NISSAN ALMERA TINO 2001 Service Repair Manual

ALMERA TINO 2001

NISSAN

NISSAN

https://www.carmanualsonline.info/img/5/57352/w960_57352-0.png

NISSAN ALMERA TINO 2001 Service Repair Manual

Page 748 of 3051

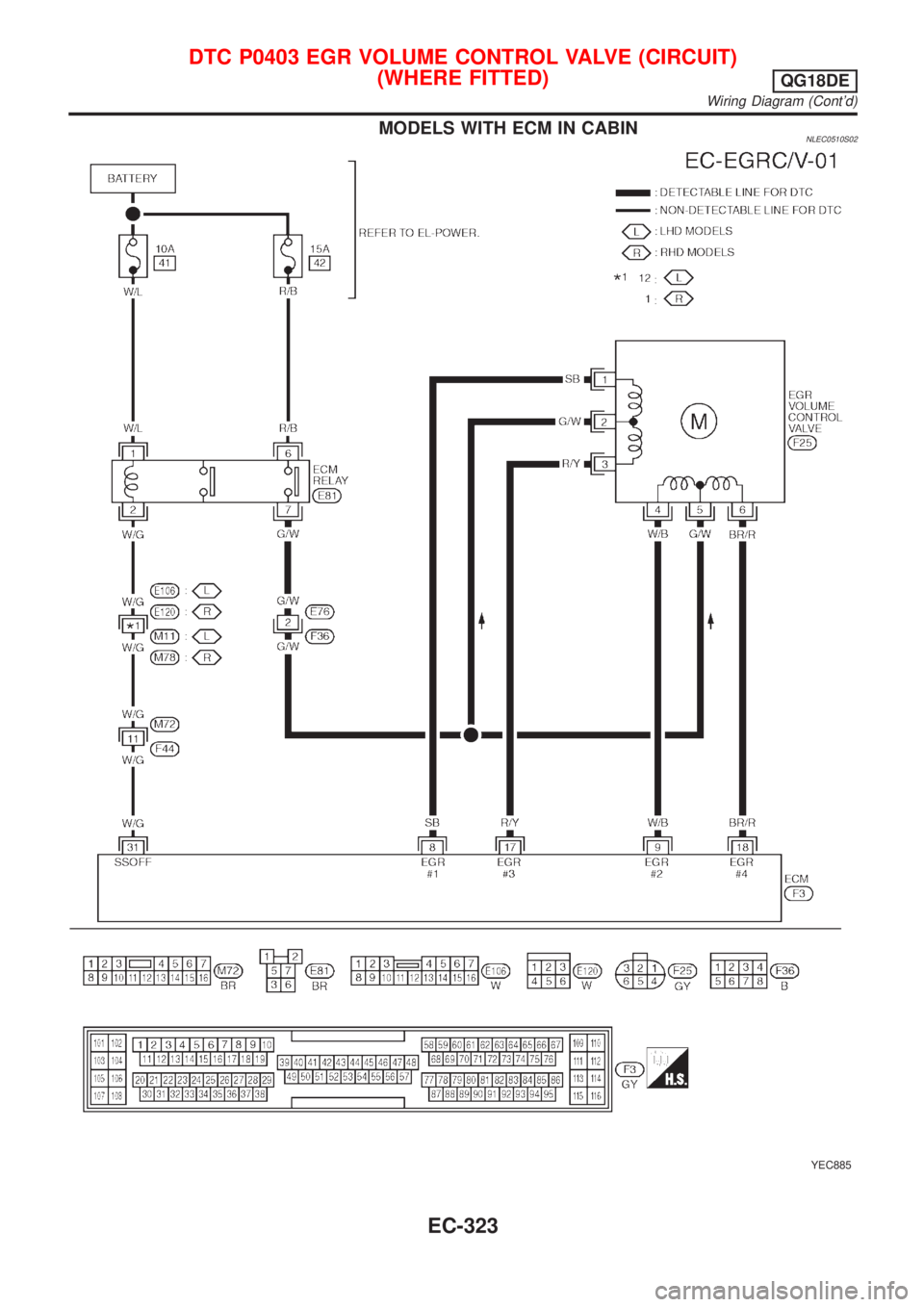

MODELS WITH ECM IN CABINNLEC0510S02

YEC885

DTC P0403 EGR VOLUME CONTROL VALVE (CIRCUIT)

(WHERE FITTED)

QG18DE

Wiring Diagram (Cont'd)

