wiring diagram NISSAN ALMERA TINO 2001 Service Workshop Manual

[x] Cancel search | Manufacturer: NISSAN, Model Year: 2001, Model line: ALMERA TINO, Model: NISSAN ALMERA TINO 2001Pages: 3051, PDF Size: 46.38 MB

Page 287 of 3051

YBR201

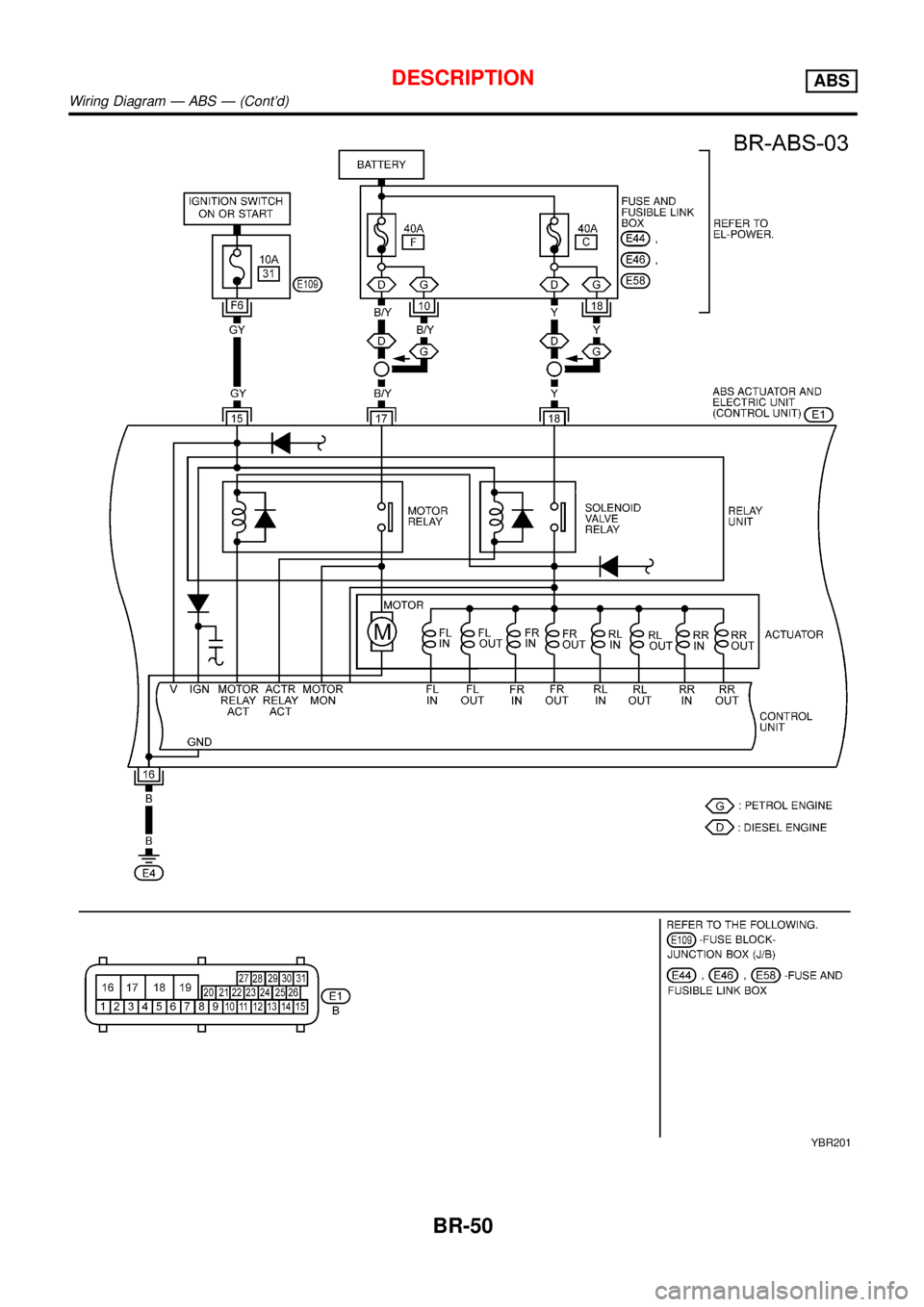

DESCRIPTIONABS

Wiring Diagram—ABS—(Cont’d)

