491 of 3051

Precautions for Supplemental Restraint System

(SRS) ªAIR BAGº and ªSEAT BELT

PRE-TENSIONERº

NLEC1263The Supplemental Restraint System ªAIR BAGº and ªSEAT BELT PRE-TENSIONERº, used along with a seat

belt, help to reduce the risk or severity of injury to the driver and front passenger in a frontal collision. The

Supplemental Restraint System consists of air bag modules (located in the center of the steering wheel and

on the instrument panel on the passenger side), seat belt pre-tensioners, a diagnosis sensor unit, warning

lamp, wiring harness and spiral cable.

In addition to the supplemental air bag modules for a frontal collision, the supplemental side air bag used along

with the seat belt helps to reduce the risk or severity of injury to the driver and front passenger in a side col-

lision. The supplemental side air bag consists of air bag modules (located in the outer side of front seats),

satellite sensor, diagnosis sensor unit (one of components of supplemental air bags for a frontal collision),

wiring harness, warning lamp (one of components of supplemental air bags for a frontal collision). Information

necessary to service the system safely is included in theRS sectionof this Service Manual.

WARNING:

+To avoid rendering the SRS inoperative, which could increase the risk of personal injury or death

in the event of a collision which would result in air bag inflation, all maintenance must be performed

by an authorized NISSAN dealer.

+Improper maintenance, including incorrect removal and installation of the SRS, can lead to per-

sonal injury caused by unintentional activation of the system.

+Do not use electrical test equipment on any circuit related to the SRS unless instructed to in this

Service Manual. SRS wiring harnesses can be identified with yellow harness connector (and with

yellow harness protector or yellow insulation tape before the harness connectors).

