belt NISSAN GT-R 1998 Service Manual

[x] Cancel search | Manufacturer: NISSAN, Model Year: 1998, Model line: GT-R, Model: NISSAN GT-R 1998Pages: 230, PDF Size: 12.66 MB

Page 40 of 230

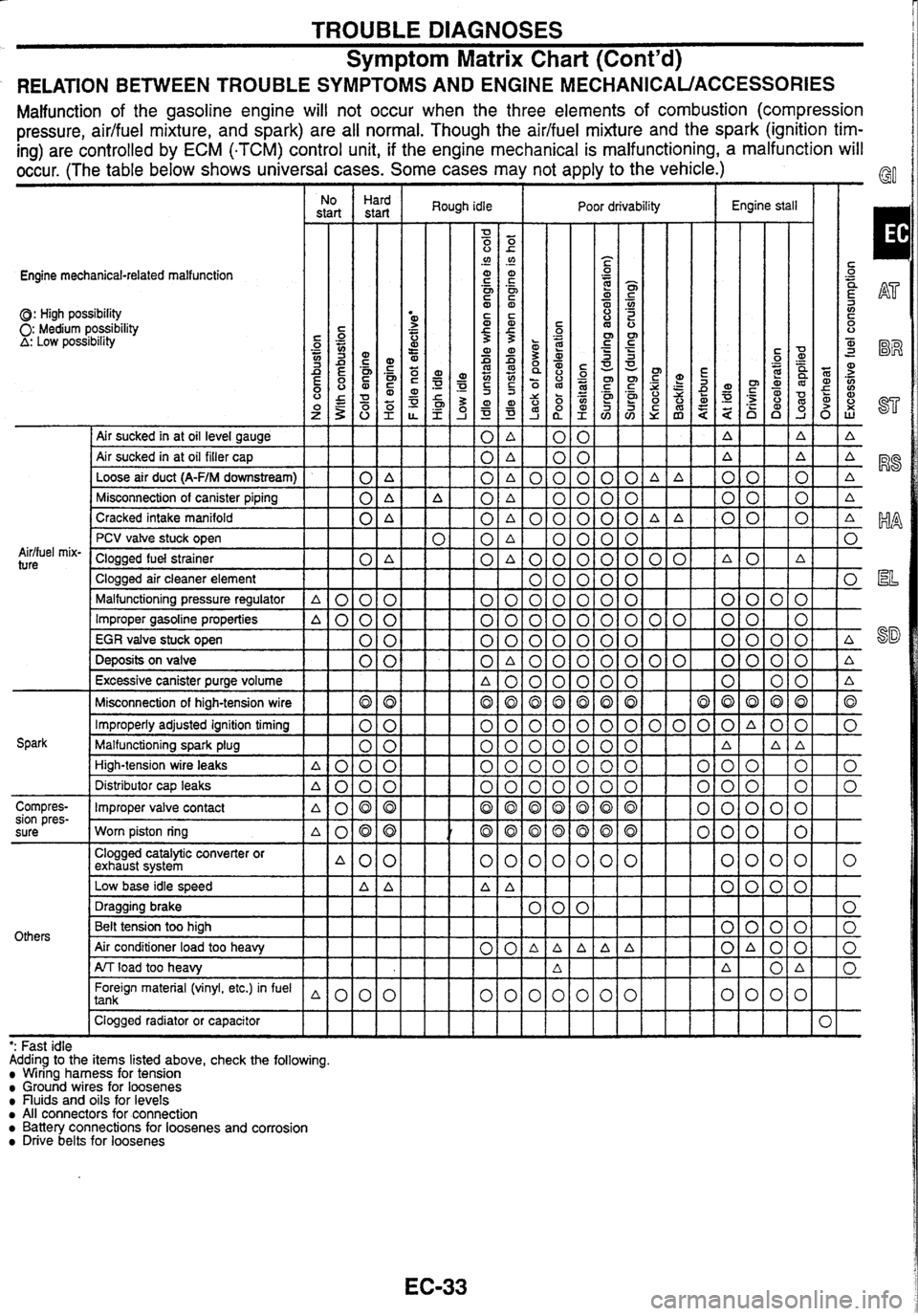

TROUBLE DIAGNOSES

Symptom Matrix Chart (Cont'd)

RELATION BETWEEN TROUBLE SYMPTOMS AND ENGINE MECHANICAUACCESSORIES

Malfunction of the gasoline engine will not occur when the three elements of combustion (compression

pressure, aidfuel mixture, and spark) are all normal. Though the

aidfuel mixture and the spark (ignition tim-

ing) are controlled by ECM

(.TCM) control unit, if the engine mechanical is malfunctioning,

a malfunction will

occur. (The table below shows universal cases. Some cases may not apply to the vehicle.)

