clutch NISSAN ALMERA TINO 2001 Service Owner's Manual

[x] Cancel search | Manufacturer: NISSAN, Model Year: 2001, Model line: ALMERA TINO, Model: NISSAN ALMERA TINO 2001Pages: 3051, PDF Size: 46.38 MB

Page 167 of 3051

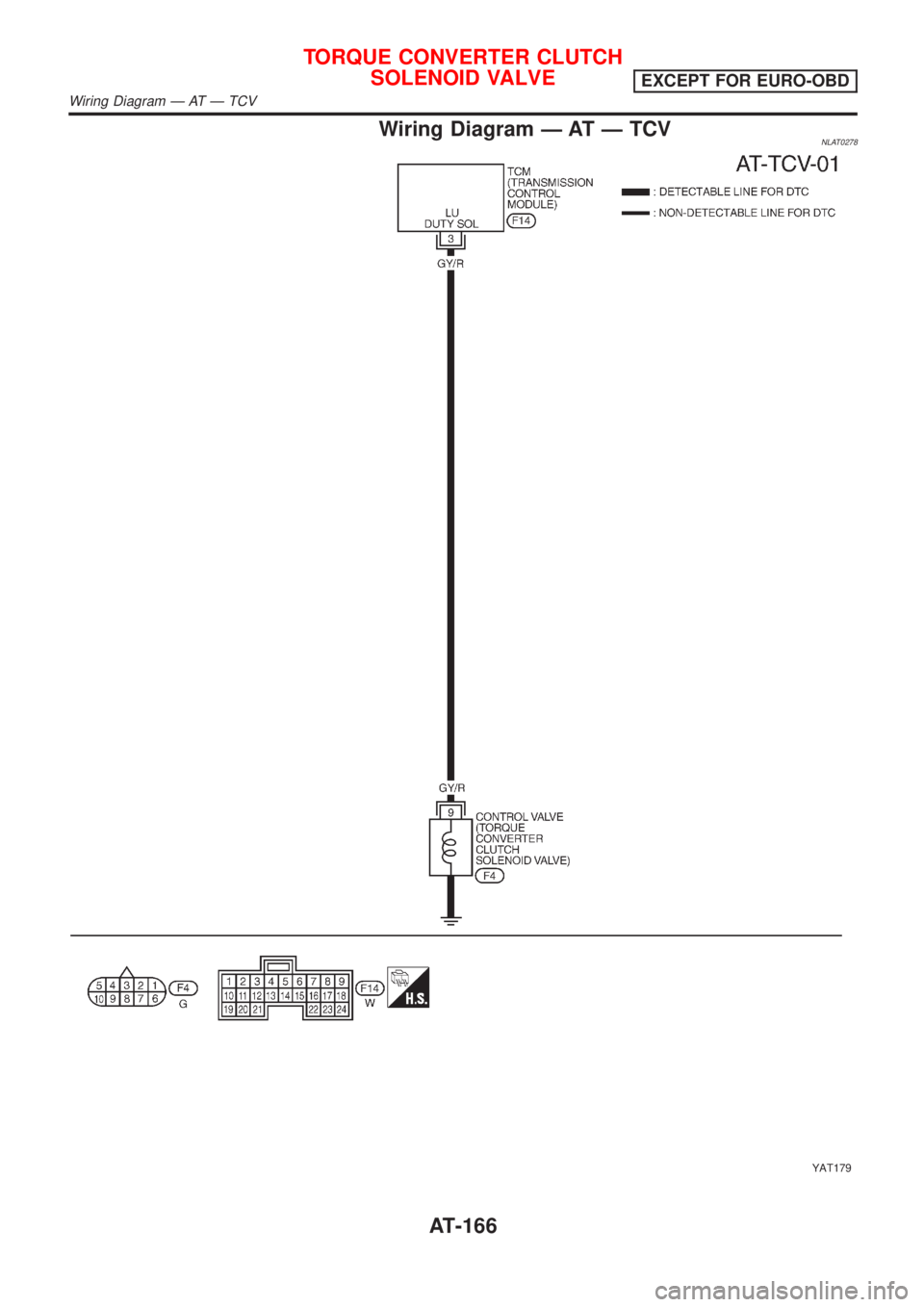

Wiring Diagram Ð AT Ð TCVNLAT0278

YAT179

TORQUE CONVERTER CLUTCH

SOLENOID VALVE

EXCEPT FOR EURO-OBD

Wiring Diagram Ð AT Ð TCV

AT-166

Page 168 of 3051

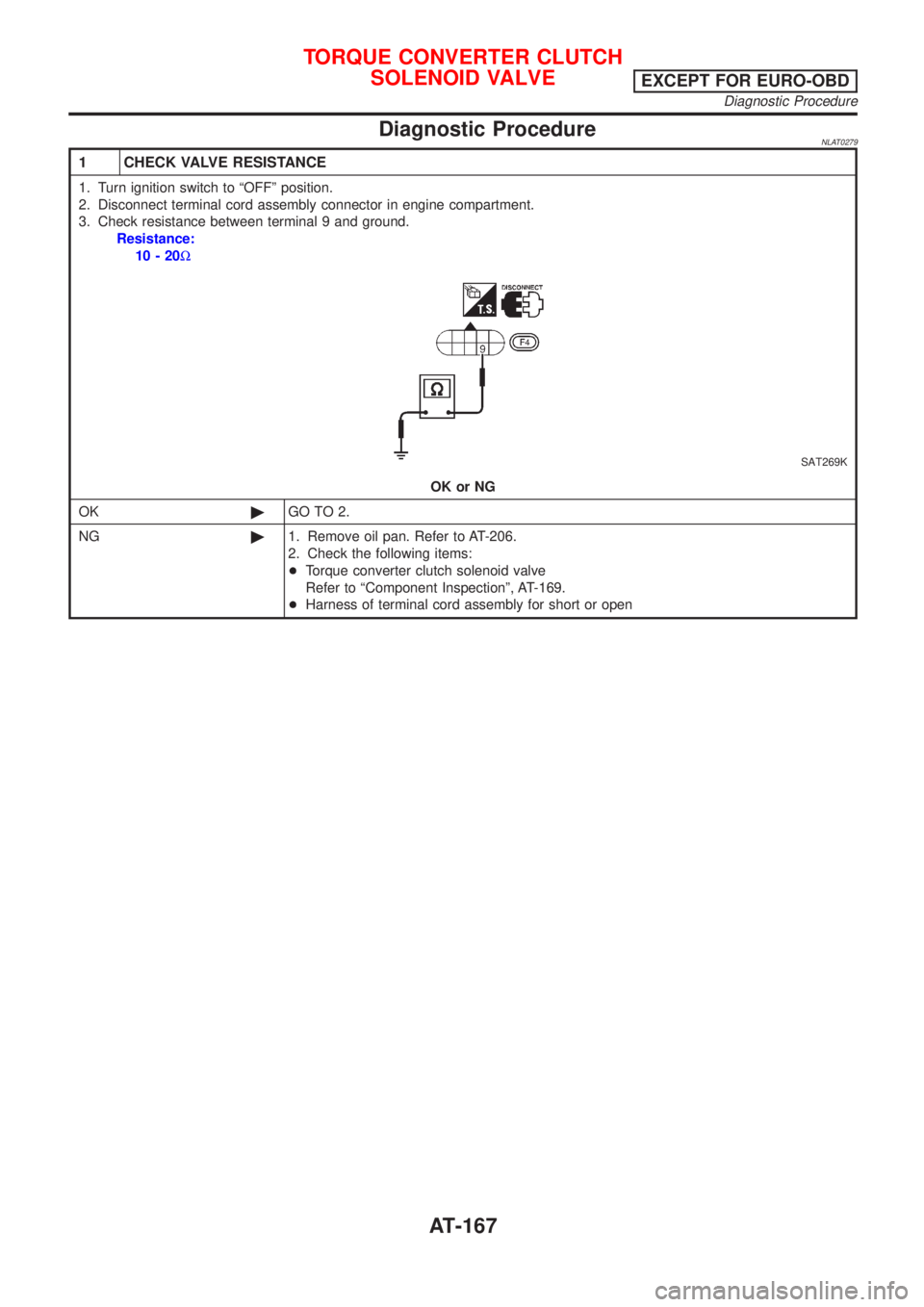

Diagnostic ProcedureNLAT0279

1 CHECK VALVE RESISTANCE

1. Turn ignition switch to ªOFFº position.

2. Disconnect terminal cord assembly connector in engine compartment.

3. Check resistance between terminal 9 and ground.

Resistance:

10-20W

SAT269K

OK or NG

OK©GO TO 2.

NG©1. Remove oil pan. Refer to AT-206.

2. Check the following items:

+Torque converter clutch solenoid valve

Refer to ªComponent Inspectionº, AT-169.

