NISSAN LATIO 2008 Service Repair Manual

Manufacturer: NISSAN, Model Year: 2008, Model line: LATIO, Model: NISSAN LATIO 2008Pages: 2771, PDF Size: 60.61 MB

Page 141 of 2771

DTC P0745 LINE PRESSURE SOLENOID VALVE

AT-129

< SERVICE INFORMATION >

D

E

F

G

H

I

J

K

L

MA

B

AT

N

O

P

DTC P0745 LINE PRESSURE SOLENOID VALVE

DescriptionINFOID:0000000001703266

The line pressure solenoid valve regulates the oil pump discharge pressure to suit the driving condition in

response to signals sent from the TCM.

The line pressure duty cycle value is not constant when the closed throttle position switch is ON. To

confirm the line pressure duty cycle at low-pressure, the accelerator (throttle) should be open until the

closed throttle position switch is OFF.

CONSULT-III Reference Value in Data Monitor ModeINFOID:0000000001703267

Remarks: Specification data are reference values.

On Board Diagnosis LogicINFOID:0000000001703268

• This is an OBD-II self-diagnostic item.

• Diagnostic trouble code “P0745 LINE PRESSURE S/V” with CONSULT-III or 11th judgement flicker without

CONSULT-III is detected when TCM detects an improper voltage drop while it tries to operate the solenoid

valve.

Possible CauseINFOID:0000000001703269

• Harness or connector

(The solenoid circuit is open or shorted.)

• Line pressure solenoid valve

DTC Confirmation ProcedureINFOID:0000000001703270

CAUTION:

If performing this “DTC Confirmation Procedure” again, always turn ignition switch OFF and wait at

least 10 seconds before continuing.

After the repair, perform the following procedure to confirm the malfunction is eliminated.

WITH CONSULT-III

1. Turn ignition switch ON and select “DATA MONITOR” mode for “A/T” with CONSULT-III.

2. Touch “START”.

3. Depress accelerator pedal completely and wait at least 1 second.

4. If the check result is NG, go to AT-131, "

Diagnosis Procedure" .

WITH GST

Follow the procedure “WITH CONSULT-III”.

WITHOUT CONSULT-III

1. Start engine.

2. With brake pedal depressed, shift the lever from “P”→“N”→“D”→“N”→“P” positions.

3. Perform self-diagnosis. Refer to AT-78, "

Diagnosis Procedure without CONSULT-III" .

4. If the check result is NG, go to AT-131, "

Diagnosis Procedure" .

Item name Condition Display value (Approx.)

LINE PRES DTYSmall throttle opening (Low line pressure) ⇔ Large

throttle opening (High line pressure)0% ⇔ 94%

Page 142 of 2771

AT-130

< SERVICE INFORMATION >

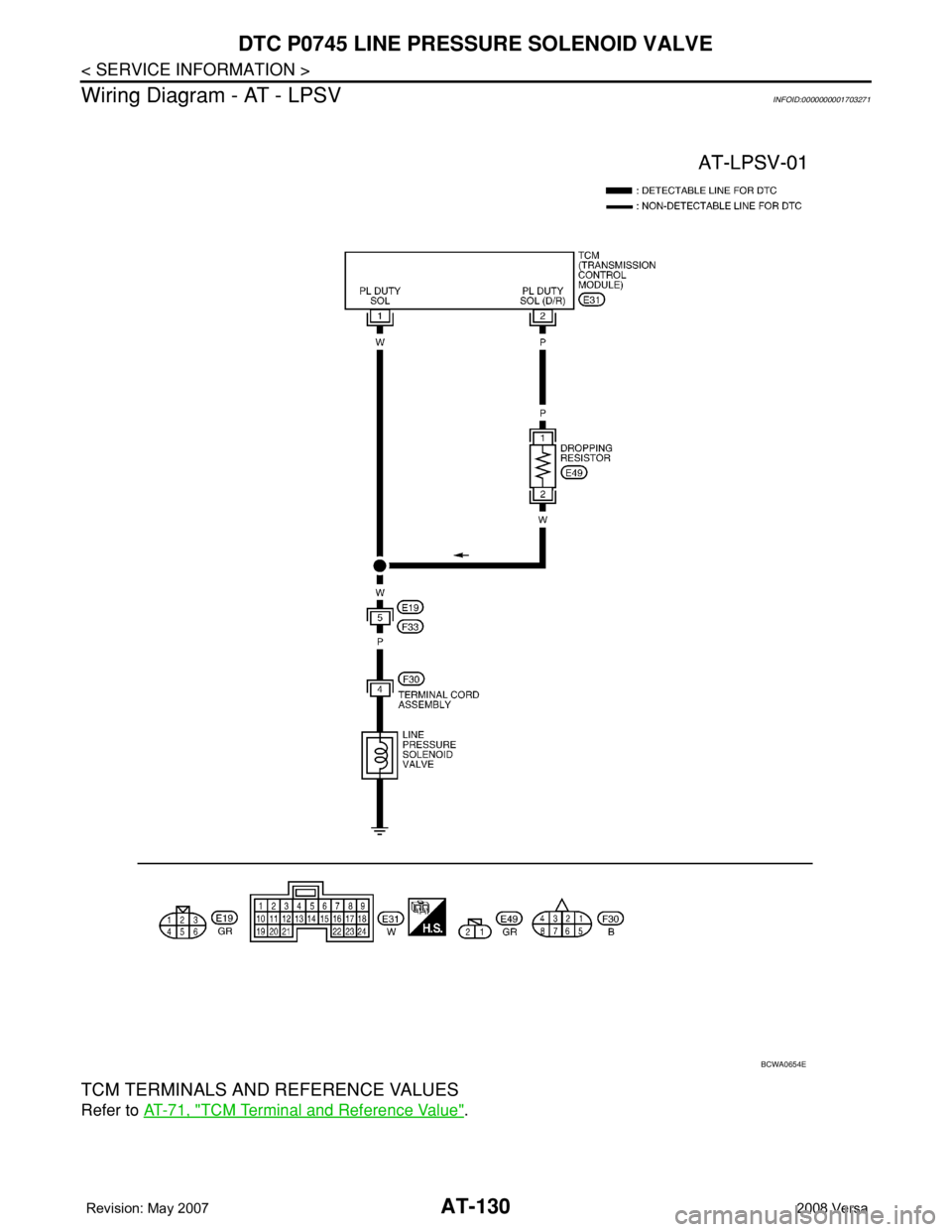

DTC P0745 LINE PRESSURE SOLENOID VALVE

Wiring Diagram - AT - LPSV

INFOID:0000000001703271

TCM TERMINALS AND REFERENCE VALUES

Refer to AT-71, "TCM Terminal and Reference Value".

