ECO mode NISSAN GT-R 1998 Service Manual

[x] Cancel search | Manufacturer: NISSAN, Model Year: 1998, Model line: GT-R, Model: NISSAN GT-R 1998Pages: 230, PDF Size: 12.66 MB

Page 2 of 230

NISSAN

MODEL R34 SERIES

FOREWORD

This Sewice Manual contains infor-

mation concerning necessary ser-

vice procedures and relevant data

for the model

R34 series.

All information, illustrations and

specifications contained in this Ser-

vice Manual are based on the latest

product information available at the

time of publication. If your NISSAN

model differs from the specifications

contained in this

Sewice Manual,

consult your NISSAN distributor for

information.

The right is resewed to make

changes in specifications and meth-

ods at any time without notice.

QUICK REFERENCE INDEX I

0 1998 KISSAN MOTOR CO., LTD. Printed in Japan

A11 rights reserved. No part of this Service Manual may be reproduced or stored in a retrieval system, or transmitted in any form, or by any means, electronic, mechanical, photocopying, recording or otherwise, without the prior written permission of Nissan Motor Company Ltd.. Tokyo, Japan.

Page 5 of 230

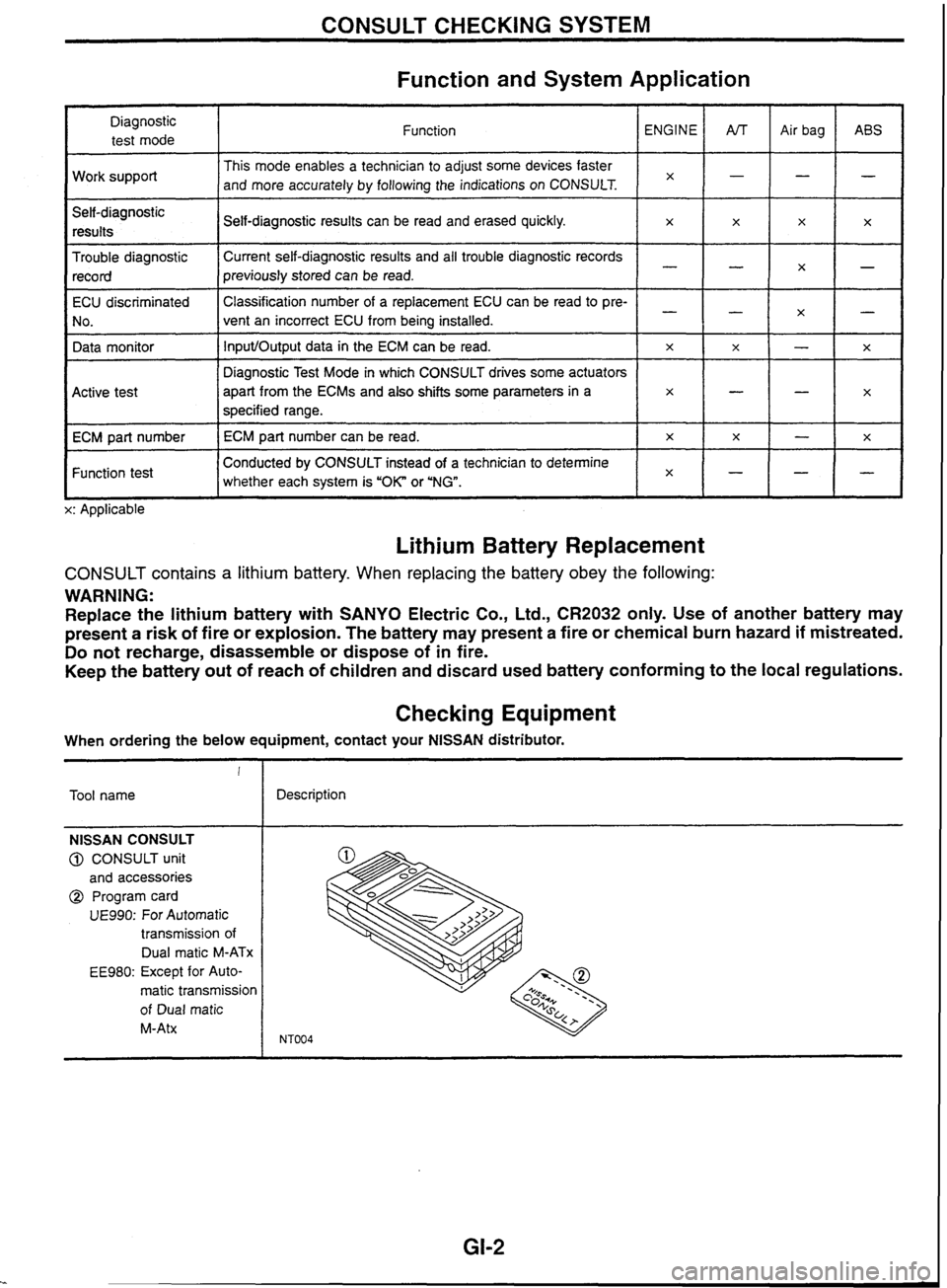

CONSULT CHECKING SYSTEM

Function and System Application

Diagnostic test mode

Work support

Self-diagnostic results

Trouble diagnostic record Function

This mode enables a technician to adjust some devices faster

and more accurately by following the indications on CONSULT.

ECU discriminated

No.

Data monitor

I I whether each system is "OK" or 'NG". lxH-1-

Conducted by CONSULT instead of a technician to determine

Function test Self-diagnostic

results can be read and erased quickly.

Current self-diagnostic results and all trouble diagnostic records

previously stored can be read.

Active test

ECM part number

L x: Applicable ENGINE

x

Classification

number of a replacement ECU can be read to pre-

vent an incorrect ECU from being installed.

InputIOutput data in the ECM can be read.

Lithium Battery Replacement

x

Diagnostic Test Mode in which CONSULT drives some actuators

apart from the

ECMs and also shifts some parameters

in a

specified range.

ECM part number can be read.

CONSULT contains a lithium battery. When replacing the battery obey the following:

WARNING:

Replace the lithium battery with SANYO Electric Co., Ltd.,

CR2032 only. Use of another battery may

present

a risk of fire or explosion. The battery may present a fire or chemical burn hazard if mistreated.