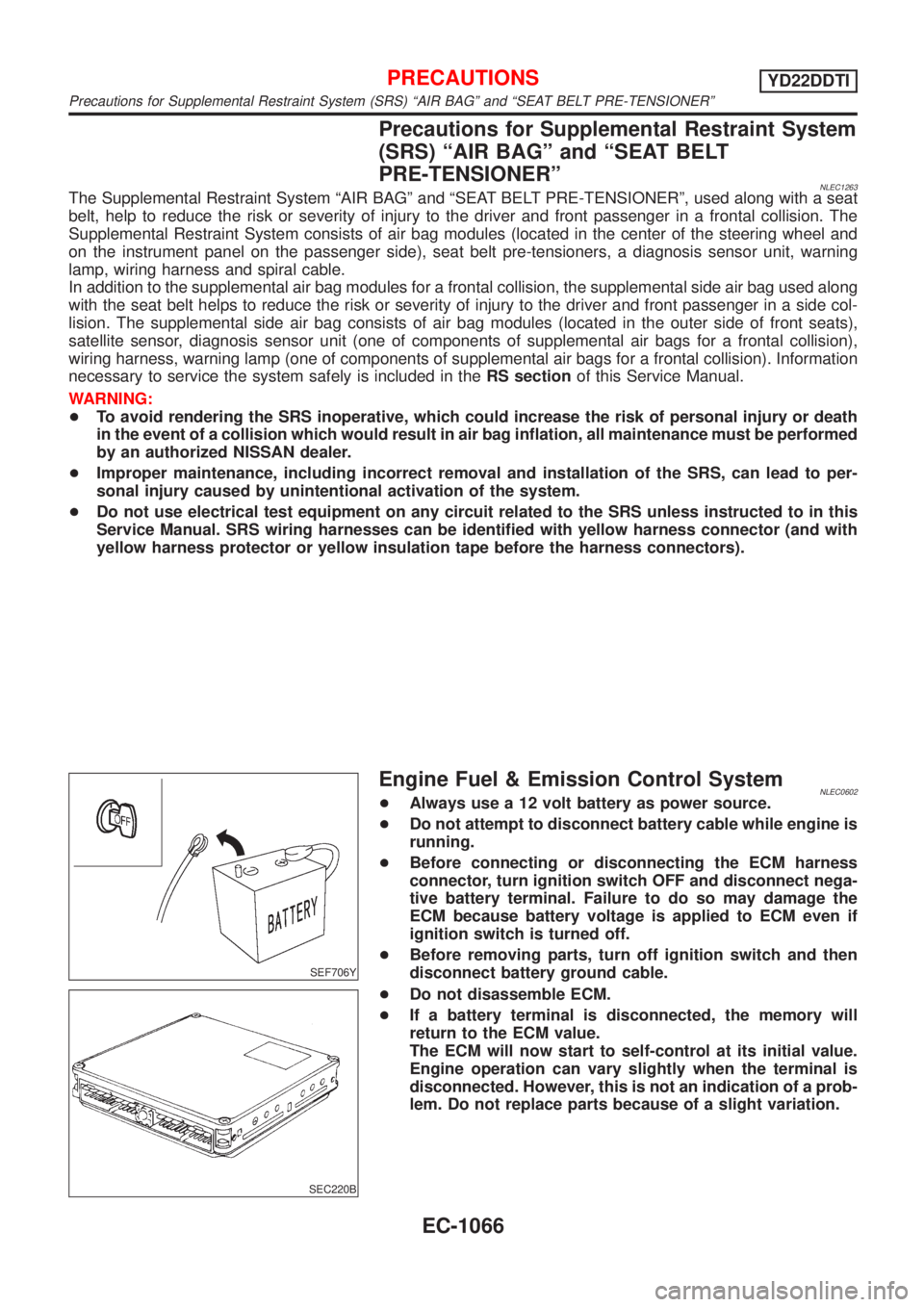

SEF706Y

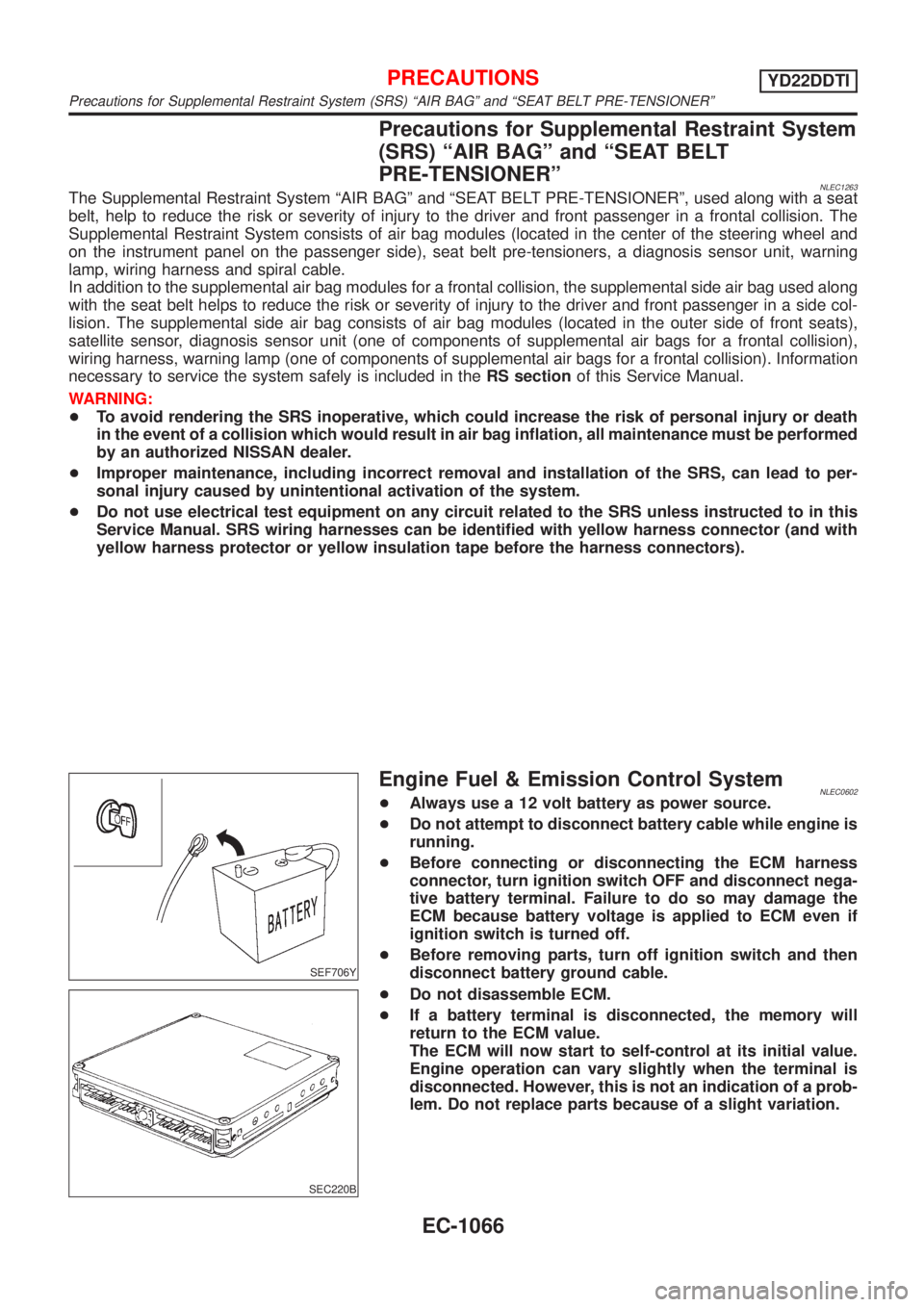

Engine Fuel & Emission Control SystemNLEC0602+Always use a 12 volt battery as power source.

+Do not attempt to disconnect battery cable while engine is

running.

+Before connecting or disconnecting the ECM harness

connector, turn ignition switch OFF and disconnect nega-

tive battery terminal. Failure to do so may damage the

ECM because battery voltage is applied to ECM even if

ignition switch is turned off.

+Before removing parts, turn off ignition switch and then

disconnect battery ground cable.

SEC220B

+Do not disassemble ECM.

+If a battery terminal is disconnected, the memory will

return to the ECM value.

The ECM will now start to self-control at its initial value.

Engine operation can vary slightly when the terminal is

disconnected. However, this is not an indication of a prob-

lem. Do not replace parts because of a slight variation.

PRECAUTIONSYD22DDTI

Precautions for Supplemental Restraint System (SRS) ªAIR BAGº and ªSEAT BELT PRE-TENSIONERº