+Harness of terminal cord assembly for short or open

TORQUE CONVERTER CLUTCH

SOLENOID VALVE

EXCEPT FOR EURO-OBD

Diagnostic Procedure

AT-167

Page 169 of 3051

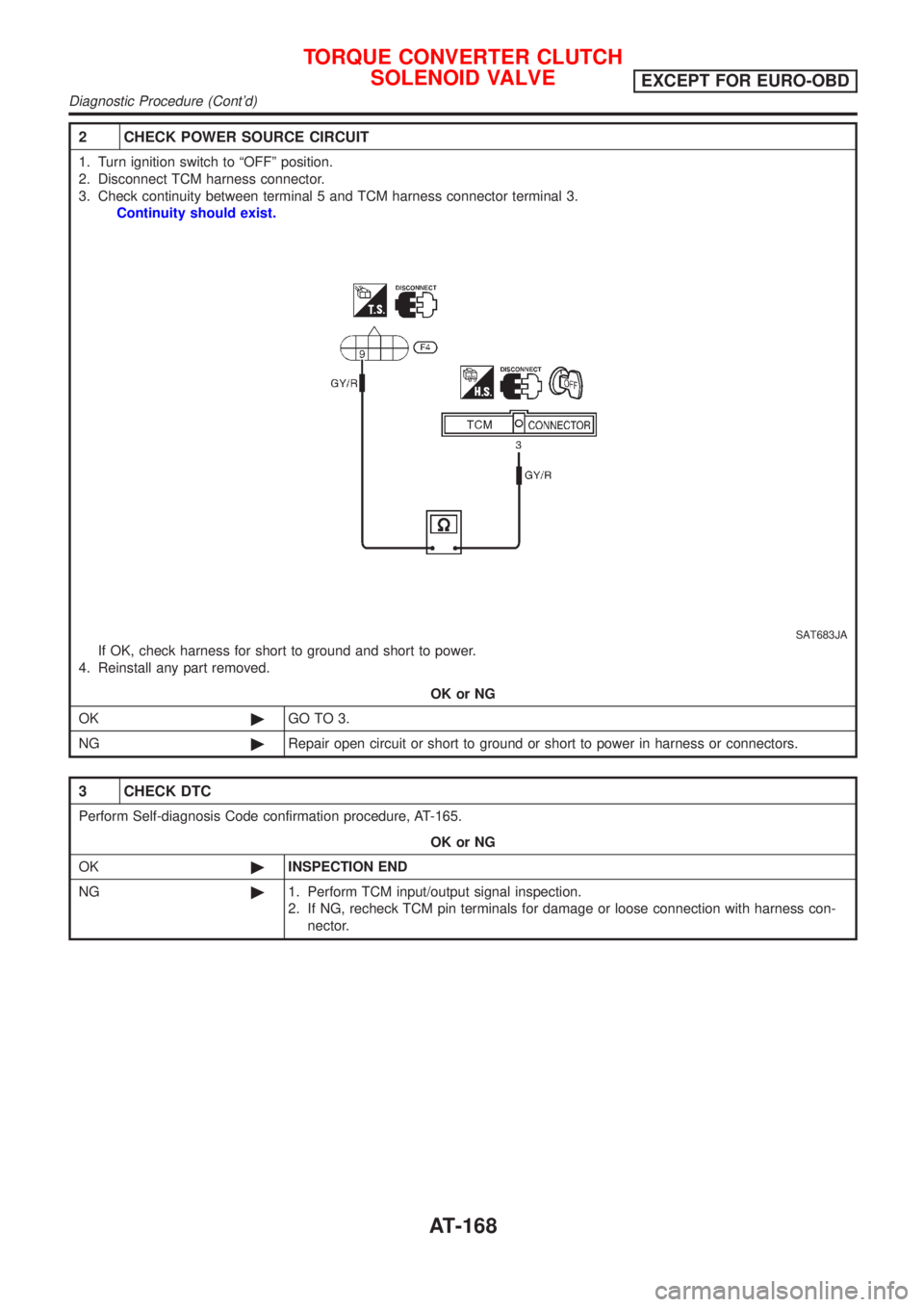

2 CHECK POWER SOURCE CIRCUIT

1. Turn ignition switch to ªOFFº position.

2. Disconnect TCM harness connector.

3. Check continuity between terminal 5 and TCM harness connector terminal 3.

Continuity should exist.

SAT683JA

If OK, check harness for short to ground and short to power.

4. Reinstall any part removed.

OK or NG

OK©GO TO 3.

