heater NISSAN GT-R 1998 Service Manual

[x] Cancel search | Manufacturer: NISSAN, Model Year: 1998, Model line: GT-R, Model: NISSAN GT-R 1998Pages: 230, PDF Size: 12.66 MB

Page 9 of 230

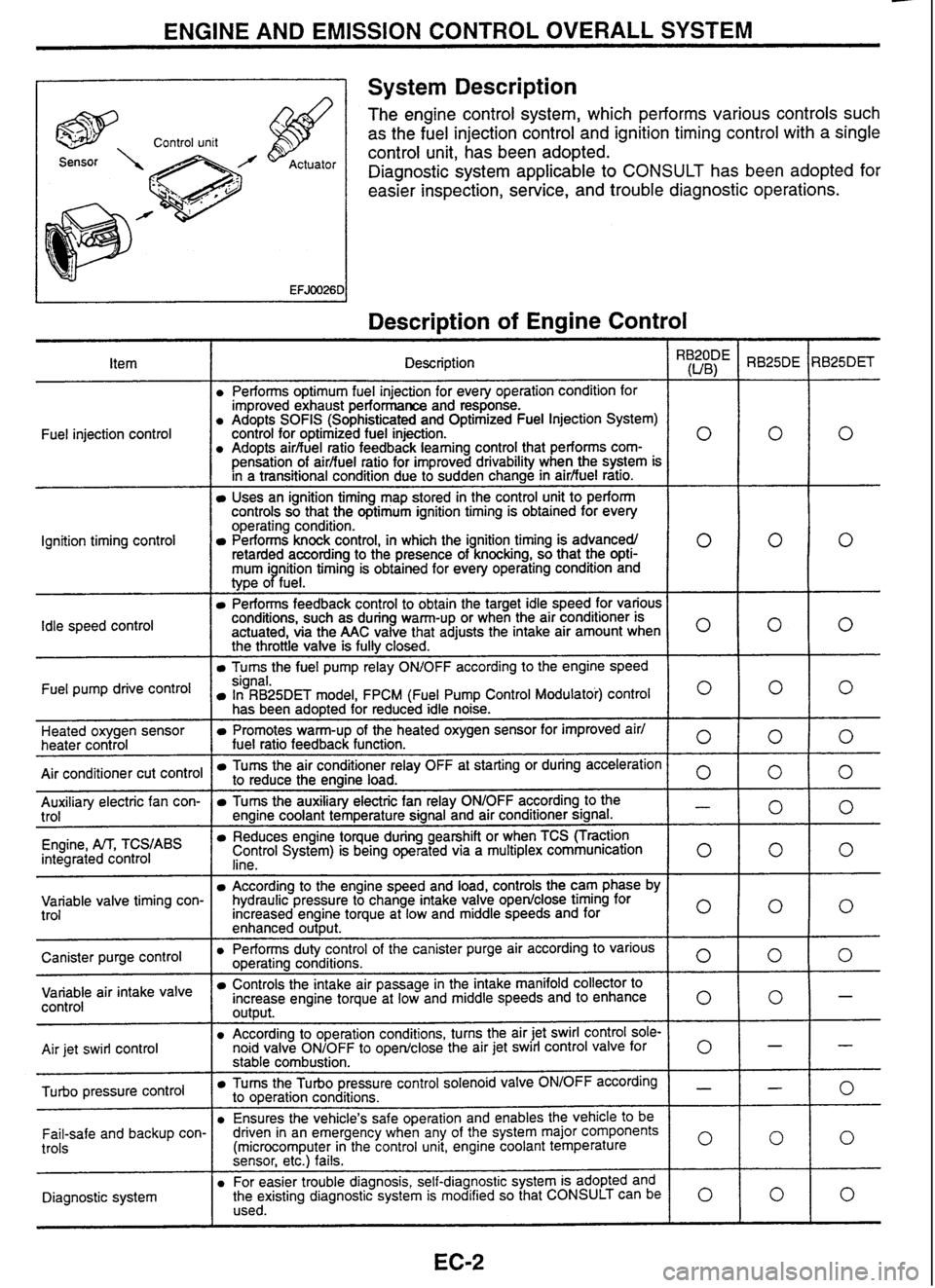

ENGINE AND EMISSION CONTROL OVERALL SYSTEM

A 1 System Description

The engine control system, which performs various controls such

as the fuel injection control and ignition timing control with a single

control unit, has been adopted.

Diagnostic system applicable to

CONSULT has been adopted for

easier inspection, service, and trouble diagnostic operations.

Description of Engine Control

I

Description \,

Performs optimum fuel injection for every operation condition for

improved exhaust performance and response.

Adopts

SOFlS (Sophisticated and Optimized Fuel Injection System)

control for optimized fuel injection.

Adopts

airbuel ratio feedback

learning control that performs

com-

0

pensation of airfiuel ratio for improved drivability when the system is

in a transitional condiiion due to sudden change in

airfiuel ratro.

