oil type NISSAN LATIO 2008 Service Owner's Guide

[x] Cancel search | Manufacturer: NISSAN, Model Year: 2008, Model line: LATIO, Model: NISSAN LATIO 2008Pages: 2771, PDF Size: 60.61 MB

Page 2342 of 2771

MTC-4

< SERVICE INFORMATION >

PRECAUTIONS

- Do not allow A/C oil to come in contact with styrofoam parts. Damage may result.

General Refrigerant PrecautionINFOID:0000000001704277

WARNING:

• Avoid breathing A/C refrigerant and oil vapor or mist. Exposure may irritate eyes, nose and throat.

Use only approved recovery/recycling equipment to discharge HFC-134a (R-134a) refrigerant. If acci-

dental system discharge occurs, ventilate work area before resuming service. Additional health and

safety information may be obtained from refrigerant and oil manufacturers.

• Do not release refrigerant into the air. Use approved recovery/recycling equipment to capture the

refrigerant every time an air conditioning system is discharged.

• Always wear eye and hand protection (goggles and gloves) when working with any refrigerant or air

conditioning system.

• Do not store or heat refrigerant containers above 52°C (126° F).

• Do not heat a refrigerant container with an open flame; if container warming is required, place the

bottom of the container in a warm pail of water.

• Do not intentionally drop, puncture, or incinerate refrigerant containers.

• Keep refrigerant away from open flames: poisonous gas will be produced if refrigerant burns.

• Refrigerant will displace oxygen, therefore be certain to work in well ventilated areas to prevent suf-

focation.

• Do not pressure test or leak test HFC-134a (R-134a) service equipment and/or vehicle air condition-

ing systems with compressed air during repair. Some mixtures of air and HFC-134a (R-134a) have

been shown to be combustible at elevated pressures. These mixtures, if ignited, may cause injury or

property damage. Additional health and safety information may be obtained from refrigerant manu-

facturers.

Oil PrecautionINFOID:0000000001704278

• Use only specified oil for the HFC-134a (R-134a) A/C system and HFC-134a (R-134a) components. If oil

other than that specified is used, compressor malfunction is likely to occur.

• The specified HFC-134a (R-134a) oil rapidly absorbs moisture from the atmosphere. The following handling

precautions must be observed:

- When removing refrigerant components from a vehicle, immediately cap (seal) the component to minimize

the entry of moisture from the atmosphere.

- When installing refrigerant components to a vehicle, do not remove the caps (unseal) until just before con-

necting the components. Connect all refrigerant loop components as quickly as possible to minimize the

entry of moisture into system.

- Only use the specified oil from a sealed container. Immediately reseal containers of oil. Without proper seal-

ing, oil will become moisture saturated and should not be used.

• Avoid breathing A/C refrigerant and oil vapor or mist. Exposure may irritate eyes, nose and throat.

Use only approved recovery/recycling equipment to discharge HFC-134a (R-134a) refrigerant. If accidental

system discharge occurs, ventilate work area before resuming service. Additional health and safety informa-

tion may be obtained from refrigerant and oil manufacturers.

• Do not allow A/C oil to come in contact with styrofoam parts. Damage may result.

Precaution for Refrigerant ConnectionINFOID:0000000001704279

A new type refrigerant connection has been introduced to all refrigerant lines except the following location.

