NISSAN ALTIMA 1997 U13 / 1.G Owners Manual

Manufacturer: NISSAN, Model Year: 1997, Model line: ALTIMA, Model: NISSAN ALTIMA 1997 U13 / 1.GPages: 203, PDF Size: 1.64 MB

Page 151 of 203

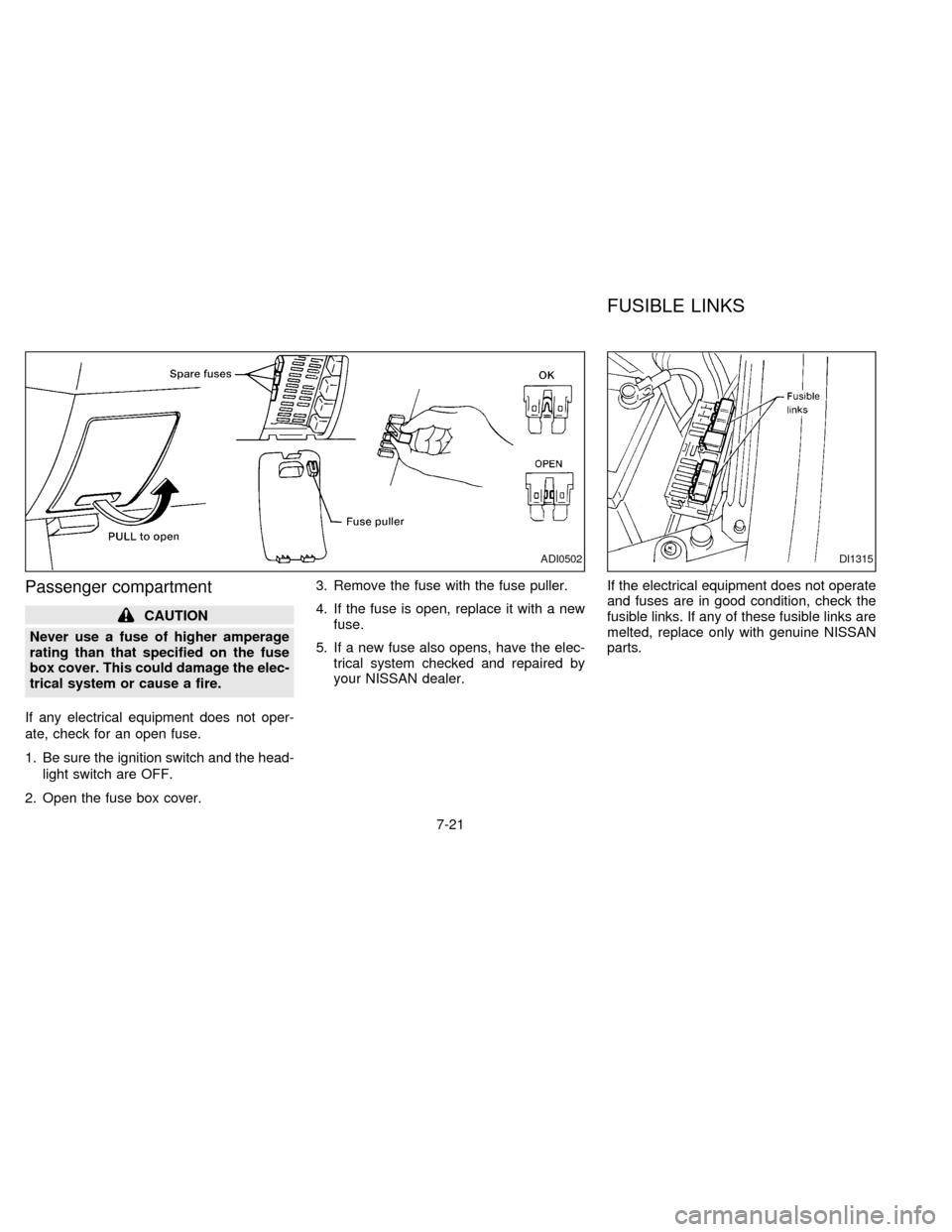

Passenger compartment

CAUTION

Never use a fuse of higher amperage

rating than that specified on the fuse

box cover. This could damage the elec-

trical system or cause a fire.

If any electrical equipment does not oper-

ate, check for an open fuse.

1. Be sure the ignition switch and the head-

light switch are OFF.

2. Open the fuse box cover.3. Remove the fuse with the fuse puller.

4. If the fuse is open, replace it with a new

fuse.

5. If a new fuse also opens, have the elec-

trical system checked and repaired by

your NISSAN dealer.If the electrical equipment does not operate

and fuses are in good condition, check the

fusible links. If any of these fusible links are

melted, replace only with genuine NISSAN

parts.

