brake pads NISSAN ALTIMA 1997 U13 / 1.G Owners Manual

[x] Cancel search | Manufacturer: NISSAN, Model Year: 1997, Model line: ALTIMA, Model: NISSAN ALTIMA 1997 U13 / 1.GPages: 203, PDF Size: 1.64 MB

Page 14 of 203

2. If the brake fluid level is correct, have the

warning system checked by your NIS-

SAN dealer.

WARNING

cYour brake system may not be work-

ing properly if the warning light is

on. Driving could be dangerous. If

you judge it to be safe, drive care-

fully to the nearest service station

for repairs. Otherwise, have your ve-

hicle towed.

cPressing the brake pedal with the

engine stopped and/or low brake

fluid level may increase your stop-

ping distance and braking will re-

quire greater pedal effort as well as

greater pedal travel.

cIf the brake fluid level is below the

minimum mark on the brake fluid

reservoir, do not drive until the brake

system has been checked at a NIS-

SAN dealer.

Brake pad wear warning

The disc brake pads have audible wear

warnings. When a brake pad requires re-

placement, it makes a high pitched scrapingsound when the vehicle is in motion,

whether or not the brake pedal is de-

pressed. Have the brakes checked as soon

as possible if the warning sound is heard.

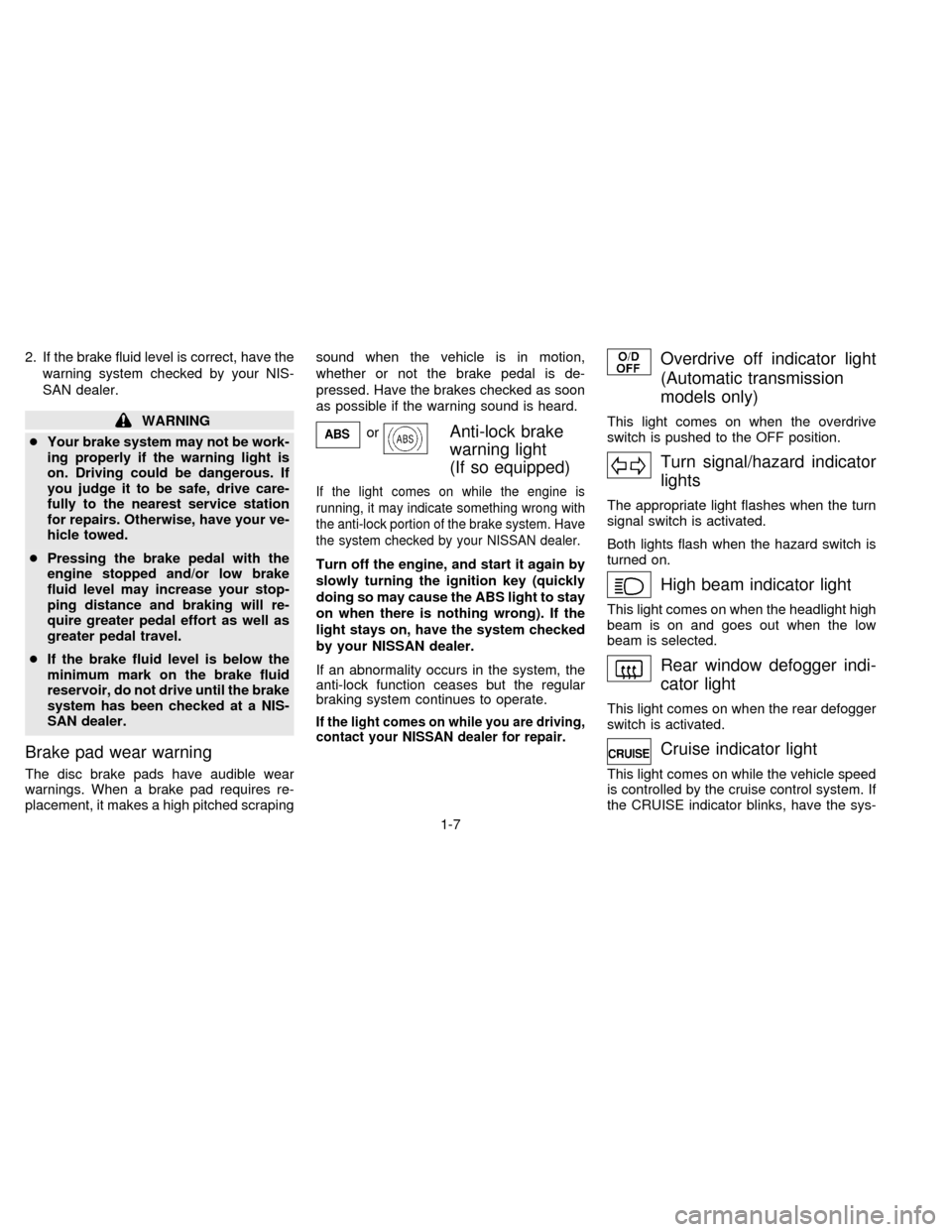

orAnti-lock brake

warning light

(If so equipped)

If the light comes on while the engine is

running, it may indicate something wrong with

the anti-lock portion of the brake system. Have

the system checked by your NISSAN dealer.

Turn off the engine, and start it again by

slowly turning the ignition key (quickly

doing so may cause the ABS light to stay

on when there is nothing wrong). If the

light stays on, have the system checked

by your NISSAN dealer.

If an abnormality occurs in the system, the

anti-lock function ceases but the regular

braking system continues to operate.

If the light comes on while you are driving,

contact your NISSAN dealer for repair.

Overdrive off indicator light

(Automatic transmission

models only)

This light comes on when the overdrive

switch is pushed to the OFF position.

Turn signal/hazard indicator

lights

The appropriate light flashes when the turn

signal switch is activated.

Both lights flash when the hazard switch is

turned on.

High beam indicator light