BCWA0654E

Page 143 of 2771

DTC P0745 LINE PRESSURE SOLENOID VALVE

AT-131

< SERVICE INFORMATION >

D

E

F

G

H

I

J

K

L

MA

B

AT

N

O

P

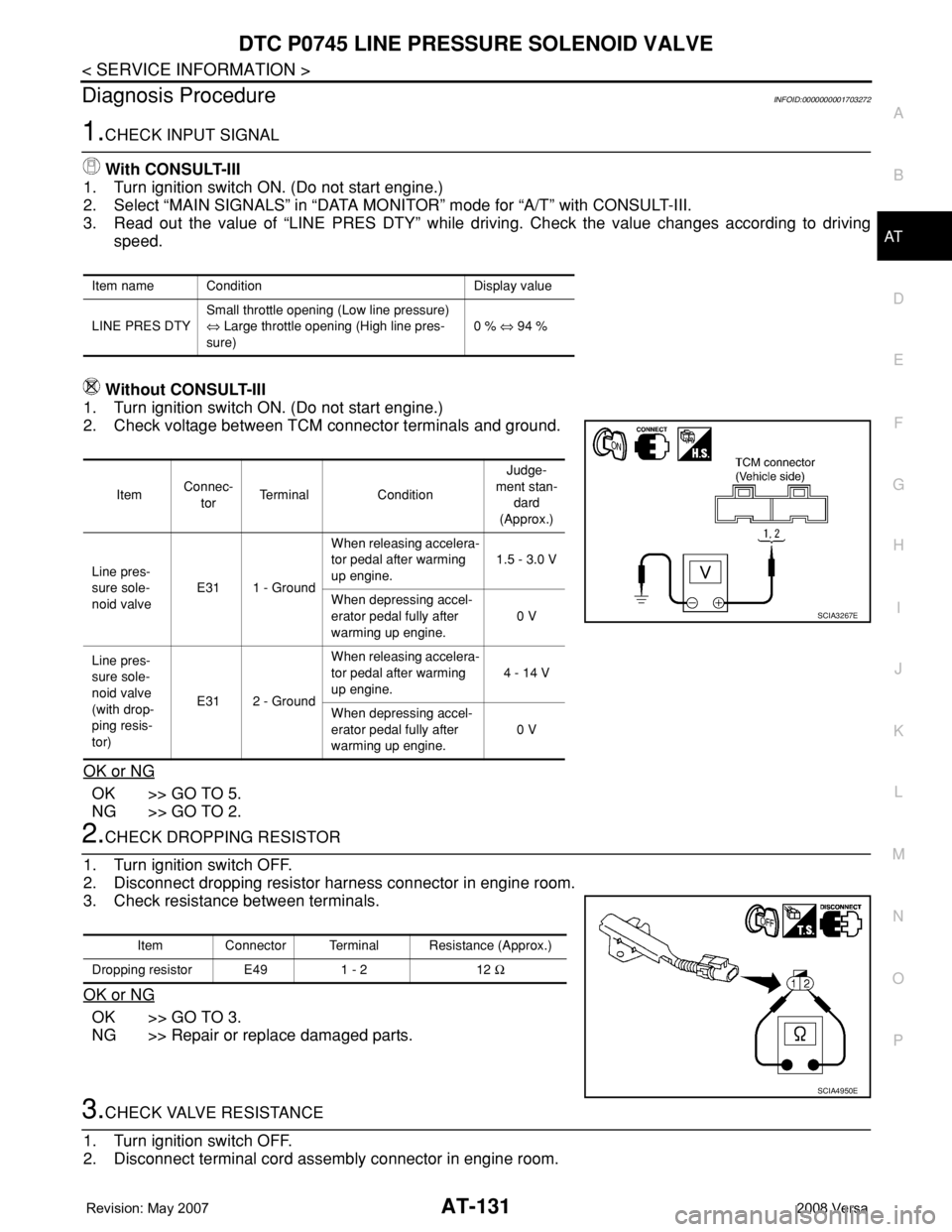

Diagnosis ProcedureINFOID:0000000001703272

1.CHECK INPUT SIGNAL

With CONSULT-III

1. Turn ignition switch ON. (Do not start engine.)

2. Select “MAIN SIGNALS” in “DATA MONITOR” mode for “A/T” with CONSULT-III.

3. Read out the value of “LINE PRES DTY” while driving. Check the value changes according to driving

speed.

Without CONSULT-III

1. Turn ignition switch ON. (Do not start engine.)

2. Check voltage between TCM connector terminals and ground.

OK or NG

OK >> GO TO 5.

NG >> GO TO 2.

2.CHECK DROPPING RESISTOR

1. Turn ignition switch OFF.

2. Disconnect dropping resistor harness connector in engine room.

3. Check resistance between terminals.

OK or NG

OK >> GO TO 3.

NG >> Repair or replace damaged parts.

3.CHECK VALVE RESISTANCE

1. Turn ignition switch OFF.

2. Disconnect terminal cord assembly connector in engine room.

Item name Condition Display value

LINE PRES DTYSmall throttle opening (Low line pressure)

⇔ Large throttle opening (High line pres-

sure)0 % ⇔ 94 %

ItemConnec-

torTerminal ConditionJudge-

ment stan-

dard

(Approx.)

Line pres-

sure sole-

noid valveE31 1 - GroundWhen releasing accelera-

tor pedal after warming

up engine.1.5 - 3.0 V

When depressing accel-

erator pedal fully after

warming up engine.0 V

Line pres-

sure sole-

noid valve

(with drop-

ping resis-

tor)E31 2 - GroundWhen releasing accelera-

tor pedal after warming

up engine.4 - 14 V

When depressing accel-

erator pedal fully after

warming up engine.0 V

SCIA3267E

Item Connector Terminal Resistance (Approx.)

