torque NISSAN GT-R 1998 User Guide

[x] Cancel search | Manufacturer: NISSAN, Model Year: 1998, Model line: GT-R, Model: NISSAN GT-R 1998Pages: 230, PDF Size: 12.66 MB

Page 105 of 230

TCSlABS SYSTEM

Precautions for Trouble

Diagnosis

After performing trouble diagnosis, be sure to erase trouble stored in memory.

Refer to "CONSULT for

TCS/ABS Control Unit Control System"

(BR-27), "Self-diagnosis for TCSIABS

Control Unit Control System"

(BR-34), "CONSULT for Throttle Control Unit Control System" (BR-37) or

"Self-diagnosis for Throttle Control Unit Control System"

(BR-41).

The concerns that are difficult to duplicate may be caused by faulty electrical connections. Move harnesses

or harness connectors by hand to check if there is any poor mating of connector halves or faulty connec-

tion. Do not force to open a connector terminal when using a circuit tester for inspection.

Read GI section thoroughly in advance and make sure of all the general precautions.

Basic Inspection

BASIC INSPECTION 1 - Brake fluid level and leakage

1. Check brake fluid level in reservoir tank. Replenish brake fluid if necessary.

2. Check for leakage at or around brake piping and ABS actuator. If leakage or seepage is noted, proceed

as follows:

If ABS actuator connectors are loose, tighten to specified torque. Recheck to ensure that leakage is no

longer present.

If flare nut threads at piping connectors or actuator threads are damaged, replace faulty parts with new

ones. Recheck to ensure that leakage is no longer present.

If brake fluid leaks through areas other than actuator connectors, wipe off using a clean cloth. Recheck

for leakage or seepage. If necessary, replace faulty parts with new ones.

If brake fluid leaks at or seeps through ABS actuator, wipe off using a clean cloth.

Recheck for leakage or seepage. If necessary, replace ABS actuator with new one.

CAUTION:

ABS actuator cannot be disassembled. Do not attempt to disassemble it.

3. Check brake disc rotors and pads for proper operation.

BASIC INSPECTION 2 - Loose power line terminal

Check battery terminals (positive and negative) and battery mounting (ground) for looseness. If necessary,

tighten to specified torque. Check the battery for lower voltage.

BASIC INSPECTION 3 - SLlP indicator lamp, TCS OFF indicator lamp and ABS warning

lamp

Turn ignition switch "ON" to ensure that TCS OFF indicator lamp lights up. If TCS OFF indicator lamp does

not light, check TCS OFF indicator lamp circuit.

Turn ignition switch

"ON" to ensure that SLlP indicator lamp lights

up. If SLlP indicator lamp does not light,

check SLlP indicator lamp circuit.

Turn ignition switch "ON" to ensure that ABS warning lamp lights up. If ABS warning lamp does not light,

check ABS warning lamp circuit.

Check that the SLlP indicator lamp and the ABS warning lamp go off approx.

1 second after the engine

has started. If either of the lamps still remains on, perform the self-diagnosis for TCSIABS control unit

control system and the self-diagnosis for throttle control unit control system.

After driving vehicle at approx. 30

km/h

for approx.

1 minute, check to ensure that the SLlP indicator lamp

and the ABS warning lamp are off. If either of the lamps still remains on, perform the self-diagnosis for

TCS/ABS

control unit control system and the self-diagnosis for throttle control unit control system.

Check that the TCS OFF indicator lamp turns ON and OFF when the TCS OFF switch is turned to

ON

and OFF respectively, with the engine running. If the lamp status does not correspond to the switch

position, check the TCS OFF switch circuit.

Check that the TCS OFF indicator lamp goes off when the engine has started with the TCS OFF switch

OFF. If the TCS

OFF indicator lamp does not go off even 10 seconds after the engine has started, per-

form the self-diagnosis for TCSIABS control unit control system and the self-diagnosis for throttle control

unit control system.

After driving vehicle at approx.

30 kmlh for approx. 1 minute with the TCS OFF switch OFF, check to ensure

that the TCS OFF indicator lamp is off. If the TCS OFF indicator lamp lights up, perform the

self-diagno-

sis for

TCS/ABS

control unit control system and the self-diagnosis for throttle control unit control system.

After performing self-diagnosis procedures, be sure to erase trouble stored in memory.