This light comes on when the headlight high

beam is on and goes out when the low

beam is selected.

Rear window defogger indi-

cator light

This light comes on when the rear defogger

switch is activated.

Cruise indicator light

This light comes on while the vehicle speed

is controlled by the cruise control system. If

the CRUISE indicator blinks, have the sys-

1-7

ZX

Page 109 of 203

while driving. This overheats the brakes,

increases wear on the brake linings and

pads, and reduces gas mileage.

To help save the brakes and to prevent the

brakes from overheating, reduce speed and

downshift to a lower gear before going down

a slope or long grade. Overheated brakes

may reduce braking performance and could

result in loss of vehicle control.

WARNING

While driving on a slippery surface, be

careful when braking, accelerating or

downshifting. Abrupt braking or accel-

erating could cause the wheels to skid

and result in an accident.The anti-lock brake system installed in

some models controls the brakes at each

wheel so the wheels do not lock when

braking abruptly or when braking on slip-

pery surfaces. The system detects the rota-

tion speed at each wheel and varies the

brake fluid pressure to prevent each wheel

from locking and sliding. By preventing

wheel lockup, the system helps the driver

maintain steering control and helps to mini-

mize swerving and spinning on slippery

surfaces.

Using the System

Depress the brake pedal and hold it down.

WARNING

Do not pump the brake pedal. Doing so

may result in increased stopping dis-

tances.

Normal operation

The anti-lock brake system does not oper-

ate at speeds below 3 to 6 MPH (5 to 10

km/h) to completely stop the vehicle. (The

speeds vary according to road conditions.)

When the anti-lock system senses that one

or more wheels are close to locking up, theactuator (under the hood) rapidly applies

and releases hydraulic pressure (like pump-

ing the brakes very quickly). While the ac-

tuator is working, you may feel a pulsation in

the brake pedal and hear a noise or vibra-

tion from the actuator under the hood. This

is normal and indicates that the anti-lock

system is working properly. However, the

pulsation may indicate that road conditions

are hazardous and extra care is required

while driving.

