bulb NISSAN GT-R 1998 Service Manual

[x] Cancel search | Manufacturer: NISSAN, Model Year: 1998, Model line: GT-R, Model: NISSAN GT-R 1998Pages: 230, PDF Size: 12.66 MB

Page 24 of 230

TROUBLE DIAGNOSES

Self-diagnosis (Cont'd)

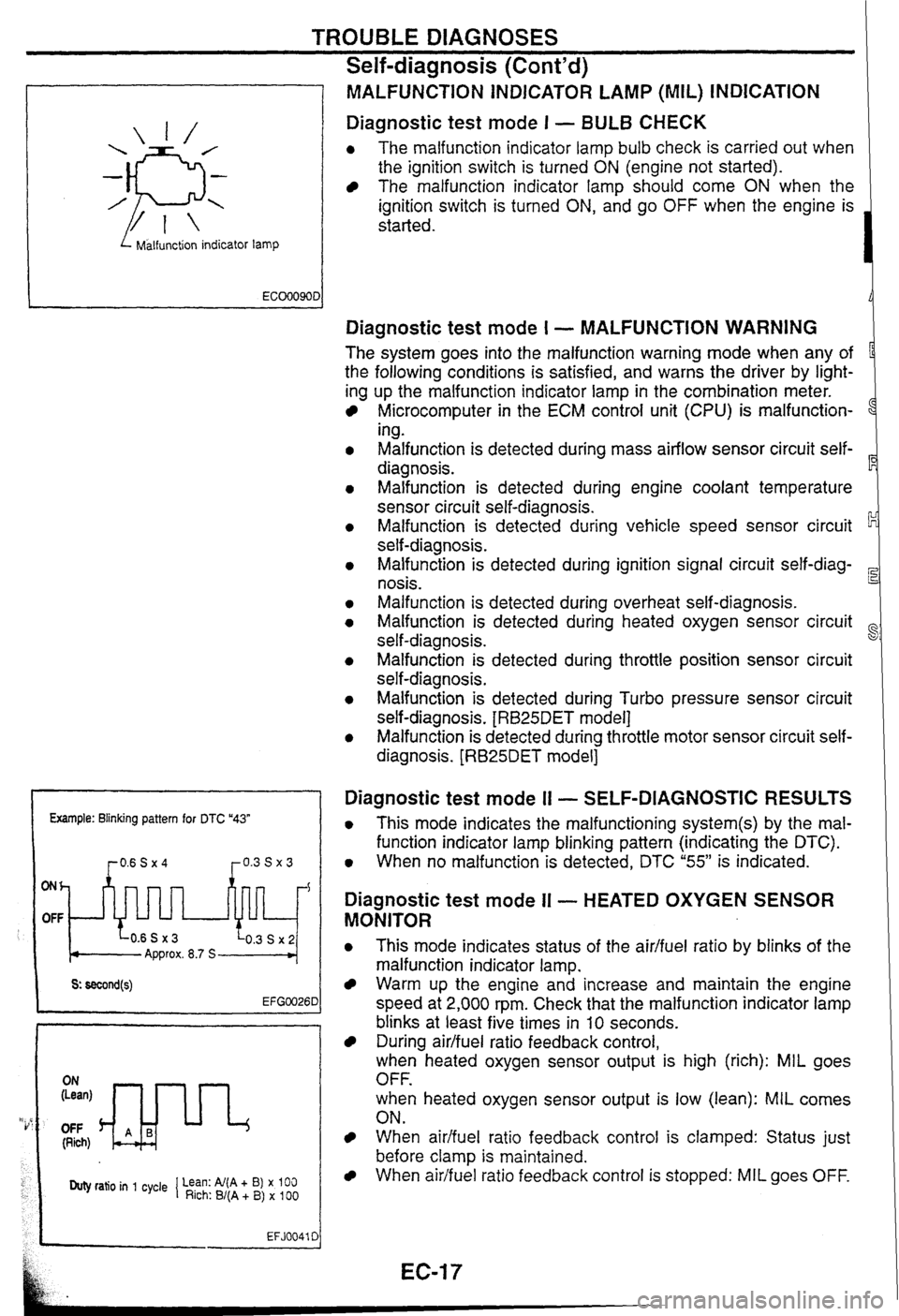

I Malfunction indicator lamp

MALFUNCTiON INDICATOR LAMP (MIL) INDICATION

Diagnostic test mode I - BULB CHECK

0 The malfunction indicator lamp bulb check is carried out when

the ignition switch is turned

ON (engine not started).

