width NISSAN GT-R 1998 Service Manual

[x] Cancel search | Manufacturer: NISSAN, Model Year: 1998, Model line: GT-R, Model: NISSAN GT-R 1998Pages: 230, PDF Size: 12.66 MB

Page 22 of 230

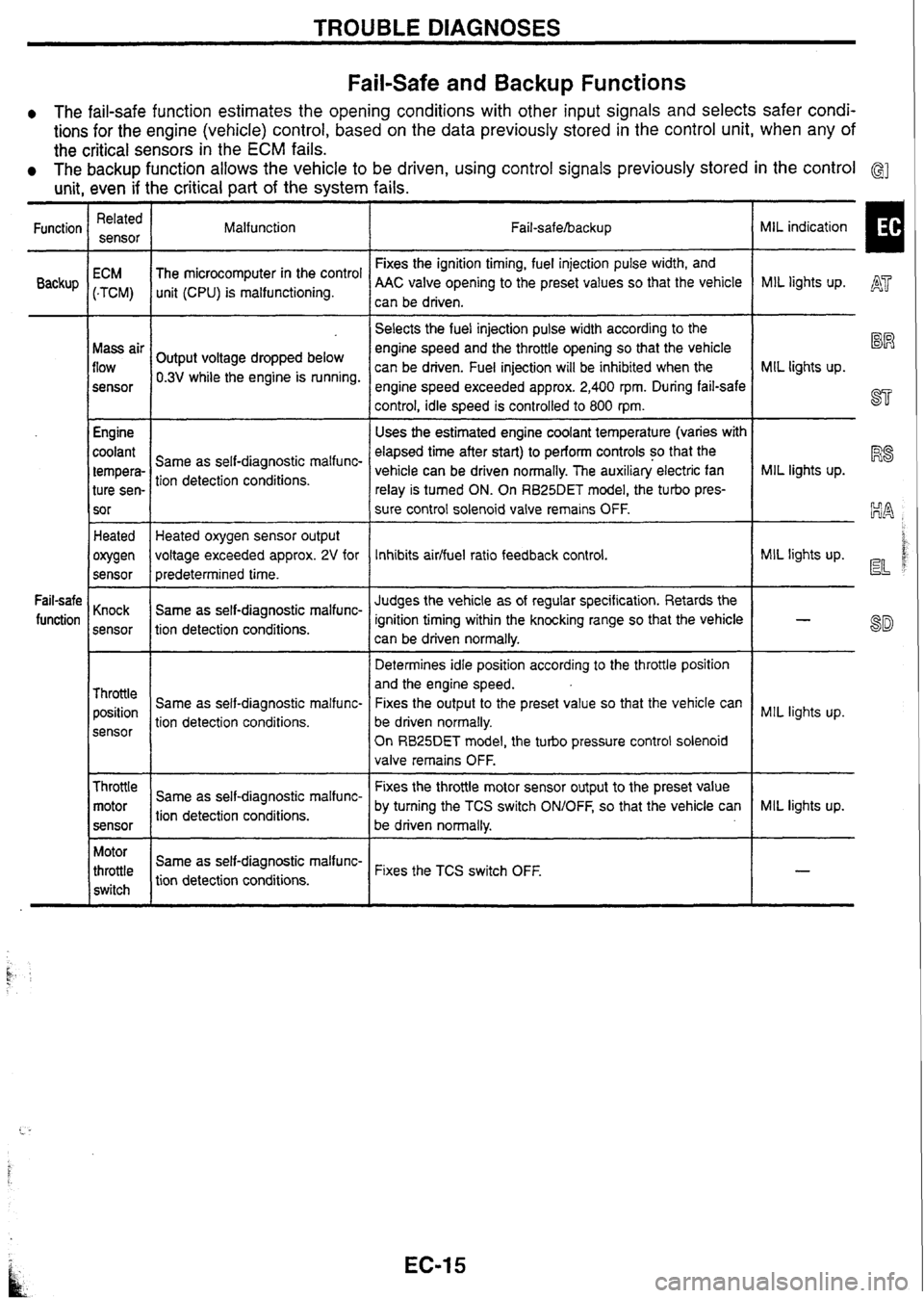

TROUBLE DIAGNOSES --- - - - -- -- - -

Fail-safe and Backup Functions

0 The fail-safe function estimates the opening conditions with other input signals and selects safer condi-

tions for the engine (vehicle) control, based on the data previously stored in the control unit, when any of

the critical sensors in the

ECM fails.

