wiring diagram NISSAN ALMERA TINO 2001 Service Manual PDF

[x] Cancel search | Manufacturer: NISSAN, Model Year: 2001, Model line: ALMERA TINO, Model: NISSAN ALMERA TINO 2001Pages: 3051, PDF Size: 46.38 MB

Page 437 of 3051

Diagnostic Procedure ............................................1019

INJECTOR.................................................................1021

Component Description .........................................1021

CONSULT-II Reference Value in Data Monitor

Mode ......................................................................1021

ECM Terminals and Reference Value ...................1021

Wiring Diagram ......................................................1022

Diagnostic Procedure ............................................1024

Component Inspection ...........................................1026

START SIGNAL.........................................................1027

CONSULT-II Reference Value in Data Monitor

Mode ......................................................................1027

ECM Terminals and Reference Value ...................1027

Wiring Diagram ......................................................1028

Diagnostic Procedure ............................................1030

FUEL PUMP...............................................................1032

System Description ................................................1032

Component Description .........................................1032

CONSULT-II Reference Value in Data Monitor

Mode ......................................................................1032

ECM Terminals and Reference Value ...................1033

Wiring Diagram ......................................................1034

Diagnostic Procedure ............................................1036

Component Inspection ...........................................1038

POWER STEERING OIL PRESSURE SWITCH.......1039

Component Description .........................................1039

CONSULT-II Reference Value in Data Monitor

Mode ......................................................................1039

ECM Terminals and Reference Value ...................1039

Wiring Diagram ......................................................1040

Diagnostic Procedure ............................................1041

Component Inspection ...........................................1043

REFRIGERANT PRESSURE SENSOR....................1044

Description .............................................................1044

ECM Terminals and Reference Value ...................1044

Wiring Diagram ......................................................1045

Diagnostic Procedure ............................................1047

ELECTRICAL LOAD SIGNAL...................................1050

CONSULT-II Reference Value in Data Monitor

Mode ......................................................................1050

ECM Terminals and Reference Value ...................1050

Wiring Diagram ......................................................1051

Diagnostic Procedure - Load Signal - ...................1055

Diagnostic Procedure - Heater Control Panel

(Fan Switch) - ........................................................1059

MI & DATA LINK CONNECTORS............................1060

Wiring Diagram ......................................................1060

SERVICE DATA AND SPECIFICATIONS (SDS).....1062

Fuel Pressure Regulator........................................1062

Idle Speed and Ignition Timing ..............................1062

Ignition Coil ............................................................1062

Mass Air Flow Sensor............................................1062Engine Coolant Temperature Sensor ....................1062

EGR Volume Control Valve (where fitted) .............1062

EGR Temperature Sensor (where fitted) ...............1062

Fuel Pump .............................................................1063

IACV-AAC Valve ....................................................1063

Injector ...................................................................1063

Resistor ..................................................................1063

Throttle Position Sensor ........................................1063

Heated Oxygen Sensor 1 (Front) Heater ..............1063

Intake Air Temperature Sensor ..............................1063

EVAP Canister Purge Volume Control Valve ........1063

Heated Oxygen Sensor 2 (Rear) Heater...............1063

Crankshaft Position Sensor (OBD)........................1063

YD22DDTI

TROUBLE DIAGNOSIS - INDEX..............................1064

Alphabetical & P No. Index for DTC .....................1064

PRECAUTIONS.........................................................1066

Precautions for Supplemental Restraint System

(SRS)²AIR BAG²and²SEAT BELT

PRE-TENSIONER²................................................1066

Engine Fuel & Emission Control System ..............1066

Wiring Diagrams and Trouble Diagnosis ...............1069

PREPARATION.........................................................1070

Special Service Tools ............................................1070

ENGINE AND EMISSION CONTROL OVERALL

SYSTEM.....................................................................1071

Engine Control Component Parts Location ...........1071

Circuit Diagram ......................................................1074

System Diagram ....................................................1076

Vacuum Hose Drawing ..........................................1077

System Chart .........................................................1078

ENGINE AND EMISSION BASIC CONTROL

SYSTEM DESCRIPTION...........................................1079

Fuel Injection Control System ...............................1079

Fuel Injection Timing Control System....................1080

Air Conditioning Cut Control ..................................1081

Fuel Cut Control (at no load & high engine

speed) ....................................................................1081

Crankcase Ventilation System ...............................1082

BASIC SERVICE PROCEDURE...............................1083

Injection Tube and Injection Nozzle ......................1083

Electronic Control Fuel Injection Pump .................1087

Fuel Filter ...............................................................1094

ON BOARD DIAGNOSTIC SYSTEM

DESCRIPTION...........................................................1096

DTC and MI Detection Logic .................................1096

Diagnostic Trouble Code (DTC) ............................1096

NATS (Nissan Anti-Theft System) .........................1097

Malfunction Indicator (MI) ......................................1097

CONSULT-II ........................................................... 1102

CONTENTS(Cont'd)