The malfunction indicator lamp should come ON when the

ignition switch is turned

ON, and go OFF when the engine is

started.

Example: Blinking pattern for DTC "43"

ONh

OFF

Approx. 8.7 S

OFF (Rich)

Duty ratio in 1 cycle 1 Lean: Al(A + B) x 100 Rich: B/(A + B) x 100

EFJ0041 C

Diagnostic test mode I - MALFUNCTION WARNING

The system goes into the malfunction warning mode when any of

the following conditions is satisfied, and warns the driver by light-

ing up the malfunction indicator lamp in the combination meter.

Microcomputer in the ECM control unit (CPU) is malfunction-

1

ing.

Malfunction is detected during mass airflow sensor circuit self-

diagnosis.

Malfunction is detected during engine coolant temperature

sensor circuit self-diagnosis.

Malfunction is detected during vehicle speed sensor circuit

self-diagnosis.

Malfunction is detected during ignition signal circuit

self-diag-

nosis.

Malfunction is detected during overheat self-diagnosis.

Malfunction is detected during heated oxygen sensor circuit

self-diagnosis.

~alfunsion is detected during throttle position sensor circuit

self-diagnosis.

Malfunction is detected during Turbo pressure sensor circuit

self-diagnosis.

[RB25DET model]

Malfunction is detected during throttle motor sensor circuit self-

diagnosis.

[RB25DET model]

Diagnostic test mode I1 - SELF-DIAGNOSTIC RESULTS

0 This mode indicates the malfunctioning system(s) by the mal-

function indicator lamp blinking pattern (indicating the DTC).

0 When no malfunction is detected, DTC "55" is indicated.

Diagnostic test mode II - HEATED OXYGEN SENSOR

MONITOR

0 This mode indicates status of the aidfuel ratio by blinks of the

malfunction indicator lamp.

Warm up the engine and increase and maintain the engine

speed at 2,000 rpm. Check that the malfunction indicator lamp

blinks at least five times in

10 seconds.

During airlfuel ratio feedback control,

when heated oxygen sensor output is high (rich): MIL goes

OFF.

when heated oxygen sensor output is low (lean):

MIL comes

ON.

When aidfuel ratio feedback control is clamped: Status just

before clamp

is maintained.

When airifuel ratio feedback control is stopped: MIL goes OFF.

Page 154 of 230

FULLY AUTOMATIC AIR CONDITIONER

Performance Test

PROCEDURE

Connect the manifold gauge to the vehicle side cooler cycle (service valve).

Attach a psychrometer to the recirculation air inlet port of the blower and cooling unit (below the glove box);

and attach a dry-bulb thermometer to the right side of the center ventilator grille.

Start and

warm up the engine.

After warming up the engine, check that the engine speed has reached the standard idle speed.

After pressing the AUTO switch, operate the fan switch, mode switch (air outlet switch),

REG switch, tem-

perature adjustment dial and switch; and satisfy the following conditions.

Fan speed: 4th

Air inlet: Recirculation

Air outlet: Ventilator (VENT)

Temperature setting:

18°C

Completely open the hood and all door windows, and close all doors.

Maintain these conditions until the cooler cycle stabilizes. (Approx.

10 minutes)

Maintain the engine speed at idle.

Measure the recirculation inlet temperature and humidity, outlet temperature, and cooler cycle high- and

low-pressures. Compare and judge the values with the "AMBIENT AIR TEMPERATURE AND PRESSURE

CHARACTERISTICS and "INTAKE AIR TEMPERATURE AND DISCHARGE AIR TEMPERATURE CHAR-

ACTERISTICS.

Page 180 of 230

XENON HEADLAMP SYSTEM

Trouble Diagnoses

DESCRIPTION

Problems with xenon headlamps are as follows:

They do not light up.

They blink.

GD

They are not bright enough.

In most cases the problems above are caused by faulty xenon bulbs.

There might be the possibility that the problems are caused by faulty HID control unit or lamp sockets.

ec

Follow the diagnostic procedure to determine what causes the problem.

PRECAUTIONS AT

Connect or disconnect connectors with the lighting switch OFF.

Do not touch harnesses, HID control unit, internal lamp, or metal part of the lamp while the lamps are

ON B2

(Lighting switch is ON).

