engine coolant NISSAN GT-R 1998 User Guide

[x] Cancel search | Manufacturer: NISSAN, Model Year: 1998, Model line: GT-R, Model: NISSAN GT-R 1998Pages: 230, PDF Size: 12.66 MB

Page 29 of 230

![NISSAN GT-R 1998 User Guide

TROUBLE DIAGNOSES

CONSULT (Contd)

DATA MONITOR MODE

ECM input

signals

Monitored item

[Unit] Main

signals Remarks

Description

lndicates the engine speed computed

from the POS signal (l NISSAN GT-R 1998 User Guide

TROUBLE DIAGNOSES

CONSULT (Contd)

DATA MONITOR MODE

ECM input

signals

Monitored item

[Unit] Main

signals Remarks

Description

lndicates the engine speed computed

from the POS signal (l](/img/5/57354/w960_57354-28.png)

TROUBLE DIAGNOSES

CONSULT (Cont'd)

DATA MONITOR MODE

ECM input

signals

Monitored item

[Unit] Main

signals Remarks

Description

lndicates the engine speed computed

from the POS signal (lo signal) of the

camshaft position sensor.

When the engine is stopped, a certain

value is indicated.

When the engine coolant temperature

sensor is open or short-circuited, ECM

enters fail-safe mode. The engine coolant

temperature determined by the ECM is

displayed.

The signai voltage of the mass air flow

0 sensor is displayed.

The engine coolant temperature (deter-

mined by the signal voltage of the engine

0 coolant temperature sensor) is displayed.

-

MAS AIRiFL SE [V]

The signal voltage of the oxygen sensor

is displayed.

02

SEN [V]'

0 After turning ON the ignition switch, "RICH" is displayed until air-fuel mixture

ratio feedback control begins.

When the air-fuel ratio feedback is

clamped, the value just before the clamp-

ing is displayed continuously.

MiR

F/C MNT*

[RICH/LEAN] Display of oxygen sensor signal during

air-fuel ratio feedback control:

RICH

... means the mixture became

"rich", and control is being affected

toward a leaner mixture.

LEAN

... means the mixture became

"lean", and control is being affected

toward

a rich mixture.

The vehicle speed computed from the

vehicle speed sensor signal is displayed. VHCL SPEED SE [krn/h] or [mph]

The power supply voltage of ECM is dis-

played. I BATTERY VOLT [V]

THRTL POS SEN [V] The throttle position sensor signal volt-

age is displayed.

Throttle motor sensor output voltage Approx. 4.6V THRTL POS SE2 [V] 0 RB25DET

TURBO BOOST

SENSOR

RB25DET

Turbo pressure sensor output voltage 0 Approx. 2.7V

Indicates [ON/OFF] condition from the After starting the engine, [OFF] is dis-

0 starter signal. played regardless of the starter signal.

lndicates [ON/OFF] condition from the 0 throttle position sensor signal.

-

START SIGNAL

[ON/OFF]

CLSD THUP SW

[0

N/O

FF]

0 lndicates [ON/OFF] condition of the air

conditioner switch as determined by the

air conditioner sianal. AIR COND SIG

[ON/OFF]

lndicates [ON/OFFj condition from the

parldneutral position switch signal.

PiN

POSl SW [ONIOFF)

PW/ST SIGNAL

[ONIOFF]

LOAD SIGNAL

[ON/OFF]

lndicates [ON/OFfl condition from the

electrical load signal

andlor lighting

switch.

ON ... rear defogger is operating.

OFF ... rear defogger is not operating.

NOTE: Any monitored item that does not match the vehicle being diagnosed is deleted from the display automatically. *: Models with three way catalyst.

