parking brake NISSAN GT-R 1998 Service Manual

[x] Cancel search | Manufacturer: NISSAN, Model Year: 1998, Model line: GT-R, Model: NISSAN GT-R 1998Pages: 230, PDF Size: 12.66 MB

Page 68 of 230

TROUBLE DIAGNOSES

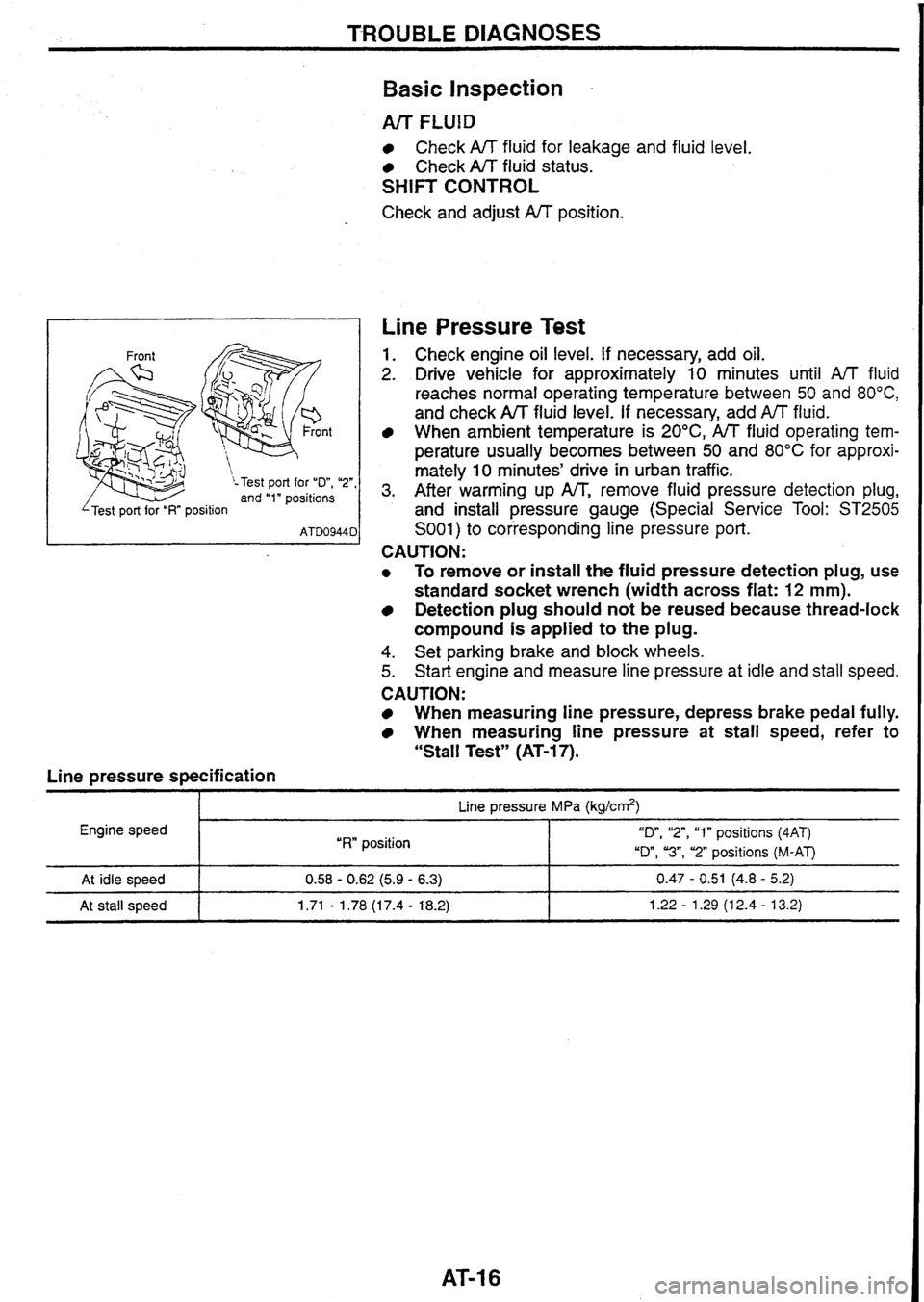

n t

\-Test port for "D", "2", and "1" positions

I 'Test port for "I?" position I

Line pressure specification

Basic Inspection

Arr FLUlD

Check A/T fluid for leakage and fluid level.

