NISSAN ALMERA TINO 2001 Service Repair Manual

ALMERA TINO 2001

NISSAN

NISSAN

https://www.carmanualsonline.info/img/5/57352/w960_57352-0.png

NISSAN ALMERA TINO 2001 Service Repair Manual

Page 642 of 3051

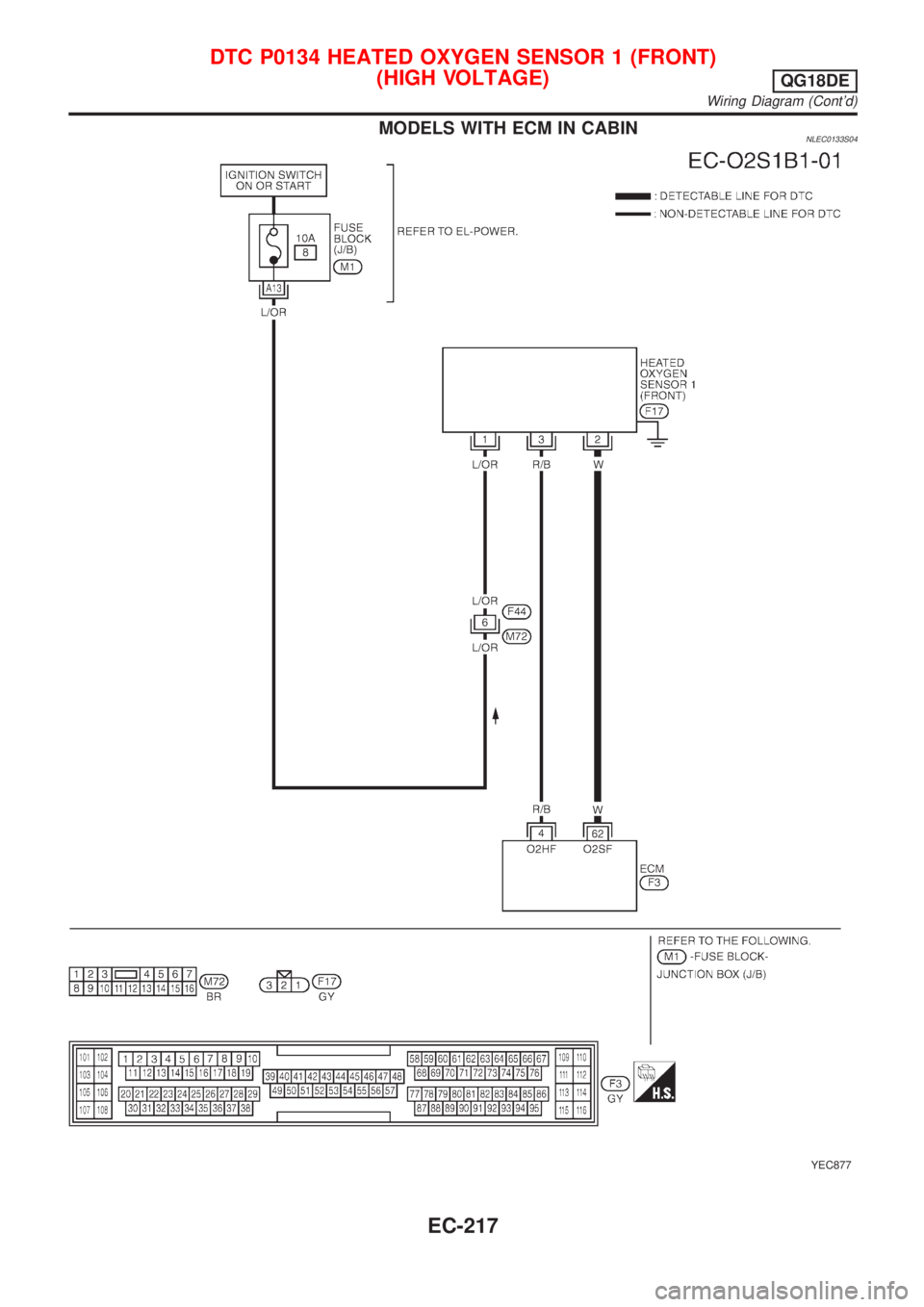

MODELS WITH ECM IN CABINNLEC0133S04

YEC877

DTC P0134 HEATED OXYGEN SENSOR 1 (FRONT)

(HIGH VOLTAGE)

QG18DE

Wiring Diagram (Cont'd)