EC-1066

Page 1492 of 3051

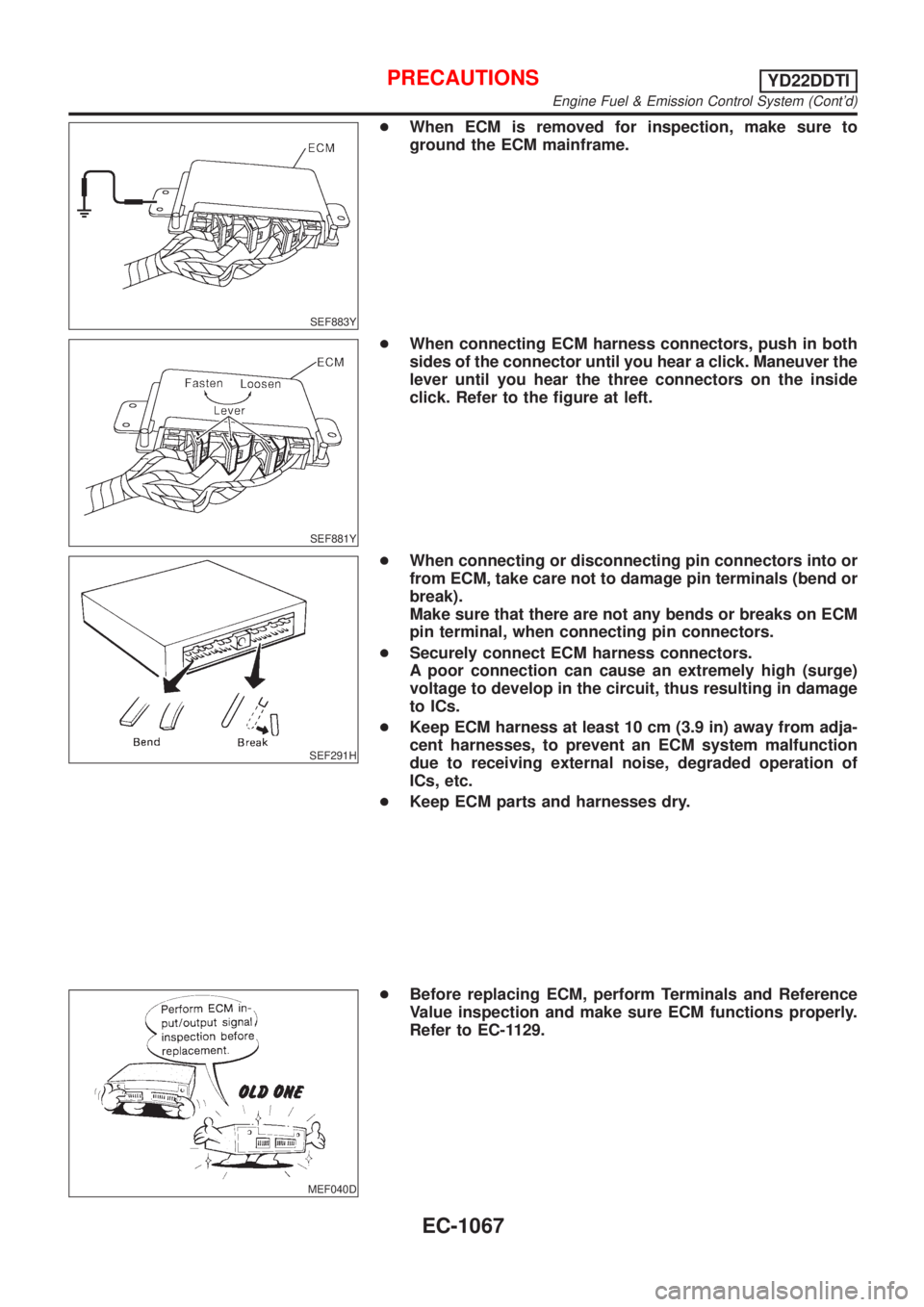

SEF883Y

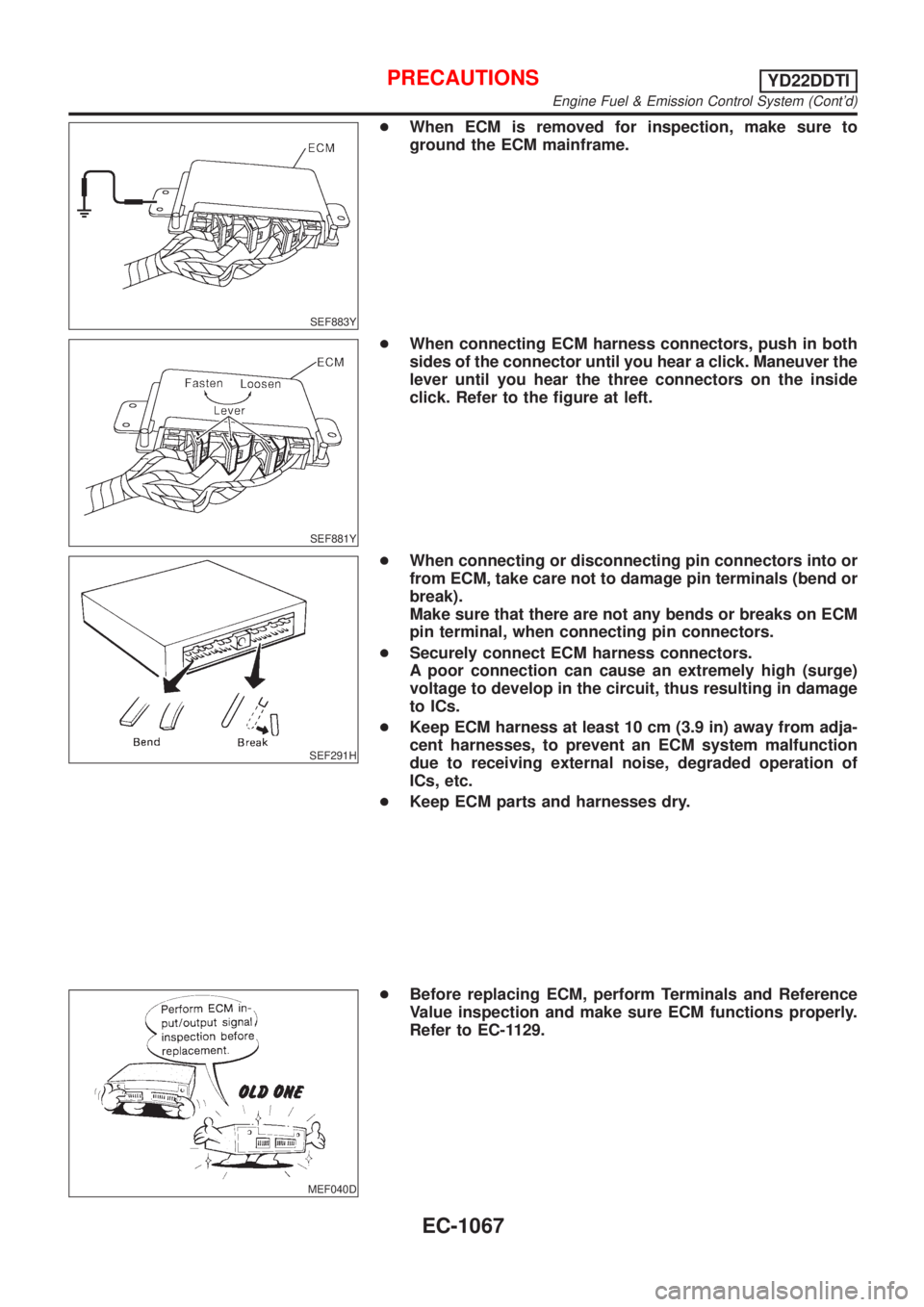

+When ECM is removed for inspection, make sure to

ground the ECM mainframe.

SEF881Y

+When connecting ECM harness connectors, push in both

sides of the connector until you hear a click. Maneuver the

lever until you hear the three connectors on the inside

click. Refer to the figure at left.

SEF291H

+When connecting or disconnecting pin connectors into or

from ECM, take care not to damage pin terminals (bend or

break).

Make sure that there are not any bends or breaks on ECM

pin terminal, when connecting pin connectors.

+Securely connect ECM harness connectors.

A poor connection can cause an extremely high (surge)

voltage to develop in the circuit, thus resulting in damage

to ICs.

