steering NISSAN GT-R 1998 User Guide

[x] Cancel search | Manufacturer: NISSAN, Model Year: 1998, Model line: GT-R, Model: NISSAN GT-R 1998Pages: 230, PDF Size: 12.66 MB

Page 36 of 230

TROUBLE DIAGNOSES

Symptom Matrix Chart (Cont'd)

-RELATION BETWEEN TROUBLE SYMPTOMS AND SENSORS

-. - Sensors No I Hard

start start Rough

idle

Poor derivability Engine

stall

Symptom

@: High possibility 0: Low possibility

Crankshaft position

sensor (POS,

REF) Instantaneous

xeak

Ring gear crankshaft

position sensor

[RB20DE

(UB)]

s 1 Signal iigh output

,ow output

"

2 Power supply

Engine coolant tem-

perature sensor

iigh resistance

-ow resistance

- -- Heated oxygen sen-

sor

Knock sensor

iigh output

.ow output

Ipedshort

Vehicle s~eed sensor

Throttle position sen-

sor Jnstable output

'oar adjustment

Turbo pressure sen-

sor

(TIC)

Refrigerant pressure

sensor

Ignition switch (IGN)

k$n;pRnT)sw

i tch

Air conditioner switch

ParWneutral position

switch

Power steering oil

pressure switch

Electrical load switch

Multiplex communica-

tion line

Control unit power

supply

Sensor ground

Control unif and con-

nector

*: Fast idle

'oor contact

Vater intrusion

Page 37 of 230

TROUBLE DIAGNOSES

Symptom Matrix Chart (Cont'd)

Sensor-related problems I Symptom characteristics and ins~ection hints

Open Engine

will not start when either REF signal circuit or POS signal circuit is open.

Neither fuel system nor ignition system outputs control signals.

Crankshaft position sensor

(POS, REF) Instanta-

neous break Symptoms

vary with the break time and the vehicle's driving conditions. Light

shock or surging will occur while the vehicle is being driven, and the engine will

stall at idle speed.

Ring gear crankshaft position

sensor

[RB20DE

(UB)]

Signal

Mass air flow sensor Open

Open

High output

Low output I Aidfuel

ratio becomes lean. Dirty hot wire or air entering the system could be the

cause. No

airfluel ratio compensation

is carried out during lean bum status. Drivability

may be affected.

Enters fail-safe mode. Driving under

2,400 rpm is allowed.

Airlfuel

ratio becomes rich. Black smoke may be noted. Poor contact at the

ground could be the cause.

Engine coolant temperature sen-

sor Open

Open

Opedshort

High resis-

tance

Low resis-

tance

Opedshort

Heated oxygen sensor

I

Airlfuel ratio becomes over-rich.

Same symptom as when signal wire is open.

Enters fail-safe mode. Malfunction indicator lamp comes ON. Ordinary driving is

allowed. Problems tend to occur when engine is cold or engine coolant tempera-

ture

is high.

Detects low engine coolant temperature. Problems tend to occur after engine

warm-up.

Detects high engine coolant temperature. Problems tend to occur when engine is

cold.

Base

aidfuel ratio is used.

lgnition timing is retarded within the knock control range. Lack of power may be

OpedShort

I noted.

Knock sensor lgnition

timing is retarded within the knock control range. Lack of power may be

High

Output

(noted.

Low output

1 lgnition timing may not be retarded when knock is detected.

Vehicle speed sensor

Throttle position sensor

Opedshort

Opedshort

Unstable out-

put

Poor adjust-

ment

Open

Turbo pressure sensor

(TE) Fuel

cut time becomes-shorter, or no fuel cut is observed.

Base idle speed is used. Fuel injection is not increased during acceleration.

AIT shift point changes for AfF vehicles.

Unnecessary cut-in fuel injection could be the cause. Poor contact at the ground

or control unit could be the cause.

ldle judgment is "OFF while idling. Condition returns

normal by turning the igni-

tion switch ON and OFF repeatedly.

Turbo pressure is judged zero. No remarkable malfunction will be detected.

Refrigerant pressure is judged high. ldle speed remains high while the air condi-

tioner is ON.