Do not recharge, disassemble or dispose of in fire.

Keep the battery out of reach of children and discard used battery conforming to the local regulations.

AfT

-

-

x

Checking Equipment

x

-

x

x

When ordering the below equipment, contact your NlSSAN distributor. Air

bag

-

-

-

x

!

Tool name ABS

-

x

X

-

x

NISSAN CONSULT

@ CONSULT unit

and accessories

@ Program card

UE990: For Automatic

transmission of

Dual

rnatic M-ATx

EE980: Except for Auto-

matic transmission

of Dual

matic

M-Atx

x

-

--

X

-

Description

-

x

-

-

x

x

Page 23 of 230

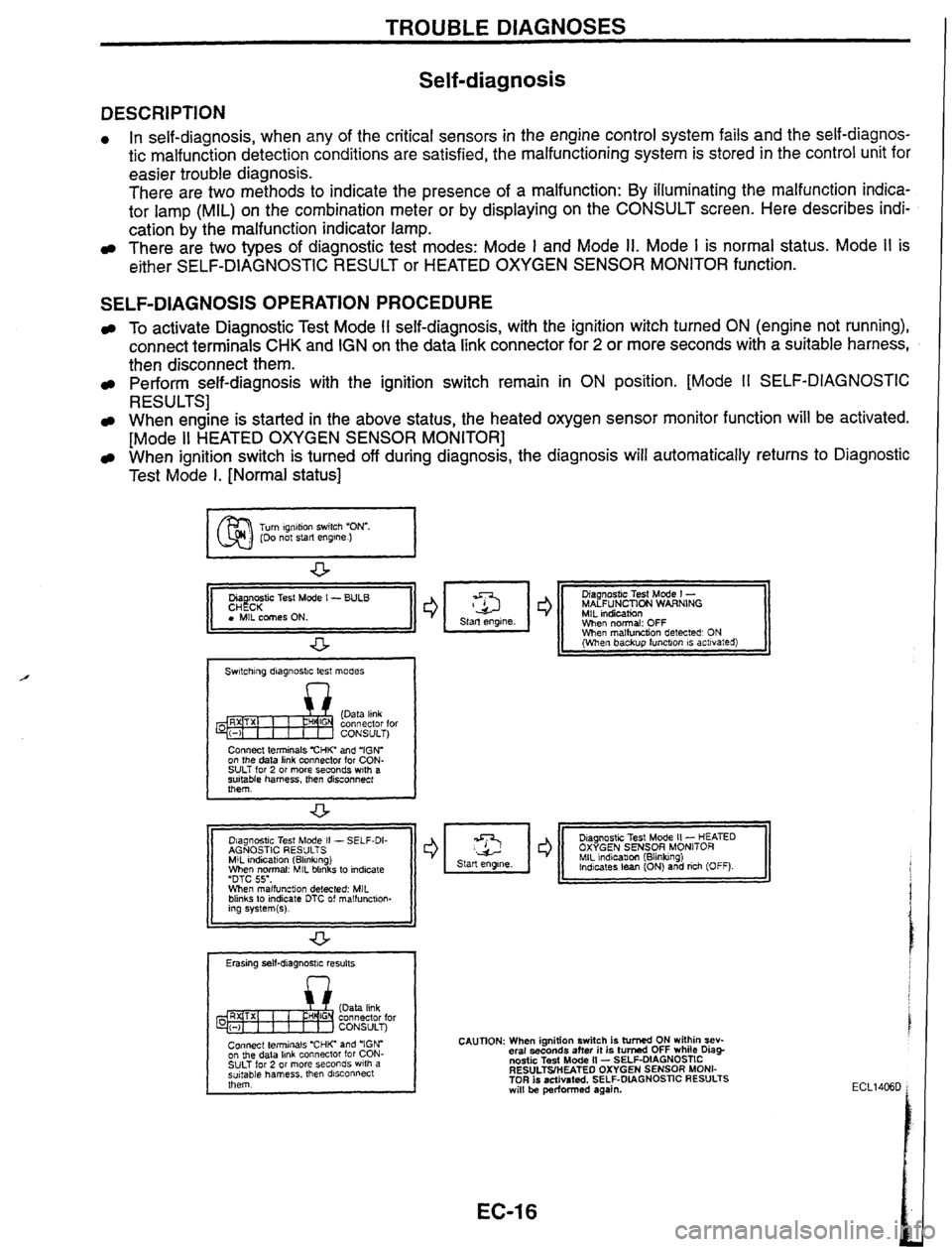

Self-diagnosis

DESCRIPTION

In self-diagnosis, when any of the critical sensors in the engine control system fails and the self-diagnos-

tic malfunction detection conditions are satisfied, the malfunctioning system is stored in the control unit for

easier trouble diagnosis.

There are two methods to indicate the presence of a malfunction: By illuminating the malfunction indica-

tor lamp (MIL) on the combination meter or by displaying on the CONSULT screen. Here describes indi-

cation by the malfunction indicator lamp.

There are two types of diagnostic test modes: Mode I and Mode 11. Mode I is normal status. Mode I1 is

either SELF-DIAGNOSTIC RESULT or

HEATED OXYGEN SENSOR MONITOR function.

SELF-DIAGNOSIS OPERATION PROCEDURE

To activate Diagnostic Test Mode I1 self-diagnosis, with the ignition witch turned ON (engine not running),

connect terminals CHK and IGN on the data link connector for

2 or more seconds with a suitable harness,

then disconnect them.

Perform self-diagnosis with the ignition switch remain in ON position. [Mode I1 SELF-DIAGNOSTIC

RESULTS]

When engine is started in the above status, the heated oxygen sensor monitor function will be activated.

[Mode

II HEATED OXYGEN SENSOR MONITOR]

When ignition switch is turned off during diagnosis, the diagnosis will automatically returns to Diagnostic

Test Mode

I. [Normal status]

I 1 r I, rest Mode I - I I I r II MAL~UNLMNI WARNlNfi +

Switching diagnostic test modes

n

Connect terminals "CHIC and 'IGN'

on the data link connector for CON-

SULT for

2 or more seconds w~th a

suitable harness, then disconnect

them.