Uses an ignition timing map stored in the control unit to perform

controls so that the optimum ignition timing is obtained for every

operating condition.

Performs knock control, in which the ignition timing is advancedl

retarded according to the presence of knocking, so that the

opti- 0

mum i nition timing is obtained for every operating condition and

type

oPfue1.

Performs feedback control to obtain the target idle speed for various

conditions, such as during warm-up or when the air conditioner is

actuated, via the

AAC valve that adjusts the intake air amount when

O

the throttle valve is fully closed.

Turns the fuel pump relay OWOFF according to the engine speed

Fuel

injection control

Ignition timing control

Idle

speed

control

Fuel pump drive signal. In RB25DET model, FPCM (Fuel Pump Control Modulatoi) control O

has been adopted for reduced idle noise.

Heated oxygen sensor

heater control

Air conditioner cut control

Promotes warm-up of the heated oxygen sensor for improved air1

fuel ratio feedback function. 0

Tums the air conditioner relay OFF at starting or during acceleration to reduce the engine load. 0 -- Auxiliary electric fan con-

trol

Engine,

M, TCS,ABS integrated control

Tums the auxiliary electric fan relay ONIOFF according to the - engine coolant temperature signal and air conditioner signal.

Reduces engine toque during gearshift or when TCS (Traction

Control System) is being operated via a multiplex communication

lino 0

- -

Variable valve timing con-

trol According to the engine speed and load, controls the cam phase by

hydraulic pressure to change intake valve

open/close timing for

Increased engine torque at low and middle speeds and for

enhanced

out~ut.

I o I

Canister purge control air

intake valve control

Air

jet swirl control Performs duty

control of the canister purge air according to various ooeratina conditions.

0 -r-~ e-- ---

-

Controls the intake air passage in the intake manifold collector to

increase engine torque at low and middle speeds and to enhance

output. 0

According to operation conditions, turns the air jet swirl control sole-

noid valve ONIOFF to openlclose the air jet swirl control valve

for 0

pressure control

stable combustion.

Tums the Turbo pressure control solenoid valve ONIOFF according - to operation conditions.

Ensures the vehicle's safe operation and enables the vehicle

to be

Fail-safe and backup con-

trols

Diagnostic system driven

in an emergency when any of the system major components

(microcomputer in the control unit, engine coolant temperature

0

sensor, etc.) fails.

For easier trouble diagnosis, self-diagnostic system is adopted and

the existing diagnostic system is modified so that CONSULT can be

0 used.