Dropping resistor E49 1 - 2 12 Ω

SCIA4950E

Page 144 of 2771

AT-132

< SERVICE INFORMATION >

DTC P0745 LINE PRESSURE SOLENOID VALVE

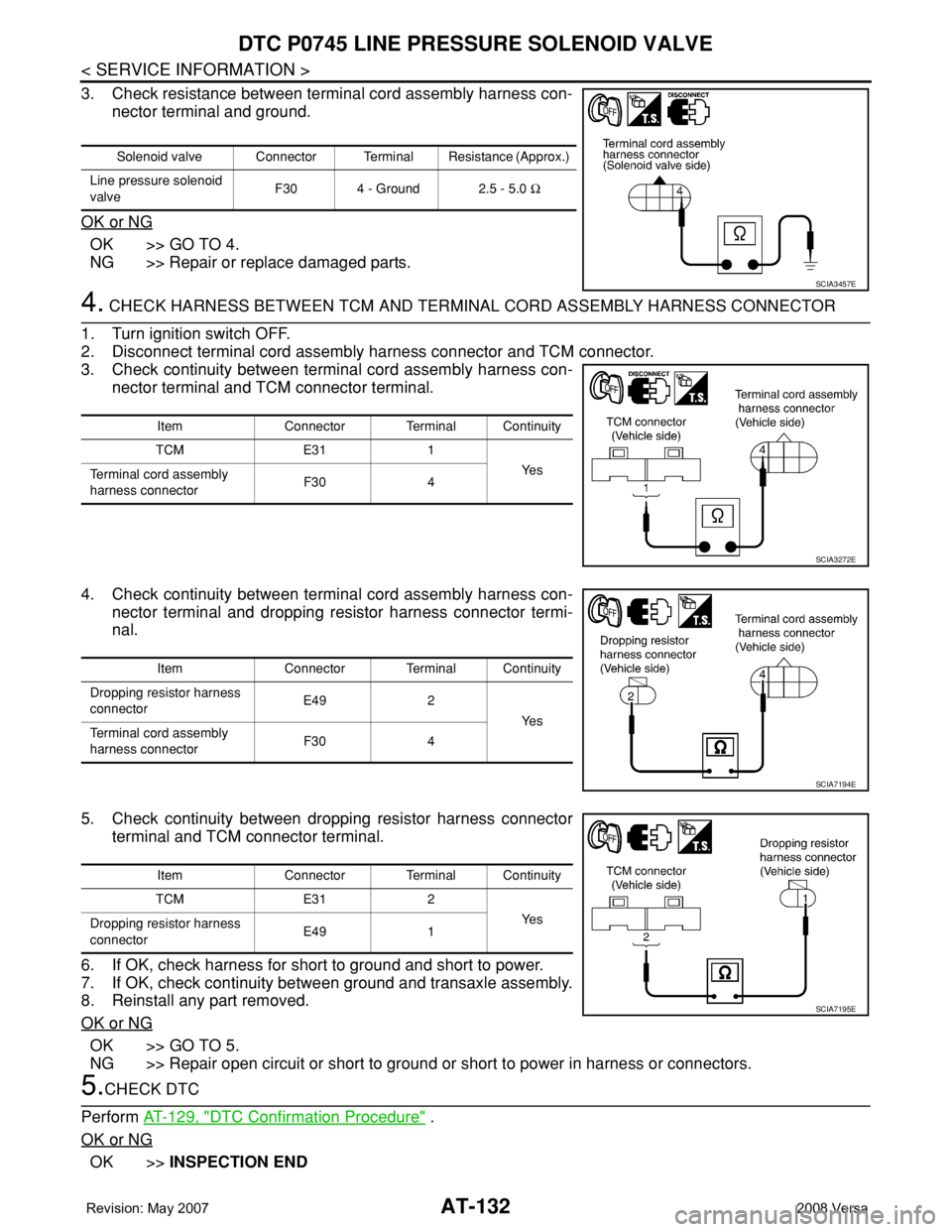

3. Check resistance between terminal cord assembly harness con-

nector terminal and ground.

OK or NG

OK >> GO TO 4.

NG >> Repair or replace damaged parts.

4. CHECK HARNESS BETWEEN TCM AND TERMINAL CORD ASSEMBLY HARNESS CONNECTOR

1. Turn ignition switch OFF.

2. Disconnect terminal cord assembly harness connector and TCM connector.

3. Check continuity between terminal cord assembly harness con-

nector terminal and TCM connector terminal.

4. Check continuity between terminal cord assembly harness con-

nector terminal and dropping resistor harness connector termi-

nal.

5. Check continuity between dropping resistor harness connector

terminal and TCM connector terminal.

6. If OK, check harness for short to ground and short to power.

7. If OK, check continuity between ground and transaxle assembly.

8. Reinstall any part removed.

OK or NG

OK >> GO TO 5.

NG >> Repair open circuit or short to ground or short to power in harness or connectors.

5.CHECK DTC

Perform AT-129, "

DTC Confirmation Procedure" .

OK or NG

OK >>INSPECTION END

Solenoid valve Connector Terminal Resistance (Approx.)

Line pressure solenoid

valveF30 4 - Ground 2.5 - 5.0 Ω

SCIA3457E

Item Connector Terminal Continuity

TCM E31 1

Ye s

Terminal cord assembly

harness connectorF30 4

SCIA3272E

Item Connector Terminal Continuity

Dropping resistor harness

connectorE49 2

Ye s

Terminal cord assembly

harness connectorF30 4

SCIA7194E

Item Connector Terminal Continuity

TCM E31 2

Ye s

Dropping resistor harness

connectorE49 1

SCIA7195E

Page 145 of 2771

DTC P0745 LINE PRESSURE SOLENOID VALVE

AT-133

< SERVICE INFORMATION >

D

E

F

G

H

I

J

K

L

MA

B

AT

N

O

P

NG >> GO TO 6.