Page 203 of 230

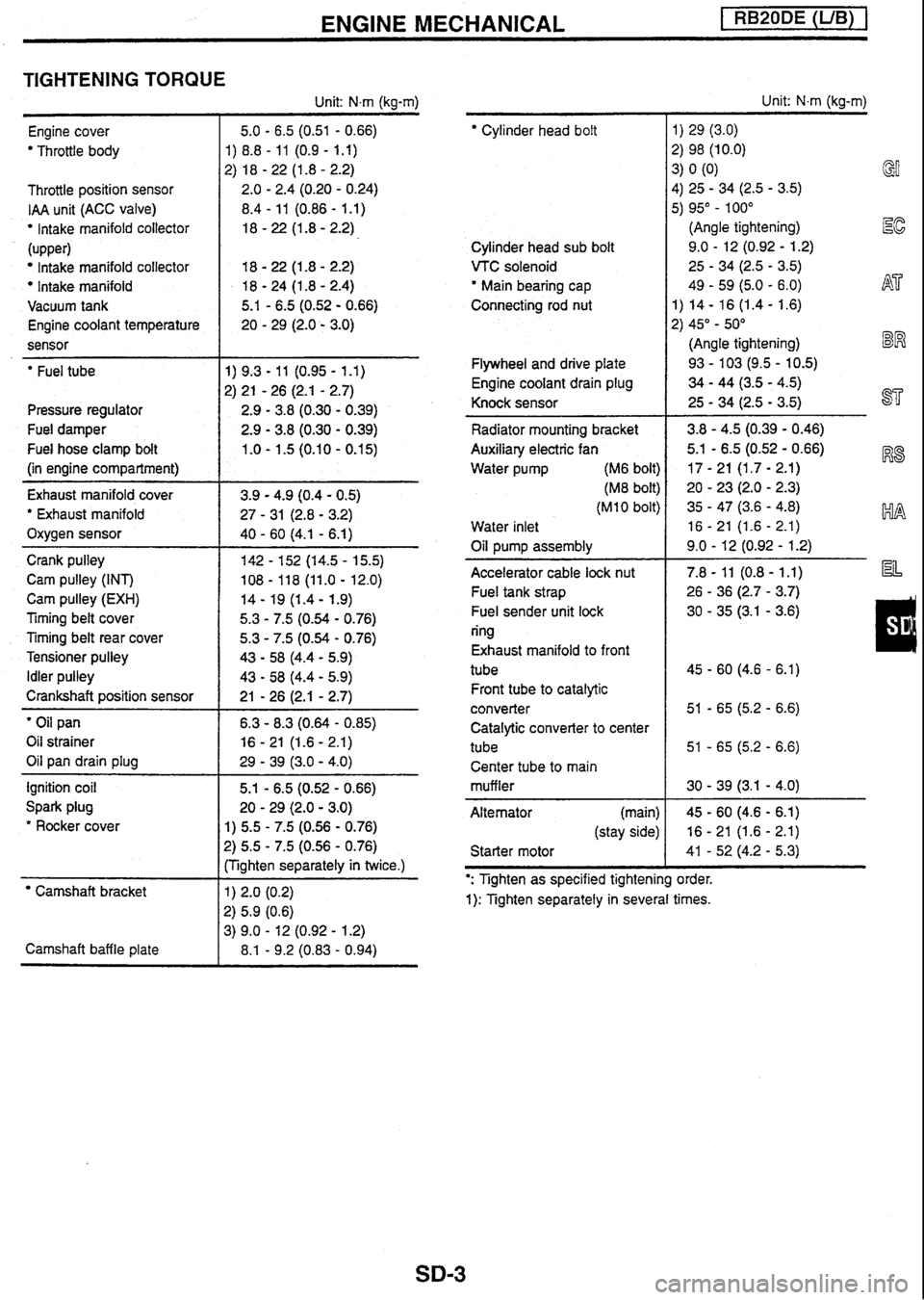

ENGINE MECHANICAL [ RB20DE (UB) 1

TIGHTENING TORQUE

Unit: N.m (kg-m)

Engine cover

Throttle body

Throttle position sensor

IAA unit (ACC valve)

lntake manifold collector

(upper)

Intake manifold collector

Intake manifold

Vacuum tank

Engine coolant temperature

sensor

- --

' Fuel tube

Pressure regulator

Fuel damper

Fuel hose clamp bolt

(in engine compartment)