+Keep ECM harness at least 10 cm (3.9 in) away from adja-

cent harnesses, to prevent an ECM system malfunction

due to receiving external noise, degraded operation of

ICs, etc.

+Keep ECM parts and harnesses dry.

MEF040D

+Before replacing ECM, perform Terminals and Reference

Value inspection and make sure ECM functions properly.

Refer to EC-1129.

PRECAUTIONSYD22DDTI

Engine Fuel & Emission Control System (Cont'd)

EC-1067

Page 1493 of 3051

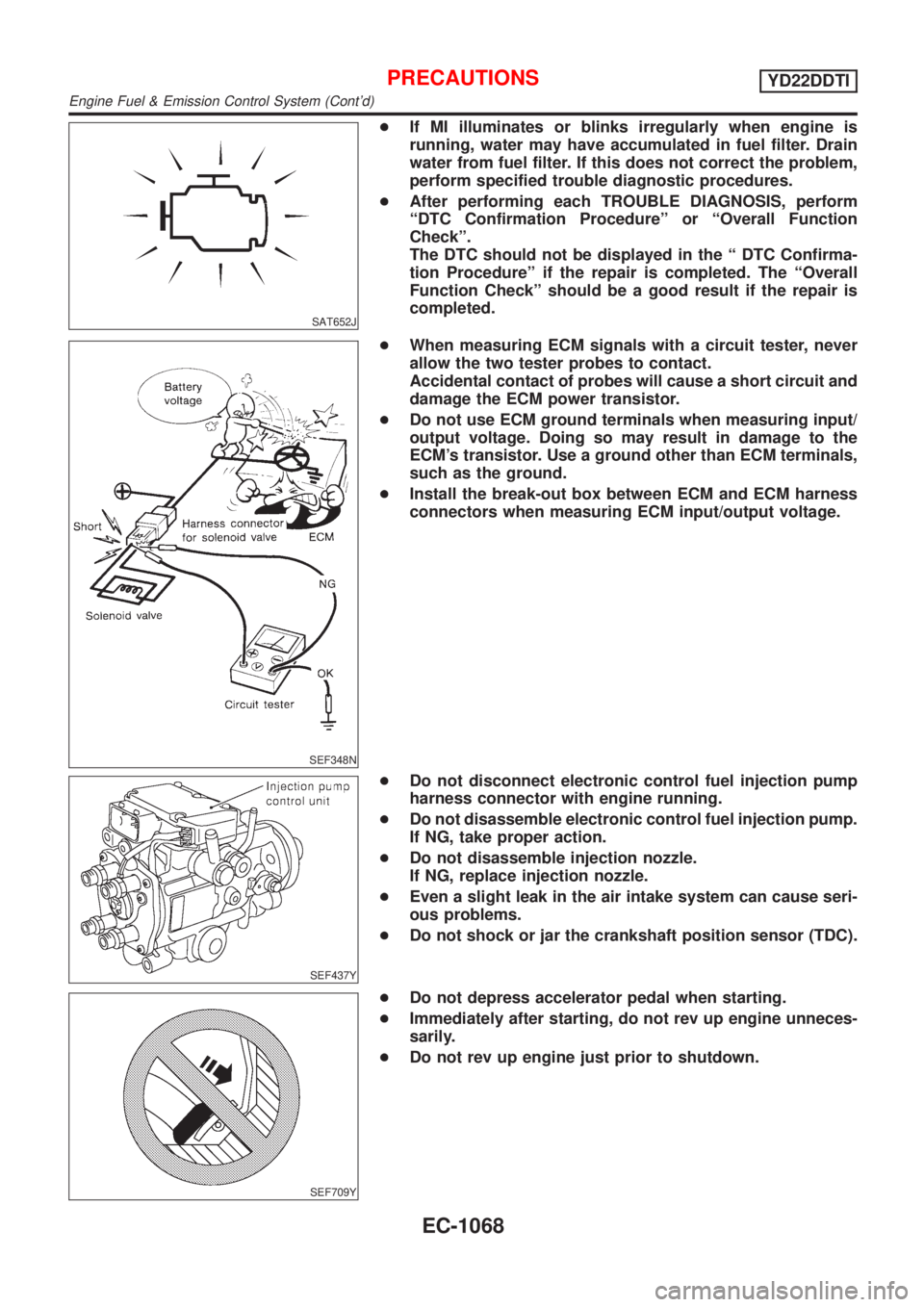

SAT652J

+If MI illuminates or blinks irregularly when engine is

running, water may have accumulated in fuel filter. Drain

water from fuel filter. If this does not correct the problem,

perform specified trouble diagnostic procedures.

+After performing each TROUBLE DIAGNOSIS, perform

ªDTC Confirmation Procedureº or ªOverall Function

Checkº.

The DTC should not be displayed in the ª DTC Confirma-

tion Procedureº if the repair is completed. The ªOverall

Function Checkº should be a good result if the repair is

completed.

