air conditioning NISSAN ALMERA TINO 2001 Service User Guide

[x] Cancel search | Manufacturer: NISSAN, Model Year: 2001, Model line: ALMERA TINO, Model: NISSAN ALMERA TINO 2001Pages: 3051, PDF Size: 46.38 MB

Page 1006 of 3051

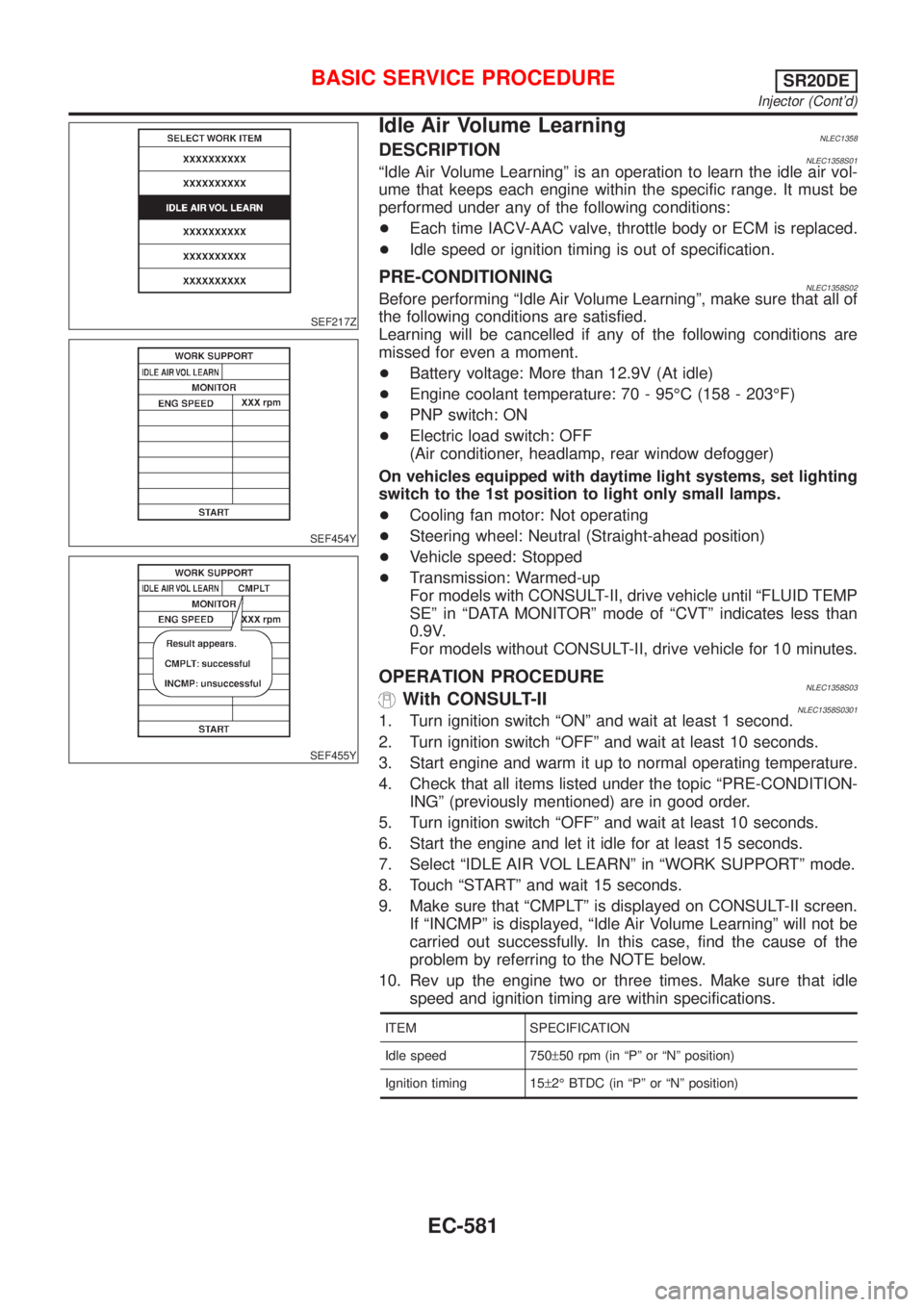

SEF217Z

SEF454Y

SEF455Y

Idle Air Volume LearningNLEC1358DESCRIPTIONNLEC1358S01ªIdle Air Volume Learningº is an operation to learn the idle air vol-

ume that keeps each engine within the specific range. It must be

performed under any of the following conditions:

+Each time IACV-AAC valve, throttle body or ECM is replaced.

+Idle speed or ignition timing is out of specification.

PRE-CONDITIONINGNLEC1358S02Before performing ªIdle Air Volume Learningº, make sure that all of

the following conditions are satisfied.

Learning will be cancelled if any of the following conditions are

missed for even a moment.

+Battery voltage: More than 12.9V (At idle)

+Engine coolant temperature: 70 - 95ÉC (158 - 203ÉF)

+PNP switch: ON

+Electric load switch: OFF

(Air conditioner, headlamp, rear window defogger)

On vehicles equipped with daytime light systems, set lighting

switch to the 1st position to light only small lamps.

+Cooling fan motor: Not operating

+Steering wheel: Neutral (Straight-ahead position)

+Vehicle speed: Stopped

+Transmission: Warmed-up

For models with CONSULT-II, drive vehicle until ªFLUID TEMP

SEº in ªDATA MONITORº mode of ªCVTº indicates less than

0.9V.

For models without CONSULT-II, drive vehicle for 10 minutes.