Check A/T fluid status.

SHIFT CONTROL

Check and adjust A/T position.

Line Pressure Test

1. Check engine oil level. If necessary, add oil.

2. Drive vehicle for approximately 10 minutes until A/T fluid

reaches normal operating temperature between

50 and 80°C,

and check A/T fluid level. If necessary, add fluid.

When

ambient temperature is 20°C, A/T fluid operating tem-

perature

usually becomes between 50 and 80°C for approxi-

mately

10 minutes' drive in urban traffic.

3. After warming up IW', remove fluid pressure detection plug,

and install pressure gauge (Special Service Tool:

ST2505

S001) to corresponding line pressure port.

CAUTION:

0 To remove or install the fluid pressure detection plug, use

standard socket wrench (width across flat:

12 mm).

Detection plug should not be reused because thread-lock

compound is applied

to the plug.

4. Set parking brake and block wheels.

5. Start engine and measure line pressure at idle and stall speed.

CAUTION:

When measuring line pressure, depress brake pedal fully.

When measuring line pressure at stall speed, refer to

"Stall Test" (AT-17).

I p- Line pressure MPa (kg/crn2)

Engine speed

I "RW position "On, 'Z", "1" positions (4AT)

"Dm,

"3", "2" positions (M-AT)

At idle speed

At stall speed 0.58 - 0.62 (5.9 - 6.3) 0.47 - 0.51 (4.8 - 5.2)

1.71

- 1.78 (1 7.4 - 18.2) 1.22 - 1.29 (1 2.4 - 13.2)

Page 69 of 230

TROUBLE DIAGNOSES

Line Pressure Test (Cont'd)

JUDGEMENT OF LINE PRESSURE TEST

At idle

speed

At stall

speed Judgement

Line pressure is low in all

positions.

Line pressure is low in par-

ticular position.

Line pressure is

high.

Line pressure increase is

poorer than that measured at

idle speed.

Line pressure increases but

does not reach specification.

Line pressure is low in par-

ticular position. Possible

causes

Pressure supply system malfunction or low oil pump output

Examples:

0 Oil pump wear

Control piston damage

Pressure regulator valve or plug sticking, and weak spring

Fluid pressure leakage between oil strainer and pressure regulator valve through oil Eg

Pump

Low idle speed

After line pressure is supplied from manual valve, fluid pressure may leak between devices

or circuits of corresponding position.

1

Malfunctions of sensors or pressure regulation function. El

Examples:

Misadjustment of throttle position sensor

PJT fluid temperature sensor damaged ST

Poor operation of line pressure solenoid (stuck with OFF status, clogged filter, or open

harness)

Pressure modifier valve sticking F%

Pressure regulator valve or plug sticking

Malfunctions of sensors or pressure regulation function

Examples:

EILA

Misadjustment of throttle position sensor

TCM, ECM.TCM damaged la

Poor operation of line pressure solenoid (stuck or shorted with ON status)

Pressure regulator valve and plug sticking

Pressure modifier valve sticking

sf$

Pilot valve sticking and pilot filter clogged

Malfunctions of pressure supply system, sensors, or pressure regulation function

Examples:

Misadjustment of throttle position sensor

Control piston damage

Poor operation of line pressure solenoid, and filter sticking or clogged

Pressure regulator valve and plug sticking

Pressure modifier valve sticking

Pilot valve sticking and pilot filter clogged

After line pressure is supplied from manual valve, fluid pressure

may leak between devices

or circuits of corresponding position.