Page 13 of 230

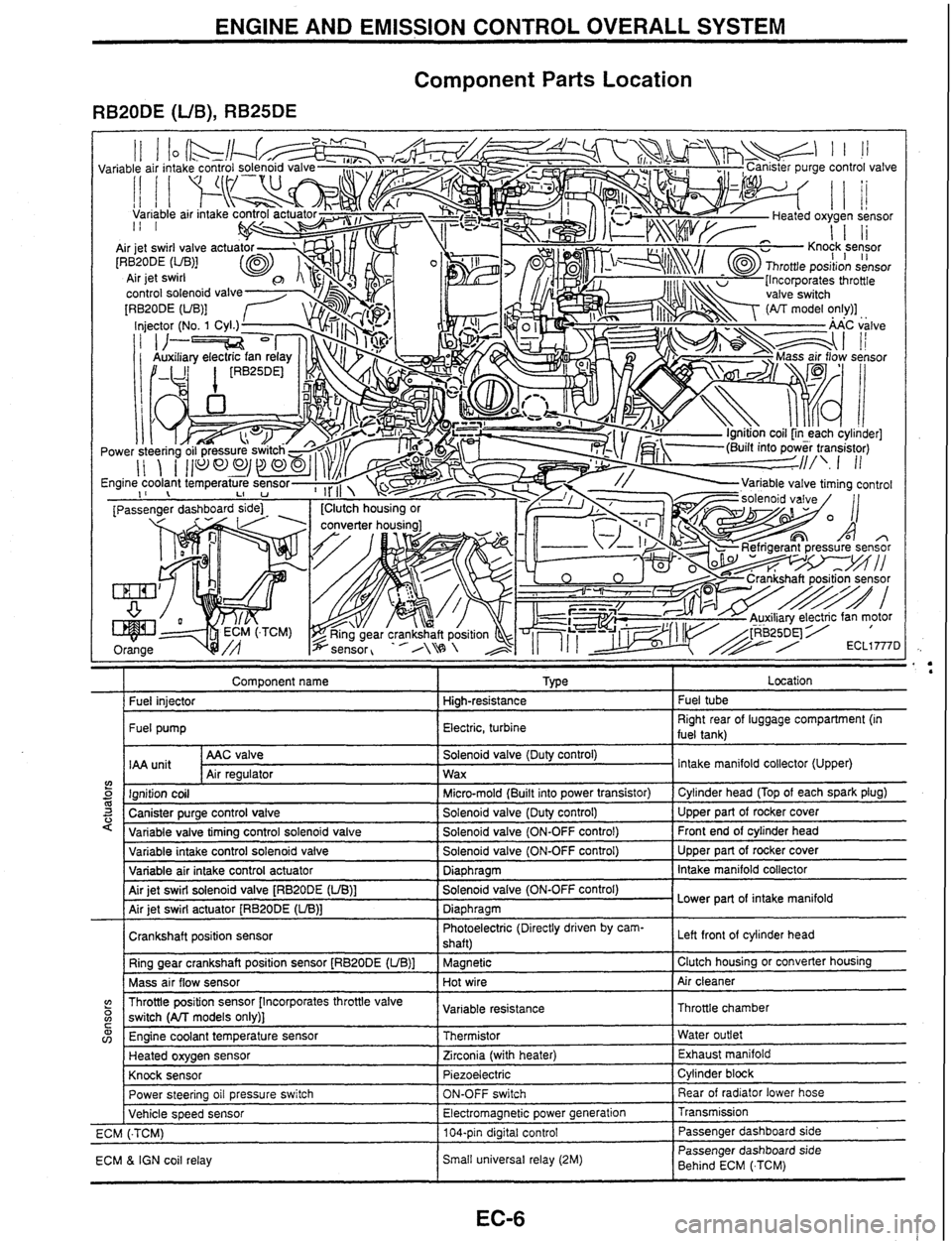

ENGINE AND EMISSION CONTROL OVERALL SYSTEM

Component Parts Location

RB20DE (UB), RB25DE

Component name I Type I Location

I Fuel iniector I Hiah-resistance I Fuel tube

I Fuel pump I Electric, turbine I Right rear of luggage compartment (in

fuel tank)

AAC valve

IAA

unit Air reaulator

5 m 3 '

Solenoid valve (Duty control)

Wax

variable intake control solenoid valve

Variable air intake control actuator

Air jet swirl solenoid valve

[RBPODE (UB)]

Air jet swirl actuator

[RB20DE (LIB)]

Crankshaft position sensor Ring gear crankshaft position sensor

[RB20DE (UB)]

Mass air flow sensor Intake

manifold collector (Upper)

Ignition coil

Canister purge control valve

Variable valve tirnina control

solenoid valve

(? o C

Solenoid valve (ON-OFF control)

Diaphragm

Solenoid valve (ON-OFF control)

Diaphragm Photoelectric (Directly driven by cam-

shaft)

Magnetic

Hot wire

w v,

Micro-mold (Built into power transistor)

Solenoid valve (Duty control)

Solenoid valve (ON-OFF control) Upper part of rocker cover

Intake manifold collector

Lower part of intake manifold

Left front

of cylinder head

Clutch housing or converter housing

Air cleaner

Throttle position sensor [Incorporates throttle valve

switch

(All models only)]

Power steering oil pressure switch

Vehicle speed sensor

ECM

(.TCM)

ECM

& IGN coil relay Cylinder head

(Top of each spark plug)

Upper part of rocker cover

Front end of cylinder head

Engine coolant temperature sensor

Heated oxygen sensor

Knock sensor Variable

resistance

ON-OFF switch

Electromagnetic power generation

104-pin digital control

Small universal relay (2M) Throttle chamber

Thermistor

Zirconia (with heater)

