engine NISSAN LATIO 2008 Service Repair Manual

[x] Cancel search | Manufacturer: NISSAN, Model Year: 2008, Model line: LATIO, Model: NISSAN LATIO 2008Pages: 2771, PDF Size: 60.61 MB

Page 1609 of 2771

IGNITION SIGNAL

EC-535

< SERVICE INFORMATION >

C

D

E

F

G

H

I

J

K

L

MA

EC

N

P O

: Average voltage for pulse signal (Actual pulse signal can be confirmed by oscilloscope.)

Diagnosis ProcedureINFOID:0000000001703073

1.CHECK ENGINE START

Turn ignition switch OFF, and restart engine.

Is engine running?

Ye s o r N o

Yes (With CONSULT-II)>>GO TO 2.

Yes (Without CONSULT-II)>>GO TO 3.

No >> GO TO 4.

2.CHECK OVERALL FUNCTION

With CONSULT-II

1. Perform “POWER BALANCE” in “ACTIVE TEST” mode with

CONSULT-II.

2. Make sure that each circuit produces a momentary engine

speed drop.

OK or NG

OK >>INSPECTION END

NG >> GO TO 10.

3.CHECK OVERALL FUNCTION

Without CONSULT-II

1. Let engine idle.

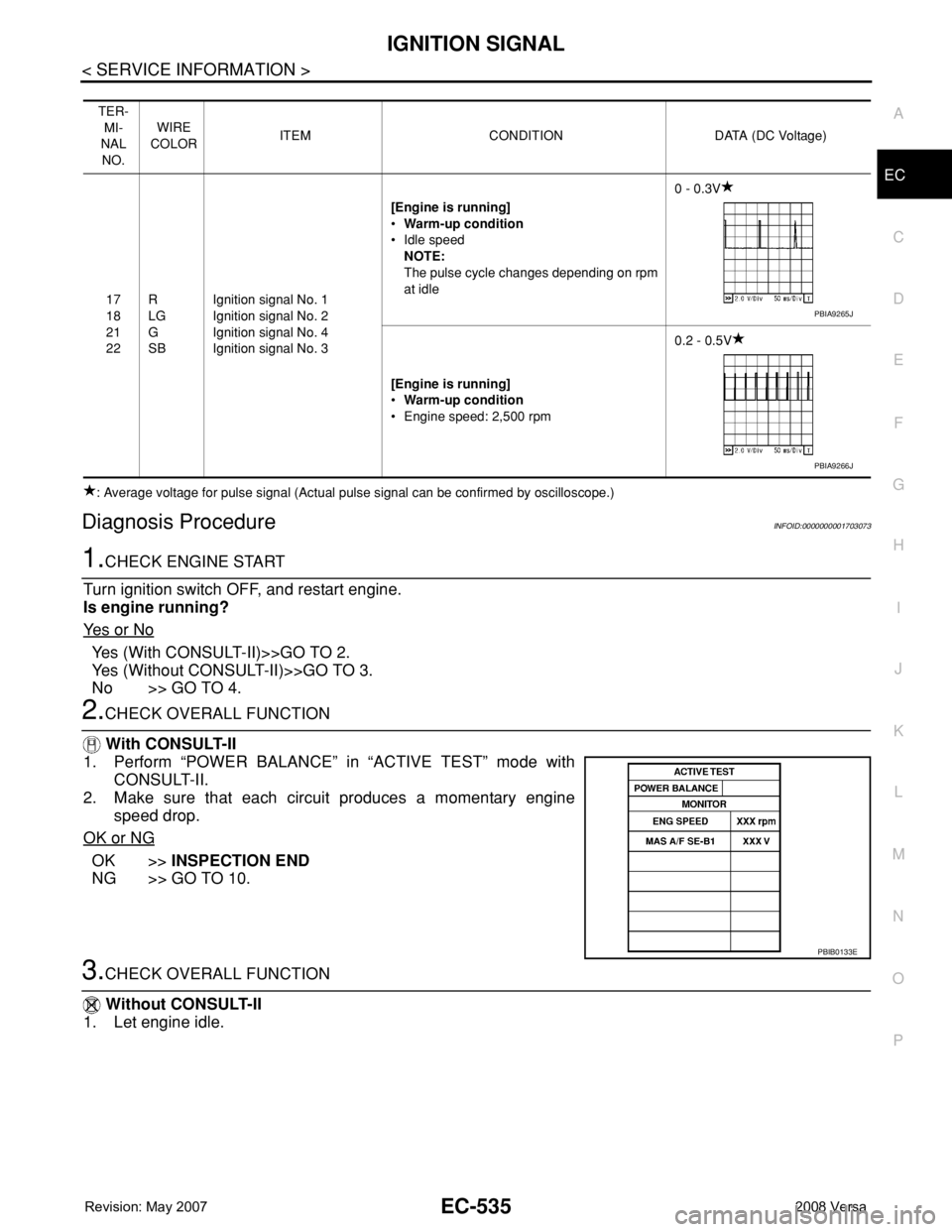

TER-

MI-

NAL

NO.WIRE

COLORITEM CONDITION DATA (DC Voltage)