Engine mechanical-related malfunction

0: High possibility 0: Medium possibility A: Low posstbility

I No I Hard

start start

I Air sucked in at oil level gauge

Air sucked in at oil filler cap

Loose air duct

(A-F/M downstream) 0 A

Misconnection of canister piping

0 A

Cracked intake manifold

0 A

Aidfuel

mix-

ture

PCV valve stuck open

Clogged fuel strainer

0 A

Clogged air cleaner element

Malfunctioning pressure regulator

A 0 0 0

Improper gasoline properties A000

EGR valve stuck open 0 0

Deposits on valve 0 0

Excessive canister purge volume

Misconnection of high-tension wire

Improperly adjusted ignition timing

Malfunctioning spark plug

High-tension wire leaks

A000

Spark Distributor cap leaks

A000

Compres-

Improper valve contact

sion pres-

. a080

sure Worn piston ring ~080

Others

Clogged catalytic converter or

exhaust system A00

Low base idle speed A

A

Foreign material (vinyl, etc.) in fuel 1 tank

Clogged radiator or capacitor

IIII

Rough idle I Poor drivability Engine stall

- - - - - - -- ': Fast

idle

Adding to the items listed above, check the following.

Wiring harness for tension Ground wires for loosenes nuids and oils for levels All connectors for connection Battery connections for loosenes and corrosion Drive belts for loosenes

Page 41 of 230

TROUBLE DIAGNOSES

Symptom Matrix Chart (Cont'd)

Engine mechanical-related malfunction I Symptom characteristics and inspection hints

Airffuel

ratio becomes lean.

Air sucked in at oil filler cap

Aidfuel ratio compensation factor becomes higher.

a Intake manifold induction vacuum becomes lower.

I Cracked intake manifold I

Misconnection of canister piping Use an induction vacuum (pressure) gauge for check.

' Common to all air sucking conditions from air intake system.

-

PCV valve stuck open

I Malfunctioning pressure regulator I Various symptoms occur depending on the fuel pressure.

Abnormal noise (peep) may

be heard.

Air/fuel

mixture

Improper gasoline properties Various

symptoms occur depending on the properties.

IEGRiale

stuck open

I

Clogged fuel strainer .

Clogged air cleaner element

Deposits on valve

r

Symptoms vary with the condition how they are clogged. However, the

symptoms tend to occur when the vehicle is driving at high speed and

under high load.

I

Air/fuel ratio becomes lean. Airfluel ratio compensation factor becomes

higher.

Excessive canister purge volume

I

Engine may stall when the accelerator pedal is lightly pressed. (Especially

in summertime.)

Misconnection of high-tension wire Check if the ignition timing

is correct. 1 Improperly adjusted ignition timing 1

Malfunctioning spark plug 1

Corn- I Improper valve contact I Symptoms vary with the degree of contact and the number of cylinders. '

High-tension wire leaks

Distributor

cap leaks Symptoms

vary with the degree of leaks.

Clogged catalytic converter or exhaust sys-

l tem , In many cases, engine stalls and then restarts after a while. I

pression I

Low base idle speed

pressure

Worn piston ring I

Engine may

stall while the vehicle is decelerating or when the power '

steering load or electrical load is applied.

Symptoms vary

with the degree of wear and the number of cylinders.

I

Air conditioner load too heavy I Too much refrigerant in the system. j

Others Dragging

brake

Belt tension too high

1

I Clogged radiator or capacitor I

ArJ load too heavy

Foreign material (vinyl, etc.) in fuel tank Insufficient A/T fluid (FR model)

Symptom tends to occur when fuel level in the tank becomes lower.