BR-50

Page 288 of 3051

YBR202

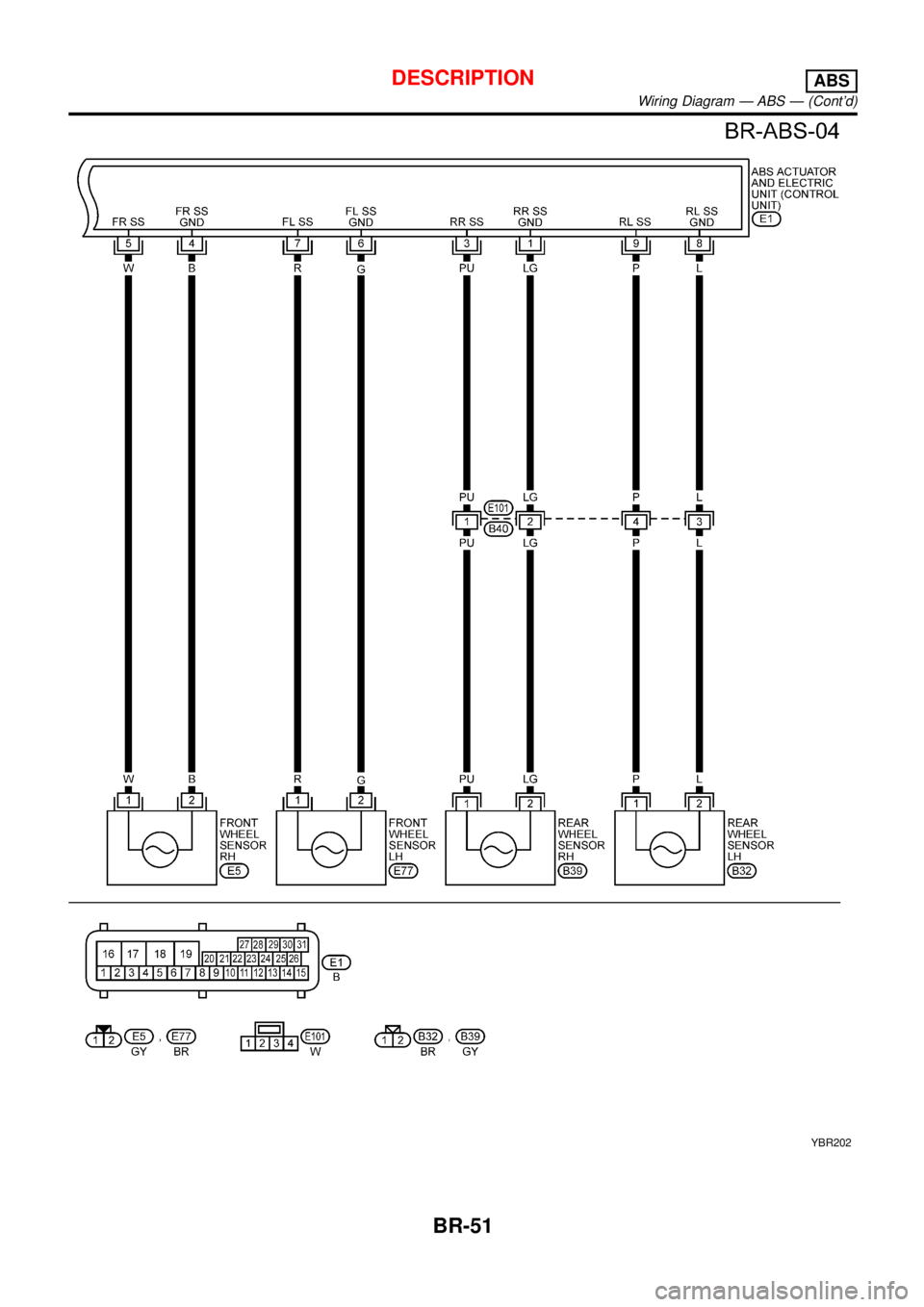

DESCRIPTIONABS

Wiring Diagram—ABS—(Cont’d)