Piezoelectric Rear of radiator lower hose

Transmission Passenger dashboard side

Passenger dashboard side

Behind ECM

(.TCM) Water

outlet

Exhaust manifold

Cylinder block

Page 14 of 230

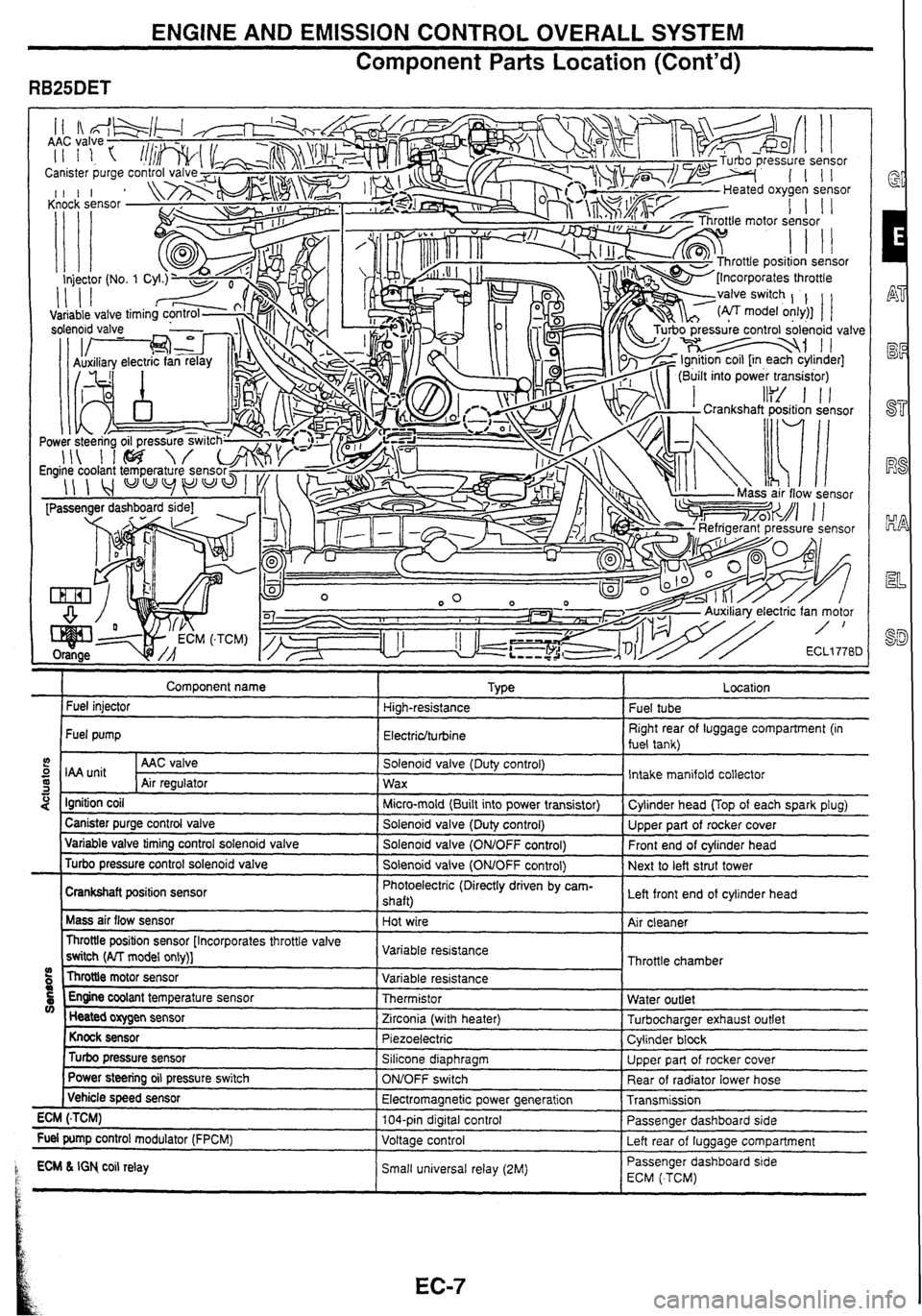

ENGINE AND EMISSION CONTROL OVERALL SYSTEM

Component

Parts Location (Cont'd)

" . . ., . .7

Comoonent name I TVLE a r Fuel injector High-resistance

Fuel pump

Electriclturbine

5 I unit I AAC valve I Solenoid valve (Duty control)

S Air reoulator 1 wax -1 I " - . -.

4 Ignition coil I Micro-mold (Built into power transistor)

I Canister purge control valve I Solenoid valve (Dutv control) ---- - Variable valve timing control solenold valve I Solenold valve (ONtOFF control)

Turbo pressure control solenoid valve

I Solenoid valve (OMOFF control)

Crankshaft position sensor Photoelectric

(Directly driven by cam-

shaft)

Mass air flow sensor

Hot wire

Throttle position sensor [Incorporates throttle valve

switch

(AlT model only)] Variable

resistance

Throttle motor sensor

09 Variable resistance

5 Engine coolant temperature sensor Thermistor V) Heated oxygen sensor

Zirconia (with heater)

Knock sensor Piezoelectric

Turbo pressure sensor Silicone diaphragm

Power

steering oil pressure switch

ONJOFF switch

( Vehicle speed sensor

Electromagnetic power generation

ECM

(.TCM) 104-pin digital control

Fuel pump control modulator (FPCM)

Voltage control

1 ECM L IGN co~l relay Small un~versal relay (2M) P t

.

Fuel tube

Right rear of luggage compartment (in

fuel tank)

Intake manifold collector

Cvlinder head

UOD of each soark olua)

Upper part of rocker cover

Front end of cylinder head

Next to left strut tower

Left front end of cylinder head

Air cleaner

Throttle chamber

Water outlet

Turbocharaer exhaust outlet

Cylinder

block

Upper part of rocker cover

Rear of radiator lower hose

Transmission

Passenger dashboard side

Left rear of

luaaaae comoartment

-- Passenger dashboard s~de

ECM ( TCM)