17

18

21

22R

LG

G

SBIgnition signal No. 1

Ignition signal No. 2

Ignition signal No. 4

Ignition signal No. 3[Engine is running]

•Warm-up condition

• Idle speed

NOTE:

The pulse cycle changes depending on rpm

at idle0 - 0.3V

[Engine is running]

•Warm-up condition

• Engine speed: 2,500 rpm0.2 - 0.5V

PBIA9265J

PBIA9266J

PBIB0133E

Page 1613 of 2771

IGNITION SIGNAL

EC-539

< SERVICE INFORMATION >

C

D

E

F

G

H

I

J

K

L

MA

EC

N

P O

1. Turn ignition switch OFF.

2. Disconnect ignition coil harness connector.

3. Check resistance between ignition coil terminals as follows.

4. If NG, replace ignition coil with power transistor.

If OK, go to next step.

5. Turn ignition switch OFF.

6. Reconnect all harness connectors disconnected.

7. Remove fuel pump fuse (1) in IPDM E/R (2) to release fuel pres-

sure.

NOTE:

Do not use CONSULT-II to release fuel pressure, or fuel pres-

sure applies again during the following procedure.

- : Vehicle front

8. Start engine.

9. After engine stalls, crank it two or three times to release all fuel

pressure.

10. Turn ignition switch OFF.

11. Remove all ignition coil harness connectors to avoid the electri-

cal discharge from the ignition coils.