SEF348N

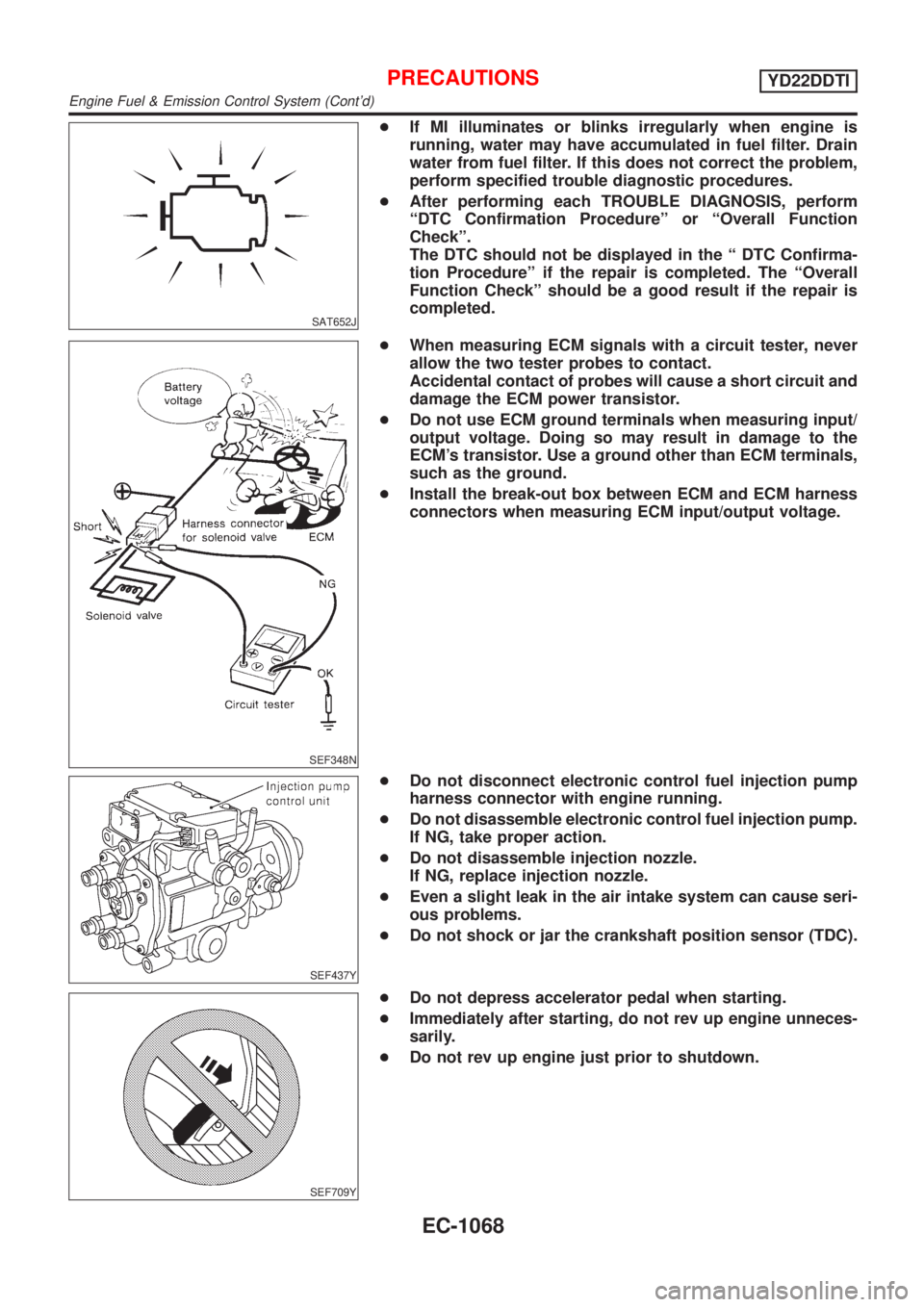

+When measuring ECM signals with a circuit tester, never

allow the two tester probes to contact.

Accidental contact of probes will cause a short circuit and

damage the ECM power transistor.

+Do not use ECM ground terminals when measuring input/

output voltage. Doing so may result in damage to the

ECM's transistor. Use a ground other than ECM terminals,

such as the ground.

+Install the break-out box between ECM and ECM harness

connectors when measuring ECM input/output voltage.

SEF437Y

+Do not disconnect electronic control fuel injection pump

harness connector with engine running.

+Do not disassemble electronic control fuel injection pump.

If NG, take proper action.

+Do not disassemble injection nozzle.

If NG, replace injection nozzle.

+Even a slight leak in the air intake system can cause seri-

ous problems.

+Do not shock or jar the crankshaft position sensor (TDC).

SEF709Y

+Do not depress accelerator pedal when starting.

+Immediately after starting, do not rev up engine unneces-

sarily.

+Do not rev up engine just prior to shutdown.

PRECAUTIONSYD22DDTI

Engine Fuel & Emission Control System (Cont'd)

EC-1068

Page 1494 of 3051

SEF708Y

Engine Fuel & Emission Control System (Cont'd)