Diagnostic Test Mode

II

- SELF-DI- Diagnostic

Test Mode I1 - HEATED AGNOSTIC RESULTS OXYGEN SENSOR MONITOR

MIL indication (Blinkmg) MIL indicabon (Blinking)

When normal: MIL blinks to indicate Indicates

lean (ON) and rich

(OFF).

'DTC 55'. When malfunction detected: MIL

blinks to indicate DTC of

malfunction-

11 ing systern(s). I I

Erasing self-diagnostic results

Connect Leyinals

'CHIC and 'IGN"

on

the

data

hnk

connector for CON-

SULT for

2 or more seconds with a

suitable harness. then

dsconnect

them.

CAUTION: When ignition switch is turned ON within sev-

eral seconds after it is

turned OFF wh~le Diag-

nostic Test Mode II - SELF-DIAGNOSTIC

RESULTSIHEATEO

OXYGEN SENSOR MONI-

TOR

is activated, SELF-DIAGNOSTIC RESULTS will be performed again.

Page 24 of 230

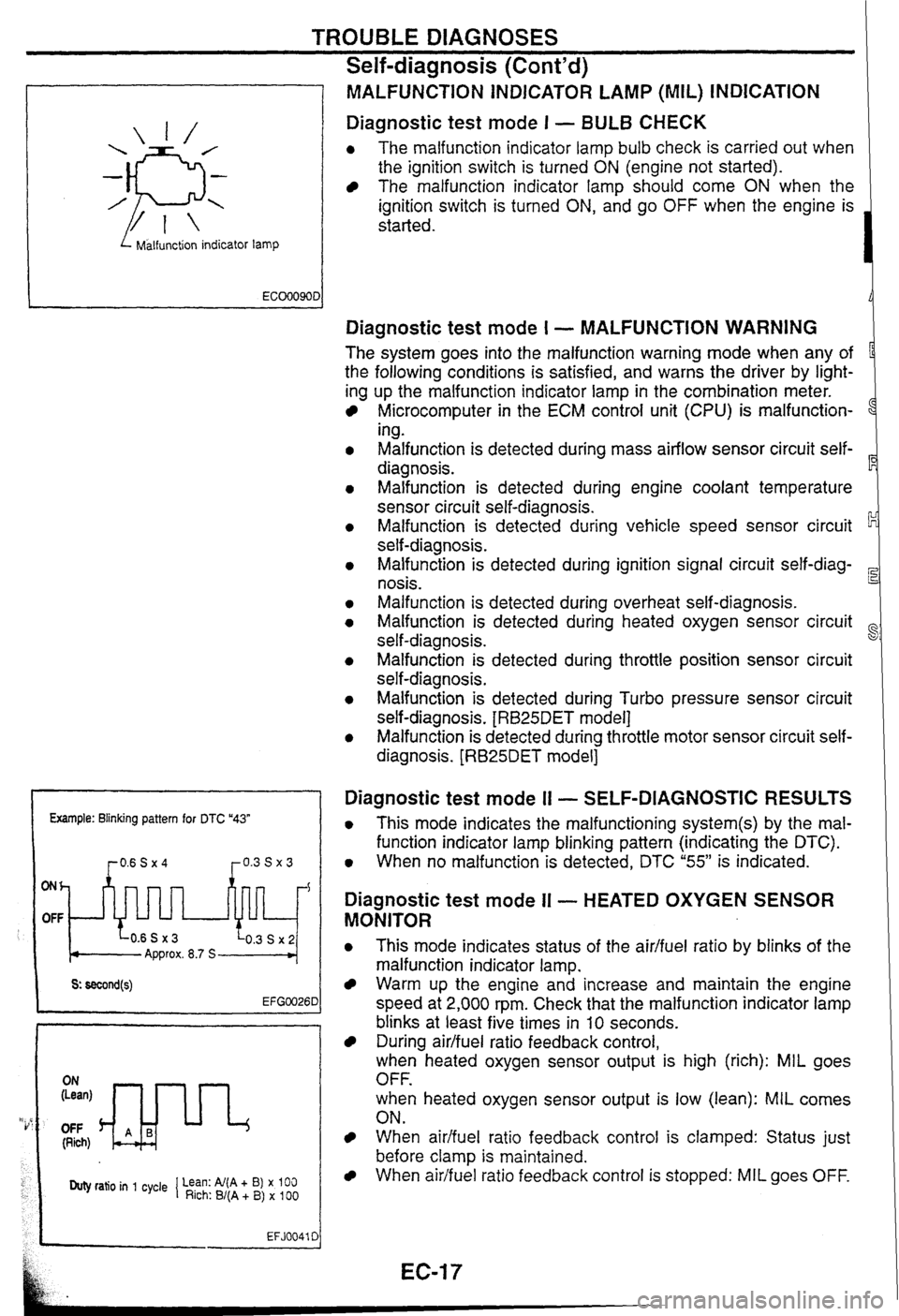

TROUBLE DIAGNOSES

Self-diagnosis (Cont'd)

I Malfunction indicator lamp

MALFUNCTiON INDICATOR LAMP (MIL) INDICATION

Diagnostic test mode I - BULB CHECK

0 The malfunction indicator lamp bulb check is carried out when

the ignition switch is turned

ON (engine not started).

The malfunction indicator lamp should come ON when the

ignition switch is turned

ON, and go OFF when the engine is

started.

Example: Blinking pattern for DTC "43"

ONh

OFF

Approx. 8.7 S

OFF (Rich)

Duty ratio in 1 cycle 1 Lean: Al(A + B) x 100 Rich: B/(A + B) x 100

EFJ0041 C

Diagnostic test mode I - MALFUNCTION WARNING

The system goes into the malfunction warning mode when any of

the following conditions is satisfied, and warns the driver by light-

ing up the malfunction indicator lamp in the combination meter.

Microcomputer in the ECM control unit (CPU) is malfunction-

1

ing.

Malfunction is detected during mass airflow sensor circuit self-

diagnosis.

Malfunction is detected during engine coolant temperature

sensor circuit self-diagnosis.