EC-323

Page 749 of 3051

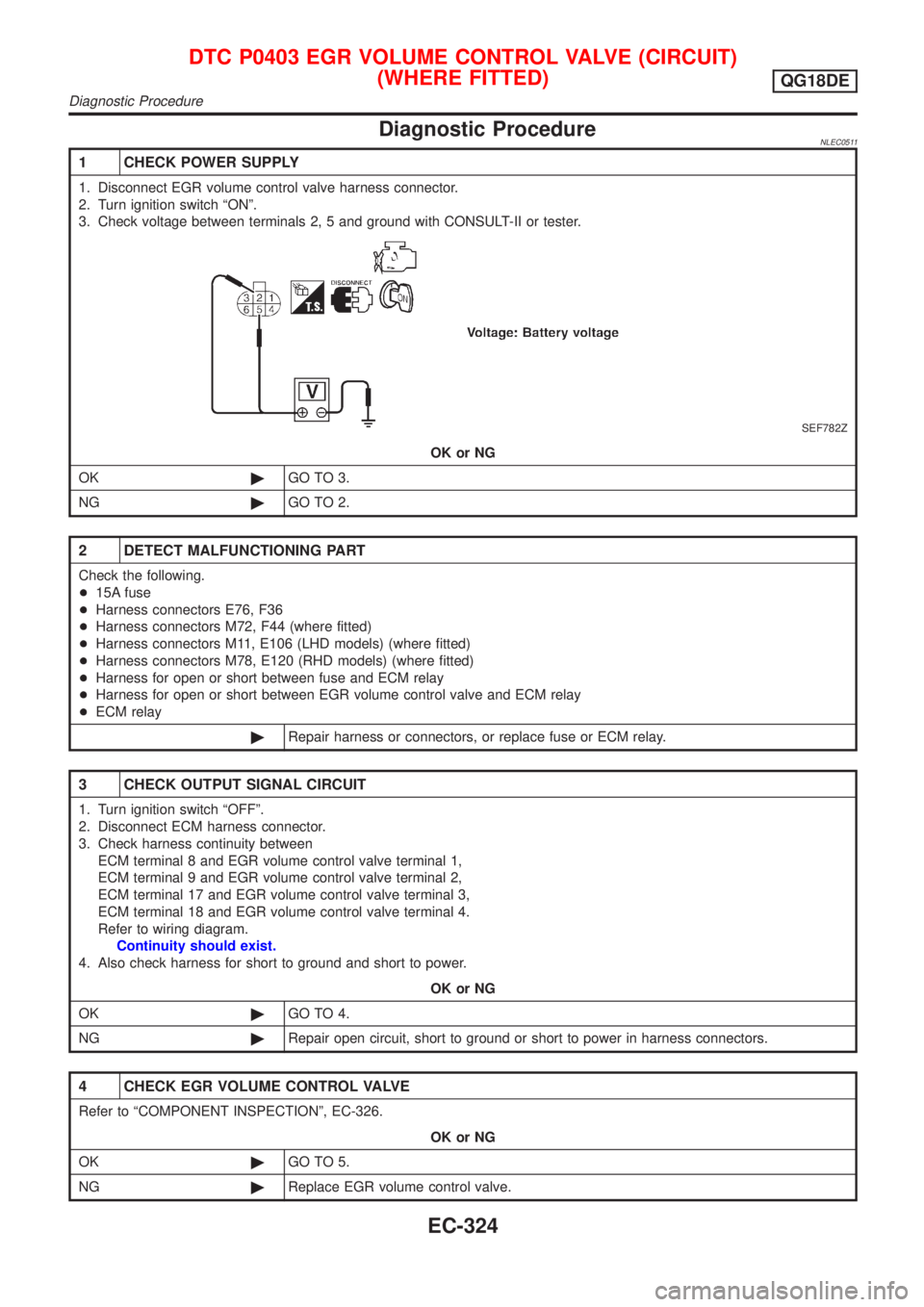

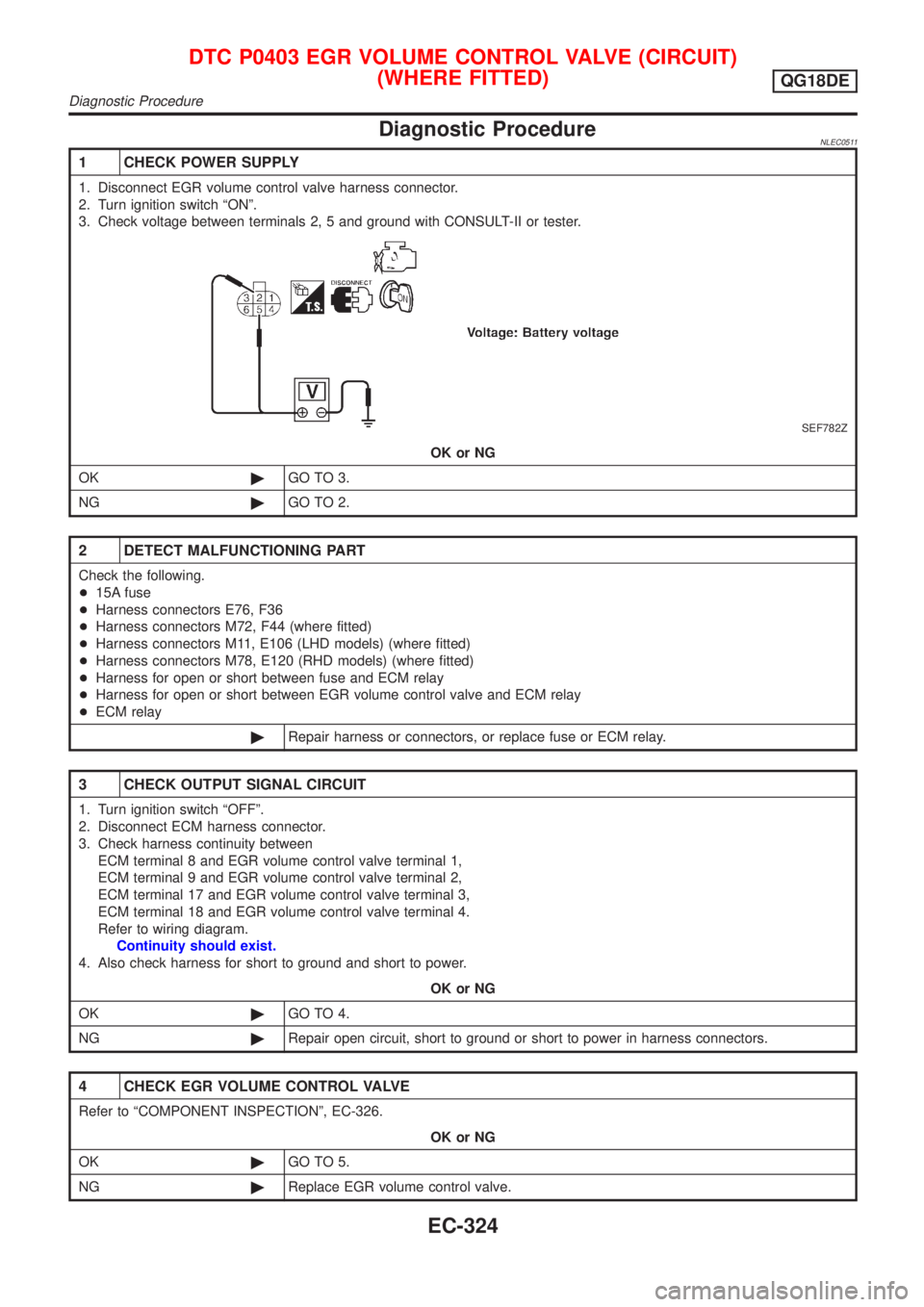

Diagnostic ProcedureNLEC0511

1 CHECK POWER SUPPLY

1. Disconnect EGR volume control valve harness connector.

2. Turn ignition switch ªONº.

3. Check voltage between terminals 2, 5 and ground with CONSULT-II or tester.

SEF782Z

OK or NG

OK©GO TO 3.

NG©GO TO 2.

2 DETECT MALFUNCTIONING PART

Check the following.

+15A fuse

+Harness connectors E76, F36

+Harness connectors M72, F44 (where fitted)

+Harness connectors M11, E106 (LHD models) (where fitted)

+Harness connectors M78, E120 (RHD models) (where fitted)

+Harness for open or short between fuse and ECM relay

+Harness for open or short between EGR volume control valve and ECM relay

+ECM relay

©Repair harness or connectors, or replace fuse or ECM relay.

3 CHECK OUTPUT SIGNAL CIRCUIT

1. Turn ignition switch ªOFFº.

2. Disconnect ECM harness connector.

3. Check harness continuity between

ECM terminal 8 and EGR volume control valve terminal 1,

ECM terminal 9 and EGR volume control valve terminal 2,

ECM terminal 17 and EGR volume control valve terminal 3,

ECM terminal 18 and EGR volume control valve terminal 4.

Refer to wiring diagram.

Continuity should exist.

4. Also check harness for short to ground and short to power.

OK or NG

OK©GO TO 4.

NG©Repair open circuit, short to ground or short to power in harness connectors.

4 CHECK EGR VOLUME CONTROL VALVE

Refer to ªCOMPONENT INSPECTIONº, EC-326.

OK or NG

OK©GO TO 5.

NG©Replace EGR volume control valve.