6.CHECK TCM

1. Check TCM input/output signal. Refer to AT-71, "

TCM Terminal and Reference Value" .

2. If NG, recheck TCM pin terminals for damage or loose connection with harness connector.

OK or NG

OK >>INSPECTION END

NG >> Repair or replace damaged parts.

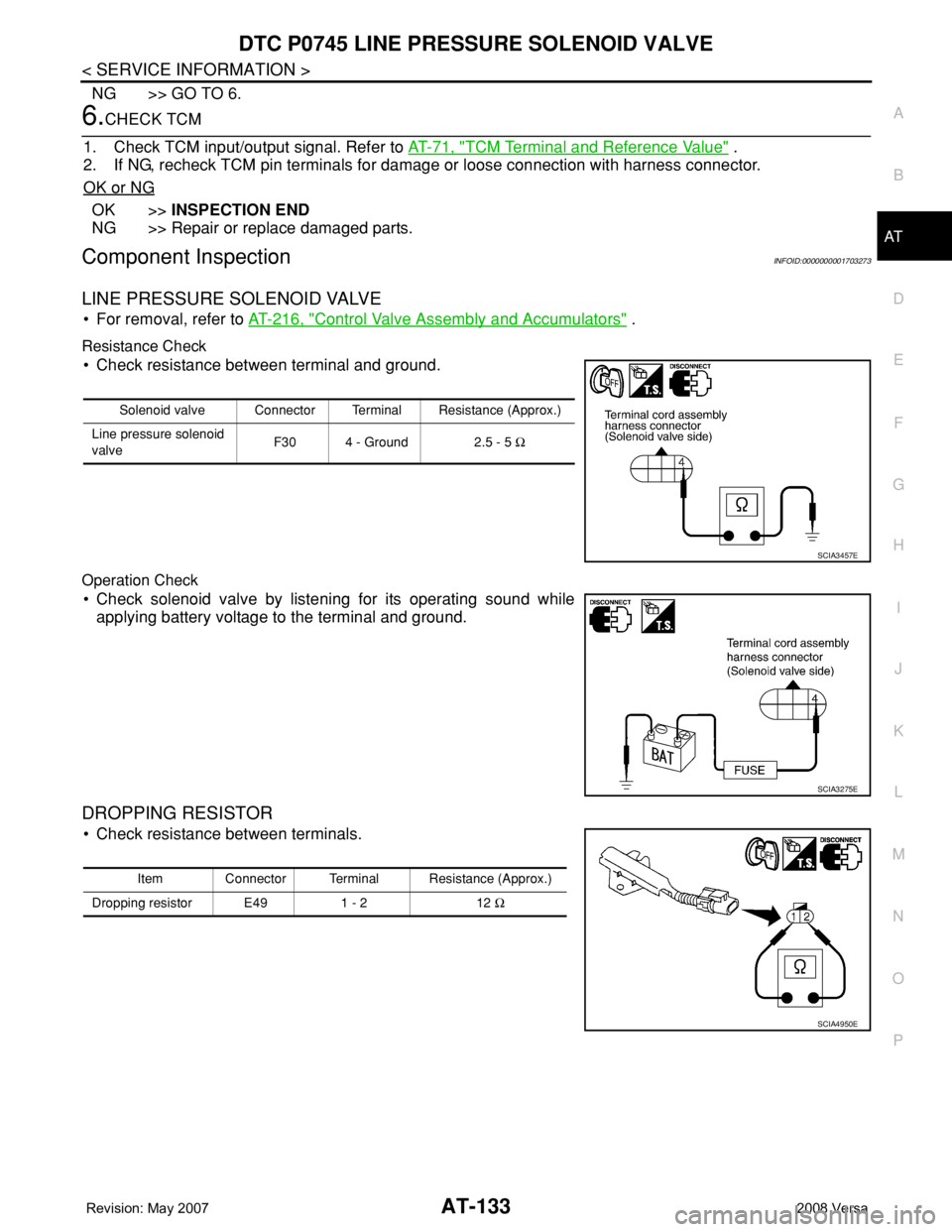

Component InspectionINFOID:0000000001703273

LINE PRESSURE SOLENOID VALVE

• For removal, refer to AT-216, "Control Valve Assembly and Accumulators" .

Resistance Check

• Check resistance between terminal and ground.

Operation Check

• Check solenoid valve by listening for its operating sound while

applying battery voltage to the terminal and ground.

DROPPING RESISTOR

• Check resistance between terminals.

Solenoid valve Connector Terminal Resistance (Approx.)

Line pressure solenoid

valveF30 4 - Ground 2.5 - 5 Ω

SCIA3457E

SCIA3275E

Item Connector Terminal Resistance (Approx.)