The backup function allows the vehicle to be driven, using control signals previously stored in the control G]

unit, even if the critical part of the system fails.

MIL indication

I

Related

sensor

Function

Backup Malfunction

Fail-safehacku p

Fixes the ignition timing, fuel injection pulse width, and

AAC valve opening to the preset values so that the vehicle

can be driven.

ECM

(-TCM)

Mass air

flow

sensor

Engine

coolant

tempera- ture sen-

sor The

microcomputer in the control

unit (CPU) is malfunctioning. MIL lights

up. A'

-- --

Selects the fuel injection pulse width according to the

engine speed and the throttle opening so that the vehicle

can be driven. Fuel injection will be inhibited when the

engine speed exceeded approx.

2,400 rpm. During fail-safe

control, idle speed is controlled to 800

rpm.

Uses the estimated engine coolant temperature (varies with

elapsed time after start) to perform controls so that the

vehicle can be driven normally. The auxiliary electric fan

relay is turned ON. On

RB25DET

model, the turbo pres-

sure control solenoid valve remains OFF.

%R

MIL lights up.

ST

Output voltage dropped below

0.3V while the engine is running.

MIL lights up.

R8 Same as self-diagnostic malfunc-

tion detection conditions.

Heated

owen

sensor Heated oxygen sensor output

voltage exceeded approx.

2V for

predetermined time.

Same as self-diagnostic malfunc-

tion detection conditions. MIL

lights up. d d Inhibits aidfuel ratio feedback control.

Judges the vehicle as of regular specification. Retards the

ignition timing within the knocking range so that the vehicle

can be driven normally.

Determines idle position according to the throttle position

and the engine speed.

Fixes the output to the preset value so that the vehicle can

be driven normally.

On

RB25DET model, the turbo pressure control solenoid

valve remains OFF.

Fail-safe

function Knock

sensor

Throttle position

sensor Same

as self-diagnostic malfunc-

tion detection conditions. MIL

lights up.

Throttle motor

sensor

--

Fixes the throttle motor sensor output to the preset value

by turning the TCS switch

ONIOFF, so that the vehicle can

Same

as self-diagnostic malfunc-

tion detection conditions. MIL

lights up.

be driven normally.

Motor

throttle

switch Same

as

self-diag

nostic

malfunc-

tion detection conditions. Fixes the

TCS switch OFF.

t.. -

Page 30 of 230

![NISSAN GT-R 1998 Service Manual

TROUBLE DIAGNOSES .

CONSULT (Contd)

Monitored item

[Unit] signals Description

Remarks

INJ

PULSE [msec]

I

When the engine is stopped, a certain

computed value is indicated. lndicates NISSAN GT-R 1998 Service Manual

TROUBLE DIAGNOSES .

CONSULT (Contd)

Monitored item

[Unit] signals Description

Remarks

INJ

PULSE [msec]

I

When the engine is stopped, a certain

computed value is indicated. lndicates](/img/5/57354/w960_57354-29.png)

TROUBLE DIAGNOSES .

CONSULT (Cont'd)

Monitored item

[Unit] signals Description

Remarks

INJ

PULSE [msec]

I

When the engine is stopped, a certain

computed value is indicated. lndicates the actual fuel injection pulse

width compensated by ECM according to

the input

siqnals.

IGN TIMING [BTDC]

I lo

lndicates the ignition timing computed by ECM according to the input signals. When the engine is stopped, a certain

value is indicated.

IACV-AACN

I%]

I lo

lndicates IACV-AACN control value com-

puted by ECM according to the input sig-

nals.

PURG VOL CN

[ONIOFF dutyj lndicates the EVAP canister purge vol-

ume control valve computed by the ECM according to the input signals. The opening becomes larger as the

value increases.