DTC P0403 EGR VOLUME CONTROL VALVE (CIRCUIT)

(WHERE FITTED)

QG18DE

Diagnostic Procedure

EC-324

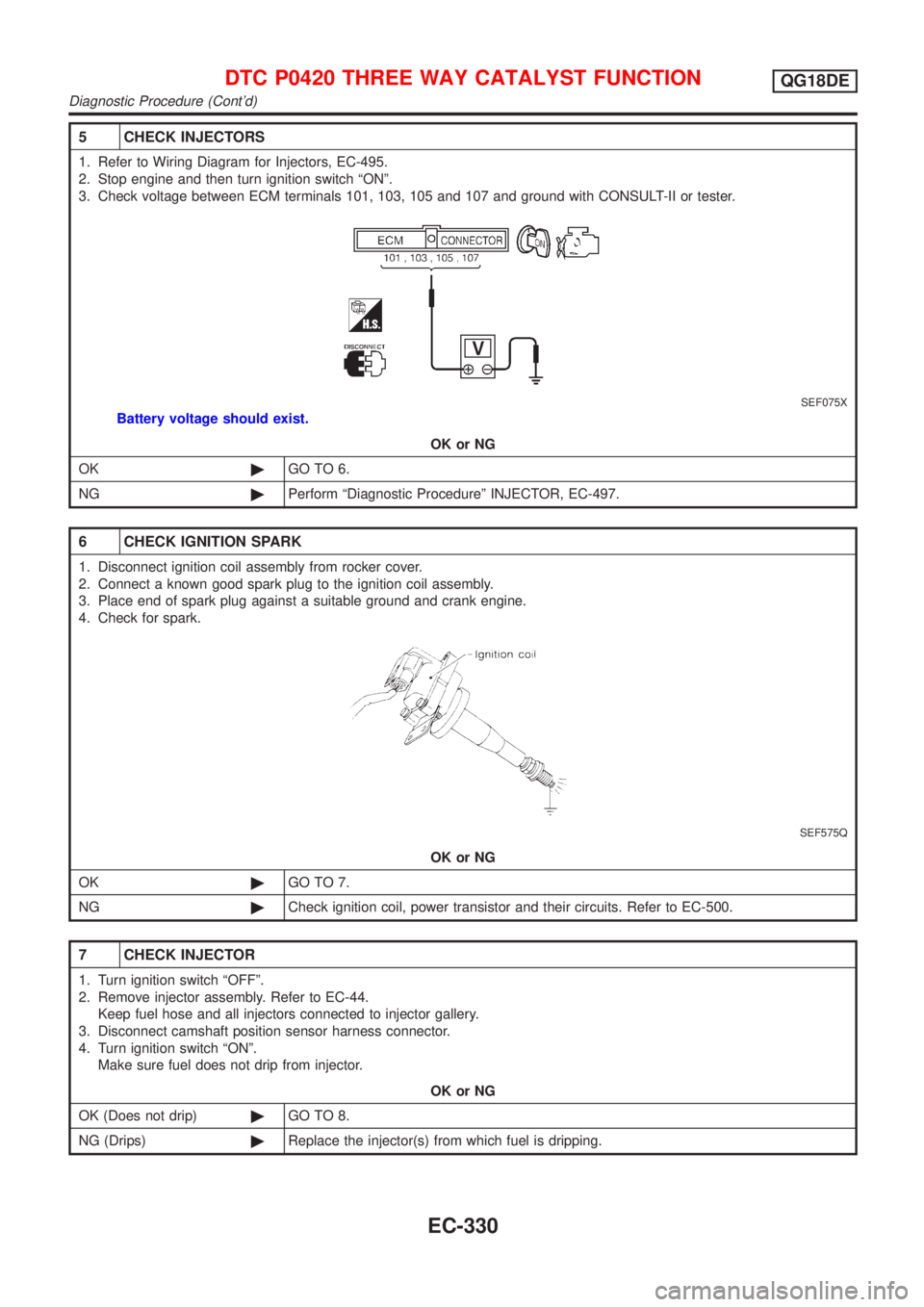

Page 755 of 3051

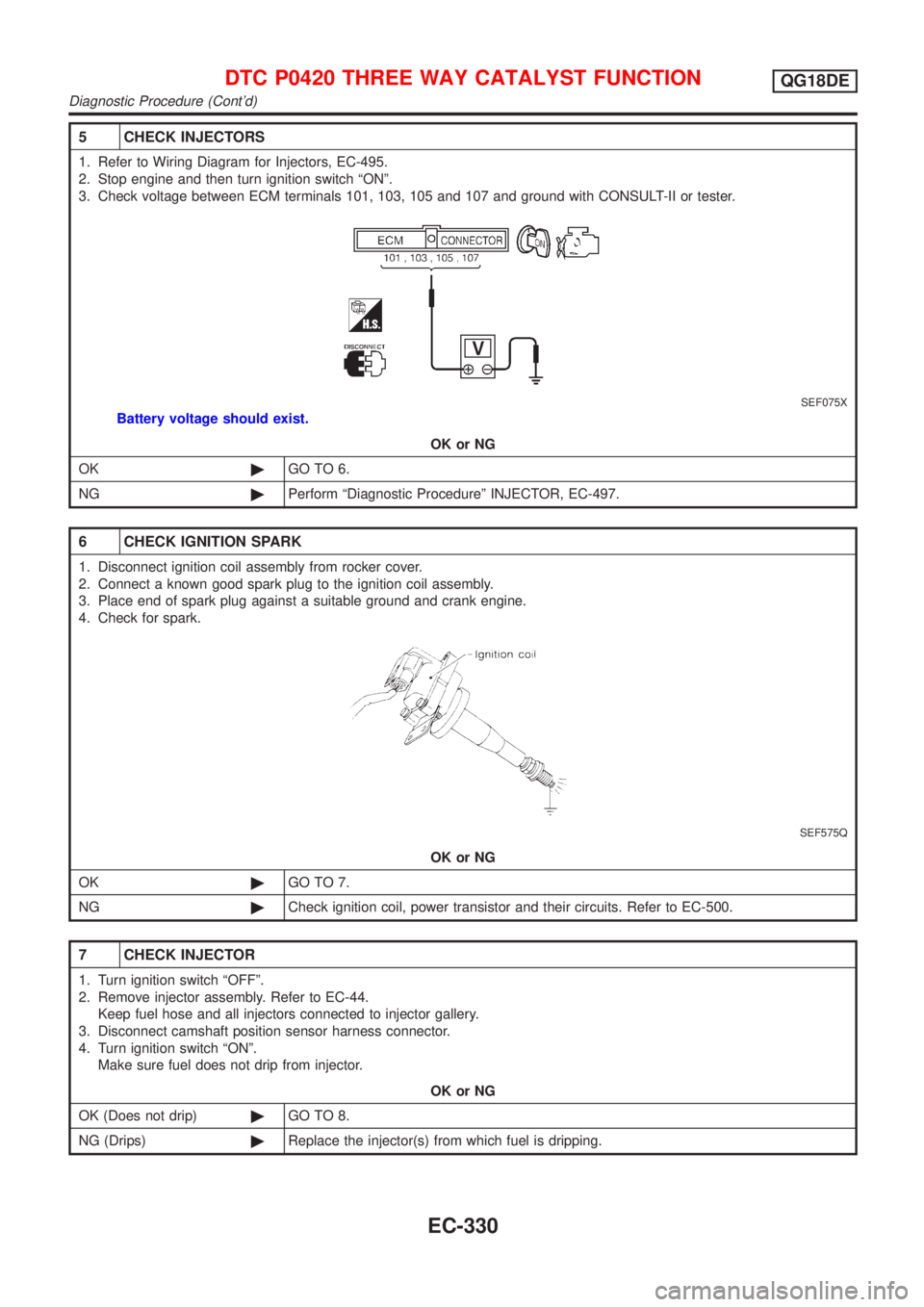

5 CHECK INJECTORS

1. Refer to Wiring Diagram for Injectors, EC-495.

2. Stop engine and then turn ignition switch ªONº.

3. Check voltage between ECM terminals 101, 103, 105 and 107 and ground with CONSULT-II or tester.

SEF075X

Battery voltage should exist.