ADI0502DI1315

FUSIBLE LINKS

7-21

ZX

Page 152 of 203

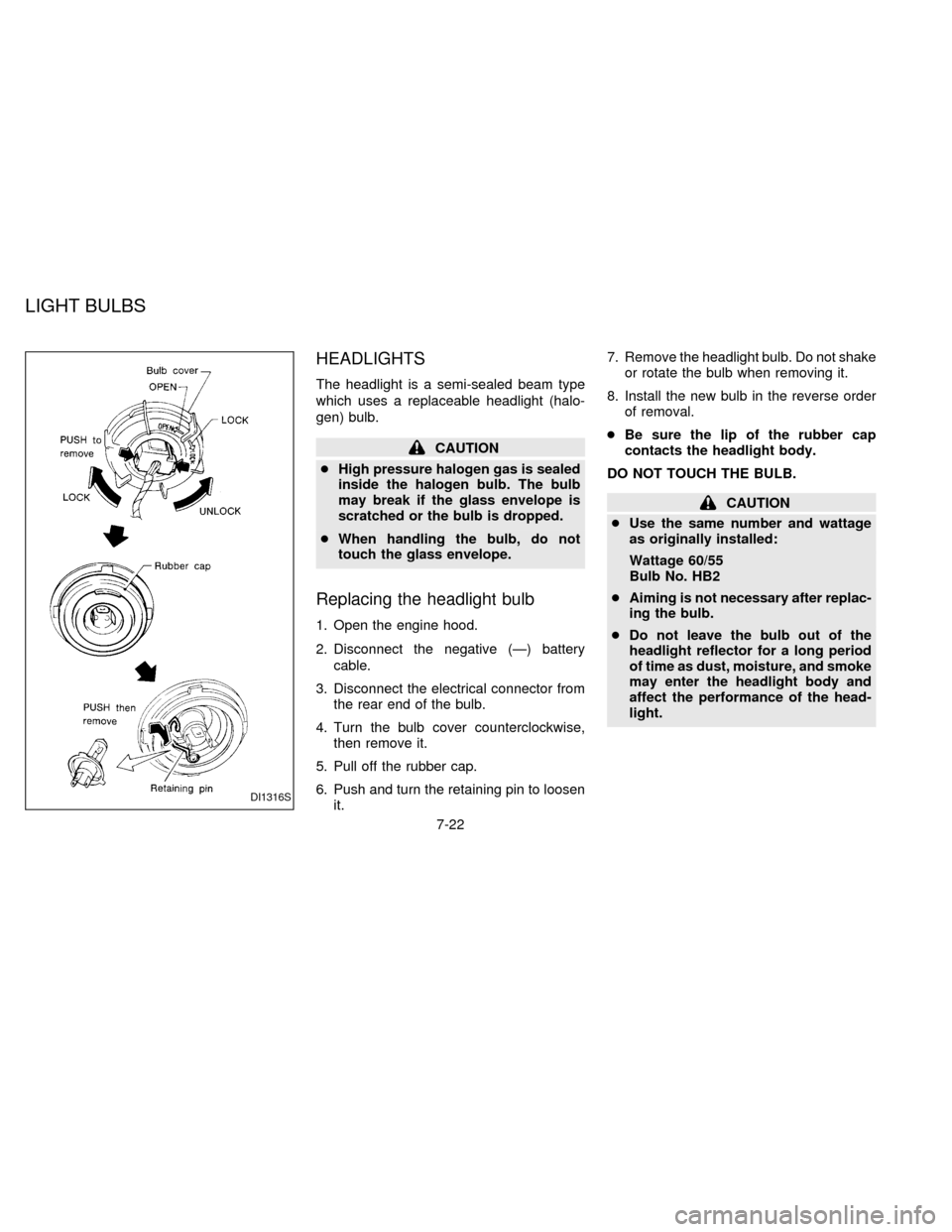

HEADLIGHTS

The headlight is a semi-sealed beam type

which uses a replaceable headlight (halo-

gen) bulb.

CAUTION

cHigh pressure halogen gas is sealed

inside the halogen bulb. The bulb

may break if the glass envelope is

scratched or the bulb is dropped.

cWhen handling the bulb, do not

touch the glass envelope.

Replacing the headlight bulb

1. Open the engine hood.

2. Disconnect the negative (Ð) battery

cable.

3. Disconnect the electrical connector from

the rear end of the bulb.

4. Turn the bulb cover counterclockwise,

then remove it.

5. Pull off the rubber cap.

6. Push and turn the retaining pin to loosen

it.7. Remove the headlight bulb. Do not shake

or rotate the bulb when removing it.

8. Install the new bulb in the reverse order

of removal.

cBe sure the lip of the rubber cap

contacts the headlight body.

DO NOT TOUCH THE BULB.

CAUTION

cUse the same number and wattage

as originally installed:

Wattage 60/55

Bulb No. HB2

cAiming is not necessary after replac-

ing the bulb.

cDo not leave the bulb out of the

headlight reflector for a long period

of time as dust, moisture, and smoke

may enter the headlight body and

affect the performance of the head-

light.