Refrigerant pressure sensor

Short Refrigerant pressure

is judged low. ldle speed remains low while the air condi-

tioner is ON.

lgnition switch (IGN)

lgnition switch (START)

Air conditioner switch Open

Engine

will not start because neither fuel system nor ignition system outputs con-

trol signals.

Engine starts in normal condition. Engine may not start when temperature is

extremefy

low.

Air conditioner will not operate. No other malfunction will be noted.

Park/neutral

position switch is judged "OFF. Target engine speed for cold engine

in

N or P position is reduced.

ParWneutral position switch is judged

"0N"I Fast Jdle is effective when the engine

is cold and the gear is in other than N and P posrtlons. Vehrcle excessrvely

creeps.

Open

Open

Parklneutral

position

switch

Short

Power steering oil pressure

switch Open

Engine may

stall when the steering wheel is turned while the vehicle is standstill

and the accelerator pedal is lightly pressed, or when the steering wheel is turned

Electrical load switch Short

Open

Open/short

Multiplex communication line

- -- during deceleration. '

Power steering switch is judged 'ON." Value will be compensated constantly.

Idle speed drops so that the engine can stall when electrical load is applied.

Torque reduction control is not performed. Therefore,

shift shock becomes

greater.

- -- -- -- -- Engine will not start because neither fuel system nor ignition system outputs con-

trol signals.

Open

Control unit power supply

- -- - - --- - - - - - O~edshort I Same symptoms as when sensor harness is open.

Sensor ground -- - Poor contact

Water intru-

sion - -- - - - - - -- -- In case of poor contact, the connector fitting may be loose. In case of water

intrusion, the engine stalls and become inoperative for a while. The engine may restart soon in some cases.

Control unit

and connector

Page 39 of 230

TROUBLE DIAGNOSES

Symptom Matrix Chart (Cont'd)

An open circuit causes no fuel injection to the corresponding cylinder, and the heated oxygen sensor output becomes lean. When the open circuits are

observed at all cylinders, the engine will not start.

Actuator-related malfunction

Injector Symptom

characteristics and inspection hints

Drive

circuit

lgnition signal

(POW&

transistor

drive

siqnal)

(open

Injection Open

Short

Fuel pump relay

1 Open 1 Engine will not start. In case of instantaneous break, surging may occur.

A

short circuit causes continuous fuel injection to the corresponding cylinder, and

over-rich airlfuel ratio and misfire will be noted. When the short circuits are

observed at all cylinders, the engine will not start.

Foreign

material

Clogs

L

Foreign

material causes continuous fuel injection to the corresponding cylinder.

Symptoms vary with the condition how the injection port is clogged.

Aidfuel ratio

compensation factor becomes larger.

(1 10 to 125%)

Canister purge control valve Ignition primary

signal (Power

transistor ground)

Auxiliary electric fan relay

[RB25DE, RB25DETI

1 Short

Open

Open -

Open

Open

Leaks

Open

Open

lgnition coil

AAC valve

The valve purges constantly. In summertime, engine may stall at idle speed due

i to rich aidfuel ratio. In wintertime, various malfunctions may occur due to lean

airlfuel ratio.

An open circuit causes no fuel injection to the corresponding cylinder, and the '

heated oxygen sensor output becomes lean. When the open circuits are observed at all cylinders, the engine will not start. In case of instantaneous break, symptoms vary with the break time and the

vehicle's driving conditions. Light shock or surging will occur while the vehicle

is being driven.

The engine will stall when break time is long.

AAC valve is fully closed. Symptoms vary with the base engine speed. When it is

too low, engine may stall while the vehicle is decelerating or when the power

steering load or electrical load is applied.

Power

supply

s~de

primary

Second-

arY side

Power

supply

Drive

circuit

Open Open Auxiliary

electric fan will not operate even after warm-up is completed.

The valve

will not purge. Gasoline smell may be noted when the weather is hot.

Variable valve timing control

solenoid valve

Variable air intake control sole-

noid valve (NA)

Air jet swirl control solenoid

valve

[RB20DE

(UB)]

Injector ground (Total ground) lnstanta- Symptoms vary

with the break time and the vehicle's driving conditions. Surging neous break or engine stall may occur when the instantaneous break occurred during fuel

I I injection. I

Open

, Open

Short

Turbo pressure control solenoid

valve (TIC) Valve

timing not switched.

