key NISSAN GT-R 1998 Service Manual

[x] Cancel search | Manufacturer: NISSAN, Model Year: 1998, Model line: GT-R, Model: NISSAN GT-R 1998Pages: 230, PDF Size: 12.66 MB

Page 54 of 230

SHIFT LOCK SYSTEM

Component Parts Location

Control device pJ/ I '-#I

Park position

Key interlock cable

Shift Lock Circuit Diagram

I AfT device connector

Brake SW connector

4AT M-AT

Terminal No. in parenthesis is used for M-AT. AfT device AT01 O57C

6 (2)

$5 - 5

IOA / 2j nI1 - (6)

Brake SW

Reverse Buzzer Circuit Diagram

Shift lock solenoid

Park position SW ~-

Connectors

1 1 )29m [ I]l~a!!b-ll1ll1 36 , &- 551 l\li I i I1 I I I I! I TK 20 pins (Wh~te)

TK 24 pins (Brown) TK 20 pins (Brown) AT01 056D

# 12

b

-

#ll PNP SW 36 Reverse lamp 29

# 28 9

1 1 Meter C/U 155 4 (with

integrated buzzer) ,

Page 91 of 230

ANTI-LOCK BRAKE SYSTEM

CONSULT (Cont'd)

I b~ SELECT DiAG MODE 01 r SELF-DIAG RESULTS

DATA MONITOR

ACTIVE TEST

ECU

PART NUMBER I

FR RH SOL TEST

I 1 !!! SELECT MONITOR ITEM I I

I I SELECTION FROM MENU I I

I I START 1

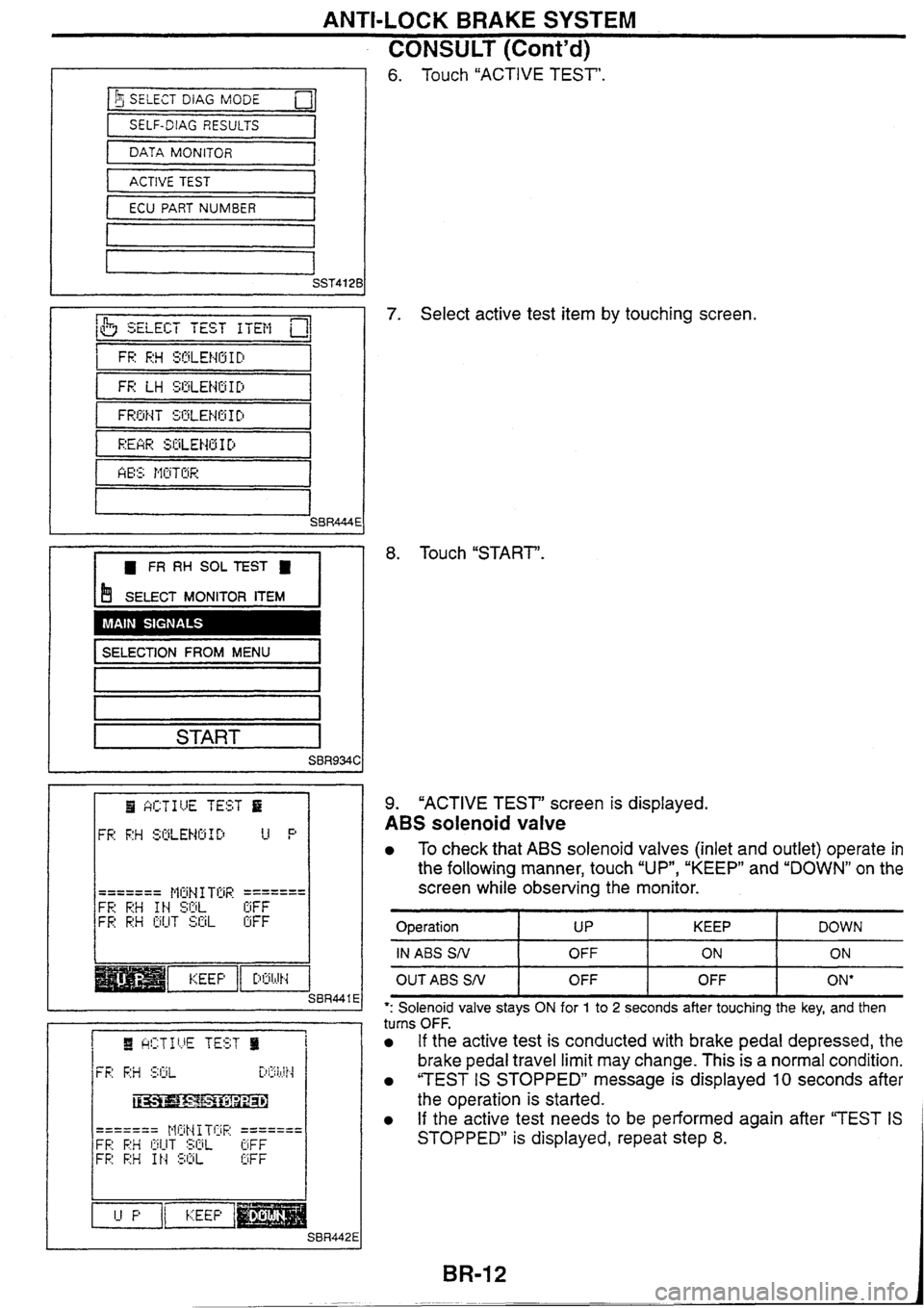

6. Touch "ACTIVE TEST'.

7. Select active test item by touching screen.

8. Touch "START'.

9. "ACTIVE TEST" screen is displayed.

ABS solenoid valve

To check that ABS solenoid valves (inlet and outlet) operate in

the following manner, touch

"UP*, "KEEP" and "DOWN" on the

screen while observing the monitor.

Operation I UP I KEEP ( DOWN

IN ABS SN I OFF 1 ON I ON

OUTABS SN I OFF I OFF I ON*

*: Solenoid valve stays ON for 1 to 2 seconds after touching the key, and then

turns OFF.

If the active test is conducted with brake pedal depressed, the

brake pedal travel limit may change. This is a normal condition.

"TEST IS STOPPED" message is displayed 10 seconds after

the operation is started.

If the active test needs to be performed again after "TEST IS

STOPPED" is displayed, repeat step 8.

Page 112 of 230

TCS/ABS SYSTEM

CONSULT for TCS/ABS Control Unit Control

System (Cont'd)

9. "ACTIVE TEST' screen is displayed.