Page 138 of 230

TROUBLE DIAGNOSES - supplemental Restraint System (SRS)

Component Parts Location

Passenger air bag module

Diagnos~s

sensor

unit Driver air bag module

S~de

air

bag nodule

Satell~te sensor Seat belt pre-tensloner SRB0568D

Precautions

To perform system diagnosis, use self-diagnosis function and

CONSULT.

Do not use electrical test equipment such as a circuit tester

because

any wrong operation caused by a weak electric cur-

rent

of a tester must be prevented.

Circuit Diagram

Page 139 of 230

![NISSAN GT-R 1998 Service Manual

TROUBLE DIAGNOSES - Su~plemental Restraint Svstem (SRS)

-

connector for

SELF-DlAG [CURRENT] C

* NO SELF DIAGNOSTIC

FAILURE INDICATED.

FURTHER TESTING

MAY BE REQUIRED. $ *

-1 PRINT

Prelimin NISSAN GT-R 1998 Service Manual

TROUBLE DIAGNOSES - Su~plemental Restraint Svstem (SRS)

-

connector for

SELF-DlAG [CURRENT] C

* NO SELF DIAGNOSTIC

FAILURE INDICATED.

FURTHER TESTING

MAY BE REQUIRED. $ *

-1 PRINT

Prelimin](/img/5/57354/w960_57354-138.png)

TROUBLE DIAGNOSES - Su~plemental Restraint Svstem (SRS)

-

connector for

SELF-DlAG [CURRENT] C

* NO SELF DIAGNOSTIC

FAILURE INDICATED.

FURTHER TESTING

MAY BE REQUIRED. $ *

-1 PRINT

Preliminary Check

Check battery voltage and specific gravity.

When battery voltage drops to less than approx. 9V, the

"AIR BAG" warning lamp starts flashing (indicating a mal-

function).

Gj

Check the connections of component connectors.

Check that the fuse is not blown.

3F

Trouble Diagnoses with CONSULT

SELF-DIAGNOSIS PROCEDURE

Connect CONSULT to data link connector on the vehicle.

Turn ignition switch "ON".

83

Touch "AIR BAG" on the CONSULT screen.

Touch an appropriate mode key on "SELECT DlAG MODE"

screen.

gL

The self-diagnostic result for the selected mode is displayed.

Repair or replace the malfunctioning part according to the

self-

diagnostic result.

89

Touch "PRINT, if printout is required.

After

repairing the malfunction, touch "SELF-DIAG

[CURRENT]", and after checking that "NO SELF DIAGNOSTIC

FAILURE INDICATED" is shown on the display, touch

"ERASE.

For seat belt pre-tensioner system, the diagnostic proce-

dure

is completed when "NO SELF DIAGNOSTIC FAILURE

INDICATED"

is displayed.

FURTHER TESTING MAY BE REQUIRED. * *

* NO SELF DIAGNOSTIC

FAILURE INDICATED.

t

PRINT SRS609

9. Return to "SELECT DlAG MODE" screen and touch "SELF-

DlAG

[PAST]".

10. After checking that "NO SELF DIAGNOSTIC FAILURE INDI-

CATED" is displayed on the "SELF-DIAG [PAST]" screen, fin-

ish the diagnosis.

Page 140 of 230

TROUBLE DIAGNOSES - Supplemental Restraint System (SRS)

Trouble Diagnoses with CONSULT (Cont'd)

SELF-DIAGNOSTIC CODE CHART - -

Diagnostic item 1 Explanation Repair order

NO SELF-DIAGNOSTIC

I NO malfunction is detected. I - FAILURE INDICATED

AIRBAG MODULE

iOPENl

Driver air bag module circuit is open (including the

spiral cable).

Driver air bag module circuit is shorted to some power

supply circuit (including the spiral cable).

Driver air bag module circuit is shorted to ground

(including the spiral cable).

Driver air bag module circuits are shorted to each

other (includina the s~iral cable).

AIRBAG

MODULE

IVB-SHORTI

1. Visually

check the wiring harness c~nnection. 2. Check conbnuity of the spiral cable. 3. Replace driver air bag module. 4. Replace the diagnosis sensor unit. 5. Replace the harness if it has visible damage.