Exhaust manifold cover

' Exhaust manifold

Oxygen sensor

Crank pulley

Cam pulley (INT)

Cam pulley

(EXH)

Timing belt cover

Timing belt rear cover

Tensioner pulley

Idler pulley

Crankshaft position sensor

' Oil pan

Oil strainer

Oil pan drain plug

ignition coil

Spark plug

* Rocker cover

Camshaft bracket

Camshaft baffle plate 5.1

- 6.5 (0.52 - 0.66)

20

- 29 (2.0 - 3.0)

1) 5.5 - 7.5 (0.56 - 0.76)

?) 5.5 - 7.5 (0.56 - 0.76)

:Tighten separately in twice.)

Cylinder head bolt

Cylinder head sub bolt

VTC solenoid

' Main bearing cap

Connecting rod nut

Flywheel and drive plate

Engine coolant drain plug

Knock sensor

Radiator mounting bracket

Auxiliary electric fan

Water pump (M6 bolt)

(M8 bolt)

(MI 0 bolt)

Water inlet

Oil pump assembly

Accelerator cable

lock nut

Fuel tank strap

Fuel sender unit lock

ring

Exhaust manifold to front

tube Front tube to catalytic

converter Catalytic converter to cent

tube Center tube to main

muffler

Alternator (main)

(stay side)

Starter motor Unit:

N-m (kg-m)

1)

29 (3.0)

2) 98 (10.0)

3)

0

(0)

4) 25

- 34 (2.5 - 3.5) GI

5) 95" - 100"

(Angle tightening)

Ec

9.0 - 12 (0.92 - 1.2)

25

- 34 (2.5 - 3.5)

49

- 59 (5.0 - 6.0) h$7'

1) 14 - 16 (1.4 - 1.6)

2) 45"

- 50"

(Angle tightening)

BW

93 - 103 (9.5 - 10.5)

34 - 44 (3.5 - 4.5)

25

- 34 (2.5 - 3.5) ST

': Tighten as specified tightening order.

1): Tighten separately in several times.