EC-12

Page 438 of 3051

TROUBLE DIAGNOSIS - INTRODUCTION.............. 1107

Introduction ............................................................ 1107

Work Flow .............................................................. 1109

TROUBLE DIAGNOSIS - BASIC INSPECTION.......1111

Basic Inspection.....................................................1111

TROUBLE DIAGNOSIS - GENERAL

DESCRIPTION........................................................... 1116

Symptom Matrix Chart ........................................... 1116

CONSULT-II Reference Value in Data Monitor

Mode ...................................................................... 1126

Major Sensor Reference Graph in Data Monitor

Mode ...................................................................... 1128

ECM Terminals and Reference Value ................... 1129

TROUBLE DIAGNOSIS FOR INTERMITTENT

INCIDENT................................................................... 1135

Description ............................................................. 1135

Diagnostic Procedure ............................................ 1135

TROUBLE DIAGNOSIS FOR POWER SUPPLY...... 1136

Main Power Supply and Ground Circuit ................ 1136

DTC P0100 MASS AIR FLOW SEN......................... 1143

Component Description ......................................... 1143

CONSULT-II Reference Value in Data Monitor

Mode ...................................................................... 1143

ECM Terminals and Reference Value ................... 1143

On Board Diagnosis Logic..................................... 1143

DTC Confirmation Procedure ................................ 1144

Wiring Diagram ...................................................... 1145

Diagnostic Procedure ............................................ 1147

DTC P0115 COOLANT TEMP SEN.......................... 1150

Description ............................................................. 1150

On Board Diagnosis Logic..................................... 1150

DTC Confirmation Procedure ................................ 1150

Wiring Diagram ...................................................... 1152

Diagnostic Procedure ............................................ 1153

DTC P0120 ACCEL POS SENSOR.......................... 1155

Description ............................................................. 1155

CONSULT-II Reference Value in Data Monitor

Mode ...................................................................... 1155

ECM Terminals and Reference Value ................... 1155

On Board Diagnosis Logic..................................... 1156

DTC Confirmation Procedure ................................ 1156

Wiring Diagram ...................................................... 1157

Diagnostic Procedure ............................................ 1159

DTC P0335 CRANK POS SEN (TDC)...................... 1166

Description ............................................................. 1166

CONSULT-II Reference Value in Data Monitor

Mode ...................................................................... 1166

ECM Terminals and Reference Value ................... 1166

On Board Diagnosis Logic..................................... 1166

DTC Confirmation Procedure ................................ 1167

Wiring Diagram ...................................................... 1168

Diagnostic Procedure ............................................ 1169DTC P0500 VEHICLE SPEED SEN.......................... 1172

Description ............................................................. 1172

ECM Terminals and Reference Value ................... 1172

On Board Diagnosis Logic..................................... 1172

Overall Function Check ......................................... 1172

Wiring Diagram ...................................................... 1174

Diagnostic Procedure ............................................ 1176

DTC P0571 BRAKE SW............................................ 1177

Description ............................................................. 1177

ECM Terminals and Reference Value ................... 1177

On Board Diagnosis Logic..................................... 1177

DTC Confirmation Procedure ................................ 1177

Wiring Diagram ...................................................... 1179

Diagnostic Procedure ............................................ 1181

DTC P1107 ECM 10.................................................. 1185

Description ............................................................. 1185

On Board Diagnosis Logic..................................... 1185

DTC Confirmation Procedure ................................ 1185

Diagnostic Procedure ............................................ 1186

DTC P1180 P9.FUEL TEMP SEN............................. 1187

Description ............................................................. 1187

CONSULT-II Reference Value in Data Monitor

Mode ...................................................................... 1187

ECM Terminals and Reference Value ................... 1188

On Board Diagnosis Logic..................................... 1188

DTC Confirmation Procedure ................................ 1188

Wiring Diagram ...................................................... 1190

Diagnostic Procedure ............................................ 1192

DTC P1202 FUEL CUT SYSTEM2........................... 1194

Description ............................................................. 1194

CONSULT-II Reference Value in Data Monitor

Mode ...................................................................... 1194

ECM Terminals and Reference Value ................... 1195

On Board Diagnosis Logic..................................... 1195

DTC Confirmation Procedure ................................ 1195

Wiring Diagram ...................................................... 1197

Diagnostic Procedure ............................................ 1199

DTC P1217 OVER HEAT..........................................1201

Description .............................................................1201

CONSULT-II Reference Value in Data Monitor

Mode ......................................................................1201

ECM Terminals and Reference Value ...................1201

On Board Diagnosis Logic.....................................1202

Overall Function Check .........................................1203

Wiring Diagram ......................................................1204

Diagnostic Procedure ............................................1206

Main 12 Causes of Overheating............................1217

DTC P1241 P7.F/INJ TIMG FB.................................1218

Description .............................................................1218

CONSULT-II Reference Value in Data Monitor

Mode ......................................................................1218

ECM Terminals and Reference Value ...................1219

CONTENTS(Cont'd)

EC-13

Page 439 of 3051

On Board Diagnosis Logic.....................................1219

DTC Confirmation Procedure ................................1219

Wiring Diagram ......................................................1221

Diagnostic Procedure ............................................1223

DTC P1251 P4.SPILL/V CIRC..................................1225

Description .............................................................1225

CONSULT-II Reference Value in Data Monitor

Mode ......................................................................1225

ECM Terminals and Reference Value ...................1226

On Board Diagnosis Logic.....................................1226

DTC Confirmation Procedure ................................1226

Wiring Diagram ......................................................1228

Diagnostic Procedure ............................................1230

DTC P1337 P2.DTC PULSE SIG..............................1232

Description .............................................................1232

CONSULT-II Reference Value in Data Monitor

Mode ......................................................................1232

ECM Terminals and Reference Value ...................1233

On Board Diagnosis Logic.....................................1233

DTC Confirmation Procedure ................................1233

Wiring Diagram ......................................................1235

Diagnostic Procedure ............................................1237

DTC P1341 P1.CAM POS SEN................................1239

Description .............................................................1239

CONSULT-II Reference Value in Data Monitor

Mode ......................................................................1239

ECM Terminals and Reference Value ...................1240

On Board Diagnosis Logic.....................................1240

DTC Confirmation Procedure ................................1240

Wiring Diagram ......................................................1242

Diagnostic Procedure ............................................1244

DTC P1600 P3.PUMP COMM LINE..........................1246

Description .............................................................1246

CONSULT-II Reference Value in Data Monitor

Mode ......................................................................1246

ECM Terminals and Reference Value ...................1247

On Board Diagnosis Logic.....................................1247

DTC Confirmation Procedure ................................1247

Wiring Diagram ......................................................1249

Diagnostic Procedure ............................................1251

DTC P1603 ECM 12, DTC P1607 ECM 2.................1253

Description .............................................................1253

On Board Diagnosis Logic.....................................1253

DTC Confirmation Procedure ................................1253

Diagnostic Procedure ............................................1254

DTC P1620 ECM RLY...............................................1255

ECM Terminals and Reference Value ...................1255

On Board Diagnosis Logic.....................................1255

DTC Confirmation Procedure ................................1255

Wiring Diagram ......................................................1256

Diagnostic Procedure ............................................1258DTC P1621 ECM 15..................................................1260