EC-217

Page 643 of 3051

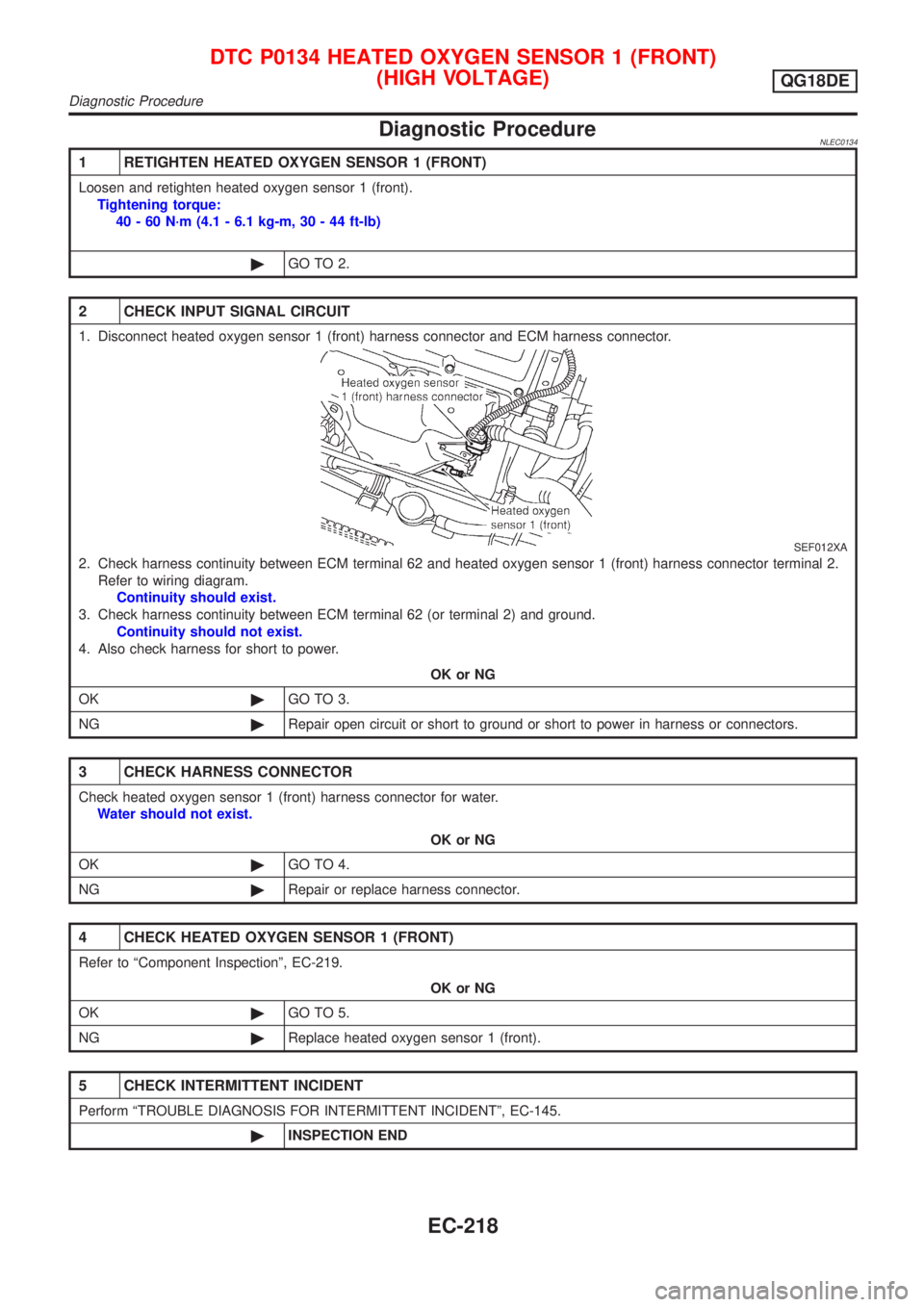

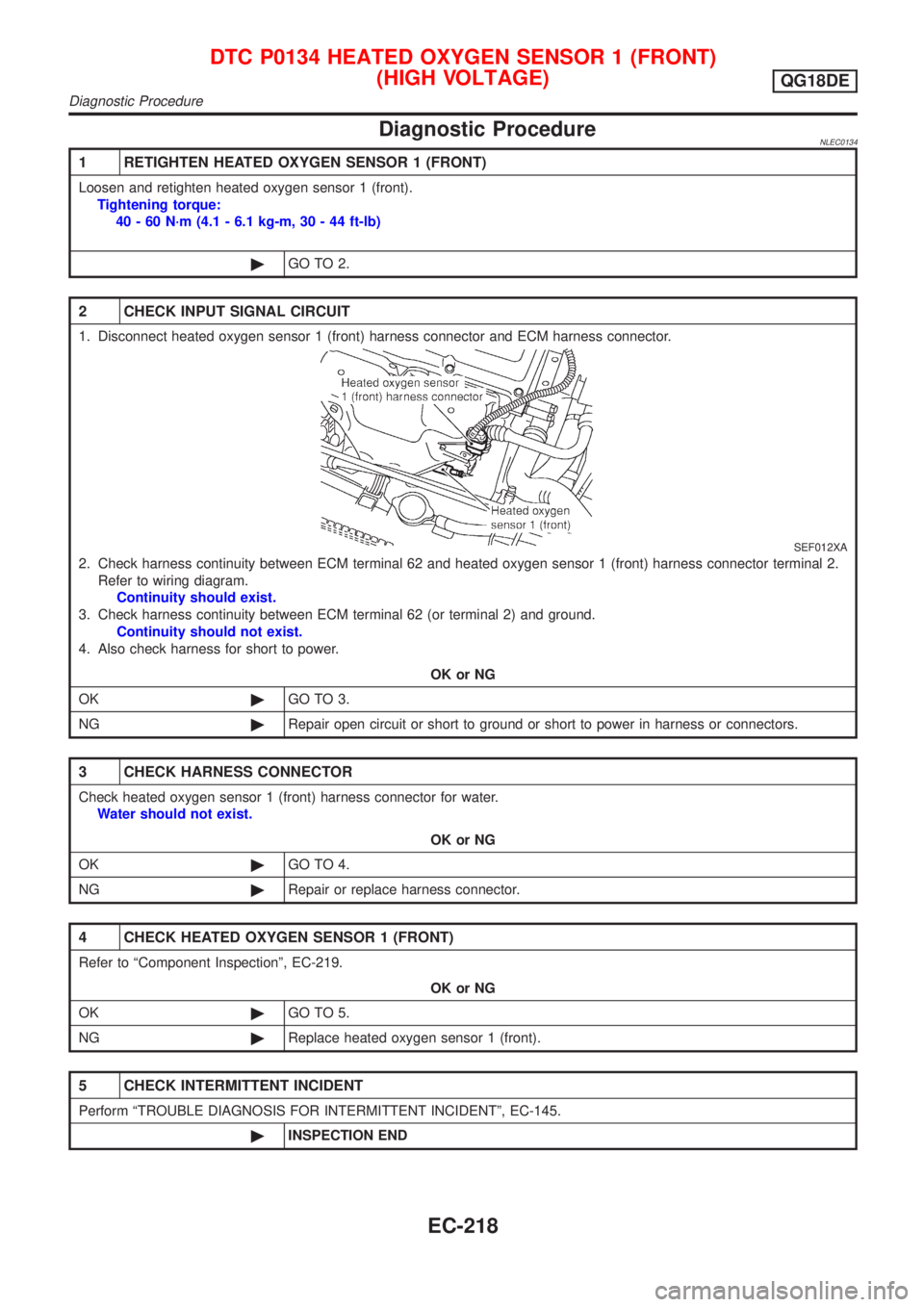

Diagnostic ProcedureNLEC0134

1 RETIGHTEN HEATED OXYGEN SENSOR 1 (FRONT)

Loosen and retighten heated oxygen sensor 1 (front).

Tightening torque:

40 - 60 N´m (4.1 - 6.1 kg-m, 30 - 44 ft-lb)

©GO TO 2.

2 CHECK INPUT SIGNAL CIRCUIT

1. Disconnect heated oxygen sensor 1 (front) harness connector and ECM harness connector.

SEF012XA

2. Check harness continuity between ECM terminal 62 and heated oxygen sensor 1 (front) harness connector terminal 2.

Refer to wiring diagram.

Continuity should exist.

3. Check harness continuity between ECM terminal 62 (or terminal 2) and ground.

Continuity should not exist.

4. Also check harness for short to power.

OK or NG

OK©GO TO 3.

NG©Repair open circuit or short to ground or short to power in harness or connectors.

3 CHECK HARNESS CONNECTOR

Check heated oxygen sensor 1 (front) harness connector for water.

Water should not exist.

OK or NG

OK©GO TO 4.

NG©Repair or replace harness connector.

4 CHECK HEATED OXYGEN SENSOR 1 (FRONT)

Refer to ªComponent Inspectionº, EC-219.

OK or NG

OK©GO TO 5.

NG©Replace heated oxygen sensor 1 (front).

5 CHECK INTERMITTENT INCIDENT

Perform ªTROUBLE DIAGNOSIS FOR INTERMITTENT INCIDENTº, EC-145.

