relay NISSAN ALMERA TINO 2001 Service Repair Manual

[x] Cancel search | Manufacturer: NISSAN, Model Year: 2001, Model line: ALMERA TINO, Model: NISSAN ALMERA TINO 2001Pages: 3051, PDF Size: 46.38 MB

Page 18 of 3051

TCM FUNCTION=NLAT0014S03The function of the TCM is to:

+Receive input signals sent from various switches and sensors.

+Determine required line pressure, shifting point and lock-up operation.

+Send required output signals to the step motor and the respective solenoids.

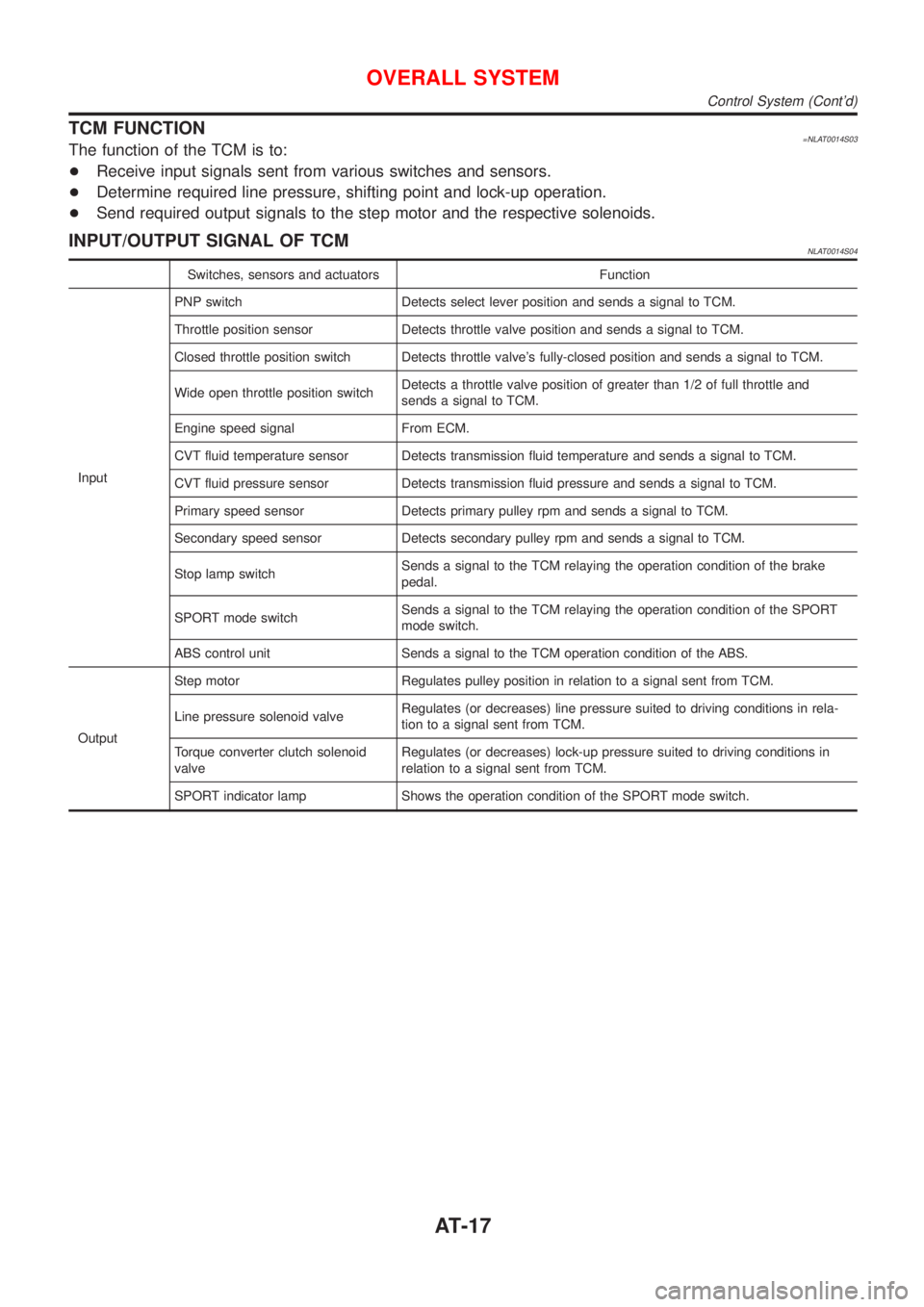

INPUT/OUTPUT SIGNAL OF TCMNLAT0014S04

Switches, sensors and actuators Function

InputPNP switch Detects select lever position and sends a signal to TCM.

Throttle position sensor Detects throttle valve position and sends a signal to TCM.

Closed throttle position switch Detects throttle valve's fully-closed position and sends a signal to TCM.

Wide open throttle position switchDetects a throttle valve position of greater than 1/2 of full throttle and

sends a signal to TCM.

Engine speed signal From ECM.

CVT fluid temperature sensor Detects transmission fluid temperature and sends a signal to TCM.

CVT fluid pressure sensor Detects transmission fluid pressure and sends a signal to TCM.

Primary speed sensor Detects primary pulley rpm and sends a signal to TCM.

Secondary speed sensor Detects secondary pulley rpm and sends a signal to TCM.

Stop lamp switchSends a signal to the TCM relaying the operation condition of the brake

pedal.

SPORT mode switchSends a signal to the TCM relaying the operation condition of the SPORT

mode switch.

ABS control unit Sends a signal to the TCM operation condition of the ABS.

OutputStep motor Regulates pulley position in relation to a signal sent from TCM.

Line pressure solenoid valveRegulates (or decreases) line pressure suited to driving conditions in rela-

tion to a signal sent from TCM.

Torque converter clutch solenoid

valveRegulates (or decreases) lock-up pressure suited to driving conditions in

relation to a signal sent from TCM.

SPORT indicator lamp Shows the operation condition of the SPORT mode switch.