OPERATION PROCEDURENLEC1358S03With CONSULT-IINLEC1358S03011. Turn ignition switch ªONº and wait at least 1 second.

2. Turn ignition switch ªOFFº and wait at least 10 seconds.

3. Start engine and warm it up to normal operating temperature.

4. Check that all items listed under the topic ªPRE-CONDITION-

INGº (previously mentioned) are in good order.

5. Turn ignition switch ªOFFº and wait at least 10 seconds.

6. Start the engine and let it idle for at least 15 seconds.

7. Select ªIDLE AIR VOL LEARNº in ªWORK SUPPORTº mode.

8. Touch ªSTARTº and wait 15 seconds.

9. Make sure that ªCMPLTº is displayed on CONSULT-II screen.

If ªINCMPº is displayed, ªIdle Air Volume Learningº will not be

carried out successfully. In this case, find the cause of the

problem by referring to the NOTE below.

10. Rev up the engine two or three times. Make sure that idle

speed and ignition timing are within specifications.

ITEM SPECIFICATION

Idle speed 750±50 rpm (in ªPº or ªNº position)

Ignition timing 15±2É BTDC (in ªPº or ªNº position)

BASIC SERVICE PROCEDURESR20DE

Injector (Cont'd)

EC-581

Page 1503 of 3051

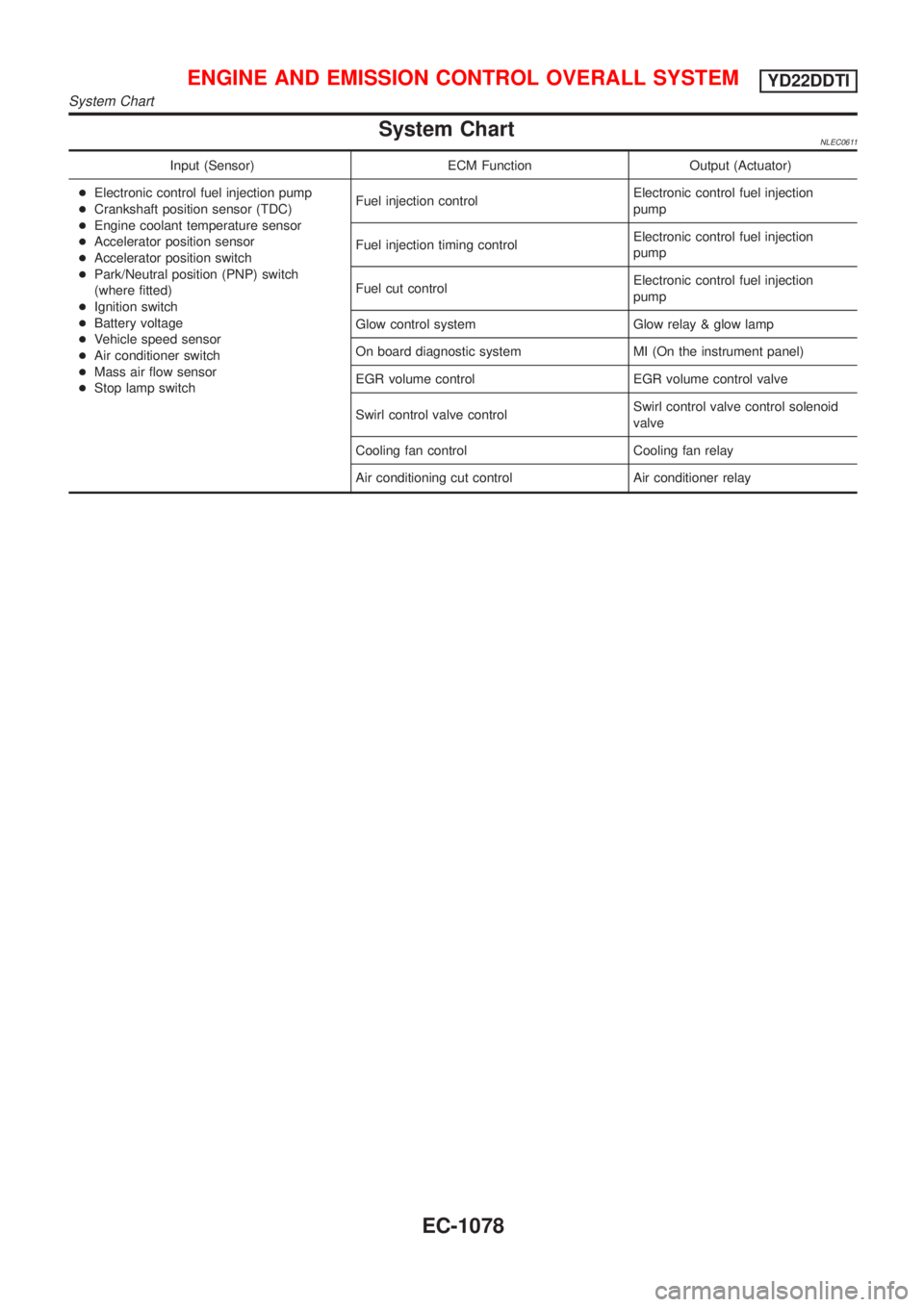

System ChartNLEC0611

Input (Sensor) ECM Function Output (Actuator)

+Electronic control fuel injection pump

+Crankshaft position sensor (TDC)

+Engine coolant temperature sensor

+Accelerator position sensor

+Accelerator position switch

+Park/Neutral position (PNP) switch

(where fitted)