Description .............................................................1260

On Board Diagnosis Logic.....................................1260

DTC Confirmation Procedure ................................1260

Diagnostic Procedure ............................................1261

DTC P1660 BATTERY VOLTAGE............................1262

On Board Diagnosis Logic.....................................1262

DTC Confirmation Procedure ................................1262

Diagnostic Procedure ............................................1262

DTC P1690 P5.PUMP C/MODULE...........................1264

Description .............................................................1264

CONSULT-II Reference Value in Data Monitor

Mode ......................................................................1264

ECM Terminals and Reference Value ...................1265

On Board Diagnosis Logic.....................................1265

DTC Confirmation Procedure ................................1265

Diagnostic Procedure ............................................1266

GLOW CONTROL SYSTEM.....................................1267

Description .............................................................1267

ECM Terminals and Reference Value ...................1268

Wiring Diagram ......................................................1269

Diagnostic Procedure ............................................1271

EGR VOLUME CONTROL SYSTEM........................1277

Description .............................................................1277

CONSULT-II Reference Value in Data Monitor

Mode ......................................................................1278

ECM Terminals and Reference Value ...................1278

Wiring Diagram ......................................................1279

Diagnostic Procedure ............................................1281

SWIRL CONTROL VALVE CONTROL SOLENOID

VALVE........................................................................1285

Description .............................................................1285

CONSULT-II Reference Value in Data Monitor

Mode ......................................................................1286

ECM Terminals and Reference Value ...................1286

Wiring Diagram ......................................................1287

Diagnostic Procedure ............................................1289

START SIGNAL.........................................................1293

Wiring Diagram ......................................................1293

Diagnostic Procedure ............................................1295

PARK/NEUTRAL POSITION (PNP) SWITCH

(WHERE FITTED)......................................................1297

Description .............................................................1297

CONSULT-II Reference Value in Data Monitor

Mode ......................................................................1297

ECM Terminals and Reference Value ...................1297

Wiring Diagram ......................................................1298

Diagnostic Procedure ............................................1299

AIR CONDITIONER CONTROL................................1301

Wiring Diagram ......................................................1301

MI & DATA LINK CONNECTORS............................1303

Wiring Diagram ......................................................1303

CONTENTS(Cont'd)

EC-14

Page 478 of 3051

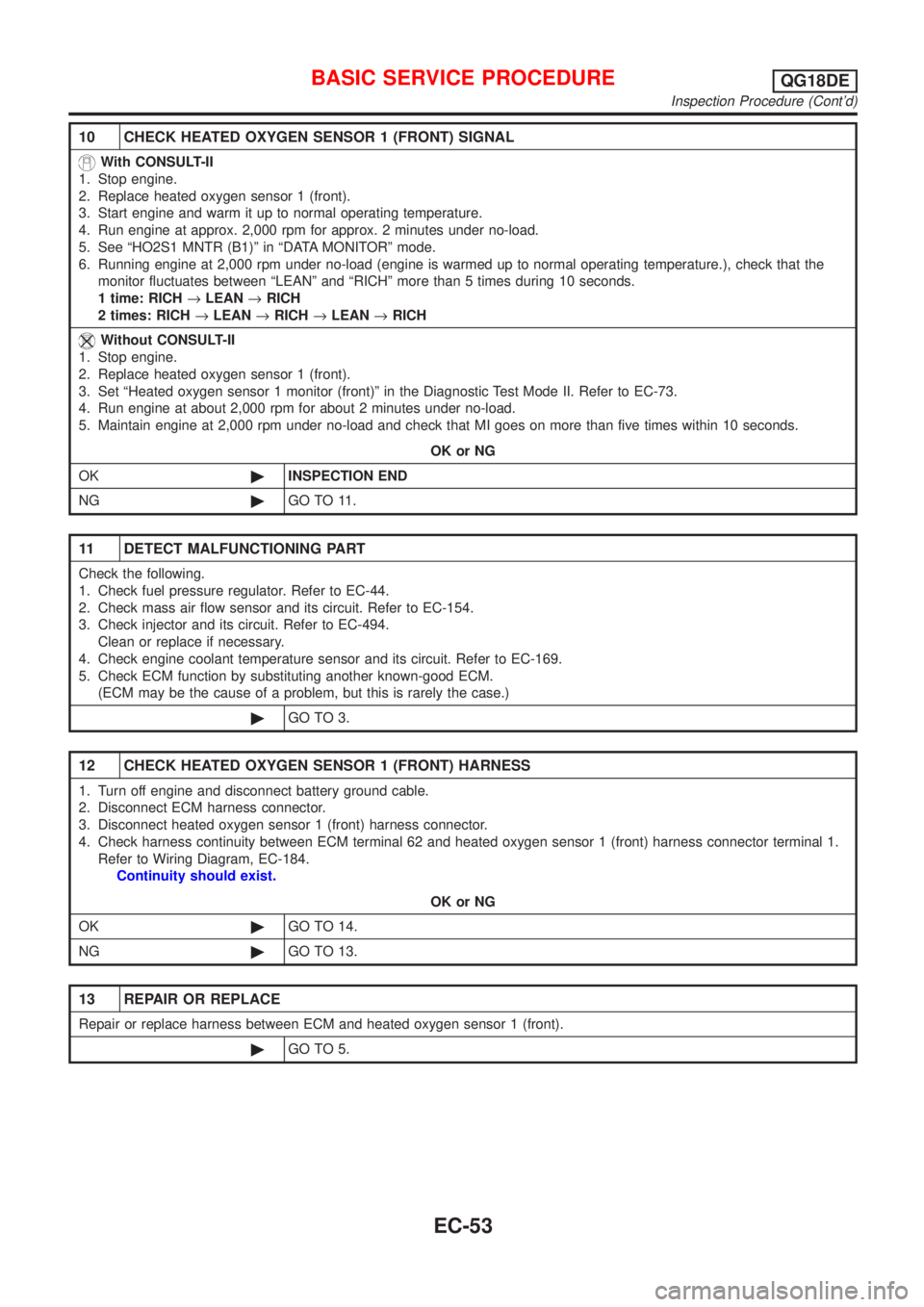

10 CHECK HEATED OXYGEN SENSOR 1 (FRONT) SIGNAL

With CONSULT-II

1. Stop engine.

2. Replace heated oxygen sensor 1 (front).

3. Start engine and warm it up to normal operating temperature.

4. Run engine at approx. 2,000 rpm for approx. 2 minutes under no-load.

5. See ªHO2S1 MNTR (B1)º in ªDATA MONITORº mode.

6. Running engine at 2,000 rpm under no-load (engine is warmed up to normal operating temperature.), check that the

monitor fluctuates between ªLEANº and ªRICHº more than 5 times during 10 seconds.