OVERALL SYSTEM

Control System (Cont'd)

AT-17

Page 201 of 3051

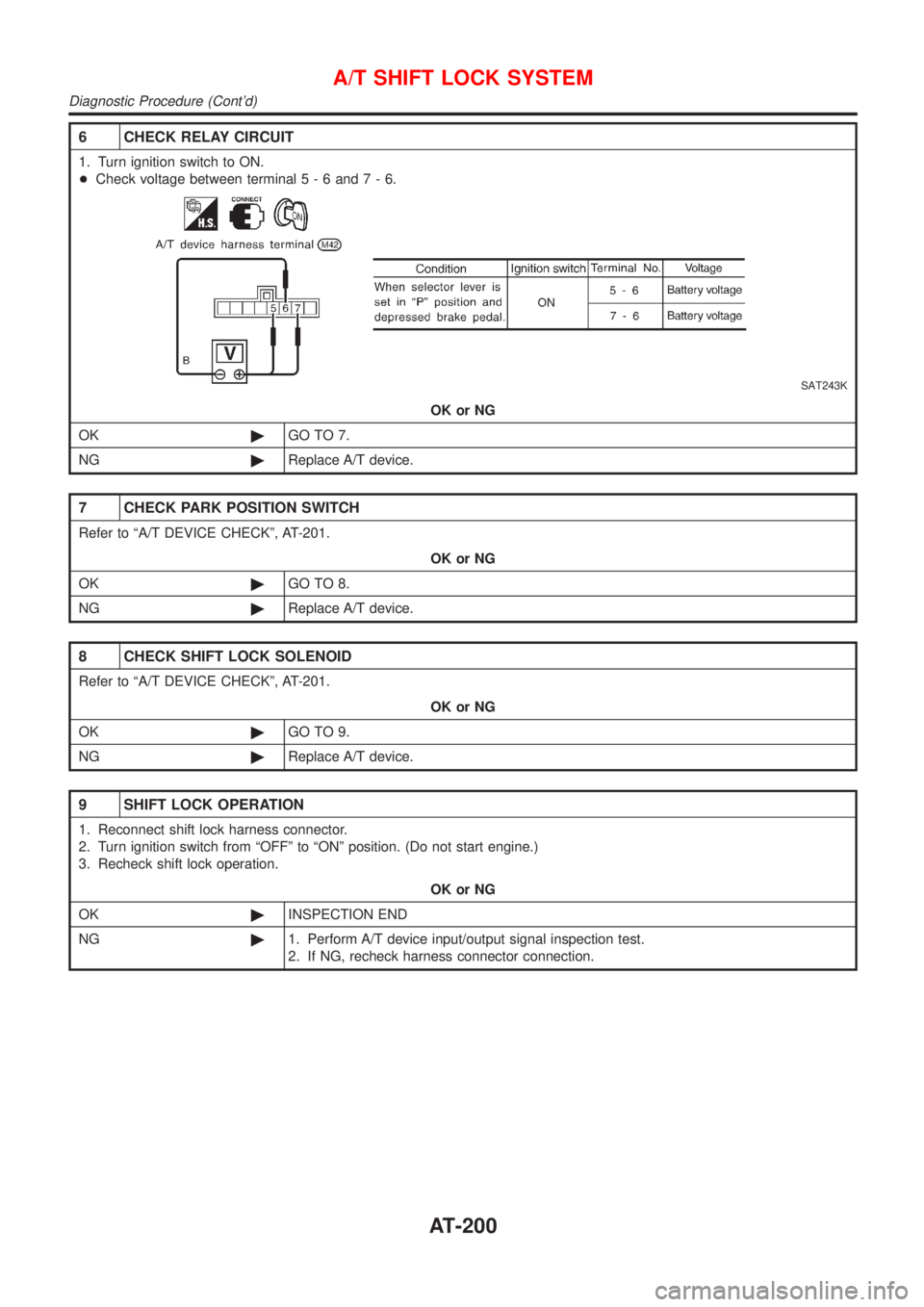

6 CHECK RELAY CIRCUIT

1. Turn ignition switch to ON.

+Check voltage between terminal5-6and7-6.

SAT243K

OK or NG

OK©GO TO 7.

NG©Replace A/T device.

7 CHECK PARK POSITION SWITCH

Refer to ªA/T DEVICE CHECKº, AT-201.

OK or NG

OK©GO TO 8.

NG©Replace A/T device.

8 CHECK SHIFT LOCK SOLENOID

Refer to ªA/T DEVICE CHECKº, AT-201.

OK or NG

OK©GO TO 9.

NG©Replace A/T device.

9 SHIFT LOCK OPERATION

1. Reconnect shift lock harness connector.

2. Turn ignition switch from ªOFFº to ªONº position. (Do not start engine.)

3. Recheck shift lock operation.

OK or NG

OK©INSPECTION END

NG©1. Perform A/T device input/output signal inspection test.

2. If NG, recheck harness connector connection.

A/T SHIFT LOCK SYSTEM

Diagnostic Procedure (Cont'd)

AT-200

Page 239 of 3051

CALIPER.................................................................38

ROTOR...................................................................39

Installation ..................................................................39

PARKING BRAKE CONTROL......................................40

Components...............................................................40

Removal and Installation ...........................................40

Inspection...................................................................40

Adjustment .................................................................41

ABS

DESCRIPTION...............................................................42

Purpose......................................................................42

ABS (Anti-Lock Brake System) Operation ................42

ABS Hydraulic Circuit ................................................42

System Components .................................................43

System Description ....................................................43

SENSOR.................................................................43

CONTROL UNIT......................................................43

ABS ACTUATOR AND ELECTRIC UNIT....................43

Component Parts and Harness Connector

Location .....................................................................45

Schematic ..................................................................46

MODELS WITH SELF-DIAGNOSIS FUNCTION

(DATA LINK CONNECTOR TERMINAL NO. 9)

...........46

MODELS WITHOUT SELF-DIAGNOSIS

FUNCTION (DATA LINK CONNECTOR TERMINAL

NO. 9)

.....................................................................47

Wiring Diagram - ABS - .............................................48

MODELS WITH SELF-DIAGNOSIS FUNCTION

(DATA LINK CONNECTOR TERMINAL NO. 9)

...........48

MODELS WITHOUT SELF-DIAGNOSIS

FUNCTION (DATA LINK CONNECTOR TERMINAL

NO. 9)

.....................................................................52

ON BOARD DIAGNOSTIC SYSTEM

DESCRIPTION...............................................................56

Self-diagnosis (Only models with data link

connector terminal No. 9) ..........................................56

FUNCTION..............................................................56

SELF-DIAGNOSIS PROCEDURE..............................56

HOW TO READ SELF-DIAGNOSTIC RESULTS

(MALFUNCTION CODES)

........................................57

HOW TO ERASE SELF-DIAGNOSTIC RESULTS

(MALFUNCTION CODES)