Page 1495 of 3051

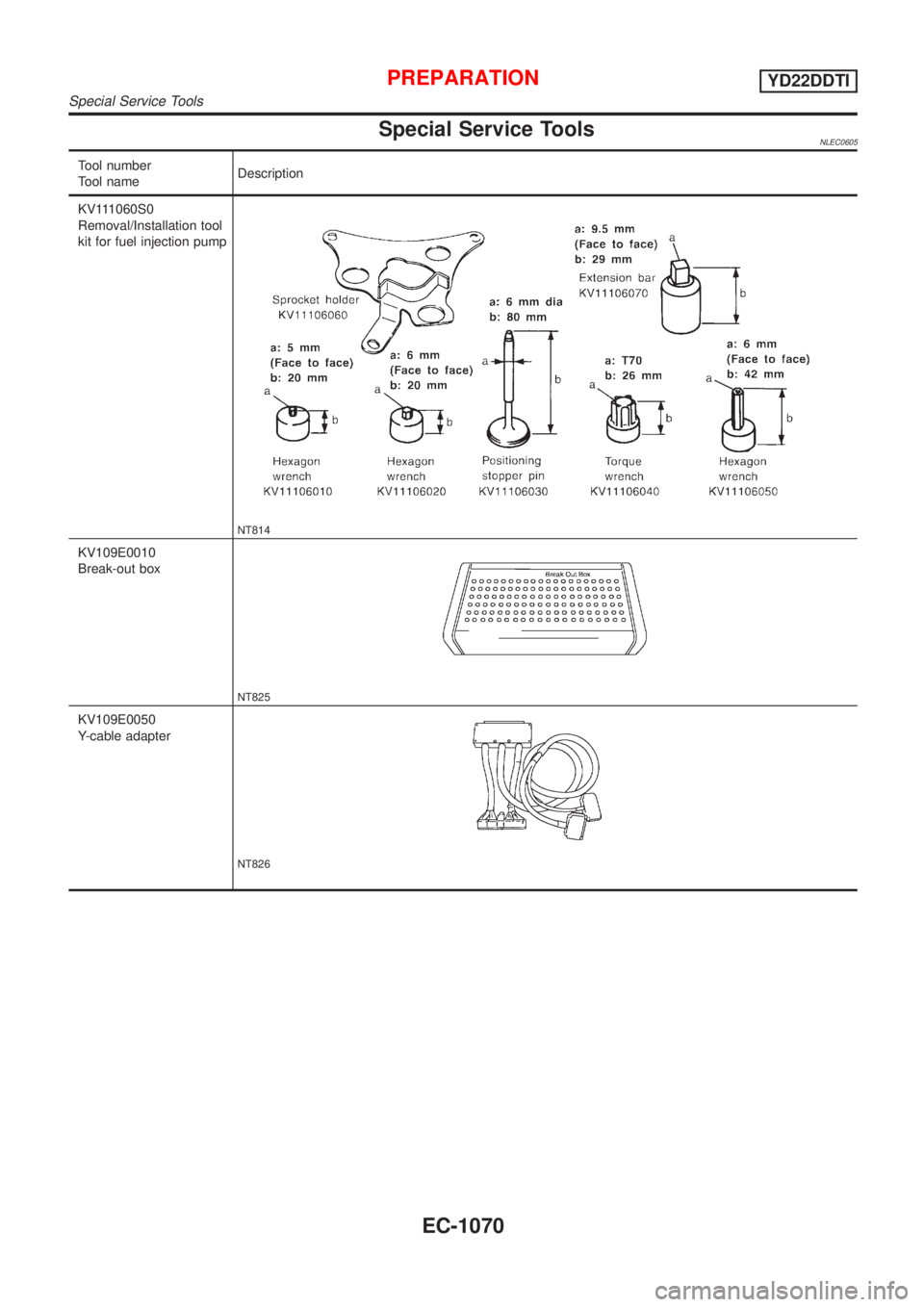

Special Service ToolsNLEC0605

Tool number

Tool nameDescription

KV111060S0

Removal/Installation tool

kit for fuel injection pump

NT814

KV109E0010

Break-out box

NT825

KV109E0050

Y-cable adapter

NT826

PREPARATIONYD22DDTI

Special Service Tools

EC-1070

Page 1496 of 3051

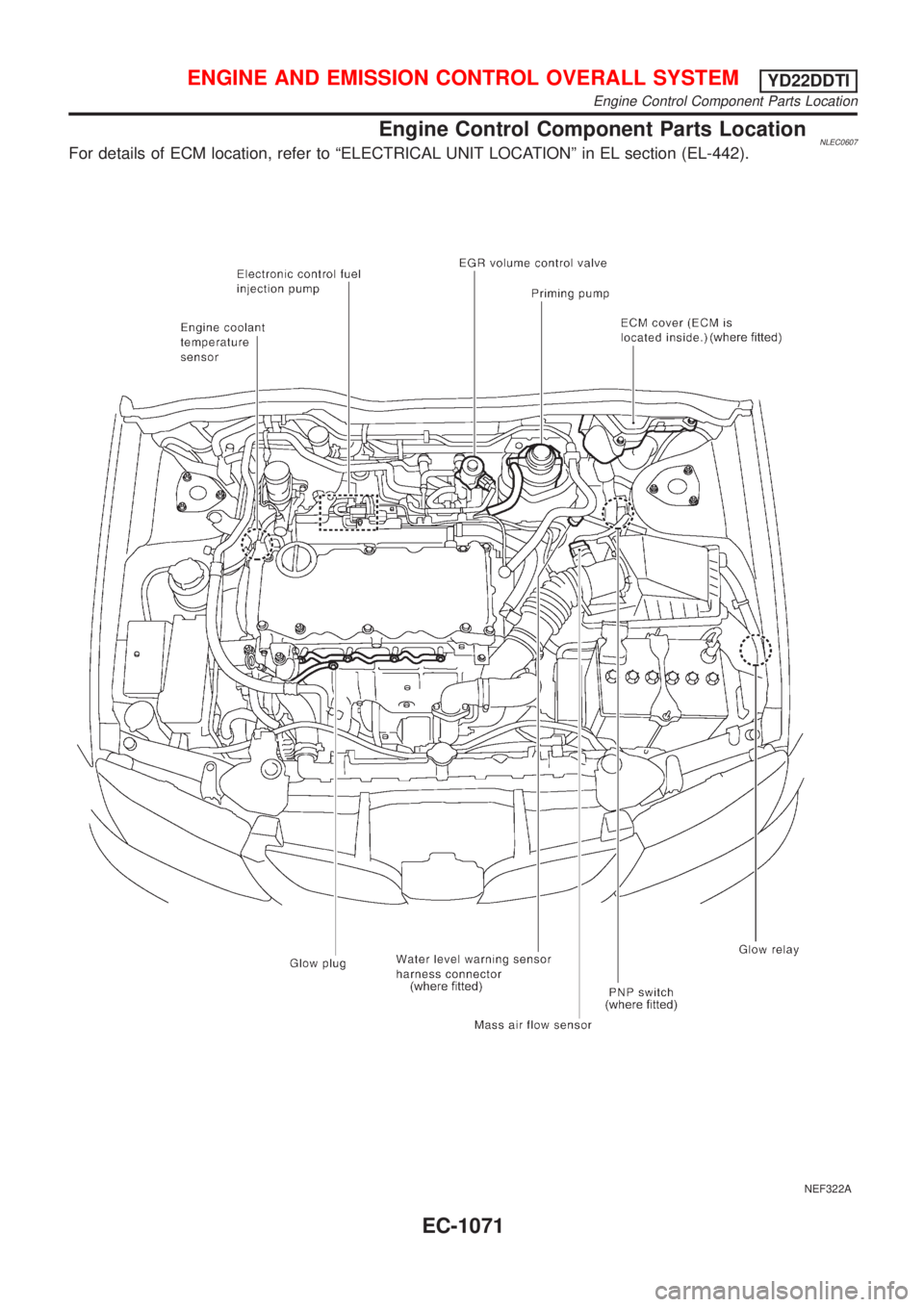

Engine Control Component Parts LocationNLEC0607For details of ECM location, refer to ªELECTRICAL UNIT LOCATIONº in EL section (EL-442).