Page 31 of 230

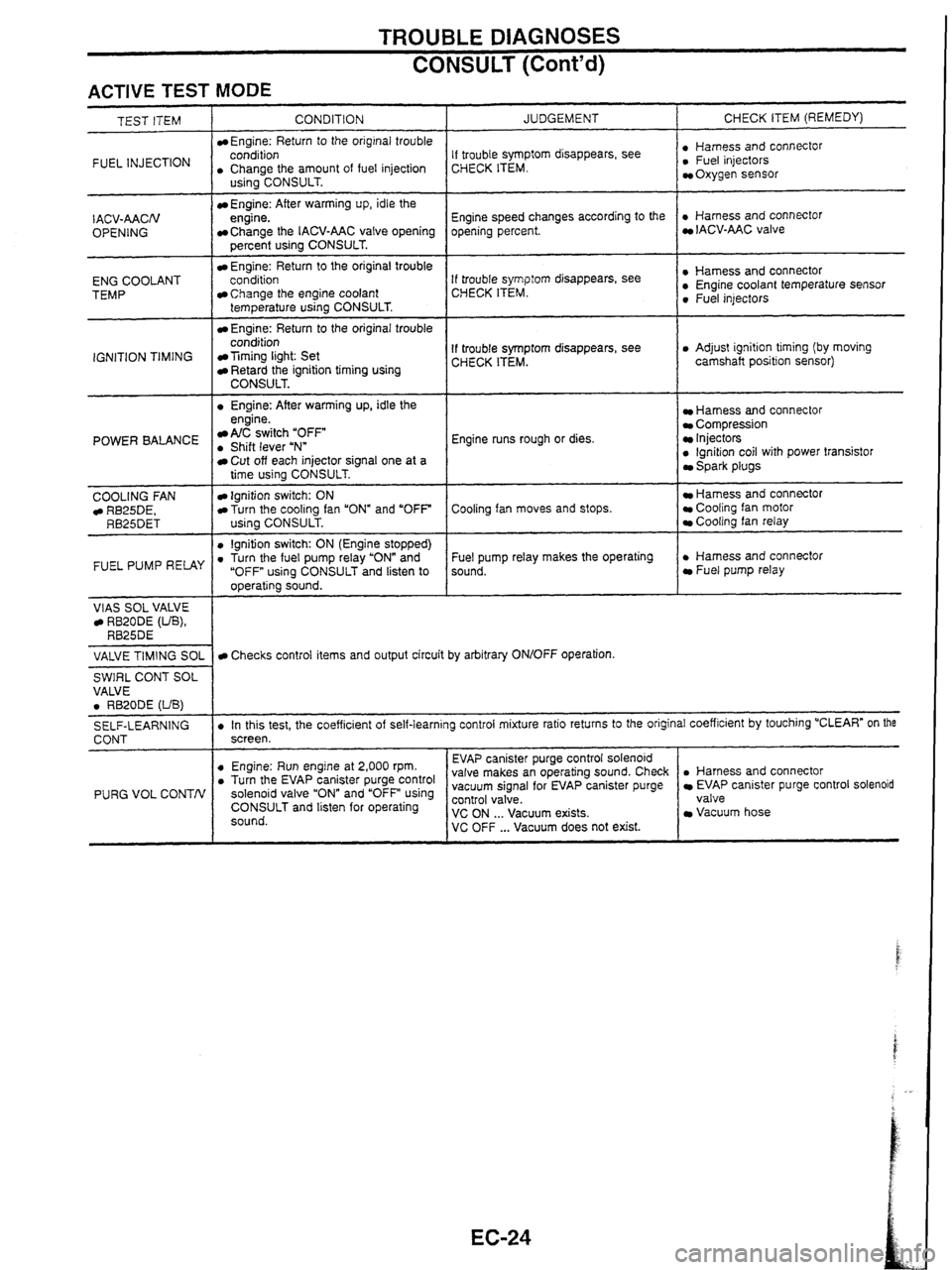

TROUBLE DIAGNOSES

CONSULT (Cont'd)

ACTIVE TEST MODE

INJECTION I . CCohArthe amount of fuel injection

TEST ITEM

CONDITION

Engine: Return

to the original trouble

- I . Engine: After warming up, idle the

IACV-AACN

OPENING

ENG COOLANT

TEMP

IGNITION TIMING

US~~~CONSULT.

Engine: After warming up, idle the

engine.

Change the IACV-AAC valve opening

percent using CONSULT.

Engine: Return to the original trouble

conditioo

Change the engine coolant

temperature using CONSULT.

Engine: Return to the original trouble

condition

Timing light: Set Retard the ignition timing using CONSULT.

POWER BALANCE engine. A/C switch "OFF . Shift lever uNn

COOLING

FAN RB25DE, RB25DET

FUEL PUMP RELAY

VlAS SOL VALVE RB20DE (UB), RB25DE

JUDGEMENT

Cut off each injector signal one at a

time using CONSULT.

Ignition switch: ON Turn the cooling fan "ON" and "OFF

using CONSULT.

0 lgnition switch: ON (Engine stopped) . Turn the fuel pump relay "ON" and

"OFF using CONSULT and listen to

operating sound. CHECK

ITEM (REMEDY)

If trouble symptom disappears, see

CHECK ITEM. : ~,"~~,,,~scOnnectOr Oxygen sensor

Engine speed changes according to the

opening percent.

. Harness and connector IACV-AAC valve

If trouble

symp:orn disappears, see

CHECK ITEM. : Sensor 0 Fuel injectors

If trouble symptom disappears, see

CHECK ITEM. 0 Adjust ignition timing (by moving

camshaft position sensor)

Engine runs rough or dies.

Harness and connector Compression Injectors 0 lgnition coil with power transistor Spark plugs

Cooling fan moves and stops.

Hamess and connector Cooling fan motor Cooling fan relay

Fuel pump relay makes the operating

sound.