NG©Repair open circuit or short to ground or short to power in harness or connectors.

3 CHECK DTC

Perform Self-diagnosis Code confirmation procedure, AT-165.

OK or NG

OK©INSPECTION END

NG©1. Perform TCM input/output signal inspection.

2. If NG, recheck TCM pin terminals for damage or loose connection with harness con-

nector.

TORQUE CONVERTER CLUTCH

SOLENOID VALVE

EXCEPT FOR EURO-OBD

Diagnostic Procedure (Cont'd)

AT-168

Page 170 of 3051

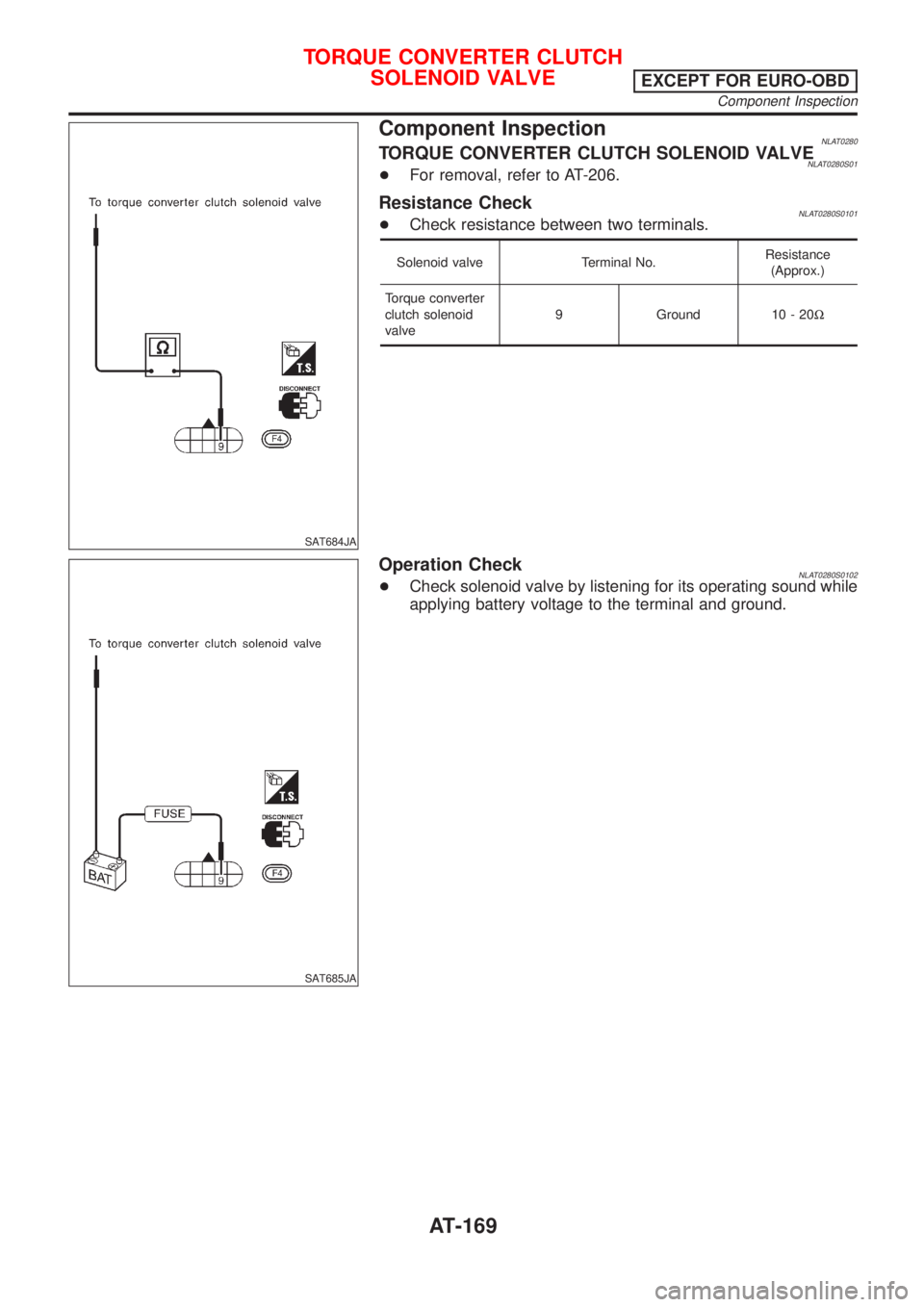

SAT684JA

Component InspectionNLAT0280TORQUE CONVERTER CLUTCH SOLENOID VALVENLAT0280S01+For removal, refer to AT-206.

