wiring NISSAN ALMERA TINO 2001 Service Repair Manual

[x] Cancel search | Manufacturer: NISSAN, Model Year: 2001, Model line: ALMERA TINO, Model: NISSAN ALMERA TINO 2001Pages: 3051, PDF Size: 46.38 MB

Page 2 of 3051

AUTOMATIC TRANSAXLE

SECTION

AT

CONTENTS

EURO-OBD

TROUBLE DIAGNOSIS - INDEX....................................4

Alphabetical & P No. Index for DTC ...........................4

PRECAUTIONS...............................................................6

Precautions for Supplemental Restraint System

(SRS)²AIR BAG²and²SEAT BELT

PRE-TENSIONER²......................................................6

Precautions for On Board Diagnostic (EURO-

OBD) System of CVT and Engine...............................6

Precautions ..................................................................6

Service Notice or Precautions .....................................7

Wiring Diagrams and Trouble Diagnoses....................8

PREPARATION...............................................................9

Special Service Tools ..................................................9

CVT FLUID.....................................................................10

Checking CVT Fluid...................................................10

Changing CVT Fluid .................................................. 11

OVERALL SYSTEM......................................................12

CVT Electrical Parts Location....................................12

Circuit Diagram ..........................................................13

Cross-sectional View - RE0F06A ..............................14

Control System ..........................................................15

EURO-OBD

ON BOARD DIAGNOSTIC SYSTEM

DESCRIPTION...............................................................18

Introduction ................................................................18

EURO-OBD Function for CVT System......................18

EURO-OBD Diagnostic Trouble Code (DTC)............18

Malfunction Indicator (MI) ..........................................21

CONSULT-II ...............................................................21

EXCEPT FOR EURO-OBD

ON BOARD DIAGNOSTIC SYSTEM

DESCRIPTION...............................................................31CONSULT-II ...............................................................31

Diagnostic Procedure Without CONSULT-II ..............35

EURO-OBD

TROUBLE DIAGNOSIS - INTRODUCTION..................41

Introduction ................................................................41

Work Flow ..................................................................44

EXCEPT FOR EURO-OBD

TROUBLE DIAGNOSIS - INTRODUCTION..................46

Introduction ................................................................46

Work Flow ..................................................................49

TROUBLE DIAGNOSIS - BASIC INSPECTION...........51

CVT Fluid Check .......................................................51

Stall Test ....................................................................51

Line Pressure Test .....................................................52

Road Test...................................................................53

TROUBLE DIAGNOSIS - GENERAL

DESCRIPTION...............................................................58

TCM Terminals and Reference Value........................58

TROUBLE DIAGNOSIS FOR POWER SUPPLY..........62

Wiring Diagram - AT - MAIN ......................................62

TCM Terminals and Reference Value........................64

Diagnostic Procedure ................................................65

EURO-OBD

DTC P0705 PARK/NEUTRAL POSITION (PNP)