ABS solenoid valve

a To check that ABS solenoid valves (inlet and outlet) ooerate in

I I I - --

': Solenoid valve stays ON for 1 to 2 seconds after touching the key, and then

turns OFF. =

the following manner, touch "UP", "KEEP" and "DOWN" on the @

screen while observing the monitor.

If the active test is conducted with brake pedal depressed, the ; <

brake pedal travel limit may change. This is a normal condition.

"TEST IS STOPPED" message is displayed 10 seconds after

Y

the operation is started. ST

a If the active test needs to be performed again after "TEST IS

STOPPED" is displayed, repeat step 8. RS

Operation

IN ABS

SN

OUTABS SN

ABS motor

Touch "ON" and "OFF' on the screen to check that ABS motor EL

relay and ABS actuator relay operate as follows:

UP

OFF

OFF

Operation ON

@

KEEP

ON

OFF

ABS actuator relay

ABS

motor relay DOWN

Ee

ON

ON'

A'

a If the active test is conducted with brake pedal depressed, the

brake pedal travel limit may change. This is a normal condition.

a "TEST IS STOPPED" message is displayed 10 seconds after

the operation is started.

ON

ON OFF

ON

OFF

Page 117 of 230

TCSIABS SYSTEM

CONSULT for Throttle Control Unit Control

System (Cont'd)

SELF-DIAGNOSTIC RESULTS MODE

- - Diagnostic item I Diagnostic item is detected when ... I Check item

THROTTLE

POSl

SEN

THROTTLE MOTOR Throttle

position sensor signal output is abnormally high or

continues to stay low for a certain period of time.

I

Throttle motor sensor signal output is abnormally high or con-

tinues to stay low for

a certain period of time. 1 Throttle motor sensor and circuit

Throttle

position sensor circuit

THRTL OPEN TRGET

THROTTLE ACTUATOR

RLY 1 Throttle motor relay is short-circuited.

[SHORT] Circuit

for throttle motor target angle signal (DKR line) is open

or shorted. TCS/ABS control unit

is abnormal.

Circuit for the communication

line between the throttle control

Throttle motor operation

does not accord with the throttle

motor target angle.