• Expansion valve to evaporator

• Refrigerant pressure sensor to condenser

Page 2344 of 2771

MTC-6

< SERVICE INFORMATION >

PRECAUTIONS

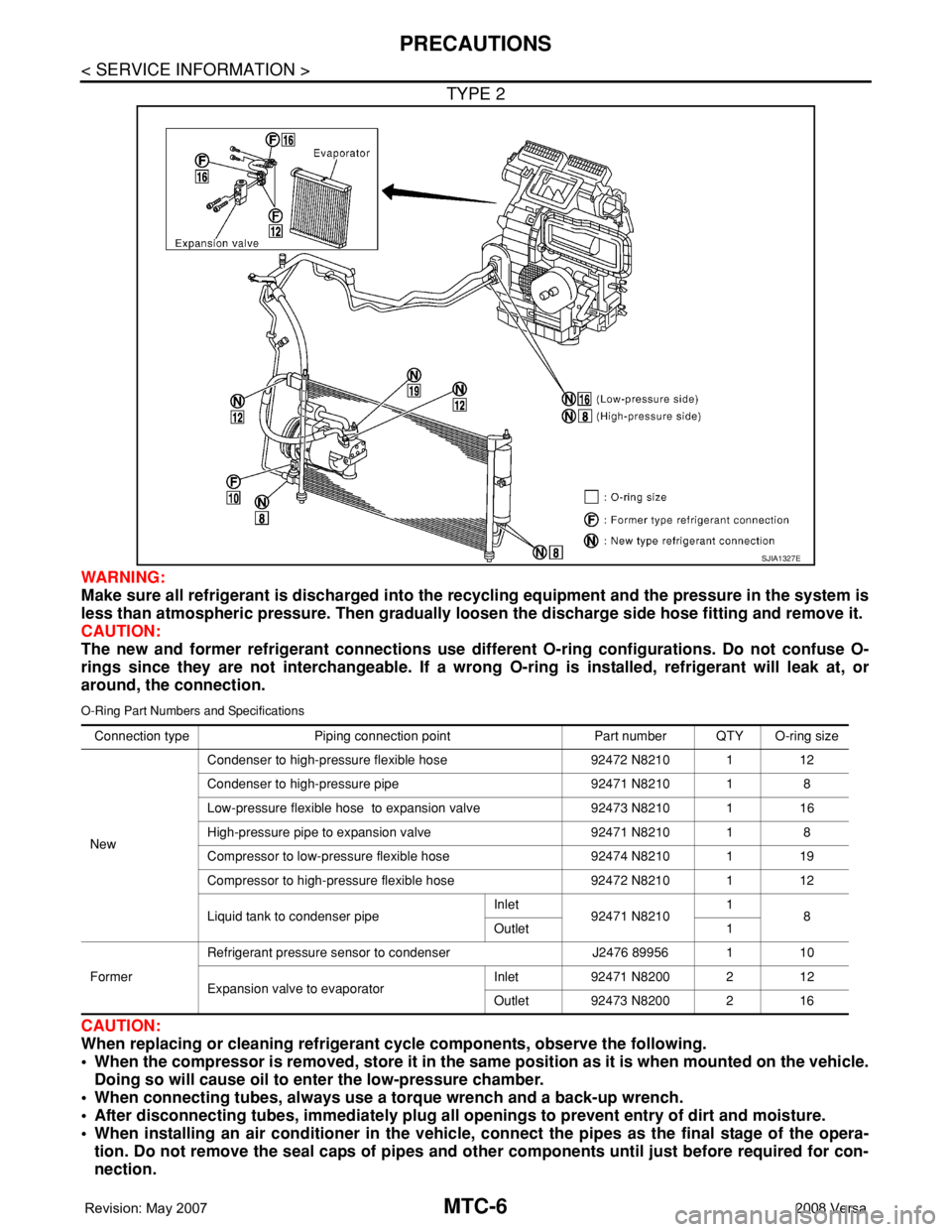

TYPE 2

WARNING:

Make sure all refrigerant is discharged into the recycling equipment and the pressure in the system is

less than atmospheric pressure. Then gradually loosen the discharge side hose fitting and remove it.

CAUTION:

The new and former refrigerant connections use different O-ring configurations. Do not confuse O-

rings since they are not interchangeable. If a wrong O-ring is installed, refrigerant will leak at, or

around, the connection.

O-Ring Part Numbers and Specifications

CAUTION:

When replacing or cleaning refrigerant cycle components, observe the following.

• When the compressor is removed, store it in the same position as it is when mounted on the vehicle.

Doing so will cause oil to enter the low-pressure chamber.

• When connecting tubes, always use a torque wrench and a back-up wrench.

• After disconnecting tubes, immediately plug all openings to prevent entry of dirt and moisture.

• When installing an air conditioner in the vehicle, connect the pipes as the final stage of the opera-

tion. Do not remove the seal caps of pipes and other components until just before required for con-

nection.

SJIA1327E

Connection type Piping connection point Part number QTY O-ring size

NewCondenser to high-pressure flexible hose 92472 N8210 1 12

Condenser to high-pressure pipe 92471 N8210 1 8

Low-pressure flexible hose to expansion valve 92473 N8210 1 16

High-pressure pipe to expansion valve 92471 N8210 1 8

Compressor to low-pressure flexible hose 92474 N8210 1 19

Compressor to high-pressure flexible hose 92472 N8210 1 12

Liquid tank to condenser pipeInlet

92471 N82101

8

Outlet 1

FormerRefrigerant pressure sensor to condenser J2476 89956 1 10

Expansion valve to evaporatorInlet 92471 N8200 2 12

Outlet 92473 N8200 2 16

Page 2348 of 2771

MTC-10

< SERVICE INFORMATION >

PREPARATION

PREPARATION

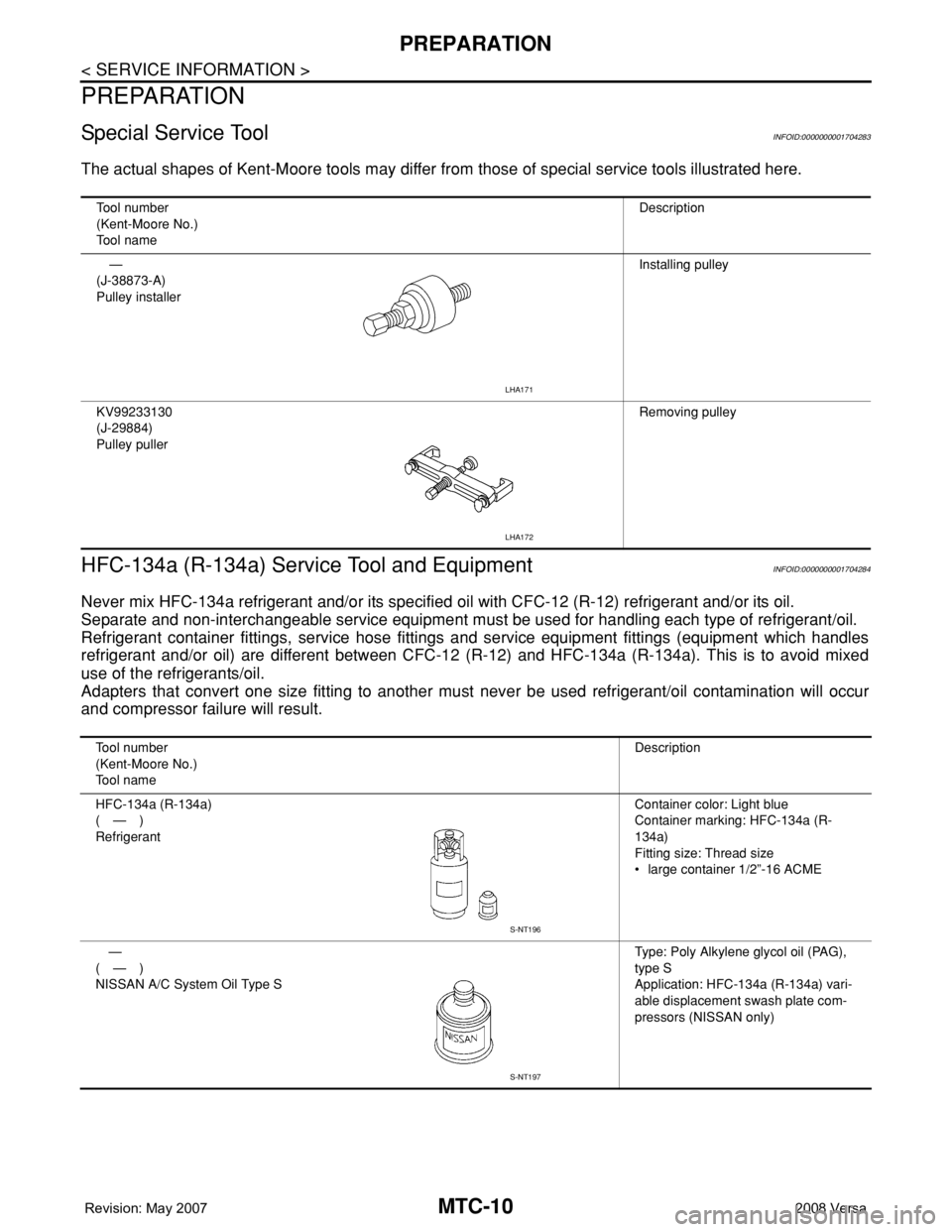

Special Service ToolINFOID:0000000001704283

The actual shapes of Kent-Moore tools may differ from those of special service tools illustrated here.