©INSPECTION END

DTC P0134 HEATED OXYGEN SENSOR 1 (FRONT)

(HIGH VOLTAGE)

QG18DE

Diagnostic Procedure

EC-218

Page 648 of 3051

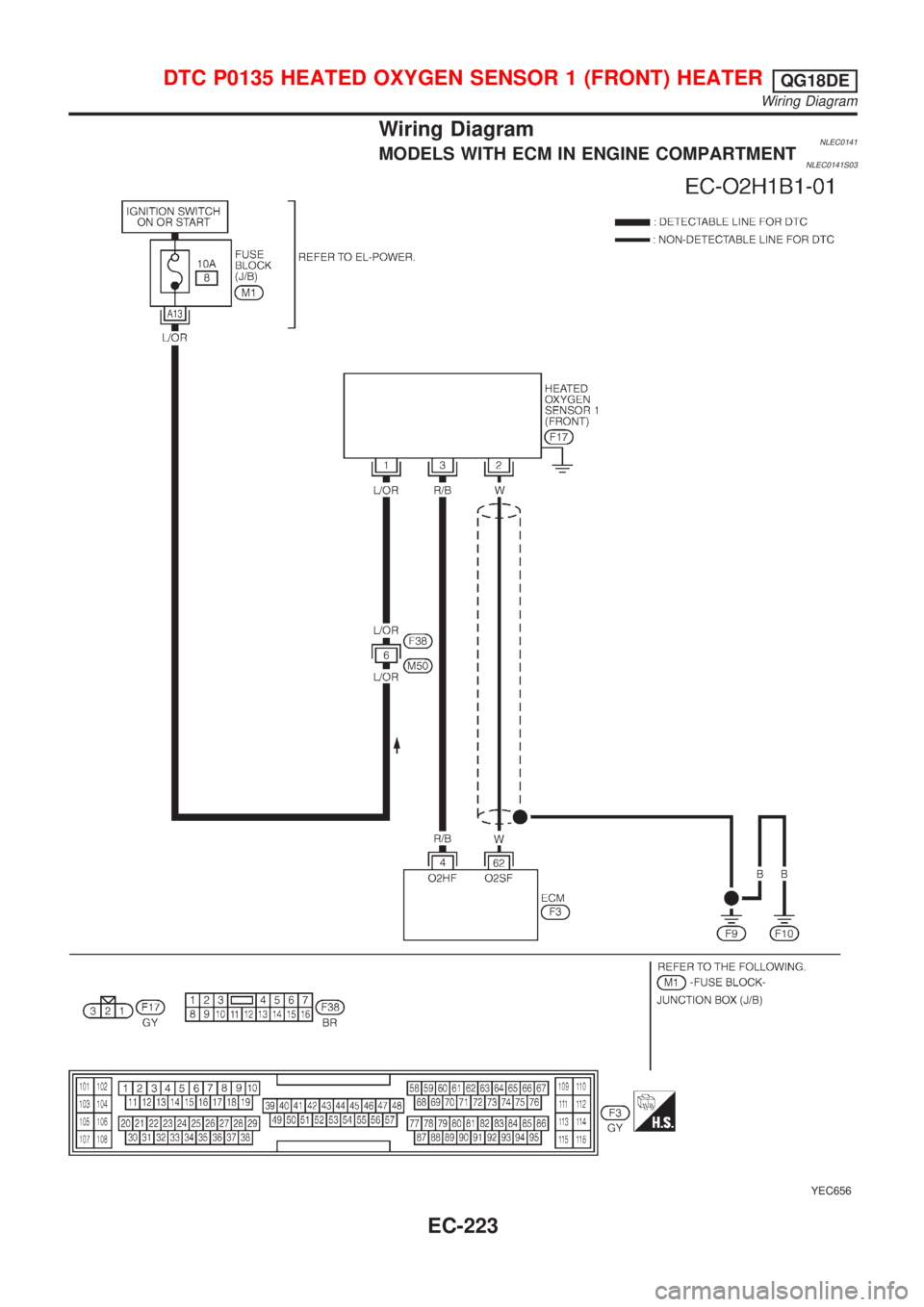

Wiring DiagramNLEC0141MODELS WITH ECM IN ENGINE COMPARTMENTNLEC0141S03

YEC656

DTC P0135 HEATED OXYGEN SENSOR 1 (FRONT) HEATERQG18DE

Wiring Diagram

EC-223

Page 649 of 3051

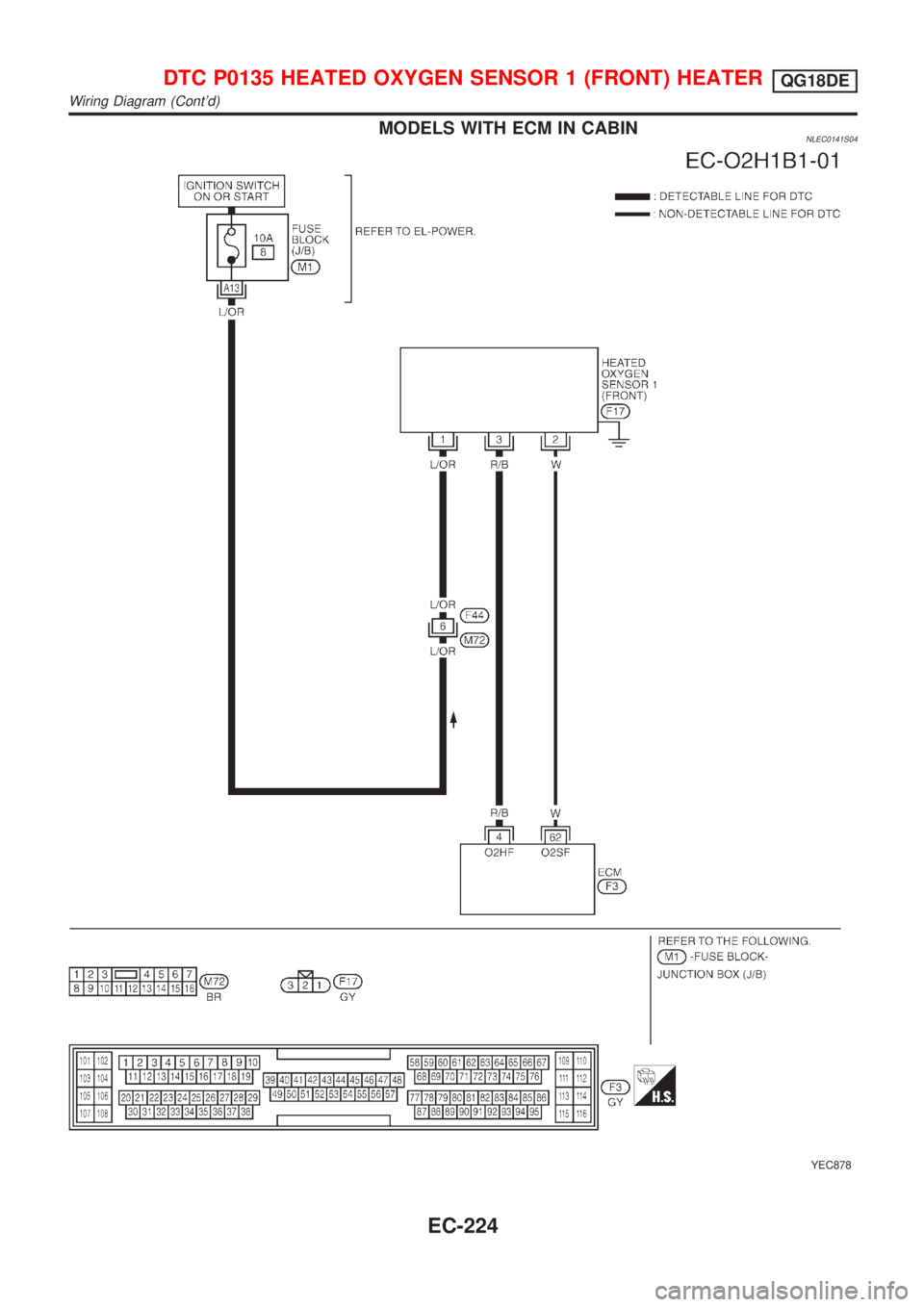

MODELS WITH ECM IN CABINNLEC0141S04

YEC878

DTC P0135 HEATED OXYGEN SENSOR 1 (FRONT) HEATERQG18DE

Wiring Diagram (Cont'd)

