fuse NISSAN GT-R 1998 Service Manual

[x] Cancel search | Manufacturer: NISSAN, Model Year: 1998, Model line: GT-R, Model: NISSAN GT-R 1998Pages: 230, PDF Size: 12.66 MB

Page 45 of 230

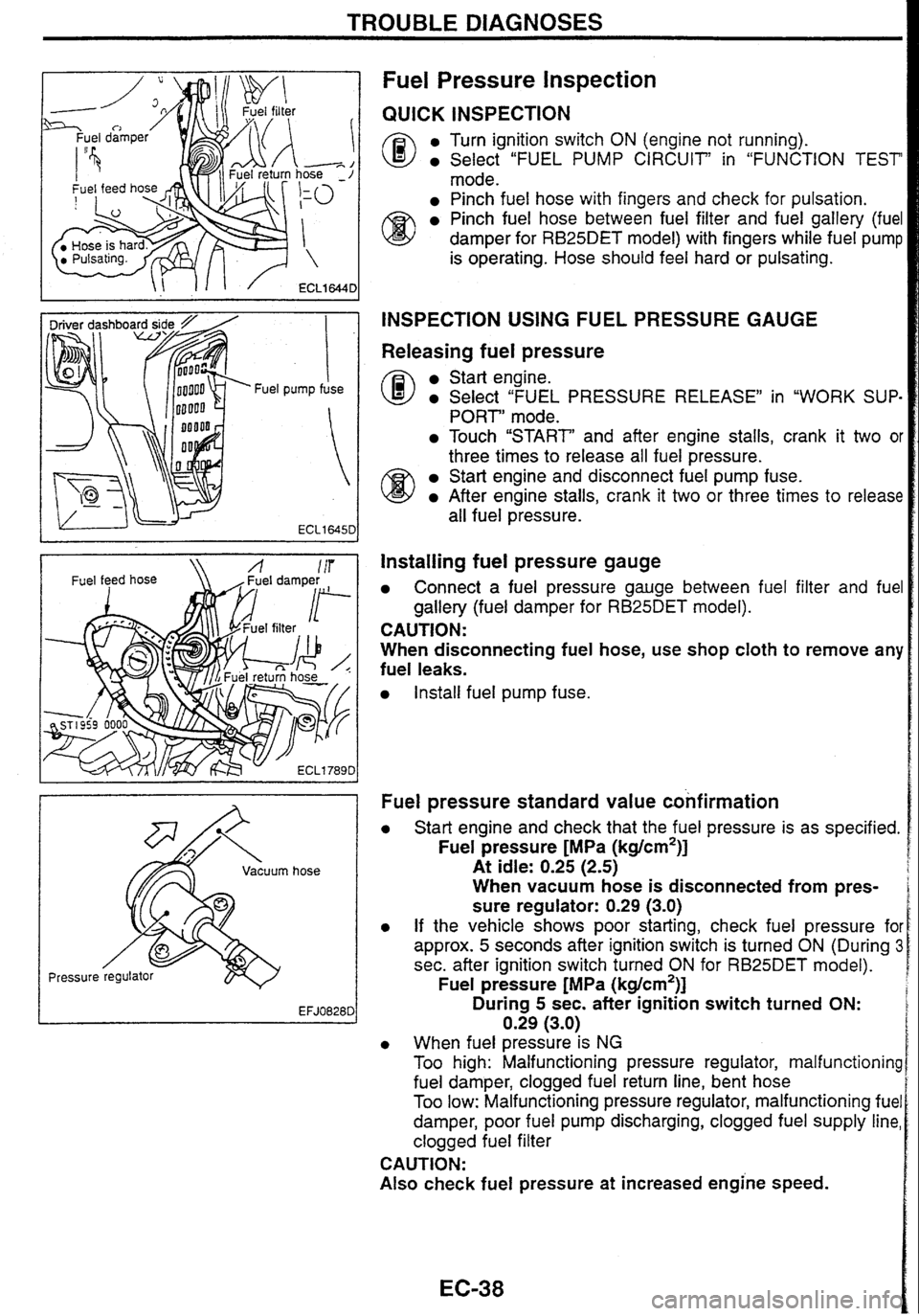

TROUBLE DIAGNOSES

Fuel Pressure Inspection

Fuel pump fuse

Pressure hose

QUICK

INSPECTION

0 Turn ignition switch ON (engine not running).

Select "FUEL PUMP CIRCUIT' in "FUNCTION TEST

mode.

Pinch fuel hose with fingers and check for pulsation.