AIRBAG

MODULE

IGND-SHORTI

AIRBAG

MODULE

[SHORT]

--

CONTROL UNIT I Diagnosis sensor unit is malfunctioning. I 1. Visually check the diagnosis sensor unit connection. 2. Replace t9e diagnosis sensor unit.

ASSIST

NB MODULE

[OPEN] I Passenger air bag circuit is open. I

ASSIST NB MODULE

NB-SHORTI

ASSIST

NB MODULE

[GND-SHORV

Passenger air bag circuit is shorted to Some Power

supply circuit. ,

Passenger air bag circuit is shorted to ground.

ASSIST

NB MODULE

lSHORTl

1. Visually check the wiring hamess connection. 2. Replace passenger air bag module. 3. Replace the diagnosis sensor unit. 4. Replace t!!e harness if it has visible damage.

Passenger air bag circuits are shorted to each other.

Driver side air bag circuit is open.

SlDE

MODULE RH

{OPEN]

SlDE MODULE RH

[VB-SHORT]

SlDE MODULE RH

[GND-SHORTI

Driver side air bag circuit is shorted to Some power

supply circuit.

Driver side air bag circuit is shorted to ground.

SlDE MODULE LH

[OPEN]

I Passenger side air bag circuit is open. I

1. Visually check the wiring hamess connection. 2. Replace driver side air bag module. 3. Replace the diagnosis sensor unit. 4. Replace the harness if it has visible damage.

SlDE MODULE

RH [SHORT]

SIDE MODULE LH

NB-SHORTI Driver side air bag circuits are shorted to each other.

SlDE MODULE LH

[GND-SHORT]

Pa~Sengef side air bag circuit is shorted to Some

power supply circuit. -

Passenger side air bag circuit is shorted to ground.

1. Visually check the wiring harness connection. 2. Replace passenger side air bag module. 3. Replace the diagnosis sensor unit. 4. Replace the harness if it has visible damage.

SlDE MODULE LH

ISHORTl

Passenger side air bag circuits are shorted to each

other.

Driver satellite sensor is malfunctioning.

SATELLITE SENS

RH

[UNIT FAIL] 1. Visually check driver satellite sensor connection. 2. Replace the driver satellite sensor. 3. ReDlace the harness if it has visible damage.

SATELLITE SENS RH

[COMM FAIL]

Driver satellite sensor is malfunctioning. Diagnosis sensor unit is malfunctioning. Wiring harness between diagnosis sensor unit and

satellite sensor is damaged.

SATELLITE SENS LH

[UNIT FAIL]

1. Visually check driver satellite sensor connection. 2. Replace the driver satellite sensor. 3. Replace the diagnosis sensor unit. 4. Replace the harness if it has visible damage.

1. Visuallv check the connection of passenqer satellite 0i 0 Passenger satellite sensor is malfunctioning. sensor: 2. Replace

C!e passenger satellite sensor. 3. Re~lace the harness if it has visible damage.

SATELLITE SENS

LH [COMM FAIL]

Passenger satellite sensor is malfunctioning. Diagnosis sensor unit is malfunctioning. Wiring harness between diagnosis sensor unit and

satellite sensor is damaged.

1. Visually check the connection of passenger satellite

sensor.

:: ~~~/~~~ ;E $~~,","$,"~~~~~t",$fnsOr' 4. Replace the harness if it has visible damage.

1. Visually check the wiring harness connection. 2. Replace driver seat belt pre-tensioner. 3. Replace the diagnosis sensor unit. 4. Replace the harness if it has visible damage.

J. I

1. Visually check the wiring harness connection. 2. Replace passenger seat belt pre-tensioner. 3. Replace the diagnosis sensor unit. 4. Replace the harness if it has visible damage.

DRIVE

PRE-TENSIONER

[OPENNB-SHORT]

DRIVE PRE-TENSIONER

[GND-SHORTJ

ASSIST PRE-TENSIONER

[OPENNB-SHORT]

ASSIST PRE-TENSIONER

[GND-SHORT] I I

a The screens for "SELF-DIAG [CURRENTJ", "SELF-DIAG [PAST]" and "TROUBLE DlAG RECORD" share the same message. Follow the repair procedures in numerical order. Check whether a malfunction is eliminated each time a repair item is

finished, and when the malfunction is eliminated, further repair work is not required.