Throttle motor and circuit

I

ENGINE START SIG unit

and the TCSIABS control

unit

1 THROTTLE MOTOR

THROlTLE MOTOR RLY

[OPEN]

I Start signal is not correctiy entered due to short.

Overcurrent

is applied to the throttle motor drive circuit. I

Start signal circuit and

ECM-TCM or

ECM

Throttle motor relay is open.

Throttle motor relay and circuit

connector for

NEUTRAL POSl SW

DATA MONITOR PROCEDURE

Refer to CONSULT Instruction Manual for details on data

monitor function.

Turn ignition switch OFF.

Connect CONSULT connector to data link connector for

CON-

SU LT.

Turn ignition switch ON.

Touch "START' on CONSULT screen.

Touch ''THROTTLE CONTROL" on CONSULT screen.

Touch "DATA MONITOR".

Touch "SETTING" to set recording condition.

Touch one key from

"AUTO TRIG", "MANUAL TRIG" and

"SPECIAL", and then touch "LONG

TIME".

With "AUTO TRIG" selected, the data is automatically recorded

if a malfunction occurs during the data monitor. With "SPE-

CIAL" selected, the data is automatically recorded when TCS

is activated.

Touch "ENTER".

Return to

"SELECT MONITOR ITEM" screen and touch "ALL

SIGNALS". Display data monitor.

If necessary, sequentially touch "REC START', "REC STOP",

"DATA DISPLAY", "NUMBER

PRINT'

and "PRINT' to print

out

the data.

Bb38

Parkheutral position switch signal is not correctly entered due

to open or shorted circuit.

--

Neutral position switch circuit

and PNP switch circuit

Page 139 of 230

![NISSAN GT-R 1998 Service Manual

TROUBLE DIAGNOSES - Su~plemental Restraint Svstem (SRS)

-

connector for

SELF-DlAG [CURRENT] C

* NO SELF DIAGNOSTIC

FAILURE INDICATED.

FURTHER TESTING

MAY BE REQUIRED. $ *

-1 PRINT

Prelimin NISSAN GT-R 1998 Service Manual

TROUBLE DIAGNOSES - Su~plemental Restraint Svstem (SRS)

-

connector for

SELF-DlAG [CURRENT] C

* NO SELF DIAGNOSTIC

FAILURE INDICATED.

FURTHER TESTING

MAY BE REQUIRED. $ *

-1 PRINT

Prelimin](/img/5/57354/w960_57354-138.png)

TROUBLE DIAGNOSES - Su~plemental Restraint Svstem (SRS)

-

connector for

SELF-DlAG [CURRENT] C

* NO SELF DIAGNOSTIC

FAILURE INDICATED.

FURTHER TESTING

MAY BE REQUIRED. $ *

-1 PRINT

Preliminary Check

Check battery voltage and specific gravity.

When battery voltage drops to less than approx. 9V, the

"AIR BAG" warning lamp starts flashing (indicating a mal-

function).

Gj

Check the connections of component connectors.

Check that the fuse is not blown.

3F

Trouble Diagnoses with CONSULT

SELF-DIAGNOSIS PROCEDURE

Connect CONSULT to data link connector on the vehicle.

Turn ignition switch "ON".

83

Touch "AIR BAG" on the CONSULT screen.

Touch an appropriate mode key on "SELECT DlAG MODE"

screen.

gL

The self-diagnostic result for the selected mode is displayed.

Repair or replace the malfunctioning part according to the

self-

diagnostic result.

89

Touch "PRINT, if printout is required.

After

repairing the malfunction, touch "SELF-DIAG

[CURRENT]", and after checking that "NO SELF DIAGNOSTIC

FAILURE INDICATED" is shown on the display, touch

"ERASE.

For seat belt pre-tensioner system, the diagnostic proce-

dure

is completed when "NO SELF DIAGNOSTIC FAILURE

INDICATED"

is displayed.

FURTHER TESTING MAY BE REQUIRED. * *

* NO SELF DIAGNOSTIC

FAILURE INDICATED.

t

PRINT SRS609

9. Return to "SELECT DlAG MODE" screen and touch "SELF-

DlAG

[PAST]".

10. After checking that "NO SELF DIAGNOSTIC FAILURE INDI-

CATED" is displayed on the "SELF-DIAG [PAST]" screen, fin-

ish the diagnosis.