Pinch fuel hose between fuel filter and fuel gallery (fue

@ damper for RB2SDET model) with fingers while fuel puml

is operating. Hose should feel hard or pulsating.

INSPECTION USING FUEL PRESSURE GAUGE

Releasing fuel pressure

Start engine.

Select "FUEL PRESSURE RELEASE" in "WORK SUP

PORT' mode.

Touch "START' and after engine stalls, crank it two o

three times to release all fuel pressure.

Start engine and disconnect fuel pump fuse.

After engine stalls, crank it two or three times to releas

all fuel pressure.

Installing fuel pressure gauge

Connect a fuel pressure gauge between fuel filter and fue

gallery (fuel damper for

RB25DET model).

CAUTION:

When disconnecting fuel hose, use shop cloth to remove an!

fuel leaks.

Install fuel pump fuse.

Fuel pressure standard value confirmation

Start engine and check that the fuel pressure is as specified.

Fuel pressure [MPa (kg/cm2)]

At idle: 0.25 (2.5)

When vacuum hose is disconnected from pres-

sure regulator:

0.29 (3.0)

If the vehicle shows poor starting, check fuel pressure fo

approx.

5 seconds after ignition switch is turned ON (During :

sec. after ignition switch turned ON for RB25DET model).

Fuel pressure [MPa (kg/cm2)]

During 5 sec. after ignition switch turned ON:

0.29 (3.0)

When fuel pressure is NG

Too high: Malfunctioning pressure regulator, malfunction in^

fuel damper, clogged fuel return line, bent hose

Too low: Malfunctioning pressure regulator, malfunctioning fue

damper, poor fuel pump discharging, clogged fuel supply line

clogged fuel filter

CAUTION:

Also check fuel pressure at increased engine speed.