HFC-134a (R-134a) Service Tool and EquipmentINFOID:0000000001704284

Never mix HFC-134a refrigerant and/or its specified oil with CFC-12 (R-12) refrigerant and/or its oil.

Separate and non-interchangeable service equipment must be used for handling each type of refrigerant/oil.

Refrigerant container fittings, service hose fittings and service equipment fittings (equipment which handles

refrigerant and/or oil) are different between CFC-12 (R-12) and HFC-134a (R-134a). This is to avoid mixed

use of the refrigerants/oil.

Adapters that convert one size fitting to another must never be used refrigerant/oil contamination will occur

and compressor failure will result.

Tool number

(Kent-Moore No.)

Tool nameDescription

—

(J-38873-A)

Pulley installerInstalling pulley

KV99233130

(J-29884)

Pulley pullerRemoving pulley

LHA171

LHA172

Tool number

(Kent-Moore No.)

Tool nameDescription

HFC-134a (R-134a)

(—)

RefrigerantContainer color: Light blue

Container marking: HFC-134a (R-

134a)

Fitting size: Thread size

• large container 1/2”-16 ACME

—

(—)

NISSAN A/C System Oil Type SType: Poly Alkylene glycol oil (PAG),

type S

Application: HFC-134a (R-134a) vari-

able displacement swash plate com-

pressors (NISSAN only)

S-NT196

S-NT197

Page 2349 of 2771

PREPARATION

MTC-11

< SERVICE INFORMATION >

C

D

E

F

G

H

I

K

L

MA

B

MTC

N

O

P

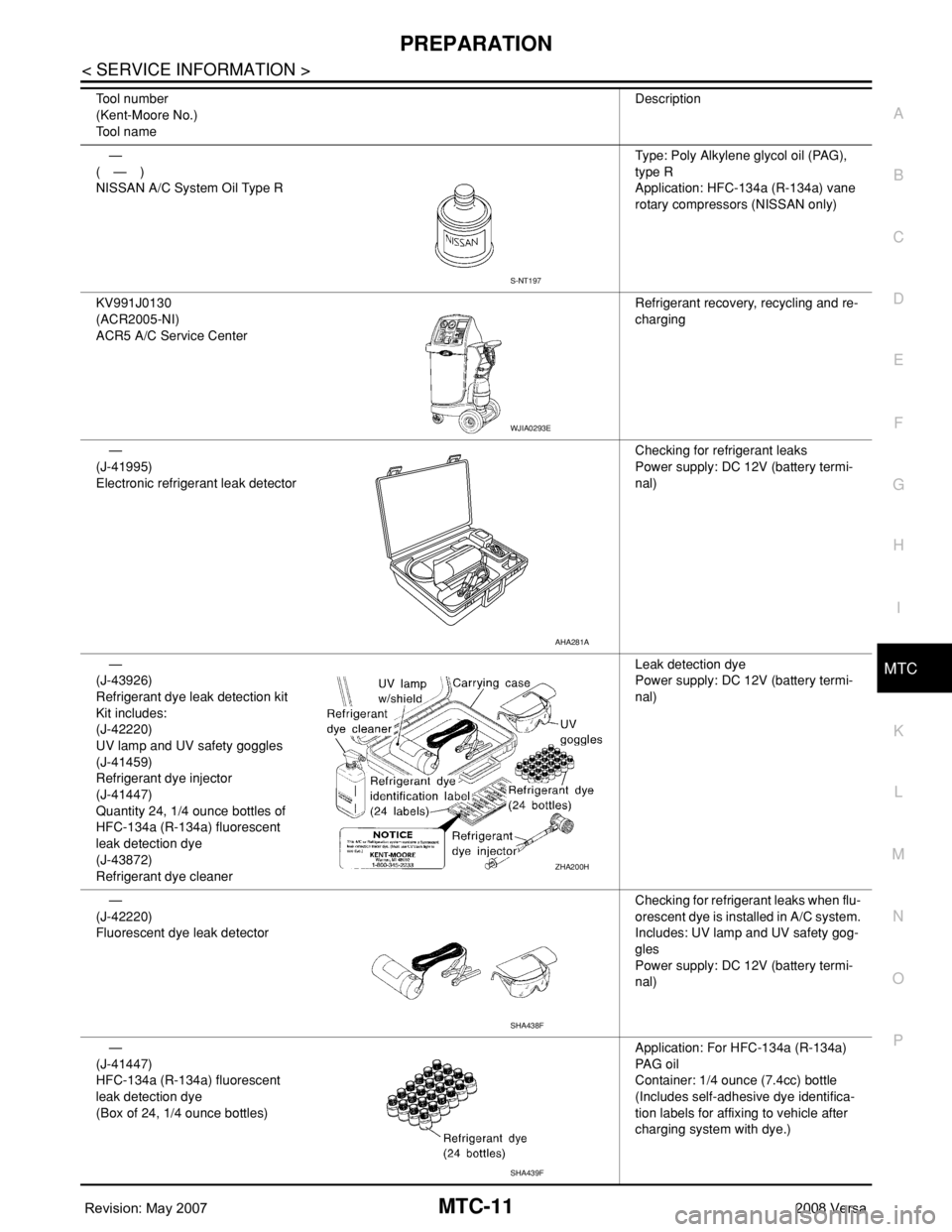

—

(—)

NISSAN A/C System Oil Type RType: Poly Alkylene glycol oil (PAG),

type R

Application: HFC-134a (R-134a) vane

rotary compressors (NISSAN only)

KV991J0130

(ACR2005-NI)

ACR5 A/C Service CenterRefrigerant recovery, recycling and re-

charging

—

(J-41995)

Electronic refrigerant leak detectorChecking for refrigerant leaks

Power supply: DC 12V (battery termi-

nal)

—

(J-43926)

Refrigerant dye leak detection kit

Kit includes:

(J-42220)

UV lamp and UV safety goggles

(J-41459)

Refrigerant dye injector

(J-41447)

Quantity 24, 1/4 ounce bottles of

HFC-134a (R-134a) fluorescent

leak detection dye

(J-43872)

Refrigerant dye cleanerLeak detection dye

Power supply: DC 12V (battery termi-

nal)

—

(J-42220)

Fluorescent dye leak detectorChecking for refrigerant leaks when flu-

orescent dye is installed in A/C system.