Dropping resistor E49 1 - 2 12 Ω

SCIA4950E

Page 146 of 2771

AT-134

< SERVICE INFORMATION >

DTC P0750 SHIFT SOLENOID VALVE A

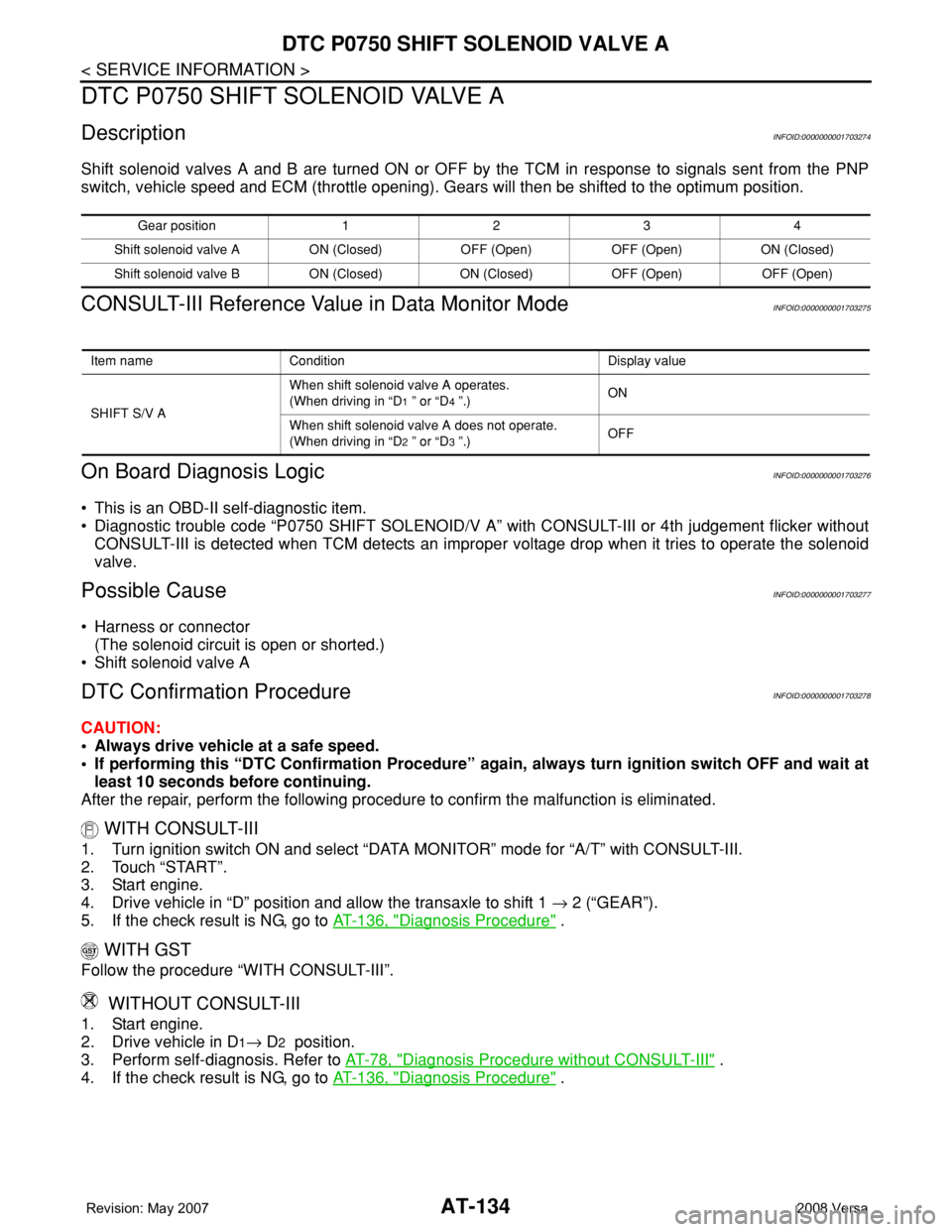

DTC P0750 SHIFT SOLENOID VALVE A

DescriptionINFOID:0000000001703274

Shift solenoid valves A and B are turned ON or OFF by the TCM in response to signals sent from the PNP

switch, vehicle speed and ECM (throttle opening). Gears will then be shifted to the optimum position.

CONSULT-III Reference Value in Data Monitor ModeINFOID:0000000001703275

On Board Diagnosis LogicINFOID:0000000001703276

• This is an OBD-II self-diagnostic item.

• Diagnostic trouble code “P0750 SHIFT SOLENOID/V A” with CONSULT-III or 4th judgement flicker without

CONSULT-III is detected when TCM detects an improper voltage drop when it tries to operate the solenoid

valve.

Possible CauseINFOID:0000000001703277

• Harness or connector

(The solenoid circuit is open or shorted.)

• Shift solenoid valve A

DTC Confirmation ProcedureINFOID:0000000001703278

CAUTION:

• Always drive vehicle at a safe speed.

• If performing this “DTC Confirmation Procedure” again, always turn ignition switch OFF and wait at

least 10 seconds before continuing.

After the repair, perform the following procedure to confirm the malfunction is eliminated.

WITH CONSULT-III

1. Turn ignition switch ON and select “DATA MONITOR” mode for “A/T” with CONSULT-III.

2. Touch “START”.

3. Start engine.

4. Drive vehicle in “D” position and allow the transaxle to shift 1 → 2 (“GEAR”).

5. If the check result is NG, go to AT-136, "

Diagnosis Procedure" .

WITH GST

Follow the procedure “WITH CONSULT-III”.

WITHOUT CONSULT-III

1. Start engine.

2. Drive vehicle in D

1→ D2 position.

3. Perform self-diagnosis. Refer to AT-78, "

Diagnosis Procedure without CONSULT-III" .

4. If the check result is NG, go to AT-136, "

Diagnosis Procedure" .

Gear position1234

Shift solenoid valve A ON (Closed) OFF (Open) OFF (Open) ON (Closed)

Shift solenoid valve B ON (Closed) ON (Closed) OFF (Open) OFF (Open)

Item name Condition Display value

SHIFT S/V AWhen shift solenoid valve A operates.

(When driving in “D

1 ” or “D4 ”.)ON

When shift solenoid valve A does not operate.