DI1316S

LIGHT BULBS

7-22

ZX

Page 153 of 203

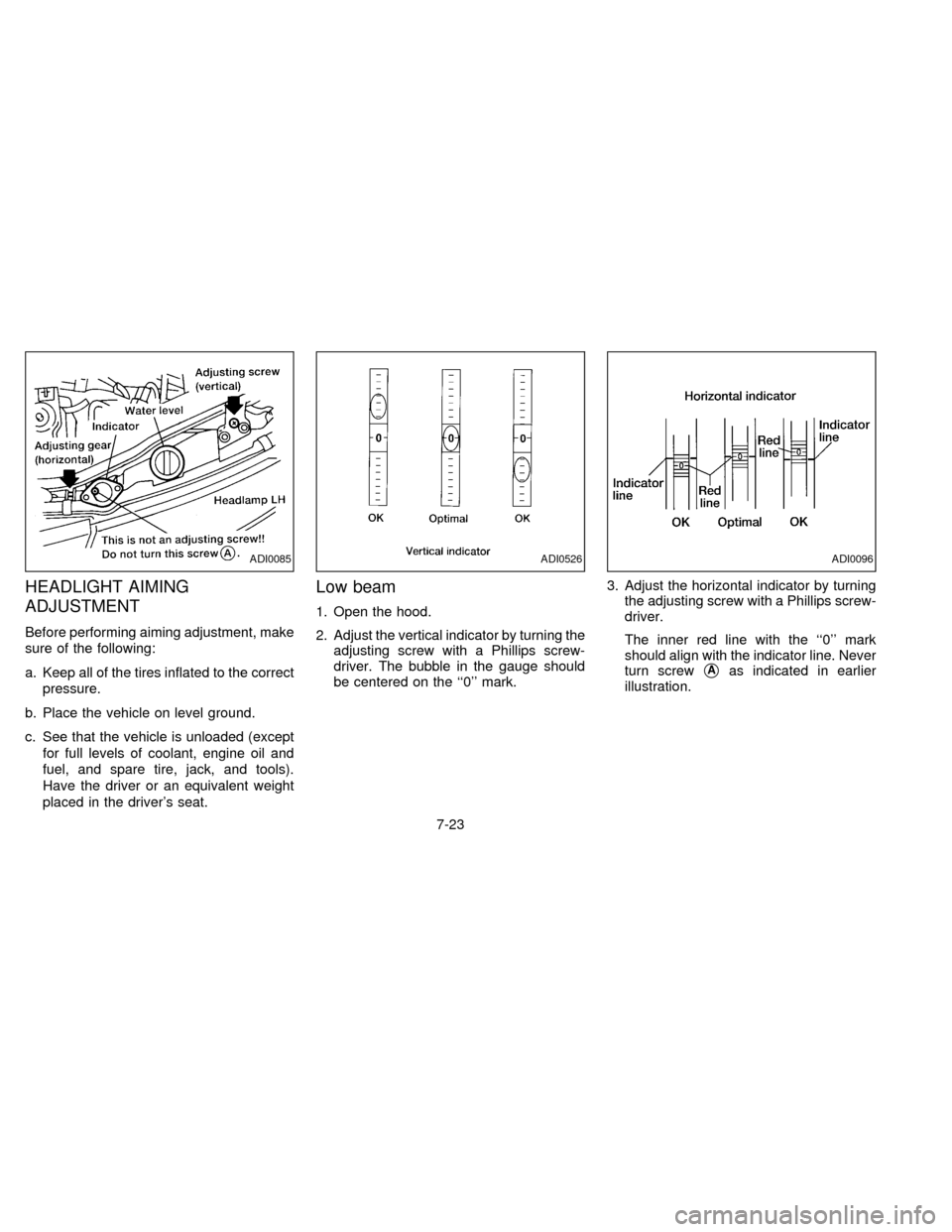

HEADLIGHT AIMING

ADJUSTMENT

Before performing aiming adjustment, make

sure of the following:

a. Keep all of the tires inflated to the correct

pressure.

b. Place the vehicle on level ground.

c. See that the vehicle is unloaded (except

for full levels of coolant, engine oil and

fuel, and spare tire, jack, and tools).

Have the driver or an equivalent weight

placed in the driver's seat.

Low beam

1. Open the hood.

2. Adjust the vertical indicator by turning the

adjusting screw with a Phillips screw-

driver. The bubble in the gauge should

be centered on the ``0'' mark.3. Adjust the horizontal indicator by turning

the adjusting screw with a Phillips screw-

driver.

The inner red line with the ``0'' mark

should align with the indicator line. Never

turn screw

sAas indicated in earlier

illustration.