Variable air intake valve opens, and torque in low speed range is reduced.

Variable air intake valve closes, and torque in high speed range is reduced.

Open

Short Air jet

swirl control valve remains closed.

Air jet swirl control valve remains open.

Open

Open Swing valve opens earlier, and

maximum turbo pressure is reduced.

Engine will not start

because the injectors do not operate.

Page 41 of 230

TROUBLE DIAGNOSES

Symptom Matrix Chart (Cont'd)

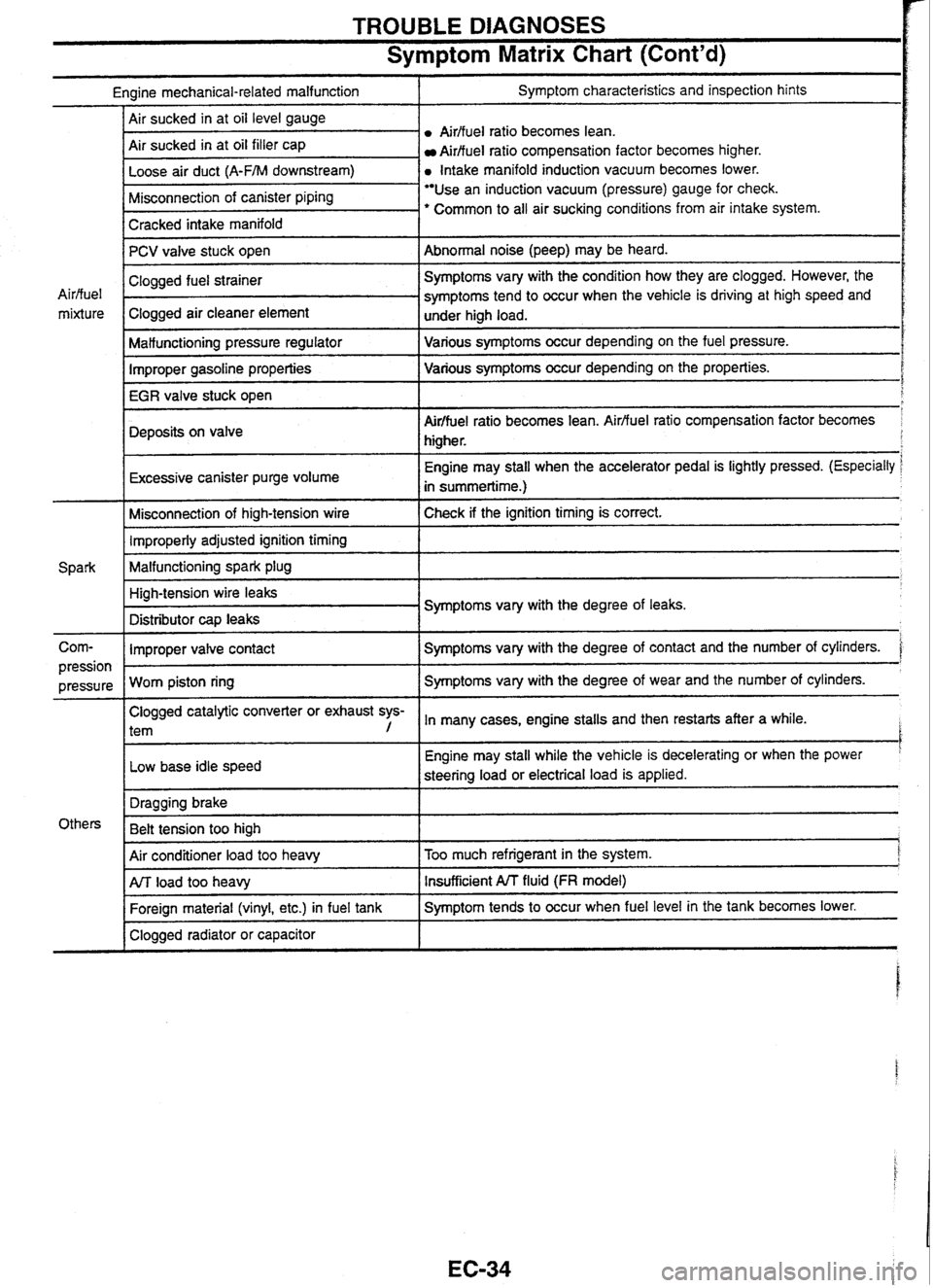

Engine mechanical-related malfunction I Symptom characteristics and inspection hints

Airffuel

ratio becomes lean.