Page 95 of 230

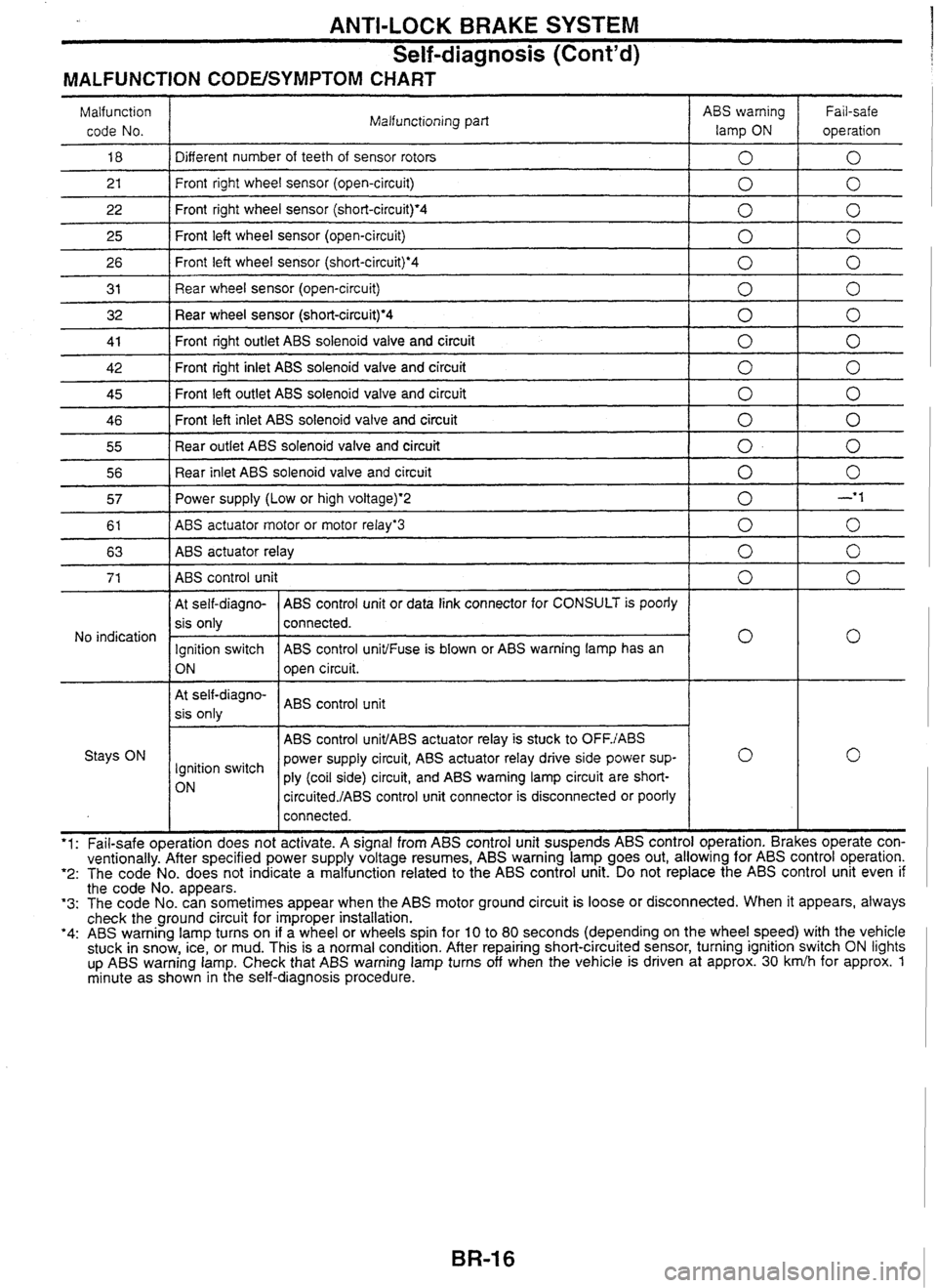

ANTI-LOCK BRAKE SYSTEM

Self-diagnosis (Cont'd)

MALFUNCTION CODEISYMPTOM CHART

Malfunction code No. Malfunctioning

part ABS warning

lamp

ON

Fail-safe

operation

18 1 Different number of teeth of sensor rotors 1010

2 1

26 I Front left wheel sensor (short-circuiQ.4 1010

- --

22

25

3 1 I Rear wheel sensor (open-circuit) 1010

Front right wheel sensor (open-circuit)

32 Rear wheel sensor (short-circuit)'4 1 0 1 0

Front right wheel sensor (short-circuit)'4

Front left wheel sensor (open-circuit)

41

I Front right outlet ABS solenoid valve and circuit 1010

0 0

0

0

0

0

- -

42

-- - -

46 Front left inlet ABS solenoid valve and circuit 0 1 0

45 Front

left outlet ABS solenoid valve and circuit

55

1 Rear outlet ABS solenoid valve and circuit 1010

Front right inlet ABS solenoid valve and circuit

56

1 Rear inlet ABS solenoid valve and circuit 1010

0

57 1 Power supply (Low or high voltage)*2 I 0 I -'I

0

0

0

I At self-diagno- ( ABS control unit or data link connector for CONSULT is poorly 1 I

61

63

At self-diagno-

I ABS control unit

sis only

ABS

actuator motor or motor relayg3

ABS

actuator relay

No indication

I I ABS control unit1ABS actuator relay is stuck to OFFJABS I Stays ON power supply circuit, ABS actuator relay drive side power sup-

lgnition switch

ply (coil side) circuit, and ABS warning lamp circuit are

short-

circuited./ABS control unit connector is disconnected or poorly

0

0

I

sis only

Ignition switch

ON

I I connected. I I

0

0

connected.

ABS control

unit1Fuse is blown or ABS warning lamp has an

open circuit.

- -- '1: Fail-safe operation does not activate. A signal from ABS control unit suspends ABS control operation. Brakes operate con-

ventionally. After specified power supply voltage resumes, ABS warning lamp goes out, allowing for ABS control operation. '2: The code No. does not indicate a malfunction related to the ABS control unit. Do not replace the ABS control unit even if the code No. appears. '3: The code No. can sometimes appear when the ABS motor ground circuit is loose or disconnected. When it appears, always

check the ground circuit for improper installation.

'4: ABS warning lamp turns on if a wheel or wheels spin for 10 to 80 seconds (depending on the wheel speed) with the vehicle

stuck in snow, ice, or mud. This is a normal condition. After repairing short-circuited sensor, turning ignition switch ON lights

up

ABS warning lamp. Check that ABS warning lamp turns off when the vehicle is driven at approx. 30 krnlh for approx. 1 minute as shown in the self-diagnosis procedure.

Page 139 of 230

![NISSAN GT-R 1998 Service Manual

TROUBLE DIAGNOSES - Su~plemental Restraint Svstem (SRS)

-

connector for

SELF-DlAG [CURRENT] C

* NO SELF DIAGNOSTIC

FAILURE INDICATED.

FURTHER TESTING

MAY BE REQUIRED. $ *

-1 PRINT

Prelimin NISSAN GT-R 1998 Service Manual

TROUBLE DIAGNOSES - Su~plemental Restraint Svstem (SRS)

-

connector for

SELF-DlAG [CURRENT] C

* NO SELF DIAGNOSTIC

FAILURE INDICATED.