After repairing the system, touch "ERASE" to clear the memory and check with CONSULT again.

If both seat belt pre-tensioner systems on the driver seat and passenger seat have failed at the same time, only one of

the two failures is displayed first. The other failure is displayed after the first failure is repaired. For seat belt pre-tensioner

systems,

only

"SELF-DIAG [CURRENTJ" is displayed; "SELF-DIAG

[PASTJ"

and "TROUBLE DlAG RECORD" are not dis-

played.

RS-4

The circuit for the driver seat belt pre-tensioner is

open or shorted to some power supply circuit.

The circuit for the driver seat belt pre-tensioner is

shorted to ground.

The circuit for the passenger seat belt pre-tensioner is

open or shorted to some power supply circuit.

The circuit for the passenger seat belt pre-tensioner is

shorted to ground.

Page 144 of 230

TROUBLE DIAGNOSES - Supplemental Restraint System (SRS)

Trouble Diagnoses without CONSULT (Cont'd)

How to erase self-diagnostic results (Reset)

After repairing the system and while staying in Diagnosis mode,

check that the system has returned to normal; then, turn

tion switch

"OFF' and then back "ON". The mode returns

mode and the diagnosis record is erased.

SEAT BELT PRE-TENSIONER SYSTEM

Self-diagnosis

Only User mode is available.

.User mode

Driver seat belt

(Seat belt buckle

switch) Warning

lamp flash pattern

Malfunctioning part

Fastened (OFF)

IGN SW: ON

Unfastened (ON)

Fastened (OFF)

I IGN SW: ON System restored

+o.s Sec.

Unfastened (ON)

( IGN SW: ON Fastened I

-'n~0.5 sec.

I I -+OS sec. I

&

Driver and passenger

seat belt pre-tensioner

circuits

Diagnosis sensor unit

the igni-

to User

Diagnostic item

No malfunction is

detected.

No malfunction is

detected.

Shorted to power sup-

ply circuit

Open circuit

Shorted to ground

Diagnosis sensor unit

malfunction

The display indicating a malfunction (flashes) changes to the display indicating no malfunction when the malfunction is

repaired.

After pre-tensioner is activated, the warning lamp stays "ON".

Page 145 of 230

TROUBLE DIAGNOSES - Supplemental Restraint System (SRS)

Symptom Chart

Trouble phenomenon I Malfunctioning unit I Possible cause

I I Warning lamp and internal circuit of combination meter are

BAG warning lamp does

not turn on. (All other warn-

ing lamps turn on.)

L-L .. AIR BAG warning lamp does I

I Harness between diagnosis sensor unit and combination

AIR

BAG warning lamp circuit

Air bag power supply circuit

not turn off (always ON). (AIR BAG warning lamp circuit

I meter is faulty (open).

faulty.

P-$ ;

Harness between

diagnosis sensor unit and combination 'bJ

Diagnosis sensor unit

0 Air bag power fuse has blown.

0 Air bag power harness is faulty.

meter is faulty

(shorted).

Diagnosis sensor unit is faulty.

I23

Diagnosis sensor unit

0 Internal circuit of combination meter is faulty. BR

Diagnosis sensor unit is faulty.

AIR BAG warning lamp

flashes.

When driver seat belt is

fas-

lamp does not illuminate for

seconds. (All other warning

Low battery voltage (Less than 9V)

Conduct either diagnosis with CONSULT (self-diagnosis, trouble diagnosis record) or diagnosis ST

without CONSULT (self-diagnosis), and repair the malfunctioning part.

After repairing the malfunctioning part, erase the memory for malfunction record.

Warning lamp and internal circuit of combination meter are 1

tened(buckleswitchisoff)

and ignition switch is turned

on, the SEAT BELT warning

1 Air bag power

SEATBELTwarninglampcircuit

circuit faulty.

Harness between

diagnosis sensor unit and combination HA

meter is faulty (open).

Air bag power fuse has blown.

0 Air bag power harness is faulty.

lamps illuminate.)

When driver seat belt is fas-

tened (buckle switch is off)

When driver seat belt is fas-.

I I

Diagnosis sensor unit

and ignition switch is turned

on, the SEAT BELT warning

lamp does not turn off

7 sec-

onds later.

tened (buckle switch is off)

I I

-.