........................................57

CONSULT-II ...............................................................58

CONSULT-II APPLICATION TO ABS..........................58

ECU (ABS CONTROL UNIT) PART NUMBER

MODE

.....................................................................58

CONSULT-II Inspection Procedure............................58

SELF-DIAGNOSIS PROCEDURE..............................58

SELF-DIAGNOSTIC RESULTS MODE.......................60

DATA MONITOR PROCEDURE................................61

ACTIVE TEST PROCEDURE....................................62

DATA MONITOR MODE...........................................63

ACTIVE TEST MODE...............................................63

TROUBLE DIAGNOSIS - INTRODUCTION..................64

How to Perform Trouble Diagnoses for Quick

and Accurate Repair ..................................................64

INTRODUCTION......................................................64

TROUBLE DIAGNOSIS - BASIC INSPECTION...........65

Preliminary Check......................................................65

Ground Circuit Check ................................................68

ABS ACTUATOR AND ELECTRIC UNIT GROUND.....68

TROUBLE DIAGNOSIS - GENERAL

DESCRIPTION...............................................................69

Malfunction Code/Symptom Chart.............................69

MODELS WITH SELF-DIAGNOSIS FUNCTION

(DATA LINK CONNECTOR TERMINAL NO. 9)

...........69

TROUBLE DIAGNOSES FOR SELF-DIAGNOSTIC

ITEMS.............................................................................71

Wheel Sensor or Rotor ..............................................71

DIAGNOSTIC PROCEDURE.....................................71

ABS Actuator Solenoid Valve or Solenoid Valve

Relay ..........................................................................74

DIAGNOSTIC PROCEDURE.....................................74

Motor Relay or Motor.................................................77

DIAGNOSTIC PROCEDURE.....................................77

Low Voltage ...............................................................79

DIAGNOSTIC PROCEDURE.....................................79

Control Unit ................................................................81

DIAGNOSTIC PROCEDURE.....................................81

TROUBLE DIAGNOSES FOR SYMPTOMS.................82

1. ABS Works Frequently ..........................................82

2. Unexpected Pedal Action ......................................82

3. Long Stopping Distance ........................................83

4. ABS Does Not Work ..............................................84

5. Pedal Vibration and Noise.....................................85

6. ABS Warning Lamp Does Not Come On

When Ignition Switch Is Turned On...........................86

7. ABS Warning Lamp Stays On When Ignition

Switch Is Turned On ..................................................88

REMOVAL AND INSTALLATION.................................90

Wheel Sensors ..........................................................90

ABS Actuator and Electric Unit..................................91

REMOVAL...............................................................91

INSTALLATION........................................................91

Sensor Rotor..............................................................92

REMOVAL...............................................................92

INSTALLATION........................................................92

SERVICE DATA AND SPECIFICATIONS (SDS).........93

General Specifications ...............................................93

Disc Brake .................................................................93

Brake Pedal ...............................................................93

Parking Brake ............................................................93

CONTENTS(Cont’d)

BR-2

Page 280 of 3051

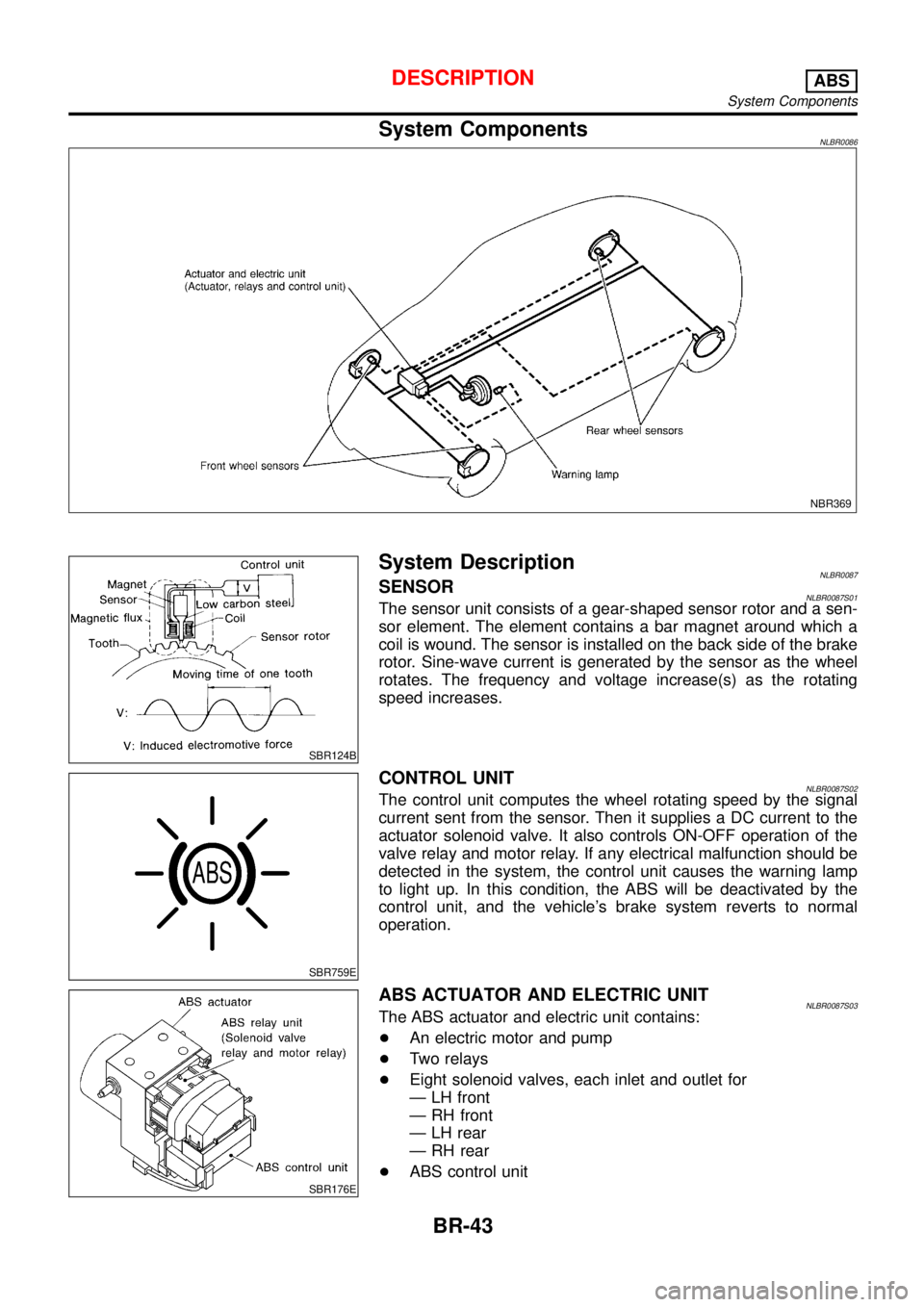

System ComponentsNLBR0086

NBR369

SBR124B

System DescriptionNLBR0087SENSORNLBR0087S01The sensor unit consists of a gear-shaped sensor rotor and a sen-

sor element. The element contains a bar magnet around which a

coil is wound. The sensor is installed on the back side of the brake

rotor. Sine-wave current is generated by the sensor as the wheel

rotates. The frequency and voltage increase(s) as the rotating

speed increases.