OK or NG

OK©GO TO 6.

NG©Perform ªDiagnostic Procedureº INJECTOR, EC-497.

6 CHECK IGNITION SPARK

1. Disconnect ignition coil assembly from rocker cover.

2. Connect a known good spark plug to the ignition coil assembly.

3. Place end of spark plug against a suitable ground and crank engine.

4. Check for spark.

SEF575Q

OK or NG

OK©GO TO 7.

NG©Check ignition coil, power transistor and their circuits. Refer to EC-500.

7 CHECK INJECTOR

1. Turn ignition switch ªOFFº.

2. Remove injector assembly. Refer to EC-44.

Keep fuel hose and all injectors connected to injector gallery.

3. Disconnect camshaft position sensor harness connector.

4. Turn ignition switch ªONº.

Make sure fuel does not drip from injector.

OK or NG

OK (Does not drip)©GO TO 8.

NG (Drips)©Replace the injector(s) from which fuel is dripping.

DTC P0420 THREE WAY CATALYST FUNCTIONQG18DE

Diagnostic Procedure (Cont'd)

EC-330

Page 759 of 3051

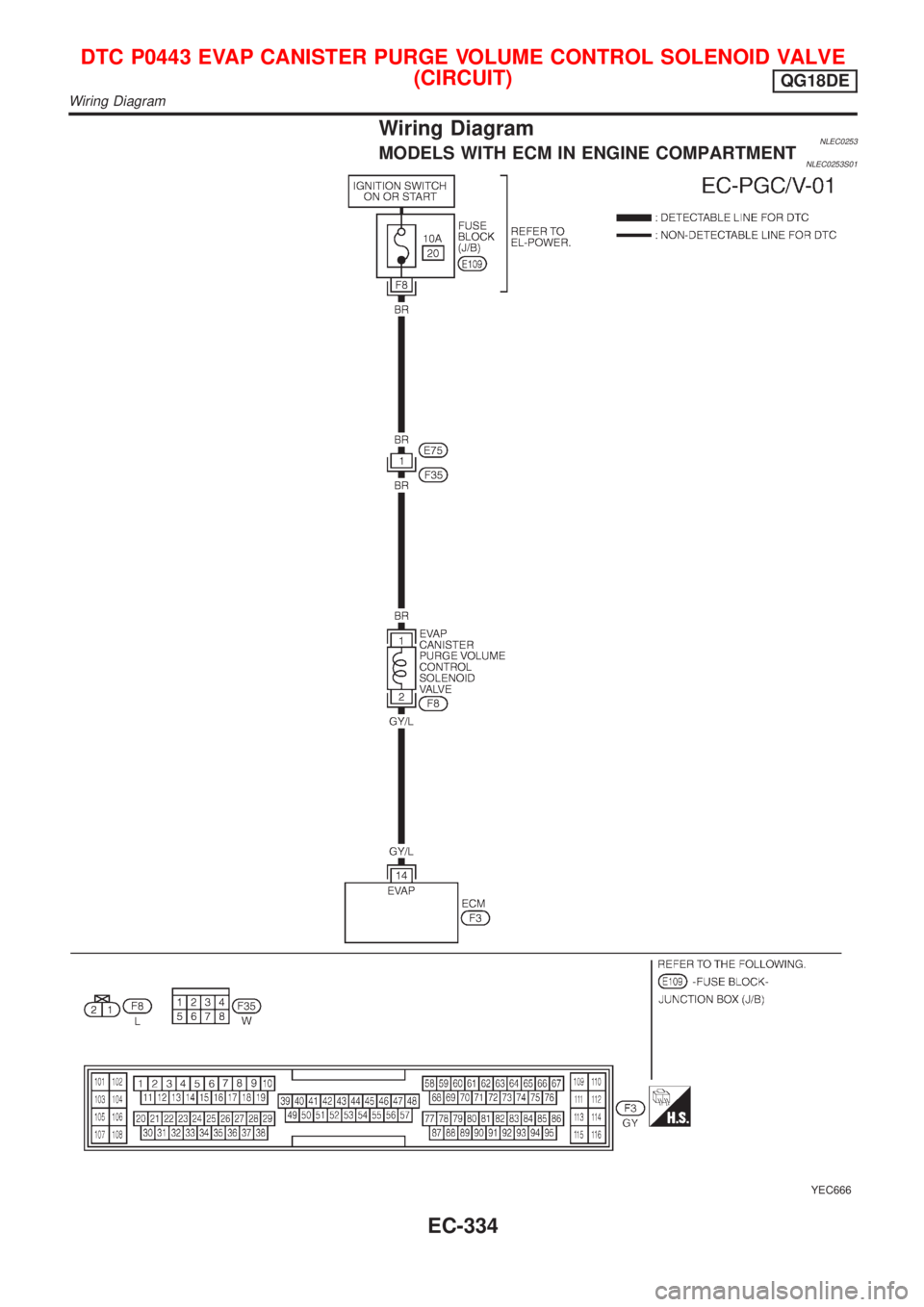

Wiring DiagramNLEC0253MODELS WITH ECM IN ENGINE COMPARTMENTNLEC0253S01

YEC666

DTC P0443 EVAP CANISTER PURGE VOLUME CONTROL SOLENOID VALVE

(CIRCUIT)