. Harness and connector Fuel pump relay

VALVE

TIMING

SOL

SWIRL CONT SOL

VALVE

0 RB20DE (UB)

SELF-LEARNING

CONT

PURG VOL CONTN

Checks control items and output circuit by arbitrary ON/OFF operation.

. In this test, the coefficient of self-learning control mixture ratio returns to the original coefficient by touching "CLEAR" on the

screen.

. Harness and connector EVAP canister purge control solenoid

valve

Vacuum hose

0 Engine: Run engine at 2,000 rpm. . Turn the EV~P canister purge control solenoid valve and using CONSULT and listen for operating

sound. EVAP

canister purge control solenoid

valve makes an operating sound. Check

vacuum signal for EVAP canister purge ~~~~~~a'cuum exists. VC OFF ... Vacuum does not exist.

Page 35 of 230

TROUBLE DIAGNOSES

Symptom Matrix Chart

RELATION BETWEEN CONTROL ITEMS AND SENSORSfACTUATORS

@: High possibility to control damage 0: Low possibility to control damage

Sensors and actuators

1$1$1$ r I I

Crankshaft position sensor 1@1@1@

Ring gear crankshaft position sensor

[RB20DE (UB)] @

Mass air flow sensor

I Engine coolant temperature sensor I 0 I @ I 0 i I

Heated oxygen sensor 0

Knock sensor

Vehicle speed sensor

e? - 01 0

Throttle position sensor 000 C. $ Turbo pressure sensor (TIC) 0 0

Refrigerant pressure sensor

START

lgnition switch

@ 0

IGN 000

Air conditioner switch

Parklneutral position switch

Power steering oil pressure switch

Electrical load switch

Battery

voltage

0

injector @GO I

I power transistor I I I Ignition system I I I lgnition coil I I I I

AAC valve

Fuel DumD relav

. . I I I

2 o ECM & IGN coil relay I@l@l@ 1 I I % Auxiliary electric fan relay 3 - 2 Air conditioner relay

Canister purge control valve

0

Variable valve timing control solenoid valve

Variable air intake control solenoid valve

, (NA) Air jet swirl control solenoid valve

[RB20DE (UB)] 0

Turbo pressure control solenoid valve

(TW

FPCM (TIC)

%' Dropping resistor (TIC) 2. I I 5 Air regulator

Canister 0

Page 36 of 230

TROUBLE DIAGNOSES

Symptom Matrix Chart (Cont'd)

-RELATION BETWEEN TROUBLE SYMPTOMS AND SENSORS

-. - Sensors No I Hard

start start Rough

idle

Poor derivability Engine

stall

Symptom

@: High possibility 0: Low possibility

Crankshaft position

sensor (POS,

REF) Instantaneous

xeak

Ring gear crankshaft

position sensor

[RB20DE

(UB)]

s 1 Signal iigh output

,ow output

"

2 Power supply

Engine coolant tem-

perature sensor

iigh resistance

-ow resistance

- -- Heated oxygen sen-

sor

Knock sensor

iigh output

.ow output

Ipedshort

Vehicle s~eed sensor

Throttle position sen-

sor Jnstable output

'oar adjustment

Turbo pressure sen-

sor

(TIC)

Refrigerant pressure

sensor

Ignition switch (IGN)

k$n;pRnT)sw

i tch

Air conditioner switch

ParWneutral position

switch

Power steering oil

pressure switch

Electrical load switch

Multiplex communica-

tion line

Control unit power

supply

Sensor ground

Control unif and con-

nector

*: Fast idle

'oor contact

Vater intrusion

Page 37 of 230

TROUBLE DIAGNOSES

Symptom Matrix Chart (Cont'd)

Sensor-related problems I Symptom characteristics and ins~ection hints

Open Engine

will not start when either REF signal circuit or POS signal circuit is open.

Neither fuel system nor ignition system outputs control signals.

Crankshaft position sensor

(POS, REF) Instanta-

neous break Symptoms

vary with the break time and the vehicle's driving conditions. Light

shock or surging will occur while the vehicle is being driven, and the engine will

stall at idle speed.

Ring gear crankshaft position

sensor

[RB20DE

(UB)]

Signal

Mass air flow sensor Open

Open

High output

Low output I Aidfuel

ratio becomes lean. Dirty hot wire or air entering the system could be the

cause. No

airfluel ratio compensation

is carried out during lean bum status. Drivability

may be affected.

Enters fail-safe mode. Driving under

2,400 rpm is allowed.

Airlfuel

ratio becomes rich. Black smoke may be noted. Poor contact at the

ground could be the cause.

Engine coolant temperature sen-

sor Open

Open

Opedshort

High resis-

tance

Low resis-

tance

Opedshort

Heated oxygen sensor

I

Airlfuel ratio becomes over-rich.

Same symptom as when signal wire is open.