12. Remove ignition coil and spark plug of the cylinder to be checked.

13. Crank engine for 5 seconds or more to remove combustion gas in the cylinder.

14. Connect spark plug and harness connector to ignition coil.

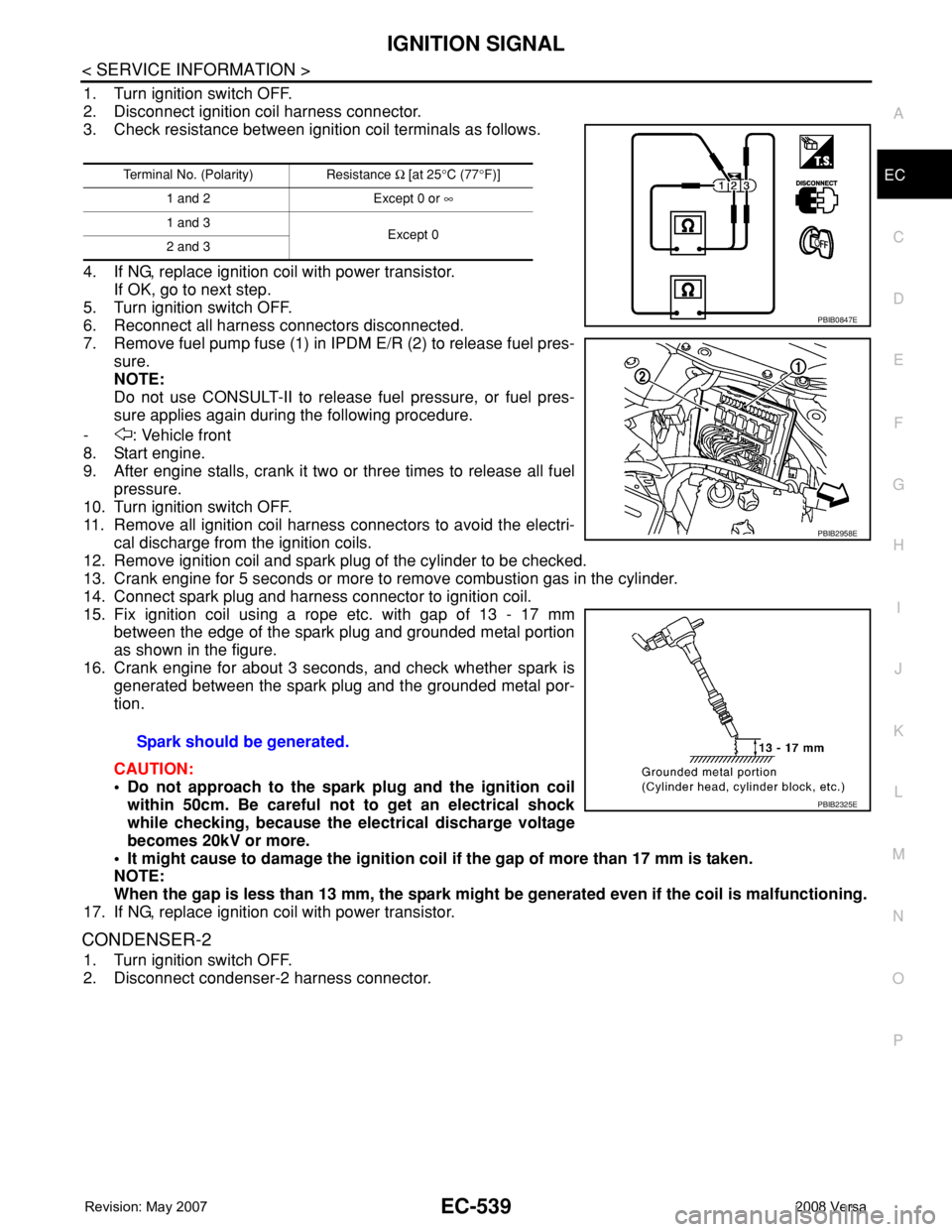

15. Fix ignition coil using a rope etc. with gap of 13 - 17 mm

between the edge of the spark plug and grounded metal portion

as shown in the figure.

16. Crank engine for about 3 seconds, and check whether spark is

generated between the spark plug and the grounded metal por-

tion.

CAUTION:

• Do not approach to the spark plug and the ignition coil

within 50cm. Be careful not to get an electrical shock

while checking, because the electrical discharge voltage

becomes 20kV or more.

• It might cause to damage the ignition coil if the gap of more than 17 mm is taken.

NOTE:

When the gap is less than 13 mm, the spark might be generated even if the coil is malfunctioning.

17. If NG, replace ignition coil with power transistor.

CONDENSER-2

1. Turn ignition switch OFF.

2. Disconnect condenser-2 harness connector.

Terminal No. (Polarity) Resistance Ω [at 25°C (77°F)]

1 and 2 Except 0 or ∞

1 and 3

Except 0

2 and 3

Spark should be generated.

PBIB0847E

PBIB2958E

PBIB2325E

Page 1617 of 2771

REFRIGERANT PRESSURE SENSOR

EC-543

< SERVICE INFORMATION >

C

D

E

F

G

H

I

J

K

L

MA

EC

N

P O

Diagnosis ProcedureINFOID:0000000001703078

1.CHECK REFRIGERANT PRESSURE SENSOR OVERALL FUNCTION

1. Start engine and warm it up to normal operating temperature.

2. Turn A/C switch and blower fan switch ON.

3. Check voltage between ECM terminal 41 and ground with CON-

SULT-II or tester.

OK or NG

OK >>INSPECTION END

NG >> GO TO 2.