1 time: RICH®LEAN®RICH

2 times: RICH®LEAN®RICH®LEAN®RICH

Without CONSULT-II

1. Stop engine.

2. Replace heated oxygen sensor 1 (front).

3. Set ªHeated oxygen sensor 1 monitor (front)º in the Diagnostic Test Mode II. Refer to EC-73.

4. Run engine at about 2,000 rpm for about 2 minutes under no-load.

5. Maintain engine at 2,000 rpm under no-load and check that MI goes on more than five times within 10 seconds.

OK or NG

OK©INSPECTION END

NG©GO TO 11.

11 DETECT MALFUNCTIONING PART

Check the following.

1. Check fuel pressure regulator. Refer to EC-44.

2. Check mass air flow sensor and its circuit. Refer to EC-154.

3. Check injector and its circuit. Refer to EC-494.

Clean or replace if necessary.

4. Check engine coolant temperature sensor and its circuit. Refer to EC-169.

5. Check ECM function by substituting another known-good ECM.

(ECM may be the cause of a problem, but this is rarely the case.)

©GO TO 3.

12 CHECK HEATED OXYGEN SENSOR 1 (FRONT) HARNESS

1. Turn off engine and disconnect battery ground cable.

2. Disconnect ECM harness connector.

3. Disconnect heated oxygen sensor 1 (front) harness connector.

4. Check harness continuity between ECM terminal 62 and heated oxygen sensor 1 (front) harness connector terminal 1.

Refer to Wiring Diagram, EC-184.

Continuity should exist.

OK or NG

OK©GO TO 14.

NG©GO TO 13.

13 REPAIR OR REPLACE

Repair or replace harness between ECM and heated oxygen sensor 1 (front).

©GO TO 5.

BASIC SERVICE PROCEDUREQG18DE

Inspection Procedure (Cont'd)