+Ignition switch

+Battery voltage

+Vehicle speed sensor

+Air conditioner switch

+Mass air flow sensor

+Stop lamp switchFuel injection controlElectronic control fuel injection

pump

Fuel injection timing controlElectronic control fuel injection

pump

Fuel cut controlElectronic control fuel injection

pump

Glow control system Glow relay & glow lamp

On board diagnostic system MI (On the instrument panel)

EGR volume control EGR volume control valve

Swirl control valve controlSwirl control valve control solenoid

valve

Cooling fan control Cooling fan relay

Air conditioning cut control Air conditioner relay

ENGINE AND EMISSION CONTROL OVERALL SYSTEMYD22DDTI

System Chart

EC-1078

Page 1506 of 3051

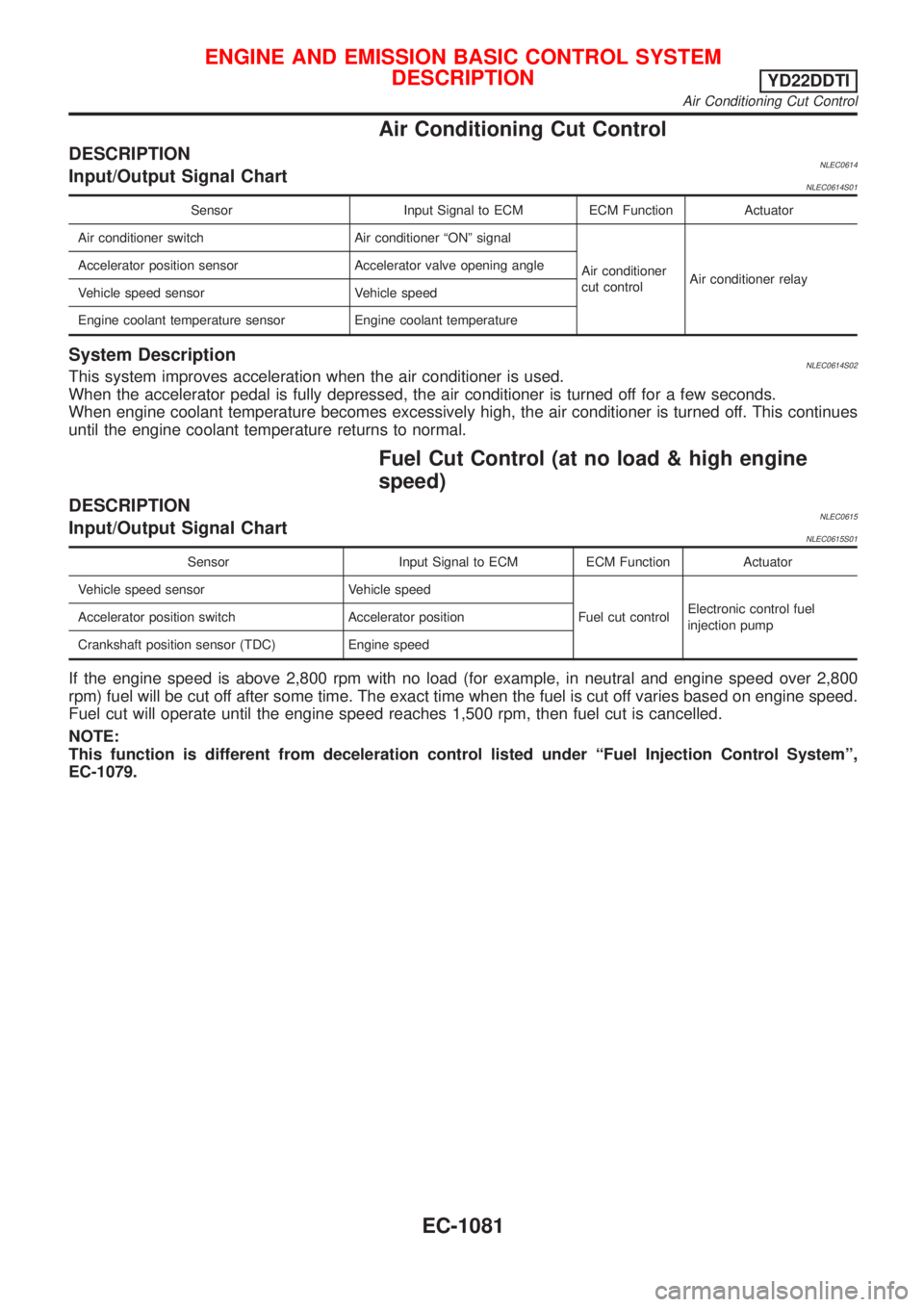

Air Conditioning Cut Control

DESCRIPTIONNLEC0614Input/Output Signal ChartNLEC0614S01

Sensor Input Signal to ECM ECM Function Actuator

Air conditioner switch Air conditioner ªONº signal

Air conditioner

cut controlAir conditioner relay Accelerator position sensor Accelerator valve opening angle

Vehicle speed sensor Vehicle speed

Engine coolant temperature sensor Engine coolant temperature

System DescriptionNLEC0614S02This system improves acceleration when the air conditioner is used.

When the accelerator pedal is fully depressed, the air conditioner is turned off for a few seconds.

When engine coolant temperature becomes excessively high, the air conditioner is turned off. This continues

until the engine coolant temperature returns to normal.

Fuel Cut Control (at no load & high engine

speed)

DESCRIPTIONNLEC0615Input/Output Signal ChartNLEC0615S01

Sensor Input Signal to ECM ECM Function Actuator

Vehicle speed sensor Vehicle speed

Fuel cut controlElectronic control fuel

injection pump Accelerator position switch Accelerator position

Crankshaft position sensor (TDC) Engine speed

If the engine speed is above 2,800 rpm with no load (for example, in neutral and engine speed over 2,800

rpm) fuel will be cut off after some time. The exact time when the fuel is cut off varies based on engine speed.