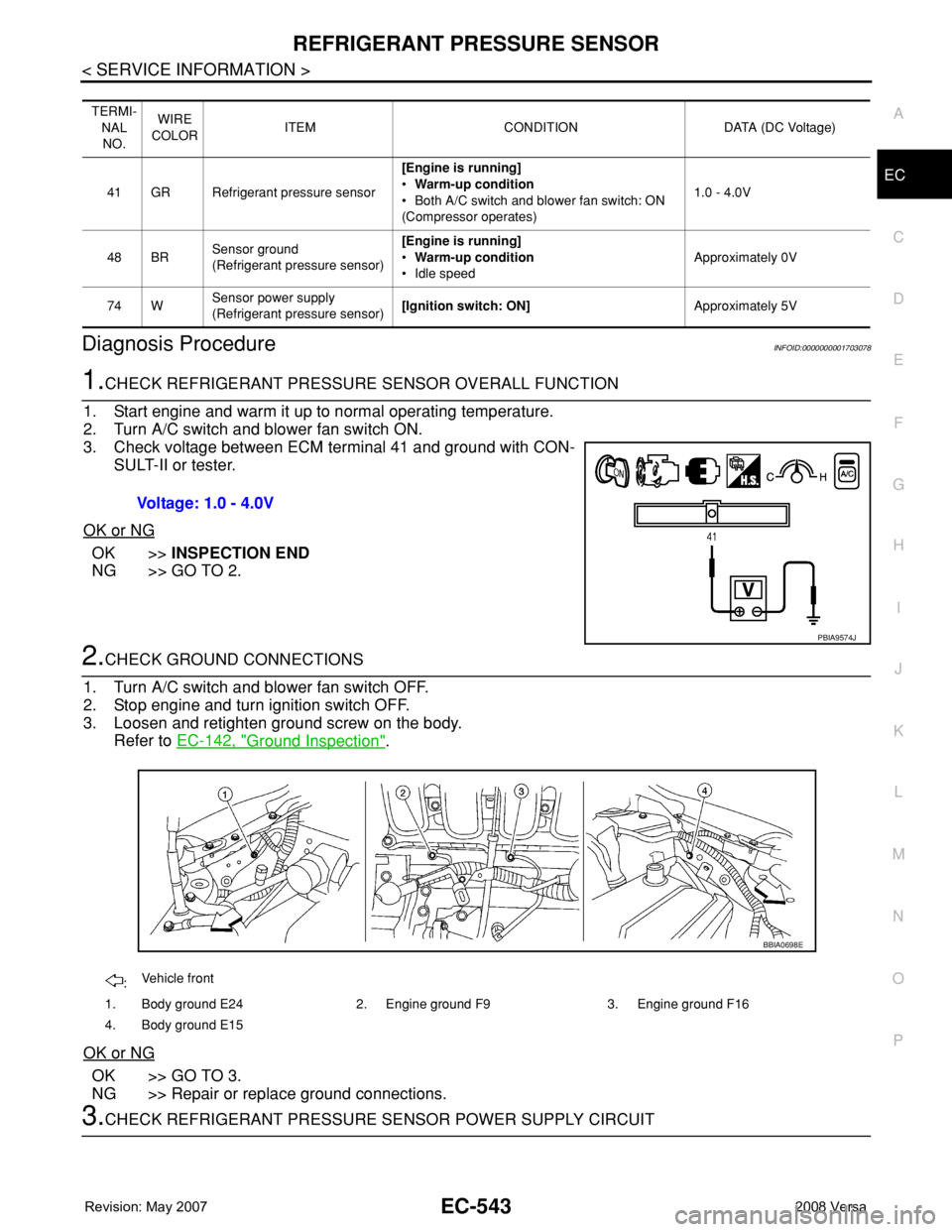

2.CHECK GROUND CONNECTIONS

1. Turn A/C switch and blower fan switch OFF.

2. Stop engine and turn ignition switch OFF.

3. Loosen and retighten ground screw on the body.

Refer to EC-142, "

Ground Inspection".

OK or NG

OK >> GO TO 3.

NG >> Repair or replace ground connections.

3.CHECK REFRIGERANT PRESSURE SENSOR POWER SUPPLY CIRCUIT

TERMI-

NAL

NO.WIRE

COLORITEM CONDITION DATA (DC Voltage)

41 GR Refrigerant pressure sensor[Engine is running]

•Warm-up condition

• Both A/C switch and blower fan switch: ON

(Compressor operates)1.0 - 4.0V

48 BRSensor ground

(Refrigerant pressure sensor)[Engine is running]

•Warm-up condition

• Idle speedApproximately 0V

74 WSensor power supply

(Refrigerant pressure sensor)[Ignition switch: ON]Approximately 5V

Voltage: 1.0 - 4.0V

PBIA9574J

:Vehicle front

1. Body ground E24 2. Engine ground F9 3. Engine ground F16

4. Body ground E15

BBIA0698E

Page 1622 of 2771

EC-548

< SERVICE INFORMATION >

SERVICE DATA AND SPECIFICATIONS (SDS)

SERVICE DATA AND SPECIFICATIONS (SDS)