ADI0085ADI0526ADI0096

7-23

ZX

Page 154 of 203

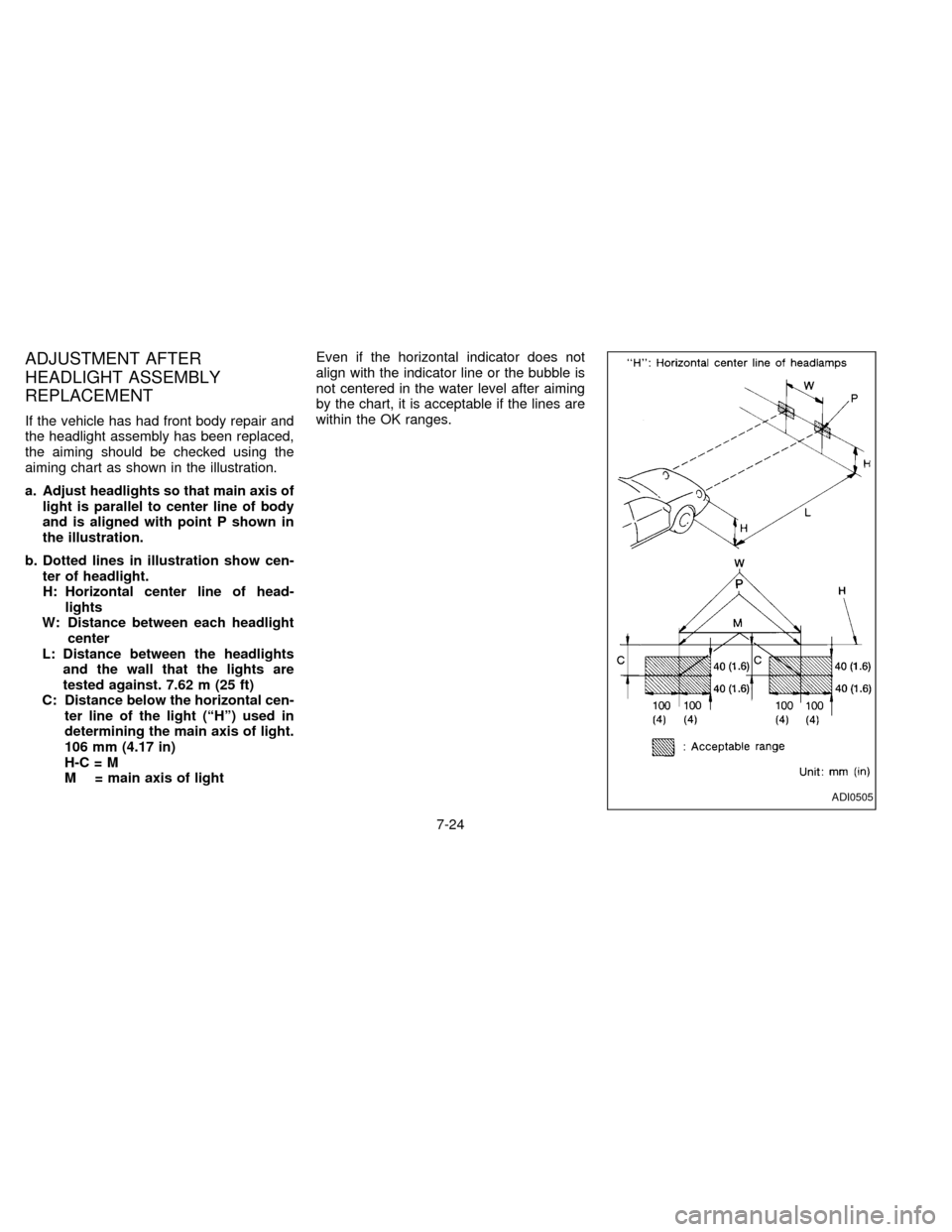

ADJUSTMENT AFTER

HEADLIGHT ASSEMBLY

REPLACEMENT

If the vehicle has had front body repair and

the headlight assembly has been replaced,

the aiming should be checked using the

aiming chart as shown in the illustration.

a. Adjust headlights so that main axis of

light is parallel to center line of body

and is aligned with point P shown in

the illustration.

b. Dotted lines in illustration show cen-

ter of headlight.

H: Horizontal center line of head-

lights

W: Distance between each headlight

center

L: Distance between the headlights

and the wall that the lights are

tested against. 7.62 m (25 ft)

C: Distance below the horizontal cen-

ter line of the light (ªHº) used in

determining the main axis of light.

106 mm (4.17 in)

H-C=M

M = main axis of lightEven if the horizontal indicator does not

align with the indicator line or the bubble is

not centered in the water level after aiming

by the chart, it is acceptable if the lines are

within the OK ranges.

ADI0505

7-24

ZX

Page 155 of 203

BULB REPLACEMENT

Item Wattage (W) Bulb No.