QG18DE

Wiring Diagram

EC-334

Page 760 of 3051

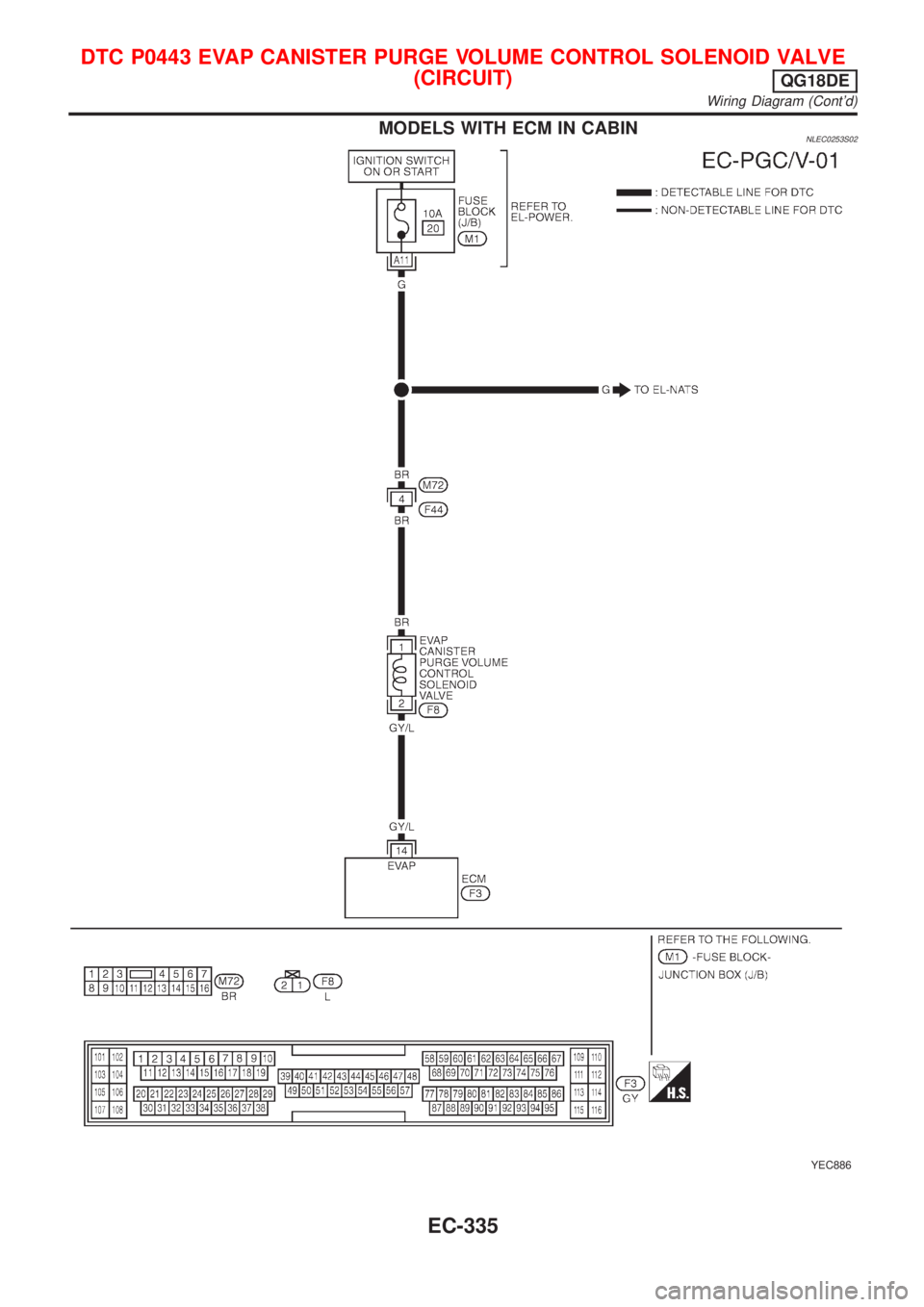

MODELS WITH ECM IN CABINNLEC0253S02

YEC886

DTC P0443 EVAP CANISTER PURGE VOLUME CONTROL SOLENOID VALVE

(CIRCUIT)

QG18DE

Wiring Diagram (Cont'd)