Air sucked in at oil filler cap

Aidfuel ratio compensation factor becomes higher.

a Intake manifold induction vacuum becomes lower.

I Cracked intake manifold I

Misconnection of canister piping Use an induction vacuum (pressure) gauge for check.

' Common to all air sucking conditions from air intake system.

-

PCV valve stuck open

I Malfunctioning pressure regulator I Various symptoms occur depending on the fuel pressure.

Abnormal noise (peep) may

be heard.

Air/fuel

mixture

Improper gasoline properties Various

symptoms occur depending on the properties.

IEGRiale

stuck open

I

Clogged fuel strainer .

Clogged air cleaner element

Deposits on valve

r

Symptoms vary with the condition how they are clogged. However, the

symptoms tend to occur when the vehicle is driving at high speed and

under high load.

I

Air/fuel ratio becomes lean. Airfluel ratio compensation factor becomes

higher.

Excessive canister purge volume

I

Engine may stall when the accelerator pedal is lightly pressed. (Especially

in summertime.)

Misconnection of high-tension wire Check if the ignition timing

is correct. 1 Improperly adjusted ignition timing 1

Malfunctioning spark plug 1

Corn- I Improper valve contact I Symptoms vary with the degree of contact and the number of cylinders. '

High-tension wire leaks

Distributor

cap leaks Symptoms

vary with the degree of leaks.

Clogged catalytic converter or exhaust sys-

l tem , In many cases, engine stalls and then restarts after a while. I

pression I

Low base idle speed

pressure

Worn piston ring I

Engine may

stall while the vehicle is decelerating or when the power '

steering load or electrical load is applied.

Symptoms vary

with the degree of wear and the number of cylinders.

I

Air conditioner load too heavy I Too much refrigerant in the system. j

Others Dragging

brake

Belt tension too high

1

I Clogged radiator or capacitor I

ArJ load too heavy

Foreign material (vinyl, etc.) in fuel tank Insufficient A/T fluid (FR model)

Symptom tends to occur when fuel level in the tank becomes lower.