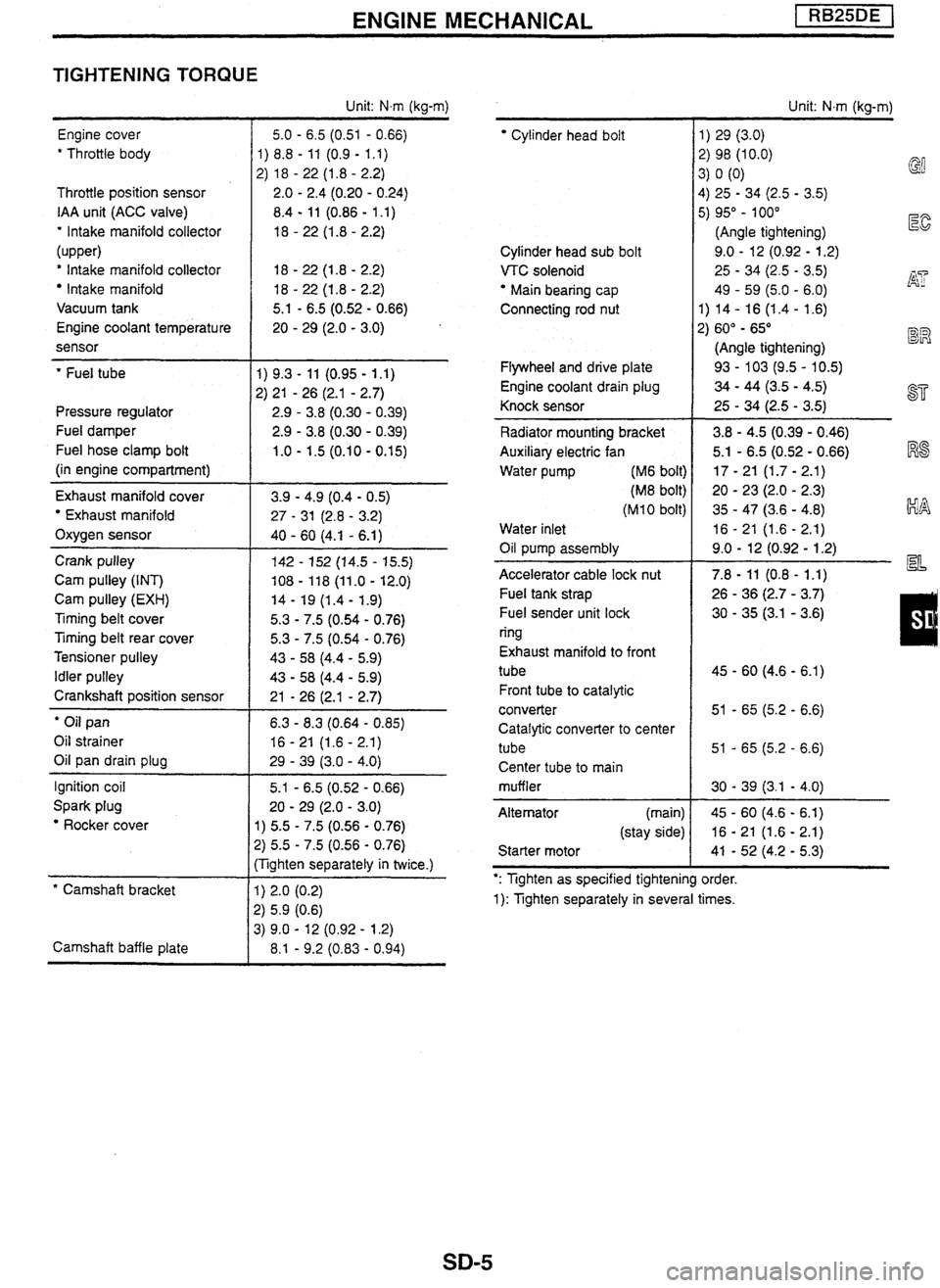

Page 205 of 230

ENGINE MECHANICAL

TIGHTENING TORQUE

Engine cover

' Throttle body

Throttle position sensor

IAA unit (ACC valve)

' Intake manifold collector

(upper)

' Intake manifold collector

Intake manifold

Vacuum tank

Engine coolant temperature

sensor

' Fuel tube

Pressure regulator

Fuel damper

Fuel hose clamp bolt

(in engine compartment)

Exhaust manifold cover

Exhaust manifold

Oxygen sensor

Crank pulley

Cam pulley (INT)

Cam pulley

(EXH)

Timing belt cover

Ttming belt rear cover

Tensioner pulley

Idler pulley

Crankshaft position sensor

' Oil pan

Oil strainer

Oil pan drain plug

Ignition coil

Spark plug

Rocker cover

* Camshaft bracket

Camshaft baffle plate Unit:

Nm (kg-m)

5.0

- 6.5 (0.51 - 0.66)

1) 8.8

- 11 (0.9 - 1.1)

2) 18

- 22 (1.8 - 2.2)

2.0

- 2.4 (0.20 - 0.24)

8.4

- 11 (0.86 - 1 .I)

18

- 22 (1.8 - 2.2)

5.1

- 6.5 (0.52 - 0.66)

20

- 29 (2.0 - 3.0)

1) 5.5 - 7.5 (0.56 - 0.76)

2) 5.5 - 7.5 (0.56 - 0.76)

:Tighten separately in twice.)

Cylinder head bolt

Cylinder head sub bolt

VTC solenoid

Main bearing cap

Connecting rod nut

Flywheel and drive plate

Engine coolant drain plug

Knock sensor

Radiator mounting bracket

Auxiliary electric fan

Water pump

(M6 bolt)

(M8 bolt)

(M 1 0 bolt)

Water inlet

Oil pump assembly

-

Accelerator cable lock nut

Fuel tank strap

Fuel sender unit lock

ring

Exhaust manifold to front

tube

Front tube to catalytic

converter

Catalytic converter to center

tube Center tube to main

muffler

Alternator (main)

(stay side)

Starter motor Unit:

N.m (kg-m)

1) 29 (3.0)

2) 98 (10.0) 3) 0 (0)

@

4)

25 - 34 (2.5 - 3.5)

5) 95" - 100"

(Angle tightening)

E

9.0 - 12 (0.92 - 1.2)

25

- 34 (2.5 - 3.5) j$? 49 - 59 (5.0 - 6.0)

1) 14- 16

(1.4- 1.6)

2) 60"

- 65" BR

(Angle tightening)

93

- 103 (9.5 - 10.5)

34 - 44 (3.5 - 4.5)

25

- 34 (2.5 - 3.5) a=

': Tighten as specified tightening order.