SBR759E

CONTROL UNITNLBR0087S02The control unit computes the wheel rotating speed by the signal

current sent from the sensor. Then it supplies a DC current to the

actuator solenoid valve. It also controls ON-OFF operation of the

valve relay and motor relay. If any electrical malfunction should be

detected in the system, the control unit causes the warning lamp

to light up. In this condition, the ABS will be deactivated by the

control unit, and the vehicle’s brake system reverts to normal

operation.

SBR176E

ABS ACTUATOR AND ELECTRIC UNITNLBR0087S03The ABS actuator and electric unit contains:

+An electric motor and pump

+Two relays

+Eight solenoid valves, each inlet and outlet for

—LH front

—RH front

—LH rear

—RH rear

+ABS control unit

DESCRIPTIONABS

System Components

BR-43

Page 295 of 3051

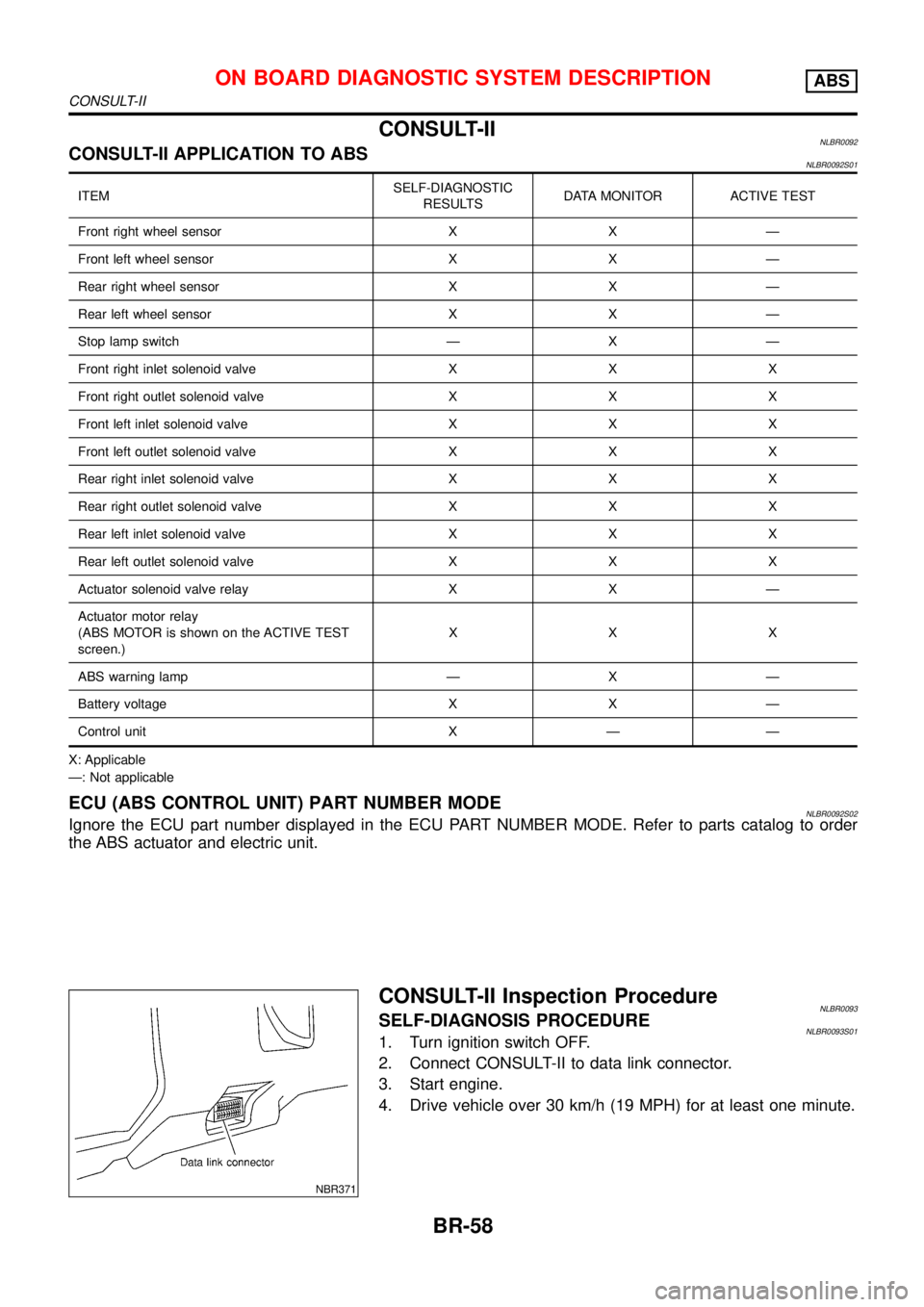

CONSULT-IINLBR0092CONSULT-II APPLICATION TO ABSNLBR0092S01

ITEMSELF-DIAGNOSTIC

RESULTSDATA MONITOR ACTIVE TEST

Front right wheel sensor X X—

Front left wheel sensor X X—

Rear right wheel sensor X X—

Rear left wheel sensor X X—

Stop lamp switch—X—

Front right inlet solenoid valve X X X

Front right outlet solenoid valve X X X

Front left inlet solenoid valve X X X

Front left outlet solenoid valve X X X

Rear right inlet solenoid valve X X X

Rear right outlet solenoid valve X X X

Rear left inlet solenoid valve X X X

Rear left outlet solenoid valve X X X

Actuator solenoid valve relay X X—

Actuator motor relay

(ABS MOTOR is shown on the ACTIVE TEST

screen.)XXX

ABS warning lamp—X—

Battery voltage X X—

Control unit X——

X: Applicable

—: Not applicable

ECU (ABS CONTROL UNIT) PART NUMBER MODENLBR0092S02Ignore the ECU part number displayed in the ECU PART NUMBER MODE. Refer to parts catalog to order

the ABS actuator and electric unit.