Headlight (Semi-sealed beam)

High/Low 60/55 HB2

Cornering light/Front parking light

127/5 1157

Front parking light25 168

Front turn signal light 27 1156NA

Front side marker light 3.8 194

Front fog light 55 H3

Rear combination light:

Turn signal 27 1156NA

Stop/Tail 27/8 1157

Back-up 27 1156

Rear side marker light 3.8 194

License plate light 5 168

High-mounted stop light 13 912

Interior light 8

Front personal light 10

Trunk light 3.4 158

Glove box light (if so equipped) 3.4 158

1: Models with cornering light

2: Models without cornering light

7-25

ZX

Page 156 of 203

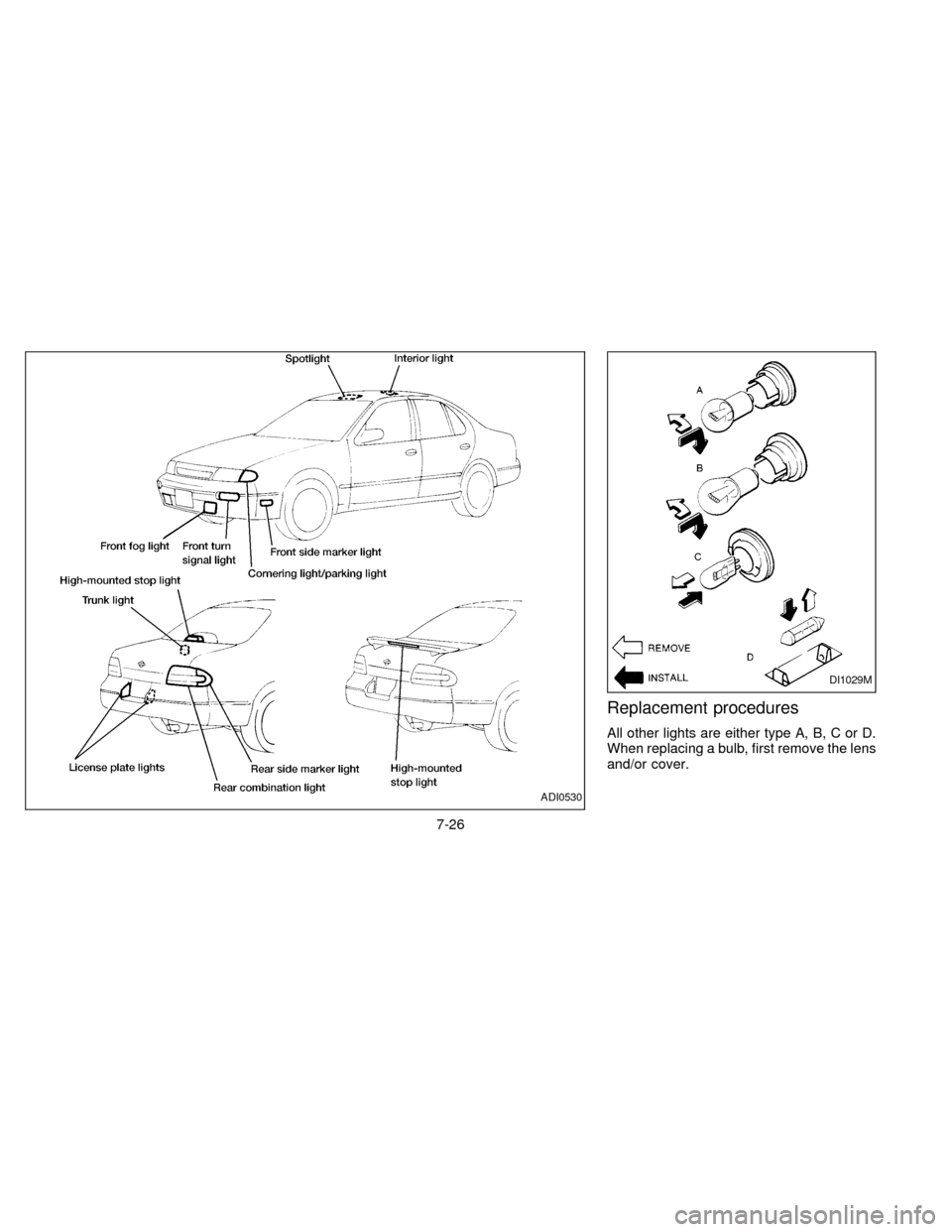

Replacement procedures

All other lights are either type A, B, C or D.

When replacing a bulb, first remove the lens

and/or cover.