Enters fail-safe mode. Malfunction indicator lamp comes ON. Ordinary driving is

allowed. Problems tend to occur when engine is cold or engine coolant tempera-

ture

is high.

Detects low engine coolant temperature. Problems tend to occur after engine

warm-up.

Detects high engine coolant temperature. Problems tend to occur when engine is

cold.

Base

aidfuel ratio is used.

lgnition timing is retarded within the knock control range. Lack of power may be

OpedShort

I noted.

Knock sensor lgnition

timing is retarded within the knock control range. Lack of power may be

High

Output

(noted.

Low output

1 lgnition timing may not be retarded when knock is detected.

Vehicle speed sensor

Throttle position sensor

Opedshort

Opedshort

Unstable out-

put

Poor adjust-

ment

Open

Turbo pressure sensor

(TE) Fuel

cut time becomes-shorter, or no fuel cut is observed.

Base idle speed is used. Fuel injection is not increased during acceleration.

AIT shift point changes for AfF vehicles.

Unnecessary cut-in fuel injection could be the cause. Poor contact at the ground

or control unit could be the cause.

ldle judgment is "OFF while idling. Condition returns

normal by turning the igni-

tion switch ON and OFF repeatedly.

Turbo pressure is judged zero. No remarkable malfunction will be detected.

Refrigerant pressure is judged high. ldle speed remains high while the air condi-

tioner is ON.

Refrigerant pressure sensor

Short Refrigerant pressure

is judged low. ldle speed remains low while the air condi-

tioner is ON.

lgnition switch (IGN)

lgnition switch (START)

Air conditioner switch Open

Engine

will not start because neither fuel system nor ignition system outputs con-

trol signals.

Engine starts in normal condition. Engine may not start when temperature is

extremefy

low.

Air conditioner will not operate. No other malfunction will be noted.

Park/neutral

position switch is judged "OFF. Target engine speed for cold engine

in

N or P position is reduced.

ParWneutral position switch is judged

"0N"I Fast Jdle is effective when the engine

is cold and the gear is in other than N and P posrtlons. Vehrcle excessrvely

creeps.

Open

Open

Parklneutral

position

switch

Short

Power steering oil pressure

switch Open

Engine may

stall when the steering wheel is turned while the vehicle is standstill

and the accelerator pedal is lightly pressed, or when the steering wheel is turned

Electrical load switch Short

Open

Open/short

Multiplex communication line

- -- during deceleration. '

Power steering switch is judged 'ON." Value will be compensated constantly.

Idle speed drops so that the engine can stall when electrical load is applied.

Torque reduction control is not performed. Therefore,

shift shock becomes

greater.

- -- -- -- -- Engine will not start because neither fuel system nor ignition system outputs con-

trol signals.

Open

Control unit power supply

- -- - - --- - - - - - O~edshort I Same symptoms as when sensor harness is open.

Sensor ground -- - Poor contact

Water intru-

sion - -- - - - - - -- -- In case of poor contact, the connector fitting may be loose. In case of water

intrusion, the engine stalls and become inoperative for a while. The engine may restart soon in some cases.

Control unit

and connector

Page 50 of 230

TROUBLE DIAGNOS

ECM (.TCM) lnpu

:s

3utput Signal Reference

Value (Cont'd)

.. No.

Fluctuates between approx. 0.1 to

0.4V and approx.

0.7 to

0.9V At

idle

- I I - I I -

I

I

- are measured

At approx. 2,000 rpm

:v: i .5 I .O 0.5 0

ECL 1 8645 11jllllllll ECL 1 8630

Throttle motor sensor

signal

[RB25DET'J Approx. 3.4V

I (Voltage becomes lower when TCS operates.)

Motor throttle switch

signal

[RB25DET]

Approx.

4.7V

Mass air flow sensor

signal

t

(When TCS is operating: Approx. OV)

Ignition switch ON: Approx.

0.2V

At idle: Approx.

1

.I - 1.2V Approx.

1.6 - 1.7V

Mass air flow sensor

ground Approx.

OV

I

Coolant temperature approx. 20°C: Approx. 3.5V

Coolant temperature approx.

80°C: Approx. 1.2V

Approx. 0.36V min.

(Voltage increases as the air conditioner refrigerant

pressure increases.)

Approx. 0.4

- 2V (') ': Voltage varies with measuring range (internal resis-

tame) of a circuit tester.

Battery voltage

C

+

+

+

56

-

62 1 Knock sensor signal 1

Engine coolant tem-

perature sensor signal

57

- -- -

63 1 Knock sensor signal 2

Refrigerant pressure

sensor

67 Control unit power

sup-

72

I PIY Receive (Data input to

control unit) 1

Transmit (Data output

from control unit) CONSULT

connected: Approx. 0.25V

CONSULT

not connected: Battery voltage

CONSULT connected: Approx.