NBR371

CONSULT-II Inspection ProcedureNLBR0093SELF-DIAGNOSIS PROCEDURENLBR0093S011. Turn ignition switch OFF.

2. Connect CONSULT-II to data link connector.

3. Start engine.

4. Drive vehicle over 30 km/h (19 MPH) for at least one minute.

ON BOARD DIAGNOSTIC SYSTEM DESCRIPTIONABS

CONSULT-II

BR-58

Page 298 of 3051

![NISSAN ALMERA TINO 2001 Service Repair Manual Diagnostic item Diagnostic item is detected when ...Reference

Page

RR RH OUT ABS SOL

[SHORT]+Circuit for rear right outlet solenoid valve is shorted.

(An abnormally high output voltage is entered.)BR- NISSAN ALMERA TINO 2001 Service Repair Manual Diagnostic item Diagnostic item is detected when ...Reference

Page

RR RH OUT ABS SOL

[SHORT]+Circuit for rear right outlet solenoid valve is shorted.

(An abnormally high output voltage is entered.)BR-](/img/5/57352/w960_57352-297.png)

Diagnostic item Diagnostic item is detected when ...Reference

Page

RR RH OUT ABS SOL

[SHORT]+Circuit for rear right outlet solenoid valve is shorted.

(An abnormally high output voltage is entered.)BR-74

RR LH OUT ABS SOL

[SHORT]+Circuit for rear left outlet solenoid valve is shorted.

(An abnormally high output voltage is entered.)BR-74

ABS ACTUATOR RELAY

[ABNORMAL]+Actuator solenoid valve relay is ON, even control unit sends off signal.

+Actuator solenoid valve relay is OFF, even control unit sends on signal.BR-74

ABS MOTOR RELAY

[ABNORMAL]+Circuit for actuator motor is open or shorted.

+Actuator motor relay is stuck.BR-77

BATTERY VOLT

[ABNORMAL]+Power source voltage supplied to ABS control unit is abnormally low. BR-79

CONTROL UNIT+Function of calculation in ABS control unit has failed. BR-81

*1: Be sure to confirm the ABS warning lamp illuminates when the ignition switch is turned ON after repairing the shorted sensor circuit,

but the lamp goes out when driving the vehicle over 30 km/h (19 MPH) for one minute in accordance with SELF-DIAGNOSIS

PROCEDURE.

PBR455D

DATA MONITOR PROCEDURENLBR0093S031. Turn ignition switch OFF.

2. Connect CONSULT-II to data link connector.

3. Turn ignition switch ON.

4. Touch“START”on CONSULT-II screen.

C2SSE01

5. Touch“ABS”.

C2SDM01

6. Touch“DATA MONITOR”.

7. Touch“SETTING”on“SELECT MONITOR ITEM”screen.

8. Touch“LONG TIME”on“SET RECORDING COND”screen.

9. Touch“START”on“SELECT MONITOR ITEM”.

ON BOARD DIAGNOSTIC SYSTEM DESCRIPTIONABS

CONSULT-II Inspection Procedure (Cont’d)