Page 165 of 230

ELECTRICAL SYSTEM

SECTION EL

CONTENTS

CENTRAL DOOR LOCK SYSTEM ................................. 2

Component Parts Location .......................................... 2

Circuit Diagram ............................................................ 2

Combination Meter (meter control unit) Input/

Output Signal Specifications

........................................ 2

Inspection before Trouble Diagnoses ......................... -3

Trouble Diagnoses ....................................................... 3

REMOTE CONTROL ENTRY SYSTEM .......................... 4

Component Parts Location .......................................... 4

Circuit Diagram ............................................................ 4

Remote Control Entry Control Unit Input/Output

Signal Specifications

.................................................... 5

System Check ............................................................. -5

Inspection before Trouble Diagnoses .......................... 6

Trouble Diagnoses ....................................................... 6

Component Parts inspection ....................................... 6

ID Code Entry Procedure ............................................ 7

POWER WINDOW SYSTEM ........................................... 8

System Description ..................................................... -8

Precautions ................................................................. -8

Component Parts Location .......................................... 8

Circuit Diagram ............................................................ 9

Power Window Main Switch Input/Output Signal

Specifications

............................................................... 9

Inspection before Trouble Diagnoses ........................ 11

Trouble Diagnoses .................................................... 11

SUNROOF SYSTEM ...................................................... 12

Component Parts Location ........................................ 12

Circuit Diagram .......................................................... 12

Sunroof Switch and Sunroof Motor Assembly

lnputiOutput Signal Specifications

............................. 12

AUTO LIGHT SYSTEM ................................................. 1 3

Component Parts Location ........................................ 13

Auto Light Control Unit Input/Output Signal

Specifications

............................................................. 13

Circuit Diagram ........................................................ 14

Trouble Diagnoses .................................................. I 4

..................................... XENON HEADLAMP SYSTEM 15

Trouble Diagnoses ..................................................... 15

IGNITION KEY-OPERATED ILLUMINATION

SYSTEM

................................................................... 7

Component Parts Location ........................................ 17

.......................................................... Circuit Diagram 17

Meter Control Unit InputlOutput Signal

....................................................... Specifications 1 7

METER ........................................................................\

18

Corn bination Meter .................................................... 18

Triple Meter ................................................................ 20

................................................ COMBINATION METER 21

.................................................... System Description 21

........................................ Component Parts Location 21

Diagnosis Function .................................................... 21

................................... Meter-related Circuit Diagram 22

..................................................... Trouble Diagnoses 23

Combination Meter InpuVOutput Signal

Specifications

............................................................ -25

..................................... Component Parts Inspection 26

TRIPLE METER ............................................................. 29

Special Service Tool ................................................... 29

........................................ Component Parts Location 29

Circuit Diagram .......................................................... 29

Triple Meter InputfOutput Signal Specifications ........ 30

Component Parts Inspection ..................................... 30

IGNITION KEY WARNING BUZZER AND LIGHT

WARNING BUZZER

...................................................... 31

Component Parts Location ........................................ 31

Circuit Diagram .......................................................... 31

Meter Control Unit InpuVOutput Signal

Specifications

............................................................. 31

FRONT WIPER .............................................................. 32

Component Parts Location ........................................ 32

Circuit Diagram .......................................................... 32

Front Wiper Input/Output Signal Specifications ........ 32

Page 169 of 230

REMOTE CONTROL ENTRY SYSTEM

1

Component Parts Location

Circuit Diagram

Key-in detection SW

Remote control entry I C/U connector -

Unlock signal

Page 170 of 230

REMOTE CONTROL ENTRY SYSTEM

Remote Control Entry Control Unit

Terminal No.

InputIOutput Signal specifications

Signal name Operation or cond~t~on Specificatton

Close the driver door. (OFF) Approx.

12V Driver door

switch input signal . @ Open the driver door. (ON) Approx. OV

Close

all the doors. (OFF) Approx. 12V All door

switch input signal Ec Open one of the doors. (ON) Approx. OV

Driver door

lock actuator lock

output signal Lock with the remote control. Changes from

approx. 0 to 12V and back to approx. OV. t

Ground - Approx. OV BR Locked (OFF) Approx. 5V Driver door lock switch signal

Unlocked (ON) Approx. OV

Key-in detection switch input Insert (ON) Approx. 12V 87

signal

Ignition key Remove (OFF)

Approx. OV

ACC power supply Ignition switch to ACC Approx. 12V Rs

Passenger door and rear RH & Press the lock switch on the remote control. Changes

from approx. 5 to OV LH door lock output signal

and back to approx. 5V.