Resistance CheckNLAT0280S0101+Check resistance between two terminals.

Solenoid valve Terminal No.Resistance

(Approx.)

Torque converter

clutch solenoid

valve9 Ground 10 - 20W

SAT685JA

Operation CheckNLAT0280S0102+Check solenoid valve by listening for its operating sound while

applying battery voltage to the terminal and ground.

TORQUE CONVERTER CLUTCH

SOLENOID VALVE

EXCEPT FOR EURO-OBD

Component Inspection

AT-169

Page 211 of 3051

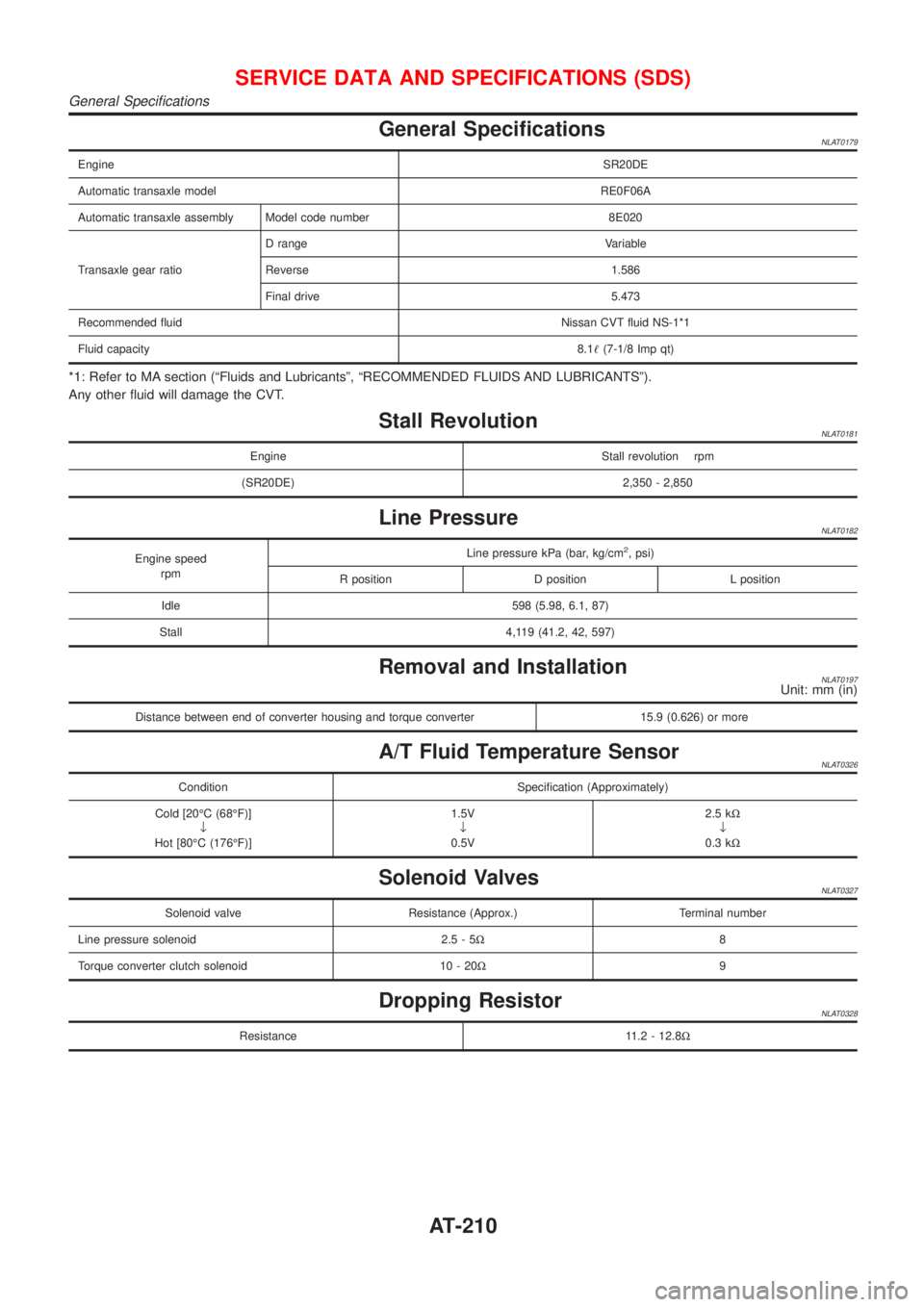

General SpecificationsNLAT0179

EngineSR20DE

Automatic transaxle modelRE0F06A

Automatic transaxle assembly Model code number 8E020

Transaxle gear ratioD range Variable

Reverse 1.586

Final drive 5.473

Recommended fluidNissan CVT fluid NS-1*1

Fluid capacity8.1!(7-1/8 Imp qt)

*1: Refer to MA section (ªFluids and Lubricantsº, ªRECOMMENDED FLUIDS AND LUBRICANTSº).

Any other fluid will damage the CVT.