BR-51

Page 289 of 3051

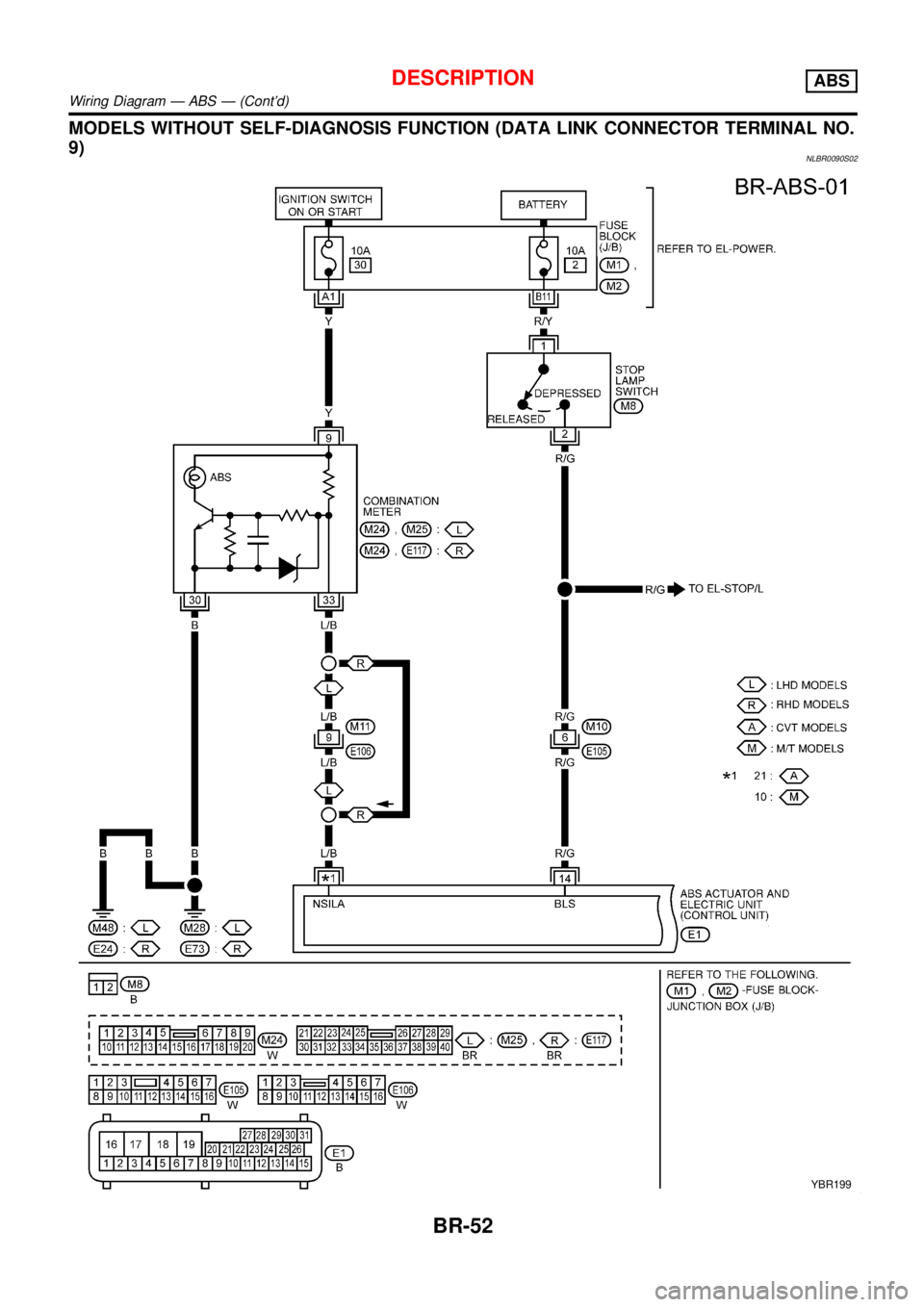

MODELS WITHOUT SELF-DIAGNOSIS FUNCTION (DATA LINK CONNECTOR TERMINAL NO.

9)

NLBR0090S02

YBR199

DESCRIPTIONABS

Wiring Diagram—ABS—(Cont’d)

BR-52

Page 290 of 3051

YBR213

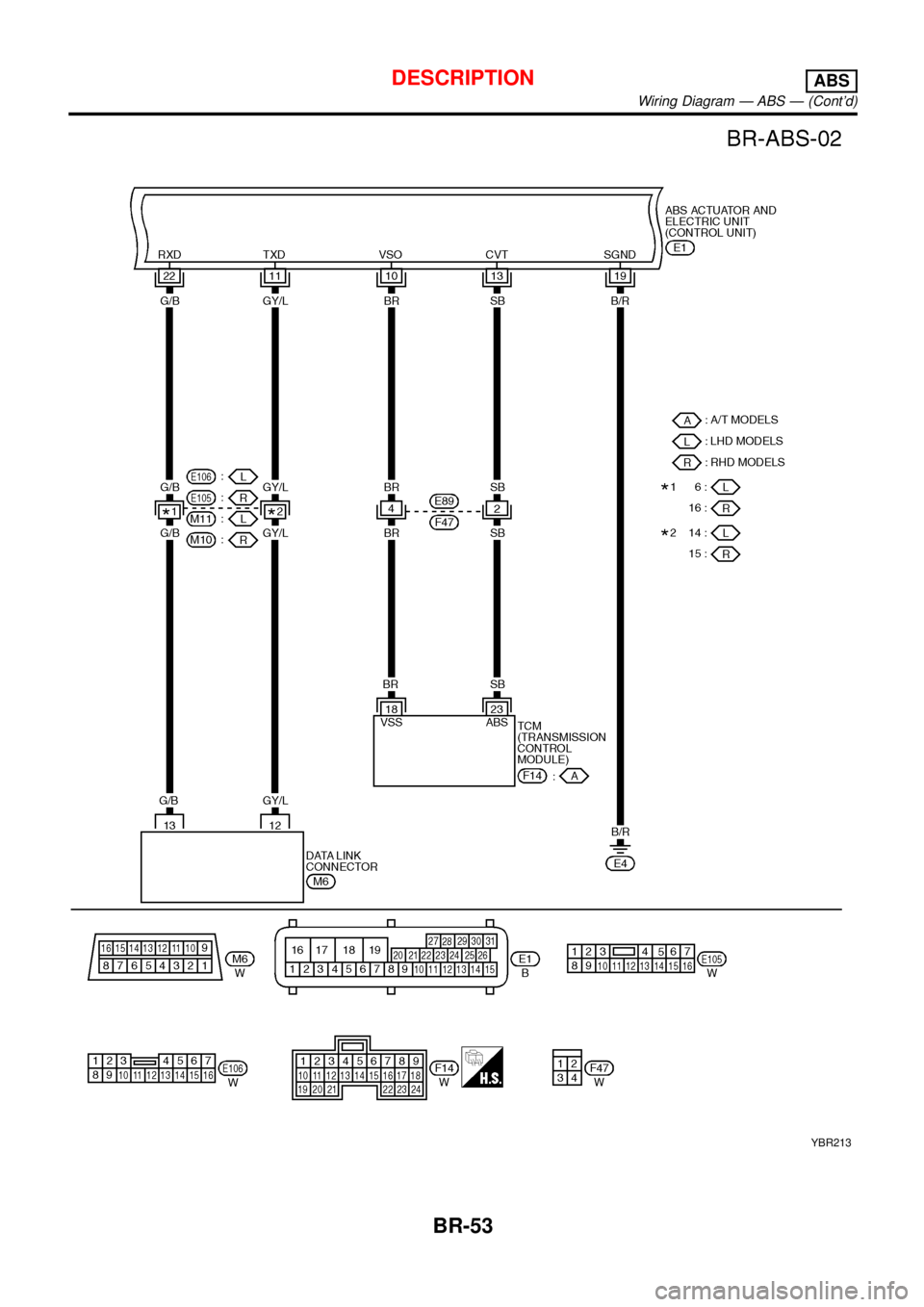

DESCRIPTIONABS

Wiring Diagram—ABS—(Cont’d)