Fuel cut will operate until the engine speed reaches 1,500 rpm, then fuel cut is cancelled.

NOTE:

This function is different from deceleration control listed under ªFuel Injection Control Systemº,

EC-1079.

ENGINE AND EMISSION BASIC CONTROL SYSTEM

DESCRIPTION

YD22DDTI

Air Conditioning Cut Control

EC-1081

Page 2450 of 3051

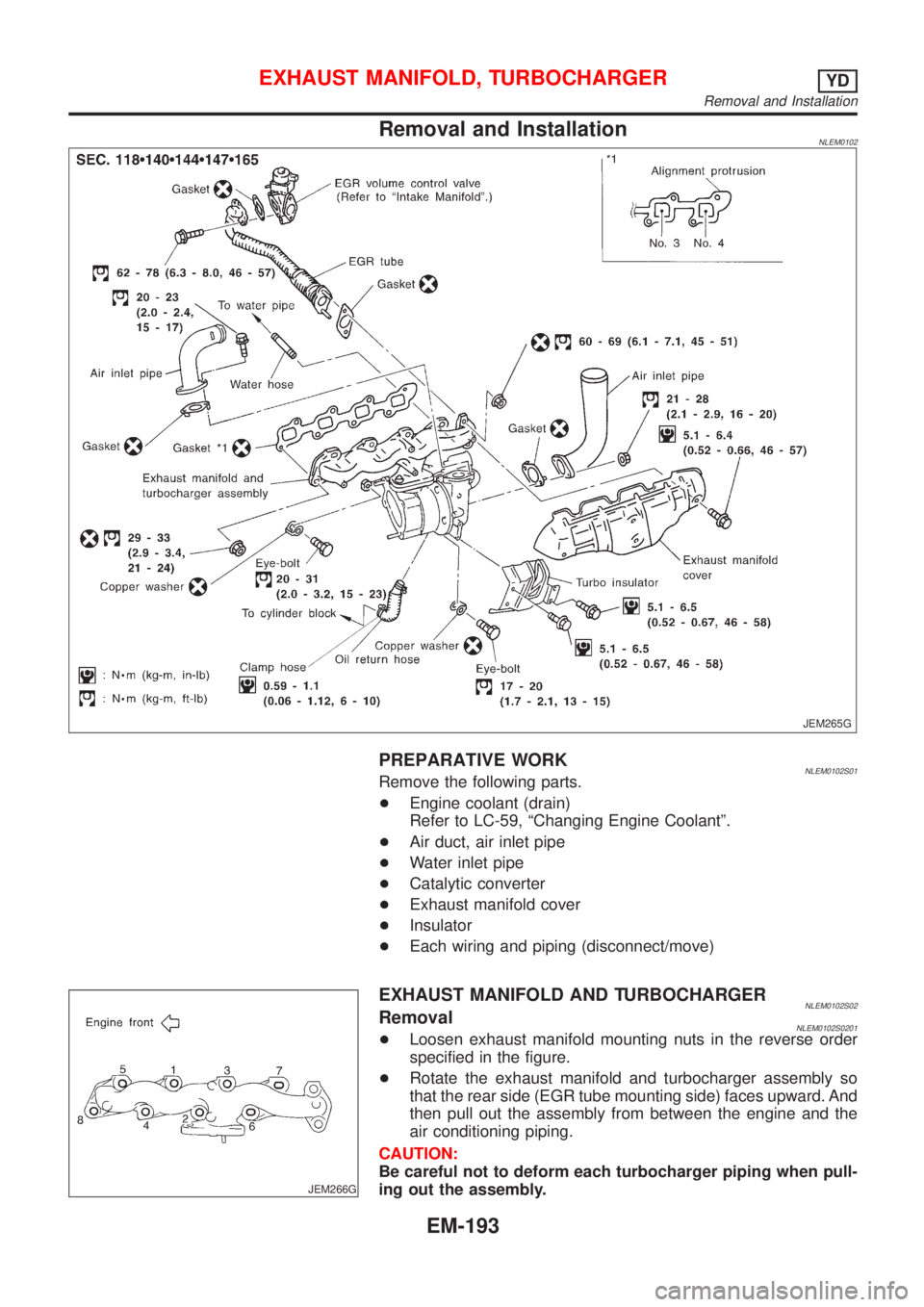

Removal and InstallationNLEM0102

JEM265G

PREPARATIVE WORKNLEM0102S01Remove the following parts.

+Engine coolant (drain)

Refer to LC-59, ªChanging Engine Coolantº.

+Air duct, air inlet pipe

+Water inlet pipe

+Catalytic converter

+Exhaust manifold cover

+Insulator

+Each wiring and piping (disconnect/move)

JEM266G

EXHAUST MANIFOLD AND TURBOCHARGERNLEM0102S02RemovalNLEM0102S0201+Loosen exhaust manifold mounting nuts in the reverse order

specified in the figure.

+Rotate the exhaust manifold and turbocharger assembly so

that the rear side (EGR tube mounting side) faces upward. And

then pull out the assembly from between the engine and the

air conditioning piping.

CAUTION:

Be careful not to deform each turbocharger piping when pull-

ing out the assembly.