1): Tighten separately in several times.

Page 207 of 230

ENGINE MECHANICAL pEZBq

TIGHTENING TORQUE

Engine cover

' Throttle body

Throttle position sensor

IAA unit

(ACC valve)

' Intake manifold collector

* Intake manifold

Engine coolant temperature

sensor

' Fuel tube

Pressure regulator

Fuel damper

Fuel hose clamp bolt

(in engine compartment)

Turbocharger Oil tube

Water tube (block side)

(turbocharger side)

Oxygen sensor

Exhaust manifold cover

' Exhaust manifold

Crank pulley

Cam pulley (INT)

Cam pulley

(EXH)

Timing belt cover

Timing belt rear cover

Tensioner pulley

Idler pulley

Crankshaft position sensor

' Oil pan

Oil strainer

Oil pan drain plug

Ignition coil

Spark plug

' Rocker cover

' Camshaft bracket

Camshaft baffle plate Unit:

N.m (kg-m)

5.0

- 6.5 (0.51 - 0.66)

1)

8.8

- 11 (0.9 - 1.1)

2)

18

- 22 (1 -8 - 2.2)

2.0

- 2.4 (0.20 - 0.24)

8.4

- 11 (0.86 - 1.1)

18

- 22 (1.8 - 2.2)

18

- 22 (1 -8 - 2.2)

20

- 29 (2.0 - 3.0)

5.1

- 6.5 (0.52 - 0.66)

20

- 29 (2.0 - 3.0)

1) 5.5

- 7.5 (0.56 - 0.76)

2) 5.5 - 7.5 (0.56 - 0.76)

(Tighten separately in twice.)

' Cylinder head boit

Cylinder head sub bolt

VTC solenoid

" Main bearing cap

Connecting rod

nut

Oil jet

Flywheel and drive plate

Engine coolant drain plug

Knock sensor

Radiator mounting bracket

Auxiliary electric fan

Water pump (M6 bolt)

(M8 bolt)

(MI

0 bolt)

Water inlet

Oil pump assembly

Accelerator cable lock nut

Fuel tank strap

Fuel sender unit lock

ring

Exhaust manifold to front

tube

Front tube to catalytic

converter

Catalytic converter to center

tube

Center tube to main

muffler

Alternator (main)

(stay side)

Starter motor Unit:

N.m (kg-m)

1) 29 (3.0)

2) 98 (10.0)

3) 0 (0)

4) 25 - 34 (2.5 - 3.5)

5) 95"

- 100"

(Angle tightening)

I%

9.0 - 12 (0.92 - 1.2)

25

- 34 (2.5 - 3.5)

49

- 59 (5.0 - 6.0) AT

1) 14 - 16 (1.4 - 1.6)

2) 60" - 65"

(Angle tightening) BR

30 - 40 (3.1 - 4.1)

93

- 103 (9.5 - 10.5)

34 - 44 (3.5 - 4.5) ST

25 - 34 (2.5 - 3.5)

3.8

- 4.5 (0.39 - 0.46) I%$

5.1 - 6.5 (0.52 - 0.66)

17

- 21 (1.7 - 2.1)

20

- 23 (2.0 - 2.3) kIA

35 - 47 (3.6 - 4.8)

16

- 21 (1.6 - 2.1)

9.0

- 12 (0.92 - 1.2) a=

': Tighten as specified tightening order.

1): Tighten separately in several times.

Page 208 of 230

CLUTCH

CLUTCH DISC

CLUTCH PEDAL

Engine type I RB20DE I RB25DE I RB25DET

Engine

type

CLUTCH COVER

RB20DE RB25DE

Size mm

Wear

limit (depth to rivet head) mm

Runout limit / diameter at measurement mm

Maximum backlash

at spline mm

Pedal

height mm

Pedal height at clutch released mm

Pedal free play (clevis pin clearance) mm

RB25DET

225 dia. I 240 dia. I 250 dia.

0.3

Engine type

Size mm

TIGHTENING TORQUE

Unit: N-m (ka-m)

172 - 182

Less than 0.7

/ 21 5 dia.

0.9

Diaphragm spring lever height mm

Variation in diaphragm spring lever height mm

Clutch cover fixing bolt More

than 82

RB20DE

225 dia.