AIF

ALPHA [%]

- The mean value of the air-fuel ratio feed-

back correction factor per cycle is indi-

cated. -- - When the engine is stopped, a certain

value is indicated.

This data also includes the data for the

air-fuel ratio learning control.

AIR COND

RLY [ONIOFF] The air conditioner relay control condition

(determined by ECM according to the

input signal) is indicated.

-- - - Indicates the fuel pump relay control con-

dition determined by ECM according to

the input signals.

The control condition of the intake valve

timing control solenoid valve is indicated.

ON

... Intake valve timing control is oper-

ating. OFF

... lntake valve timing control is not

operating.

VlAS

SN [ONIOFF] RB20DE (UB), RB25DE

Control conditions computed by ECM Solenoid valve activated: ON Solenoid valve not activated: OFF

SWRL CONT SN

[ON/OFF]

0 RB20DE (UB)

COOLING FAN

[HVLOW/O FF] RB25DE, RB25DET

The control condition of the cooling fan

(determined by ECM according to the

input signal) is indicated.

HI

... High speed operation LOW ... Low speed operation

OFF ... Stop

TURBO CONT

SN 0 RB25DET Control conditions computed by ECM

Solenoid valve activated: ON Solenoid valve not activated: OFF

PD PRESSURE

SENSOR M Refrigerant pressure sensor output volt-

age Approx. 0.36V min.

(Varies with air conditioner refrigerant

pressure)

, VOLTAGE Voltage measured by the voltage probe.

Pulse width, frequency or duty cycle

measured by the pulse probe. Only "#" is displayed if item is unable to

be measured.

r Figures with "#"s are temporary ones.

They are the same figures as an actual

piece of data which was just previously

measured.