EXHAUST MANIFOLD, TURBOCHARGERYD

Removal and Installation

EM-193

Page 2540 of 3051

GENERAL INFORMATION

SECTION

GI

CONTENTS

PRECAUTIONS...............................................................3

Precautions ..................................................................3

PRECAUTIONS FOR SUPPLEMENTAL

RESTRAINT SYSTEM (SRS)″AIR BAG″AND

″SEAT BELT PRE-TENSIONER″

.................................3

PRECAUTIONS FOR NATS (NISSAN ANTI-THEFT

SYSTEM)

..................................................................3

GENERAL PRECAUTIONS.........................................4

PRECAUTIONS FOR MULTIPORT FUEL

INJECTION SYSTEM OR ENGINE CONTROL

SYSTEM

...................................................................6

PRECAUTIONS FOR THREE WAY CATALYST...........6

PRECAUTIONS FOR HOSES.....................................6

PRECAUTIONS FOR ENGINE OILS...........................7

PRECAUTIONS FOR FUEL........................................8

PRECAUTIONS FOR AIR CONDITIONING..................8

HOW TO USE THIS MANUAL........................................9

HOW TO READ WIRING DIAGRAMS.......................... 11

Sample/Wiring Diagram - EXAMPL - ........................ 11

OPTIONAL SPLICE..................................................12

Description .................................................................13

CONNECTOR SYMBOLS.........................................15

HARNESS INDICATION...........................................16

COMPONENT INDICATION......................................16

SWITCH POSITIONS...............................................16

DETECTABLE LINES AND NON-DETECTABLE

LINES

.....................................................................17

MULTIPLE SWITCH.................................................18

REFERENCE AREA.................................................19

HOW TO PERFORM EFFICIENT DIAGNOSES

FOR AN ELECTRICAL INCIDENT...............................21

Work Flow ..................................................................21

Incident Simulation Tests ...........................................22

INTRODUCTION......................................................22

VEHICLE VIBRATION..............................................22

HEAT SENSITIVE....................................................23

FREEZING..............................................................23

WATER INTRUSION................................................24

ELECTRICAL LOAD.................................................24

COLD OR HOT START UP.......................................24

Circuit Inspection .......................................................24

INTRODUCTION......................................................24

TESTING FOR″OPENS″IN THE CIRCUIT................25

TESTING FOR″SHORTS″IN THE CIRCUIT..............26

GROUND INSPECTION...........................................27

VOLTAGE DROP TESTS..........................................27

CONTROL UNIT CIRCUIT TEST...............................29

HOW TO FOLLOW TROUBLE DIAGNOSES...............31

How to Follow Test Groups in Trouble Diagnoses ....32

Key to Symbols Signifying Measurements or

Procedures.................................................................33

CONSULT-II CHECKING SYSTEM...............................35

Function and System Application ..............................35

Nickel Metal Hydride Battery Replacement...............35

Checking Equipment..................................................36

CONSULT-II Data Link Connector (DLC) Circuit ......36

INSPECTION PROCEDURE.....................................36

IDENTIFICATION INFORMATION................................37

Model Variation ..........................................................37

PREFIX AND SUFFIX DESIGNATIONS.....................37

Identification Number .................................................38

VEHICLE IDENTIFICATION NUMBER

ARRANGEMENT

.....................................................38

IDENTIFICATION PLATE..........................................39

ENGINE SERIAL NUMBER.......................................39

H.CVT NUMBER......................................................40

MANUAL TRANSAXLE NUMBER..............................40

Dimensions ................................................................41

Wheels and Tires .......................................................41

LIFTING POINTS AND TOW TRUCK TOWING...........42

Preparation ................................................................42

SPECIAL SERVICE TOOLS......................................42

Board-on Lift ..............................................................42

Garage Jack and Safety Stand .................................43

2-pole Lift ...................................................................44

Tow Truck Towing ......................................................45

TOWING A H.CVT MODEL WITH FOUR WHEELS

ON GROUND

..........................................................45

TOWING A H.CVT MODEL WITH REAR WHEELS

RAISED (WITH FRONT WHEELS ON GROUND)

.......45

TOWING POINT.......................................................46

Page 2547 of 3051

+Do not use gasoline, kerosine, diesel fuel, gas oil, thinners or

solvents for cleaning skin.

+If skin disorders develop, obtain medical advice without delay.

+Where practicable, degrease components prior to handling.

+Where there is a risk of eye contact, eye protection should be

worn, for example, chemical goggles or face shields; in addi-

tion an eye wash facility should be provided.

Environmental Protection PrecautionsNLGI0001S0702Burning used engine oil in small space heaters or boilers can be

recommended only for units of approved design. The heating sys-

tem must meet the requirements of HM Inspectorate of Pollution for

small burners of less than 0.4 MW. If in doubt, check with the

appropriate local authority and/or manufacturer of the approved

appliance.

Dispose of used oil and used oil filters through authorized waste

disposal contractors to licensed waste disposal sites, or to the

waste oil reclamation trade. If in doubt, contact the local authority

for advice on disposal facilities.

It is illegal to pour used oil on to the ground, down sewers or drains,

or into water courses.

The regulations concerning the pollution vary between

regions.

PRECAUTIONS FOR FUELNLGI0001S08Gasoline EngineNLGI0001S0804Models with three way catalyst

Unleaded premium gasoline of at least 95 octane (RON)

If premium gasoline is not available, unleaded regular gaso-

line with an octane rating of 91 (RON) may be temporarily

used, but only under the following precautions:

+Have the fuel tank filled only partially with unleaded regu-

lar gasoline, and fill up with premium unleaded gasoline

as soon as possible.

+Avoid full throttle driving and abrupt acceleration.

CAUTION:

Do not use leaded gasoline. Using leaded gasoline will dam-

age the three way catalyst.