EC-335

Page 761 of 3051

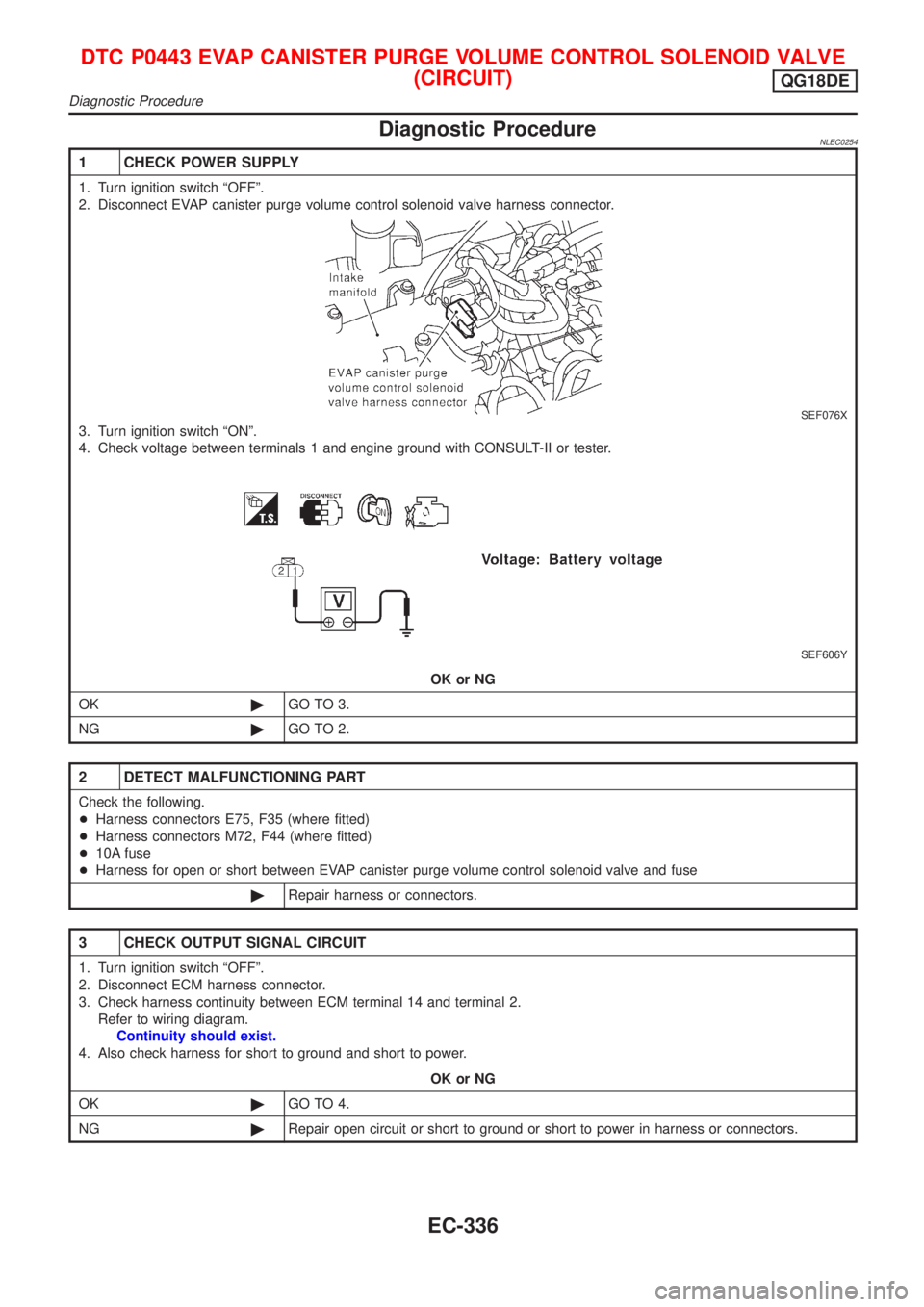

Diagnostic ProcedureNLEC0254

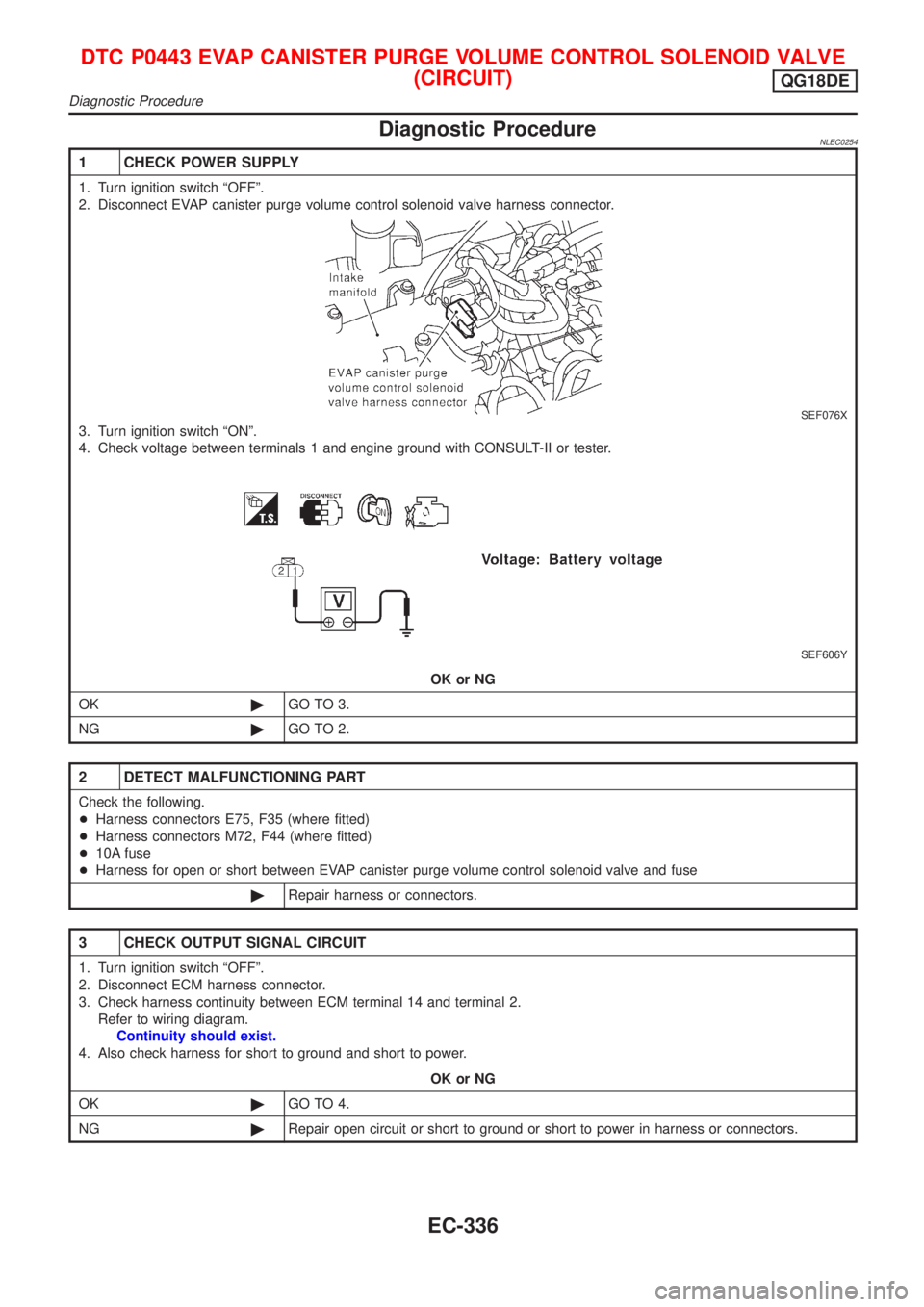

1 CHECK POWER SUPPLY

1. Turn ignition switch ªOFFº.

2. Disconnect EVAP canister purge volume control solenoid valve harness connector.

SEF076X

3. Turn ignition switch ªONº.

4. Check voltage between terminals 1 and engine ground with CONSULT-II or tester.

SEF606Y

OK or NG

OK©GO TO 3.

NG©GO TO 2.

2 DETECT MALFUNCTIONING PART

Check the following.

+Harness connectors E75, F35 (where fitted)

+Harness connectors M72, F44 (where fitted)

+10A fuse

+Harness for open or short between EVAP canister purge volume control solenoid valve and fuse

©Repair harness or connectors.

3 CHECK OUTPUT SIGNAL CIRCUIT

1. Turn ignition switch ªOFFº.

2. Disconnect ECM harness connector.

3. Check harness continuity between ECM terminal 14 and terminal 2.

Refer to wiring diagram.

Continuity should exist.

4. Also check harness for short to ground and short to power.

OK or NG

OK©GO TO 4.

NG©Repair open circuit or short to ground or short to power in harness or connectors.

DTC P0443 EVAP CANISTER PURGE VOLUME CONTROL SOLENOID VALVE

(CIRCUIT)