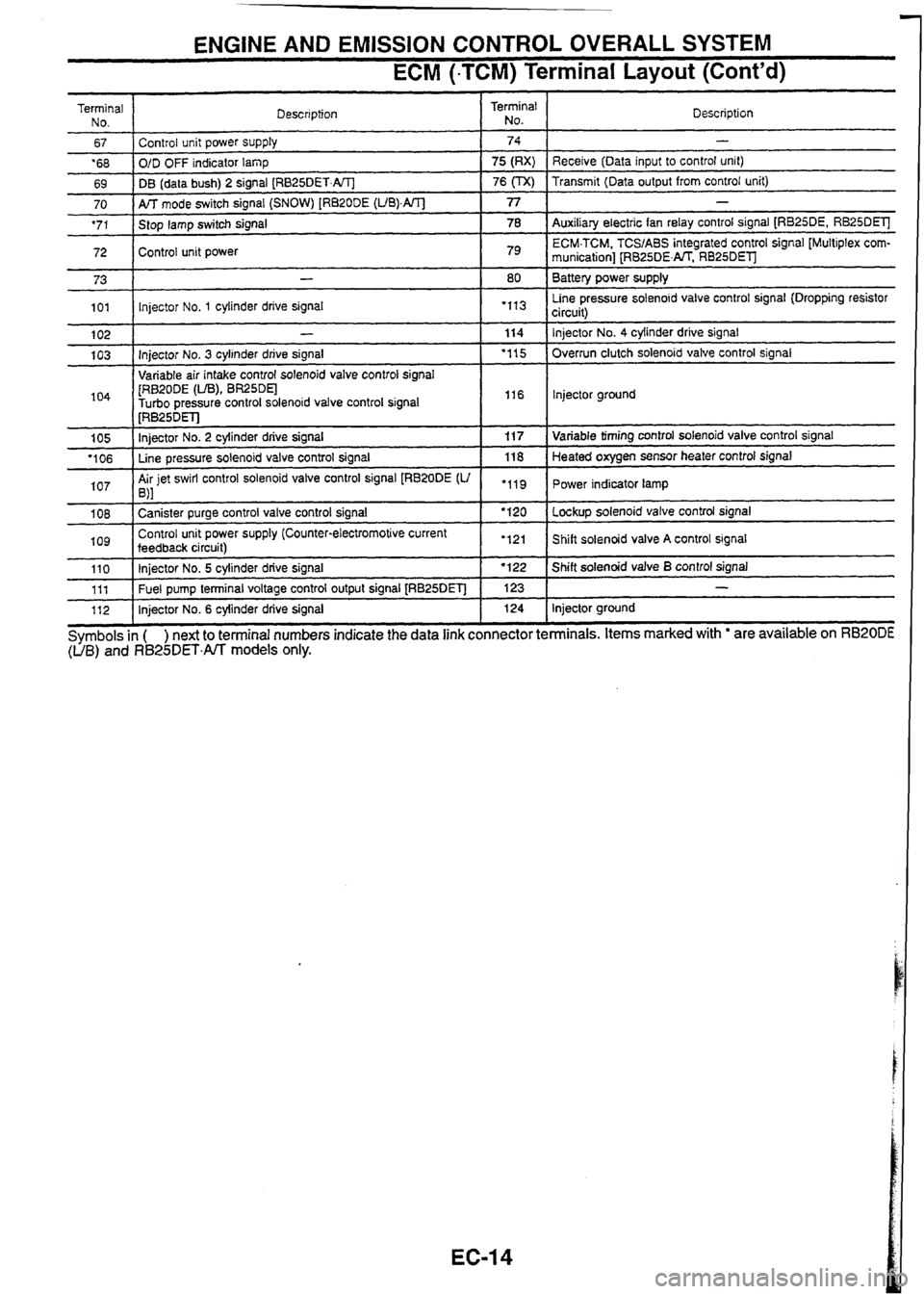

Page 21 of 230

ENGINE AND EMISSION CONTROL OVERALL SYSTEM

ECM (-TCM) Terminal Layout (Cont'd)

Terminal

No.

67

'68

69 Description

70

'71

72 I

Control unit power supply

O/D OFF indicator

lamp

DB (data bush) 2 signal

[RB25DET.AIT]

73

101

104

1 [RB~ODE (LIB), BR25DEl -

Turbo oressure control solenoid valve control signal I I16 I lnjector ground

Terminal

No.

AK mode switch signal (SNOW) [RB20DE (UB).AIT]

Stop lamp switch signal

Control unit power

102

103 Description

74

75 (RX)

76

(TX)

1 I . .

-

Receive (Data input to control unit)

Transmit (Data output from control unit)

77

78

79

-

Injector No. 3 cylinder drive signal

Variable air intake control solenoid valve control

sianal

105

'106

107

-

Auxiliary electric fan relay control signal [RB25DE, RB25DElJ

ECM.TCM. TCSIABS integrated control signal [Multiplex

com-

munication] [RB25DENT. RB25DEl

Battery power supply

Line pressure solenoid valve control signal (Dropping resistor

circuit)

-

lnjector No. 1 cylinder drive signal

1 08

log

80

"I3

114

'1 15

[RB~~DET]

Injector No. 2 cylinder drive signal

Line pressure solenoid valve control signal

Air jet swirl control solenoid valve control signal

[RB20DE

(U ,\I

110 111

112 Injector No.

4 cylinder

drive signal

Overrun clutch solenoid valve control signal

"11

Canister purge control valve control signal

Control unit power supply (Counter-electromotive current

feedback

circuit) 11

7

118

.119

Symbols

in ( ) next to terminal numbers indicate the data link connector terminals. Items marked with ' are available on RB20DE (UB) and R825DET.All models only.