Stall RevolutionNLAT0181

Engine Stall revolution rpm

(SR20DE) 2,350 - 2,850

Line PressureNLAT0182

Engine speed

rpmLine pressure kPa (bar, kg/cm2, psi)

R position D position L position

Idle 598 (5.98, 6.1, 87)

Stall 4,119 (41.2, 42, 597)

Removal and InstallationNLAT0197Unit: mm (in)

Distance between end of converter housing and torque converter 15.9 (0.626) or more

A/T Fluid Temperature SensorNLAT0326

Condition Specification (Approximately)

Cold [20ÉC (68ÉF)]

¯

Hot [80ÉC (176ÉF)]1.5V

¯

0.5V2.5 kW

¯

0.3 kW

Solenoid ValvesNLAT0327

Solenoid valve Resistance (Approx.) Terminal number

Line pressure solenoid 2.5 - 5W8

Torque converter clutch solenoid 10 - 20W9

Dropping ResistorNLAT0328

Resistance 11.2 - 12.8W

SERVICE DATA AND SPECIFICATIONS (SDS)

General Specifications

AT-210

Page 252 of 3051

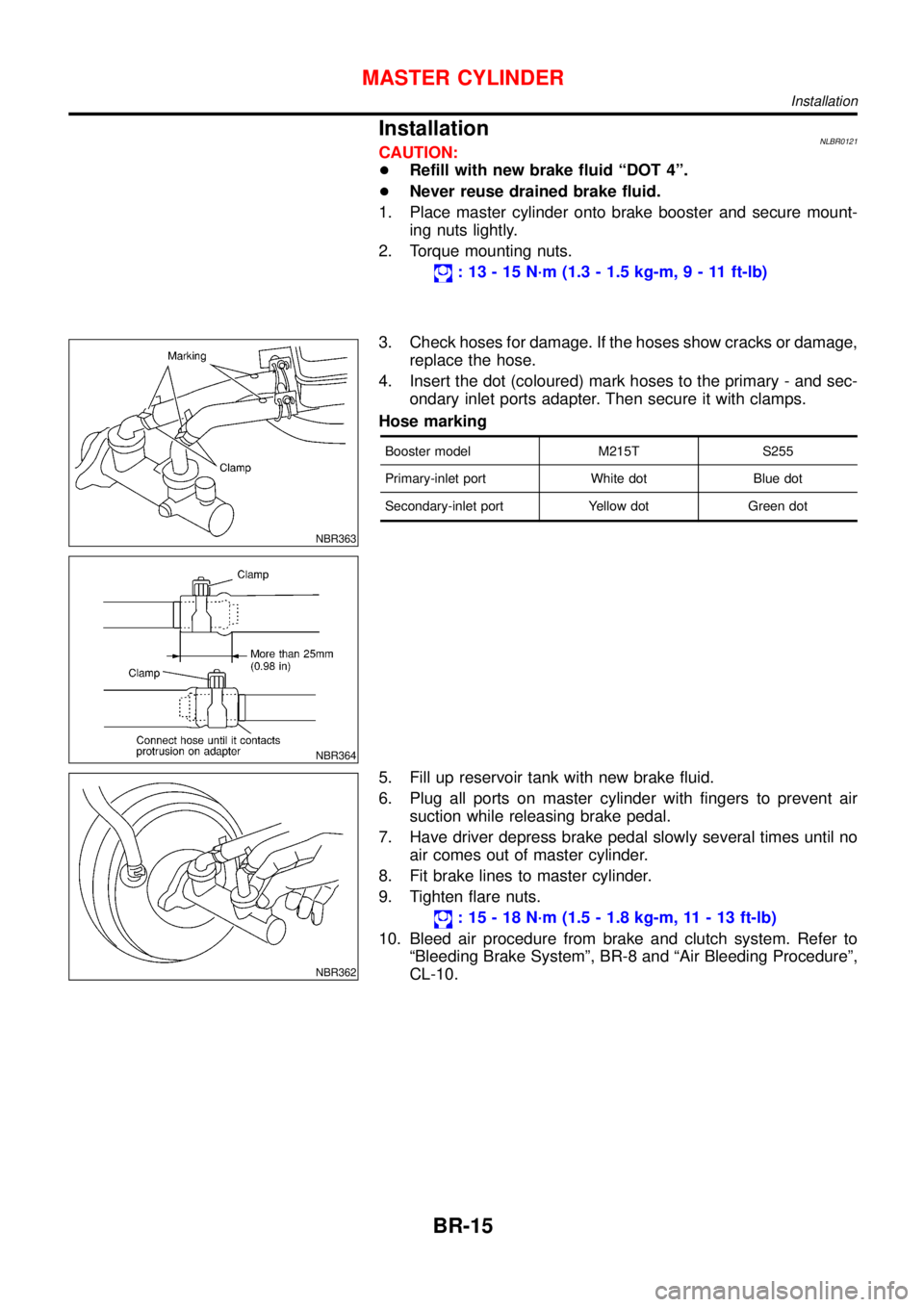

InstallationNLBR0121CAUTION:

+Refill with new brake fluid“DOT 4”.

+Never reuse drained brake fluid.

1. Place master cylinder onto brake booster and secure mount-

ing nuts lightly.

2. Torque mounting nuts.

:13-15N·m (1.3 - 1.5 kg-m,9-11ft-lb)

NBR363

NBR364

3. Check hoses for damage. If the hoses show cracks or damage,

replace the hose.

4. Insert the dot (coloured) mark hoses to the primary - and sec-

ondary inlet ports adapter. Then secure it with clamps.

Hose marking

Booster model M215T S255

Primary-inlet port White dot Blue dot

Secondary-inlet port Yellow dot Green dot

NBR362

5. Fill up reservoir tank with new brake fluid.

6. Plug all ports on master cylinder with fingers to prevent air

suction while releasing brake pedal.

7. Have driver depress brake pedal slowly several times until no

air comes out of master cylinder.

8. Fit brake lines to master cylinder.

9. Tighten flare nuts.

:15-18N·m (1.5 - 1.8 kg-m, 11 - 13 ft-lb)

10. Bleed air procedure from brake and clutch system. Refer to

“Bleeding Brake System”, BR-8 and“Air Bleeding Procedure”,

CL-10.