QG18DE

Diagnostic Procedure

EC-336

Page 765 of 3051

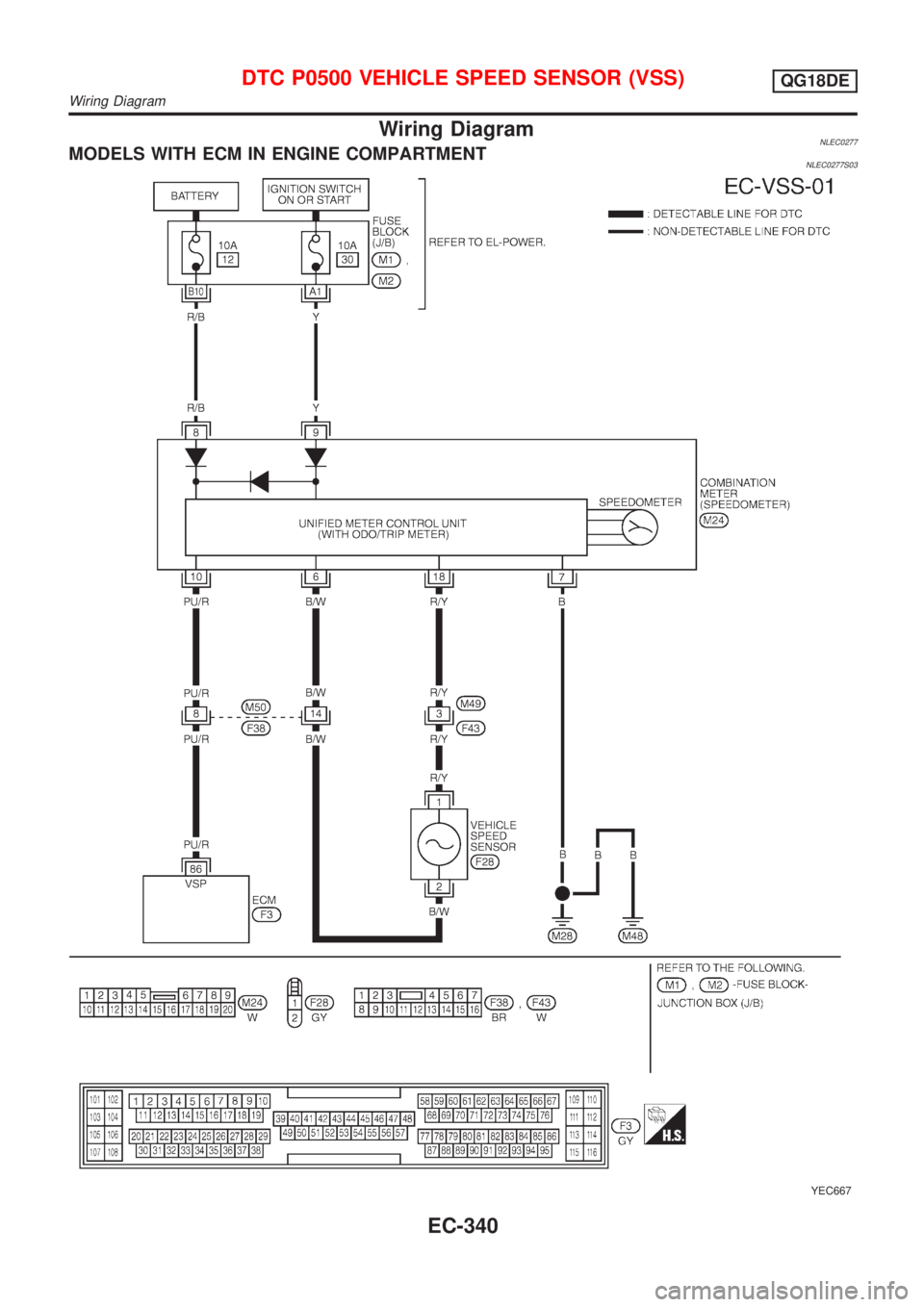

Wiring DiagramNLEC0277MODELS WITH ECM IN ENGINE COMPARTMENTNLEC0277S03

YEC667

DTC P0500 VEHICLE SPEED SENSOR (VSS)QG18DE

Wiring Diagram

EC-340

Page 766 of 3051

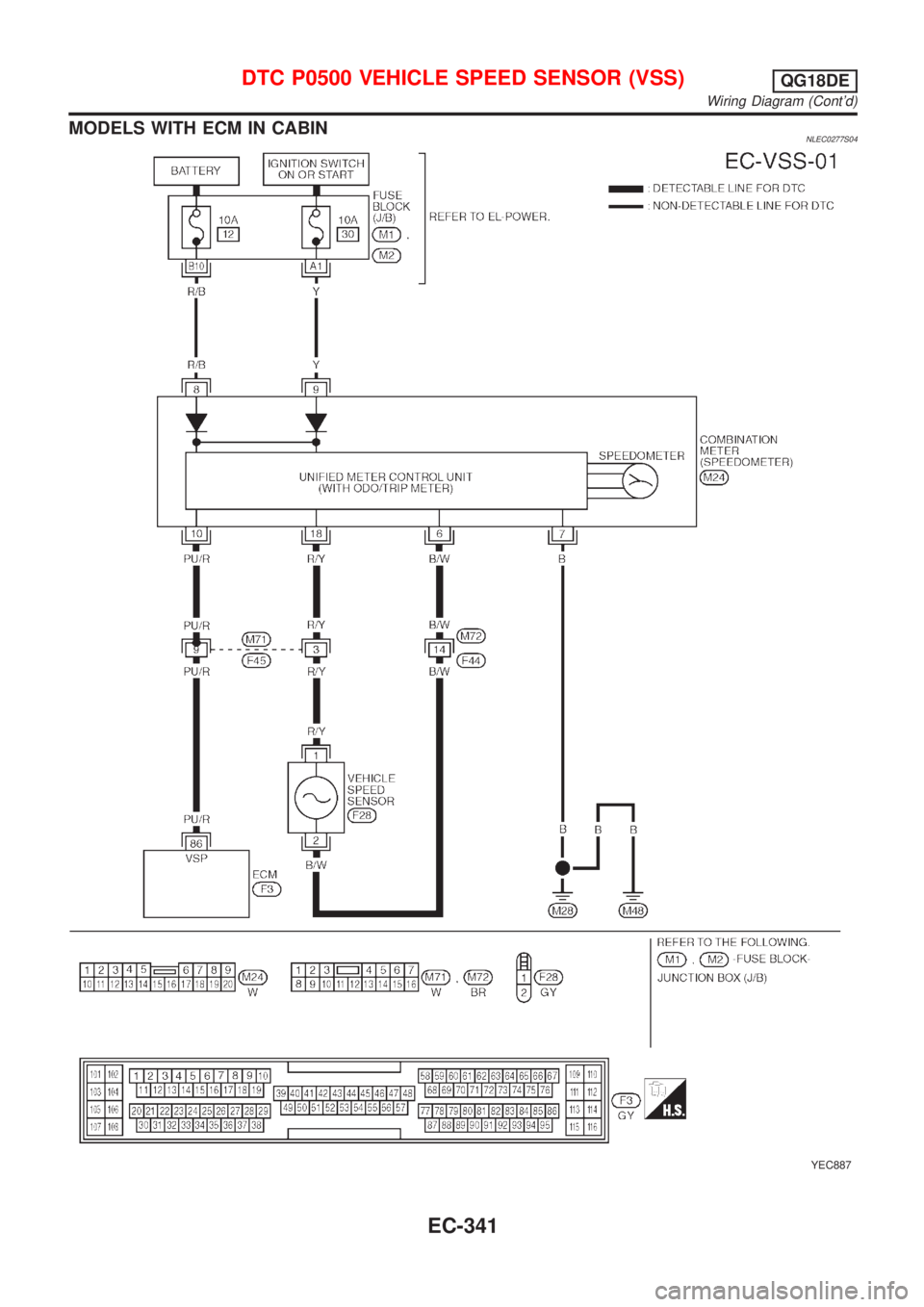

MODELS WITH ECM IN CABINNLEC0277S04

YEC887

DTC P0500 VEHICLE SPEED SENSOR (VSS)QG18DE

Wiring Diagram (Cont'd)