(When driving in “D

2 ” or “D3 ”.)OFF

Page 147 of 2771

DTC P0750 SHIFT SOLENOID VALVE A

AT-135

< SERVICE INFORMATION >

D

E

F

G

H

I

J

K

L

MA

B

AT

N

O

P

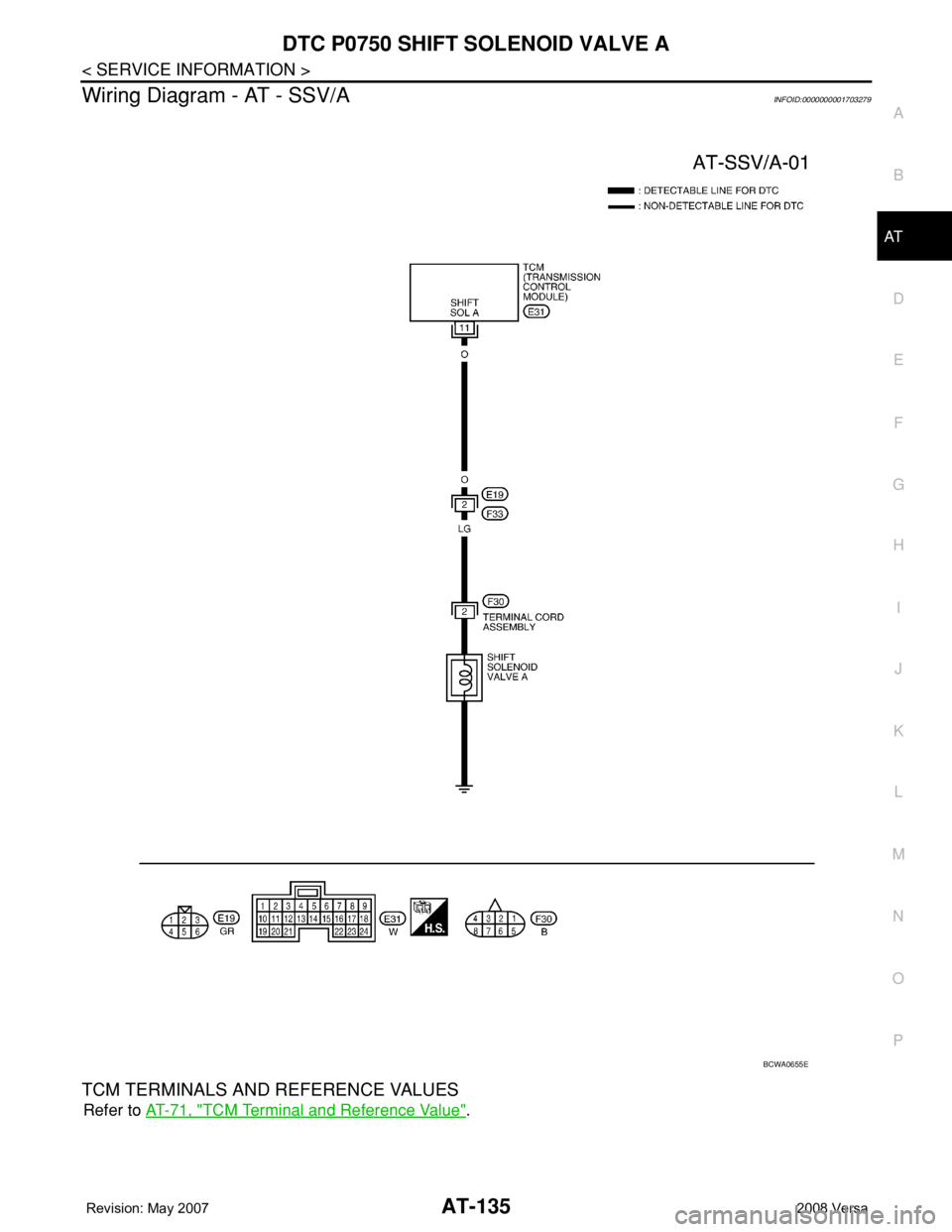

Wiring Diagram - AT - SSV/AINFOID:0000000001703279

TCM TERMINALS AND REFERENCE VALUES

Refer to AT-71, "TCM Terminal and Reference Value".