BR-61

Page 300 of 3051

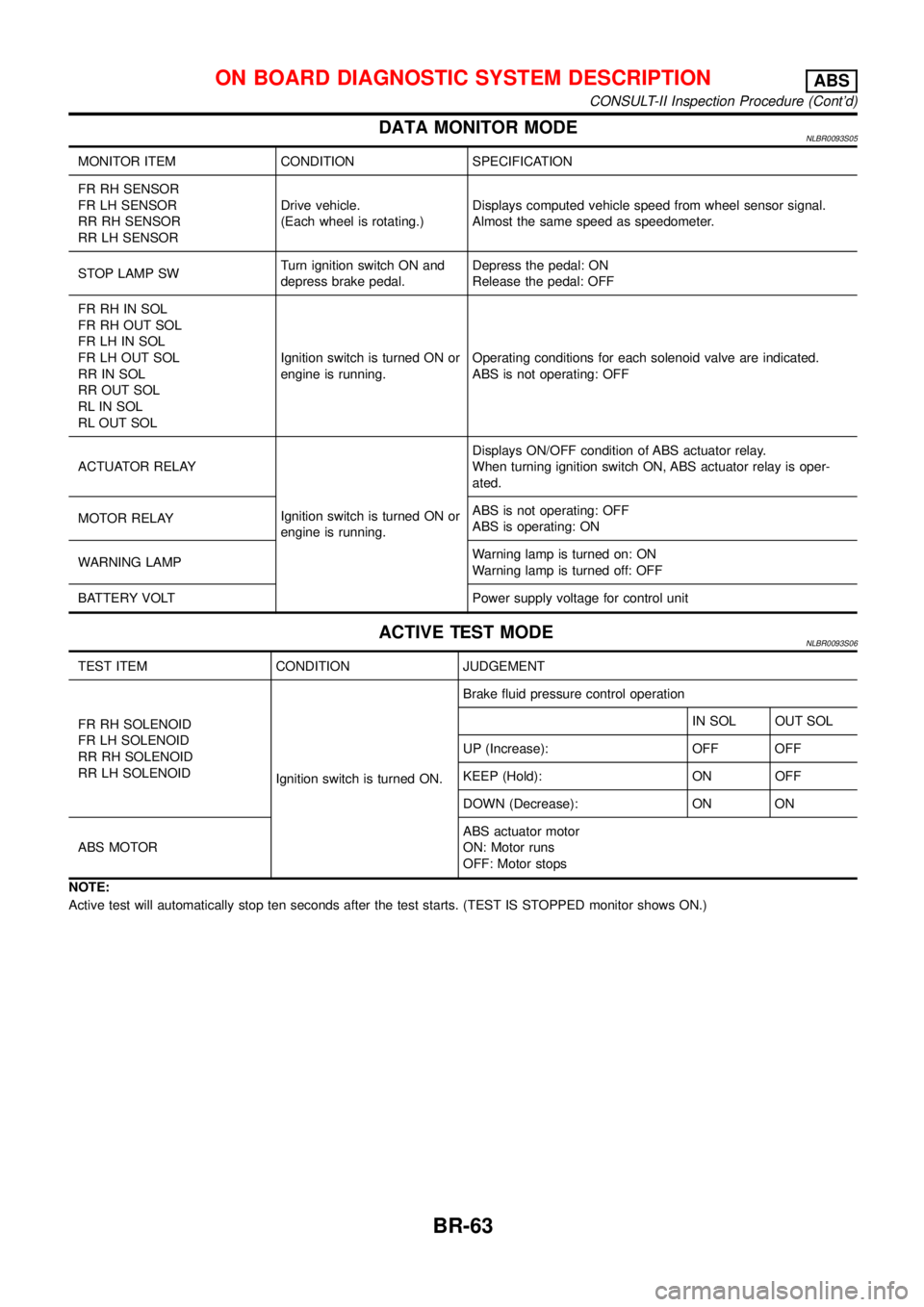

DATA MONITOR MODENLBR0093S05

MONITOR ITEM CONDITION SPECIFICATION

FR RH SENSOR

FR LH SENSOR

RR RH SENSOR

RR LH SENSORDrive vehicle.

(Each wheel is rotating.)Displays computed vehicle speed from wheel sensor signal.

Almost the same speed as speedometer.

STOP LAMP SWTurn ignition switch ON and

depress brake pedal.Depress the pedal: ON

Release the pedal: OFF

FR RH IN SOL

FR RH OUT SOL

FR LH IN SOL

FR LH OUT SOL

RR IN SOL

RR OUT SOL

RL IN SOL

RL OUT SOLIgnition switch is turned ON or

engine is running.Operating conditions for each solenoid valve are indicated.

ABS is not operating: OFF

ACTUATOR RELAY

Ignition switch is turned ON or

engine is running.Displays ON/OFF condition of ABS actuator relay.

When turning ignition switch ON, ABS actuator relay is oper-

ated.

MOTOR RELAYABS is not operating: OFF

ABS is operating: ON

WARNING LAMPWarning lamp is turned on: ON

Warning lamp is turned off: OFF

BATTERY VOLT Power supply voltage for control unit

ACTIVE TEST MODENLBR0093S06

TEST ITEM CONDITION JUDGEMENT

FR RH SOLENOID

FR LH SOLENOID

RR RH SOLENOID

RR LH SOLENOID

Ignition switch is turned ON.Brake fluid pressure control operation

IN SOL OUT SOL

UP (Increase): OFF OFF

KEEP (Hold): ON OFF

DOWN (Decrease): ON ON

ABS MOTORABS actuator motor

ON: Motor runs

OFF: Motor stops

NOTE:

Active test will automatically stop ten seconds after the test starts. (TEST IS STOPPED monitor shows ON.)

ON BOARD DIAGNOSTIC SYSTEM DESCRIPTIONABS

CONSULT-II Inspection Procedure (Cont’d)

BR-63

Page 306 of 3051

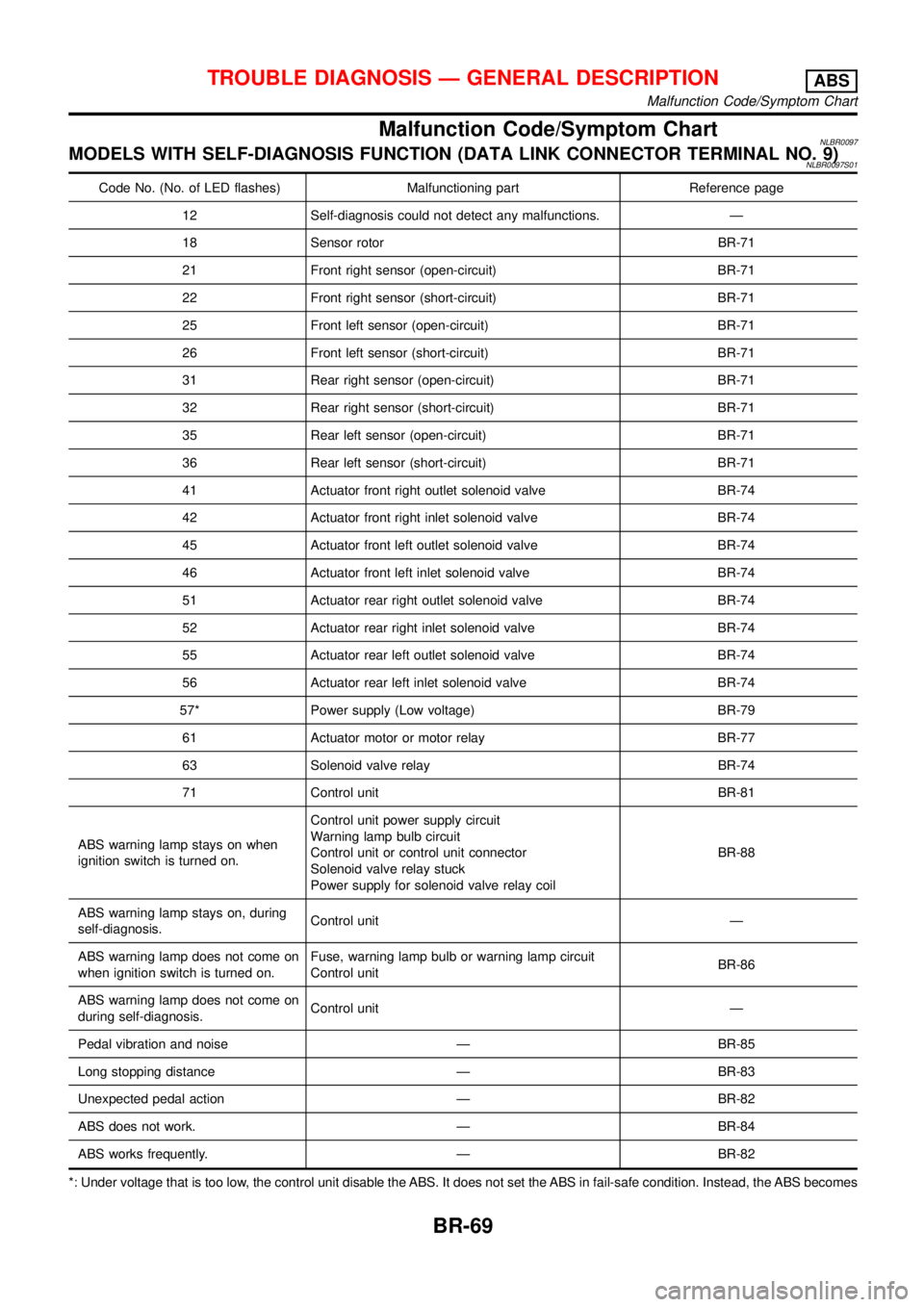

Malfunction Code/Symptom ChartNLBR0097MODELS WITH SELF-DIAGNOSIS FUNCTION (DATA LINK CONNECTOR TERMINAL NO. 9)NLBR0097S01