BR-53

Page 291 of 3051

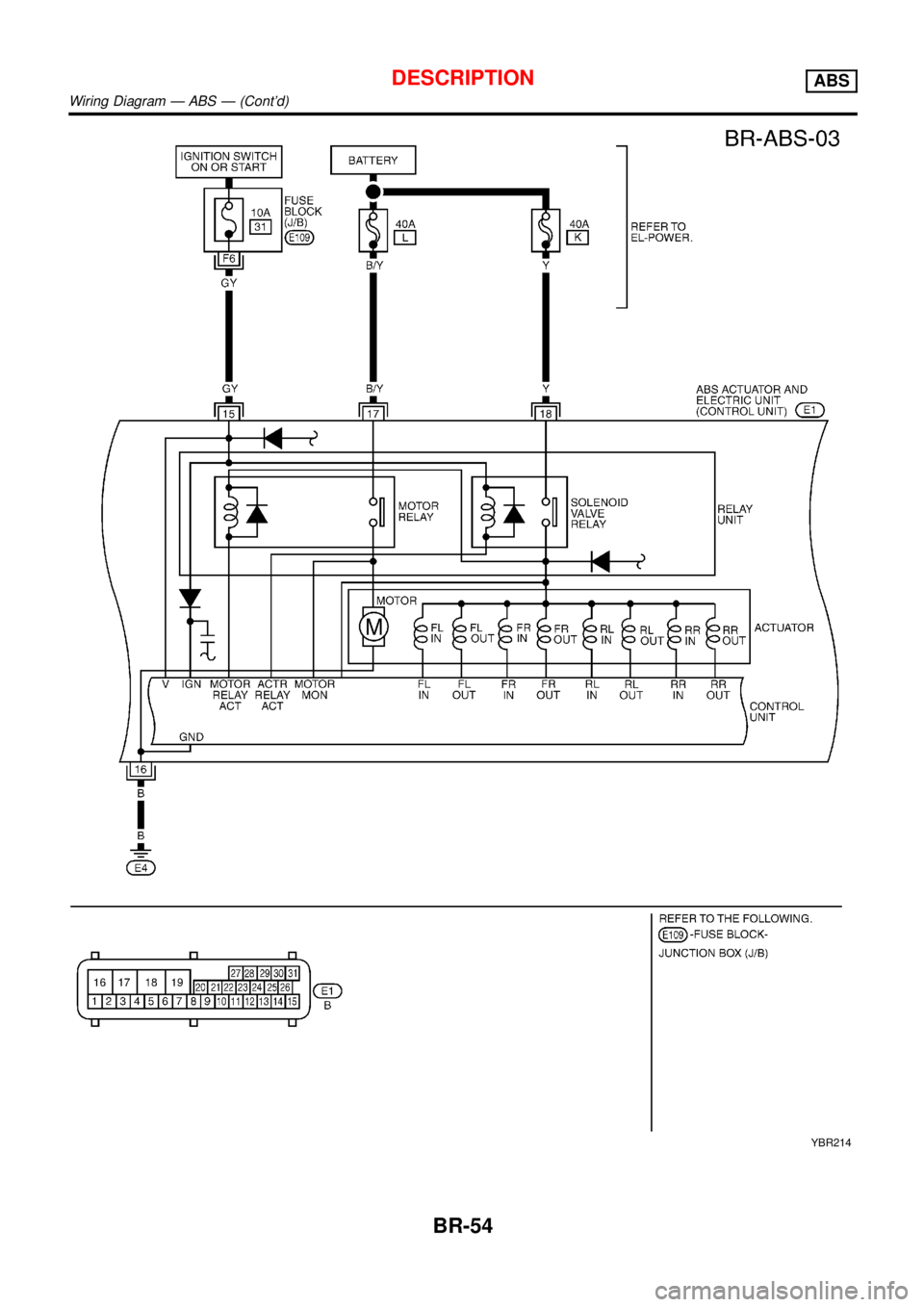

YBR214

DESCRIPTIONABS

Wiring Diagram—ABS—(Cont’d)