Injector No. 5 cylinder drive signal

Fuel pump terminal voltage control output signal

[RB25DET]

Injector No. 6 cylinder drive signal Variable

timing control solenoid valve control signal

Heated oxygen sensor heater control signal

Power indicator lamp

'120

'121 Lockup solenoid valve control signal

Shift solenoid valve

A control signal I '122

123 124 Shift solenoid valve B control signal

-

Injector ground

Page 147 of 230

HEATER &

AIR CONDITIONER

CONTENTS

HA SECTION

............................................................. COOLER CYCLE 2

Deodorizing Clean Filter .............................................. 2

FULLY AUTOMATIC AIR CONDITIONER ...................... 3

System Description ...................................................... 3

Component Parts Location .......................................... 4

Circuit Diagram ............................................................ 5

Automatic Amplifier Input /Output Signal

Specifications

.............................................................. .6

GI

EG

Performance Test ......................................................... 8 Rs

Trouble Diagnosis by Gauge Pressure ..................... 10

.......... Trouble Diagnosis by Self-diagnosis Function 11

Magnet Clutch System Check ................................... 15

Blower Fan Motor System Check 15

I ..............................

Actuator System Check ............................................. 16 EL

Trouble Diagnosis for Each Symptom ....................... 17

Component Parts Inspection ..................................... 18 SD

Page 163 of 230

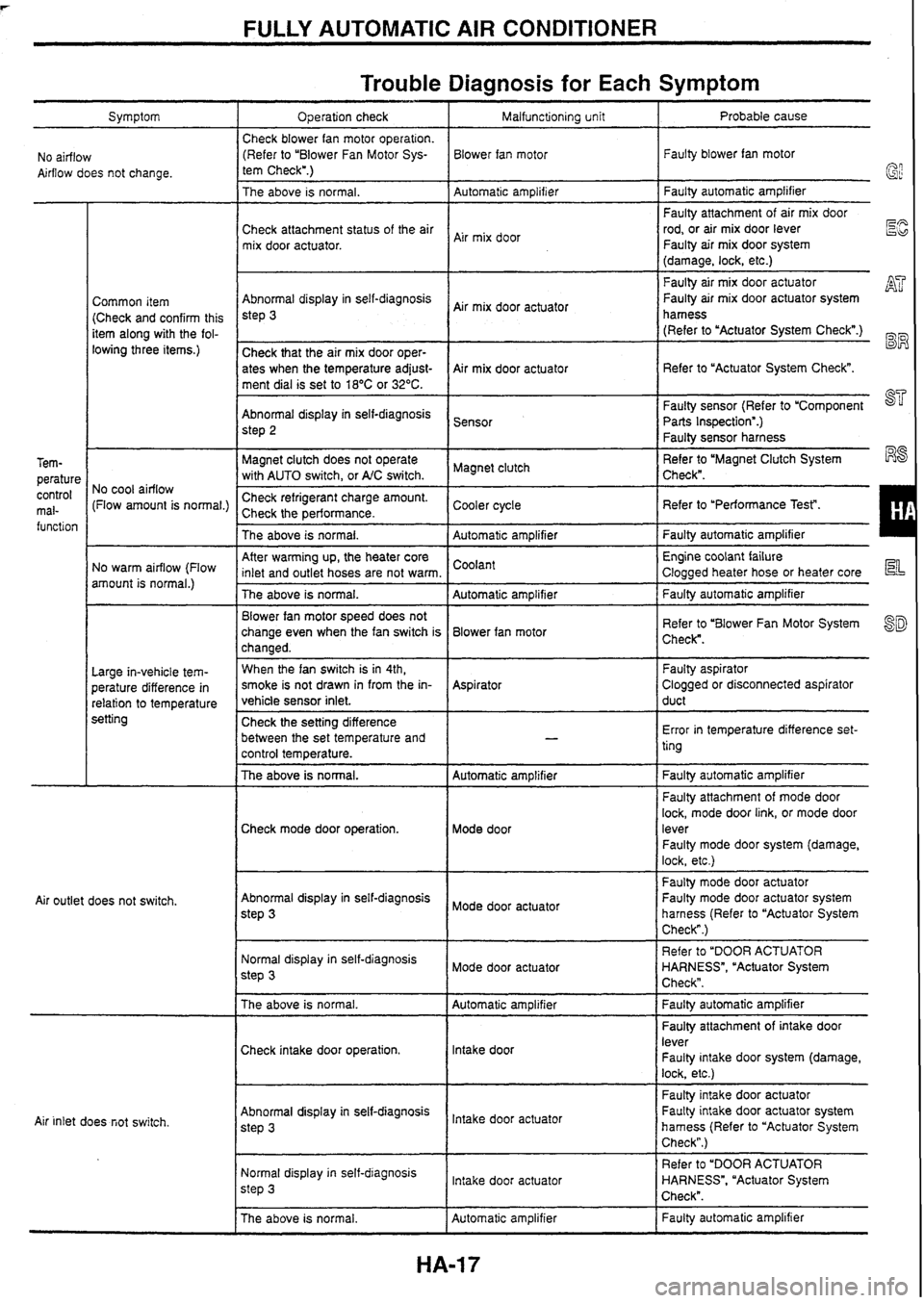

FULLY AUTOMATIC AIR CONDITIONER

Symptom

Trouble Diagnosis for Each Symptom

No airflow

Airflow does not change. Operation check

Check blower fan motor operation. (Refer to "Blower Fan Motor Sys-

tem Check".)