EC-224

Page 650 of 3051

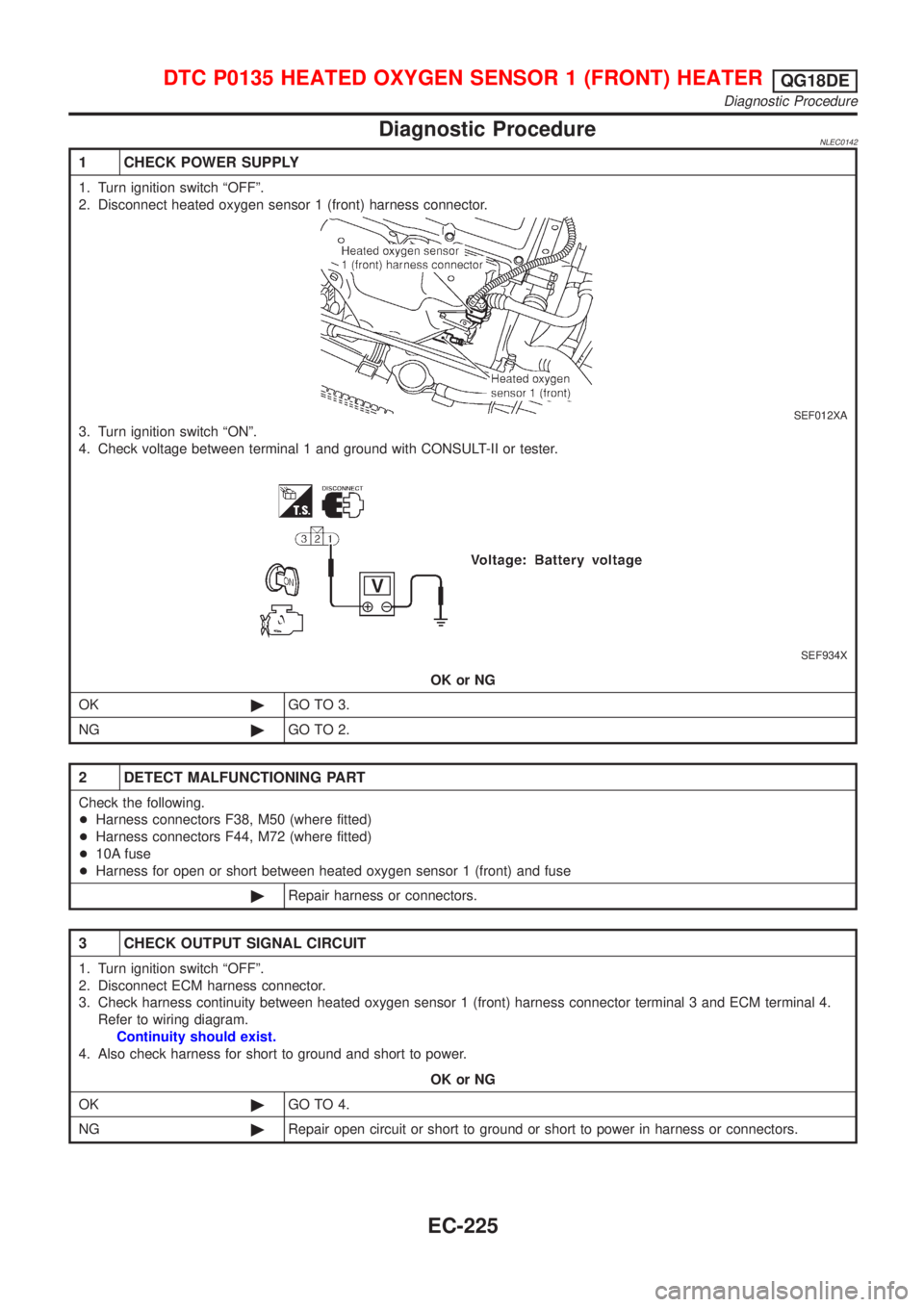

Diagnostic ProcedureNLEC0142

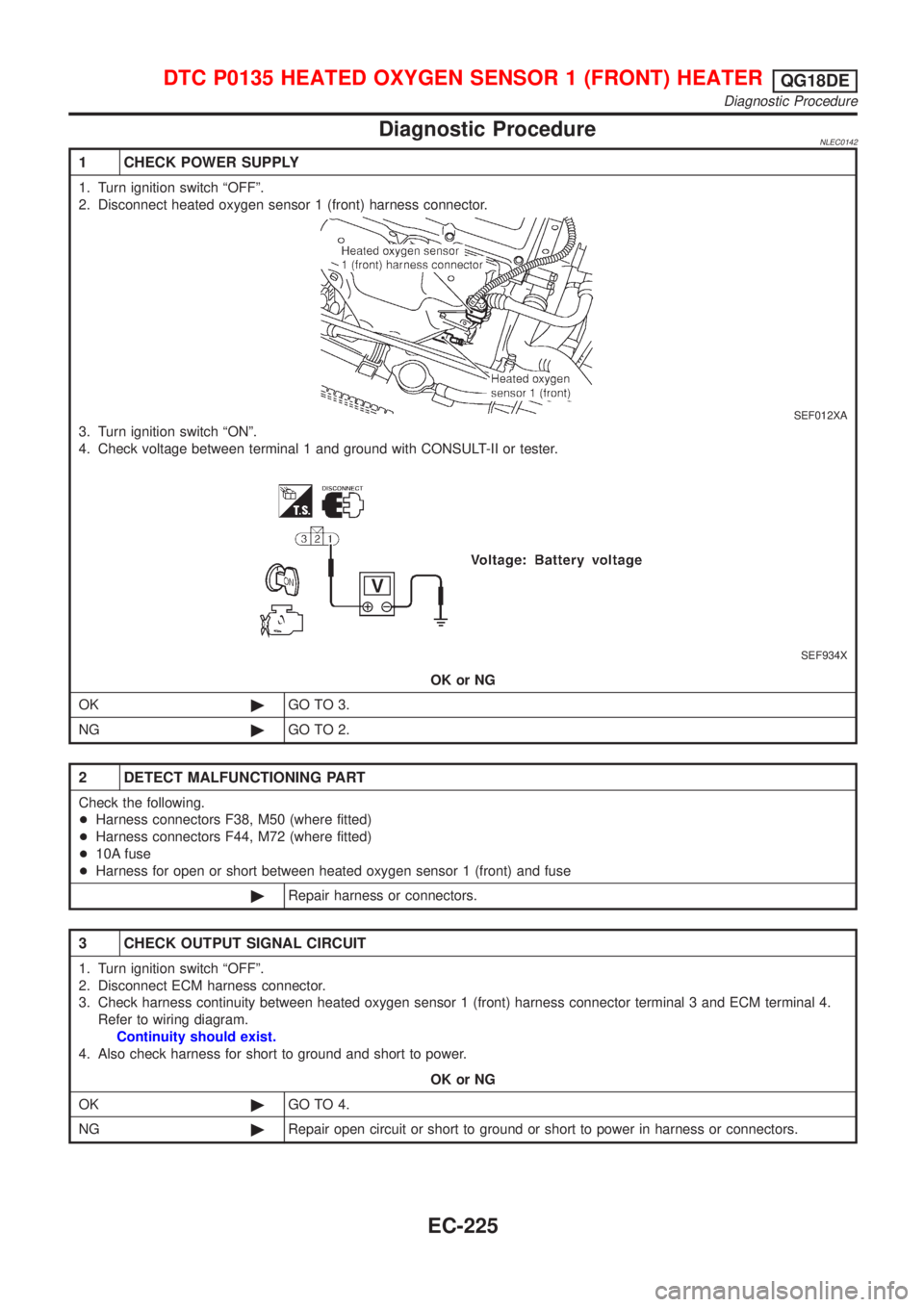

1 CHECK POWER SUPPLY

1. Turn ignition switch ªOFFº.

2. Disconnect heated oxygen sensor 1 (front) harness connector.

SEF012XA

3. Turn ignition switch ªONº.

4. Check voltage between terminal 1 and ground with CONSULT-II or tester.

SEF934X

OK or NG

OK©GO TO 3.

NG©GO TO 2.

2 DETECT MALFUNCTIONING PART

Check the following.

+Harness connectors F38, M50 (where fitted)

+Harness connectors F44, M72 (where fitted)

+10A fuse

+Harness for open or short between heated oxygen sensor 1 (front) and fuse

©Repair harness or connectors.

3 CHECK OUTPUT SIGNAL CIRCUIT