Code No. (No. of LED flashes) Malfunctioning part Reference page

12 Self-diagnosis could not detect any malfunctions.—

18 Sensor rotor BR-71

21 Front right sensor (open-circuit) BR-71

22 Front right sensor (short-circuit) BR-71

25 Front left sensor (open-circuit) BR-71

26 Front left sensor (short-circuit) BR-71

31 Rear right sensor (open-circuit) BR-71

32 Rear right sensor (short-circuit) BR-71

35 Rear left sensor (open-circuit) BR-71

36 Rear left sensor (short-circuit) BR-71

41 Actuator front right outlet solenoid valve BR-74

42 Actuator front right inlet solenoid valve BR-74

45 Actuator front left outlet solenoid valve BR-74

46 Actuator front left inlet solenoid valve BR-74

51 Actuator rear right outlet solenoid valve BR-74

52 Actuator rear right inlet solenoid valve BR-74

55 Actuator rear left outlet solenoid valve BR-74

56 Actuator rear left inlet solenoid valve BR-74

57* Power supply (Low voltage) BR-79

61 Actuator motor or motor relay BR-77

63 Solenoid valve relay BR-74

71 Control unit BR-81

ABS warning lamp stays on when

ignition switch is turned on.Control unit power supply circuit

Warning lamp bulb circuit

Control unit or control unit connector

Solenoid valve relay stuck

Power supply for solenoid valve relay coilBR-88

ABS warning lamp stays on, during

self-diagnosis.Control unit—

ABS warning lamp does not come on

when ignition switch is turned on.Fuse, warning lamp bulb or warning lamp circuit

Control unitBR-86

ABS warning lamp does not come on

during self-diagnosis.Control unit—

Pedal vibration and noise—BR-85

Long stopping distance—BR-83

Unexpected pedal action—BR-82

ABS does not work.—BR-84

ABS works frequently.—BR-82

*: Under voltage that is too low, the control unit disable the ABS. It does not set the ABS in fail-safe condition. Instead, the ABS becomes

TROUBLE DIAGNOSIS—GENERAL DESCRIPTIONABS

Malfunction Code/Symptom Chart

BR-69

Page 311 of 3051

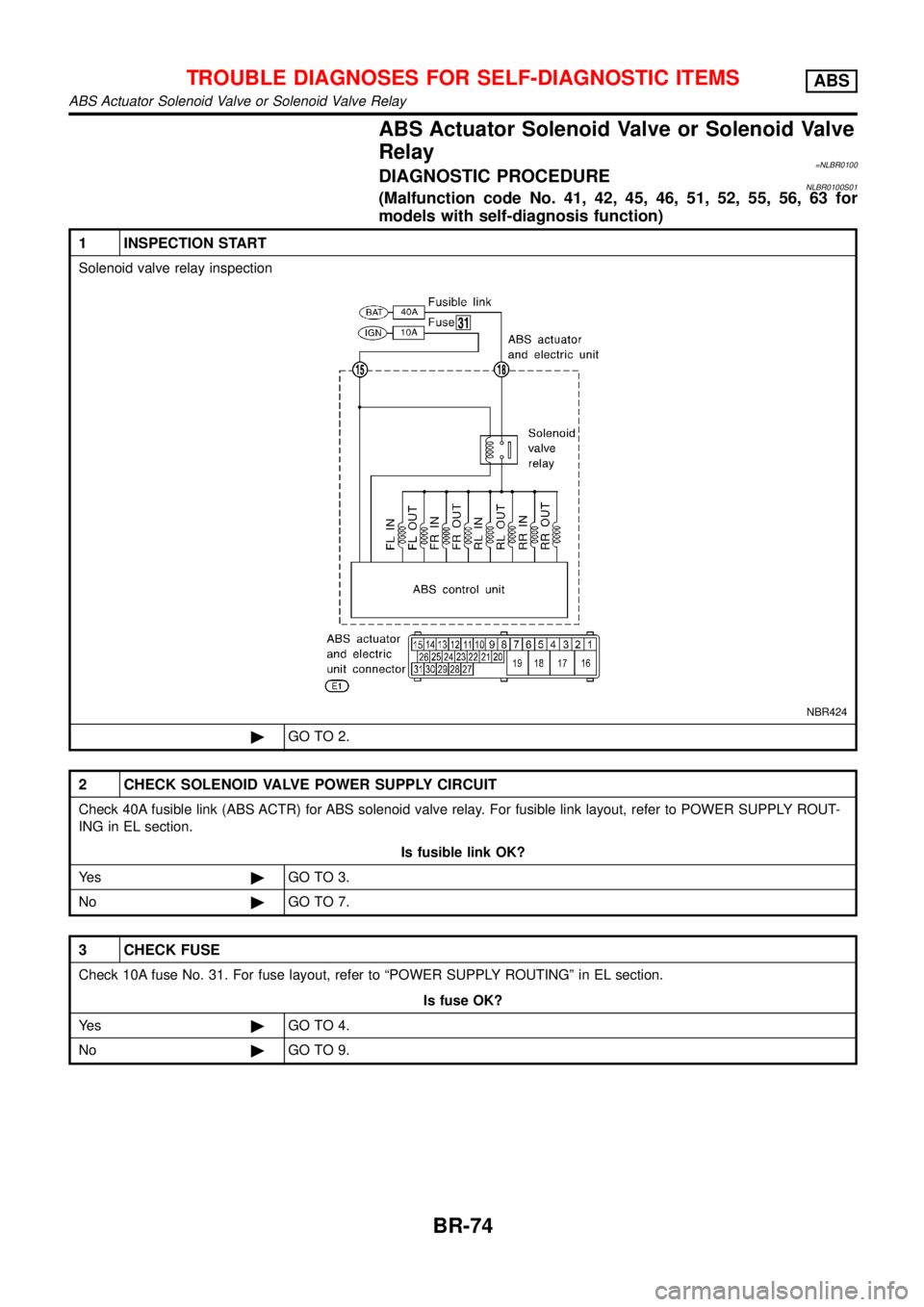

ABS Actuator Solenoid Valve or Solenoid Valve

Relay

=NLBR0100DIAGNOSTIC PROCEDURENLBR0100S01(Malfunction code No. 41, 42, 45, 46, 51, 52, 55, 56, 63 for

models with self-diagnosis function)

1 INSPECTION START

Solenoid valve relay inspection

NBR424

©GO TO 2.