MASTER CYLINDER

Installation

BR-15

Page 322 of 3051

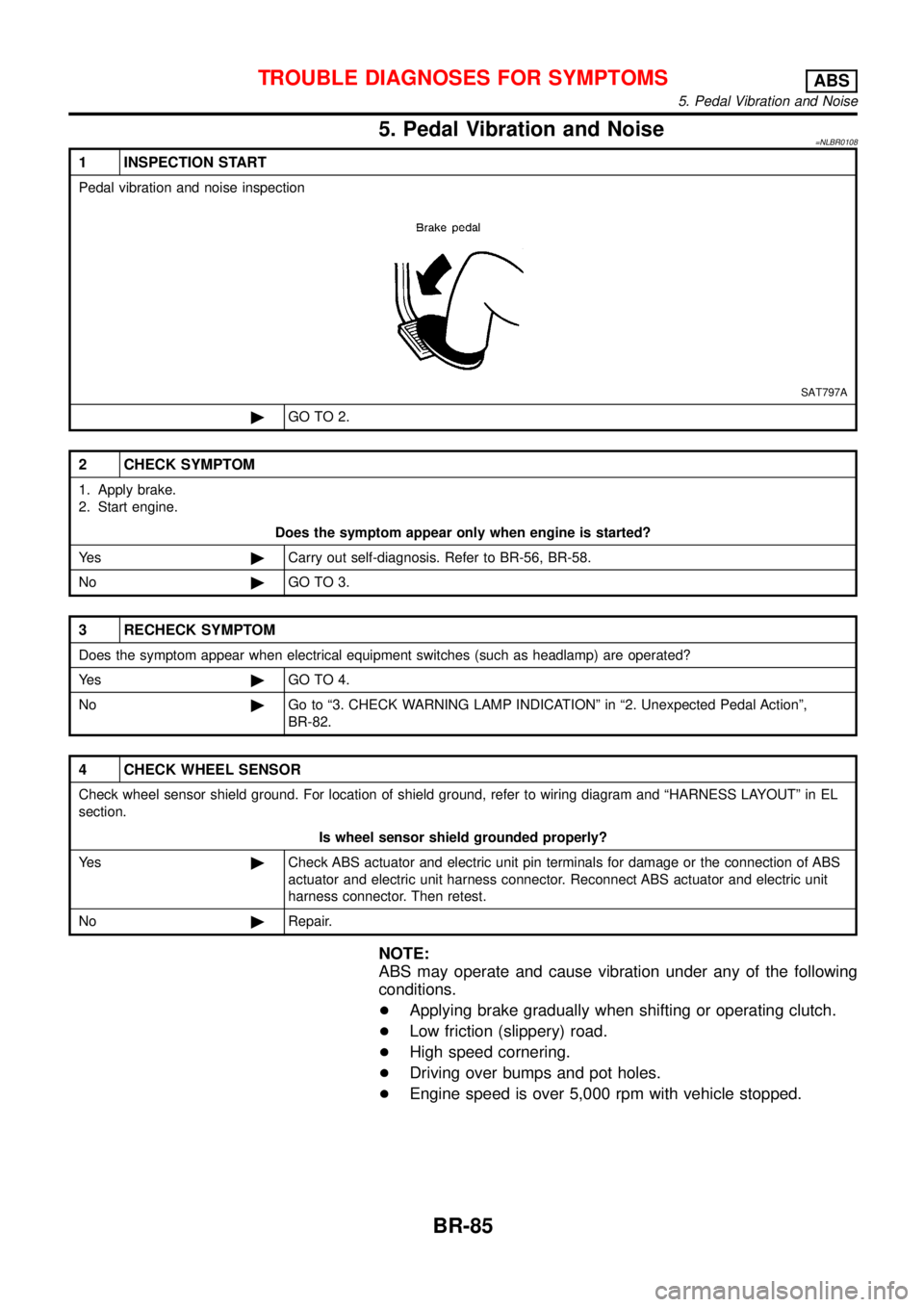

5. Pedal Vibration and Noise=NLBR0108

1 INSPECTION START

Pedal vibration and noise inspection

SAT797A

©GO TO 2.

2 CHECK SYMPTOM

1. Apply brake.

2. Start engine.

Does the symptom appear only when engine is started?

Ye s©Carry out self-diagnosis. Refer to BR-56, BR-58.

No©GO TO 3.

3 RECHECK SYMPTOM

Does the symptom appear when electrical equipment switches (such as headlamp) are operated?

Ye s©GO TO 4.

No©Go to“3. CHECK WARNING LAMP INDICATION”in“2. Unexpected Pedal Action”,

BR-82.

4 CHECK WHEEL SENSOR

Check wheel sensor shield ground. For location of shield ground, refer to wiring diagram and“HARNESS LAYOUT”in EL

section.

Is wheel sensor shield grounded properly?

Ye s©Check ABS actuator and electric unit pin terminals for damage or the connection of ABS

actuator and electric unit harness connector. Reconnect ABS actuator and electric unit

harness connector. Then retest.

No©Repair.

NOTE:

ABS may operate and cause vibration under any of the following

conditions.

+Applying brake gradually when shifting or operating clutch.

+Low friction (slippery) road.

+High speed cornering.

+Driving over bumps and pot holes.

+Engine speed is over 5,000 rpm with vehicle stopped.