Before verifying that the lamps are ON, install the parts to the vehicle temporarily and connect the battery

cable with

the connector on the vehicle. ST

If the electrical system is suspected to be the cause of the symptom, check for blown fuse or fusible link,

broken connectors, disconnected terminals, or faulty engagement.

Do not use wet hands when performing the trouble diagnoses.

F@

CIRCUIT DIAGRAM

, MA Xenon

headlamp

relay

To clearance

JJ$Rkj

lamp and

tail lamp

Headlamp

1 -- - -1 : High-voltage parts

Driver door SM

CAUTION:

0 Do not use a tester to diagnose the HID control unit circuit.

0 Do not disassemble the HID control unit and harnesses (bulb socket harness and control unit har-

ness).

0 Immediately after the headlamps turn ON, brightness and emission color vary. This is a normal

condition.

When a bulb has reached the end of its life, the brightness becomes extremely low, the bulb con-

tinues to blink, or the light looks reddish.

Page 181 of 230

XENON HEADLAMP SYSTEM

Trouble Diagnoses (Cont'd)

DIAGNOSTIC PROCEDURE

I

FUSE, FUSIBLE LINK, AND XENON Fuse, fusible link, or xenon

HEADLAMP RELAY CHECK headlamp relay is faulty.

CONNECTOR CHECK ON THE VEHICLE Harness on the vehicle is

FOR BATTERY VOLTAGE faulty.

With lighting switch ON, check HID control

unit connector on the vehicle for battery

I voltage. I

OK

XENON HEADLAMP BULB REPLACE- Xenon bulb is faulty.

MENT

Replace the xenon headiamp bulb with a

known

good bulb and check for proper

operation.

HID CONTROL UNIT REPLACEMENT HID control unit is faulty.

Install a known good

HID control unit to

I

the xenon headlarnp and check for proper

operation.

NG

XENON HEADLAMP HOUSING ASSEM- OK, BLY REPLACEMENT

Install a known good xenon headlamp

housing assembly to the xenon

headlamp

and check for proper operation.

---

Starter in xenon headlamp

housing (boost circuit) is

faulty. (Xenon

headlamp housing

assembly

is faulty.)