EC-53

Page 571 of 3051

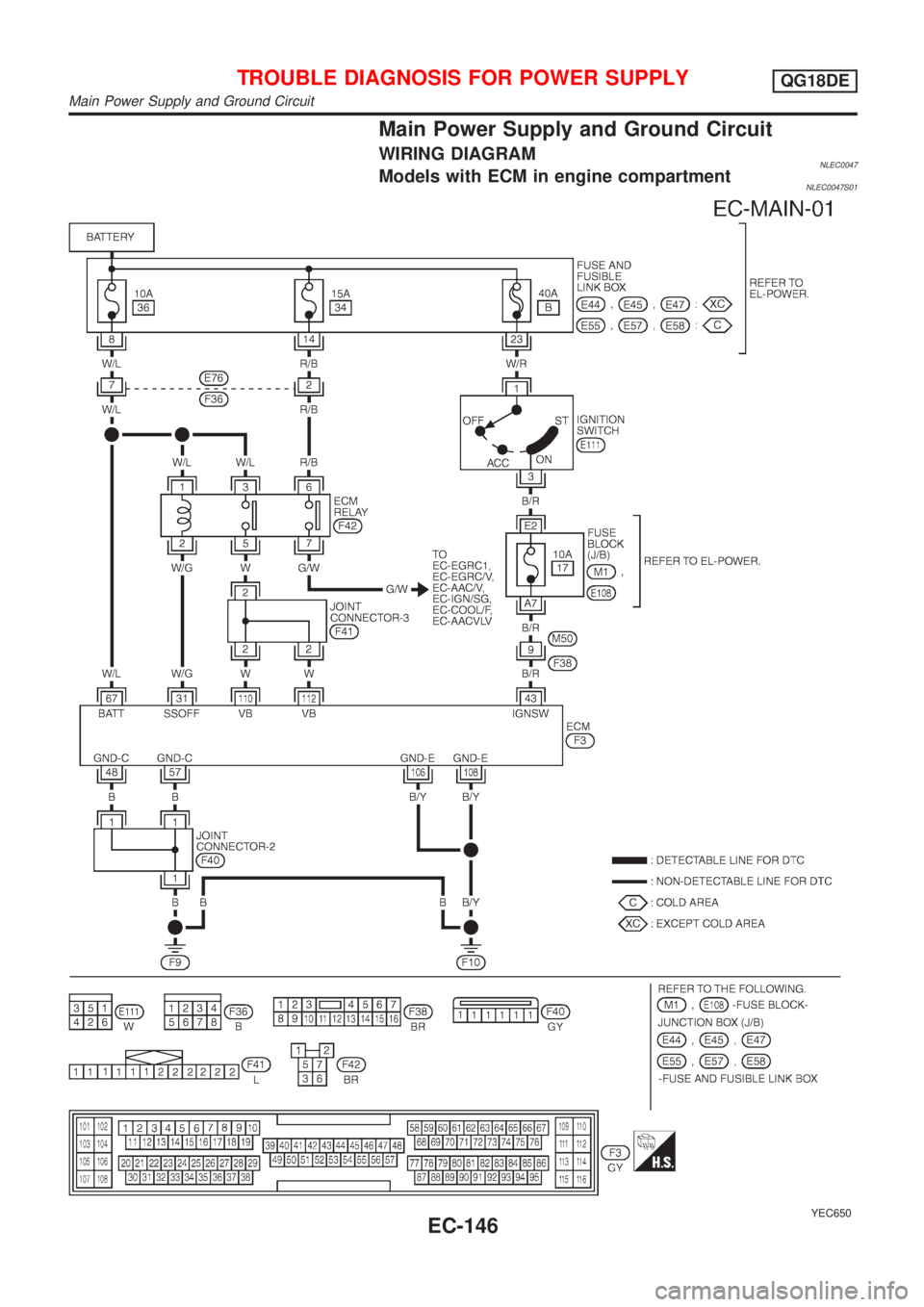

Main Power Supply and Ground Circuit

WIRING DIAGRAMNLEC0047Models with ECM in engine compartmentNLEC0047S01

YEC650

TROUBLE DIAGNOSIS FOR POWER SUPPLYQG18DE

Main Power Supply and Ground Circuit

EC-146

Page 574 of 3051

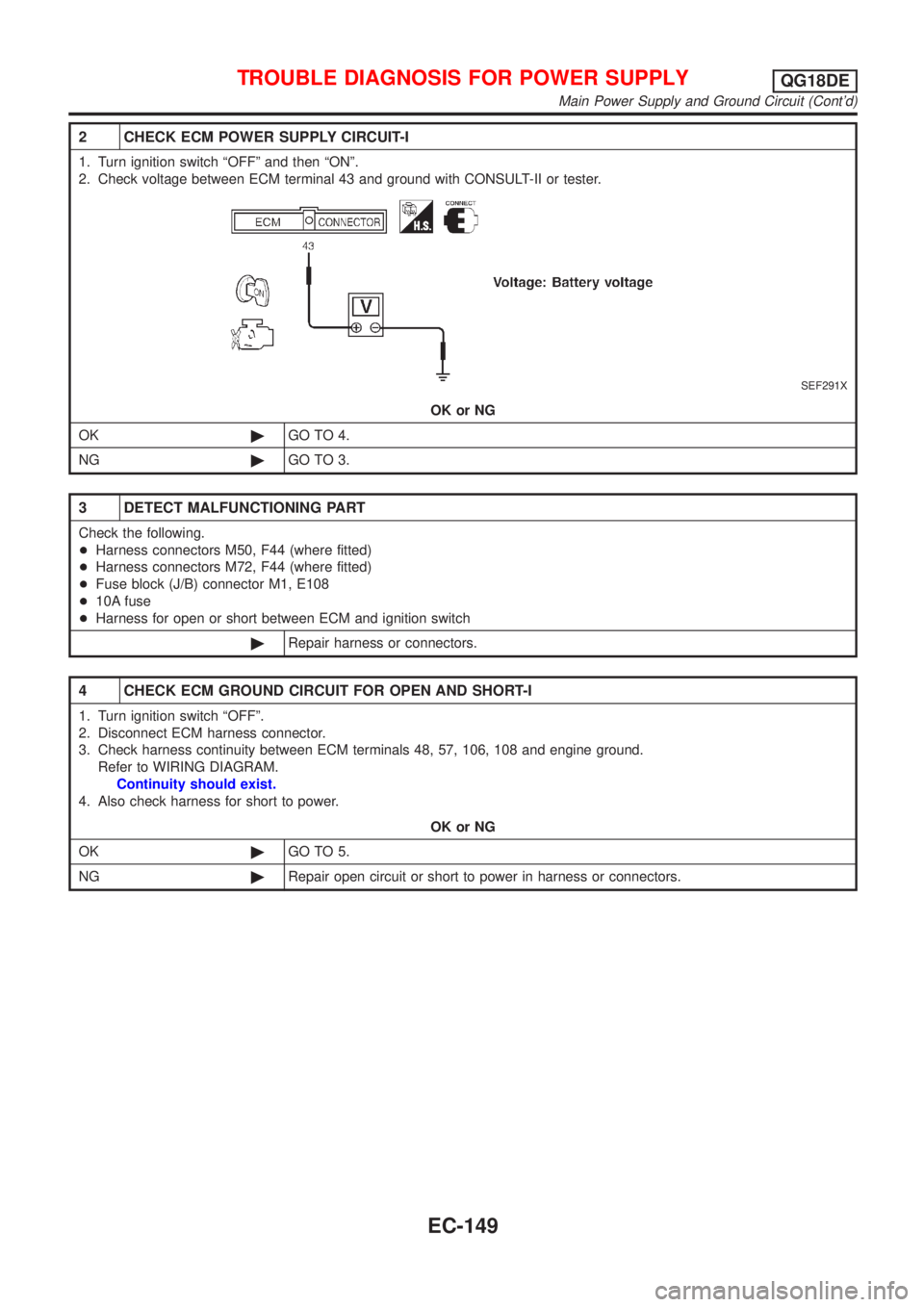

2 CHECK ECM POWER SUPPLY CIRCUIT-I

1. Turn ignition switch ªOFFº and then ªONº.

2. Check voltage between ECM terminal 43 and ground with CONSULT-II or tester.

SEF291X

OK or NG

OK©GO TO 4.

NG©GO TO 3.

3 DETECT MALFUNCTIONING PART

Check the following.

+Harness connectors M50, F44 (where fitted)

+Harness connectors M72, F44 (where fitted)

+Fuse block (J/B) connector M1, E108

+10A fuse

+Harness for open or short between ECM and ignition switch

©Repair harness or connectors.

4 CHECK ECM GROUND CIRCUIT FOR OPEN AND SHORT-I

1. Turn ignition switch ªOFFº.

2. Disconnect ECM harness connector.

3. Check harness continuity between ECM terminals 48, 57, 106, 108 and engine ground.

Refer to WIRING DIAGRAM.

Continuity should exist.

4. Also check harness for short to power.

OK or NG

OK©GO TO 5.

NG©Repair open circuit or short to power in harness or connectors.