TROUBLE DIAGNOSES FOR SYMPTOMSABS

5. Pedal Vibration and Noise

BR-85

Page 402 of 3051

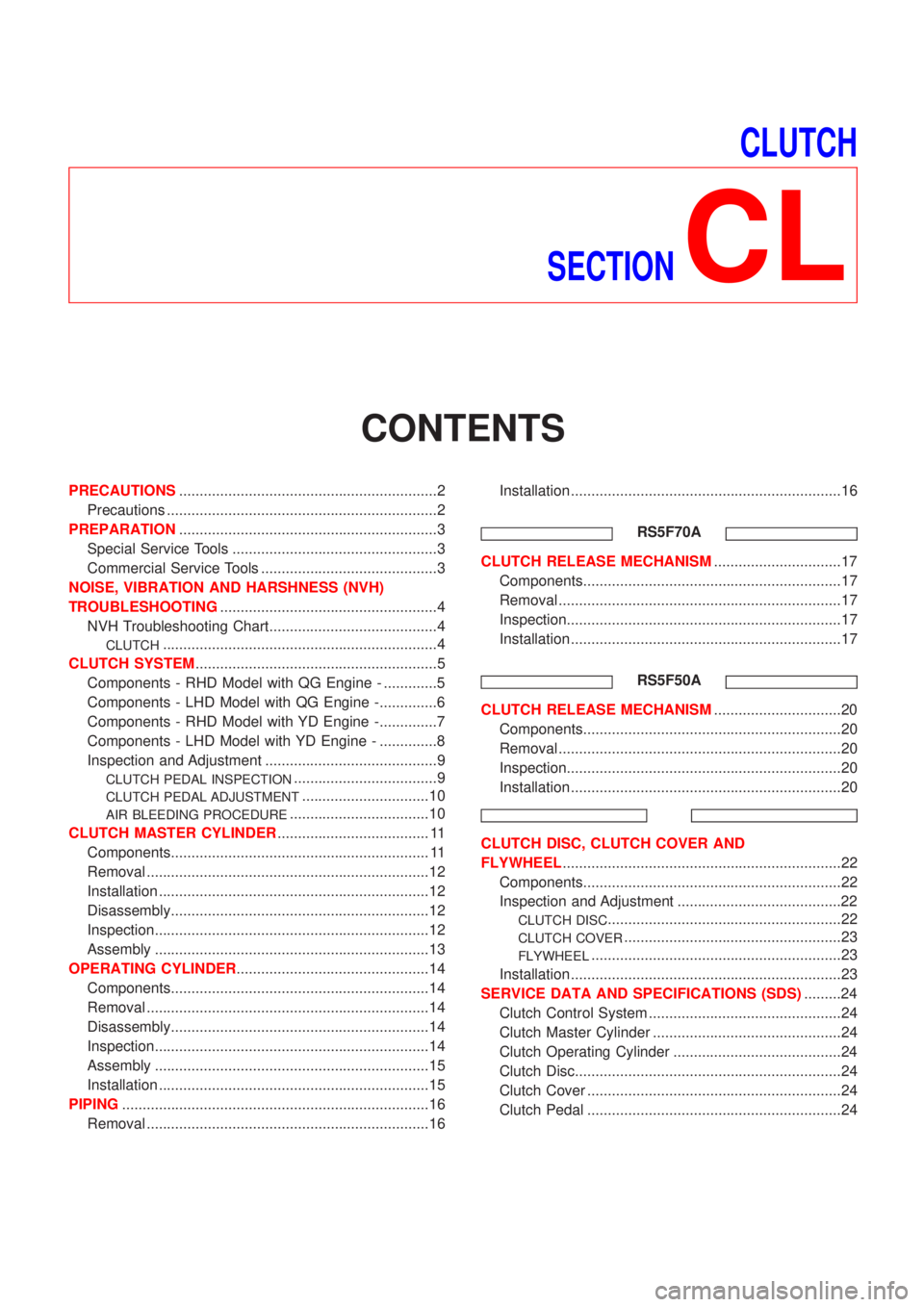

CLUTCH

SECTION

CL

CONTENTS

PRECAUTIONS...............................................................2

Precautions ..................................................................2

PREPARATION...............................................................3

Special Service Tools ..................................................3

Commercial Service Tools ...........................................3

NOISE, VIBRATION AND HARSHNESS (NVH)

TROUBLESHOOTING.....................................................4

NVH Troubleshooting Chart.........................................4

CLUTCH...................................................................4

CLUTCH SYSTEM...........................................................5

Components - RHD Model with QG Engine - .............5

Components - LHD Model with QG Engine -..............6

Components - RHD Model with YD Engine -..............7

Components - LHD Model with YD Engine - ..............8

Inspection and Adjustment ..........................................9

CLUTCH PEDAL INSPECTION...................................9

CLUTCH PEDAL ADJUSTMENT...............................10

AIR BLEEDING PROCEDURE..................................10

CLUTCH MASTER CYLINDER..................................... 11

Components............................................................... 11

Removal .....................................................................12

Installation ..................................................................12

Disassembly...............................................................12

Inspection...................................................................12

Assembly ...................................................................13

OPERATING CYLINDER...............................................14

Components...............................................................14

Removal .....................................................................14

Disassembly...............................................................14

Inspection...................................................................14

Assembly ...................................................................15

Installation ..................................................................15

PIPING...........................................................................16

Removal .....................................................................16Installation ..................................................................16

RS5F70A

CLUTCH RELEASE MECHANISM...............................17

Components...............................................................17

Removal .....................................................................17

Inspection...................................................................17

Installation ..................................................................17

RS5F50A

CLUTCH RELEASE MECHANISM...............................20

Components...............................................................20

Removal .....................................................................20

Inspection...................................................................20

Installation ..................................................................20

CLUTCH DISC, CLUTCH COVER AND

FLYWHEEL....................................................................22

Components...............................................................22

Inspection and Adjustment ........................................22

CLUTCH DISC.........................................................22

CLUTCH COVER.....................................................23

FLYWHEEL.............................................................23

Installation ..................................................................23

SERVICE DATA AND SPECIFICATIONS (SDS).........24

Clutch Control System ...............................................24

Clutch Master Cylinder ..............................................24

Clutch Operating Cylinder .........................................24

Clutch Disc.................................................................24

Clutch Cover ..............................................................24

Clutch Pedal ..............................................................24

Page 403 of 3051

SBR820BA

PrecautionsNLCL0001+Recommended fluid is brake fluid ªDOT 4º. Refer to

MA-20, ªFluid and Lubricantsº.