9V max. CONSULT not connected: Approx. OV

C

Fan stopped: Battery voltage

Fan operating: Approx. 0.2 - 0.3V 78

NOTE: Above

Auxiliary electric fan

relay control signal

[RB25DE, RB25Dm

voltages values obtained

analog circuit

tester.

Page 51 of 230

TROUBLE DIAGNOSES

ECM (-TCM) Input/Output Signal Reference

Terminal No.

108

- NOTE:

Signal name

CM.TCM, TCS/ABS

tegrated control signal

dultiplex communica-

&DE.m,

B25DETj

attery power supply

ijector drive signal

3attery voltage When cranking: Approx.

10.5V

Value (Cont'd)

(v) 50 40 30 20 10

0

At idle: &Wry voltage

A:

idle

Approx. 2V

rariable

air intake con-

:ol solenoid valve con- switch ON: Battery voltage (Solenoid valve

rot signal

RB20DE (UB), At idle: Approx. 0.2

- 0.3V (Solenoid valve ON) At

approx. 2,000

rpm

t

3B25DEI ' .

-urbo pressure control iO1enOid valve Battery voltage (Solenoid valve OFF)

iianal

4ir jet swirl sole- Coolant temperature below approx. 70°C: Approx.

0.9V (Solenoid valve ON)

'Oid Coolant temperature approx. 70°C and above: Battery

RB20DE (VB)] voltage (Solenold valve OFF)

[RB20DE (UB), RB25DEl

Air conditioner OFF: Battery voltage

Air conditioner ON: Battery voltage Approx.

10V

(After approx.

15 sec.)

Zanister

purge control

~alve

control signal

M 30 20 10 0

(Waveform indicates when air conditioner is

ON.)

[RB20DETJ

Air conditioner OFF: Battery voltage

Air conditioner ON: Battery voltage

4 Approx. 1OV

(After approx. 15 sec.) Slightly lower than battery voltage

t At

approx. 3,650 rpm and above [RB2ODE (UB)]

At approx. 3,500 rpm and above [RB25Dq : Battery voltage (Solenotd valve OFF)

t [When engine raced suddenly: Approx. 0.3V (Solenoid

valve ON)]

t Coolant temperature approx. 70°C and above, and

driving at approx. 3,300 rpm and above [MTT] Coolant temperature approx. 70°C and above, and

driving at approx. 3,000 rpm and above [A/T1 : Approx. 0.9V (Solenoid valve ON)

Approx.

9V

Approx. 9V

I (Waveform indicates when air conditioner is ON.)

tester.