BR-54

Page 292 of 3051

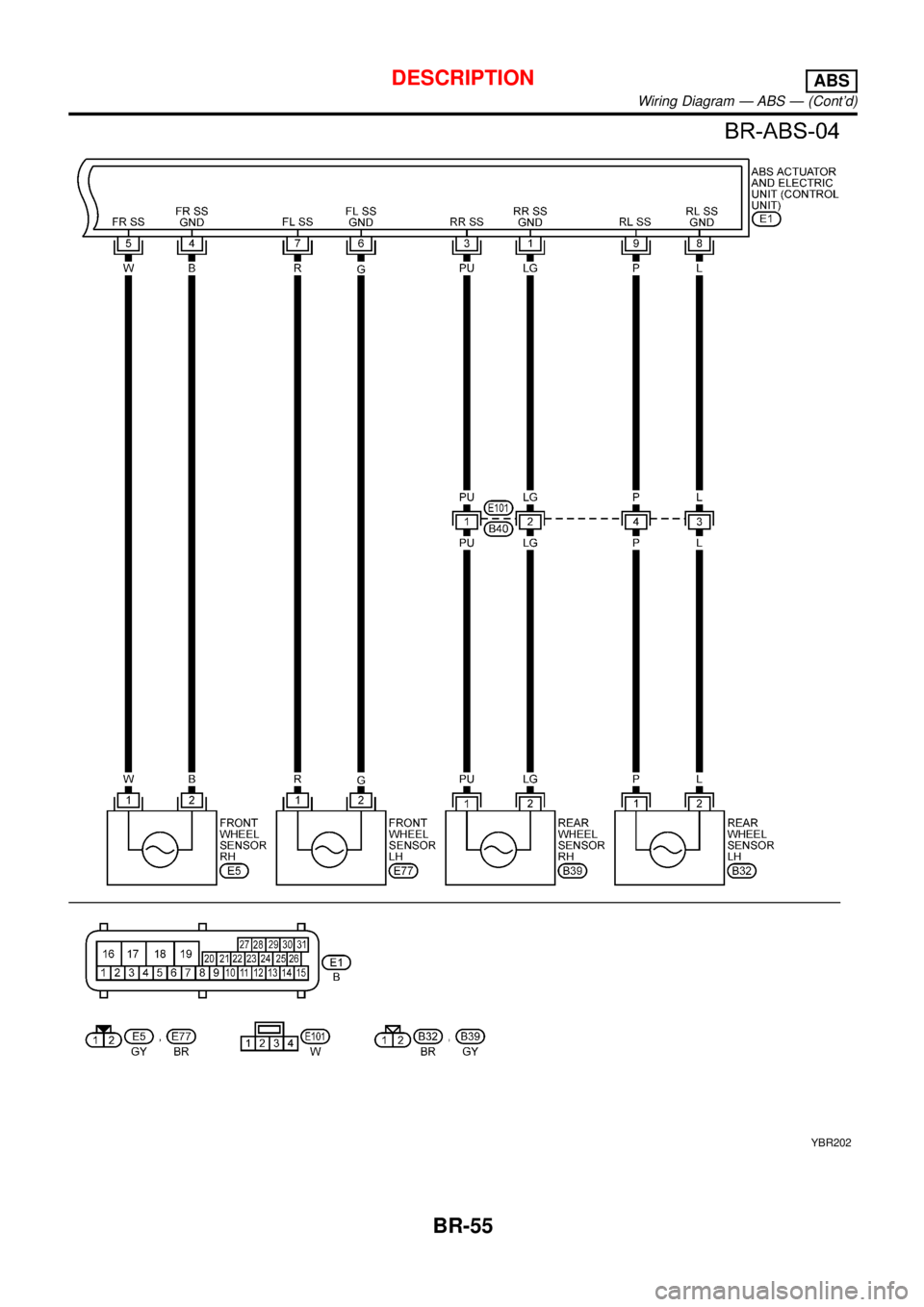

YBR202

DESCRIPTIONABS

Wiring Diagram—ABS—(Cont’d)