+Never reuse drained brake fluid.

+Be careful not to splash brake fluid on painted areas.

+When removing and installing clutch piping, use Tool.

+Use new brake fluid to clean or wash all parts of master

cylinder and operating cylinder.

+Never use mineral oils such as gasoline or kerosene. It will

ruin the rubber parts of the hydraulic system.

WARNING:

After cleaning clutch disc, wipe it with a dust collector. Do not

use compressed air.

PRECAUTIONS

Precautions

CL-2

Page 404 of 3051

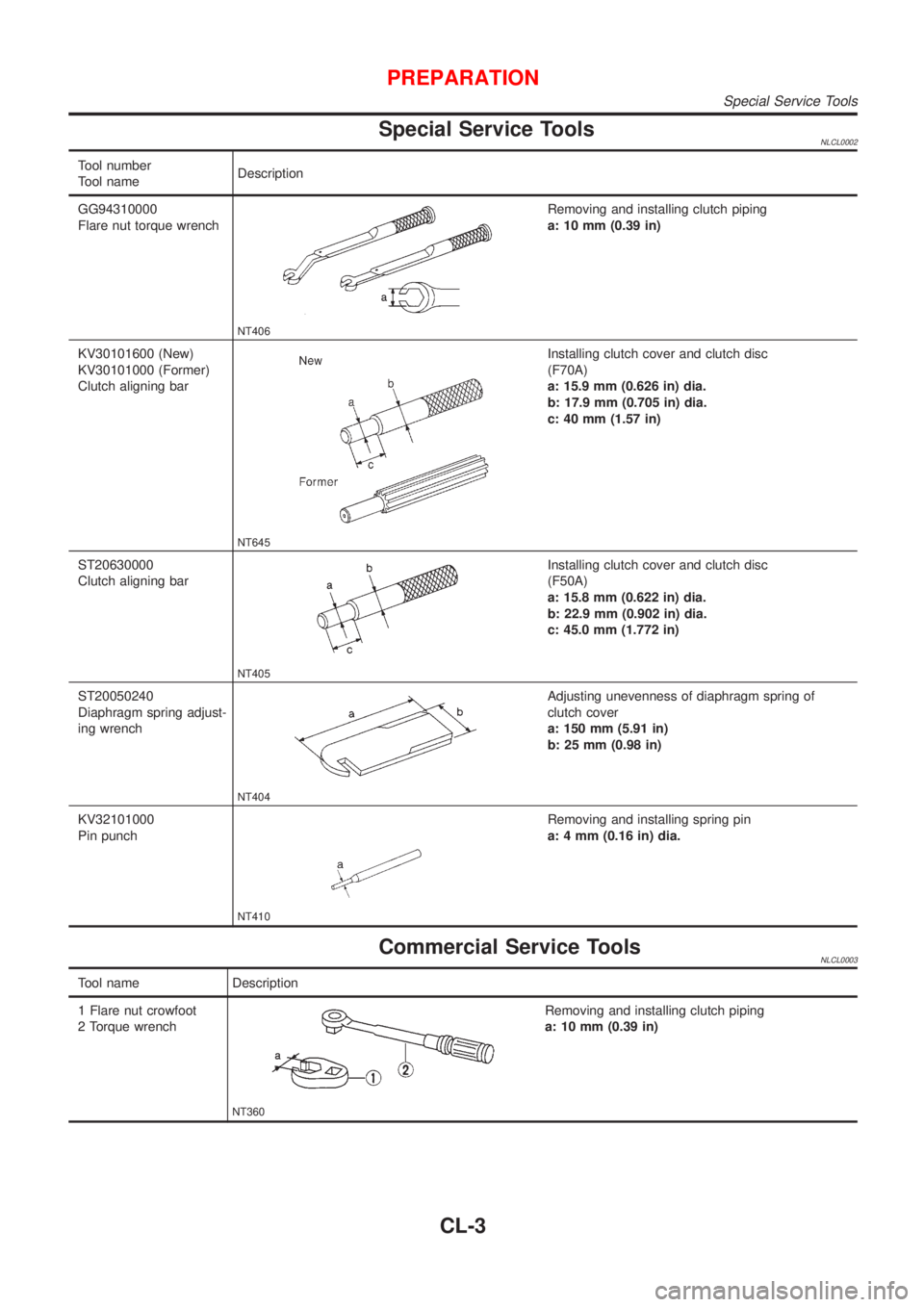

Special Service ToolsNLCL0002

Tool number

Tool nameDescription

GG94310000

Flare nut torque wrench

NT406

Removing and installing clutch piping

a: 10 mm (0.39 in)

KV30101600 (New)

KV30101000 (Former)

Clutch aligning bar

NT645

Installing clutch cover and clutch disc

(F70A)

a: 15.9 mm (0.626 in) dia.

b: 17.9 mm (0.705 in) dia.

c: 40 mm (1.57 in)

ST20630000

Clutch aligning bar

NT405

Installing clutch cover and clutch disc

(F50A)

a: 15.8 mm (0.622 in) dia.

b: 22.9 mm (0.902 in) dia.

c: 45.0 mm (1.772 in)

ST20050240

Diaphragm spring adjust-

ing wrench

NT404

Adjusting unevenness of diaphragm spring of

clutch cover

a: 150 mm (5.91 in)

b: 25 mm (0.98 in)

KV32101000

Pin punch

NT410

Removing and installing spring pin

a: 4 mm (0.16 in) dia.

Commercial Service ToolsNLCL0003

Tool name Description

1 Flare nut crowfoot

2 Torque wrench

NT360

Removing and installing clutch piping

a: 10 mm (0.39 in)

PREPARATION

Special Service Tools

CL-3