Page 68 of 230

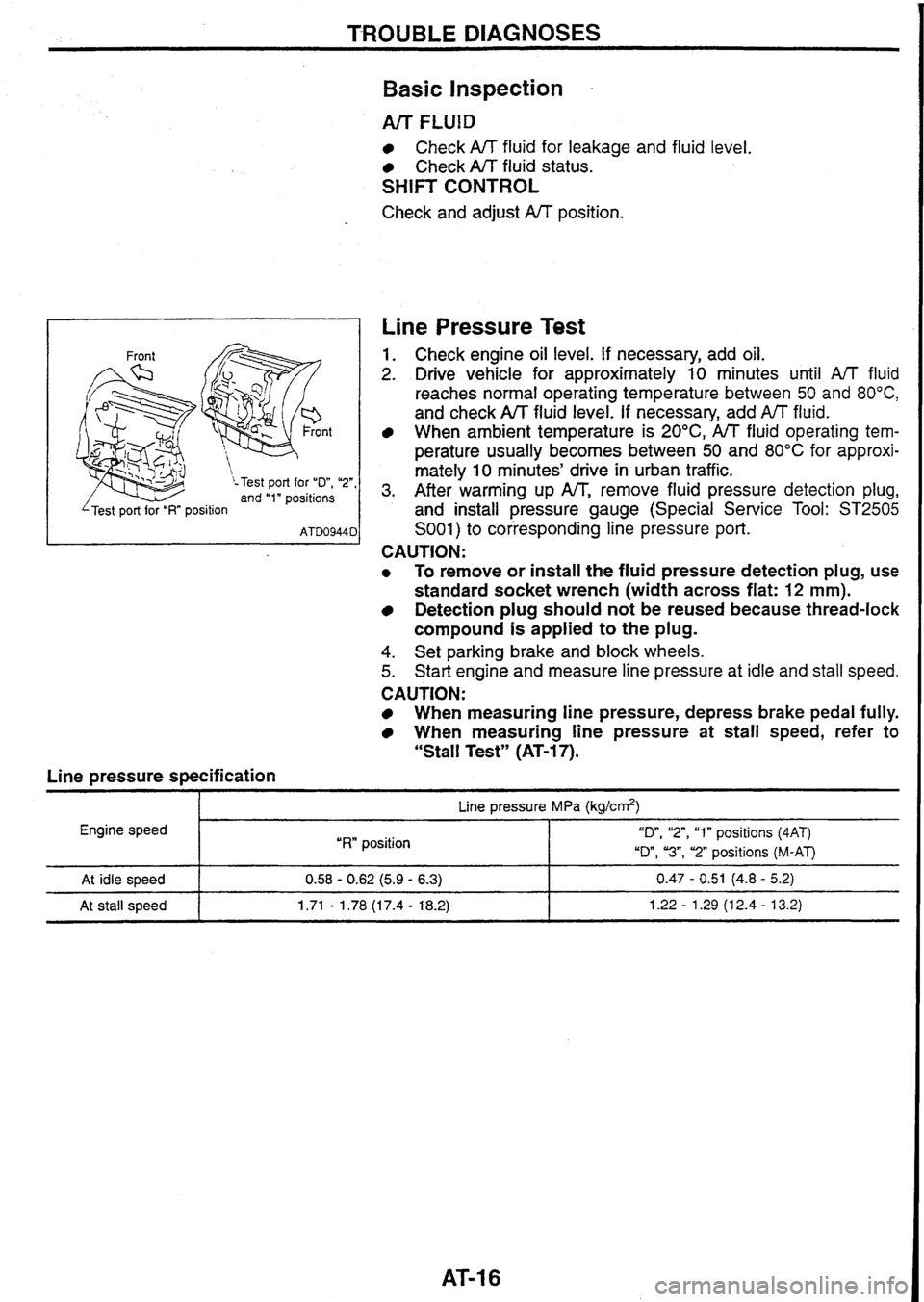

TROUBLE DIAGNOSES

n t

\-Test port for "D", "2", and "1" positions

I 'Test port for "I?" position I

Line pressure specification

Basic Inspection

Arr FLUlD

Check A/T fluid for leakage and fluid level.

Check A/T fluid status.

SHIFT CONTROL

Check and adjust A/T position.

Line Pressure Test

1. Check engine oil level. If necessary, add oil.

2. Drive vehicle for approximately 10 minutes until A/T fluid

reaches normal operating temperature between

50 and 80°C,

and check A/T fluid level. If necessary, add fluid.

When

ambient temperature is 20°C, A/T fluid operating tem-

perature

usually becomes between 50 and 80°C for approxi-

mately

10 minutes' drive in urban traffic.

3. After warming up IW', remove fluid pressure detection plug,

and install pressure gauge (Special Service Tool:

ST2505

S001) to corresponding line pressure port.

CAUTION:

0 To remove or install the fluid pressure detection plug, use

standard socket wrench (width across flat:

12 mm).

Detection plug should not be reused because thread-lock

compound is applied

to the plug.

4. Set parking brake and block wheels.

5. Start engine and measure line pressure at idle and stall speed.

CAUTION:

When measuring line pressure, depress brake pedal fully.

When measuring line pressure at stall speed, refer to

"Stall Test" (AT-17).

I p- Line pressure MPa (kg/crn2)

Engine speed

I "RW position "On, 'Z", "1" positions (4AT)

"Dm,

"3", "2" positions (M-AT)

At idle speed

At stall speed 0.58 - 0.62 (5.9 - 6.3) 0.47 - 0.51 (4.8 - 5.2)

1.71

- 1.78 (1 7.4 - 18.2) 1.22 - 1.29 (1 2.4 - 13.2)