The above is normal.

I Automatic amolifier 1 Faultv automatic amplifier

Faulty attachment of air mix door

rod, or air mix door lever

Faulty air mix door system

ElG

(damage, lock, etc.)

Malfunctioning unit

Blower fan motor Probable cause

Faulty blower fan motor

Check attachment status of the air

mix door actuator.

Common item (Check and confirm this

item along with the fol-

lowing three items.)

Air mix door

Abnormal display in self-diagnosis

step

3

Check that the air mix door oper-

ates when the temperature

adjust-

ment dial is set to

18OC or 32°C.

Faulty sensor (Refer to 'Component a

Parts Inspection".)

Faulty sensor harness

Air

mix door actuator

Air mix door actuator

Abnormal display in self-diagnosis

step 2

Magnet clutch does not operate

Magnet clutch Refer

to 'Magnet Clutch System R8

with AUTO switch, or A/C switch. Check".

I Faulty

air mix door actuator

Faulty air mix door actuator system AT

hamess

(Refer to "Actuator System Check".)

BW

Refer to "Actuator System Check".

@'i?

Sensor

Tem- perature

control mal-

function No

cool airflow

(Flow amount is normal.)

ngeranr

cnarge

amounr.

( Cooler cycle 2 ~erformance. I Refer to 'Performance Test". I

The above is normal. I Automatic amolifier 1 Faulty automatic amplifier I

After warming up, the heater core

inlet and outlet hoses are not warm. 1 Coolant I

Engine coolant failure

Clogged heater hose or heater core

No warm airflow

(Flow

amount is normal.)

The above is normal. Automatic amplifier

1 Faulty automatic amplifier

Blower fan motor speed does not

change even when the fan switch is Blower fan motor

changed. Refer

to "Blower Fan Motor System

Check".

I

When the fan switch is in 4th, Faulty aspirator

smoke is not drawn in from the

in-

Aspirator Clogged

or disconnected aspirator

vehicle sensor inlet. duct

Large

in-vehicle tem-

perature difference in

relation to temperature

setting Check the setting difference

between the set temperature and

control temperature. Error

in temperature difference set-

ting

- The above isnormal.- Automatic amplifier Faulty automatic amplifier

Faulty attachment of mode door

lock, mode door link, or mode door

Check mode door operation. Mode door lever

Faulty mode door system (damage,

lock, etc.)

Faulty mode door actuator

Abnormal display in self-diagnosis Faulty mode door actuator system

step

3 Mode door actuator

harness (Refer to "Actuator System

Check".)

Air

outlet does not switch.

Normal display in self-diagnosis

Mode door actuator

step

3

Refer to "DOOR ACTUATOR

HARNESS", "Actuator System

Check".

The above is normal.

I Automatic amplifier I Faulty automatic amplifier - - I I Faulty attachment of intake door

Check intake door operation. lntake

door lever

Faulty intake door system (damage,

lock, etc.)

~aulG intake door actuator

Faulty intake door actuator system

hamess (Refer to "Actuator System

Check".)

Abnormal

display in self-diagnosis

door step 3 Air inlet does fiot switch.

Normal display in self-diagnosis

lntake door actuator

step

3

Refer to "DOOR ACTUATOR

HARNESS", "Actuator System

Check".

I I The above is normal. I Automatic amplifier I Faulty automatic amplifier

Page 166 of 230

CONTENTS (cm9d)

REAR WIPER ................................................................ 33 Meter Control Unit InpuVOutput Signal

Component

Parts Location ....................................... .33 Specifications -34 ............................................................

Circuit Diagram .......................................................... 33 WIPER DEICER ............................................................. 35

Rear Wiper Amplifier

Input/Output

Signal Component Parts Location

.35 @I .......................................

Specifications ............................................................ .33 Circuit Diagram 35 ..........................................................