Malfunction is detected during vehicle speed sensor circuit

self-diagnosis.

Malfunction is detected during ignition signal circuit

self-diag-

nosis.

Malfunction is detected during overheat self-diagnosis.

Malfunction is detected during heated oxygen sensor circuit

self-diagnosis.

~alfunsion is detected during throttle position sensor circuit

self-diagnosis.

Malfunction is detected during Turbo pressure sensor circuit

self-diagnosis.

[RB25DET model]

Malfunction is detected during throttle motor sensor circuit self-

diagnosis.

[RB25DET model]

Diagnostic test mode I1 - SELF-DIAGNOSTIC RESULTS

0 This mode indicates the malfunctioning system(s) by the mal-

function indicator lamp blinking pattern (indicating the DTC).

0 When no malfunction is detected, DTC "55" is indicated.

Diagnostic test mode II - HEATED OXYGEN SENSOR

MONITOR

0 This mode indicates status of the aidfuel ratio by blinks of the

malfunction indicator lamp.

Warm up the engine and increase and maintain the engine

speed at 2,000 rpm. Check that the malfunction indicator lamp

blinks at least five times in

10 seconds.

During airlfuel ratio feedback control,

when heated oxygen sensor output is high (rich): MIL goes

OFF.

when heated oxygen sensor output is low (lean):

MIL comes

ON.

When aidfuel ratio feedback control is clamped: Status just

before clamp

is maintained.

When airifuel ratio feedback control is stopped: MIL goes OFF.

Page 25 of 230

TROUBLE DIAGNOSES

Self-diagnosis

(Cont'd)

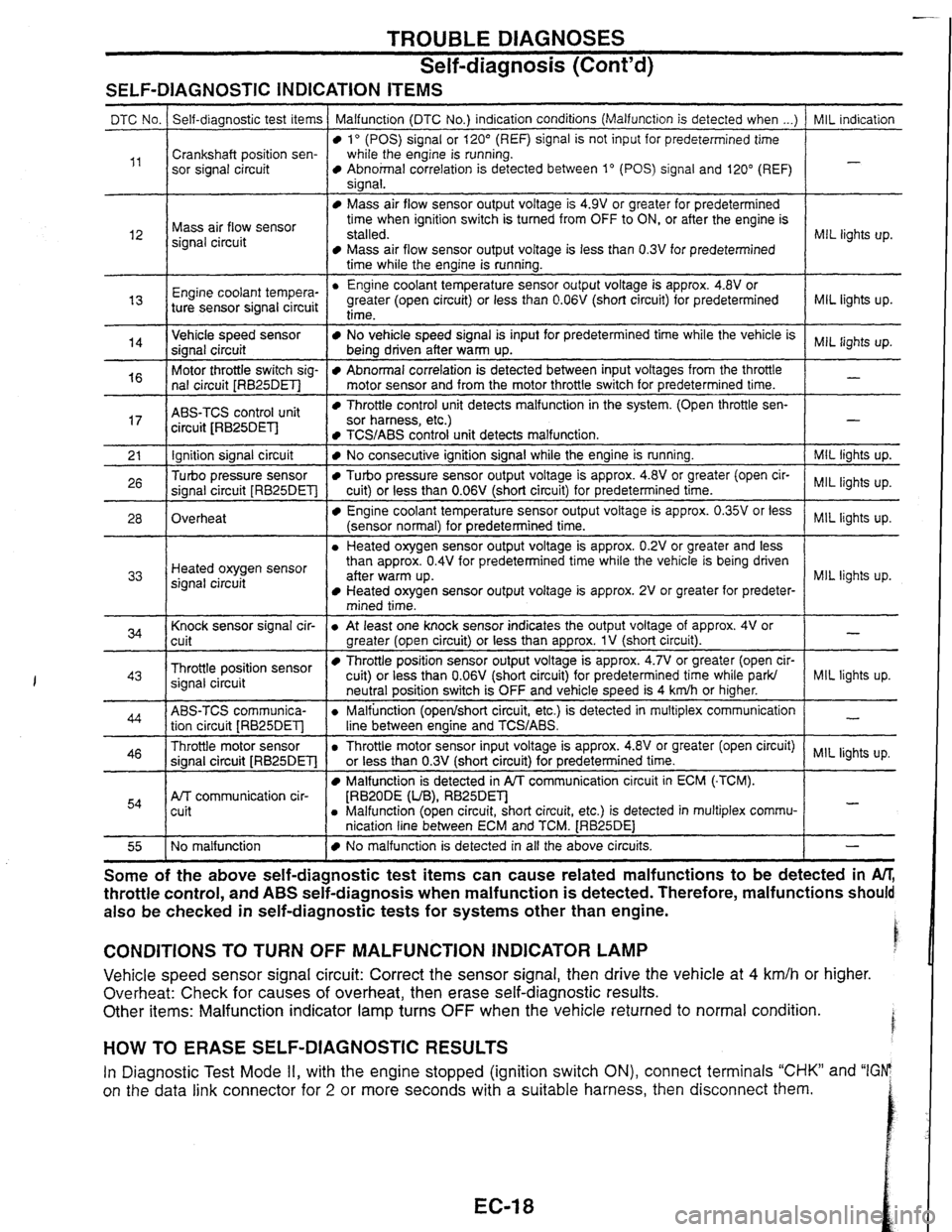

SELF-DIAGNOSTIC INDICATION ITEMS

I time while the engine is running. I

MIL indication

-

DTC No.

,,

MIL lights up. l2

Self-diagnostic test items

Crankshaft position sen-

sor signal circuit Malfunction (DTC No.)

indication conditions (Malfunction is detected when ...)

lo (POS) signal or 120" (REF) signal is not input for predetermined time

while the engine is running.

Abnohal correlation is detected between 1" (POS) signal and 120" (REF)

sianal.

Mass air flow sensor

signal circuit

MIL lights up.

Engine coo'ant tempera-

"

Mass air flow sensor output voltage is 4.9V or greater for predetermined

time when ignition switch is turned from OFF to ON, or after the engine is

stalled.

Mass air flow sensor output voltage is less than 0.3V for predetermined

Engine coolant temperature sensor output voltage is approx.