Diesel Engine*:NLGI0001S0805Diesel fuel of at least 50 cetane

* If two types of diesel fuel are available, use summer or winter

fuel properly according to the following temperature conditions.

+Above �7°C (20°F) ... Summer type diesel fuel.

+Below �7°C (20°F) ... Winter type diesel fuel.

CAUTION:

+Do not use home heating oil, gasoline, or other alternate

fuels in your diesel engine. The use of those can cause

engine damage.

+Do not use summer fuel at temperatures below �7°C

(20°F). The cold temperatures will cause wax to form in the

fuel. As a result, it may prevent the engine from running

smoothly.

+Do not add gasoline or other alternate fuels to diesel fuel.

PRECAUTIONS FOR AIR CONDITIONINGNLGI0001S09Use an approved refrigerant recovery unit any time the air condi-

tioning system must be discharged. Refer to HA-85, “HFC-134a

(R-134a) Service Procedure” for specific instructions.

PRECAUTIONS

Precautions (Cont’d)

GI-8

Page 2593 of 3051

Supplemental Restraint System (SRS) “AIR

BAG” and “SEAT BELT PRE-TENSIONER”

NLHA0190The Supplemental Restraint System such as “AIR BAG” and “SEAT BELT PRE-TENSIONER” used along with

a seat belt, helps to reduce the risk or severity of injury to the driver and front passenger for certain types of

collision. The SRS system composition which is available to NISSAN MODEL V10 is as follows (The compo-

sition varies according to the destination and optional equipment.):

+For a frontal collision

The Supplemental Restraint System consists of driver air bag module (located in the center of the steer-

ing wheel), front passenger air bag module (located on the instrument panel on passenger side), front seat

belt pre-tensioners, a diagnosis sensor unit, warning lamp, wiring harness and spiral cable.

+For a side collision

The Supplemental Restraint System consists of front side air bag module (located in the outer side of front

seat), side air bag (satellite) sensor, diagnosis sensor unit (one of components of air bags for a frontal

collision), wiring harness, warning lamp (one of components of air bags for a frontal collision).

Information necessary to service the system safely is included in theRS sectionof this Service Manual.

WARNING:

+To avoid rendering the SRS inoperative, which could increase the risk of personal injury or death

in the event of a collision which would result in air bag inflation, all maintenance should be per-

formed by an authorized NISSAN dealer.

+Improper maintenance, including incorrect removal and installation of the SRS, can lead to per-

sonal injury caused by unintentional activation of the system. For removal of Spiral Cable and Air

Bag Module, see the RS section.

+Do not use electrical test equipment on any circuit related to the SRS unless instructed to in this

Service Manual. Spiral cable and wiring harnesses covered with yellow insulation tape either just

before the harness connectors or for the complete harness are related to the SRS.

Precautions for Working with HFC-134a

(R-134a)

NLHA0113WARNING:

+CFC-12 (R-12) refrigerant and HFC-134a (R-134a) refrigerant are not compatible. These refrigerants

must never be mixed, even in the smallest amounts. If the refrigerants are mixed, compressor fail-

ure is likely to occur.

+Use only specified lubricant for the HFC-134a (R-134a) A/C system and HFC-134a (R-134a) compo-

nents. If lubricant other than that specified is used, compressor failure is likely to occur.

+The specified HFC-134a (R-134a) lubricant rapidly absorbs moisture from the atmosphere. The fol-

lowing handling precautions must be observed:

a) When removing refrigerant components from a vehicle, immediately cap (seal) the component to

minimize the entry of moisture from the atmosphere.

b) When installing refrigerant components to a vehicle, do not remove the caps (unseal) until just

before connecting the components. Connect all refrigerant loop components as quickly as pos-

sible to minimize the entry of moisture into system.

c) Only use the specified lubricant from a sealed container. Immediately reseal containers of lubri-

cant. Without proper sealing, lubricant will become moisture saturated and should not be used.

d) Avoid breathing A/C refrigerant and lubricant vapor or mist. Exposure may irritate eyes, nose

and throat. Remove R-134a from the A/C system, using certified service equipment meeting

requirements of R-134a recycling equipment, or R-134a recovery equipment. If accidental system

discharge occurs, ventilate work area before resuming service. Additional health and safety

information may be obtained from refrigerant and lubricant manufacturers.

e) Do not allow lubricant (Nissan A/C System Oil Type S) to come in contact with styrofoam parts.

Damage may result.

General Refrigerant PrecautionsNLHA0114WARNING:

+Do not release refrigerant into the air. Use approved recovery/recycling equipment to capture the

refrigerant every time an air conditioning system is discharged.

+Always wear eye and hand protection (goggles and gloves) when working with any refrigerant or

air conditioning system.

PRECAUTIONS

Supplemental Restraint System (SRS) “AIR BAG” and “SEAT BELT PRE-TENSIONER”

HA-2

Page 2604 of 3051

CSV613 Variable Displacement Compressor

GENERAL INFORMATIONNLHA02061. The CSV613 compressor differs from previous units. The vent temperatures of the CSV613 compressor

do not drop too far below 5°C (41°F) when:

+evaporator intake air temperature is less than 20°C (68°F)

+engine is running at speeds less than 1,500 rpm.

This is because the CSV613 compressor provides a means of“capacity”control.

2. The CSV613 compressor provides refrigerant control under varying conditions. During cold winters, it may

not produce high refrigerant pressure discharge (compared to previous units) when used with air condi-

tioning systems.

3. A“clanking”sound may occasionally be heard during refrigerant charge. The sound indicates that the tilt

angle of the swash plate has changed and is not a problem.