Clutch master cylinder fixing bolt

I 7.9 - 10 (0.8 - 1 .I)

Less

than 1.0

/ 230 dia.

33.0

- 35.0

Less than 0.7

9 - 16 (1.0 - 3.0)

More

than 81

Less than 0.7

/ 240 dia.

RB25DE

240 dia. More

than 85

1

.O

RB25DET

250 dia.

37.5

- 39.5

Less than 0.5 48.2

- 50.2

Less than 0.6

Page 209 of 230

MANUAL TRANSMISSION

BACKLASH ADJUSTING SHIMS

Measurement height

mm

--

Items

Main drive gear

1st gear

2nd gear

3rd gear Thickness

mm Standard mm

0.05 - 0.10

0.05

- 0.20

0.05

- 0.20

0.05

- 0.20

Selective parts Parts number

Counter shaft

front bearing

4th gear I -

5th gear 1 0.05 - 0.20 Ail

BAULK RlNG CLEARANCE Reverse idler gear 1 0.05 - 0.20

END PLAY Measurement

position

2nd and 3rd

Inner baulk ring clearance 'an

1 st gear 1 0.31 - 0.41

Items

2nd gear

1 0.11-0.21

Standard

mm

3rd gear 1 0.11 - 0.21

Outer

baulk ring

lnn'er baulk ring

7 4th gear 5th gear

Reverse idler gear

Counter gear Main drive gear end play

Mainshaft high-synchro side

Rear end of mainshaft end bearing

SNAP RlNG

- -

0.24 - 0.41

0.05

- 0.50

0

- 0.16

0

- 0.13

0 - 0.18

0

- 0.14

4th and 5th ( 1.20 - 1.60 1 Less than 0.8

Selective parts

Thickness

mm I Parts number - -- Reverse gear 1 1.10 - 1.55 1 Less than 0.7

Main drive gear

TIGHTENING TORQUE

Unit: N.m (kg-rn)

Counter drive gear

I

TIM side to 40 - 49

Transmission to engine mounting bolt Engine side to 30

- 39

TIM side (3.0 - 4.0) I High-synchro side 32263 V5200 1 32263

"5201

Rear end of shaft I I

Mainshaft 1.1

32228 20 1 00

Page 211 of 230

MANUAL TRANSMISSION pmtq

THRUST WASHER BAULK RING CLEARANCE

Selective parts I Thickness mm I Parts number

Counter gear

(front)

Reverse idler Measurement

position

,

Ist, 2nd and 3rd (double cone)

lnner baulk ring clearance "a*

Outer baulk ring clearance

"bn

3221

8

01

GOO

32218

01G11

3221

8

01G12

32218

01G13

32218

01G14

32218

01G04

32218

01G15

32218

01G16

3221

8 01 GI7

32284

01G10

3228401G11

Outer baulk ring L,

Syncf

cone

4th and 5th

lnner baulk ring

MTA0004D

Reverse gear

Reverse baulk ring

clearance

"cn

Reverse cone

Standard mm Wear

limit

mm

Less than

0.2

Less than

0.2

EC

Less than &$ 0.7

Less than

0.7

--

TIGHTENING TORQUE

Unit: N.m (kg-m)

1 TIM side to 1 40 - 49

Transmission to engine

mounting bolt Engine side to

30 - 39

I T/M side 1 (3.0 - 4.0)