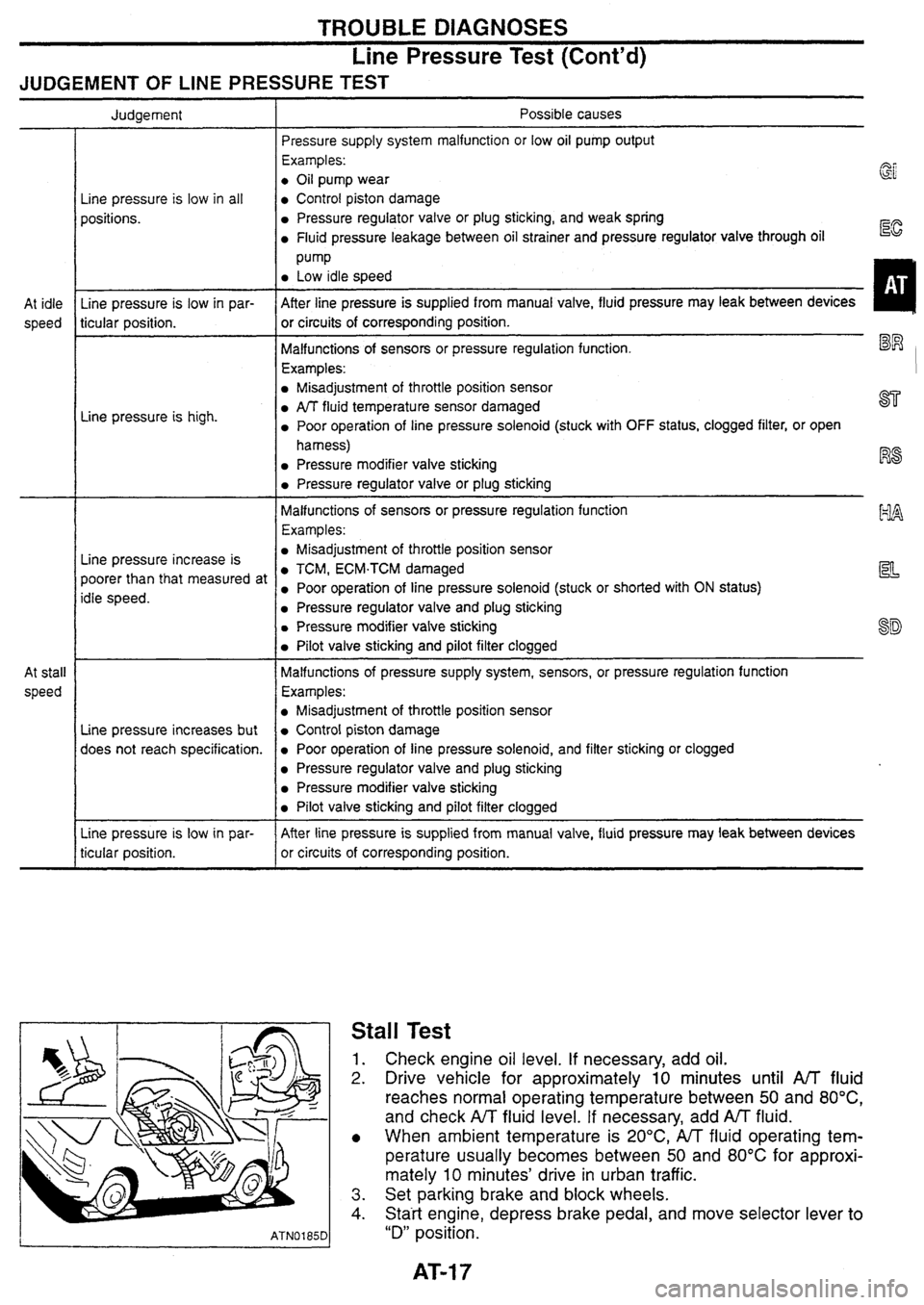

Stall Test

1. Check engine oil level. If necessary, add oil.

2. Drive vehicle for approximately 10 minutes until A/T fluid

reaches normal operating temperature between

50 and 80°C,

and check A/T fluid level. If necessary, add AfT fluid.