Page 163 of 230

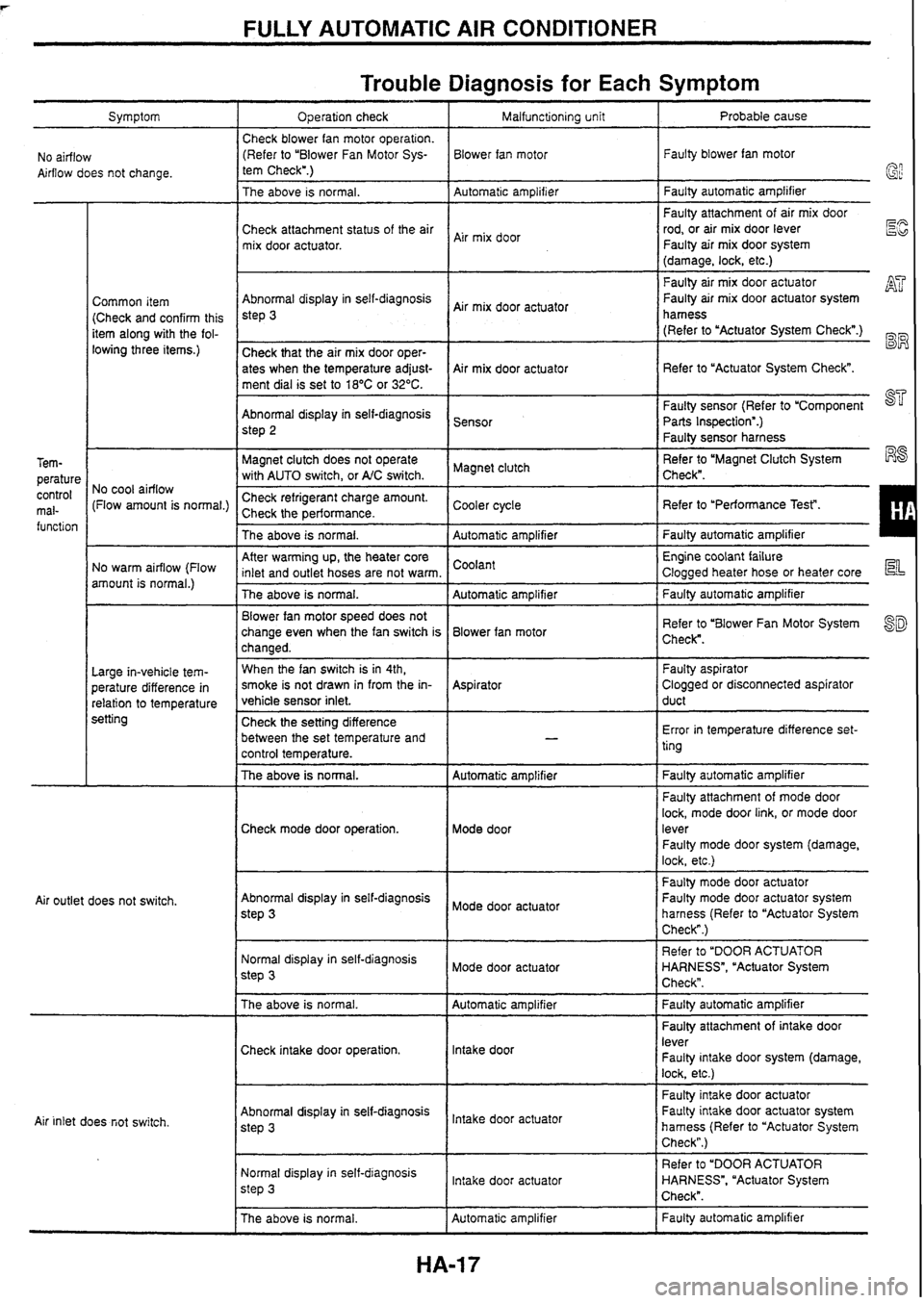

FULLY AUTOMATIC AIR CONDITIONER

Symptom

Trouble Diagnosis for Each Symptom

No airflow

Airflow does not change. Operation check

Check blower fan motor operation. (Refer to "Blower Fan Motor Sys-

tem Check".)

The above is normal.

I Automatic amolifier 1 Faultv automatic amplifier

Faulty attachment of air mix door

rod, or air mix door lever

Faulty air mix door system

ElG

(damage, lock, etc.)

Malfunctioning unit

Blower fan motor Probable cause

Faulty blower fan motor

Check attachment status of the air

mix door actuator.

Common item (Check and confirm this

item along with the fol-

lowing three items.)

Air mix door

Abnormal display in self-diagnosis

step

3

Check that the air mix door oper-

ates when the temperature

adjust-

ment dial is set to

18OC or 32°C.

Faulty sensor (Refer to 'Component a

Parts Inspection".)

Faulty sensor harness

Air

mix door actuator

Air mix door actuator

Abnormal display in self-diagnosis

step 2

Magnet clutch does not operate

Magnet clutch Refer

to 'Magnet Clutch System R8

with AUTO switch, or A/C switch. Check".

I Faulty

air mix door actuator

Faulty air mix door actuator system AT

hamess

(Refer to "Actuator System Check".)

BW

Refer to "Actuator System Check".

@'i?

Sensor

Tem- perature

control mal-

function No

cool airflow

(Flow amount is normal.)

ngeranr

cnarge

amounr.

( Cooler cycle 2 ~erformance. I Refer to 'Performance Test". I

The above is normal. I Automatic amolifier 1 Faulty automatic amplifier I

After warming up, the heater core

inlet and outlet hoses are not warm. 1 Coolant I

Engine coolant failure

Clogged heater hose or heater core

No warm airflow

(Flow

amount is normal.)

The above is normal. Automatic amplifier

1 Faulty automatic amplifier

Blower fan motor speed does not

change even when the fan switch is Blower fan motor

changed. Refer

to "Blower Fan Motor System

Check".

I

When the fan switch is in 4th, Faulty aspirator

smoke is not drawn in from the

in-

Aspirator Clogged

or disconnected aspirator

vehicle sensor inlet. duct

Large

in-vehicle tem-

perature difference in

relation to temperature

setting Check the setting difference

between the set temperature and

control temperature. Error

in temperature difference set-

ting

- The above isnormal.- Automatic amplifier Faulty automatic amplifier

Faulty attachment of mode door

lock, mode door link, or mode door

Check mode door operation. Mode door lever

Faulty mode door system (damage,

lock, etc.)

Faulty mode door actuator

Abnormal display in self-diagnosis Faulty mode door actuator system

step

3 Mode door actuator

harness (Refer to "Actuator System

Check".)

Air

outlet does not switch.

Normal display in self-diagnosis

Mode door actuator

step

3

Refer to "DOOR ACTUATOR

HARNESS", "Actuator System

Check".

The above is normal.

I Automatic amplifier I Faulty automatic amplifier - - I I Faulty attachment of intake door

Check intake door operation. lntake

door lever

Faulty intake door system (damage,

lock, etc.)

~aulG intake door actuator

Faulty intake door actuator system

hamess (Refer to "Actuator System

Check".)