FURTHER TESTING

MAY BE REQUIRED. $ *

-1 PRINT

Prelimin](/img/5/57354/w960_57354-138.png)

TROUBLE DIAGNOSES - Su~plemental Restraint Svstem (SRS)

-

connector for

SELF-DlAG [CURRENT] C

* NO SELF DIAGNOSTIC

FAILURE INDICATED.

FURTHER TESTING

MAY BE REQUIRED. $ *

-1 PRINT

Preliminary Check

Check battery voltage and specific gravity.

When battery voltage drops to less than approx. 9V, the

"AIR BAG" warning lamp starts flashing (indicating a mal-

function).

Gj

Check the connections of component connectors.

Check that the fuse is not blown.

3F

Trouble Diagnoses with CONSULT

SELF-DIAGNOSIS PROCEDURE

Connect CONSULT to data link connector on the vehicle.

Turn ignition switch "ON".

83

Touch "AIR BAG" on the CONSULT screen.

Touch an appropriate mode key on "SELECT DlAG MODE"

screen.

gL

The self-diagnostic result for the selected mode is displayed.

Repair or replace the malfunctioning part according to the

self-

diagnostic result.

89

Touch "PRINT, if printout is required.

After

repairing the malfunction, touch "SELF-DIAG

[CURRENT]", and after checking that "NO SELF DIAGNOSTIC

FAILURE INDICATED" is shown on the display, touch

"ERASE.

For seat belt pre-tensioner system, the diagnostic proce-

dure

is completed when "NO SELF DIAGNOSTIC FAILURE

INDICATED"

is displayed.

FURTHER TESTING MAY BE REQUIRED. * *

* NO SELF DIAGNOSTIC

FAILURE INDICATED.

t

PRINT SRS609

9. Return to "SELECT DlAG MODE" screen and touch "SELF-

DlAG

[PAST]".

10. After checking that "NO SELF DIAGNOSTIC FAILURE INDI-

CATED" is displayed on the "SELF-DIAG [PAST]" screen, fin-

ish the diagnosis.

Page 145 of 230

TROUBLE DIAGNOSES - Supplemental Restraint System (SRS)

Symptom Chart

Trouble phenomenon I Malfunctioning unit I Possible cause

I I Warning lamp and internal circuit of combination meter are

BAG warning lamp does

not turn on. (All other warn-

ing lamps turn on.)

L-L .. AIR BAG warning lamp does I

I Harness between diagnosis sensor unit and combination

AIR

BAG warning lamp circuit

Air bag power supply circuit

not turn off (always ON). (AIR BAG warning lamp circuit

I meter is faulty (open).

faulty.

P-$ ;

Harness between

diagnosis sensor unit and combination 'bJ

Diagnosis sensor unit

0 Air bag power fuse has blown.

0 Air bag power harness is faulty.

meter is faulty

(shorted).

Diagnosis sensor unit is faulty.

I23

Diagnosis sensor unit

0 Internal circuit of combination meter is faulty. BR

Diagnosis sensor unit is faulty.

AIR BAG warning lamp

flashes.

When driver seat belt is

fas-

lamp does not illuminate for

seconds. (All other warning

Low battery voltage (Less than 9V)

Conduct either diagnosis with CONSULT (self-diagnosis, trouble diagnosis record) or diagnosis ST

without CONSULT (self-diagnosis), and repair the malfunctioning part.

After repairing the malfunctioning part, erase the memory for malfunction record.

Warning lamp and internal circuit of combination meter are 1

tened(buckleswitchisoff)

and ignition switch is turned

on, the SEAT BELT warning

1 Air bag power

SEATBELTwarninglampcircuit

circuit faulty.

Harness between

diagnosis sensor unit and combination HA

meter is faulty (open).

Air bag power fuse has blown.

0 Air bag power harness is faulty.

lamps illuminate.)

When driver seat belt is fas-

tened (buckle switch is off)

When driver seat belt is fas-.

I I

Diagnosis sensor unit

and ignition switch is turned

on, the SEAT BELT warning

lamp does not turn off

7 sec-

onds later.

tened (buckle switch is off)

I I

-.

0 Diagnosis sensor unit is faulty.

SEAT

BELT warning lamp circuit

,

and ignition switch is turned

on, the SEAT BELT warning

fa> Harness between diagnosis sensor unit and combination su

meter is faulty (shorted).