Includes: UV lamp and UV safety gog-

gles

Power supply: DC 12V (battery termi-

nal)

—

(J-41447)

HFC-134a (R-134a) fluorescent

leak detection dye

(Box of 24, 1/4 ounce bottles)Application: For HFC-134a (R-134a)

PA G o i l

Container: 1/4 ounce (7.4cc) bottle

(Includes self-adhesive dye identifica-

tion labels for affixing to vehicle after

charging system with dye.) Tool number

(Kent-Moore No.)

Tool nameDescription

S-NT197

WJIA0293E

AHA281A

ZHA200H

SHA438F

SHA439F

Page 2354 of 2771

MTC-16

< SERVICE INFORMATION >

OIL

OIL

Maintenance of Oil Quantity in CompressorINFOID:0000000001704289

The oil in the compressor circulates through the system with the refrigerant. Add oil to compressor when

replacing any component or after a large refrigerant leakage occurred. It is important to maintain the specified

amount.

If oil quantity is not maintained properly, the following malfunctions may result:

• Lack of oil: May lead to a seized compressor.

• Excessive oil: Inadequate cooling (thermal exchange interference)

OIL

OIL RETURN OPERATION

Adjust the oil quantity according to the test group shown below.

1.CHECK OIL RETURN OPERATION

Can oil return operation be performed?

• A/C system works properly.

• There is no evidence of a large amount of oil leakage.

CAUTION:

If excessive oil leakage is noted, do not perform the oil return operation.

OK or NG

OK >> GO TO 2.

NG >> GO TO 3.

2.PERFORM OIL RETURN OPERATION, PROCEEDING AS FOLLOWS

1. Start engine, and set the following conditions:

- Engine speed: Idling to 1,200 rpm

- A/C blower switch: ON

- Blower speed: Max. position

- Temp. control: Optional [Set so that intake air temperature is 25° to 30°C (77° to 86° F)].

- Intake position: Recirculation (REC)

2. Perform oil return operation for about 10 minutes.

3. Stop engine.

>> GO TO 3.

3.CHECK REPLACEMENT PART

Should the compressor be replaced?

YES >> GO TO "OIL ADJUSTING PROCEDURE FOR COMPRESSOR REPLACEMENT".

NO >> GO TO "OIL ADJUSTING PROCEDURE FOR COMPONENTS REPLACEMENT EXCEPT COM-

PRESSOR".

OIL ADJUSTING PROCEDURE FOR COMPONENTS REPLACEMENT EXCEPT COMPRESSOR

After replacing any of the following major components, add the correct amount of oil to the system.

Amount Of Oil To Be Added

TYPE 1 Compressor (CR-10) : NISSAN A/C System Oil Type R

TYPE 2 Compressor (CSV511) : NISSAN A/C System Oil Type S

Part replacedOil to be added to system

Remarks

Amount of oil

m (US fl oz, Imp fl oz)