1. Turn ignition switch ªOFFº.

2. Disconnect ECM harness connector.

3. Check harness continuity between heated oxygen sensor 1 (front) harness connector terminal 3 and ECM terminal 4.

Refer to wiring diagram.

Continuity should exist.

4. Also check harness for short to ground and short to power.

OK or NG

OK©GO TO 4.

NG©Repair open circuit or short to ground or short to power in harness or connectors.

DTC P0135 HEATED OXYGEN SENSOR 1 (FRONT) HEATERQG18DE

Diagnostic Procedure

EC-225

Page 655 of 3051

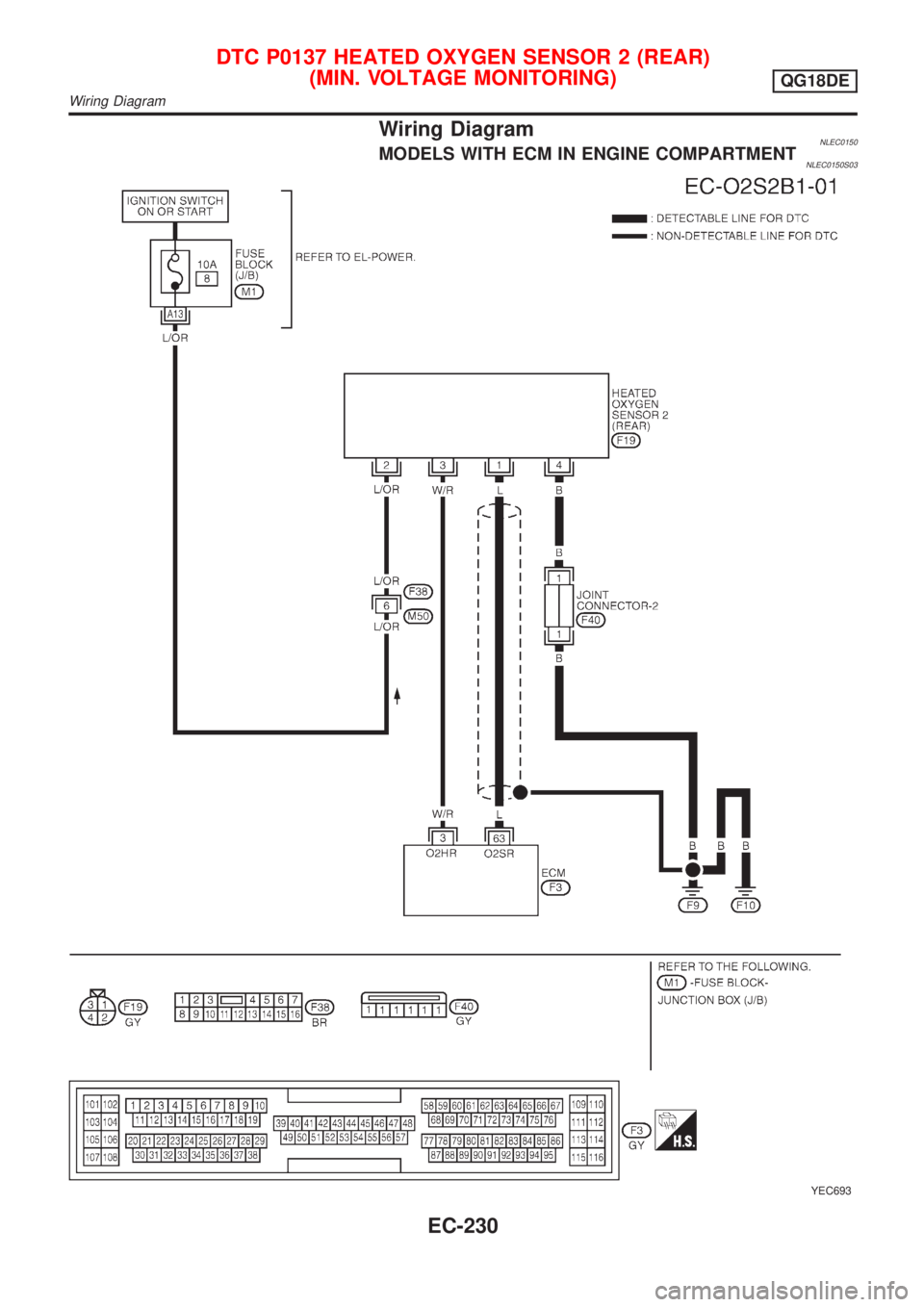

Wiring DiagramNLEC0150MODELS WITH ECM IN ENGINE COMPARTMENTNLEC0150S03

YEC693

DTC P0137 HEATED OXYGEN SENSOR 2 (REAR)

(MIN. VOLTAGE MONITORING)