Page 42 of 230

TROUBLE DIAGNOSES

ldle speed adjusting screw

ECL1641 C

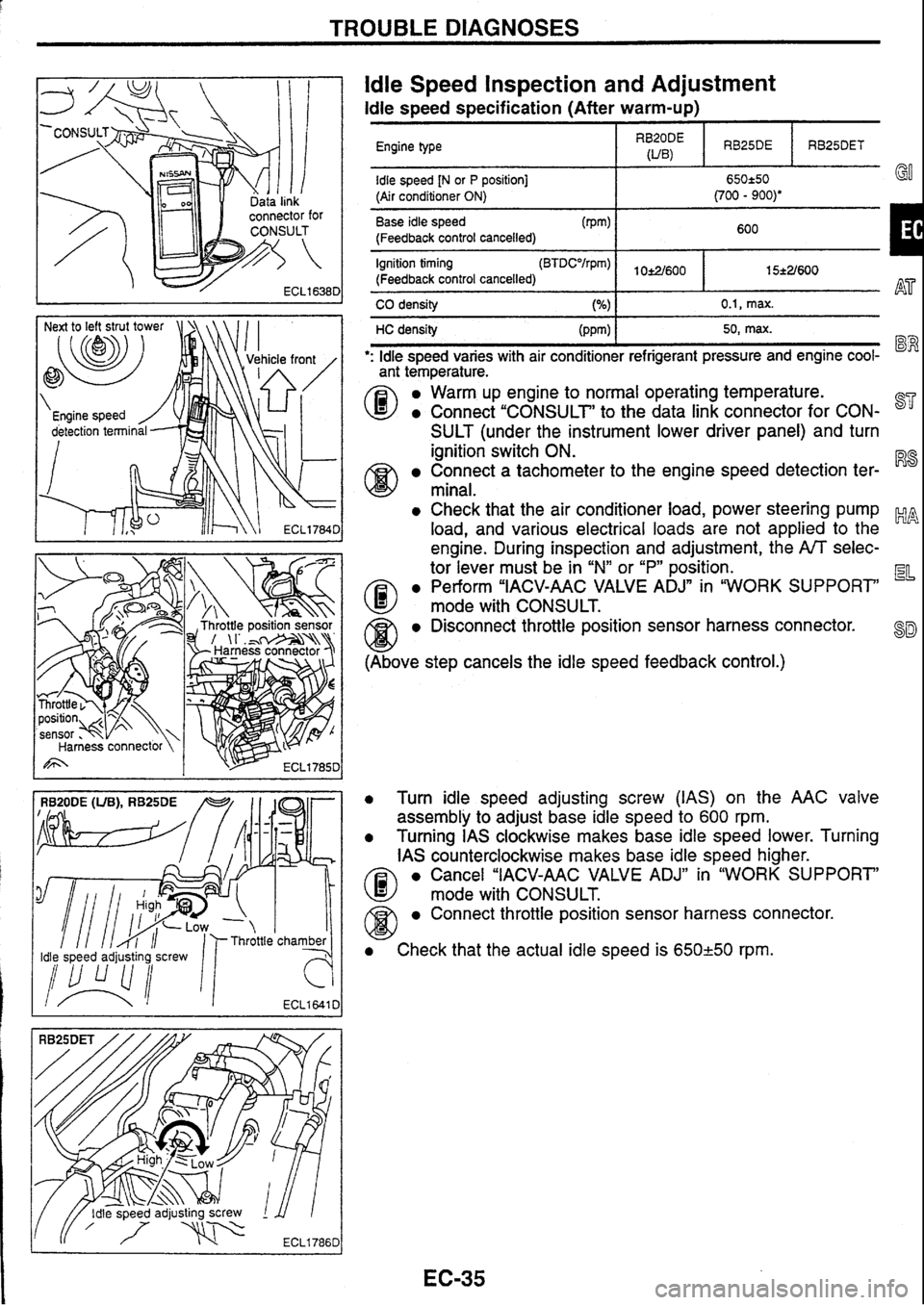

ldle Speed Inspection and Adjustment

ldle speed specification (After warm-up)

Engine type I RygE I RB25DE I RB25DET

Base idle speed (Pm)

(Feedback control cancelled) 600

I 1

idle speed [N or P position] (Air conditioner ON)

Ignition timing

(Feedback control cancelled) I 15*2/600

. . I I

650250 Go (700 - 900)'

CO density 0.1, max.

HC density 50, max.

': ldle speed varies with air conditioner refrigerant pressure and engine cool- "" "

ant temperature.

0

a Warm up engine to normal operating temperature.

a Connect "CONSULT' to the data link connector for CON- 87'

SULT (under the instrument lower driver panel) and turn

ignition switch ON.

Connect a tachometer to the engine speed detection ter- R8

minal.

a Check that the air conditioner load, power steering pump ~p, -4 load, and various electrical loads are not applied to the

engine. During inspection and adjustment, the

A/T selec-

tor lever must be in

"N"

or

"P"

position.

a Perform "IACV-AAC VALVE ADJn in "WORK SUPPORT EL

@ mode with CONSULS.

@ a Disconnect throttle position sensor harness connector. 8~

(Above step cancels the idle speed feedback control.)

0 Turn idle speed adjusting screw (IAS) on the AAC valve

assembly to adjust base idle speed to

600 rpm.

a Turning IAS clockwise makes base idle speed lower. Turning

IAS counterclockwise makes base idle speed higher.

a Cancel "IACV-AAC VALVE ADJ" in "WORK SUPPORT'

@ mode with CONSULT.

a Connect throttle position sensor harness connector.

a Check that the actual idle speed is 650-1-50 rpm.