SWITCH.........................................................................66

Description .................................................................66

Wiring Diagram - AT - PNP/SW.................................68

Diagnostic Procedure ................................................70

Component Inspection ...............................................72

DTC P0710 CVT FLUID TEMPERATURE SENSOR

CIRCUIT.........................................................................73

Description .................................................................73

Page 3 of 3051

Wiring Diagram - AT - FTS ........................................75

Diagnostic Procedure ................................................77

DTC P0715 PRIMARY SPEED SENSOR.....................79

Description .................................................................79

Wiring Diagram - AT - PSSA/T ..................................80

Diagnostic Procedure ................................................82

Component Inspection ...............................................83

DTC P0720 VEHICLE SPEED SENSOR

(SECONDARY SPEED SENSOR)................................84

Description .................................................................84

Wiring Diagram - AT - VSSA/T ..................................86

Diagnostic Procedure ................................................88

Component Inspection ...............................................89

DTC P0725 ENGINE SPEED SIGNAL.........................90

Description .................................................................90

Wiring Diagram - AT - ENGSS ..................................91

Diagnostic Procedure ................................................92

DTC P0740 TORQUE CONVERTER CLUTCH

SOLENOID VALVE........................................................94

Description .................................................................94

Wiring Diagram - AT - TCV........................................96

Diagnostic Procedure ................................................97

Component Inspection ...............................................98

DTC P0745 LINE PRESSURE SOLENOID VALVE.....99

Description .................................................................99

Wiring Diagram - AT - LPSV....................................101

Diagnostic Procedure ..............................................102

Component Inspection .............................................103

DTC P1705 THROTTLE POSITION SENSOR...........104

Description ...............................................................104

Wiring Diagram - AT - TPS ......................................106

Diagnostic Procedure ..............................................108

Component Inspection ............................................. 111

DTC P1777 STEP MOTOR - CIRCUIT....................... 112

Description ............................................................... 112

Wiring Diagram - AT - STM ..................................... 114

Diagnostic Procedure .............................................. 115

Component Inspection ............................................. 116

DTC P1778 STEP MOTOR - FUNCTION................... 117

Description ............................................................... 117

Diagnostic Procedure .............................................. 118

DTC P1791 LINE PRESSURE SENSOR.................... 119

Description ............................................................... 119

Wiring Diagram - AT - LPS ......................................121

Diagnostic Procedure ..............................................123

Component Inspection .............................................124

CVT SAFE FUNCTION................................................125

Description ...............................................................125

Diagnostic Procedure ..............................................125EXCEPT FOR EURO-OBD

VEHICLE SPEED SENSOR CVT (SECONDARY

SPEED SENSOR)........................................................126

Description ...............................................................126

Wiring Diagram - AT - VSSA/T ................................128

Diagnostic Procedure ..............................................130

PRIMARY SPEED SENSOR.......................................132

Description ...............................................................132

Wiring Diagram - AT - VSSMTR ..............................134

Diagnostic Procedure ..............................................136

THROTTLE POSITION SENSOR................................137

Description ...............................................................137

Wiring Diagram - AT - TPS ......................................139

Diagnostic Procedure ..............................................141

Component Inspection .............................................145

STEPPING MOTOR - CIRCUIT...................................146

Description ...............................................................146

Wiring Diagram - AT - STM .....................................147

Diagnostic Procedure ..............................................148

Component Inspection .............................................149

STEP MOTOR - FUNCTION.......................................150

Description ...............................................................150

Diagnostic Procedure ..............................................150

LINE PRESSURE SENSOR........................................151

Description ...............................................................151

Wiring Diagram - AT - LPS ......................................153

Diagnostic Procedure ..............................................155

Component Inspection .............................................156

LINE PRESSURE SOLENOID VALVE.......................157

Description ...............................................................157

Wiring Diagram - AT - LPSV....................................159

Diagnostic Procedure ..............................................160

Component Inspection .............................................163

TORQUE CONVERTER CLUTCH SOLENOID

VALVE..........................................................................164

Description ...............................................................164

Wiring Diagram - AT - TCV......................................166

Diagnostic Procedure ..............................................167

Component Inspection .............................................169

CVT FLUID TEMPERATURE SENSOR CIRCUIT......170

Description ...............................................................170

Wiring Diagram - AT - FTS ......................................172

Diagnostic Procedure ..............................................174

ENGINE SPEED SIGNAL............................................176

Description ...............................................................176

Wiring Diagram - AT - ENGSS ................................177

Diagnostic Procedure ..............................................178

CONTROL UNIT (RAM), CONTROL UNIT (ROM).....180

Description ...............................................................180

Diagnostic Procedure ..............................................181

CONTENTS(Cont'd)

AT-2

Page 4 of 3051

CONTROL UNIT (EEPROM).......................................182

Description ...............................................................182

Diagnostic Procedure ..............................................183

TROUBLE DIAGNOSES FOR NON-DETECTABLE

ITEMS...........................................................................184

PNP Switch, Stop Lamp Switch and Throttle

Position Switch ........................................................184

Diagnostic Procedure ..............................................184

Wiring Diagram - AT - NONDTC .............................188

TROUBLE DIAGNOSES FOR SYMPTOMS...............192

SPORT Indicator Lamp Does Not Come On ..........192

A/T SHIFT LOCK SYSTEM.........................................195

Description ...............................................................195

Shift Lock System Electrical Parts Location............195

Wiring Diagram - SHIFT -........................................196

Diagnostic Procedure ..............................................198

KEY INTERLOCK CABLE..........................................202

Components.............................................................202

Removal ...................................................................202

Installation ................................................................203ON-VEHICLE SERVICE..............................................204

Control Cable Adjustment ........................................204

Park/Neutral Position (PNP) Switch Adjustment .....204

Differential Side Oil Seal Replacement ...................204

REMOVAL AND INSTALLATION...............................206

Removal ...................................................................206

Inspection.................................................................206

Installation ................................................................207

Air Breather Hose ....................................................208

CVT Fluid Cooler .....................................................208

Components.............................................................209

SERVICE DATA AND SPECIFICATIONS (SDS).......210

General Specifications .............................................210

Stall Revolution ........................................................210

Line Pressure...........................................................210

Removal and Installation .........................................210

A/T Fluid Temperature Sensor.................................210

Solenoid Valves .......................................................210

Dropping Resistor ....................................................210

CONTENTS(Cont'd)

AT-3

Page 7 of 3051

Precautions for Supplemental Restraint System

(SRS) ªAIR BAGº and ªSEAT BELT

PRE-TENSIONERº

NLAT0002The Supplemental Restraint System ªAIR BAGº and ªSEAT BELT PRE-TENSIONERº, used along with a seat

belt, help to reduce the risk or severity of injury to the driver and front passenger in a frontal collision. The

Supplemental Restraint System consists of air bag modules (located in the center of the steering wheel and

on the instrument panel on the passenger side), seat belt pre-tensioners, a diagnosis sensor unit, warning

lamp, wiring harness and spiral cable.