Evaporator 35 (1.2, 1.2) -

Condenser 15 (0.5, 0.5) -

Liquid tank 5 (0.2, 0.2) -

Page 2395 of 2771

THERMO CONTROL AMPLIFIER

MTC-57

< SERVICE INFORMATION >

C

D

E

F

G

H

I

K

L

MA

B

MTC

N

O

P

THERMO CONTROL AMPLIFIER

Removal and InstallationINFOID:0000000001704311

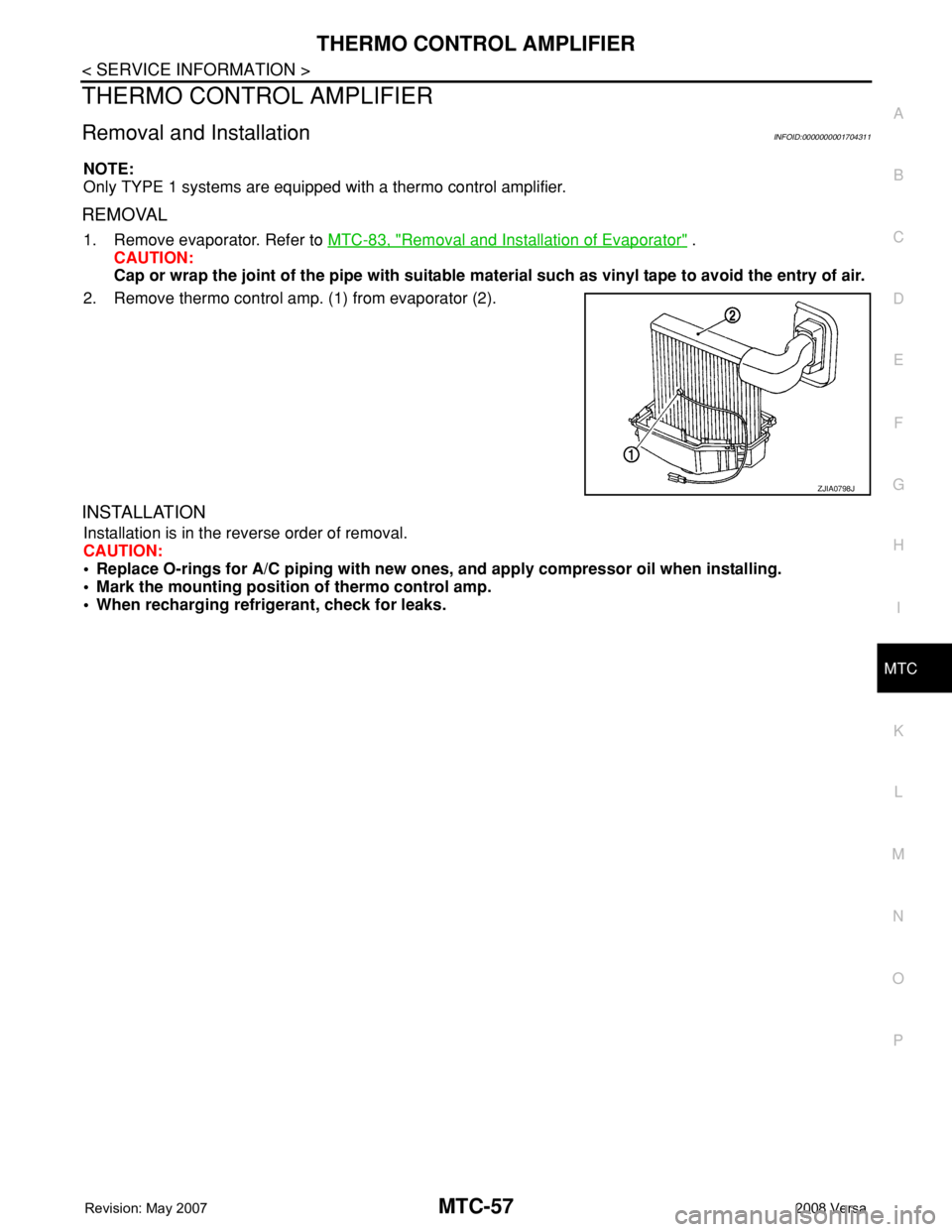

NOTE:

Only TYPE 1 systems are equipped with a thermo control amplifier.

REMOVAL

1. Remove evaporator. Refer to MTC-83, "Removal and Installation of Evaporator" .

CAUTION:

Cap or wrap the joint of the pipe with suitable material such as vinyl tape to avoid the entry of air.

2. Remove thermo control amp. (1) from evaporator (2).

INSTALLATION

Installation is in the reverse order of removal.

CAUTION:

• Replace O-rings for A/C piping with new ones, and apply compressor oil when installing.

• Mark the mounting position of thermo control amp.

• When recharging refrigerant, check for leaks.

ZJIA0798J

Page 2397 of 2771

A/C UNIT ASSEMBLY

MTC-59

< SERVICE INFORMATION >

C

D

E

F

G

H

I

K

L

MA

B

MTC

N

O

P

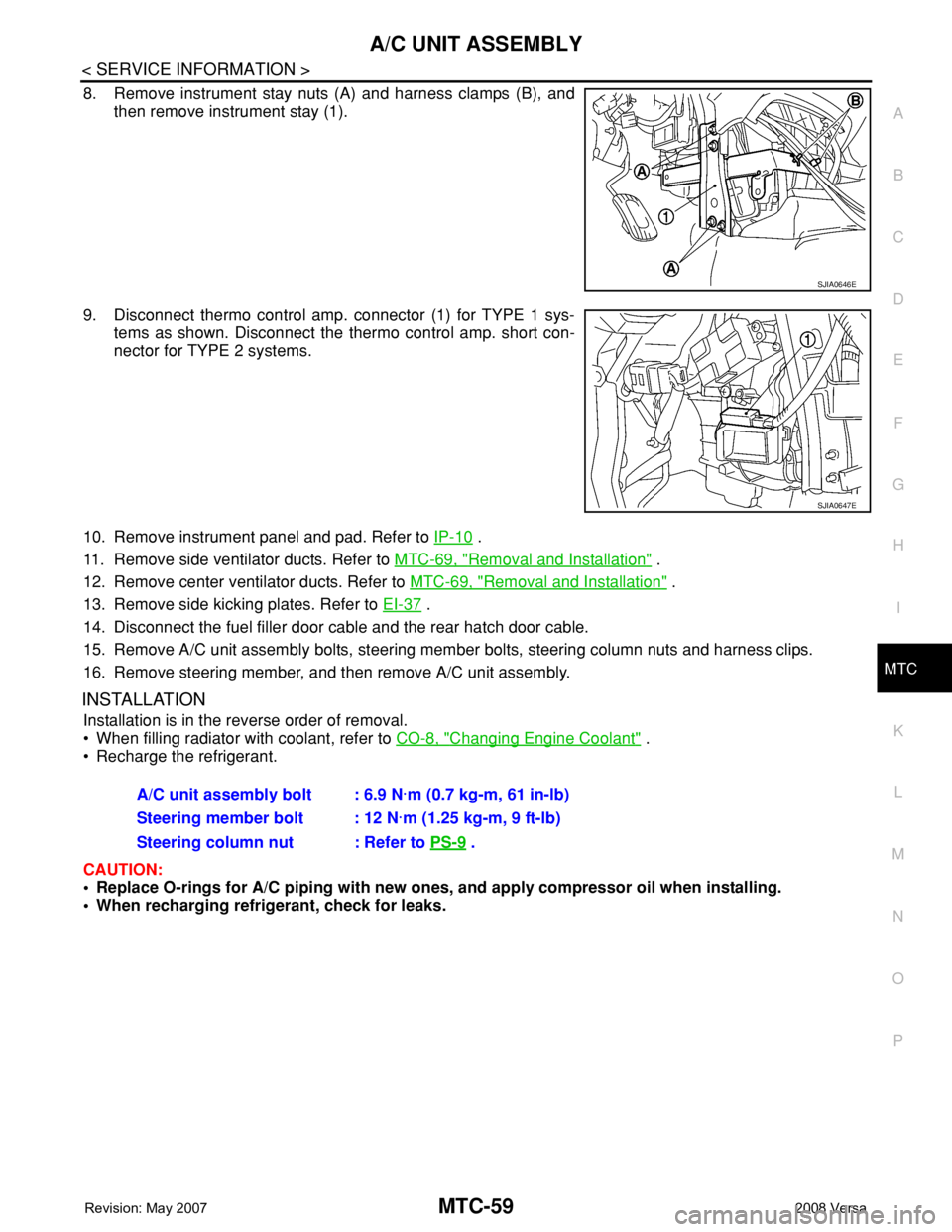

8. Remove instrument stay nuts (A) and harness clamps (B), and

then remove instrument stay (1).