QG18DE

Wiring Diagram

EC-230

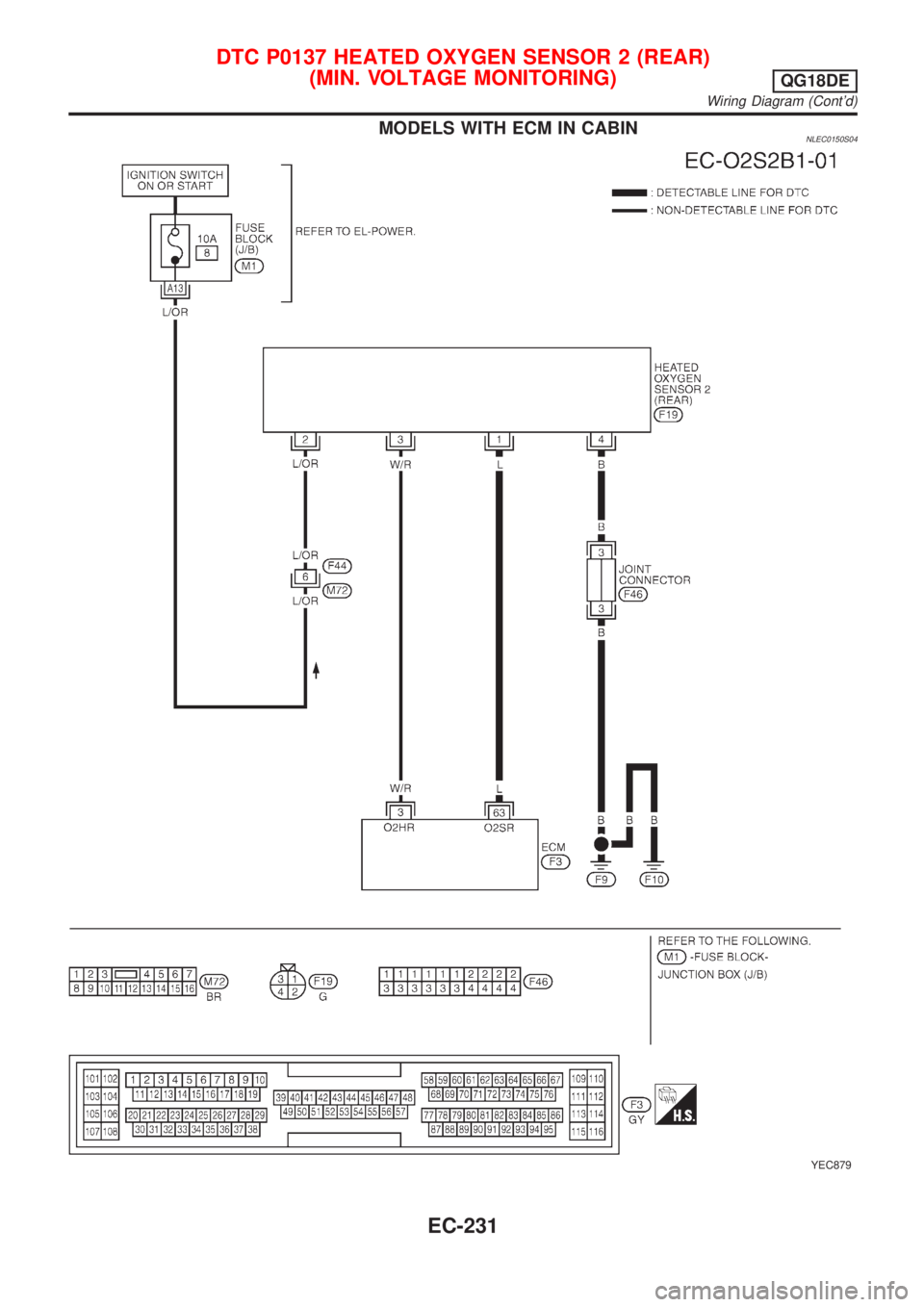

Page 656 of 3051

MODELS WITH ECM IN CABINNLEC0150S04

YEC879

DTC P0137 HEATED OXYGEN SENSOR 2 (REAR)

(MIN. VOLTAGE MONITORING)

QG18DE

Wiring Diagram (Cont'd)