BR-55

Page 322 of 3051

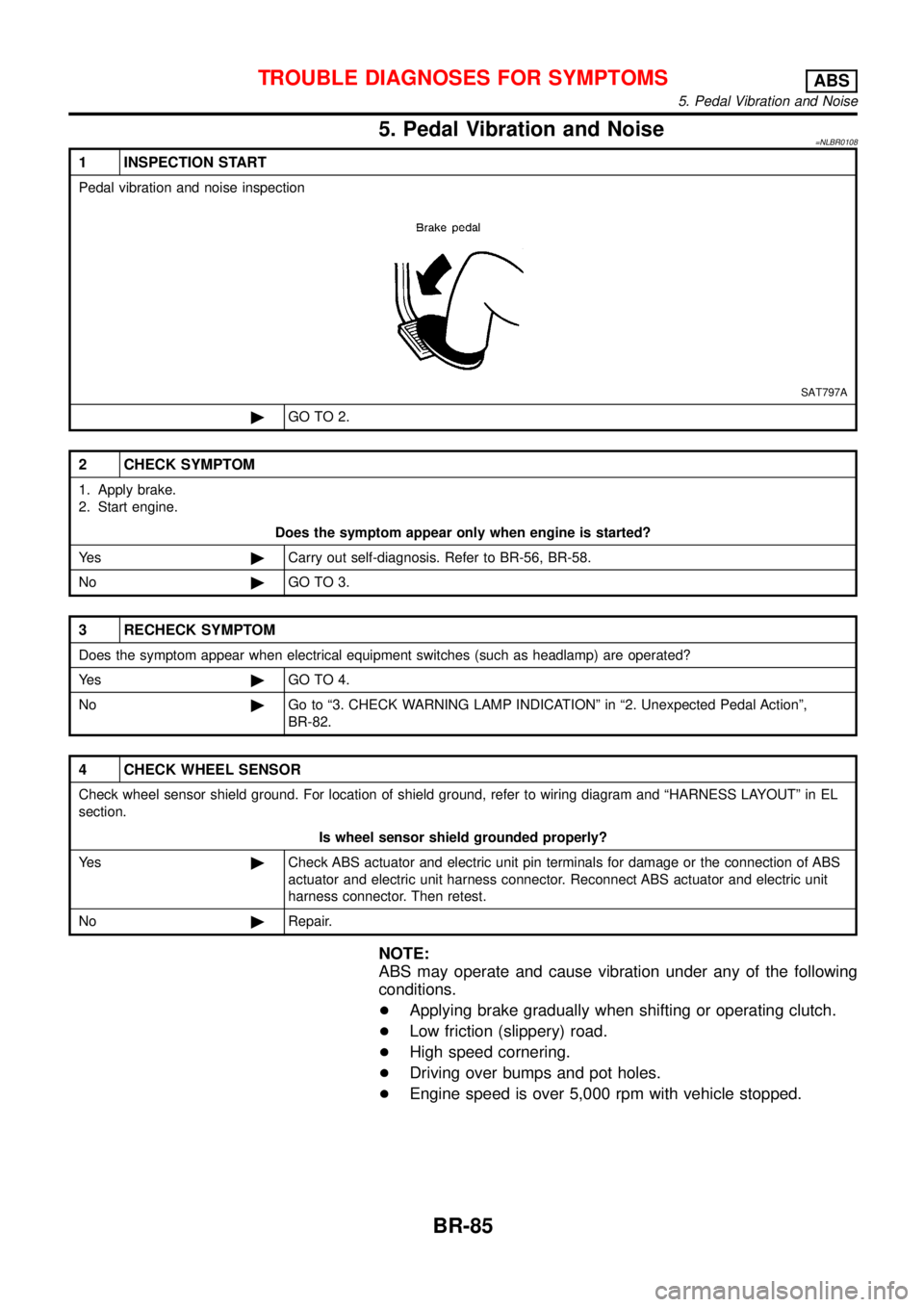

5. Pedal Vibration and Noise=NLBR0108

1 INSPECTION START

Pedal vibration and noise inspection

SAT797A

©GO TO 2.

2 CHECK SYMPTOM

1. Apply brake.

2. Start engine.

Does the symptom appear only when engine is started?

Ye s©Carry out self-diagnosis. Refer to BR-56, BR-58.

No©GO TO 3.

3 RECHECK SYMPTOM

Does the symptom appear when electrical equipment switches (such as headlamp) are operated?

Ye s©GO TO 4.

No©Go to“3. CHECK WARNING LAMP INDICATION”in“2. Unexpected Pedal Action”,

BR-82.

4 CHECK WHEEL SENSOR

Check wheel sensor shield ground. For location of shield ground, refer to wiring diagram and“HARNESS LAYOUT”in EL

section.

Is wheel sensor shield grounded properly?

Ye s©Check ABS actuator and electric unit pin terminals for damage or the connection of ABS

actuator and electric unit harness connector. Reconnect ABS actuator and electric unit

harness connector. Then retest.

No©Repair.

NOTE:

ABS may operate and cause vibration under any of the following

conditions.

+Applying brake gradually when shifting or operating clutch.

+Low friction (slippery) road.

+High speed cornering.

+Driving over bumps and pot holes.

+Engine speed is over 5,000 rpm with vehicle stopped.