When ambient temperature is

20°C,

A/T fluid operating tem-

perature usually becomes between 50 and

80°C for approxi-

mately

10 minutes' drive in urban traffic.

3. Set parking brake and block wheels.

4. Statt engine, depress brake pedal, and move selector lever to

"D" position.

Page 77 of 230

TROUBLE DIAGNOSES

Symptom Chart

Sharp shock in Engine brake

applied

Shifting

Malfunctions

Slip

(Racing)

hifting

.- erator pedal

Shifting

Shifting

inspection item

Fluid level and status

Control linkage

PNP switch (short/open circuit)

Throttle ~osition sensor (installed)

I Vehicle weed sensor

I Enaine meed sensor

A/T fluid temperature sensor

Engine idle speed

Line

Dressure

Control valve assembly

Shift solenoid

A

Shift solenoid B

Line pressure solenoid

Lock-up solenoid

Overrun clutch solenoid

Accumulator N-D

Accumulator

1-2

Accumulator 2-3

Accumulator 3-4 (N-R) Ignition coil and starter motor

Overdrive control switch

I AfT mode switch (AUTO)

Torque converter

1 Oil pump

I Reverse clutch

I High clutch

I Forward clutch

I Forward one-wav clutch

I Overrun ciutch

1 Low one-wav clutch

I Low reverse brake

Brake. band (including servo)

Parking linkage

Page 78 of 230

Symptom Chart (Cont'd)

Greater noise

Malfunctions

Inspection item No shifting

I Shifting I

Fluid level

and status 11

Control linkage

-

(I) C 0 .- c. .- (I) 0 a

v

-CU

n - 1

PNP switch

(shortlopen

circuit)

Throttle position sensor (installed)

2 2

Vehicle speed sensor

I Engine speed sensor -

-T

L o 1 Control valve assembly .- - -- Shift solenoid A 4 3

. ' Shift solenoid 6 4 cut I1

--, Line pressure solenoid .- 5 -t Lock-up solenoid ?

6 Overrun clutch solenoid 3

Accumulator N-D

1 Accumulator 1-2 I 1-

Accumulator 2-3

Accumulator 3-4 (N-R)

Ignition coil and starter motor

I Overdrive control switch I 1-

A/T mode switch (AUTO)

A/T mode switch (POWER) I - I Ail mode switch (SNOW) I

I Torque converter I I

1 Oil pump I I -- - - Reverse clutch 0 -

'g High clutch a 4 6

%I Forward clutch I I - .- a Forward one-way clutch -

$ Overrun clutch a, 8

Low one-way clutch

O Low reverse brake 7

Brake band (including servo) 7

Parking linkage

Page 79 of 230

TROUBLE DIAGNOSES

Symptom Chart (Cont'd)

xi - - ([I C V) a, C .- cn C W

t 0 .- .L 2 a, - 8 0 ([I L 0 0 Q

& 0 a, a, Q V)

5 E .- X

i! L a

zl -I - 1 -

- 2 -

-

-

-

-

-

5 - 3 - 4 -

-

-

-

-

-

-

-

-

-

-

-

-

I1 - 0 - 6 - 7 -

-

-

-

-

9 - 8 -

-

vj c 0 .- - .- V) 0 n

Q 7J C ([I

t C .- r ([I c. V) c. 0 C V) a 0 7J 0, C .- 0 C W -

- 2 - 3 -

-

- -

-

1 -

-

-

-

- - a +- ([I a a, 2 0 c. 0 C V) a, 0 u a, - 0 2

8 - 1 -

-

-

-

-

-

-

-

2 - 3 -

-

-

-

-

-

-

-

-

-

-

- I

i

g

- 4 -

-

-

-

-

-

-

B- ; 2 to a =? - 0,

2 5.j c 2.z 2 a0 - 0- z & 5 0 gE V) V)o C 02 .s nu 5 ng %-([I C O c --t .- V) a V) r aa ([I z gz a, a- c 50 -6 s