0 Diagnosis sensor unit is faulty.

SEAT

BELT warning lamp circuit

,

and ignition switch is turned

on, the SEAT BELT warning

fa> Harness between diagnosis sensor unit and combination su

meter is faulty (shorted).

Driver seat belt buckle switch circuit

Diagnosis sensor unit

Seat belt pre-tensioner circuit

Harness between combination meter and driver seat belt

buckle switch is faulty (shorted).

Driver seat belt buckle switch is faulty (sticking).

Diaqnosis sensor unit is faultv.

Conduct either diagnosis with CONSULT or diagnosis with-

out CONSULT, and repair the malfunctioning part.

lamp turns on, and

7 sec- I I

onds later, flashes.

When driver seat belt is not

fastened (buckle switch is on)

I I Driver seat belt buckle switch ground harness is faulty

lamp turns off about

7 sec-

onds later.

and ignition switch

is tumed

on, the SEAT BELT warning

tence).

Driver seat

belt buckle switch circuit I !::);eat belt buckle switch is faulty (contact intermit-

If the flashing of AIR BAG warning lamp is caused by low battery voltage, self-diagnosis mode cannot be switched from User

mode to Diagnosis mode. In this case, diagnosis with CONSULT displays "NO SELF-DIAGNOSTIC FAILURE INDICATED".

Page 202 of 230

![NISSAN GT-R 1998 Service Manual

ENGINE MECHANICAL I RB~ODE (UB) ]

STANDARD AND REPAIR LIMIT

Firing order I 1-5-3-6-2-4

Compression pressure

MPa

(kg/cm2)/rpm

Distortion limit mm

- - -- --- - Ignition advance device

Electr NISSAN GT-R 1998 Service Manual

ENGINE MECHANICAL I RB~ODE (UB) ]

STANDARD AND REPAIR LIMIT

Firing order I 1-5-3-6-2-4

Compression pressure

MPa

(kg/cm2)/rpm

Distortion limit mm

- - -- --- - Ignition advance device

Electr](/img/5/57354/w960_57354-201.png)

ENGINE MECHANICAL I RB~ODE (UB) ]

STANDARD AND REPAIR LIMIT

Firing order I 1-5-3-6-2-4

Compression pressure

MPa

(kg/cm2)/rpm

Distortion limit mm

- - -- --- - Ignition advance device

Electronically-controlled ignition advance

Engine

oil capacity

e

Spark plug standard

Limit

. Limit

of variation between cylinders

Intake manifold

Intake manifold collector

Exhaust manifold

Cylinder head

Cvlinder block

lgnition timing (during no feed back control) 1.23

(1 2%)/300

0.93 (9.5)1300

0.1 (1.0)/300

0.1 0.1

0.3

0.2

0.1

Without filter

With filter

MakerlTypeISpark

plug gap mm

Engine idling speed

W'

Idle base speed (during no feed back control)

rPm

Density of

COIHC at idling speed

Wppm Approx.

3.8

Approx. 4.2

NG WPFR5G-11 11.0

- 1

-1

650-.50

(N or P position for

A/T)

600 (N or P position for AlT)

Less than O.l/Less than 50

I New I Used I Limit

Valve

clearance

(INTIEXH)

mm

Deflection

amount of accessory V-belt

Measured with tension gauge

N (kg) Hot

engine

.

Cold engine (at ambient temperature)

Measured by pushing at 98 N (10 kg)

mm 0.36+0.062/0.53+0.062

0.31 1~,0.04/0.50i0.04

Fuel tank capacity

e

Engine coolant total capacity [with reservoir tank (max. level)] e

Thermostat opening temperature [start to open - full open]

"C

Radiator cap opening pressure

MPa (kg/cm2) Approx.