EC-341

Page 770 of 3051

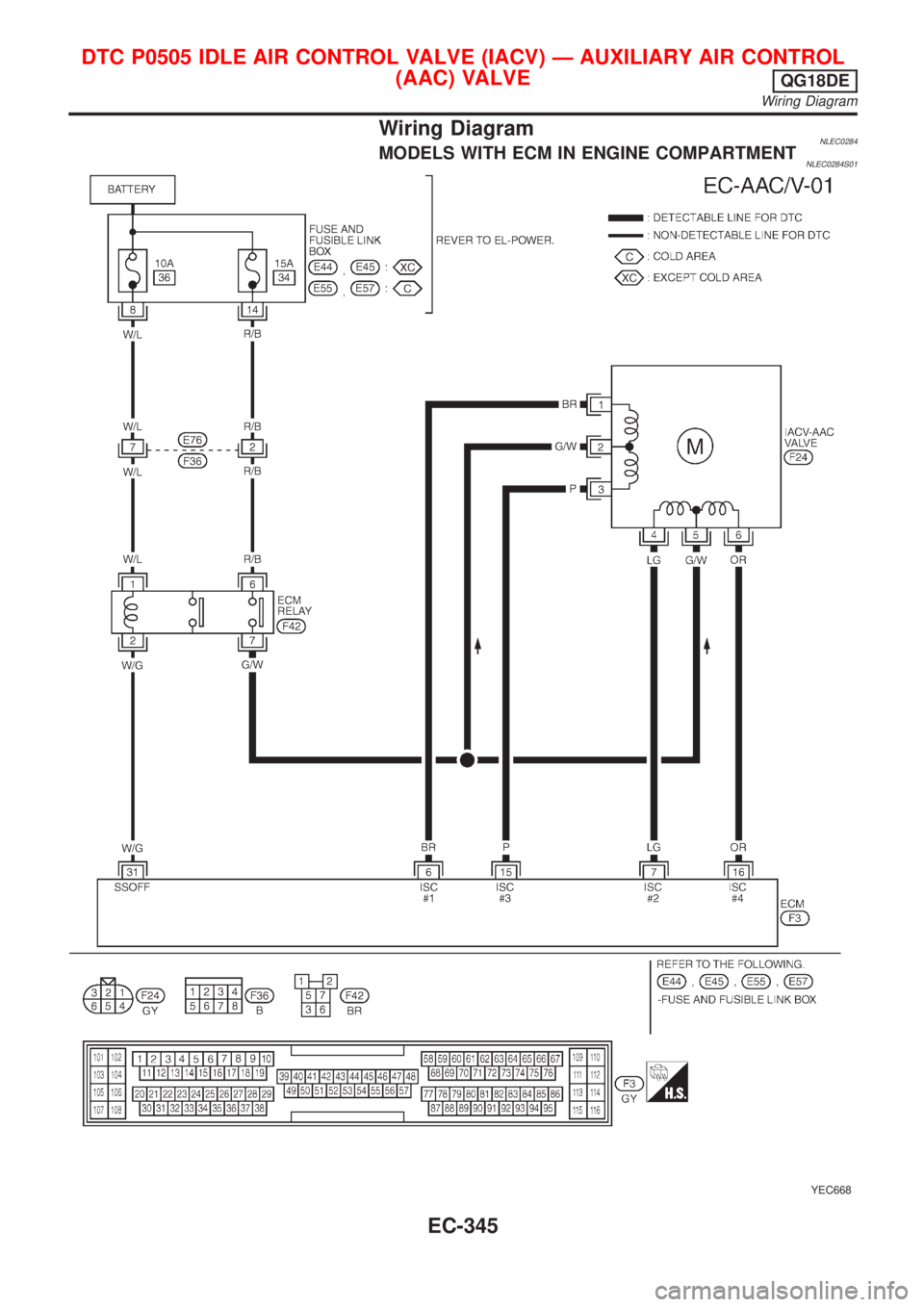

Wiring DiagramNLEC0284MODELS WITH ECM IN ENGINE COMPARTMENTNLEC0284S01

YEC668

DTC P0505 IDLE AIR CONTROL VALVE (IACV) Ð AUXILIARY AIR CONTROL

(AAC) VALVE

QG18DE

Wiring Diagram

EC-345

Page 771 of 3051

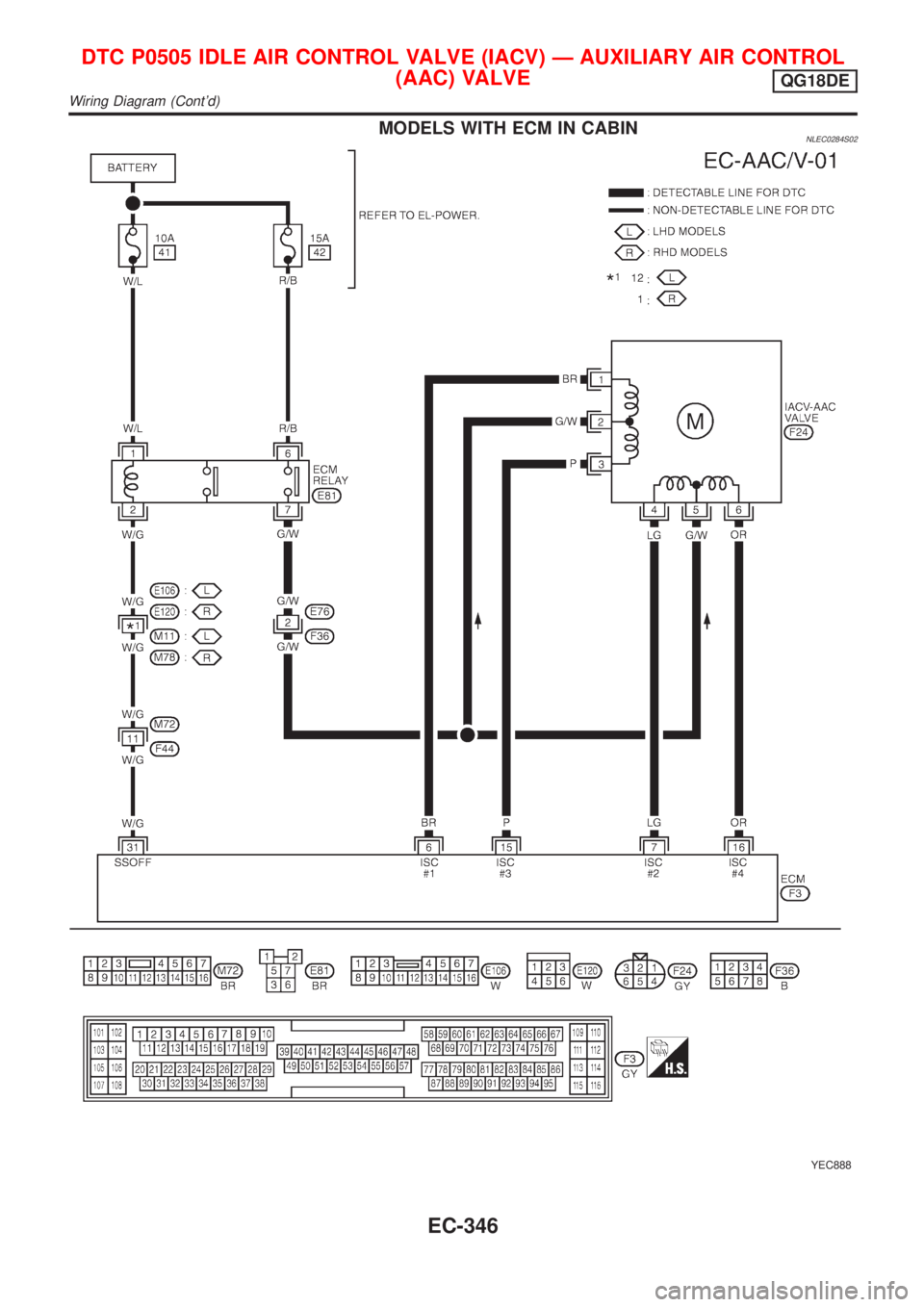

MODELS WITH ECM IN CABINNLEC0284S02

YEC888

DTC P0505 IDLE AIR CONTROL VALVE (IACV) Ð AUXILIARY AIR CONTROL

(AAC) VALVE

QG18DE

Wiring Diagram (Cont'd)

EC-346