Abnormal

display in self-diagnosis

door step 3 Air inlet does fiot switch.

Normal display in self-diagnosis

lntake door actuator

step

3

Refer to "DOOR ACTUATOR

HARNESS", "Actuator System

Check".

I I The above is normal. I Automatic amplifier I Faulty automatic amplifier

Page 202 of 230

![NISSAN GT-R 1998 User Guide

ENGINE MECHANICAL I RB~ODE (UB) ]

STANDARD AND REPAIR LIMIT

Firing order I 1-5-3-6-2-4

Compression pressure

MPa

(kg/cm2)/rpm

Distortion limit mm

- - -- --- - Ignition advance device

Electr NISSAN GT-R 1998 User Guide

ENGINE MECHANICAL I RB~ODE (UB) ]

STANDARD AND REPAIR LIMIT

Firing order I 1-5-3-6-2-4

Compression pressure

MPa

(kg/cm2)/rpm

Distortion limit mm

- - -- --- - Ignition advance device

Electr](/img/5/57354/w960_57354-201.png)

ENGINE MECHANICAL I RB~ODE (UB) ]

STANDARD AND REPAIR LIMIT

Firing order I 1-5-3-6-2-4

Compression pressure

MPa

(kg/cm2)/rpm

Distortion limit mm

- - -- --- - Ignition advance device

Electronically-controlled ignition advance

Engine

oil capacity

e

Spark plug standard

Limit

. Limit

of variation between cylinders

Intake manifold

Intake manifold collector

Exhaust manifold

Cylinder head

Cvlinder block

lgnition timing (during no feed back control) 1.23

(1 2%)/300

0.93 (9.5)1300

0.1 (1.0)/300

0.1 0.1

0.3

0.2

0.1

Without filter

With filter

MakerlTypeISpark

plug gap mm

Engine idling speed

W'

Idle base speed (during no feed back control)

rPm

Density of

COIHC at idling speed

Wppm Approx.

3.8

Approx. 4.2

NG WPFR5G-11 11.0

- 1

-1

650-.50

(N or P position for

A/T)

600 (N or P position for AlT)

Less than O.l/Less than 50

I New I Used I Limit

Valve

clearance

(INTIEXH)

mm

Deflection

amount of accessory V-belt

Measured with tension gauge

N (kg) Hot

engine

.

Cold engine (at ambient temperature)

Measured by pushing at 98 N (10 kg)

mm 0.36+0.062/0.53+0.062

0.31 1~,0.04/0.50i0.04

Fuel tank capacity

e

Engine coolant total capacity [with reservoir tank (max. level)] e

Thermostat opening temperature [start to open - full open]

"C

Radiator cap opening pressure

MPa (kg/cm2) Approx.

65

Approx. 9.4 82 - 95

0.06

- 0.1 0 (0.6 - 1 .O)

A/C compressor belt

Power

steering pump belt

Fan belt

Power steering pump belt

1 8-10 1 10-12 1 16

667

- 755

(68

- 77)

A/C compressor belt 1 6-8 1 7-9 / 12

Fan belt

1 3-5 1 4-6 1 7.5

559 - 637

(57

- 65)

SEC.117 Power steering

Fan belt pump be1 t

284 (29)