TROUBLE DIAGNOSIS FOR POWER SUPPLYQG18DE

Main Power Supply and Ground Circuit (Cont'd)

EC-149

Page 577 of 3051

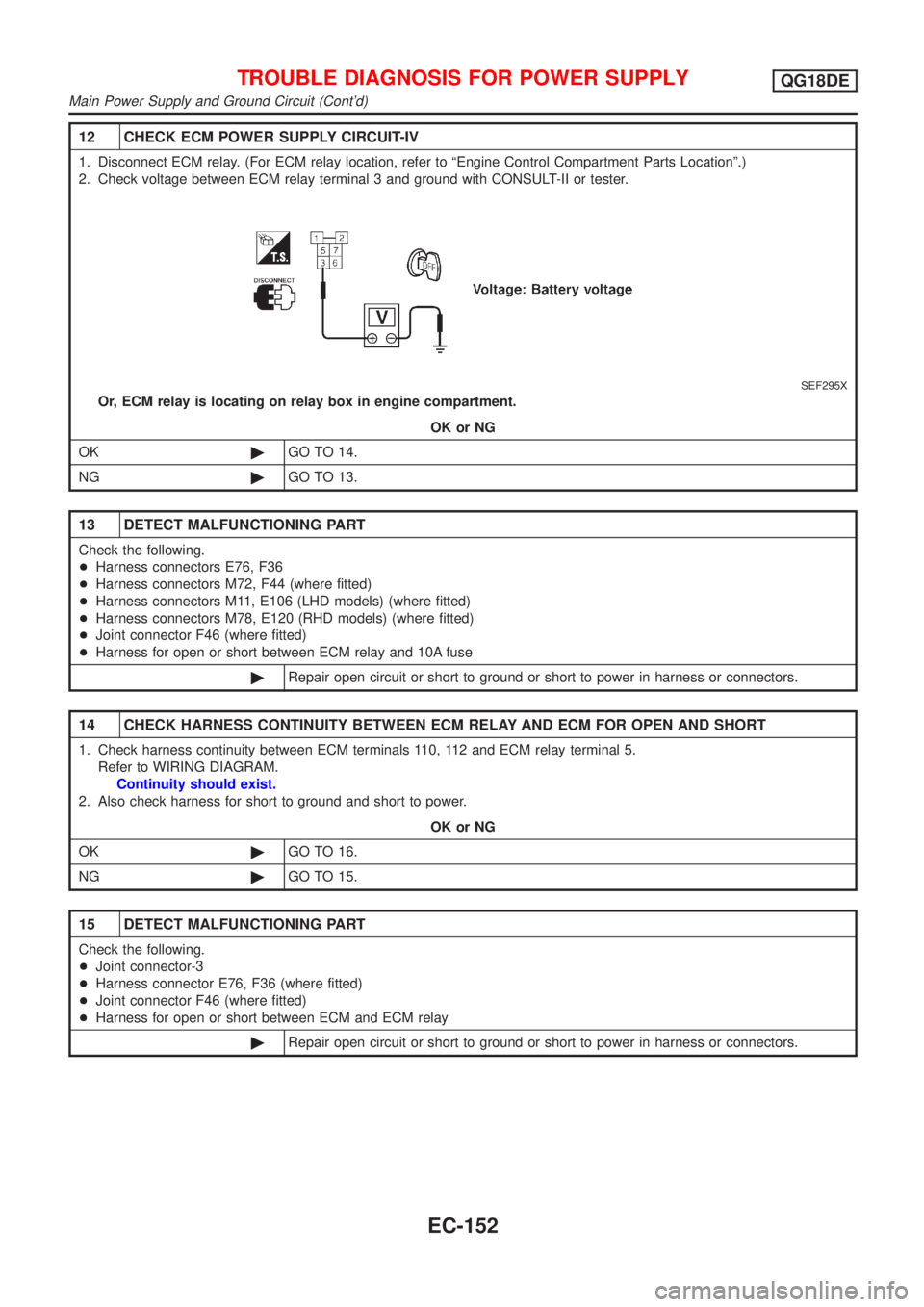

12 CHECK ECM POWER SUPPLY CIRCUIT-IV

1. Disconnect ECM relay. (For ECM relay location, refer to ªEngine Control Compartment Parts Locationº.)

2. Check voltage between ECM relay terminal 3 and ground with CONSULT-II or tester.

SEF295X

Or, ECM relay is locating on relay box in engine compartment.

OK or NG

OK©GO TO 14.

NG©GO TO 13.

13 DETECT MALFUNCTIONING PART

Check the following.

+Harness connectors E76, F36

+Harness connectors M72, F44 (where fitted)

+Harness connectors M11, E106 (LHD models) (where fitted)

+Harness connectors M78, E120 (RHD models) (where fitted)

+Joint connector F46 (where fitted)

+Harness for open or short between ECM relay and 10A fuse

©Repair open circuit or short to ground or short to power in harness or connectors.

14 CHECK HARNESS CONTINUITY BETWEEN ECM RELAY AND ECM FOR OPEN AND SHORT

1. Check harness continuity between ECM terminals 110, 112 and ECM relay terminal 5.

Refer to WIRING DIAGRAM.

Continuity should exist.

2. Also check harness for short to ground and short to power.

OK or NG

OK©GO TO 16.

NG©GO TO 15.

15 DETECT MALFUNCTIONING PART

Check the following.

+Joint connector-3

+Harness connector E76, F36 (where fitted)

+Joint connector F46 (where fitted)

+Harness for open or short between ECM and ECM relay

©Repair open circuit or short to ground or short to power in harness or connectors.

TROUBLE DIAGNOSIS FOR POWER SUPPLYQG18DE

Main Power Supply and Ground Circuit (Cont'd)