Page 90 of 230

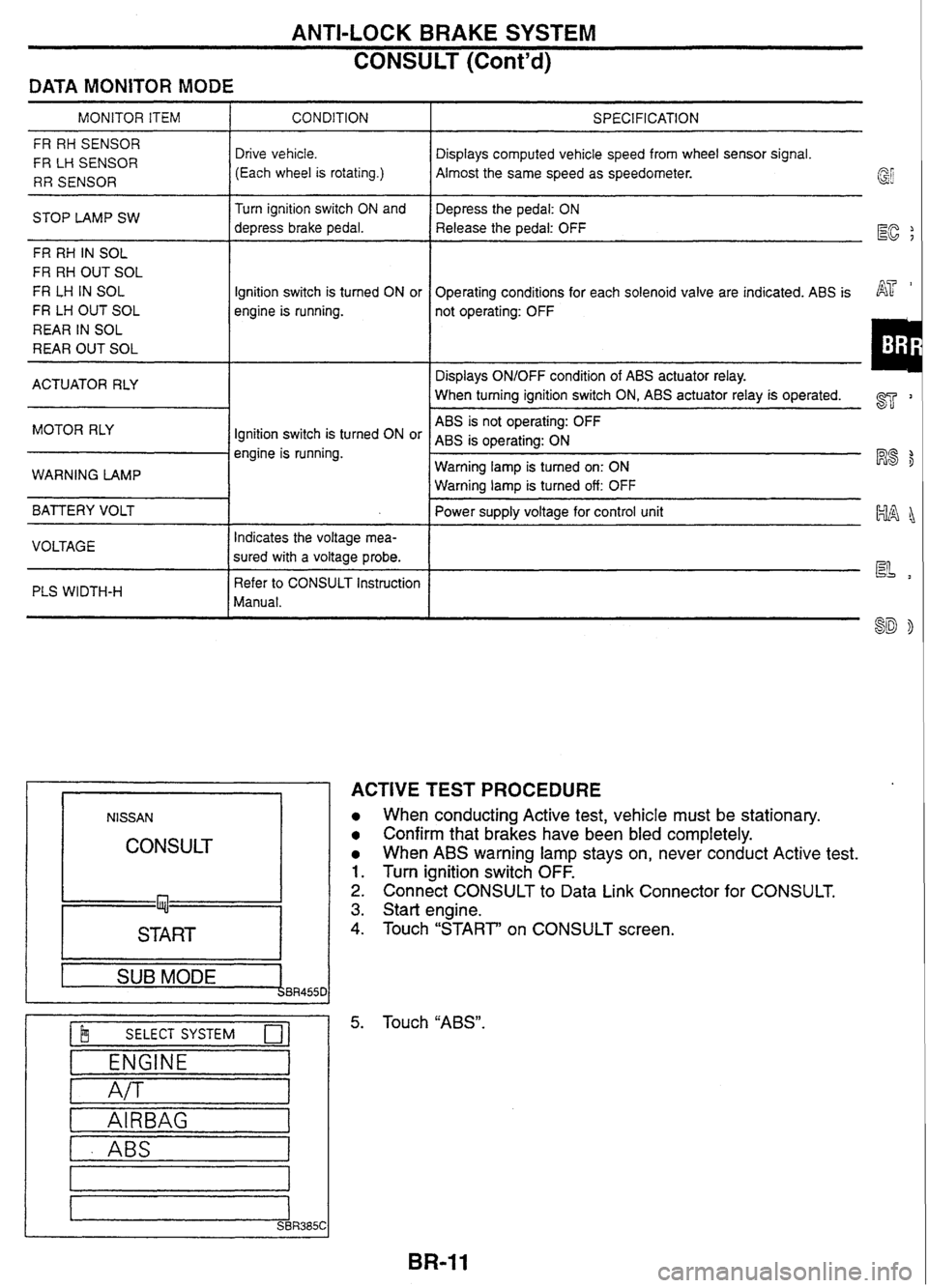

ANTI-LOCK BRAKE SYSTEM

CONSULT (Cont'd)

DATA MONITOR MODE

MONITOR ITEM I CONDITION

FR RH SENSOR

FR

LH SENSOR

RR SENSOR Drive vehicle.

(Each wheel is rotating.)

STOP LAMP SW Turn

ignition switch ON and

depress brake pedal.

FR RH

IN SOL

FR RH OUT SOL

FR

LH IN SOL

FR LH OUT SOL

REAR IN SOL

REAR OUT SOL Ignition

switch is turned ON or

engine is running.

ACTUATOR RLY

MOTOR RLY

Ignition switch is turned ON or

engine is running.