In addition to the supplemental air bag modules for a frontal collision, the supplemental side air bag used along

with the seat belt helps to reduce the risk or severity of injury to the driver and front passenger in a side col-

lision. The supplemental side air bag consists of air bag modules (located in the outer side of front seats),

satellite sensor, diagnosis sensor unit (one of components of supplemental air bags for a frontal collision),

wiring harness, warning lamp (one of components of supplemental air bags for a frontal collision). Information

necessary to service the system safely is included in theRS sectionof this Service Manual.

WARNING:

+To avoid rendering the SRS inoperative, which could increase the risk of personal injury or death

in the event of a collision which would result in air bag inflation, all maintenance must be performed

by an authorized NISSAN dealer.

+Improper maintenance, including incorrect removal and installation of the SRS, can lead to per-

sonal injury caused by unintentional activation of the system.

+Do not use electrical test equipment on any circuit related to the SRS unless instructed to in this

Service Manual. SRS wiring harnesses can be identified with yellow harness connector (and with

yellow harness protector or yellow insulation tape before the harness connectors).

Precautions for On Board Diagnostic (EURO-

OBD) System of CVT and Engine

NLAT0198The ECM has an on board diagnostic system. It will light up the malfunction indicator lamp (MI) to warn the

driver of a malfunction causing emission deterioration.

CAUTION:

+Be sure to turn the ignition switch ªOFFº and disconnect the negative battery terminal before any

repair or inspection work. The open/short circuit of related switches, sensors, solenoid valves, etc.

will cause the MI to light up.

+Be sure to connect and lock the connectors securely after work. A loose (unlocked) connector will

cause the MI to light up due to an open circuit. (Be sure the connector is free from water, grease,

dirt, bent terminals, etc.)

+Be sure to route and secure the harnesses properly after work. Interference of the harness with a

bracket, etc. may cause the MI to light up due to a short circuit.

+Be sure to connect rubber tubes properly after work. A misconnected or disconnected rubber tube

may cause the MI to light up due to a malfunction of the EGR system or fuel injection system, etc.

+Be sure to erase the unnecessary malfunction information (repairs completed) from the TCM and

ECM before returning the vehicle to the customer.

SEF289H

PrecautionsNLAT0003+Before connecting or disconnecting the TCM harness

connector, turn ignition switch OFF and disconnect nega-

tive battery terminal. Failure to do so may damage the

TCM. Because battery voltage is applied to TCM even if

ignition switch is turned off.

PRECAUTIONS

Precautions for Supplemental Restraint System (SRS) ªAIR BAGº and ªSEAT BELT PRE-TENSIONERº

AT-6

Page 9 of 3051

The SELF-DIAGNOSIS results will be as follows:

The first SELF-DIAGNOSIS will indicate damage to the vehicle speed sensor or the revolution sensor.

During the next SELF-DIAGNOSIS, performed after checking the sensor, no damages will be indicated.

EURO-OBD SELF-DIAGNOSISNLAT0004S04+CVT self-diagnosis is performed by the TCM in combination with the ECM. The results can be read through

the blinking pattern of the SPORT indicator lamp. Refer to the table on AT-22 for the indicator used to dis-

play each self-diagnostic result.

+The self-diagnostic results indicated by the MI are automatically stored in both the ECM and TCM memo-

ries.

Always perform the procedure ªHOW TO ERASE DTCº on AT-19 to complete the repair and avoid

unnecessary blinking of the MI.

For details of EURO-OBD, refer to EC section (ªON BOARD DIAGNOSTIC SYSTEM DESCRIPTIONº).

+Certain systems and components, especially those related to EURO-OBD, may use a new style

slide-locking type harness connector.

For description and how to disconnect, refer to EL section, ªDescriptionº, ªHARNESS CONNEC-

TORº.