9. Disconnect thermo control amp. connector (1) for TYPE 1 sys-

tems as shown. Disconnect the thermo control amp. short con-

nector for TYPE 2 systems.

10. Remove instrument panel and pad. Refer to IP-10

.

11. Remove side ventilator ducts. Refer to MTC-69, "

Removal and Installation" .

12. Remove center ventilator ducts. Refer to MTC-69, "

Removal and Installation" .

13. Remove side kicking plates. Refer to EI-37

.

14. Disconnect the fuel filler door cable and the rear hatch door cable.

15. Remove A/C unit assembly bolts, steering member bolts, steering column nuts and harness clips.

16. Remove steering member, and then remove A/C unit assembly.

INSTALLATION

Installation is in the reverse order of removal.

• When filling radiator with coolant, refer to CO-8, "

Changing Engine Coolant" .

• Recharge the refrigerant.

CAUTION:

• Replace O-rings for A/C piping with new ones, and apply compressor oil when installing.

• When recharging refrigerant, check for leaks.

SJIA0646E

SJIA0647E

A/C unit assembly bolt : 6.9 N·m (0.7 kg-m, 61 in-lb)

Steering member bolt : 12 N·m (1.25 kg-m, 9 ft-lb)

Steering column nut : Refer to PS-9

.

Page 2417 of 2771

REFRIGERANT LINES

MTC-79

< SERVICE INFORMATION >

C

D

E

F

G

H

I

K

L

MA

B

MTC

N

O

P

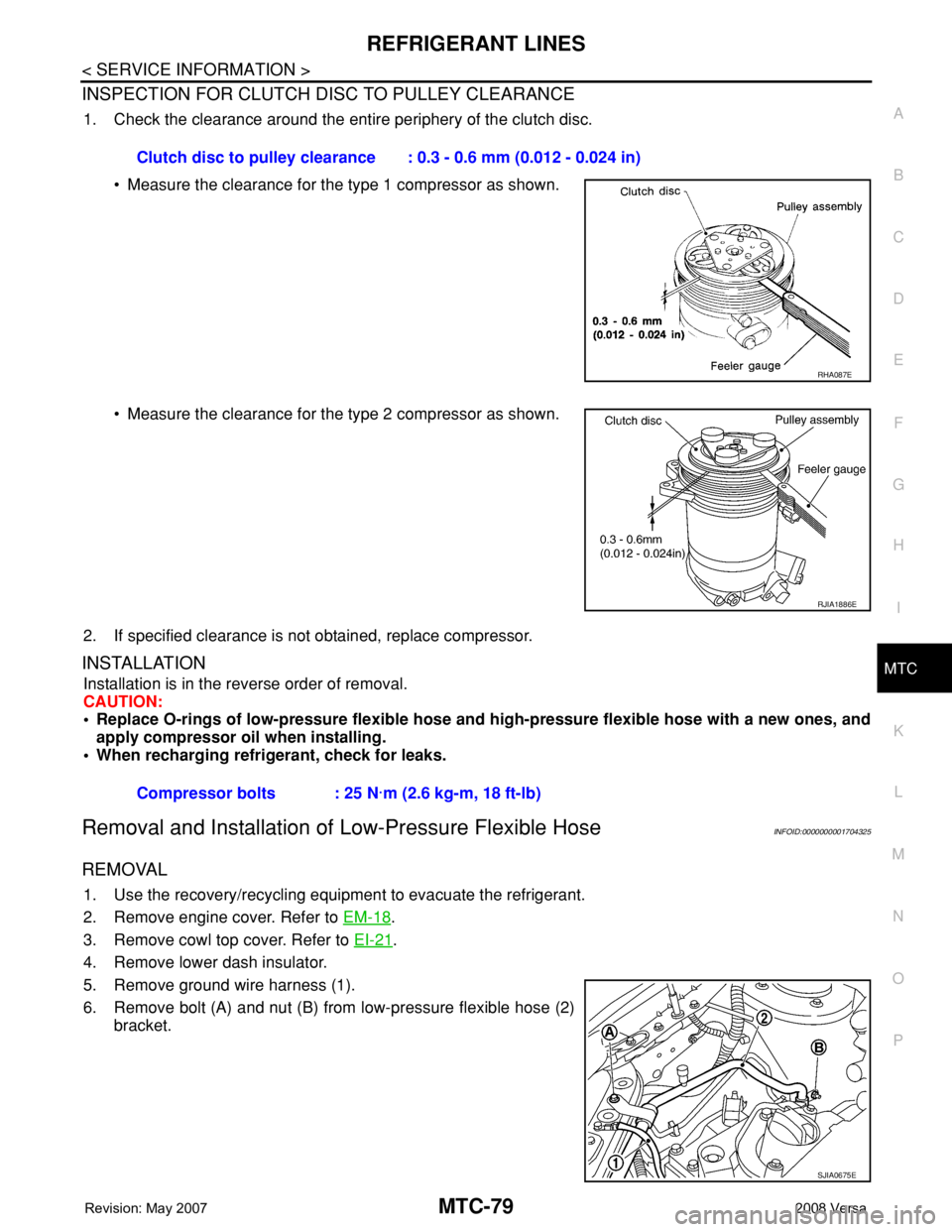

INSPECTION FOR CLUTCH DISC TO PULLEY CLEARANCE

1. Check the clearance around the entire periphery of the clutch disc.

• Measure the clearance for the type 1 compressor as shown.

• Measure the clearance for the type 2 compressor as shown.

2. If specified clearance is not obtained, replace compressor.

INSTALLATION

Installation is in the reverse order of removal.

CAUTION:

• Replace O-rings of low-pressure flexible hose and high-pressure flexible hose with a new ones, and

apply compressor oil when installing.