WARNING LAMP

BATTERY VOLT

I

VOLTAGE Indicates

the voltage mea-

sured with a voltage probe.

PLS WIDTH-H

I

Refer to CONSULT Instruction

Manual.

NlSSAN

CONSULT

START I --

1 SUB MODE BR455C

$ SELECT SYSTEM 0-

ENGINE

A/T

I - ABS I

SPECIFICATION

Displays computed vehicle speed from wheel sensor signal.

Almost the same speed as speedometer.

Depress the pedal: ON

Release the pedal: OFF

EC ;

Operating conditions for each solenoid valve are indicated. ABS is AT '

not operating: OFF

Displays ON/OFF condition of ABS actuator relay.

When turning ignition switch ON,

ABS actuator relay

is operated. 2

ABS is not operating: OFF

ABS

is operating: ON

Warning lamp is turned on: ON

R8 $

Warning lamp is turned off: OFF

Power supply voltage for control unit

~~~~

ACTIVE TEST PROCEDURE

When conducting Active test, vehicle must be stationary.

Confirm that brakes have been bled completely.

When ABS warning lamp stays on, never conduct Active test.

Turn ignition switch OFF.

Connect CONSULT to Data Link Connector for CONSULT.

Start engine.

Touch "START' on CONSULT screen.

Touch

"ABS".

Page 118 of 230

TCS/ABS SYSTEM

CONSULT for Throttle Control Unit Control

System (Cont'd)

DATA MONITOR MODE -- -

I Select monitor item

Display

I I

THRTL POS SEN [~l l o I n

I All signals

THRTL OPENING

lo] 1 0 I

Selection

from menu

THRTL POS SE2

MI 0 1;

THRL2 OPENING rOl / 0

BATTERY VOLT MI 0 I A

TH OPEN SIG ims]/ 0 I A

TH MOTOR DUTY I"/.] I 0 I A

CLOSED THUSW [ONIOFF]

NEUT POSl SW [ONIOFF]

START SIGNAL

[ONIOFF]

TH OPEN CONT

["I

TCS SIGNAL [ONIOFF] / OIa

TCS FLAG

0

0

0

0

A

A

A

A

TH CLSD LRN

PoNwEqI 0 / A

COMM COND [ONIOFFJ

VOLTAGE

PI I I A

0

Remarks

A

PULSE [ms, Hz, %I

Dispiays throttle position sensor signal voltage.

Displays throttle angle computed based on throttle position

EG

sensor signal voltage.

Displays throttle motor sensor signal voltage.

AT

-

Displays throttle motor angle computed based on throttle

motor sensor signal voltage.

Displays the battery voltage for the control unit.

h

Displays the pulse width of the throttle motor target angle

signal from the

TCSIABS control unit.

lndicates the switch status (ONIOFF) based on the throttle

position sensor signal.

lndicates the switch status (ONIOFF) based on the

parW

neutral position switch signal. lndicates the status (ONIOFF) based on the starter signal.

Displays the throttle motor control target computed by the

control unit based on each input signal.

lndicates the throttle motor drive duty.

lndicates the throttle motor relay status

(ON/OFF).

lndicates ON when the throttle motor angle reaches a

specified

iower limit.

lndicates "VALID" when throttle motor target angle signal is

received from the

TCS/ABS control unit and the throttle

control unit closes the throttle motor.

lndicates the condition of the communication between

TCS/

ABS control unit and throttle control unit. Normally ON is

indicated, and OFF is shown when there is failure.

lndicates

if the throttle motor has been fully closed before.

"DONE" is indicated when it has, and

"YET" is shown when

it has not yet.

lndicates the voltage measured with a voltage probe.

lndicates the pulse measured with a pulse probe.

If it cannot be measured,

"%" is shown on the display. The

%" mark is also shown to the left of the final data until the

measuring result is output.

I ACTIVE TEST PROCEDURE

1. Turn ignition switch OFF.

2. Connect CONSULT connector to data link connector for CON-

S U LT.

3. Turn ignition switch ON.

4. Touch "START" on CONSULT screen.

5. Touch "THROTTLE CONTROL" on CONSULT screen.