BCWA0655E

Page 148 of 2771

AT-136

< SERVICE INFORMATION >

DTC P0750 SHIFT SOLENOID VALVE A

Diagnosis Procedure

INFOID:0000000001703280

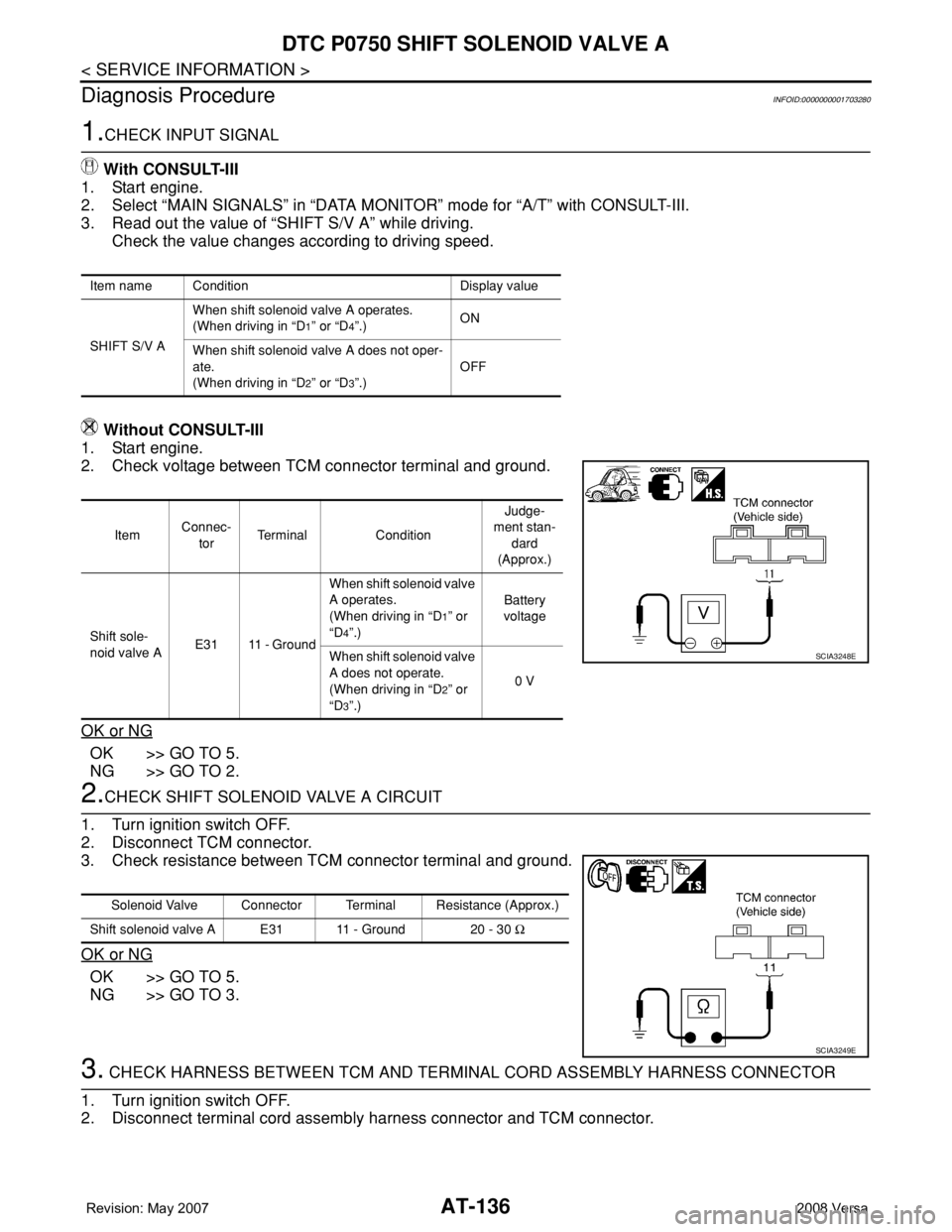

1.CHECK INPUT SIGNAL

With CONSULT-III

1. Start engine.

2. Select “MAIN SIGNALS” in “DATA MONITOR” mode for “A/T” with CONSULT-III.

3. Read out the value of “SHIFT S/V A” while driving.

Check the value changes according to driving speed.

Without CONSULT-III

1. Start engine.

2. Check voltage between TCM connector terminal and ground.

OK or NG

OK >> GO TO 5.

NG >> GO TO 2.

2.CHECK SHIFT SOLENOID VALVE A CIRCUIT

1. Turn ignition switch OFF.

2. Disconnect TCM connector.

3. Check resistance between TCM connector terminal and ground.

OK or NG

OK >> GO TO 5.

NG >> GO TO 3.

3. CHECK HARNESS BETWEEN TCM AND TERMINAL CORD ASSEMBLY HARNESS CONNECTOR

1. Turn ignition switch OFF.

2. Disconnect terminal cord assembly harness connector and TCM connector.

Item name Condition Display value

SHIFT S/V AWhen shift solenoid valve A operates.

(When driving in “D

1” or “D4”.)ON

When shift solenoid valve A does not oper-

ate.

(When driving in “D

2” or “D3”.)OFF

ItemConnec-

torTerminal ConditionJudge-

ment stan-

dard

(Approx.)

Shift sole-

noid valve AE31 11 - GroundWhen shift solenoid valve

A operates.

(When driving in “D

1” or

“D

4”.)Battery

voltage

When shift solenoid valve

A does not operate.

(When driving in “D

2” or

“D

3”.)0 V

SCIA3248E

Solenoid Valve Connector Terminal Resistance (Approx.)

Shift solenoid valve A E31 11 - Ground 20 - 30 Ω

SCIA3249E

Page 149 of 2771

DTC P0750 SHIFT SOLENOID VALVE A

AT-137

< SERVICE INFORMATION >

D

E

F

G

H

I

J

K

L

MA

B

AT

N

O

P

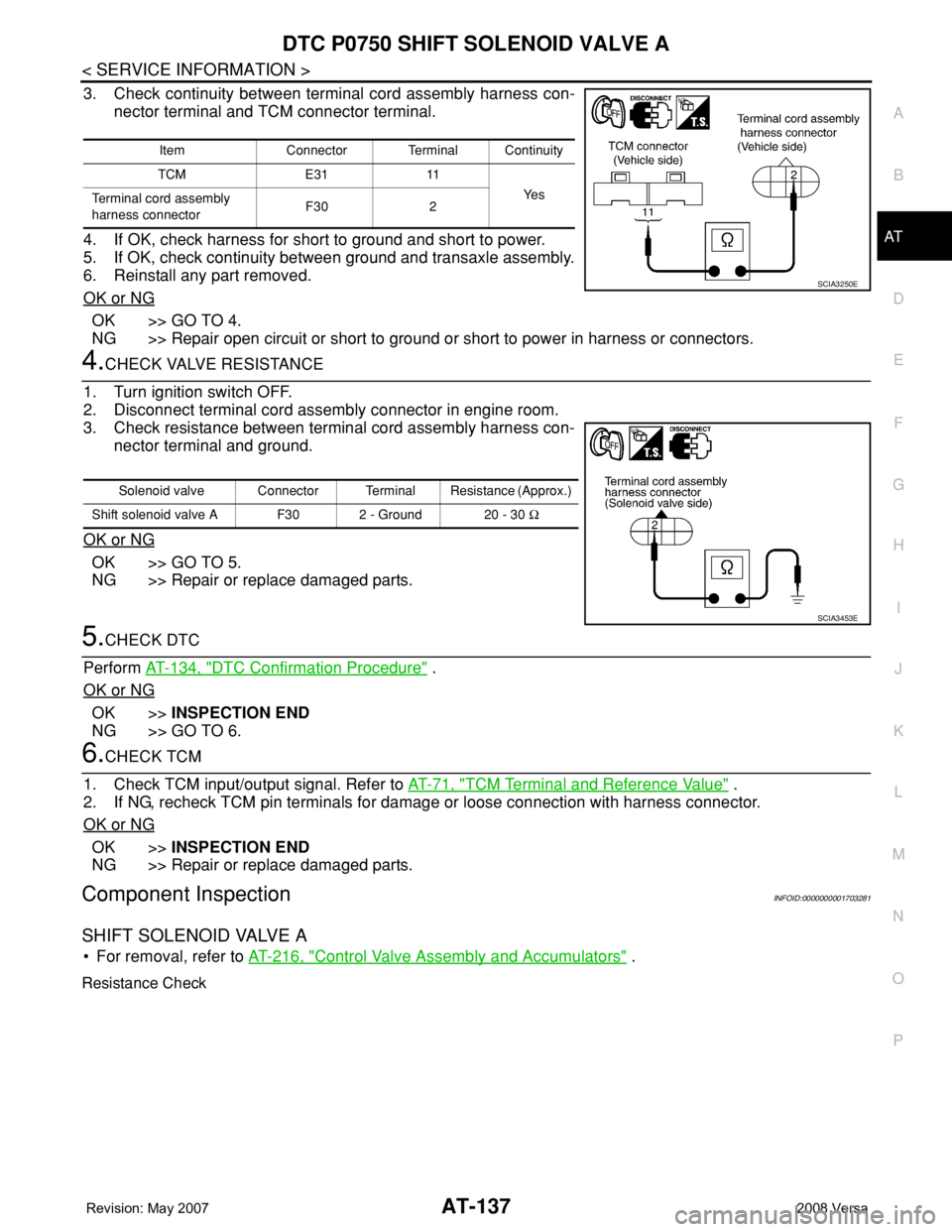

3. Check continuity between terminal cord assembly harness con-

nector terminal and TCM connector terminal.