Page 183 of 230

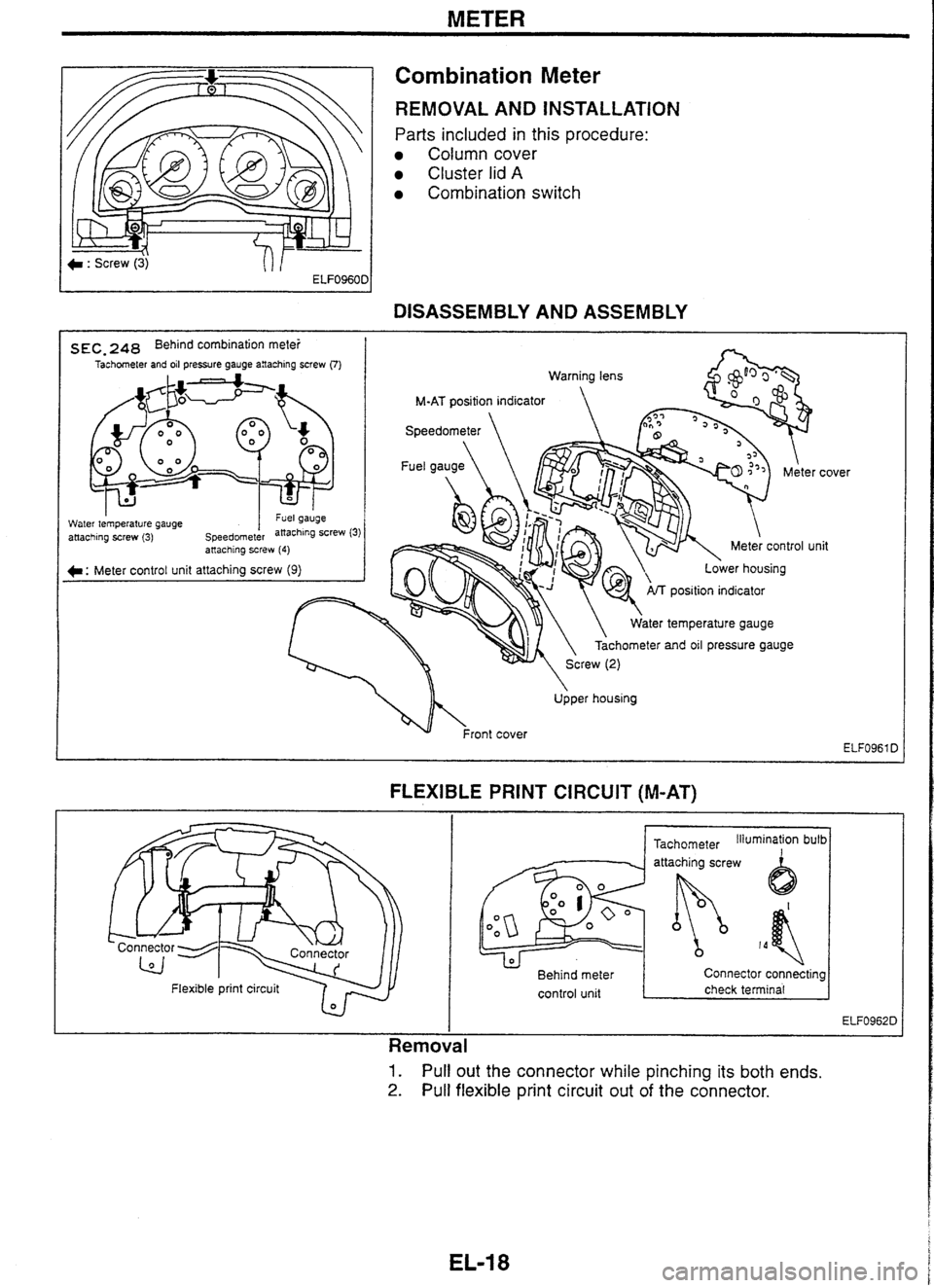

METER

Combination Meter

REMOVAL AND INSTALLATION

Parts included in this procedure:

Column cover

Cluster lid A

Combination switch

-

DISASSEMBLY AND ASSEMBLY

s EC, 248 Behind combination mete! I Tachometer and oil pressure gauge anaching screw (7)

Water tem~erature cauae I "GI yauyc - .. attaching screw (3) speedornet&

position indicator

ater temperature gauge

Tachometer

and oil pressure gauge

. . anaching screw (4)

C: Meter control unit attaching screw (9)

Upper housing cover

lit

FLEXIBLE PRINT CIRCUIT (M-AT)