4.8V or

greater (open circuit) or less than

0.06V (short circuit) for predetermined

MIL lights up.

-

14

ABS-TCS control unit

circuit JRB25DEl-l

ture sensor signal circuit Throttle control unit detects malfunction

in the system. (Open throttle sen- sor harness, etc.)

Ignition signal circuit

Turbo pressure sensor

signal circuit

[RB25DET]

Overheat

I 1 mined time. I

time-

Vehicle speed sensor

signal circuit

Motor throttle switch sig-

nal circuit

[RB25DET]

TCS/ABS control unit detects malfunction. 1 -

I Knock sensor signal cir-

cuit

- --

No vehicle speed signal is input for predetermined time while the vehicle is

being driven after warm up.

Abnormal correlation is detected between input voltages from the throttle

motor sensor and from the motor throttle switch for predetermined time.

I

MIL lights up. Heated oxygen sensor

signal circuit

Throttle position sensor

signal circuit

No consecutive ignition signal while the engine is running.

Turbo pressure sensor output voltage is approx. 4.8V or greater (open cir-

cuit) or less than

0.06V (short circuit) for predetermined time.

Engine coolant temperature sensor output voltage is approx. 0.35V or less

(sensor normal) for predetermined time.

a Heated oxygen sensor output voltage is approx. 0.2V or greater and less

than approx.

0.4V for predetermined time while the vehicle is being driven

aner warm up. Heated oxygen sensor output voltage is approx. 2V or greater for predeter-

ABS-TCS communica- tion circuit

[RB25DET]

Throttle motor sensor

signal circuit

[RB25DET]

Afr communication cir-

cuit

MIL lights up.

lights

up.

MIL lights up.

NQ malfunction

I a At least one knock sensor indicates the output voltage of approx. 4V or

greater (open circuit) or less than approx.

1V (short circuit).

Throttle position sensor output voltage is approx. 4.7V or greater (open cir-

cuit) or less than

0.06V

(short circuit) for predetermined time while ark/

a Throttle motor sensor input voltage is approx. 418~or greater (open circuit) MIL lights up.

or less than

0.3V

(short circuit) for predetermined time. I

-

MIL liqhts up. neutral position switch is OFF and vehicle speed is 4 kdh or higher.

a Malfunction (openlshort circuit, etc.) is detected in multiplex communication

line between enaine and

TCWABS.

Malfunction is detected in PA communication circuit in ECM (-TCM).

[RBZODE (UB), RB25Dm a Malfunction (open circuit, short circuit, etc.) is detected in multiplex commu-

nication line between ECM and TCM.

[RB25DE1

-

-

No malfunction is detected in all the above circuits. I - - --

Some of the above ~elfaia~nostic test items can cause related malfunctions to be detected in M,

throttle control, and ABS seif-diagnosis when malfunction is detected. Therefore, malfunctions should

also be checked in self-diagnostic tests for systems other than engine.

CONDITIONS TO TURN OFF MALFUNCTION INDICATOR LAMP

Vehicle speed sensor signal circuit: Correct the sensor signal, then drive the vehicle at 4 km/h or higher.

Overheat: Check

for causes of overheat, then erase self-diagnostic results.

Other items: Malfunction indicator lamp turns

OFF when the vehicle returned to normal condition.

HOW TO ERASE SELF-DIAGNOSTIC RESULTS

In Diagnostic Test Mode II, with the engine stopped (ignition switch ON), connect terminals "CHK" and "IGFP

on the data link connector for

2 or more seconds with a suitable harness, then disconnect them.

Page 32 of 230

TROUBLE DIAGNOSES

CONSULT (Cont'd)

REAL TlME DIAGNOSIS IN DATA MONITOR MODE

CONSULT has two kinds of triggers and they can be selected by touching "SETTINGJy in "DATA MONITOR"

mode.

1. "AUTO TRIG" (Automatic trigger):

The malfunction will be identified on the CONSULT screen in real time.

In other words, malfunction item will be displayed at the moment the malfunction is detected by ECM. GI

DATA MONITOR can be performed continuously until a malfunction is detected. However, DATA MONI-

TOR cannot continue any longer after the malfunction detection.

2. "MANU TRIG" (Manual trigger):

Malfunction item will not be displayed automatically on CONSULT screen even though a malfunction

is detected by ECM.

DATA MONITOR can be performed continuously even though a malfunction is detected. I

AT

Use these triggers as follows: . 1. "AUTO TRIG"

While trying to detect the DTC by performing the "DTC CONFIRMATION PROCEDURE", be sure to BR

select to "DATA MONITOR (AUTO TRIG)" mode. You can confirm the malfunction at the moment it is

detected.

While narrowing down the possible causes, CONSULT should be set in "DATA MONITOR (AUTO ST

TRIG)" mode, especially in case the incident is intermittent.

When you are inspecting the circuit by gently shaking (or twisting) the suspicious connectors, compo-

Rs

nents and harness in the "DTC CONFIRMATION PROCEDURE, the moment a malfunction is found

the malfunction item will be displayed. (Refer to GI section,

"Incident

Simulation Tests" in

"HOW TO

PERFORM EFFICIENT DIAGNOSIS

FOR AN ELECTRICAL INCIDENT'.) HA

2. "MANU TRIG"

If the malfunction is displayed as soon as "DATA MONITOR" is selected, reset CONSULT to "MANU

TRIG".

By selecting "MANU TRIG" you can monitor and store the data. The data can be utilized for

further diagnosis, such as a comparison with the value for the normal operating condition.

I

I SELECT MONITOR ITEM 1

I MAIN SIGNALS

SELECTION FROM MENU

I I

-11 START I

I h SET RECORDING COND 1 1 k SET RECORDING CON0 1

I MANU TRIG I

I LONG TlME I

"AUTO TRIG"

A malfunction

can be

displayed on "DATA

MONITOR" screen

automatically

if detected. "MANU TRIG"

A

malfunction can not be

displayed

on "DATA

MONITOR" screen

automatically even

if

detected.

Page 33 of 230

TROUBLE DIAGNOSES t i

CONSULT (Cont'd) i

FUNCTION TEST MODE

CHECK ITEM (REMEDY)

FUNCTION

TEST

ITEM JUDGEMENT

CONDITION

lgnition switch: ON

(Engine stopped)

Displays the results of on board

diagnostic system.