EC-152

Page 578 of 3051

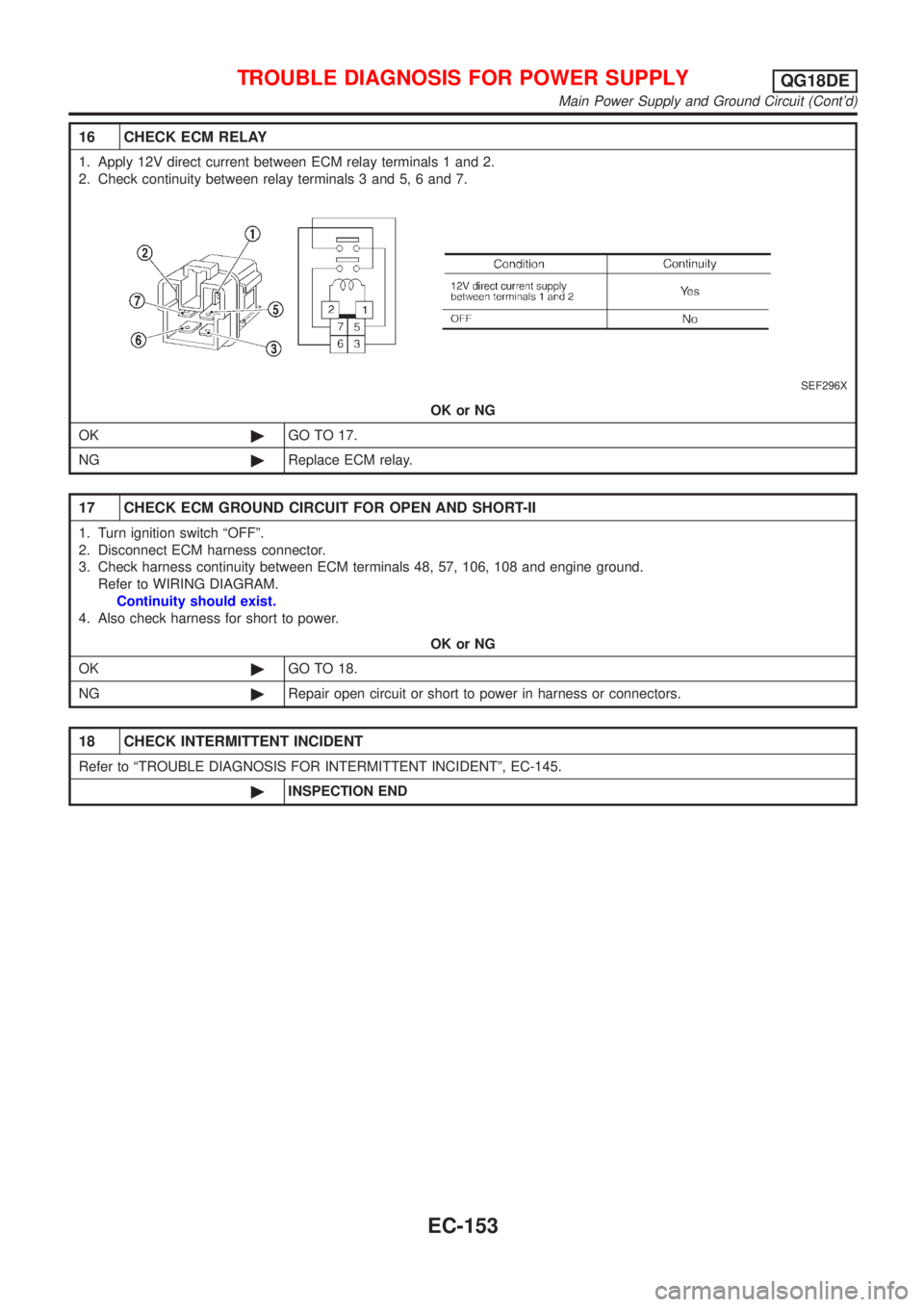

16 CHECK ECM RELAY

1. Apply 12V direct current between ECM relay terminals 1 and 2.

2. Check continuity between relay terminals 3 and 5, 6 and 7.

SEF296X

OK or NG

OK©GO TO 17.

NG©Replace ECM relay.

17 CHECK ECM GROUND CIRCUIT FOR OPEN AND SHORT-II

1. Turn ignition switch ªOFFº.

2. Disconnect ECM harness connector.

3. Check harness continuity between ECM terminals 48, 57, 106, 108 and engine ground.

Refer to WIRING DIAGRAM.

Continuity should exist.

4. Also check harness for short to power.

OK or NG

OK©GO TO 18.

NG©Repair open circuit or short to power in harness or connectors.

18 CHECK INTERMITTENT INCIDENT

Refer to ªTROUBLE DIAGNOSIS FOR INTERMITTENT INCIDENTº, EC-145.

©INSPECTION END

TROUBLE DIAGNOSIS FOR POWER SUPPLYQG18DE

Main Power Supply and Ground Circuit (Cont'd)