6 $2

11

2

I

I

Malfunctions

Inspection item

I I I Fluid level and status I I Control linkage 2

PNP switch (shortfopen circuit) 1 I I I Throttle position sensor (installed) 111213

Vehicle speed sensor

214

Engine speed sensor L -

AIT fluid temperature sensor

Engine idle weed

Line pressure

Control valve assembly

Shift solenoid A 3

3

Shift solenoid B 4 4

Line pressure solenoid

Lock-up solenoid

Overrun clutch solenoid

u I I I -

Accumulator N-D I I 1 I Accumulator 1-2

Accumulator 2-3 I Accumulator 3-4 (N-R)

Ignition coil and starter motor

Overdrive control switch

Torque converter

tg Reverse clutch .- High clutch

2 Forward clutch C .- a Forward one-way clutch -.

$ Overrun clutch 0, 8

? Low one-way clutch 3= O Low reverse brake 9

Brake band (including servo)

Parking linkage

Page 228 of 230

BRAKE

BRAKING FORCE

More than 10% of axle

weight

REAR DlSC BRAKE

Total braking force of rear wheels

Variation between right and left of

each wheel Brake

type

Less than 8% of axle weight ADllVC

9.3

Brake

pad

Disc rotor

Total

braking force OPZ11V

11.5

Standard

thickness (New) mm

Wear limit of thickness mm

Standard thickness (New) mm

Wear limit of thickness mm

Runout limit mm

More than 50%

of vehicle

weight at inspected

Note: The braking force when both front wheels are locked up can be considered to meet the total braking force.

2.0

16

14

BRAKE PEDAL

18

16

PARKING BRAKE

Free play (at pedal top surface)

mm I 3 - 11 Less than

0.07 Type DS17HD I

Brake

lining

Depressed pedal height under force

of 490 N (50 kg)

(from dash panel top surface)

mm

Brake

pedal height

(from dash panel top surface)

mm

Standard inner diameter

I (New) mm I

Standard thickness (New) mrn

Wear limit of thickness

mm M/T: 163 - 173 IVT: 170 - 180

172 dia. 3.0 1.5

M/T: More

than 85 A. More than 90 . . Drum I

I

Wear limit of inner diameter

mm I 173 dia.

Clearance between the edge of stop

lamp switch screw and pedal stopper

mm Operating

stroke

[under force of 196 N (20

kg)] 5 - 7 notches

CHECK VALVE I

I

Maximum stroke

19 notches

Number of notches when brake warning

lamp turns on

TIGHTENING TORQUE

Unit: N.m (kg-m)

Within 1 notch

Vacuum leakage

[at

vacuum Of 66'7 kPa (-500 mmHg)]

BRAKE BOOSTER

Within 1.3 kPa (10 mmHg) of

vacuum for 15 seconds

Master cylinder fixing nut

I 12 - 14 (1.2 - 1.5)

Vacuum leakage

[at vacuum of 66.7

kPa

(-500

mmHg)l

Within 3.3

kPa

(25

mmHg)

of

vacuum for 15 seconds Front

caliper mounting bolt

Brake tube flare nut -- - 152 - 154 (15.5 - 15.8)

15

- 17 (1.5 - 1.8)

FRONT DlSC BRAKE

Input rod standard length at installed

mm

Brake type

I AD25VB I CUSVD [OPZ~~VC

140

Standard thickness

Wear limit of

thickness

Standard thickness

mm

1 22 1 26 1 30

Disc rotor Wear limit of

thickness

Runout

limit Less than 0.07