SELF-DIAG

RESULTS Objective

system

--

ignition switch: ON

(Engine stopped)

Throttle position sensor circuit is

tested when throttle is opened and

closed fully. ("IDLE POSITION" is

the test item name for the vehicles

in which idle is selected by throttle

position sensor.) Harness and connector

Throttle position sensor (Closed

throttle position)

Throttle position sensor (Closed

throttle position) adjustment

Throttle linkage

Venfy operation in DATA

MONITOR mode.

Throttle

valve:

opened OFF

ON

CLOSED THROTTLE

POSl Throttle valve:

closed

lgnition switch: ON

(Engine stopped)

Throttle position sensor circuit is

tested when throttle is opened and

closed fully.

Harness and connector

Throttle position sensor

Throttle position sensor

adjustment

Throttle linkage

Verify operation in DATA

MONITOR mode.

Range

(Throttle

valve fully opened

- Throttle valve

fully closed) More

than 3.0V THROTTLE POSl

SEN CKT

lgnition switch: ON

(Engine stopped)

Neutral position switch circuit is

tested when shift lever is

manipulated.

lgnition switch: ON

(Engine stopped)

Fuel pump circuit is tested by

checking the pulsation in fuel

pressure when fuel tube is

pinched. Out of

N/P

positions OFF

Harness

and connector

Neutral position switch

Linkage adjustment

PARWNEUT POSl SW CKT

In

N/P positions

Harness and connector

Fuel pump

Fuel pump relay

Fuel filter clogging

Fuel level

There

is pressure pulsation on

the fuel feed hose.

FUEL PUMP

CIRCUIT

--

The valve timing control system is

diagnosed by checking for

operating sound of the solenoid

valve.

lgnition switch: ON

(Engine stopped)

Cooling fan circuit is tested when

cooling fan is rotated.

VALVE

TIMING

SN

CKT

Harness and connector

Cooling fan motor

Cooling fan relay

COOLING

FAN

CIRCUIT RB25DE, RB25DET

The cooling fan rotates and

stops every

3 seconds.

lgnition switch: ON -+ START

Start signal circuit is tested when

engine is started by operating the

starter. Battery voltage and water

temperature before cranking, and

average battery voltage, mass air

flow sensor output voltage and

cranking speed during cranking

are displayed.

Harness and connector

lgnition switch

START

SIGNAL

CIRCUIT Start

signal: OFF 3 ON

Page 37 of 230

TROUBLE DIAGNOSES

Symptom Matrix Chart (Cont'd)

Sensor-related problems I Symptom characteristics and ins~ection hints

Open Engine

will not start when either REF signal circuit or POS signal circuit is open.

Neither fuel system nor ignition system outputs control signals.

Crankshaft position sensor

(POS, REF) Instanta-

neous break Symptoms

vary with the break time and the vehicle's driving conditions. Light

shock or surging will occur while the vehicle is being driven, and the engine will

stall at idle speed.

Ring gear crankshaft position

sensor

[RB20DE

(UB)]

Signal

Mass air flow sensor Open

Open

High output

Low output I Aidfuel

ratio becomes lean. Dirty hot wire or air entering the system could be the

cause. No

airfluel ratio compensation

is carried out during lean bum status. Drivability

may be affected.

Enters fail-safe mode. Driving under

2,400 rpm is allowed.

Airlfuel

ratio becomes rich. Black smoke may be noted. Poor contact at the

ground could be the cause.

Engine coolant temperature sen-

sor Open

Open

Opedshort

High resis-

tance

Low resis-

tance

Opedshort

Heated oxygen sensor

I

Airlfuel ratio becomes over-rich.

Same symptom as when signal wire is open.

Enters fail-safe mode. Malfunction indicator lamp comes ON. Ordinary driving is

allowed. Problems tend to occur when engine is cold or engine coolant tempera-

ture

is high.

Detects low engine coolant temperature. Problems tend to occur after engine

warm-up.

Detects high engine coolant temperature. Problems tend to occur when engine is

cold.

Base

aidfuel ratio is used.

lgnition timing is retarded within the knock control range. Lack of power may be

OpedShort

I noted.

Knock sensor lgnition

timing is retarded within the knock control range. Lack of power may be

High

Output

(noted.

Low output

1 lgnition timing may not be retarded when knock is detected.

Vehicle speed sensor

Throttle position sensor

Opedshort

Opedshort

Unstable out-

put

Poor adjust-

ment

Open

Turbo pressure sensor

(TE) Fuel

cut time becomes-shorter, or no fuel cut is observed.

Base idle speed is used. Fuel injection is not increased during acceleration.

AIT shift point changes for AfF vehicles.

Unnecessary cut-in fuel injection could be the cause. Poor contact at the ground

or control unit could be the cause.

ldle judgment is "OFF while idling. Condition returns

normal by turning the igni-

tion switch ON and OFF repeatedly.

Turbo pressure is judged zero. No remarkable malfunction will be detected.

Refrigerant pressure is judged high. ldle speed remains high while the air condi-

tioner is ON.

Refrigerant pressure sensor

Short Refrigerant pressure

is judged low. ldle speed remains low while the air condi-

tioner is ON.

lgnition switch (IGN)

lgnition switch (START)

Air conditioner switch Open

Engine

will not start because neither fuel system nor ignition system outputs con-

trol signals.

Engine starts in normal condition. Engine may not start when temperature is

extremefy

low.

Air conditioner will not operate. No other malfunction will be noted.

Park/neutral

position switch is judged "OFF. Target engine speed for cold engine

in

N or P position is reduced.

ParWneutral position switch is judged

"0N"I Fast Jdle is effective when the engine

is cold and the gear is in other than N and P posrtlons. Vehrcle excessrvely

creeps.

Open

Open

Parklneutral

position

switch

Short

Power steering oil pressure

switch Open

Engine may

stall when the steering wheel is turned while the vehicle is standstill

and the accelerator pedal is lightly pressed, or when the steering wheel is turned

Electrical load switch Short

Open

Open/short

Multiplex communication line

- -- during deceleration. '

Power steering switch is judged 'ON." Value will be compensated constantly.