Self-test feature

The anti-lock brake system is sophisticated,

with electronic sensors, electric pumps, and

hydraulic solenoids controlled by a com-

puter. The computer has a built-in diagnos-

tic feature that tests the system each time

you start the engine and move the vehicle at

a low speed in forward or reverse. When the

self-test occurs, you may hear a ``clunk''

noise and/or feel a pulsation in the brake

pedal. This is normal and is not an indica-

tion of any malfunction. If the computer

senses any malfunction, it switches the anti-

lock brake system OFF and turns on the

ABS brake warning light in the dashboard.

The brake system then operates normally,

but without anti-lock assistance.

ANTI-LOCK BRAKE SYSTEM

(ABS) (If so equipped)

4-17

ZX

Page 149 of 203

The front (and rear, if equipped) disc-type

brakes self-adjust every time the brake

pedal is applied. The rear drum- type brakes

also self-adjust every time the brake pedal

is applied.

If the brake pedal goes down farther than

normal, it may be due to a lack of adjust-

ment of the rear drum brakes. Apply the

parking brake several times.

WARNING

See your NISSAN dealer and have it

checked if the brake pedal height does

not return to normal.

Brake pad wear indicators

The disc brake pads on your vehicle have

audible wear indicators. When a brake pad

requires replacement, it makes a high

pitched scraping or screeching sound when

the vehicle is in motion whether or not the

brake pedal is depressed. Have the brakes

checked as soon as possible if the wear

indicator sound is heard.

Under some driving or climate conditions,

occasional brake squeak, squeal or other

noise may be heard. Occasional brakenoise during light to moderate stops is nor-

mal and does not affect the function or

performance of the brake system.

The rear drum brakes (if so equipped) do

not have audible wear indicators. Should

you ever hear an unusually loud noise from

the rear drum brakes, have them inspected

as soon as possible by your NISSAN

dealer.

Proper brake inspection intervals should

be followed.For more information regard-

ing brake inspections, see the appropriate

maintenance schedule information in the

``Maintenance Schedule'' section of this

manual.Check the brake booster function as fol-

lows:

1. With the engine off, press and release

the brake pedal several times. When

brake pedal movement (distance of

travel) remains the same from one pedal

application to the next, continue on to the

next step.

2. While depressing the brake pedal, start

the engine. The pedal height should drop

a little.

3. With the brake pedal depressed, stop the

engine. Keep the pedal depressed for

about 30 seconds. The pedal height

should not change.

4. Run the engine for one minute without

depressing the brake pedal, then turn it

off. Depress the brake pedal several

times. The pedal travel distance will de-

crease gradually with each depression

as the vacuum is released from the

booster.

If the brakes do not operate properly, see

your NISSAN dealer.