EC-153

Page 581 of 3051

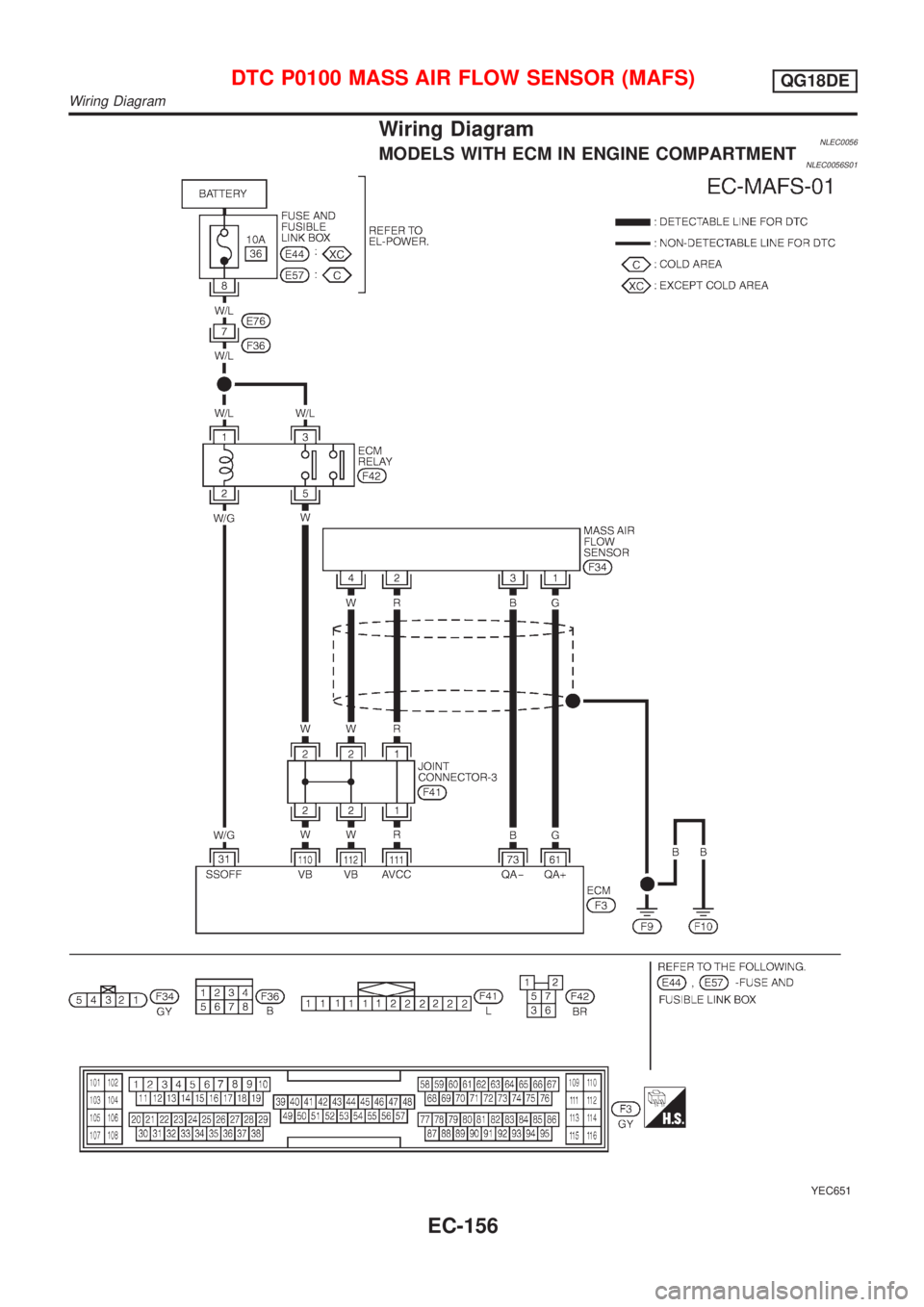

Wiring DiagramNLEC0056MODELS WITH ECM IN ENGINE COMPARTMENTNLEC0056S01

YEC651

DTC P0100 MASS AIR FLOW SENSOR (MAFS)QG18DE

Wiring Diagram

EC-156

Page 582 of 3051

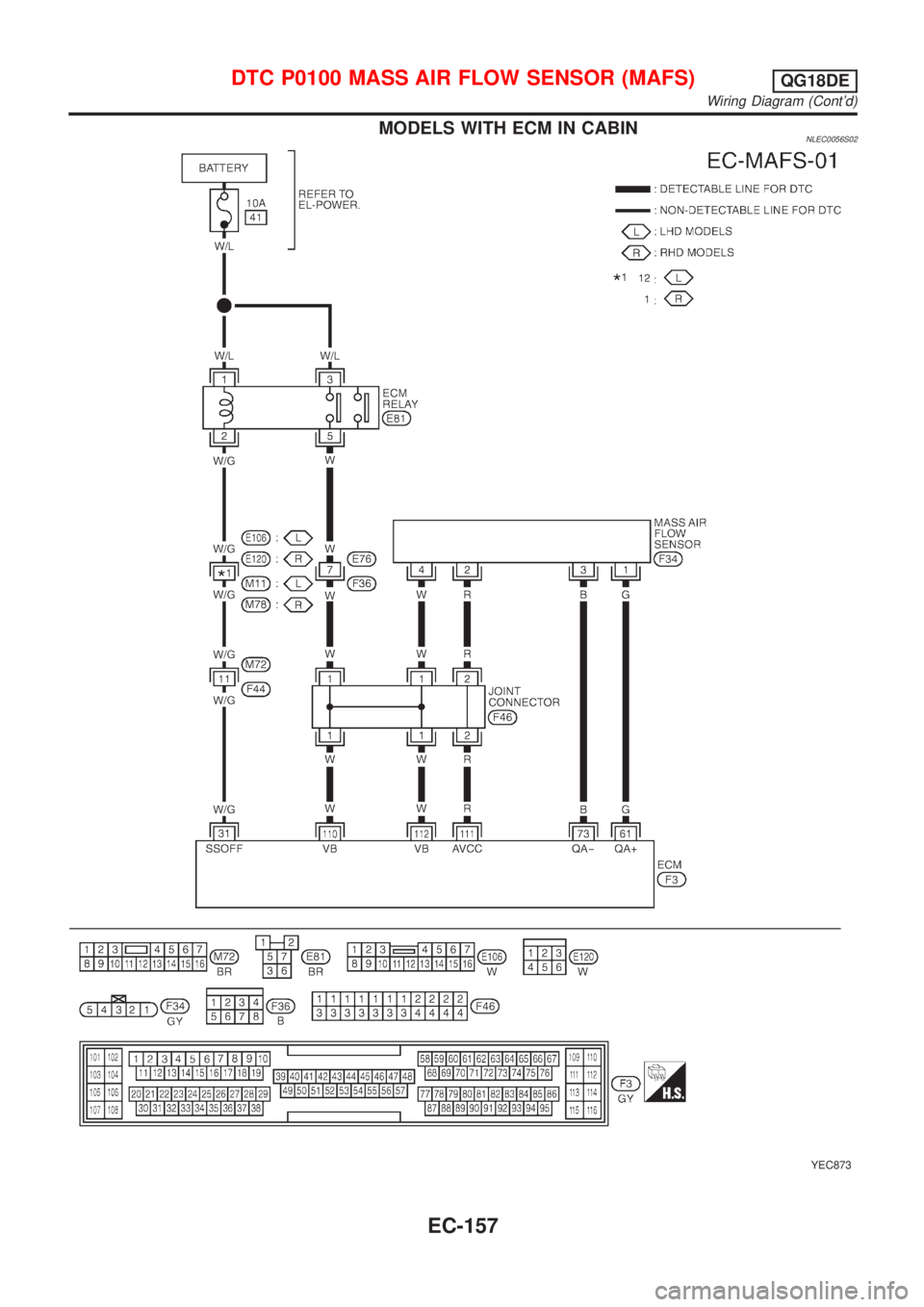

MODELS WITH ECM IN CABINNLEC0056S02

YEC873

DTC P0100 MASS AIR FLOW SENSOR (MAFS)QG18DE

Wiring Diagram (Cont'd)

EC-157