Wiring Diagrams and Trouble DiagnosesNLAT0005When you read wiring diagrams, refer to the following:

+ªHOW TO READ WIRING DIAGRAMSº in GI section

+ªPOWER SUPPLY ROUTINGº for power distribution circuit in EL section

When you perform trouble diagnoses, refer to the following:

+ªHOW TO FOLLOW TEST GROUPS IN TROUBLE DIAGNOSESº in GI section

+ªHOW TO PERFORM EFFICIENT DIAGNOSIS FOR AN ELECTRICAL INCIDENTº in GI section

PRECAUTIONS

Service Notice or Precautions (Cont'd)

AT-8

Page 42 of 3051

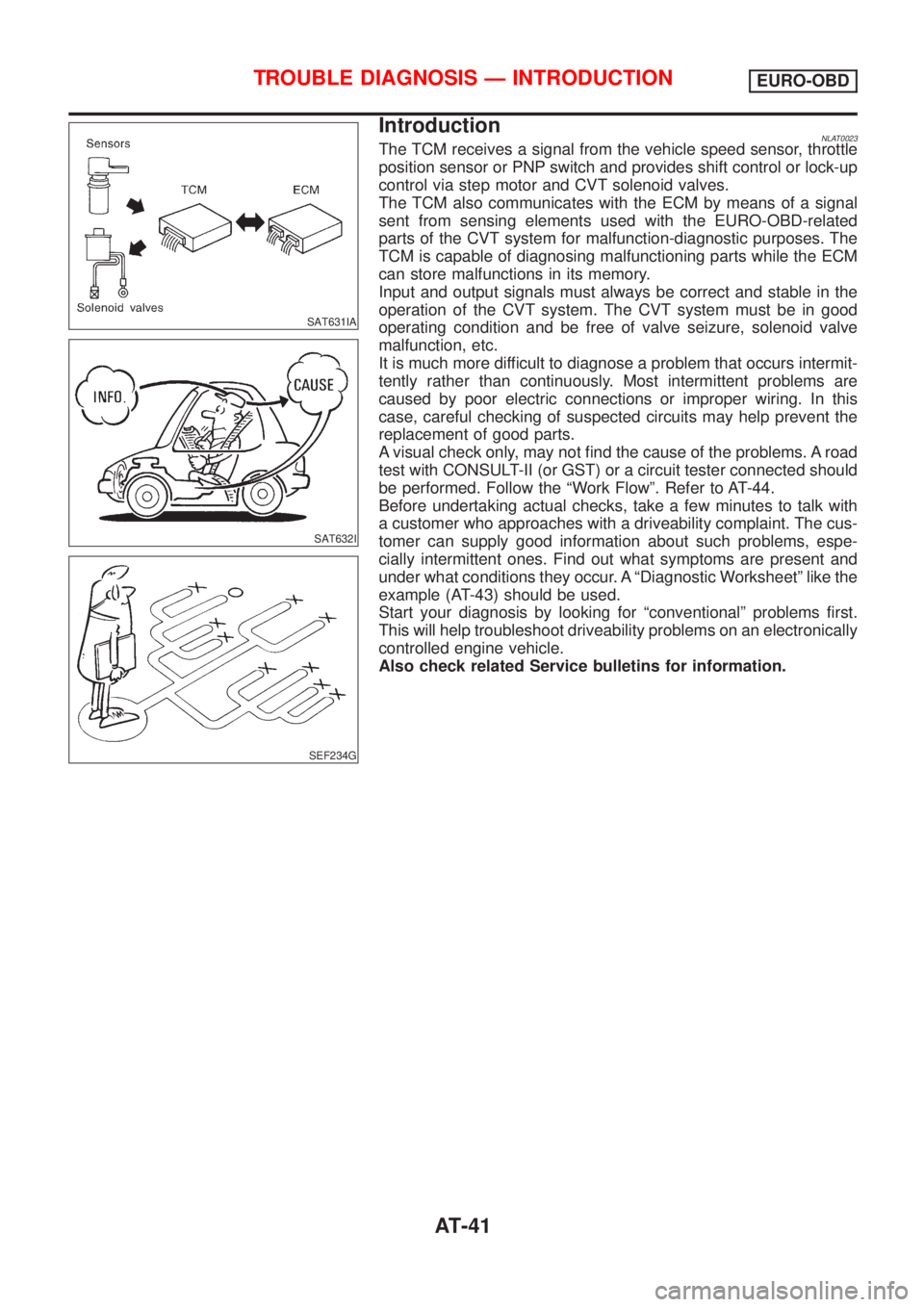

SAT631IA

SAT632I

SEF234G

IntroductionNLAT0023The TCM receives a signal from the vehicle speed sensor, throttle

position sensor or PNP switch and provides shift control or lock-up

control via step motor and CVT solenoid valves.

The TCM also communicates with the ECM by means of a signal

sent from sensing elements used with the EURO-OBD-related

parts of the CVT system for malfunction-diagnostic purposes. The

TCM is capable of diagnosing malfunctioning parts while the ECM

can store malfunctions in its memory.

Input and output signals must always be correct and stable in the

operation of the CVT system. The CVT system must be in good

operating condition and be free of valve seizure, solenoid valve

malfunction, etc.