BRAKE BOOSTER

7-19

ZX

Page 171 of 203

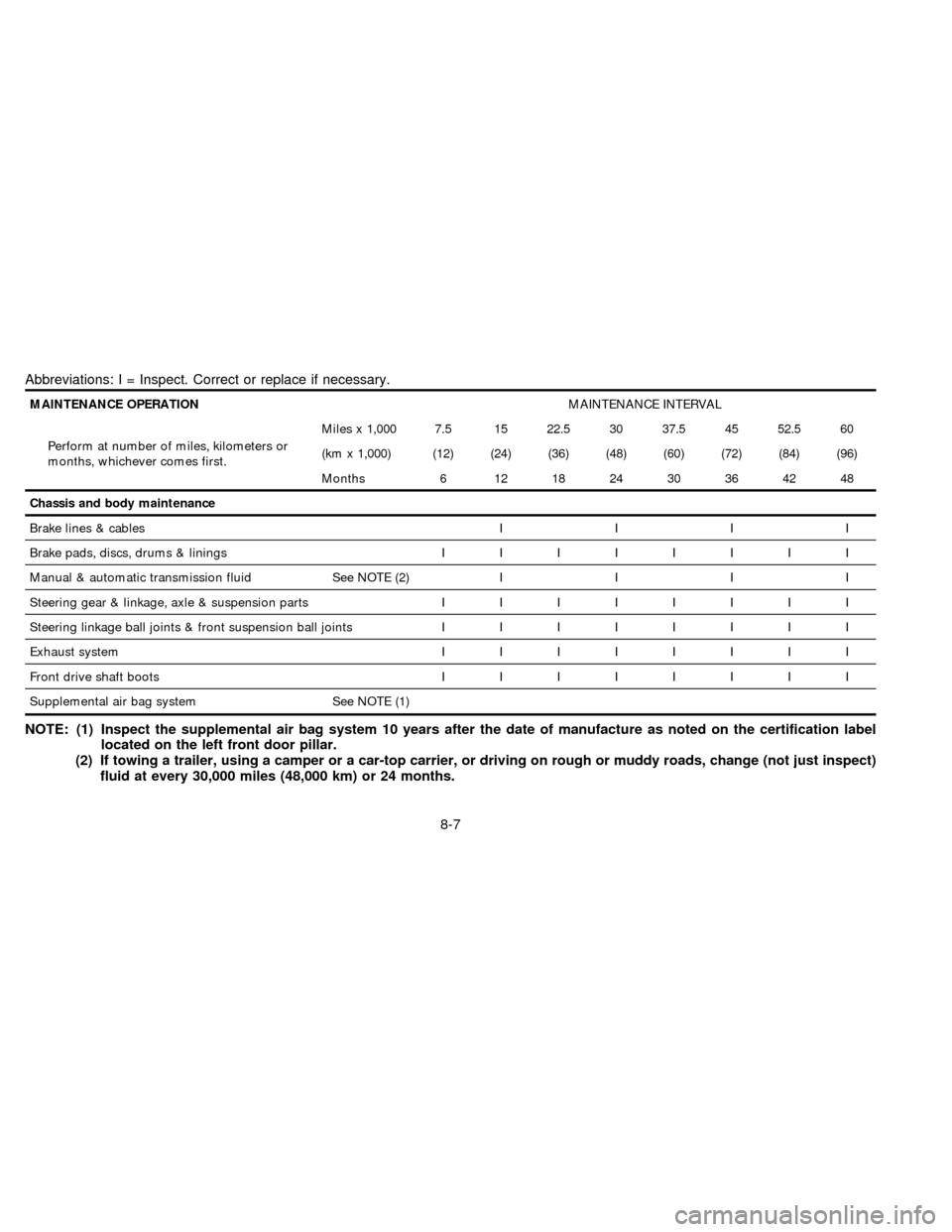

Abbreviations: I = Inspect. Correct or replace if necessary.

MAINTENANCE OPERATIONMAINTENANCE INTERVAL

Perform at number of miles, kilometers or

months, whichever comes first.Miles x 1,000 7.5 15 22.5 30 37.5 45 52.5 60

(km x 1,000) (12) (24) (36) (48) (60) (72) (84) (96)

Months 6 12 18 24 30 36 42 48

Chassis and body maintenance

Brake lines & cablesIIII

Brake pads, discs, drums & liningsIIIIIIII

Manual & automatic transmission fluid See NOTE (2)IIII

Steering gear & linkage, axle & suspension partsIIIIIIII

Steering linkage ball joints & front suspension ball jointsIIIIIIII

Exhaust systemIIIIIIII

Front drive shaft bootsIIIIIIII

Supplemental air bag system See NOTE (1)

NOTE: (1) Inspect the supplemental air bag system 10 years after the date of manufacture as noted on the certification label

located on the left front door pillar.