Page 203 of 230

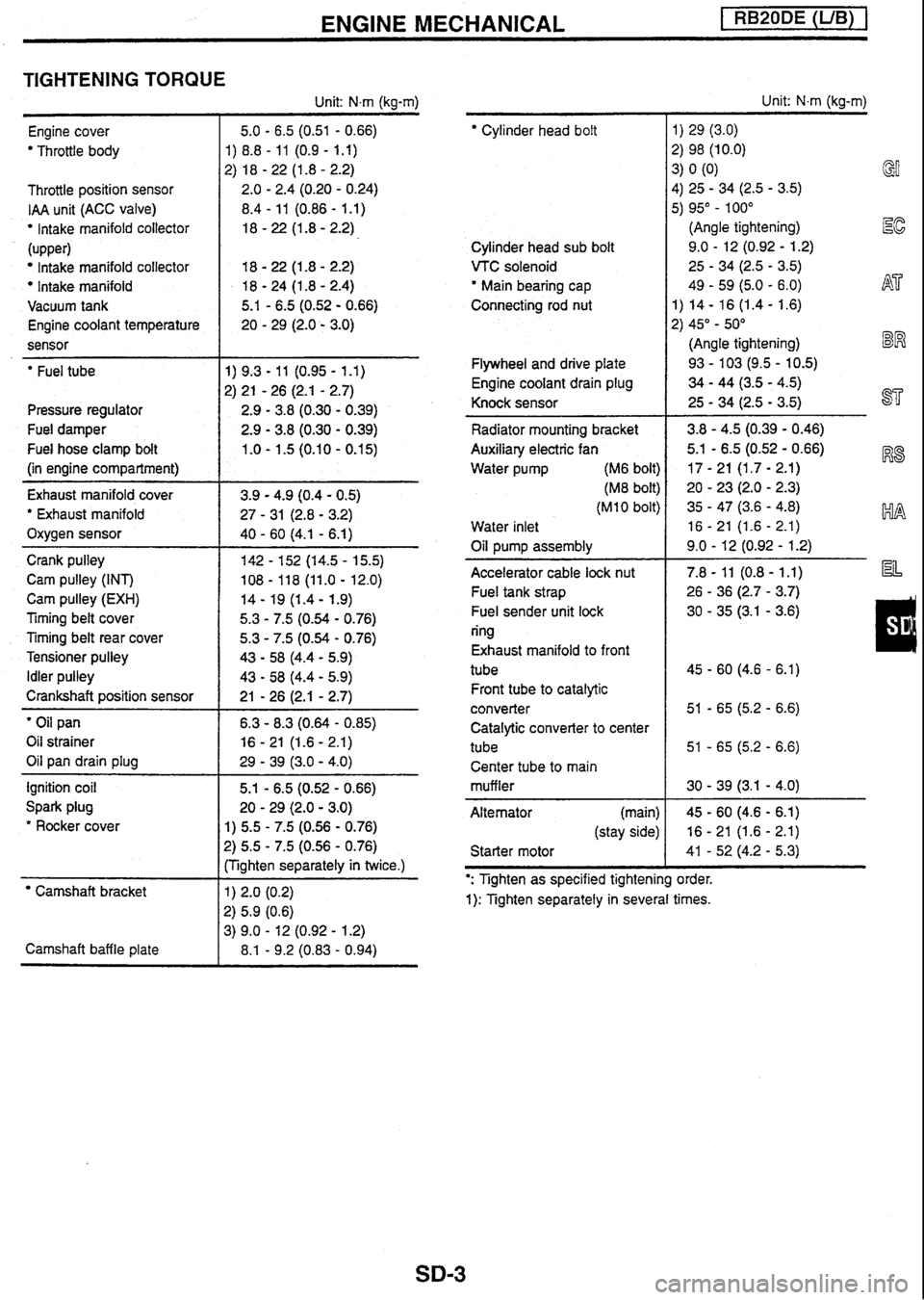

ENGINE MECHANICAL [ RB20DE (UB) 1

TIGHTENING TORQUE

Unit: N.m (kg-m)

Engine cover

Throttle body

Throttle position sensor

IAA unit (ACC valve)

lntake manifold collector

(upper)

Intake manifold collector

Intake manifold

Vacuum tank

Engine coolant temperature

sensor

- --

' Fuel tube

Pressure regulator

Fuel damper

Fuel hose clamp bolt

(in engine compartment)

Exhaust manifold cover

' Exhaust manifold

Oxygen sensor

Crank pulley

Cam pulley (INT)

Cam pulley

(EXH)

Timing belt cover

Timing belt rear cover

Tensioner pulley

Idler pulley

Crankshaft position sensor

' Oil pan

Oil strainer

Oil pan drain plug

ignition coil

Spark plug

* Rocker cover

Camshaft bracket

Camshaft baffle plate 5.1

- 6.5 (0.52 - 0.66)

20

- 29 (2.0 - 3.0)

1) 5.5 - 7.5 (0.56 - 0.76)

?) 5.5 - 7.5 (0.56 - 0.76)

:Tighten separately in twice.)

Cylinder head bolt

Cylinder head sub bolt

VTC solenoid

' Main bearing cap

Connecting rod nut

Flywheel and drive plate

Engine coolant drain plug

Knock sensor

Radiator mounting bracket

Auxiliary electric fan

Water pump (M6 bolt)

(M8 bolt)

(MI 0 bolt)

Water inlet

Oil pump assembly

Accelerator cable

lock nut

Fuel tank strap

Fuel sender unit lock

ring

Exhaust manifold to front

tube Front tube to catalytic

converter Catalytic converter to cent

tube Center tube to main

muffler

Alternator (main)

(stay side)

Starter motor Unit:

N-m (kg-m)

1)

29 (3.0)

2) 98 (10.0)

3)

0

(0)

4) 25

- 34 (2.5 - 3.5) GI

5) 95" - 100"

(Angle tightening)

Ec

9.0 - 12 (0.92 - 1.2)

25

- 34 (2.5 - 3.5)

49

- 59 (5.0 - 6.0) h$7'

1) 14 - 16 (1.4 - 1.6)

2) 45"

- 50"

(Angle tightening)

BW

93 - 103 (9.5 - 10.5)

34 - 44 (3.5 - 4.5)

25

- 34 (2.5 - 3.5) ST

': Tighten as specified tightening order.

1): Tighten separately in several times.