ADI0530

DI1029M

7-26

ZX

Page 157 of 203

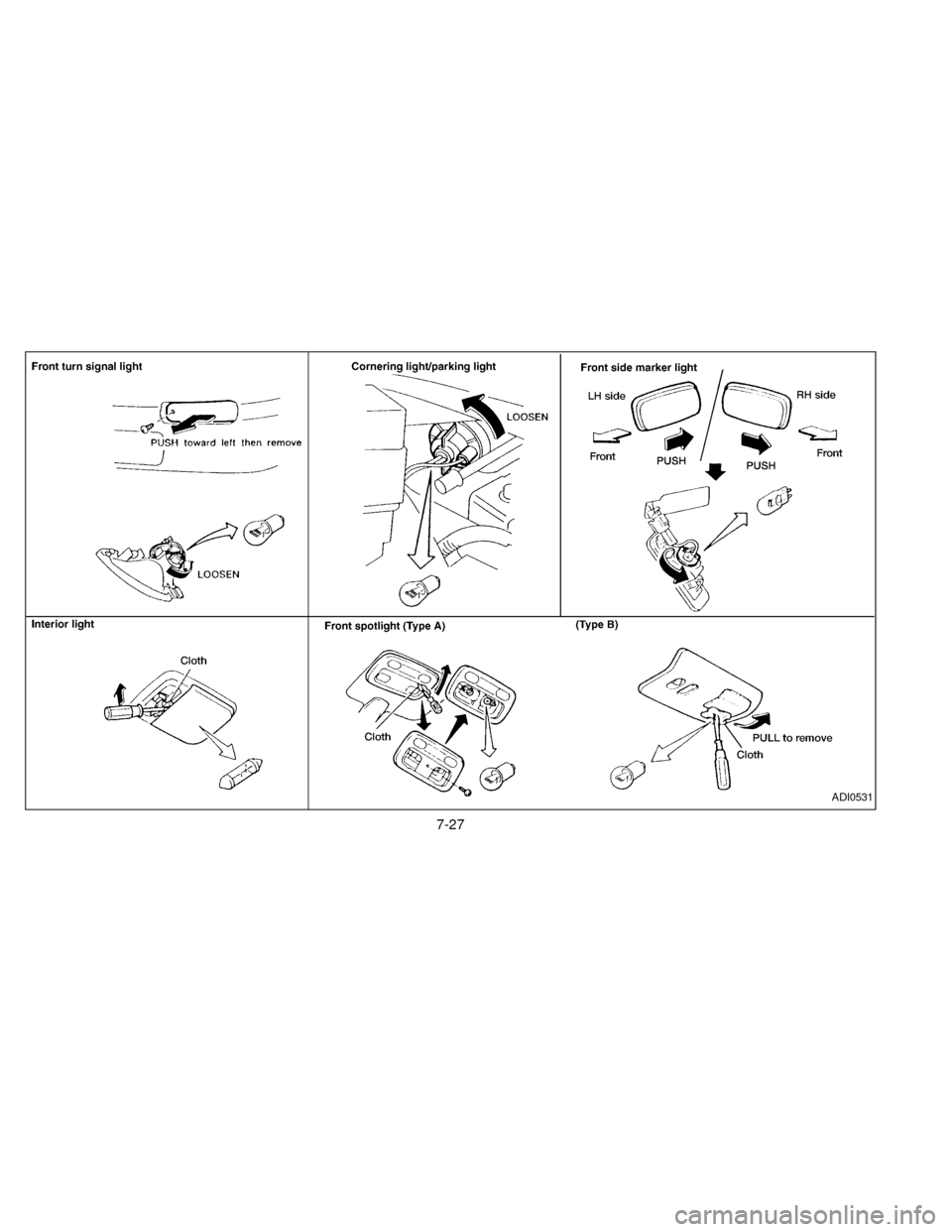

ADI0531

7-27

ZX

Page 158 of 203

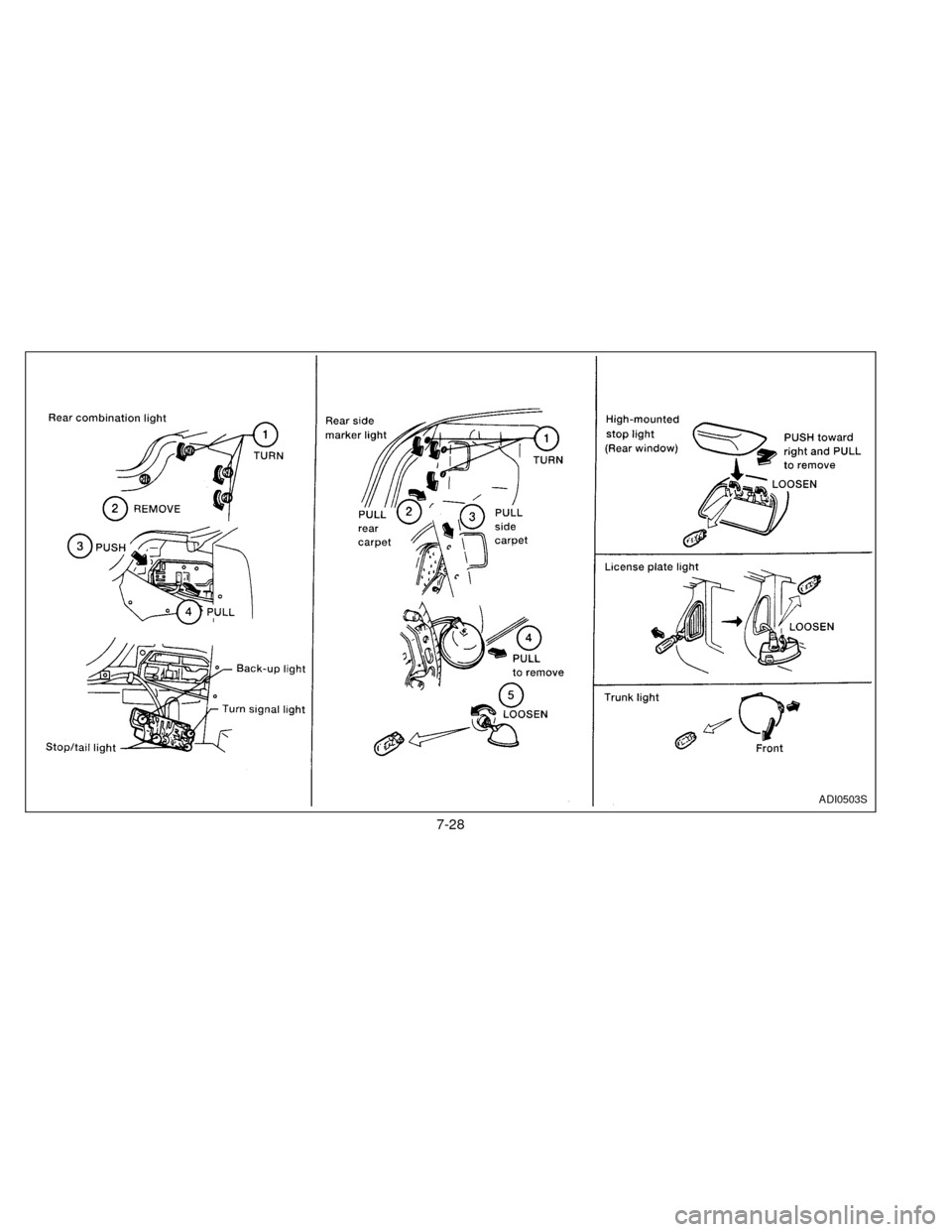

ADI0503S

7-28

ZX

Page 159 of 203

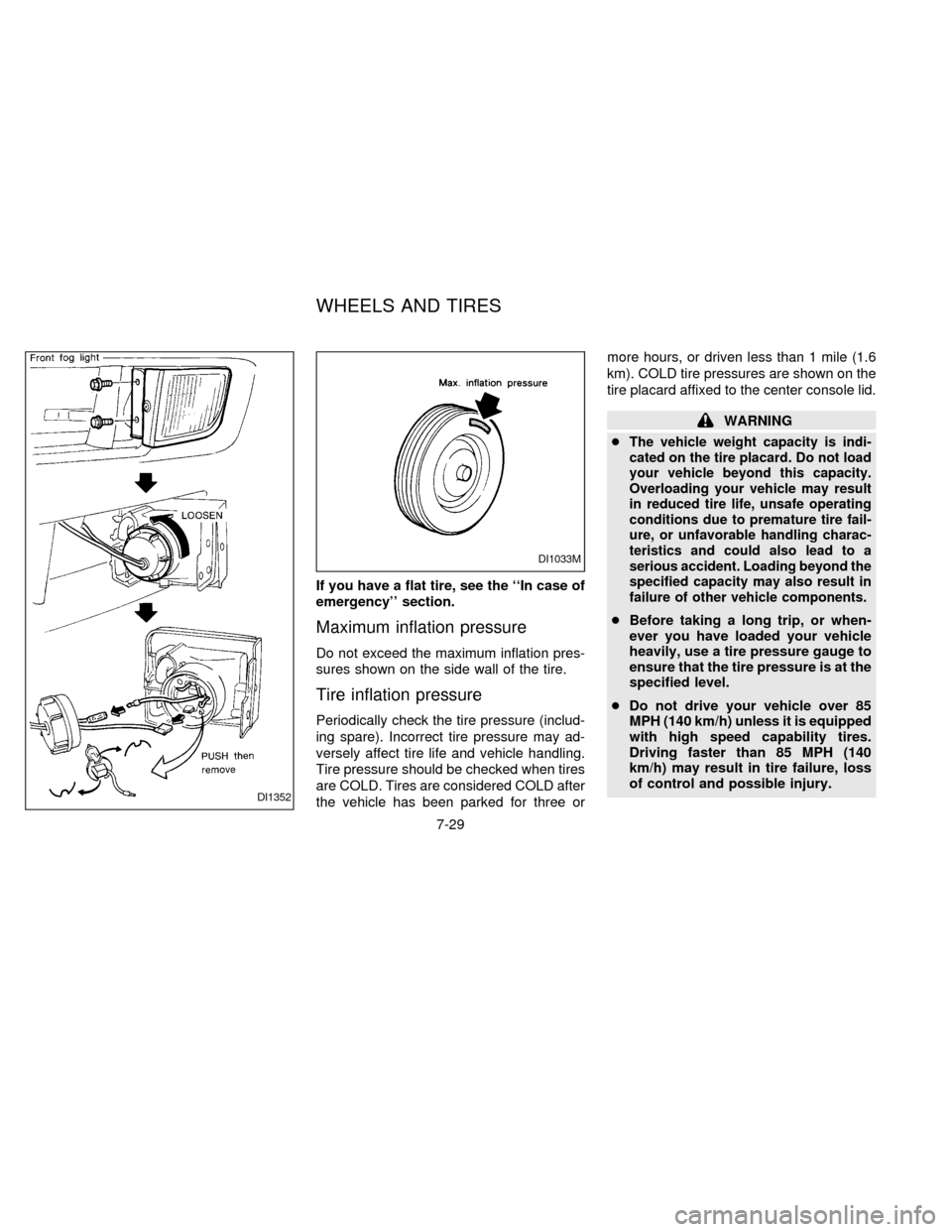

If you have a flat tire, see the ``In case of

emergency'' section.

Maximum inflation pressure

Do not exceed the maximum inflation pres-

sures shown on the side wall of the tire.

Tire inflation pressure

Periodically check the tire pressure (includ-

ing spare). Incorrect tire pressure may ad-

versely affect tire life and vehicle handling.

Tire pressure should be checked when tires

are COLD. Tires are considered COLD after

the vehicle has been parked for three ormore hours, or driven less than 1 mile (1.6

km). COLD tire pressures are shown on the

tire placard affixed to the center console lid.

WARNING

c

The vehicle weight capacity is indi-

cated on the tire placard. Do not load

your vehicle beyond this capacity.

Overloading your vehicle may result

in reduced tire life, unsafe operating

conditions due to premature tire fail-

ure, or unfavorable handling charac-

teristics and could also lead to a

serious accident. Loading beyond the

specified capacity may also result in

failure of other vehicle components.

cBefore taking a long trip, or when-

ever you have loaded your vehicle

heavily, use a tire pressure gauge to

ensure that the tire pressure is at the

specified level.

cDo not drive your vehicle over 85

MPH (140 km/h) unless it is equipped