(2) If towing a trailer, using a camper or a car-top carrier, or driving on rough or muddy roads, change (not just inspect)

fluid at every 30,000 miles (48,000 km) or 24 months.

8-7

ZX

Page 173 of 203

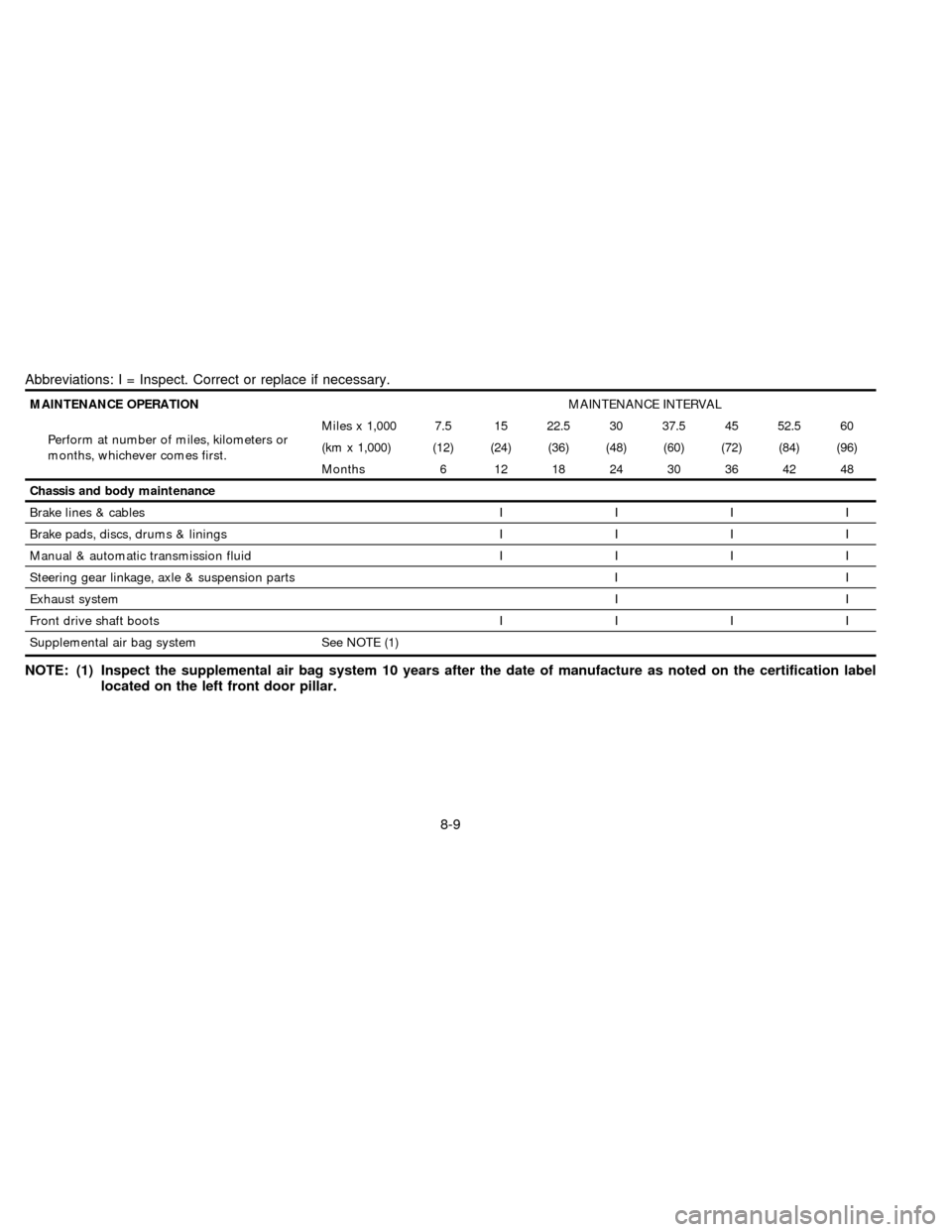

Abbreviations: I = Inspect. Correct or replace if necessary.