EC-231

Page 659 of 3051

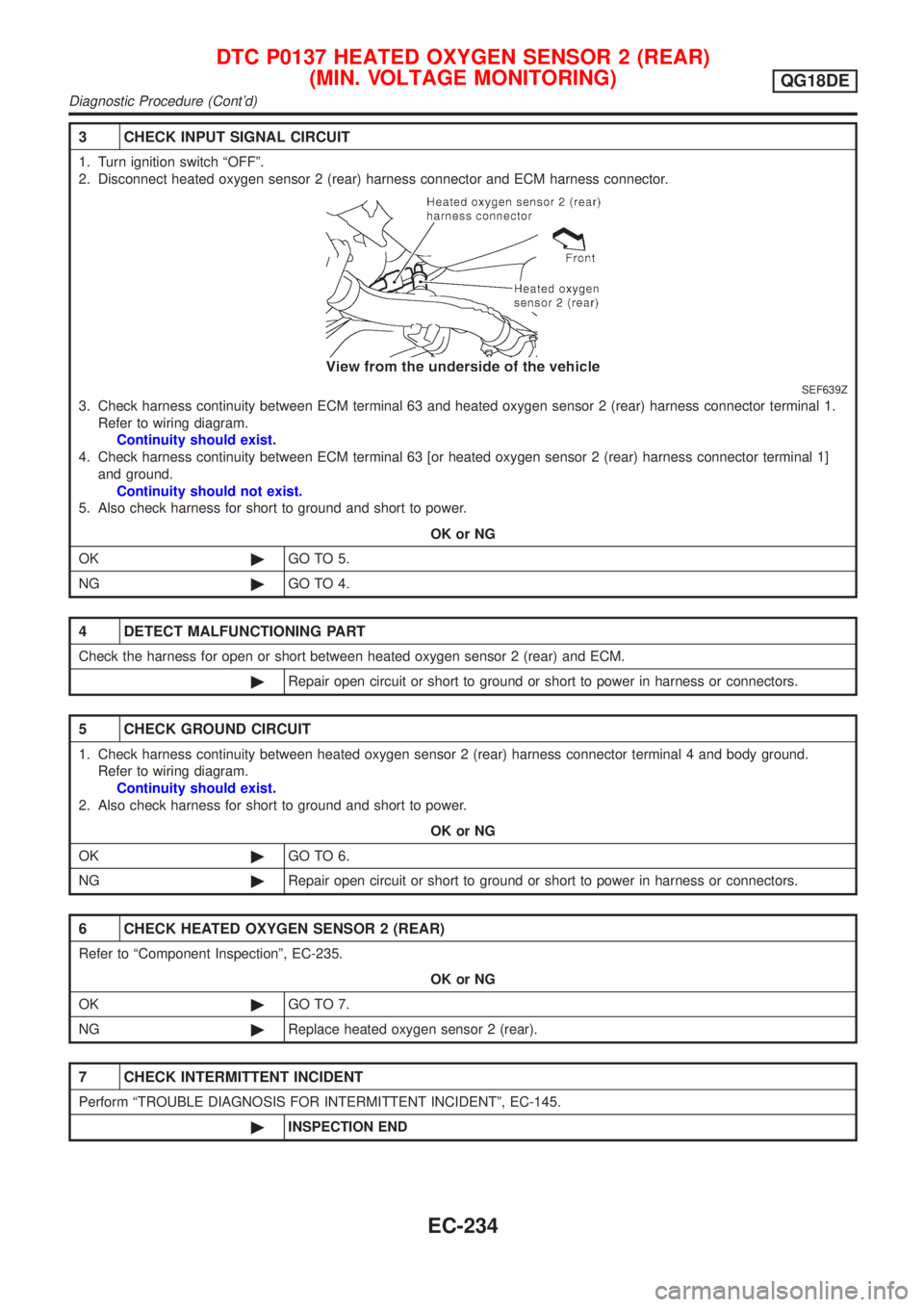

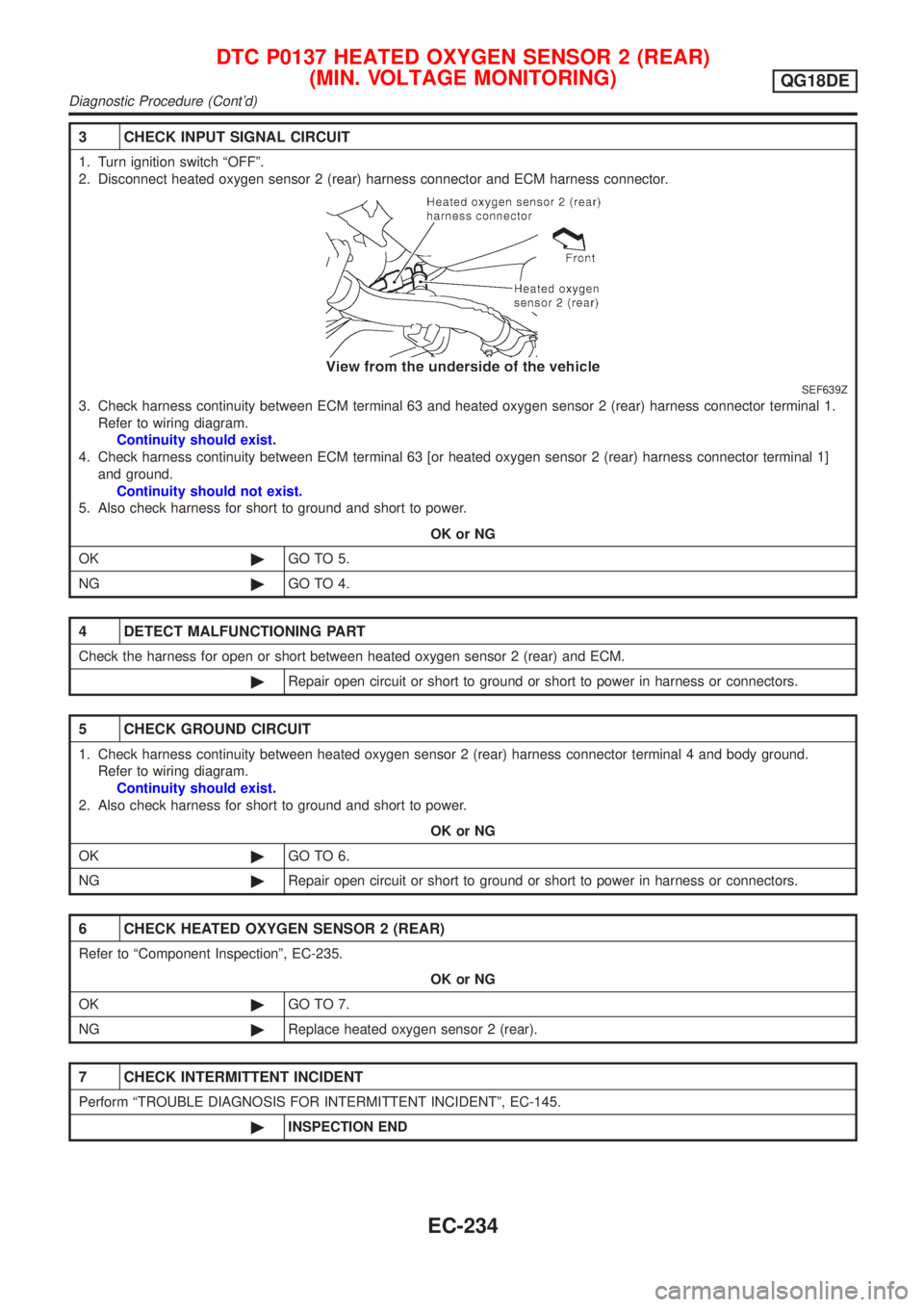

3 CHECK INPUT SIGNAL CIRCUIT

1. Turn ignition switch ªOFFº.

2. Disconnect heated oxygen sensor 2 (rear) harness connector and ECM harness connector.

SEF639Z

3. Check harness continuity between ECM terminal 63 and heated oxygen sensor 2 (rear) harness connector terminal 1.

Refer to wiring diagram.

Continuity should exist.

4. Check harness continuity between ECM terminal 63 [or heated oxygen sensor 2 (rear) harness connector terminal 1]

and ground.

Continuity should not exist.

5. Also check harness for short to ground and short to power.

OK or NG

OK©GO TO 5.

NG©GO TO 4.

4 DETECT MALFUNCTIONING PART

Check the harness for open or short between heated oxygen sensor 2 (rear) and ECM.

©Repair open circuit or short to ground or short to power in harness or connectors.

5 CHECK GROUND CIRCUIT

1. Check harness continuity between heated oxygen sensor 2 (rear) harness connector terminal 4 and body ground.

Refer to wiring diagram.

Continuity should exist.

2. Also check harness for short to ground and short to power.

OK or NG

OK©GO TO 6.

NG©Repair open circuit or short to ground or short to power in harness or connectors.

6 CHECK HEATED OXYGEN SENSOR 2 (REAR)

Refer to ªComponent Inspectionº, EC-235.

OK or NG

OK©GO TO 7.

NG©Replace heated oxygen sensor 2 (rear).

7 CHECK INTERMITTENT INCIDENT

Perform ªTROUBLE DIAGNOSIS FOR INTERMITTENT INCIDENTº, EC-145.

©INSPECTION END

DTC P0137 HEATED OXYGEN SENSOR 2 (REAR)

(MIN. VOLTAGE MONITORING)

QG18DE

Diagnostic Procedure (Cont'd)