Page 214 of 230

CONTROL VALVE SPECIFICATIONS

Val ve loc

Upper body

Lower body :ation

L1

L2

L3

L4

L5

L6

CONTROL VALVE SPRING SPECIFICATIONS

L7

L8

L9

L10

L11

L13

L14

L15

L16

Unit: mm I 1 I I I I

Valve designation

Torque converter regulator valve

Pressure modifier valve

Pressure regulator valve

Overrun clutch control valve

Lower body Total

length mm

27.5

43.5

68.0

55.5

19.5

56.0

75.0

Accumulator control valve Parts

number

31780 41x01

31751 41x02

31741 80x00

3 1 772

4AXOO

3 1 772

4AX02

31 675 41 X07

31766

- 4AXOO

31766 51x03

4AX03

model

Except

4AX03 model

4AX03 model

Except

4AX03 model

Valve

spring location Throttle accumulator piston

Shift valve

B

Shift valve A

Upper body

Overrun clutch reducing

63.5

65.0

Overrun clutch reducing valve

Pilot valve

Torque converter clutch control valve

L1

L2 L3

L4

L5

L6

L7

Valve spring designation

Torque converter regulator valve spring

Pressure modifier valve spring

Pressure regulator valve spring

Throttle accumulator piston spring

A

Shift valve B spring

Shift valve

A spring

31 766 51 X04

31766 4AX02

54.5

38.5 58.0

57.0

67.0

37.5

37.5

41

.O

66.0 38.5

Shuttle shift valve S

Free length

36.0

31.95

31.8

30.5

23.5 25.0

23.6

38.3

Overrun clutch control valve

spring

4AX03 model

Pilot valve spring

r

Torque converter clutch control valve spring

31 772 41 X06

31772 41x01

31 832

4AX01

31766 51x05

31766 4AX01

31772 41x12

31772 4AX01

31772 71x00

31 772 41 X03

31772

21x00

4AX03

model

Except

4AX03 model

4AX03 model

Except

4AX03 model

/ L~ / valve spring

26.5

46.5

54.0

25.0

22.6

25.4

23.0

23.0

33.89

I

I I

Shuttle shift valve S spring

1 reducing valve spring Outer

diameter

'D"

9.0

6.8

15.0

9.8

11.0

7.0

7.0

8.0

Except 4AX03 model

32.5

4AX03

model

Except

4AX03 model

4AX00 model

Except

4AX00 model

1 reducing valve

9.0

6.5

5.65

7.0

6.7

6.75

6.7

6.7

6.95

3-2

timing

valve spring

Servo charger valve spring

Lock-up regulator valve spring

3-2 timing valve

Wire

diameter

"d"

1.4

0.8 1.3

1.3

0.8

0.65

0.6

0.55

35.5 7.0

4AX03

model

Except

4AX03 model

1.1

0.8

0.75

0.65 0.7

0.75

0.7

0.7

0.55

Servo charger valve

Lock-up regulator valve

Winding

direction Right

4

1

7

t

?

T

T

7.0 0.85

T

?

T

T

?

T

T

T

.. I

Parts

number

31742

4AXOO

3 1 742

41x19

31742

4AXO 1

31 742

41

XI 5

31742

4AX02

3

1762

41x01

3 1762

41x03

31762

4AXOO

0.9

T 31742

t

41 X63

31742

41x65

Page 217 of 230

AUTOMATIC TRANSMISSIO

Standard 0.10 - 0.25 Low one-way clutch inner race to seal ring clearance mm

Limit 0.25

OIL PUMP AND LOW ONE-WAY CLUTCH

-

TOTAL END PLAY --

Total end play mm 0.25 - 0.55 I

0.1 5 - 0.22

0.11

- 0.18 Oil pump clearance mm

Thickness mm

Inner gear and outer gear to housing

0.03 - 0.05

Standard 0.1 0 - 0.25 Oil pump cover to seal ring clearance mm , Limit 0.25

Outer

gear to crescendo

Outer gear to housing

I Parts number

Bearing race

REVERSECLUTCHENDPLAY

Reverse clutch drum end play mm 0.55 - 0.90 I

Oil pump thrust washer

ADJUSTMENT OF TANDEM BRAKE BAND TENSION

Number of turns of anchor end pin back-off I 2.375 - 2.625

Anchor end pin tightening torque N.m (kg-m) 4.0 - 5.8

(0.4 - 0.6)

TIGHTENING TORQUE

Unit: N.m (kg-m)

Lock

nut tightening torque N-m

(kg-m)

Transmission to engine mounting bolt

41 - 50 (4.1 - 5.2)

I TIM side to engine side I 40 - 49 (4.0 - 5.0) - - - - - - -- - - - - - -

I Engine side to TIM side I 30 - 39 (3.0 - 4.0)

Page 219 of 230

PROPELLER SHAFT

Type

2S56A 3S63C-T

3S71 C-T

3F80A-2VL107

Journal bearing end play mm

TIGHTENING TORQUE

Unit: N.m (kg-m)

Amount of runout mm

0

Center bearing bracket to underbody

Propeller

shaft flange yoke to companion flange Less

than

0.6

42

- 48 (4.2 - 4.9)

55 - 64 (5.6 - 6.6) .