It is much more difficult to diagnose a problem that occurs intermit-

tently rather than continuously. Most intermittent problems are

caused by poor electric connections or improper wiring. In this

case, careful checking of suspected circuits may help prevent the

replacement of good parts.

A visual check only, may not find the cause of the problems. A road

test with CONSULT-II (or GST) or a circuit tester connected should

be performed. Follow the ªWork Flowº. Refer to AT-44.

Before undertaking actual checks, take a few minutes to talk with

a customer who approaches with a driveability complaint. The cus-

tomer can supply good information about such problems, espe-

cially intermittent ones. Find out what symptoms are present and

under what conditions they occur. A ªDiagnostic Worksheetº like the

example (AT-43) should be used.

Start your diagnosis by looking for ªconventionalº problems first.

This will help troubleshoot driveability problems on an electronically

controlled engine vehicle.

Also check related Service bulletins for information.

TROUBLE DIAGNOSIS Ð INTRODUCTIONEURO-OBD

AT-41

Page 47 of 3051

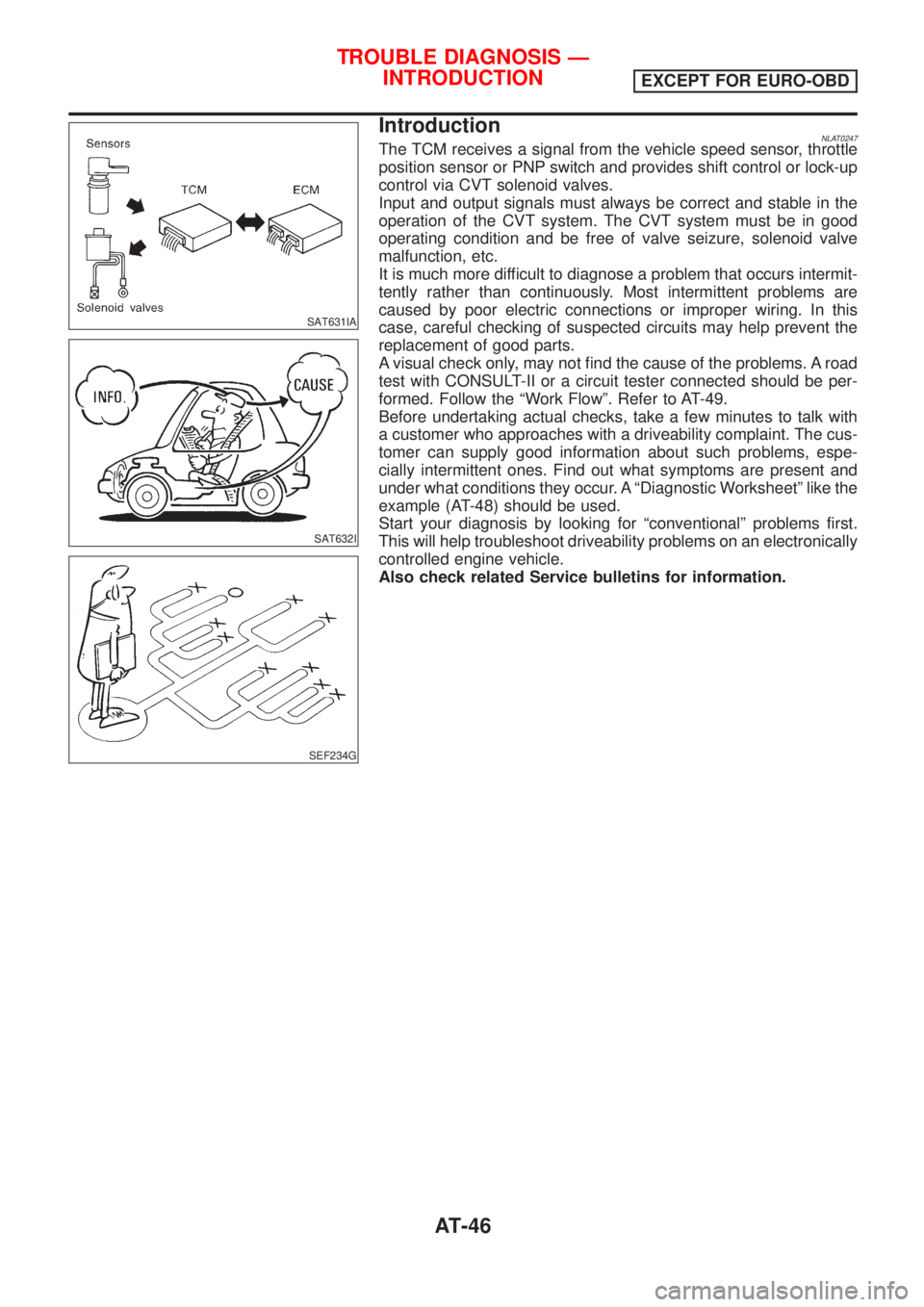

SAT631IA

SAT632I

SEF234G

IntroductionNLAT0247The TCM receives a signal from the vehicle speed sensor, throttle

position sensor or PNP switch and provides shift control or lock-up

control via CVT solenoid valves.