Idle speed drops so that the engine can stall when electrical load is applied.

Torque reduction control is not performed. Therefore,

shift shock becomes

greater.

- -- -- -- -- Engine will not start because neither fuel system nor ignition system outputs con-

trol signals.

Open

Control unit power supply

- -- - - --- - - - - - O~edshort I Same symptoms as when sensor harness is open.

Sensor ground -- - Poor contact

Water intru-

sion - -- - - - - - -- -- In case of poor contact, the connector fitting may be loose. In case of water

intrusion, the engine stalls and become inoperative for a while. The engine may restart soon in some cases.

Control unit

and connector

Page 41 of 230

TROUBLE DIAGNOSES

Symptom Matrix Chart (Cont'd)

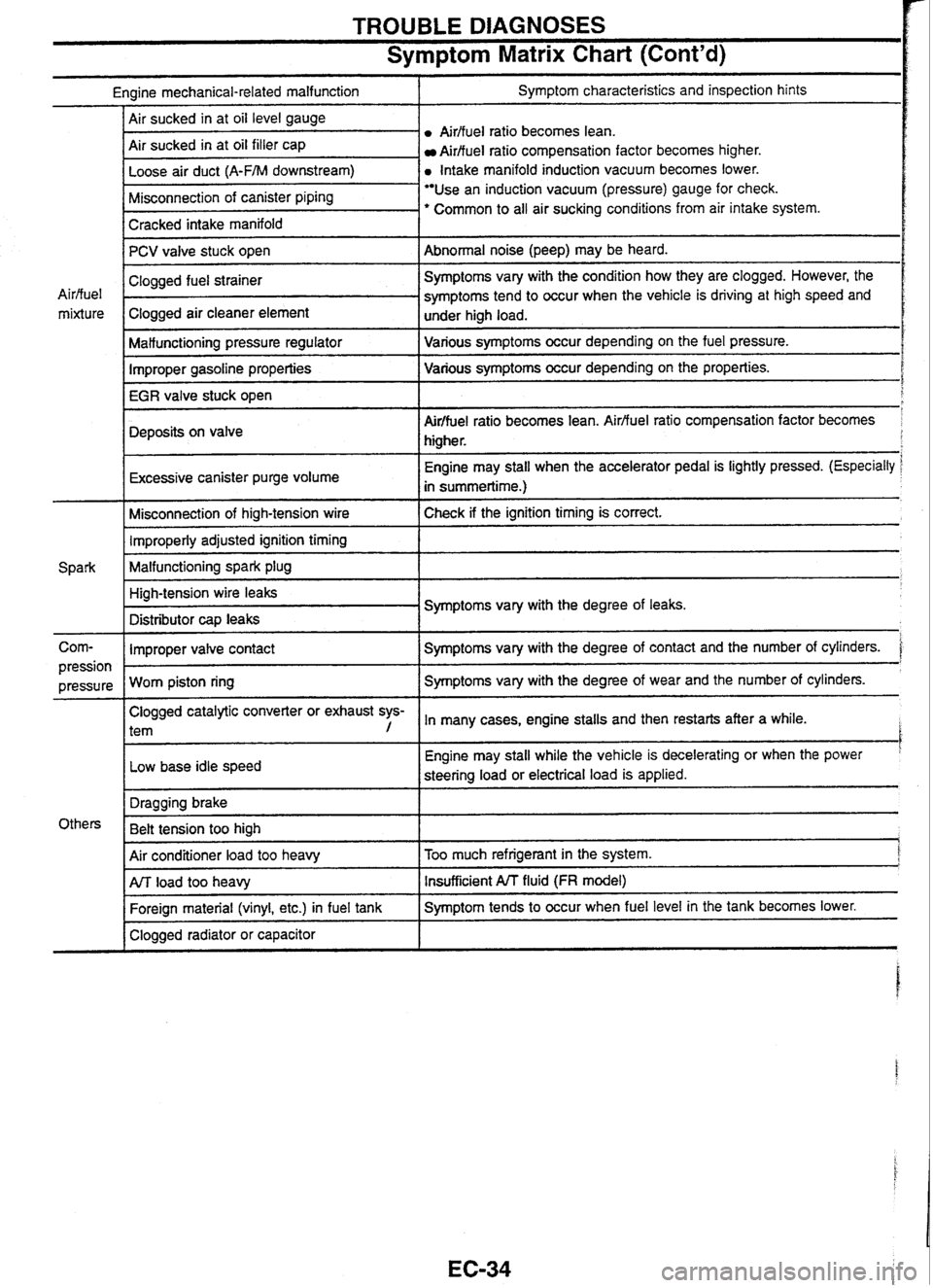

Engine mechanical-related malfunction I Symptom characteristics and inspection hints

Airffuel

ratio becomes lean.

Air sucked in at oil filler cap

Aidfuel ratio compensation factor becomes higher.

a Intake manifold induction vacuum becomes lower.

I Cracked intake manifold I

Misconnection of canister piping Use an induction vacuum (pressure) gauge for check.

' Common to all air sucking conditions from air intake system.

-

PCV valve stuck open

I Malfunctioning pressure regulator I Various symptoms occur depending on the fuel pressure.

Abnormal noise (peep) may

be heard.

Air/fuel

mixture

Improper gasoline properties Various

symptoms occur depending on the properties.

IEGRiale

stuck open

I

Clogged fuel strainer .

Clogged air cleaner element

Deposits on valve

r

Symptoms vary with the condition how they are clogged. However, the

symptoms tend to occur when the vehicle is driving at high speed and

under high load.

I

Air/fuel ratio becomes lean. Airfluel ratio compensation factor becomes

higher.

Excessive canister purge volume

I

Engine may stall when the accelerator pedal is lightly pressed. (Especially

in summertime.)

Misconnection of high-tension wire Check if the ignition timing

is correct. 1 Improperly adjusted ignition timing 1

Malfunctioning spark plug 1

Corn- I Improper valve contact I Symptoms vary with the degree of contact and the number of cylinders. '

High-tension wire leaks

Distributor

cap leaks Symptoms

vary with the degree of leaks.