TROUBLE DIAGNOSES FOR SYMPTOMSABS

5. Pedal Vibration and Noise

BR-85

Page 379 of 3051

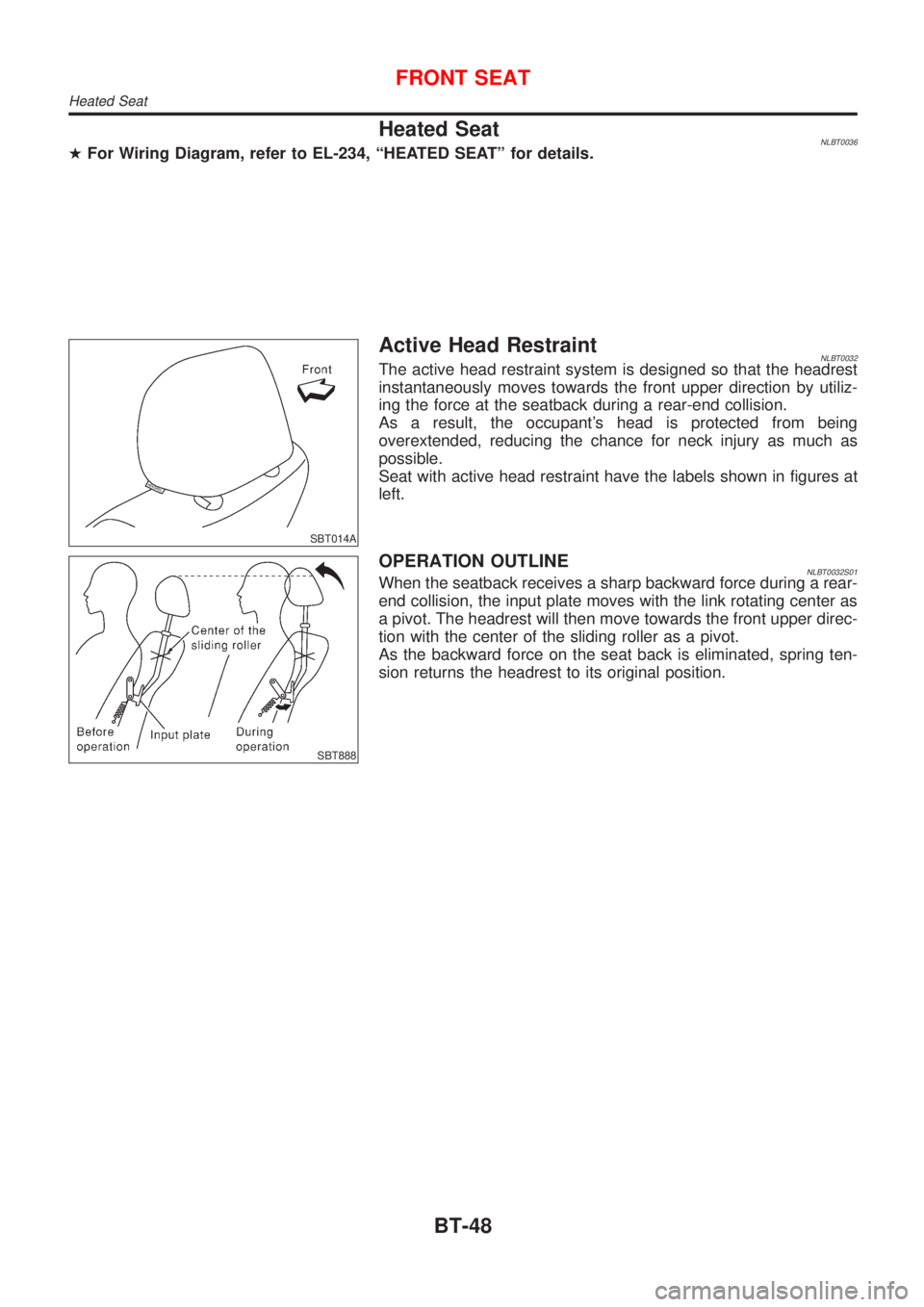

Heated SeatNLBT0036HFor Wiring Diagram, refer to EL-234, ªHEATED SEATº for details.

SBT014A

Active Head RestraintNLBT0032The active head restraint system is designed so that the headrest

instantaneously moves towards the front upper direction by utiliz-

ing the force at the seatback during a rear-end collision.

As a result, the occupant's head is protected from being

overextended, reducing the chance for neck injury as much as

possible.

Seat with active head restraint have the labels shown in figures at

left.

SBT888

OPERATION OUTLINENLBT0032S01When the seatback receives a sharp backward force during a rear-

end collision, the input plate moves with the link rotating center as

a pivot. The headrest will then move towards the front upper direc-

tion with the center of the sliding roller as a pivot.

As the backward force on the seat back is eliminated, spring ten-

sion returns the headrest to its original position.