• When recharging refrigerant, check for leaks.

Removal and Installation of Low-Pressure Flexible HoseINFOID:0000000001704325

REMOVAL

1. Use the recovery/recycling equipment to evacuate the refrigerant.

2. Remove engine cover. Refer to EM-18

.

3. Remove cowl top cover. Refer to EI-21

.

4. Remove lower dash insulator.

5. Remove ground wire harness (1).

6. Remove bolt (A) and nut (B) from low-pressure flexible hose (2)

bracket.Clutch disc to pulley clearance : 0.3 - 0.6 mm (0.012 - 0.024 in)

RHA087E

RJIA1886E

Compressor bolts : 25 N·m (2.6 kg-m, 18 ft-lb)

SJIA0675E

Page 2422 of 2771

MTC-84

< SERVICE INFORMATION >

REFRIGERANT LINES

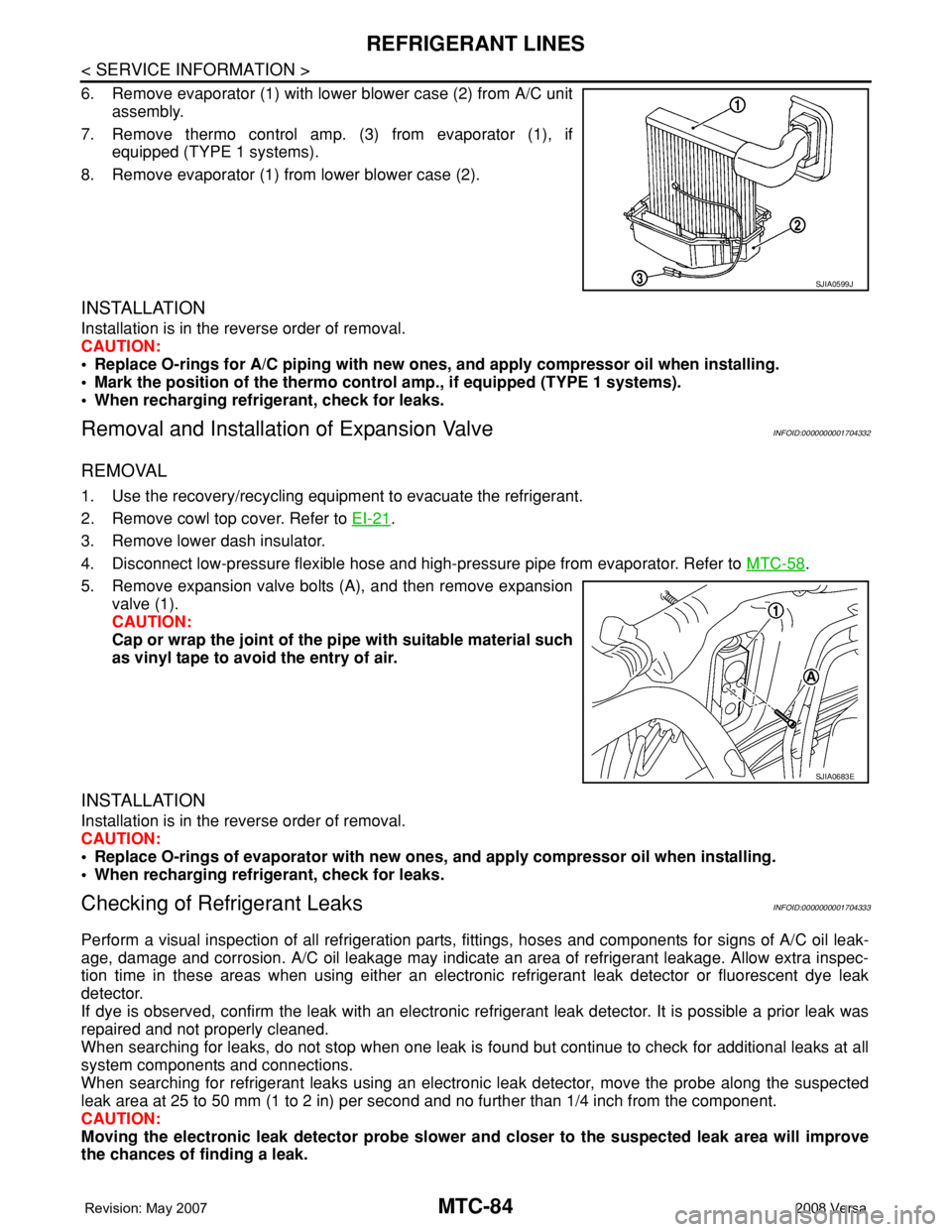

6. Remove evaporator (1) with lower blower case (2) from A/C unit

assembly.

7. Remove thermo control amp. (3) from evaporator (1), if

equipped (TYPE 1 systems).

8. Remove evaporator (1) from lower blower case (2).

INSTALLATION

Installation is in the reverse order of removal.

CAUTION:

• Replace O-rings for A/C piping with new ones, and apply compressor oil when installing.

• Mark the position of the thermo control amp., if equipped (TYPE 1 systems).

• When recharging refrigerant, check for leaks.

Removal and Installation of Expansion ValveINFOID:0000000001704332

REMOVAL

1. Use the recovery/recycling equipment to evacuate the refrigerant.

2. Remove cowl top cover. Refer to EI-21

.

3. Remove lower dash insulator.

4. Disconnect low-pressure flexible hose and high-pressure pipe from evaporator. Refer to MTC-58

.

5. Remove expansion valve bolts (A), and then remove expansion

valve (1).

CAUTION:

Cap or wrap the joint of the pipe with suitable material such

as vinyl tape to avoid the entry of air.

INSTALLATION

Installation is in the reverse order of removal.

CAUTION:

• Replace O-rings of evaporator with new ones, and apply compressor oil when installing.

• When recharging refrigerant, check for leaks.

Checking of Refrigerant LeaksINFOID:0000000001704333

Perform a visual inspection of all refrigeration parts, fittings, hoses and components for signs of A/C oil leak-

age, damage and corrosion. A/C oil leakage may indicate an area of refrigerant leakage. Allow extra inspec-

tion time in these areas when using either an electronic refrigerant leak detector or fluorescent dye leak

detector.