MAINTENANCE OPERATIONMAINTENANCE INTERVAL

Perform at number of miles, kilometers or

months, whichever comes first.Miles x 1,000 7.5 15 22.5 30 37.5 45 52.5 60

(km x 1,000) (12) (24) (36) (48) (60) (72) (84) (96)

Months 6 12 18 24 30 36 42 48

Chassis and body maintenance

Brake lines & cablesIIII

Brake pads, discs, drums & liningsIIII

Manual & automatic transmission fluidIIII

Steering gear linkage, axle & suspension parts I I

Exhaust systemII

Front drive shaft bootsIIII

Supplemental air bag system See NOTE (1)

NOTE: (1) Inspect the supplemental air bag system 10 years after the date of manufacture as noted on the certification label

located on the left front door pillar.

8-9

ZX

Page 174 of 203

Additional information on the following

items marked with ``*'' is found in the

``Do-it- yourself operations'' section.

Emission control system

maintenance

Drive belts*Ð Check drive belts for wear,

fraying or cracking and also for proper ten-

sion. Replace the drive belts if damaged.

Air cleaner filterÐ Under normal driving

conditions, the air cleaner filter should be

replaced in accordance with the mainte-

nance schedule. However, driving the ve-

hicle in dusty areas may cause more rapid

clogging of the element. Consequently, the

element may have to be replaced more

frequently.

Vapor linesÐ Check vapor lines and con-

nections for failure or looseness. If leaks are

found, replace them.

Fuel linesÐ Check the fuel hoses, piping

and connections for leaks, looseness or

deterioration. Replace any parts if they are

damaged.

Fuel filterÐ If the vehicle is operated under

extremely adverse weather conditions or in

areas where ambient temperatures are ei-

ther extremely low or extremely high, the

filter might become clogged. In such an

event, replace the filter immediately.

Engine coolant*Ð Drain and flush the

cooling system.

Engine oil & oil filter*Ð Under normal

driving conditions, the engine oil and oil filter

should be replaced in accordance with the

maintenance schedule. However, under se-

vere driving conditions, they may have to be

replaced more frequently.

Spark plugs*Ð Replace with new plugs

having the correct heat range.

Intake & exhaust valve clearanceÐ Check

the valve clearance if valve noise increases.

Chassis and body maintenance

Brake lines & cablesÐ Check the brake

lines and hoses (including brake booster

vacuum hoses, connections & check valve)

and parking brake cables for proper attach-

ment, leaks, cracks, chafing, abrasion, de-

terioration, etc.

Brake pads, discs, drums & liningsÐ

Check these and the other neighboring brake

components for wear, deterioration and

leaks. Under severe driving conditions, theymay have to be inspected more frequently.

Manual & automatic transmission fluid*

Ð Check the fluid level and visually inspect

for signs of leakage.

Under severe driving conditions, the fluid

should be replaced at the specified interval.

Steering gear & linkage, axle & suspen-

sion parts, and drive shaft bootsÐ

Check for damage, looseness and leakage

of oil or grease. Under severe driving con-

ditions, more frequent inspection should be

performed.

Steering linkage ball joints & front sus-

pension ball jointsÐ Check the ball joints

for damage, looseness and grease leakage.

Exhaust systemÐ Visually check the ex-

haust pipes, muffler, and hangers for proper

attachment, leaks, cracks, chafing, abra-

sion, deterioration, etc. Under severe driv-

ing conditions, inspection should be per-

formed more frequently.

Supplemental air bag systemÐ Check

the supplemental air bag system compo-

nents for proper attachment, damage, de-

formities, cracks, rust, etc. Work around and

on the supplemental air bag system should

be done by an authorized NISSAN dealer.

EXPLANATION OF

MAINTENANCE ITEMS

8-10

ZX