I I

- Flexible

print circuit 7 r,

Tachometer Illumination bulb I

Behind meter Connector connecting

control unit

I check terminal I

I

Removal

1. Pull out the connector while pinching its both ends.

2. Pull flexible print circuit out of the connector.

Page 184 of 230

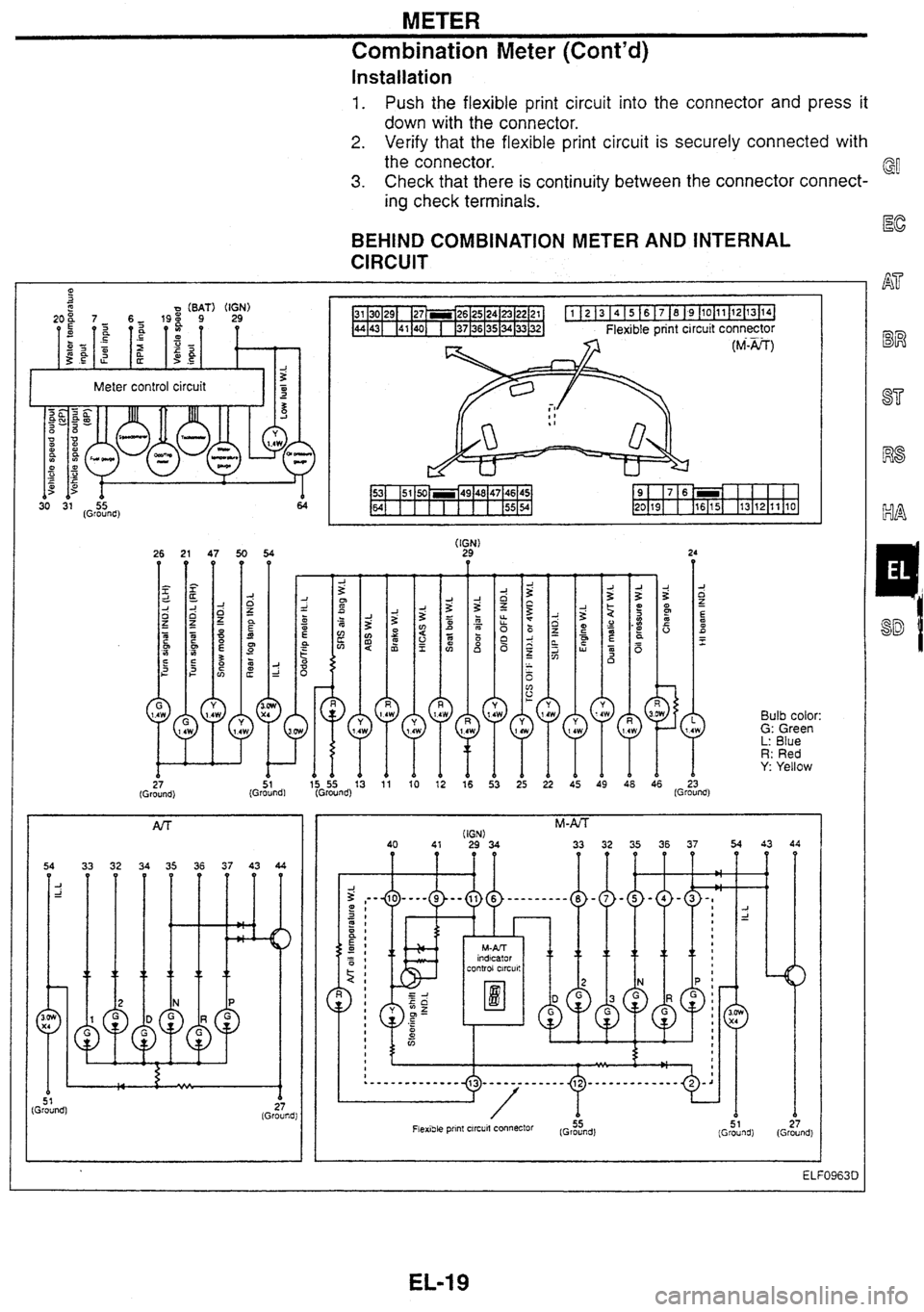

METER

Combination Meter (Cont'd)

Installation

1. Push the flexible print circuit into the connector and press it

down with the connector.

2. Verify that the flexible print circuit is securely connected with

the connector.

3. Check that there is continuity between the connector connect-

ing check terminals.

BEHIND COMBINATION METER AND INTERNAL

CIRCUIT

1 27 (Ground)

2 x

z g2

15 55 13 (Ground)

1 51 (Ground)

5 1 Ground) z I (Ground!

Bulb color: G: Green L: Blue R: Red Y: Yellow

51 27 (Ground)

(Ground)