4. If OK, check harness for short to ground and short to power.

5. If OK, check continuity between ground and transaxle assembly.

6. Reinstall any part removed.

OK or NG

OK >> GO TO 4.

NG >> Repair open circuit or short to ground or short to power in harness or connectors.

4.CHECK VALVE RESISTANCE

1. Turn ignition switch OFF.

2. Disconnect terminal cord assembly connector in engine room.

3. Check resistance between terminal cord assembly harness con-

nector terminal and ground.

OK or NG

OK >> GO TO 5.

NG >> Repair or replace damaged parts.

5.CHECK DTC

Perform AT-134, "

DTC Confirmation Procedure" .

OK or NG

OK >>INSPECTION END

NG >> GO TO 6.

6.CHECK TCM

1. Check TCM input/output signal. Refer to AT-71, "

TCM Terminal and Reference Value" .

2. If NG, recheck TCM pin terminals for damage or loose connection with harness connector.

OK or NG

OK >>INSPECTION END

NG >> Repair or replace damaged parts.

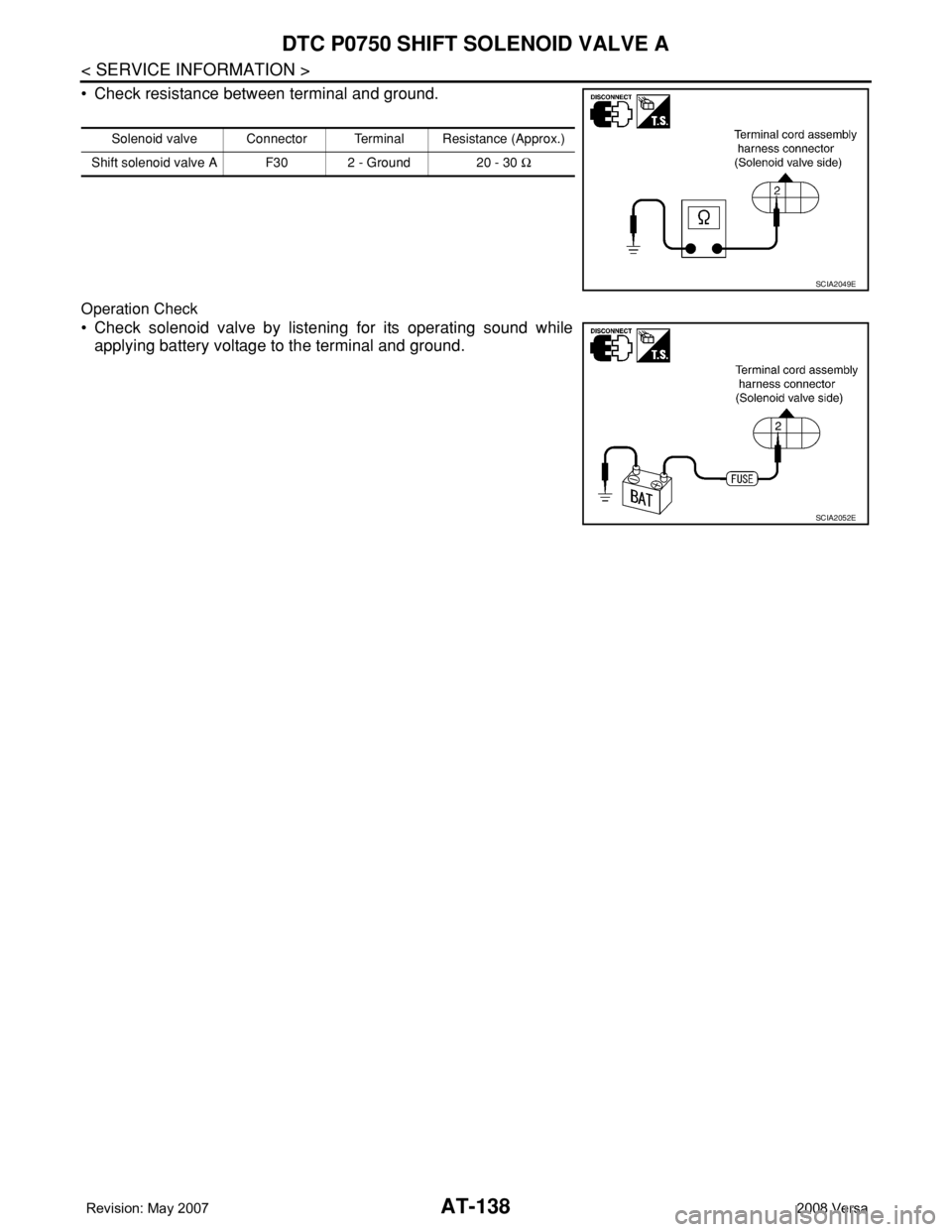

Component InspectionINFOID:0000000001703281

SHIFT SOLENOID VALVE A

• For removal, refer to AT-216, "Control Valve Assembly and Accumulators" .

Resistance Check

Item Connector Terminal Continuity

TCM E31 11

Ye s

Terminal cord assembly

harness connectorF30 2

SCIA3250E

Solenoid valve Connector Terminal Resistance (Approx.)

Shift solenoid valve A F30 2 - Ground 20 - 30 Ω

SCIA3453E

Page 150 of 2771

AT-138

< SERVICE INFORMATION >

DTC P0750 SHIFT SOLENOID VALVE A

• Check resistance between terminal and ground.

Operation Check

• Check solenoid valve by listening for its operating sound while

applying battery voltage to the terminal and ground.

Solenoid valve Connector Terminal Resistance (Approx.)

Shift solenoid valve A F30 2 - Ground 20 - 30 Ω

SCIA2049E

SCIA2052E