4. For air conditioning systems with the CSV613 compressor, the clutch remains engaged unless: the sys-

tem main switch, fan switch or ignition switch is turned OFF. When ambient (outside) temperatures are

low or when the amount of refrigerant is insufficient, the clutch is disengaged to protect the compressor.

5. A constant range of suction pressure is maintained when engine speed is greater than a certain value. It

normally ranges from 147 to 177 kPa (1.47 to 1.77 bar, 1.5 to 1.8 kg/cm

2, 21 to 26 psi) under varying con-

ditions.

In previous compressors, however, suction pressure was reduced with increases in engine speed.

DESCRIPTION

CSV613 Variable Displacement Compressor

HA-13

Page 2669 of 3051

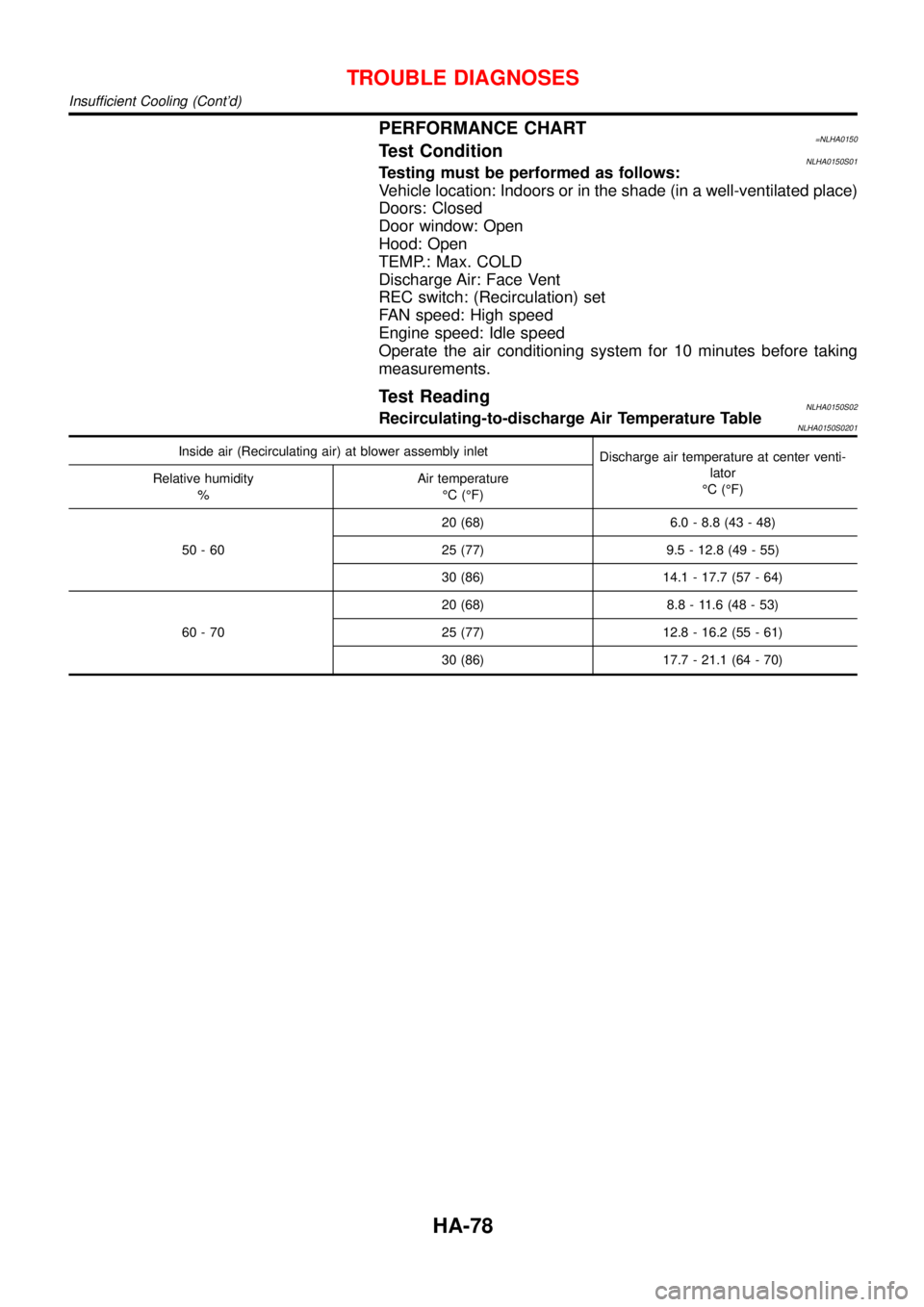

PERFORMANCE CHART=NLHA0150Test ConditionNLHA0150S01Testing must be performed as follows:

Vehicle location: Indoors or in the shade (in a well-ventilated place)

Doors: Closed

Door window: Open

Hood: Open

TEMP.: Max. COLD

Discharge Air: Face Vent

REC switch: (Recirculation) set

FAN speed: High speed

Engine speed: Idle speed

Operate the air conditioning system for 10 minutes before taking

measurements.