Page 188 of 230

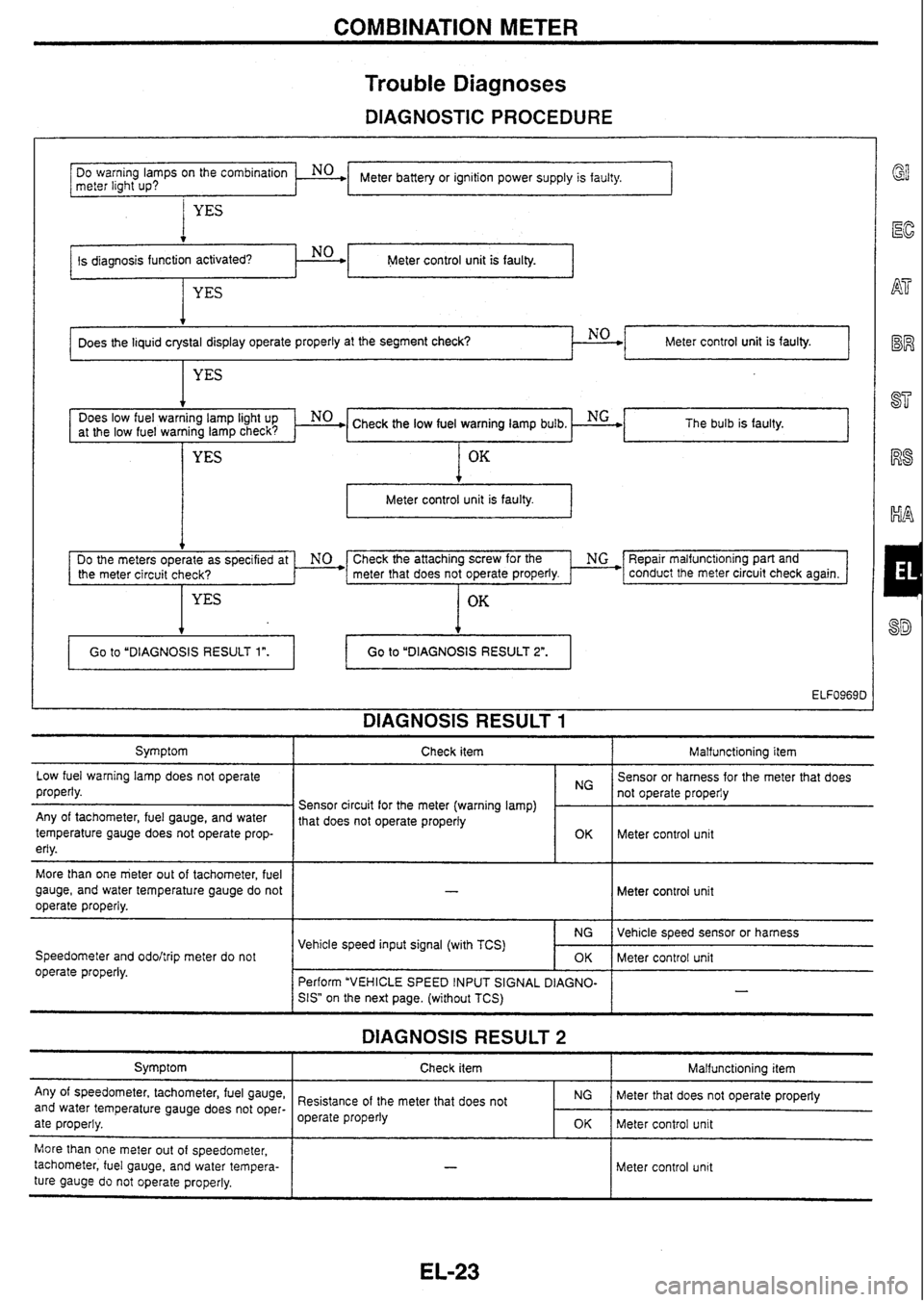

COMBINATION METER

Trouble

Diagnoses

DIAGNOSTIC PROCEDURE

I YES

Meter control unit is faulty.

Meter battery or ignition power supply is faulty.

DO

warning

lamps

on

the

meter light

up?

. No .

at the low fuel warning lamp check? The bulb

is faulty.

t

Meter control unit is faulty. I

Does the liquid crystal display operate properly at the segment check? NO

Check the attaching screw for the ' NG *F3epair malfunct~oning part and

the meter circuit check? meter that

does not operate properly. * conduct the meter circuit check again.

OK

Meter control unit is faulty.

YES

DIAGNOSIS RESULT 1

4

Symptom I Check item I Malfunctioning item

Go

to "DIAGNOSIS RESULT

1".

Low fuel warning lamp does not operate

properly. Go to

"DIAGNOSIS RESULT

2".

Any of tachometer, fuel gauge, and water

temperature gauge does not operate prop-

erly.

More than one meter out of tachometer, fuel

gauge, and water temperature gauge do not

operate properly.

Speedometer and

odohrip meter do not

operate properly. Sensor

or harness for the meter that does

Sensor circuit for the meter (warning lamp)

1 1: 1 not operate properiy

1 that does not operate properly

~ Meter control unit

Meter control unit

DIAGNOSIS RESULT 2

Symptom

Any of speedometer, tachometer, fuel gauge,

and water temperature gauge does not oper-

ate properly. Vehicle

speed sensor or harness

Meter control unit

-

Vehicle speed input signal (with TCS)

Check item

I Malfunctioning item

NG

OK

Perform "VEHICLE SPEED INPUT SIGNAL

DIAGNO-

SIS"

on the next page. (without TCS)

More than one meter out of speedometer,

tachometer, fuel gauge, and water tempera-

ture gauge

do not operate properly. Resistance

of the meter that does not

operate properly

Meter control unit

NG

OK

- -

Meter that does not operate properly

Meter control unit