Input and output signals must always be correct and stable in the

operation of the CVT system. The CVT system must be in good

operating condition and be free of valve seizure, solenoid valve

malfunction, etc.

It is much more difficult to diagnose a problem that occurs intermit-

tently rather than continuously. Most intermittent problems are

caused by poor electric connections or improper wiring. In this

case, careful checking of suspected circuits may help prevent the

replacement of good parts.

A visual check only, may not find the cause of the problems. A road

test with CONSULT-II or a circuit tester connected should be per-

formed. Follow the ªWork Flowº. Refer to AT-49.

Before undertaking actual checks, take a few minutes to talk with

a customer who approaches with a driveability complaint. The cus-

tomer can supply good information about such problems, espe-

cially intermittent ones. Find out what symptoms are present and

under what conditions they occur. A ªDiagnostic Worksheetº like the

example (AT-48) should be used.

Start your diagnosis by looking for ªconventionalº problems first.

This will help troubleshoot driveability problems on an electronically

controlled engine vehicle.

Also check related Service bulletins for information.

TROUBLE DIAGNOSIS Ð

INTRODUCTION

EXCEPT FOR EURO-OBD

AT-46

Page 63 of 3051

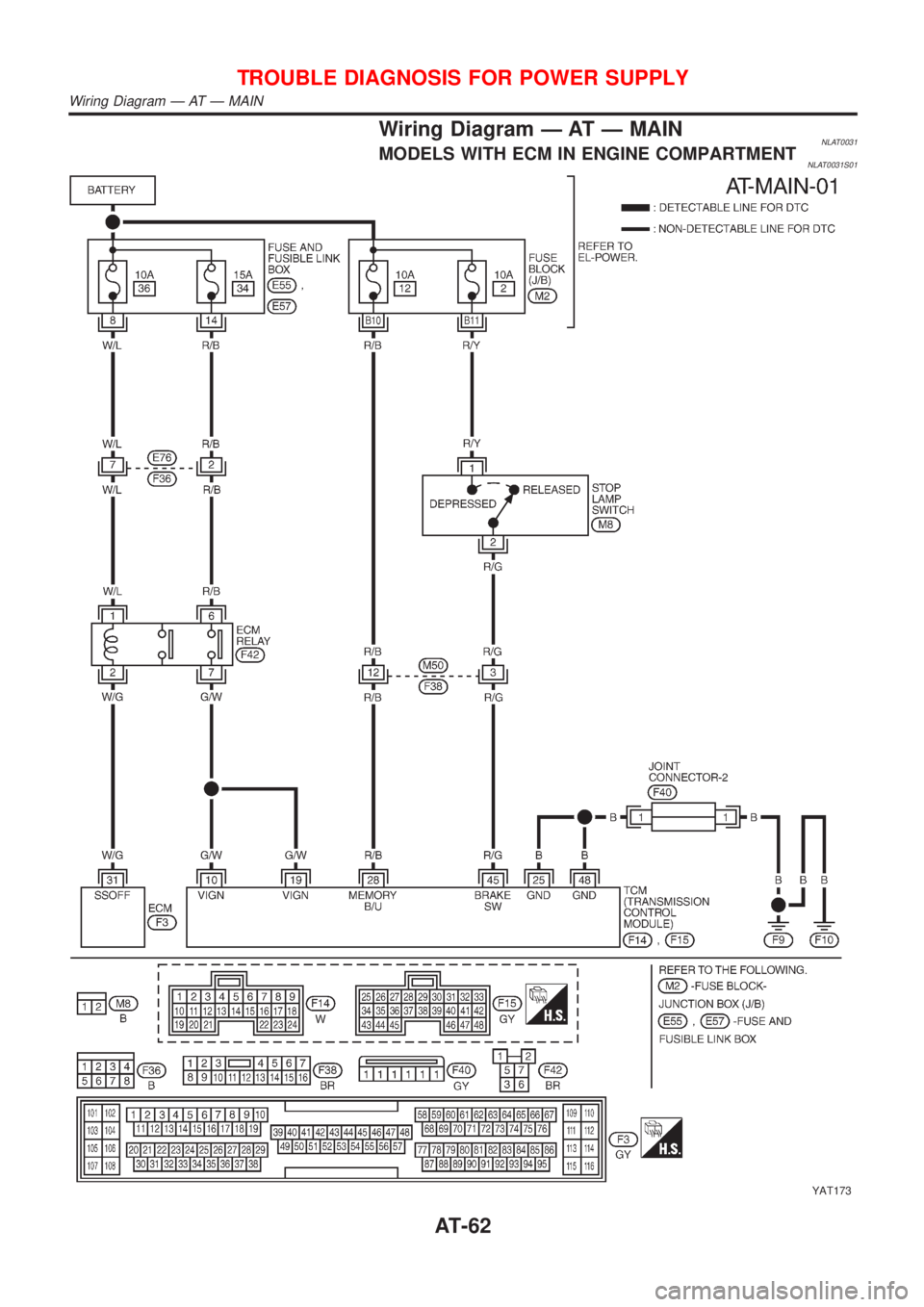

Wiring Diagram Ð AT Ð MAINNLAT0031MODELS WITH ECM IN ENGINE COMPARTMENTNLAT0031S01

YAT173

TROUBLE DIAGNOSIS FOR POWER SUPPLY

Wiring Diagram Ð AT Ð MAIN

AT-62

Page 64 of 3051

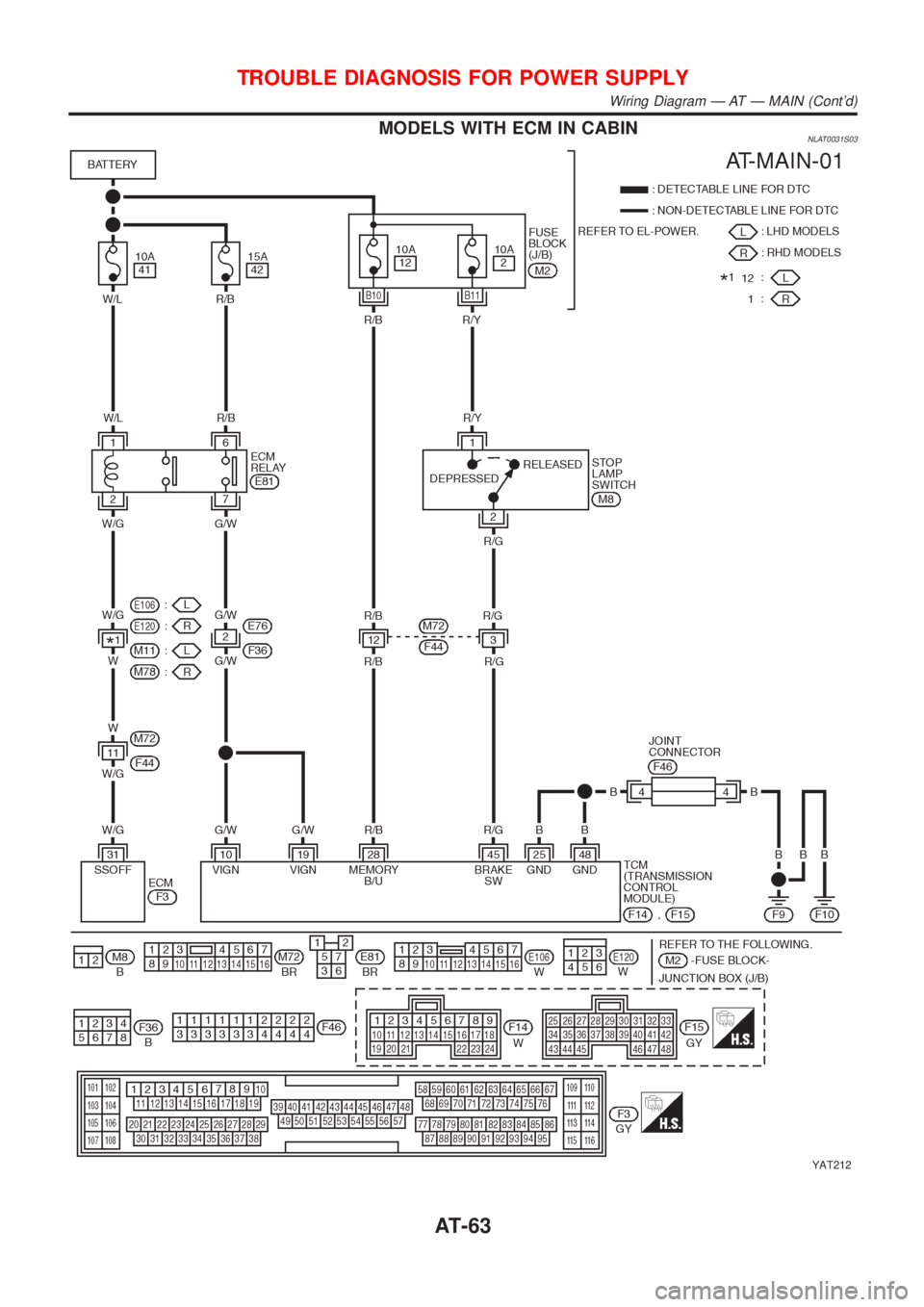

MODELS WITH ECM IN CABINNLAT0031S03

YAT212

TROUBLE DIAGNOSIS FOR POWER SUPPLY

Wiring Diagram Ð AT Ð MAIN (Cont'd)