with high speed capability tires.

Driving faster than 85 MPH (140

km/h) may result in tire failure, loss

of control and possible injury.

DI1352

DI1033M

WHEELS AND TIRES

7-29

ZX

Page 160 of 203

Types of tires

CAUTION

When changing or replacing tires, be

sure all four tires are of the same type

(i.e., Summer, All Season or Snow) and

construction. Your NISSAN dealer may

be able to help you with information

about tire type, size, speed rating and

availability. Replacement tires may

have a lower speed rating than the

factory equipped tires, and may not

match the potential maximum vehicle

speed. Never exceed the maximum

speed rating of the tire.

All Season tires

NISSAN specifies All Season tires on some

models to provide good performance for

use all year around, including snowy and icy

road conditions. All Season Tires are iden-

tified by ``ALL SEASON'' and/or ``M&S'' on

the tire sidewall. Snow tires have better

snow traction than All Season tires and may

be more appropriate in some areas.

Summer tires

NISSAN specifies summer tires on some

models to provide superior performance on

dry roads. Summer tire performance in

snow and ice is substantially reduced. Sum-

mer tires do not have the tire traction rating

``M&S'' on the tire sidewall.

If you plan to operate your vehicle in snowy

or icy conditions, NISSAN recommends the

use of ``SNOW'' or ``ALL SEASON'' tires on

all four wheels.

Snow tires

If snow tires are needed, it is necessary to

select tires equivalent in size and load rating