Driver seat belt buckle switch circuit

Diagnosis sensor unit

Seat belt pre-tensioner circuit

Harness between combination meter and driver seat belt

buckle switch is faulty (shorted).

Driver seat belt buckle switch is faulty (sticking).

Diaqnosis sensor unit is faultv.

Conduct either diagnosis with CONSULT or diagnosis with-

out CONSULT, and repair the malfunctioning part.

lamp turns on, and

7 sec- I I

onds later, flashes.

When driver seat belt is not

fastened (buckle switch is on)

I I Driver seat belt buckle switch ground harness is faulty

lamp turns off about

7 sec-

onds later.

and ignition switch

is tumed

on, the SEAT BELT warning

tence).

Driver seat

belt buckle switch circuit I !::);eat belt buckle switch is faulty (contact intermit-

If the flashing of AIR BAG warning lamp is caused by low battery voltage, self-diagnosis mode cannot be switched from User

mode to Diagnosis mode. In this case, diagnosis with CONSULT displays "NO SELF-DIAGNOSTIC FAILURE INDICATED".

Page 150 of 230

FULLY AUTOMATIC AIR CONDlTlONER

Component Parts Location

Intake door actua:or

,

Sunload sensor

Controller

B&wer temperature sensor

fan motor

@ Radiator core lower support I

Front defros!er grille (left)

1 ,?efros:er gnlie (left) t I

0 Blower fan motor relay

Engine room, right relay box I / Air conditioner relay I

Blower and cooling unit

I Blower fan motor

? Ar condlboner relay

@ Refrigerant

pressure sensor @ Compressor @ Ambtent sensor

a Liquid tank I @ Englne room. front left

I

Blower and cooling unit

lnta Instrument panel, center I

7 IJj Cluster

lid A 0 Fuse block, rear face 1

Page 180 of 230

XENON HEADLAMP SYSTEM

Trouble Diagnoses

DESCRIPTION

Problems with xenon headlamps are as follows:

They do not light up.

They blink.

GD

They are not bright enough.

In most cases the problems above are caused by faulty xenon bulbs.

There might be the possibility that the problems are caused by faulty HID control unit or lamp sockets.

ec

Follow the diagnostic procedure to determine what causes the problem.

PRECAUTIONS AT

Connect or disconnect connectors with the lighting switch OFF.

Do not touch harnesses, HID control unit, internal lamp, or metal part of the lamp while the lamps are

ON B2

(Lighting switch is ON).

Before verifying that the lamps are ON, install the parts to the vehicle temporarily and connect the battery

cable with

the connector on the vehicle. ST

If the electrical system is suspected to be the cause of the symptom, check for blown fuse or fusible link,

broken connectors, disconnected terminals, or faulty engagement.

Do not use wet hands when performing the trouble diagnoses.

F@

CIRCUIT DIAGRAM

, MA Xenon

headlamp

relay

To clearance

JJ$Rkj

lamp and

tail lamp

Headlamp

1 -- - -1 : High-voltage parts

Driver door SM

CAUTION:

0 Do not use a tester to diagnose the HID control unit circuit.

0 Do not disassemble the HID control unit and harnesses (bulb socket harness and control unit har-

ness).

0 Immediately after the headlamps turn ON, brightness and emission color vary. This is a normal

condition.

When a bulb has reached the end of its life, the brightness becomes extremely low, the bulb con-

tinues to blink, or the light looks reddish.

Page 181 of 230

XENON HEADLAMP SYSTEM

Trouble Diagnoses (Cont'd)

DIAGNOSTIC PROCEDURE

I

FUSE, FUSIBLE LINK, AND XENON Fuse, fusible link, or xenon

HEADLAMP RELAY CHECK headlamp relay is faulty.

CONNECTOR CHECK ON THE VEHICLE Harness on the vehicle is

FOR BATTERY VOLTAGE faulty.

With lighting switch ON, check HID control

unit connector on the vehicle for battery

I voltage. I

OK

XENON HEADLAMP BULB REPLACE- Xenon bulb is faulty.

MENT

Replace the xenon headiamp bulb with a

known

good bulb and check for proper

operation.

HID CONTROL UNIT REPLACEMENT HID control unit is faulty.

Install a known good

HID control unit to

I

the xenon headlarnp and check for proper

operation.

NG

XENON HEADLAMP HOUSING ASSEM- OK, BLY REPLACEMENT

Install a known good xenon headlamp

housing assembly to the xenon

headlamp

and check for proper operation.

---

Starter in xenon headlamp

housing (boost circuit) is

faulty. (Xenon

headlamp housing

assembly

is faulty.)