AT-63

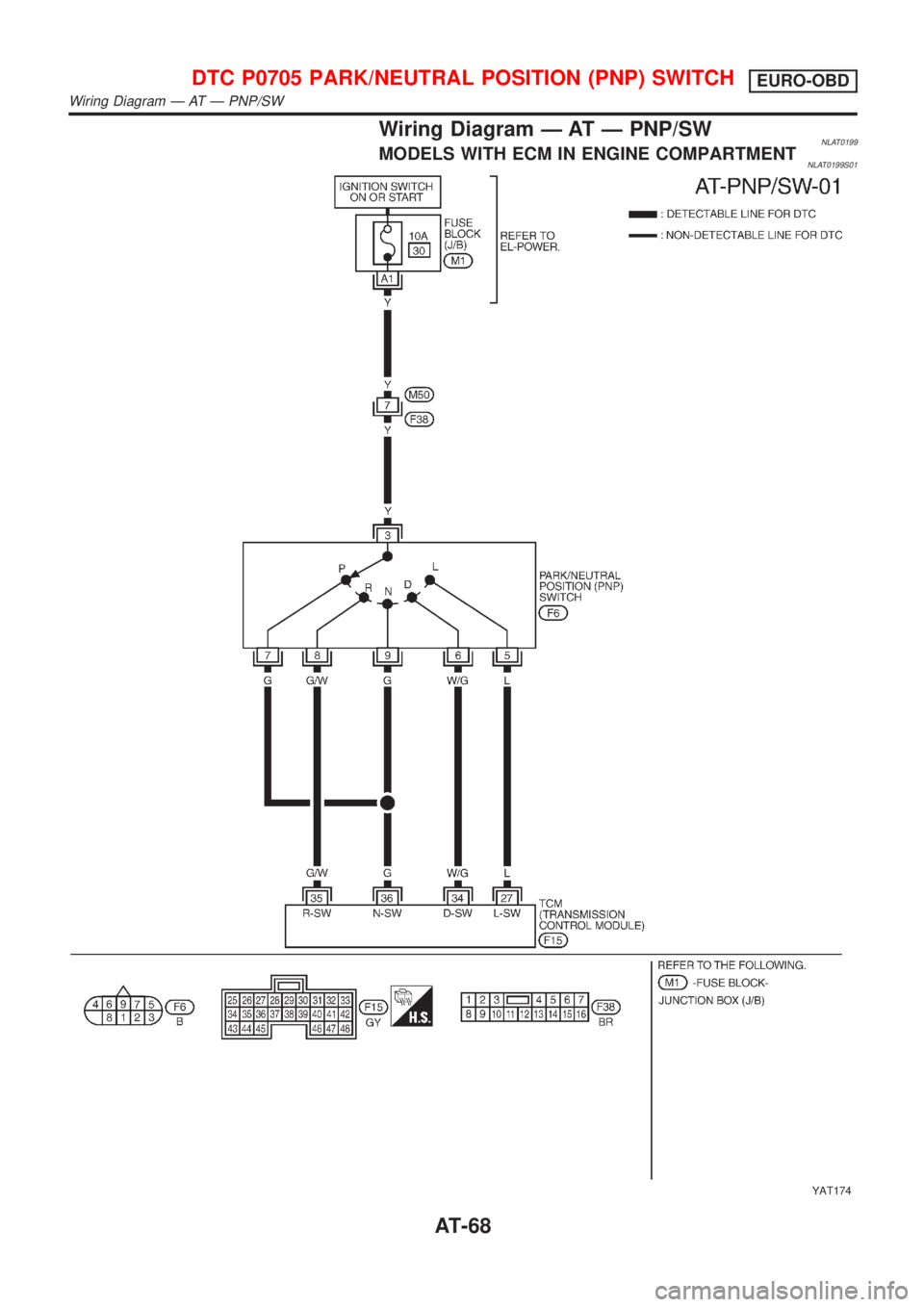

Page 69 of 3051

Wiring Diagram Ð AT Ð PNP/SWNLAT0199MODELS WITH ECM IN ENGINE COMPARTMENTNLAT0199S01

YAT174

DTC P0705 PARK/NEUTRAL POSITION (PNP) SWITCHEURO-OBD

Wiring Diagram Ð AT Ð PNP/SW

AT-68