FRONT SEAT

Heated Seat

BT-48

Page 394 of 3051

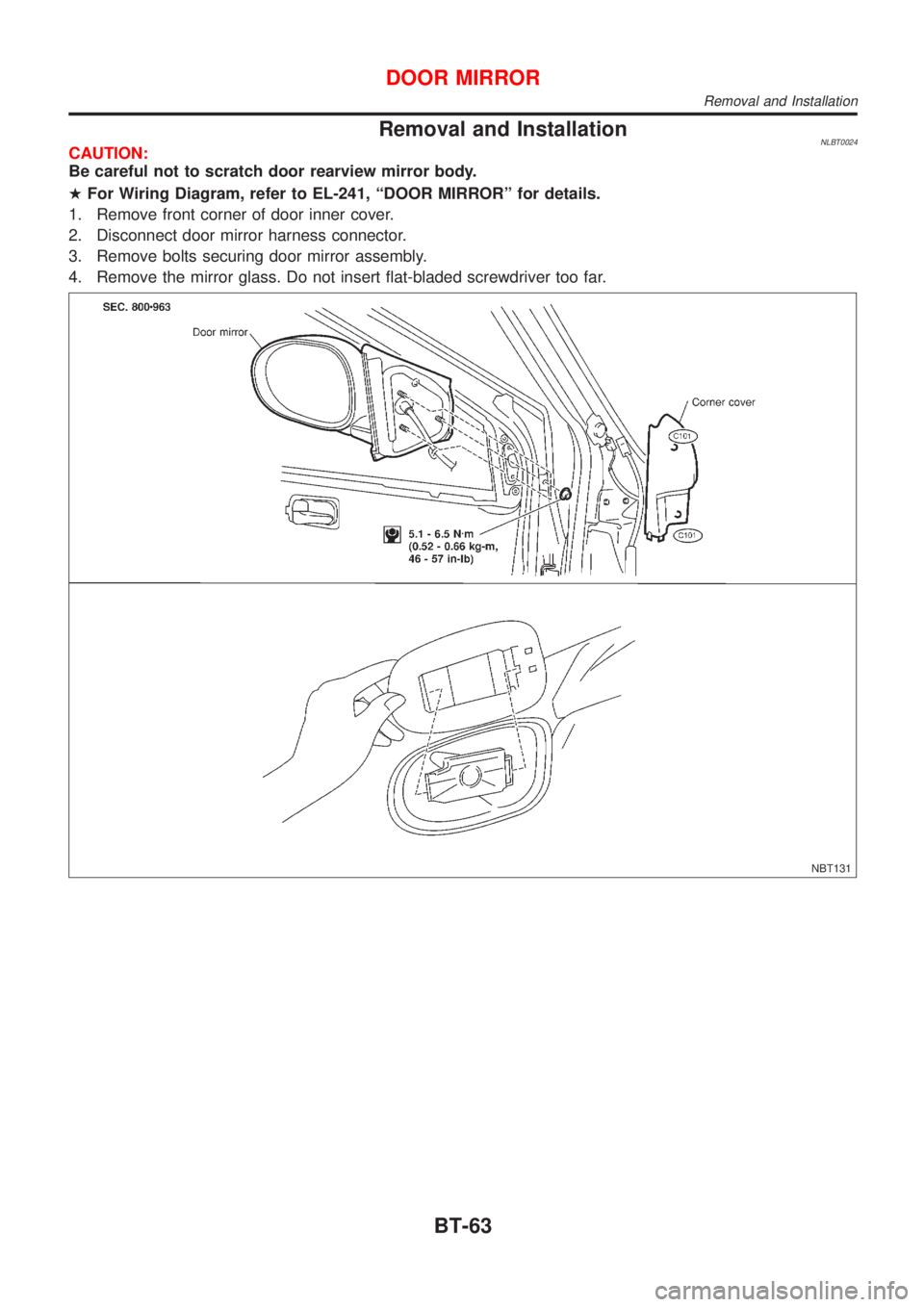

Removal and InstallationNLBT0024CAUTION:

Be careful not to scratch door rearview mirror body.

HFor Wiring Diagram, refer to EL-241, ªDOOR MIRRORº for details.

1. Remove front corner of door inner cover.

2. Disconnect door mirror harness connector.

3. Remove bolts securing door mirror assembly.

4. Remove the mirror glass. Do not insert flat-bladed screwdriver too far.

NBT131

DOOR MIRROR

Removal and Installation

BT-63

Page 426 of 3051

ENGINE CONTROL SYSTEM

SECTION

EC

CONTENTS

QG18DE

TROUBLE DIAGNOSIS - INDEX..................................16

Alphabetical & P No. Index for DTC .........................16

PRECAUTIONS.............................................................21

Precautions for Supplemental Restraint System

(SRS)²AIR BAG²and²SEAT BELT

PRE-TENSIONER²....................................................21

Precautions for On Board Diagnostic (OBD)

System of Engine ......................................................21

Engine Fuel & Emission Control System ..................22

Wiring Diagrams and Trouble Diagnosis ...................24

PREPARATION.............................................................25

Special Service Tools ................................................25

Commercial Service Tools .........................................25

ENGINE AND EMISSION CONTROL OVERALL

SYSTEM.........................................................................26

Engine Control Component Parts Location ...............26

Circuit Diagram ..........................................................30

System Diagram ........................................................32

Vacuum Hose Drawing ..............................................33

System Chart .............................................................34

ENGINE AND EMISSION BASIC CONTROL

SYSTEM DESCRIPTION...............................................35

Multiport Fuel Injection (MFI) System .......................35

Electronic Ignition (EI) System ..................................37

Air Conditioning Cut Control ......................................38

Fuel Cut Control (at no load & high engine

speed) ........................................................................39

Evaporative Emission System ...................................39

Positive Crankcase Ventilation ..................................42

BASIC SERVICE PROCEDURE...................................43

Fuel Pressure Release ..............................................43

Fuel Pressure Check .................................................43

Fuel Pressure Regulator Check ................................44

Injector .......................................................................44

How to Check Idle Speed and Ignition Timing ..........46

Preparation ................................................................47

Inspection Procedure .................................................49Idle Air Volume Learning ...........................................57

ON BOARD DIAGNOSTIC SYSTEM

DESCRIPTION...............................................................59

Introduction ................................................................59

Two Trip Detection Logic ...........................................59

Emission-related Diagnostic Information ...................60

NATS (Nissan Anti-theft System) ..............................72

Malfunction Indicator (MI) ..........................................73

OBD System Operation Chart (With Euro-OBD

Models Only)..............................................................77

CONSULT-II ...............................................................82

Generic Scan Tool (GST) ..........................................93

TROUBLE DIAGNOSIS - INTRODUCTION..................95

Introduction ................................................................95

Work Flow ..................................................................97

TROUBLE DIAGNOSIS - BASIC INSPECTION...........99

Basic Inspection.........................................................99

TROUBLE DIAGNOSIS - GENERAL

DESCRIPTION.............................................................122

DTC Inspection Priority Chart..................................122

Fail-safe Chart .........................................................123

Symptom Matrix Chart .............................................124

CONSULT-II Reference Value in Data Monitor

Mode ........................................................................128

Major Sensor Reference Graph in Data Monitor

Mode ........................................................................130

ECM Terminals and Reference Value .....................133

TROUBLE DIAGNOSIS - SPECIFICATION VALUE..141

Description ...............................................................141

Testing Condition .....................................................141

Inspection Procedure ...............................................141

Diagnostic Procedure ..............................................142

TROUBLE DIAGNOSIS FOR INTERMITTENT

INCIDENT.....................................................................145

Description ...............................................................145

Diagnostic Procedure ..............................................145

TROUBLE DIAGNOSIS FOR POWER SUPPLY........146

Main Power Supply and Ground Circuit ..................146