Page 47 of 230

TROUBLE DIAGNOSES

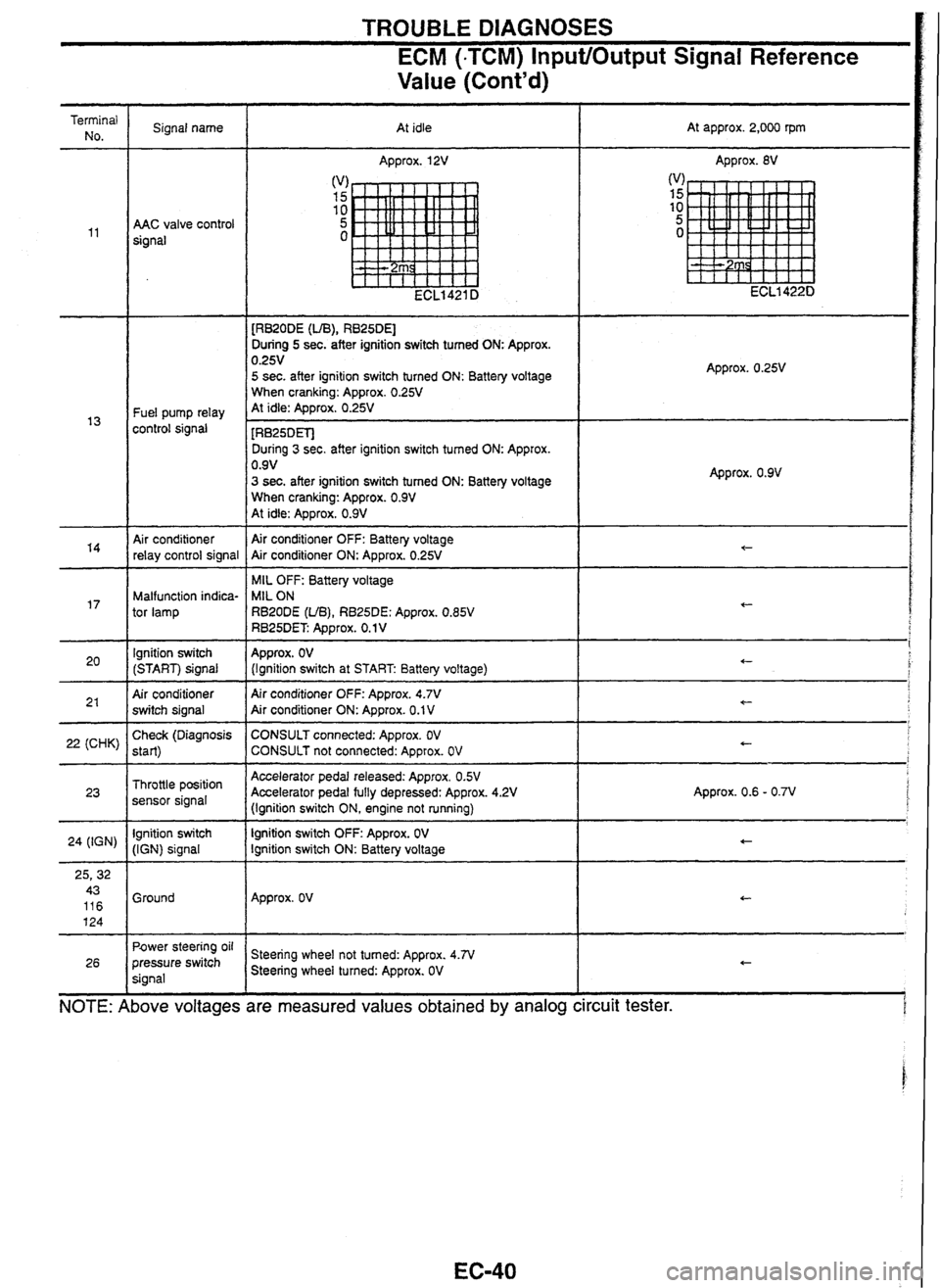

ECM (-TCM) InputlOutput Signal Reference

Value (Cont'd)

d

voltages are

Terminal No. Signal name

At idle At

approx. 2,000 rpm

Approx.

12V Approx. 8V

AAC valve control

signal

[RB20DE

(UB), RB25DEl

During 5 sec. after ignition switch tumed ON: Approx. 0.25V 5 sec. after ignition switch turned ON: Battery voltage

When cranking: Approx. 0.25V At idle: Approx. 0.25V Fuel pump relay

control signal - - [RB25DETJ

During 3 sec. after ignition switch tumed ON: Approx.