65

Approx. 9.4 82 - 95

0.06

- 0.1 0 (0.6 - 1 .O)

A/C compressor belt

Power

steering pump belt

Fan belt

Power steering pump belt

1 8-10 1 10-12 1 16

667

- 755

(68

- 77)

A/C compressor belt 1 6-8 1 7-9 / 12

Fan belt

1 3-5 1 4-6 1 7.5

559 - 637

(57

- 65)

SEC.117 Power steering

Fan belt pump be1 t

284 (29)

Page 203 of 230

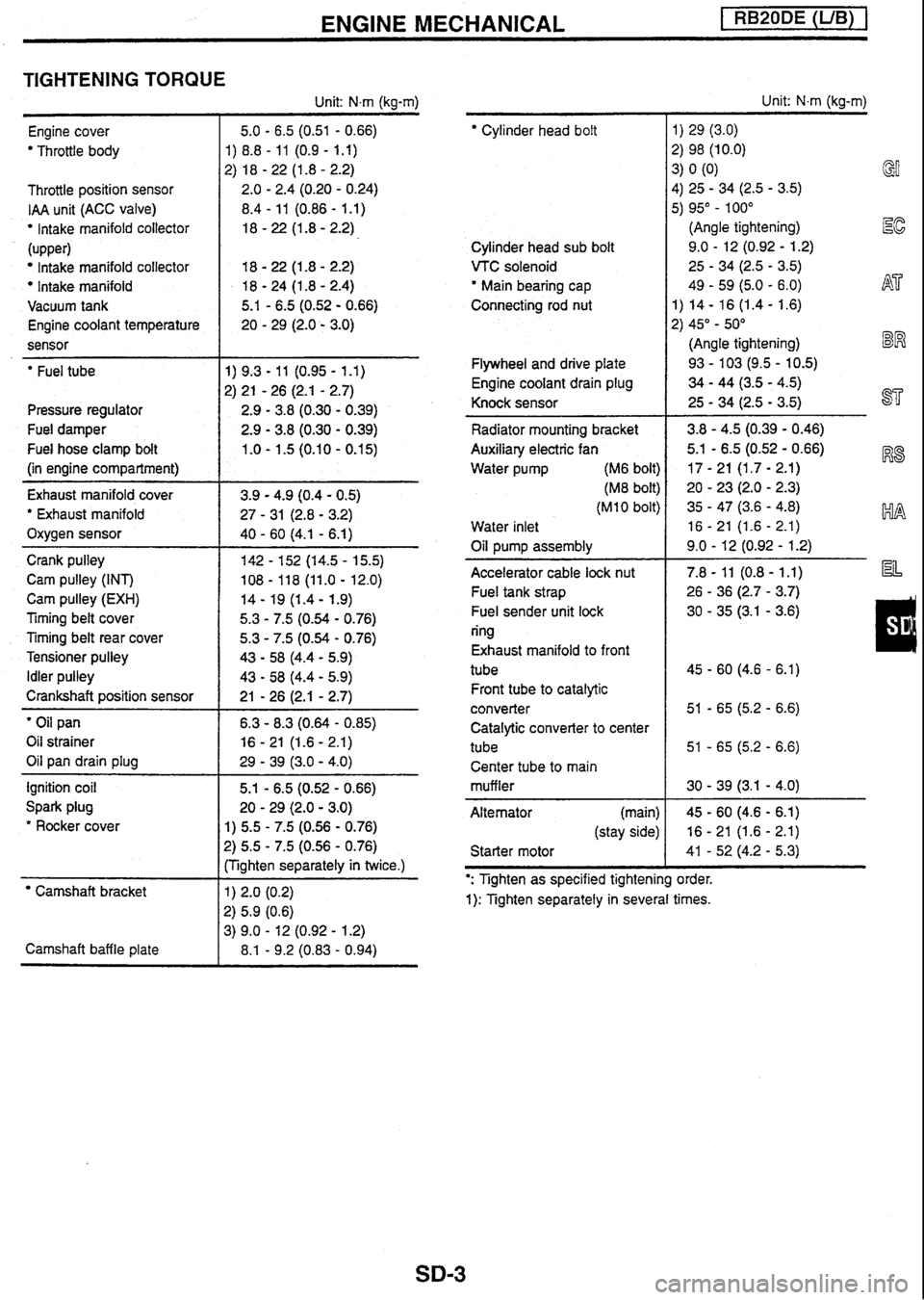

ENGINE MECHANICAL [ RB20DE (UB) 1

TIGHTENING TORQUE

Unit: N.m (kg-m)

Engine cover

Throttle body

Throttle position sensor

IAA unit (ACC valve)

lntake manifold collector

(upper)