2 CHECK SOLENOID VALVE POWER SUPPLY CIRCUIT

Check 40A fusible link (ABS ACTR) for ABS solenoid valve relay. For fusible link layout, refer to POWER SUPPLY ROUT-

ING in EL section.

Is fusible link OK?

Ye s©GO TO 3.

No©GO TO 7.

3 CHECK FUSE

Check 10A fuse No. 31. For fuse layout, refer to“POWER SUPPLY ROUTING”in EL section.

Is fuse OK?

Ye s©GO TO 4.

No©GO TO 9.

TROUBLE DIAGNOSES FOR SELF-DIAGNOSTIC ITEMSABS

ABS Actuator Solenoid Valve or Solenoid Valve Relay

BR-74

Page 312 of 3051

4 CHECK CONNECTOR

1. Disconnect ABS actuator and electric unit connector. Check terminals for damage or loose connection. Then reconnect

connector.

2. Carry out self-diagnosis again.

Does warning lamp activate again?

Ye s©GO TO 5.

No©INSPECTION END

5 CHECK GROUND CIRCUIT

Refer to ABS ACTUATOR AND ELECTRIC UNIT in Ground Circuit Check, BR-68.

Is ground circuit OK?

Ye s©GO TO 6.

No©Repair harness and connectors.

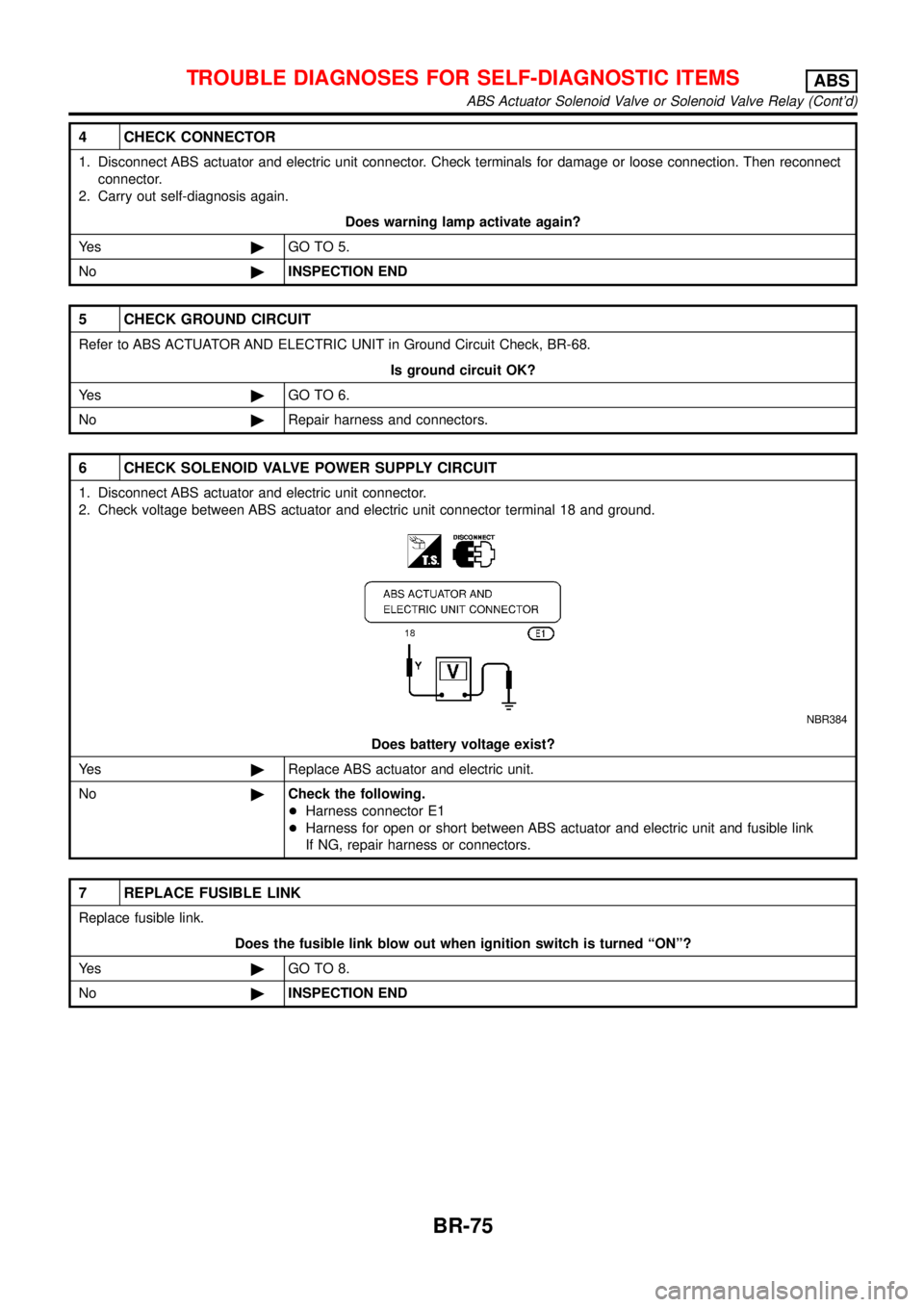

6 CHECK SOLENOID VALVE POWER SUPPLY CIRCUIT

1. Disconnect ABS actuator and electric unit connector.

2. Check voltage between ABS actuator and electric unit connector terminal 18 and ground.

NBR384

Does battery voltage exist?

Ye s©Replace ABS actuator and electric unit.

No©Check the following.

+Harness connector E1

+Harness for open or short between ABS actuator and electric unit and fusible link

If NG, repair harness or connectors.

7 REPLACE FUSIBLE LINK

Replace fusible link.

Does the fusible link blow out when ignition switch is turned“ON”?

Ye s©GO TO 8.

No©INSPECTION END

TROUBLE DIAGNOSES FOR SELF-DIAGNOSTIC ITEMSABS

ABS Actuator Solenoid Valve or Solenoid Valve Relay (Cont’d)

BR-75