If dye is observed, confirm the leak with an electronic refrigerant leak detector. It is possible a prior leak was

repaired and not properly cleaned.

When searching for leaks, do not stop when one leak is found but continue to check for additional leaks at all

system components and connections.

When searching for refrigerant leaks using an electronic leak detector, move the probe along the suspected

leak area at 25 to 50 mm (1 to 2 in) per second and no further than 1/4 inch from the component.

CAUTION:

Moving the electronic leak detector probe slower and closer to the suspected leak area will improve

the chances of finding a leak.

SJIA0599J

SJIA0683E

Page 2426 of 2771

MTC-88

< SERVICE INFORMATION >

SERVICE DATA AND SPECIFICATIONS (SDS)

SERVICE DATA AND SPECIFICATIONS (SDS)

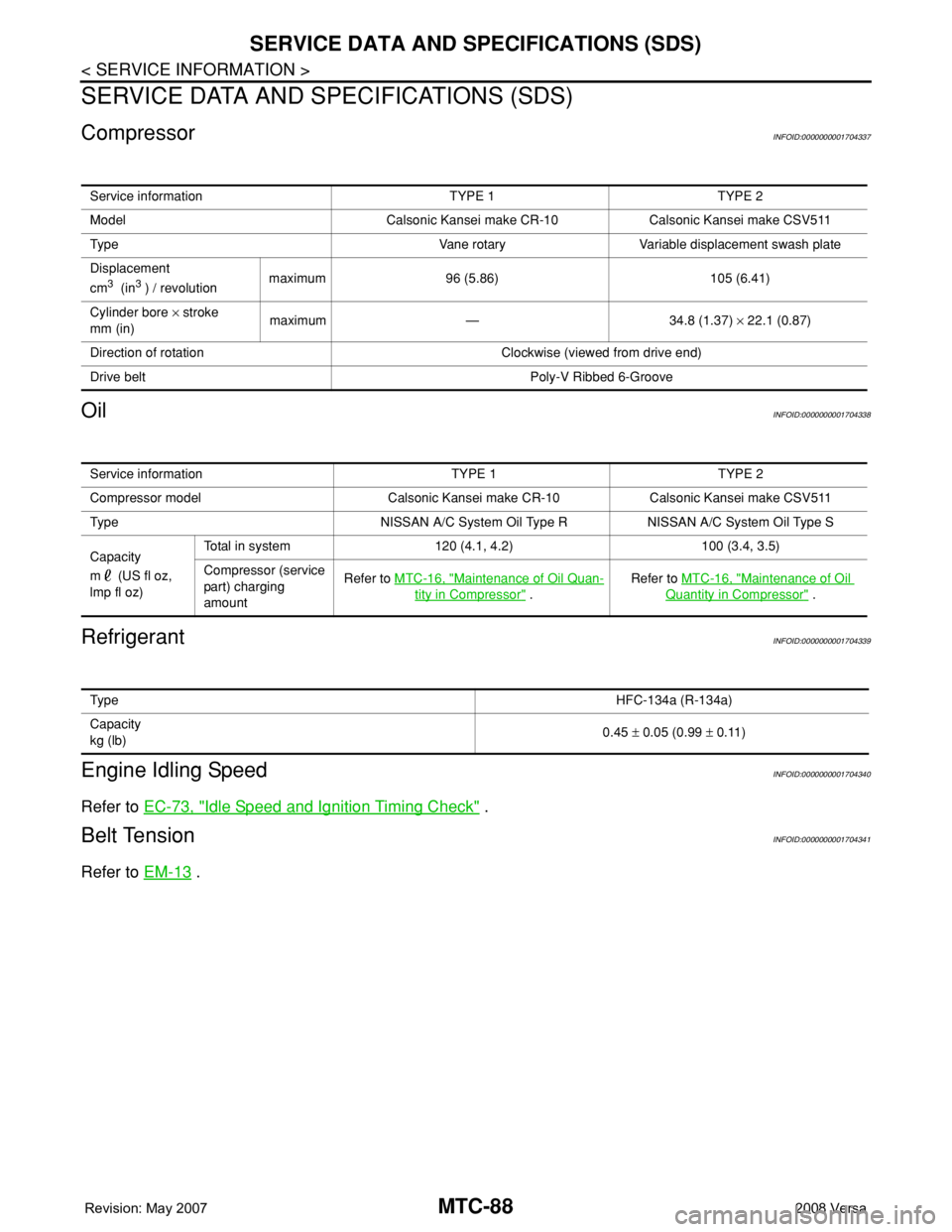

CompressorINFOID:0000000001704337

OilINFOID:0000000001704338

RefrigerantINFOID:0000000001704339

Engine Idling SpeedINFOID:0000000001704340

Refer to EC-73, "Idle Speed and Ignition Timing Check" .

Belt TensionINFOID:0000000001704341

Refer to EM-13 .

Service information TYPE 1 TYPE 2

Model Calsonic Kansei make CR-10 Calsonic Kansei make CSV511

Type Vane rotary Variable displacement swash plate

Displacement

cm

3 (in3 ) / revolutionmaximum 96 (5.86) 105 (6.41)

Cylinder bore × stroke

mm (in)maximum — 34.8 (1.37) × 22.1 (0.87)

Direction of rotation Clockwise (viewed from drive end)

Drive belt Poly-V Ribbed 6-Groove

Service information TYPE 1 TYPE 2

Compressor model Calsonic Kansei make CR-10 Calsonic Kansei make CSV511

Type NISSAN A/C System Oil Type R NISSAN A/C System Oil Type S

Capacity

m (US fl oz,

lmp fl oz)Total in system 120 (4.1, 4.2) 100 (3.4, 3.5)

Compressor (service

part) charging

amountRefer to MTC-16, "

Maintenance of Oil Quan-

tity in Compressor" .Refer to MTC-16, "

Maintenance of Oil

Quantity in Compressor" .

Ty p eHFC-134a (R-134a)

Capacity

kg (lb)0.45 ± 0.05 (0.99 ± 0.11)