0.9V

3 sec. after ignition switch tumed ON: Battery voltage

When cranking: Approx. 0.9V At idle: Approx. 0.9V

Approx. 0.9V

Air conditioner

relay control signal Air conditioner

OFF: Battery voltage

Air conditioner ON: Approx. 0.25V

MIL OFF: Battery voltage

MIL ON

RBZODE

(UB), RB25DE: Approx. 0.85V RB25DET Approx. 0.1 V

Malfunction indica-

tor lamp

lgnition switch

(START) signal

Air conditioner

switch signal Approx.

OV (Ignition

switch at START Battery voltage)

Air conditioner OFF: Approx.

4.7V Air conditioner ON: Approx. 0.1 V -

22 (CHK) Check

(Diagnosis

start)

Throttle position

sensor signal

lgnition switch

(IGN) signal CONSULT

connected: Approx. OV CONSULT not connected: Approx. OV

Accelerator pedal released: Approx. OSV Accelerator pedal fully depressed: Approx. 4.2V

(Ignition switch ON, engine not running)

lgnition switch

OFF: Approx. OV lgnition switch ON: Battery voltage Approx.

0.6 - 0.7V

24

(IGN)

Ground Approx.

OV

Power

steering oil

pressure switch

signal Steering

wheel not tumed: Approx. 4.N Steering wheel turned: Approx. OV

26

NOTE: I bove measured values obtained by analog ircuit

tester.

Page 57 of 230

TROUBLE DIAGNOSES

Shift Mechanism

1 Turbine sensor 1

tine pressure solenoid I 1

Shift solenoid B

Full switch

ECM-TCM

(All side) (RB20DE, RB25DET) or TCM (RB25DE) p-

ECM.TCM (Engine side) * I

(RB20DE. RB25DET) or Venrle speed sensor 2

ECM (RB25DE) ,

1 (RB25DET)

POWER ~nd~calor lamp @AT;

( POWER (Except M-AT) ] 1 SNOW I

Shift control unit

(Except RB20DE)

Overdrive control switch

I

O/D OFF

indicator lamp

Steering shift main switch

- ATN 1983D

Page 59 of 230

![NISSAN GT-R 1998 User Guide

TROUBLE DIAGNOSES

Component Parts Location

[M-AT (Except TCS)]

Control valve uppe:

Line pressure

solenoid Shift solenoid A

Shift solenoid B Overrun clutch

solenoid

Steering switch relay I NISSAN GT-R 1998 User Guide

TROUBLE DIAGNOSES

Component Parts Location

[M-AT (Except TCS)]

Control valve uppe:

Line pressure

solenoid Shift solenoid A

Shift solenoid B Overrun clutch

solenoid

Steering switch relay I](/img/5/57354/w960_57354-58.png)

TROUBLE DIAGNOSES

Component Parts Location

[M-AT (Except TCS)]

Control valve uppe:

Line pressure

solenoid Shift solenoid A

Shift solenoid B Overrun clutch

solenoid

Steering switch relay I Ql Shift control unit (Except RB20DE) ?

ATN 1 985D

AT-?

Page 60 of 230

TROUBLE DIAGNOSES

Circuit Diagram

1 Data link connector for CONSULT

I I Vehicle speed sensor 1 I I (Output shaft speed sensor)

Turbine sensor (Exceot RB20DE)

Shifi CRI (M-AT)

65 10 Steering shifl SW (M-AT)

Steering shift main SW

1

Manual mode SW I

Terminal No. in parenthesis ( ) of throttle position sensor and throttle posit~on switch 1s used for RB25DET.

AT-8

Page 122 of 230

STEERING SYSTEM

SECTION ST

CONTENTS

.......... ELECTRIC SUPER HICAS 2 Control Unit Input/Output Signal Specifications 5 RS ..............................................

....................................................... ............................................................. Pre-inspection -2 Preliminary Check -7

System Description ...................................................... 2 Trouble Diagnosis with CONSULT .............................. 7 M!gJ

....................... Com~onent Parts Location .......................................... 3 Trouble Diagnosis with Self-diagnosis 12

Circuit Diagram ............................................................ 4 Symptom Chalt .......................................................... 14