Clogged catalytic converter or exhaust sys-

l tem , In many cases, engine stalls and then restarts after a while. I

pression I

Low base idle speed

pressure

Worn piston ring I

Engine may

stall while the vehicle is decelerating or when the power '

steering load or electrical load is applied.

Symptoms vary

with the degree of wear and the number of cylinders.

I

Air conditioner load too heavy I Too much refrigerant in the system. j

Others Dragging

brake

Belt tension too high

1

I Clogged radiator or capacitor I

ArJ load too heavy

Foreign material (vinyl, etc.) in fuel tank Insufficient A/T fluid (FR model)

Symptom tends to occur when fuel level in the tank becomes lower.

Page 44 of 230

TROUBLE DIAGNOSES

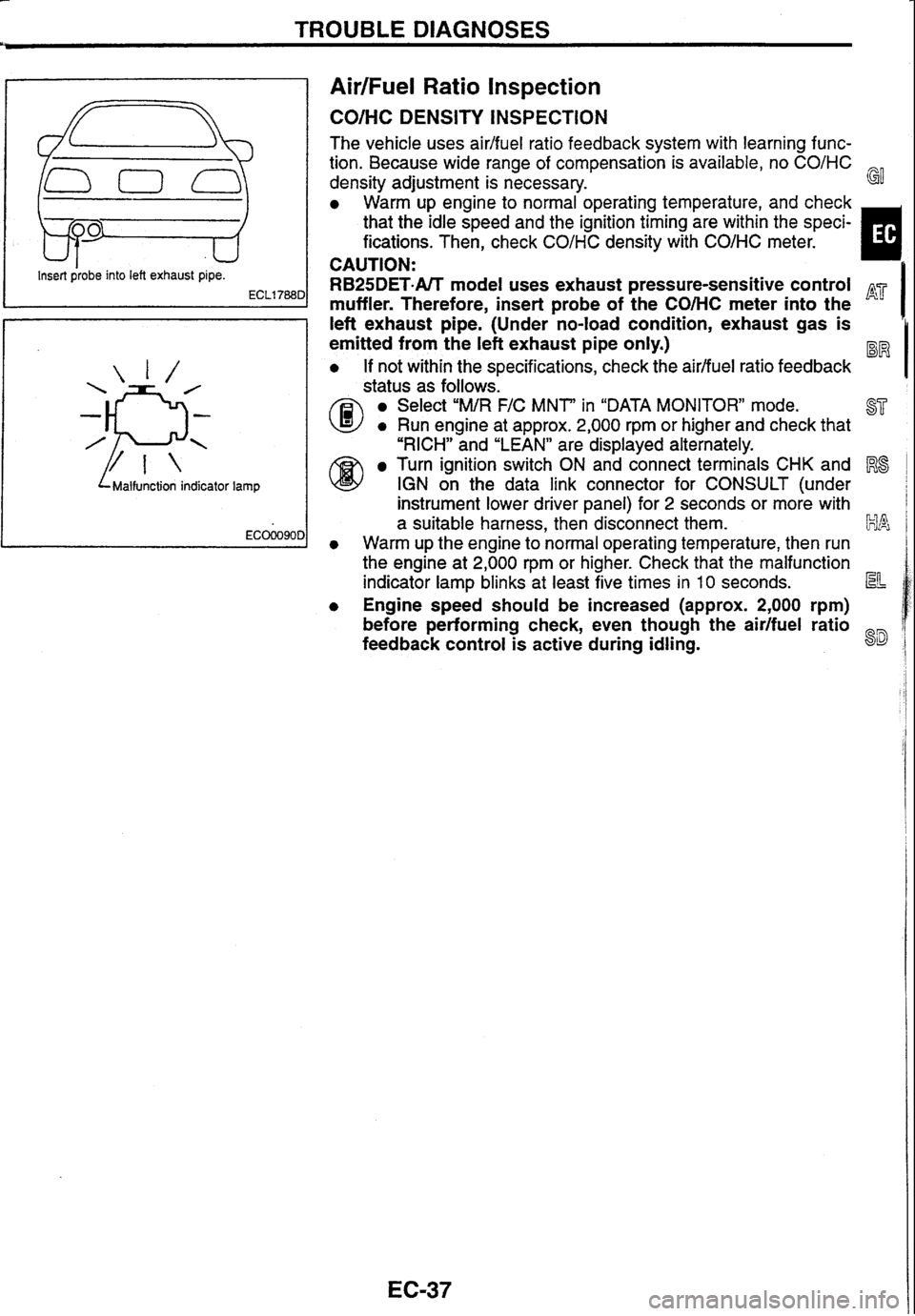

AirIFuel Ratio Inspection

Insert probe into left exhaust pipe.

ECLl788D

L Malfunction indicator lamp

CO/HC DENSITY INSPECTION

The vehicle uses aidfuel ratio feedback system with learning func-

tion. Because wide range of compensation is available, no

CO/HC

density adjustment is necessary. G!

Warm up engine to normal operating temperature, and check

that the idle speed and the ignition timing are within the speci-

fications. Then, check

CO/HC density with COIHC meter.

CAUTION:

muffler. Therefore, insert probe of the COMC meter into the

I

RB25DET-NT model uses exhaust pressure-sensitive control

I left exhaust pipe. (under -no-load condition, exhaust gas is

emitted from the left exhaust pipe only.)

a If not within the specifications, check the airlfuel ratio feedback

@status as follows.

Select "MIR FIC MNT" in "DATA MONITOR" mode.

a Run engine at approx. 2,000 rpm or higher and check that ST

I "RICH" and "LEAN" are displayed alternately.

Turn ignition switch ON and connect terminals CHK and Rs

@ IGN on the data link connector for CONSULT (under

instrument lower driver panel) for

2 seconds or more with

a suitable harness, then disconnect them. klk~

a Warm up the engine to normal operating temperature, then run

the engine at 2,000

rpm or higher. Check that the malfunction

indicator lamp blinks at least five times in

10 seconds. La=

0 Engine speed should be increased (approx. 2,000 rpm)

before performing check, even though the

air/fuel ratio

feedback control is active during idling.

8D