REAR DEFOGGER AND HEATER MIRROR ............... 34 Wiper Deicer Switch InpuVOutput Signal

Component Parts Location ..34 Specifications.. 35 EG ...................................... ........................................................... .......................................................... Circuit Diagram 34

Page 199 of 230

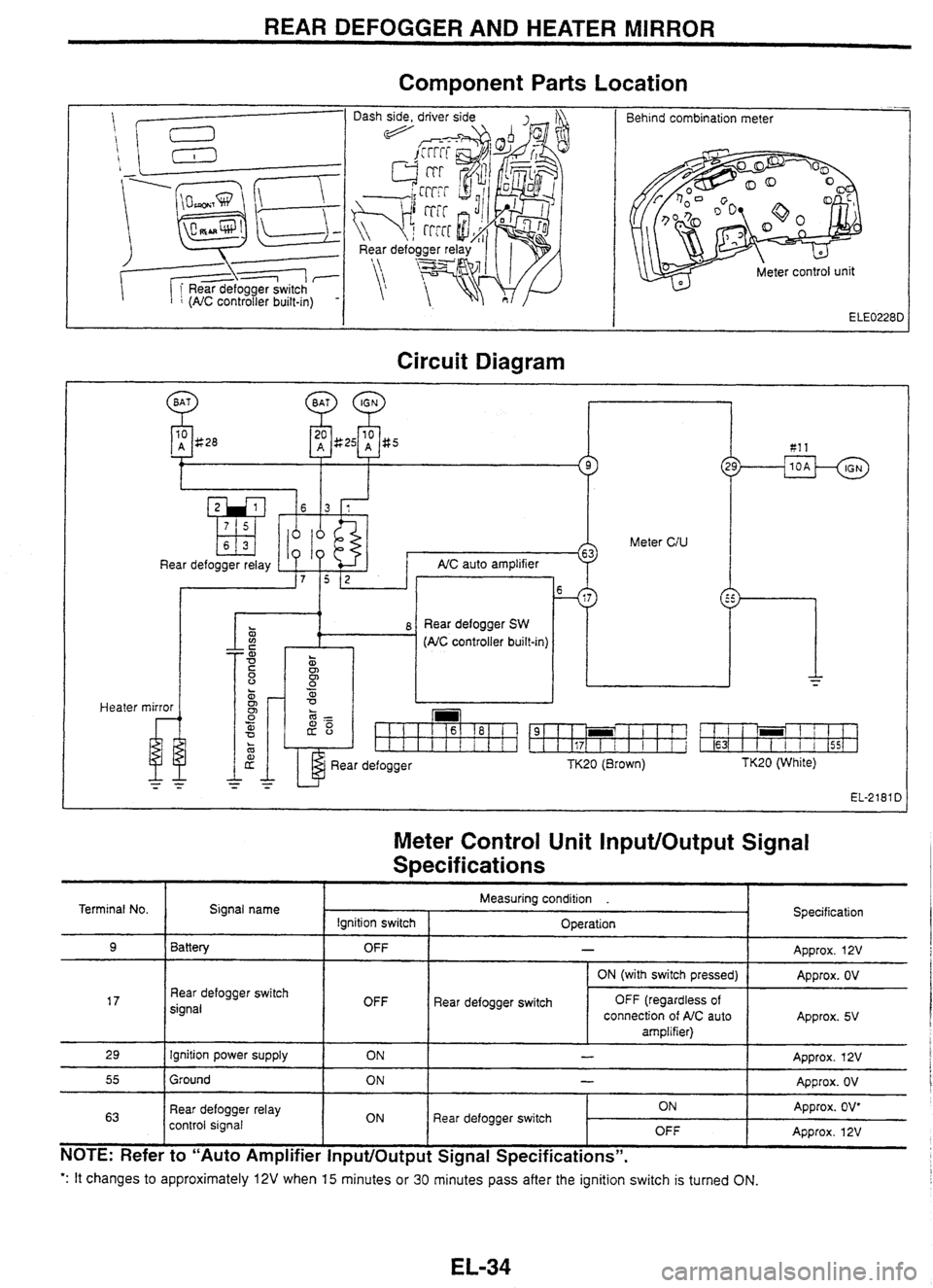

REAR DEFOGGER AND HEATER MIRROR

Component

Parts Location

-- Behind combination meter

Circuit Diagram

Heater

10 A g28 81 1

Meter CIU

Rear defogger relay AIC auto ampl~f~er

. 0

z i 8 Rear defogger SW a (AC controller built-m)

mirror

u

Rear defogger TK20 (Brown) TK20 (White)

EL-2181 D

Meter Control Unit InputlOutput Signal

S~ecif ications

': It changes to approximately 12V when 15 minutes or 30 minutes pass after the ignition switch is turned ON.

Terminal No.

9

17

29

55

63

NOTE: Refer to "Auto Amplifier InputlOutput Signal Specifications".

Signal name

Battery

Rear defogger switch

signal

Ignition power supply

Ground

Rear defogger relay

control signal Specification

Approx.

12V

Approx. OV

Approx. 5V

Approx. 12V

Approx. OV

Approx. OV*

Approx. 12V

Measuring condition .

Ignition switch OFF

OFF ON

ON

ON Operation

-

Rear

defogger switch ON (with switch

pressed)

OFF (regardless of

connection of AIC auto

amplifier)

-

-

Rear defogger switch ON OFF