Test ReadingNLHA0150S02Recirculating-to-discharge Air Temperature TableNLHA0150S0201

Inside air (Recirculating air) at blower assembly inlet

Discharge air temperature at center venti-

lator

°C(°F) Relative humidity

%Air temperature

°C(°F)

50-6020 (68) 6.0 - 8.8 (43 - 48)

25 (77) 9.5 - 12.8 (49 - 55)

30 (86) 14.1 - 17.7 (57 - 64)

60-7020 (68) 8.8 - 11.6 (48 - 53)

25 (77) 12.8 - 16.2 (55 - 61)

30 (86) 17.7 - 21.1 (64 - 70)

TROUBLE DIAGNOSES

Insufficient Cooling (Cont’d)

HA-78

Page 2673 of 3051

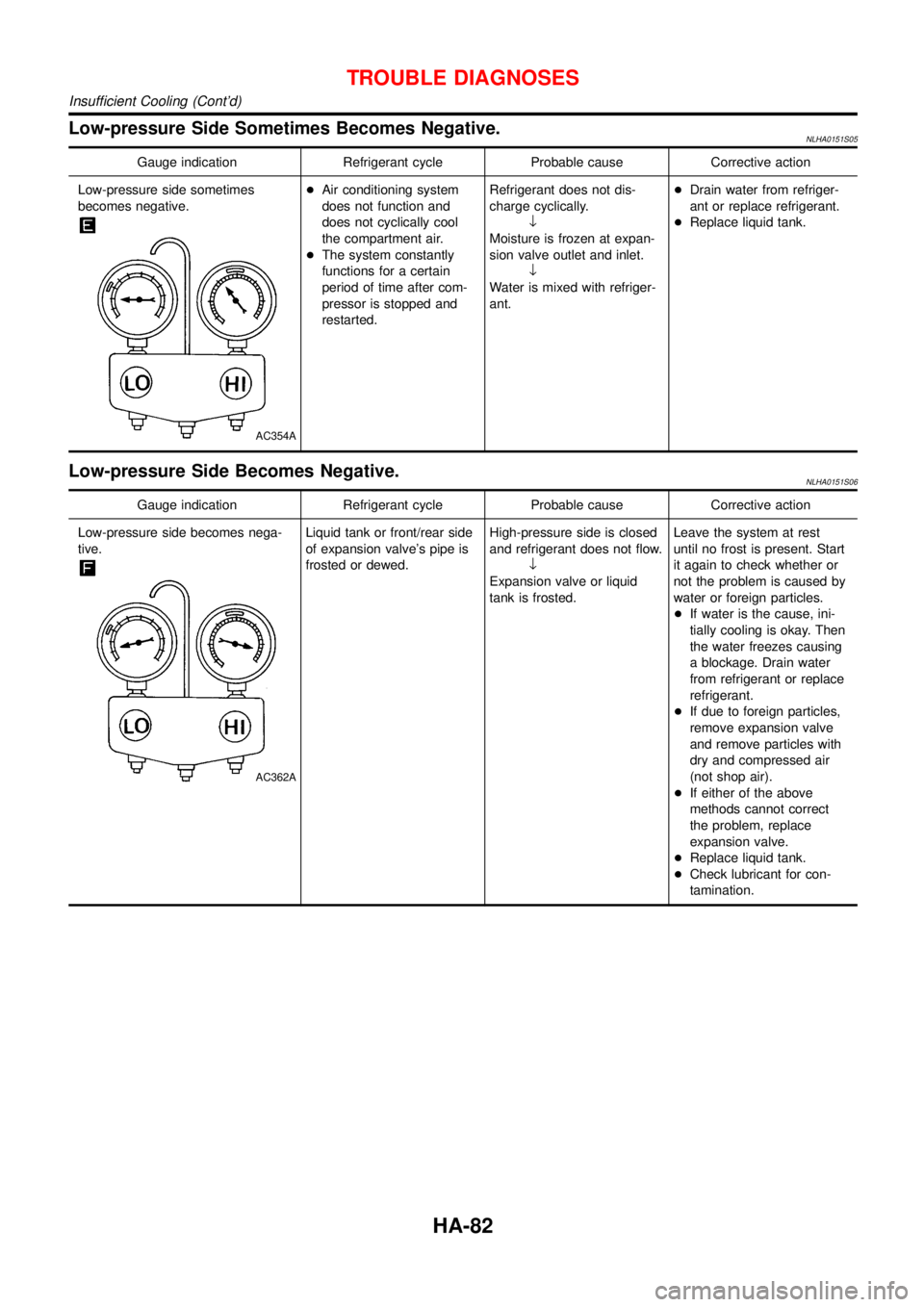

Low-pressure Side Sometimes Becomes Negative.NLHA0151S05

Gauge indication Refrigerant cycle Probable cause Corrective action

Low-pressure side sometimes

becomes negative.

AC354A

+Air conditioning system

does not function and

does not cyclically cool

the compartment air.

+The system constantly

functions for a certain

period of time after com-

pressor is stopped and

restarted.Refrigerant does not dis-

charge cyclically.

↓

Moisture is frozen at expan-

sion valve outlet and inlet.

↓

Water is mixed with refriger-

ant.+Drain water from refriger-

ant or replace refrigerant.

+Replace liquid tank.

Low-pressure Side Becomes Negative.NLHA0151S06

Gauge indication Refrigerant cycle Probable cause Corrective action

Low-pressure side becomes nega-

tive.

AC362A

Liquid tank or front/rear side

of expansion valve’s pipe is

frosted or dewed.High-pressure side is closed

and refrigerant does not flow.

↓

Expansion valve or liquid

tank is frosted.Leave the system at rest

until no frost is present. Start

it again to check whether or

not the problem is caused by

water or foreign particles.

+If water is the cause, ini-

tially cooling is okay. Then

the water freezes causing

a blockage. Drain water

from refrigerant or replace

refrigerant.

+If due to foreign particles,

remove expansion valve

and remove particles with

dry and compressed air

(not shop air).

+If either of the above

methods cannot correct

the problem, replace

expansion valve.

+Replace liquid tank.

+Check lubricant for con-

tamination.

TROUBLE DIAGNOSES

Insufficient Cooling (Cont’d)

HA-82