NEF322A

ENGINE AND EMISSION CONTROL OVERALL SYSTEMYD22DDTI

Engine Control Component Parts Location

EC-1071

Page 1497 of 3051

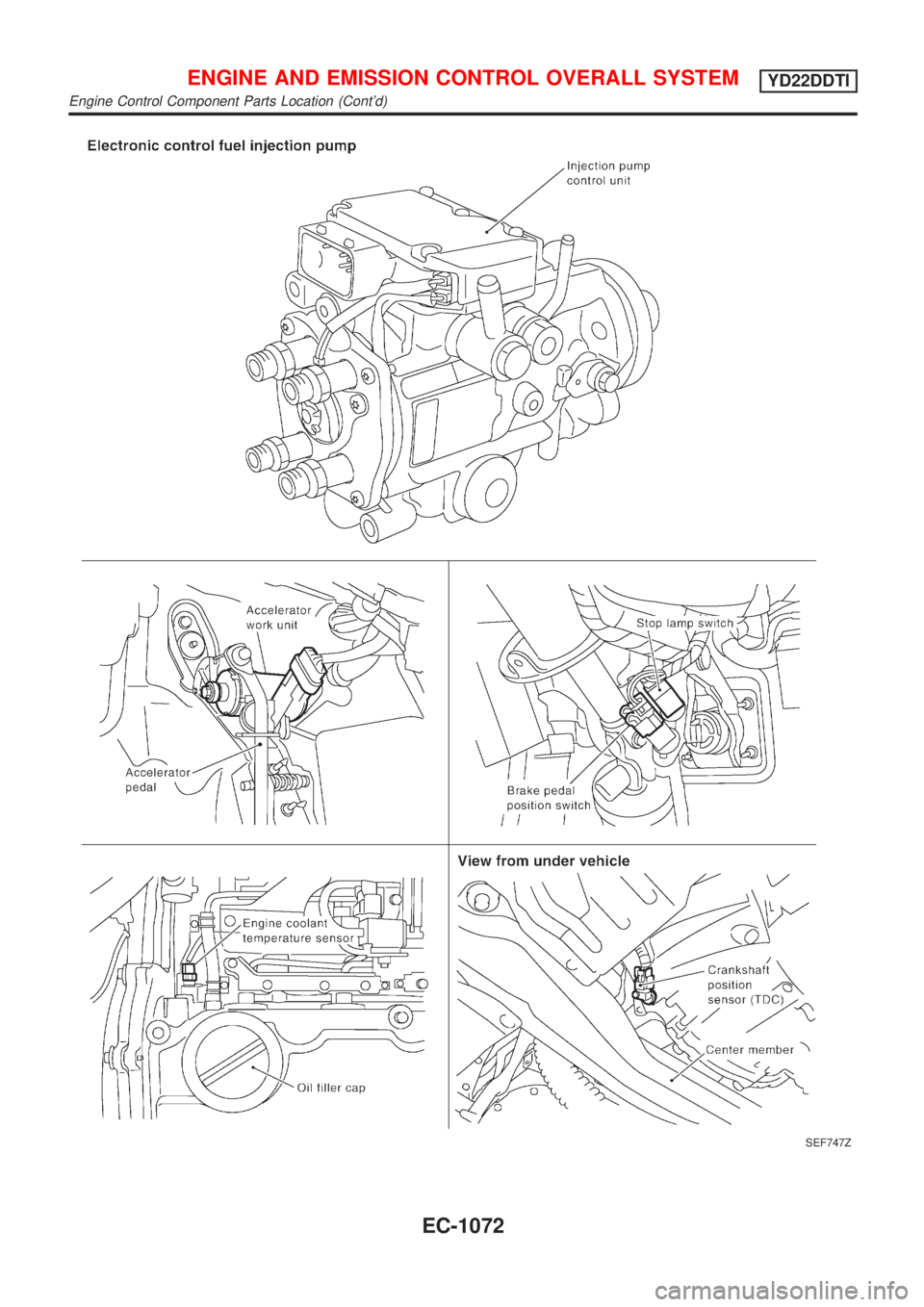

SEF747Z

ENGINE AND EMISSION CONTROL OVERALL SYSTEMYD22DDTI

Engine Control Component Parts Location (Cont'd)