Passenger door and rear RH & Changes from approx. 5 to OV HA

LH door unlock output signal Press the unlock switch

on the remote control.

and back to approx. 5V.

Driver door lock actuator

Unlock with the remote control. Changes from approx. 0 to

unlock output signal 12V and back to approx. OV.

System Check

Easy way to confirm the func+ion of the remote control: Works

properly.

Program the remote control (A) to another vehicle

of the

same type and check if the remote control works properly. Does not work. is OK.

Turn

a radio ON. Touch the radio aerial with the remote

control (A). Press a switch on the remote control with . is heard.

the

remote

control on the aerial. Listen for noise.

(Radio frequency: around

78.6, 78.7, 78.8 MHz)

B f ' Works properly.

I

Program another remote control (6) to the vehicle

concerned and check if the remote control works properly. No noise

is heard. t The vehicle is OK.

Does not work.

Check item

Operation check

Remote control

(A) is OK. Remote control (A)

is

NG.

r The vehicle is NG. 0CC3078D

I

I System check A

Remote control

(A) is OK.

Remote control (A) is

NG.

System check B

The vehicle is OK.

Remote control (A) is NG. Program the remote control

(A) to the vehicle concerned again and check

for proper operation.

The vehicle is NG.

The vehicle is OK. Perform trouble diagnosis

to determine what causes the problem.

Check the remote control

(A) battery voltage.

The vehicle is NG. Check the

remote control (A) battery voltage and then perform trouble

diag- nosis to determine what causes the problem.

Page 171 of 230

REMOTE CONTROL ENTRY SYSTEM

lnspection before Trouble Diagnoses

Check system.

Check that other systems that use the following signals work

properly.

Check that component connectors are connected properly.

Trouble Diagnoses

SYMPTOM CHART

Symptom

None of the doors lock with the remote

control switch.

None of the doors unlock with the

remote control switch.

Door locks other than the driver door do

not operate with the remote control

switches.

Only the driver door lock does not oper-

ate with the remote control switch. Door

switch circuit Malfunctioning item

Faulty door switch to

remote control entry control unit

harness Possible cause

Key-in detection switch circuit

Faulty key-in detection switch to remote control entry control

unit harness

Remote control entry control unit

Key-in detection switch circuit

Faulty remote control entry control unit

Faulty key-in detection switch to remote control entry control

unit harness

Remote control entry control unit

Central door lock system circuit

Remote control entry control unit

Driver door lock actuator circuit

Remote control entry control unit

Faulty remote control entry control unit

Refer to

"CENTRAL DOOR LOCK SYSTEM", EL-2. Faulty combination meter (meter control unit) to remote

control entry control unit harness

Faulty remote control entry control unit

Faulty driver door lock actuator Faulty driver door lock actuator to remote control entry

control unit harness

Faulty remote control entry control unit

mA before

Use lithium

checking ihe battery.

photo battery (CRI 620

Component Parts lnspection

BATERY CHECK

Specification: Approx. 2.5 - 3.OV

CAUTION:

Connect resistance

(300Q) so that the current is approx. 10

or equivalent) for

replacement.

Page 172 of 230

REMOTE CONTROL ENTRY SYSTEM

ID Code Entry Procedure

Enter the identity (ID) code manually when:

remote controller or control unit is replaced.

an additional remote controller is activated.

To enter the ID code, follow the procedures below.

PROCEDURE

I Close all doors and lock driveis side door. I

Insert and remove the key from the ignition more than six times within 10 seconds.

(Power door lock will then unlock.)

Within

3 seconds after door lock is unlocked, turn ignition key switch to "ACCn posi-

tion and lock the driver's side door.

At this time, the original ID codes are erased.

Push any button on the new remote controller once. (Power door lock will then

unlock.)

At this time, the new ID code is entered. e

Lock driver's side door.

Do you

want to enter any additional remote controller ID codes?

A maximum four ID codes may be entered. Any attempt to enter more will be

ignored.

I Open driver's side door or turn the ignition key switch to 'OFF position. I

No

END.

After entering the identity (ID) code, check the operation of remote control

entry system.

Yes

NOTE

If you need to activate more than two additional new remote controllers, repeat the procedure

"Additional ID code entry" for each new remote controller.

If the same ID code that exists in the memory is input, the entry will be ignored.

Entry of maximum four ID codes is allowed and any attempt to enter more will be ignored.