EC-234

Page 665 of 3051

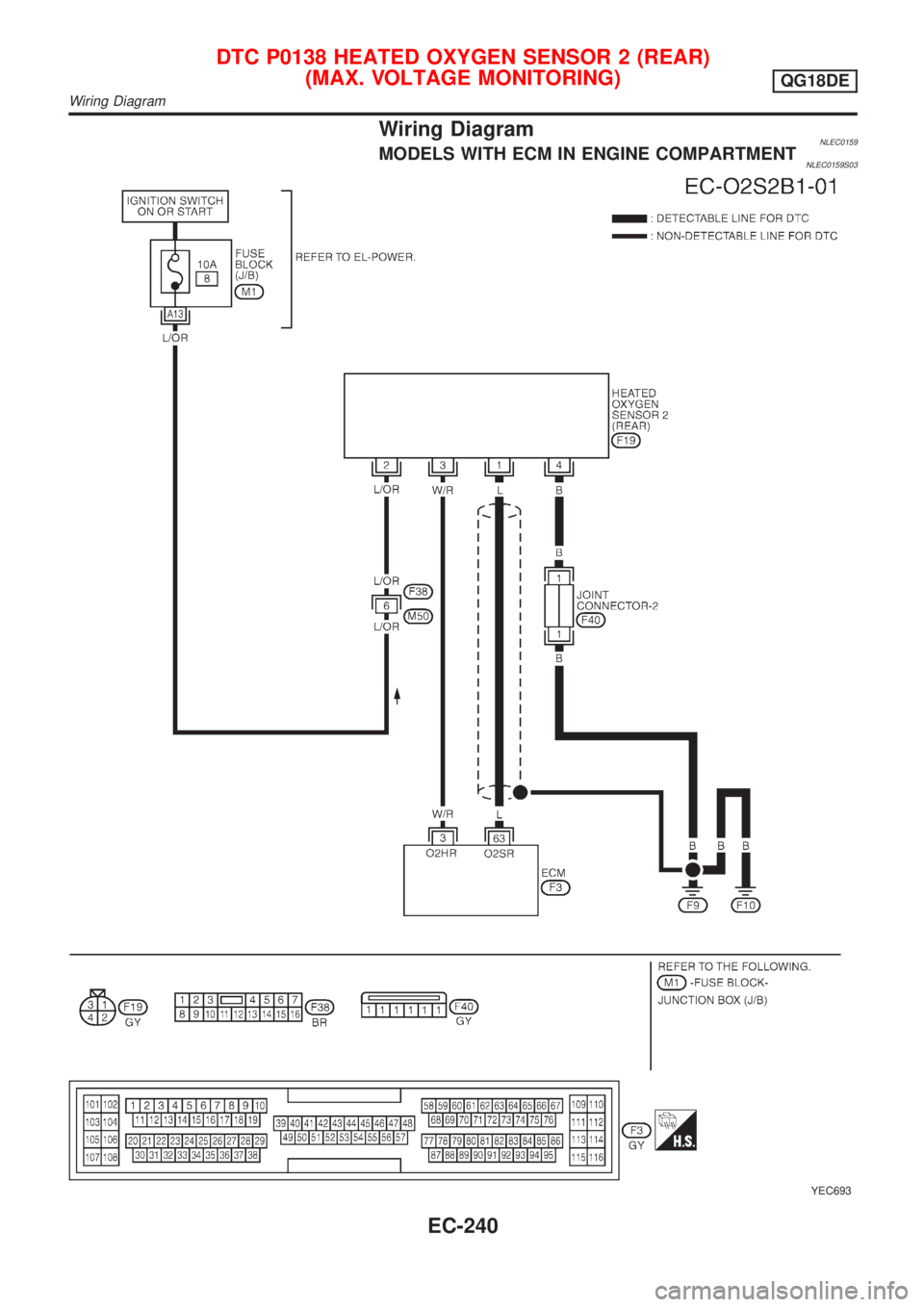

Wiring DiagramNLEC0159MODELS WITH ECM IN ENGINE COMPARTMENTNLEC0159S03

YEC693

DTC P0138 HEATED OXYGEN SENSOR 2 (REAR)

(MAX. VOLTAGE MONITORING)

QG18DE

Wiring Diagram

EC-240

Page 666 of 3051

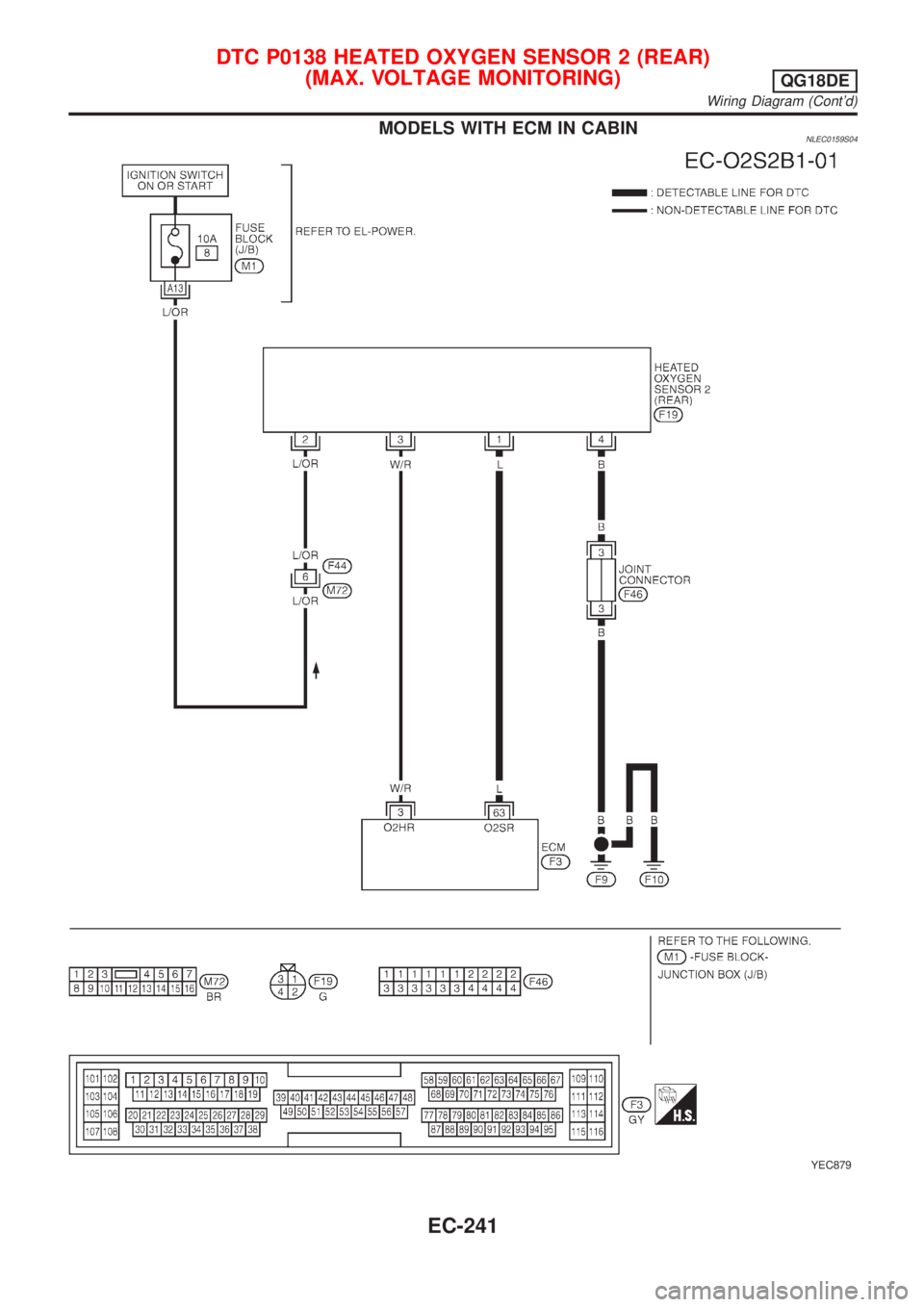

MODELS WITH ECM IN CABINNLEC0159S04

YEC879

DTC P0138 HEATED OXYGEN SENSOR 2 (REAR)

(MAX. VOLTAGE MONITORING)

QG18DE

Wiring Diagram (Cont'd)

EC-241