EC-1072

Page 1498 of 3051

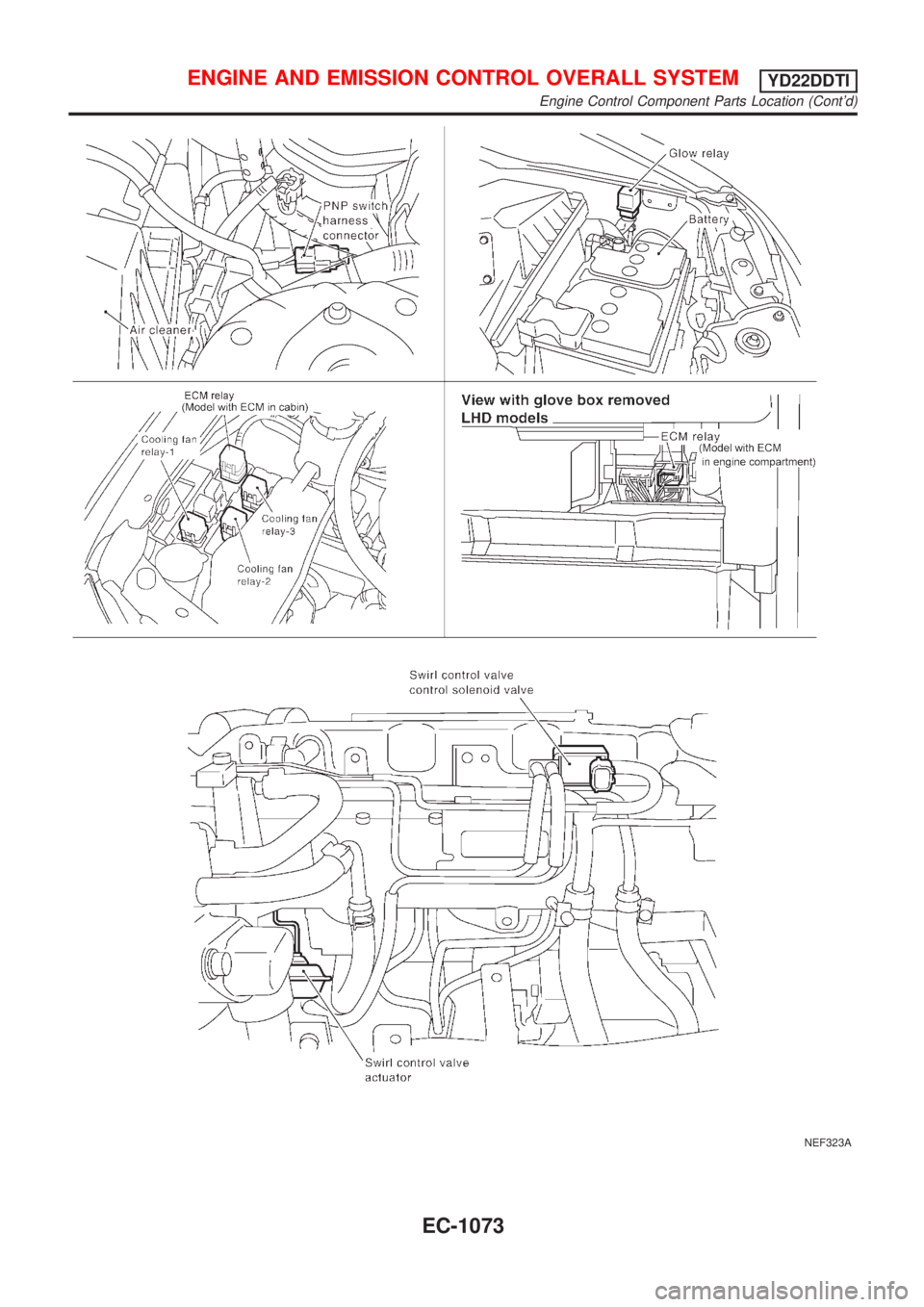

NEF323A

ENGINE AND EMISSION CONTROL OVERALL SYSTEMYD22DDTI

Engine Control Component Parts Location (Cont'd)

EC-1073

Page 1499 of 3051

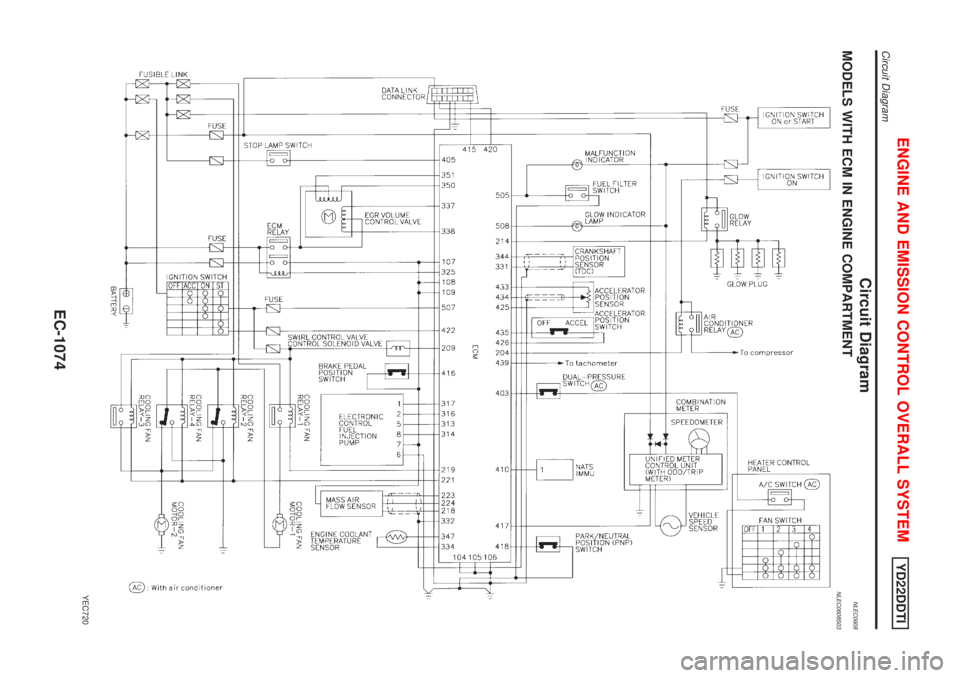

Circuit DiagramNLEC0608MODELS WITH ECM IN ENGINE COMPARTMENTNLEC0608S03

YEC720

ENGINE AND EMISSION CONTROL OVERALL SYSTEMYD22DDTI

Circuit Diagram

EC-1074

Page 1500 of 3051

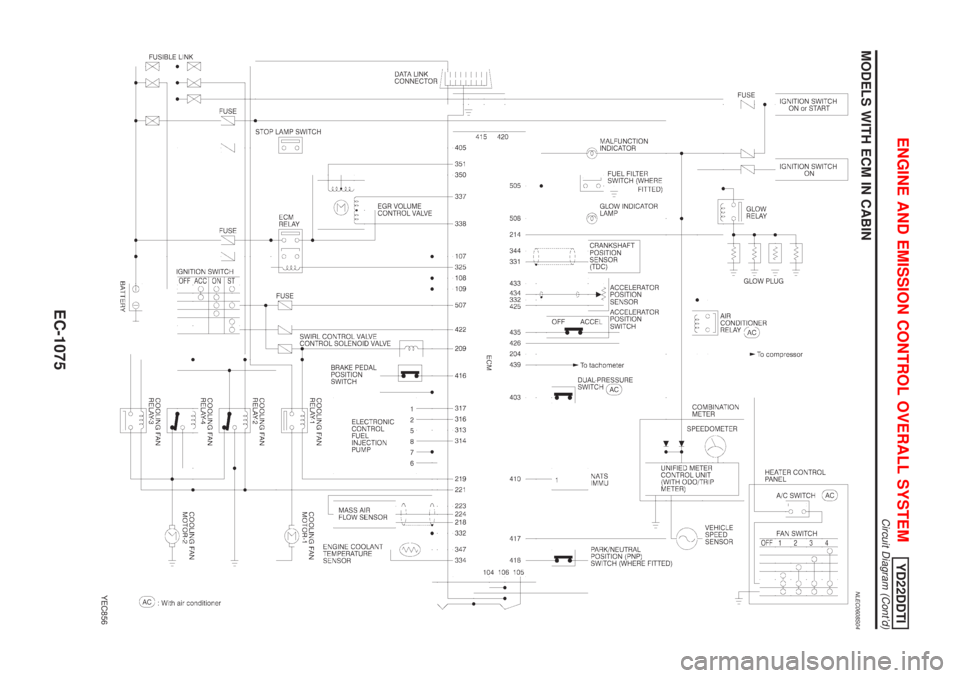

MODELS WITH ECM IN CABINNLEC0608S04

YEC856

ENGINE AND EMISSION CONTROL OVERALL SYSTEMYD22DDTI

Circuit Diagram (Cont'd)

EC-1075

Trending: BT-1, seats, brake rotor, tow, manual radio set, radiator cap, fuel consumption