to the original equipment tires. If you do not,

it can adversely affect the safety and han-

dling of your vehicle.

Generally, snow tires have lower speed

ratings than factory equipped tires and may

not match the potential maximum vehicle

speed. Never exceed the maximum speed

rating of the tire.

For additional traction on icy roads, studded

tires may be used. However, some prov-

inces and states prohibit their use. Check

local, state and provincial laws before in-stalling studded tires. Skid and traction ca-

pabilities of studded snow tires on wet or dry

surfaces may be poorer than that of non-

studded snow tires.

Tire chains

Use of tire chains may be prohibited accord-

ing to location. Check the local laws before

installing tire chains. When installing tire

chains, make sure they are of proper size

for the tires on your vehicle and are installed

according to the chain manufacturer's sug-

gestions.Use only SAE class ``S'' chains.

Other types may damage your vehicle. Use

chain tensioners when recommended by

the tire chain manufacturer to ensure a tight

fit. Loose end links of the tire chain must be

secured or removed to prevent the possibil-

ity of whipping action damage to the fenders

or underbody. If possible, avoid fully loading

your vehicle when using tire chains. In ad-

dition, drive at a reduced speed. Otherwise,

your vehicle may be damaged and/or ve-

hicle handling and performance may be

adversely affected.

Never install tire chains on T-type spare

tires. Do not use tire chains on dry roads.

7-30

ZX