Intake manifold collector

Intake manifold

Vacuum tank

Engine coolant temperature

sensor

- --

' Fuel tube

Pressure regulator

Fuel damper

Fuel hose clamp bolt

(in engine compartment)

Exhaust manifold cover

' Exhaust manifold

Oxygen sensor

Crank pulley

Cam pulley (INT)

Cam pulley

(EXH)

Timing belt cover

Timing belt rear cover

Tensioner pulley

Idler pulley

Crankshaft position sensor

' Oil pan

Oil strainer

Oil pan drain plug

ignition coil

Spark plug

* Rocker cover

Camshaft bracket

Camshaft baffle plate 5.1

- 6.5 (0.52 - 0.66)

20

- 29 (2.0 - 3.0)

1) 5.5 - 7.5 (0.56 - 0.76)

?) 5.5 - 7.5 (0.56 - 0.76)

:Tighten separately in twice.)

Cylinder head bolt

Cylinder head sub bolt

VTC solenoid

' Main bearing cap

Connecting rod nut

Flywheel and drive plate

Engine coolant drain plug

Knock sensor

Radiator mounting bracket

Auxiliary electric fan

Water pump (M6 bolt)

(M8 bolt)

(MI 0 bolt)

Water inlet

Oil pump assembly

Accelerator cable

lock nut

Fuel tank strap

Fuel sender unit lock

ring

Exhaust manifold to front

tube Front tube to catalytic

converter Catalytic converter to cent

tube Center tube to main

muffler

Alternator (main)

(stay side)

Starter motor Unit:

N-m (kg-m)

1)

29 (3.0)

2) 98 (10.0)

3)

0

(0)

4) 25

- 34 (2.5 - 3.5) GI

5) 95" - 100"

(Angle tightening)

Ec

9.0 - 12 (0.92 - 1.2)

25

- 34 (2.5 - 3.5)

49

- 59 (5.0 - 6.0) h$7'

1) 14 - 16 (1.4 - 1.6)

2) 45"

- 50"

(Angle tightening)

BW

93 - 103 (9.5 - 10.5)

34 - 44 (3.5 - 4.5)

25

- 34 (2.5 - 3.5) ST

': Tighten as specified tightening order.

1): Tighten separately in several times.

Page 204 of 230

ENGINE MECHANICAL

STANDARD AND REPAIR LIMIT

Firing order

Compression pressure

MPa (kg/cm2)/rpm

-

Intake manifold

Intake manifold collector

--- - Standard Limit

Limit of variation between

cylinders

0.1

0.1

Distortion limit mm

Engine oil capacity

P

Spark plug

Deflection amount of accessory

V-belt Power steering pump

belt

I

- -- - - 1.26 (1 2.8)/300

0.96 (9.8)/300

0.1

(1 .OY300

Measured with tension gauge Exhaust

manifold

Cylinder head

Cylinder block

Without filter

With filter

MakerKype/Spark

plug gap

mrn

I "

650.-50 (N or P position for CVT)

600 (N or P position for AIT)

Less than O.l/Less than 50

15U600

0.36~0.06210.53~0.062

0.31 -.0.04/0.50~0.04

Approx. 65

Approx. 9.4

82 - 95

0.06 - 0.10 (0.6 - 1 .O)

"

Engine idling speed rpm

Idle base speed (during no feed back control)

rpm

Density of

COIHC at idling speed

%/ppm

Ignition timing (during no feed back control)

BTDCO/rpm

I NC compressor err

0.3

0.2

0.1

Approx. 3.8

Approx. 4.2

NGWPFR5G-11/1.0

- 1.1

lanition

advance device

1

Valve clearance (INTIEXH) mm

(kg)

/ Fan belt Electronicallv-controlled

ianition

advance

Hot engine

Cold engine (at ambient temperature)

I power steerina DU~D belt 1 8-10

Fuel tank capacity

Q

Engine

coolant total capacity [with reservoir tank (max. level)] e

Thermostat opening temperature [start to open - full open] OC

Radiator cap opening pressure

MPa (kg/crn2)

,

I Fan belt 1 3-5

Measured

by pushing at 98

N (10 kg)

mm

I SEC.! I7 Power steering I

*I I 1

AK compressor belt 1 6-8

Fan belt pump beit

Used 1 Limit