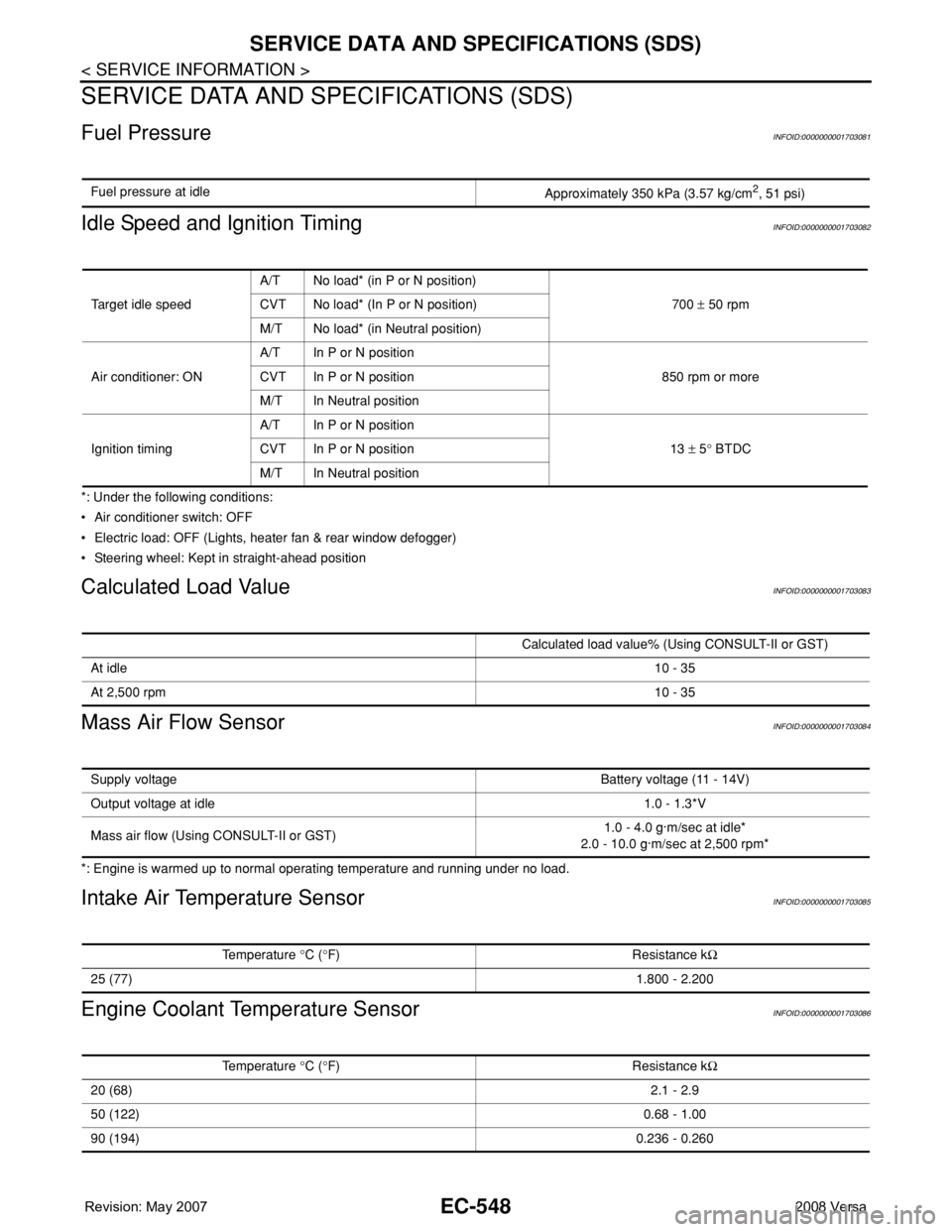

Fuel PressureINFOID:0000000001703081

Idle Speed and Ignition TimingINFOID:0000000001703082

*: Under the following conditions:

• Air conditioner switch: OFF

• Electric load: OFF (Lights, heater fan & rear window defogger)

• Steering wheel: Kept in straight-ahead position

Calculated Load ValueINFOID:0000000001703083

Mass Air Flow SensorINFOID:0000000001703084

*: Engine is warmed up to normal operating temperature and running under no load.

Intake Air Temperature SensorINFOID:0000000001703085

Engine Coolant Temperature SensorINFOID:0000000001703086

Fuel pressure at idle

Approximately 350 kPa (3.57 kg/cm2, 51 psi)

Target idle speedA/T No load* (in P or N position)

700 ± 50 rpm CVT No load* (In P or N position)

M/T No load* (in Neutral position)

Air conditioner: ONA/T In P or N position

850 rpm or more CVT In P or N position

M/T In Neutral position

Ignition timingA/T In P or N position

13 ± 5° BTDC CVT In P or N position

M/T In Neutral position

Calculated load value% (Using CONSULT-II or GST)

At idle10 - 35

At 2,500 rpm10 - 35

Supply voltageBattery voltage (11 - 14V)

Output voltage at idle1.0 - 1.3*V

Mass air flow (Using CONSULT-II or GST)1.0 - 4.0 g·m/sec at idle*

2.0 - 10.0 g·m/sec at 2,500 rpm*

Temperature °C (°F) Resistance kΩ

25 (77)1.800 - 2.200

Temperature °C (°F) Resistance kΩ

20 (68)2.1 - 2.9

50 (122)0.68 - 1.00

90 (194)0.236 - 0.260

Page 1627 of 2771

EI-4

< PREPARATION >

PREPARATION

PREPARATION

PREPARATION

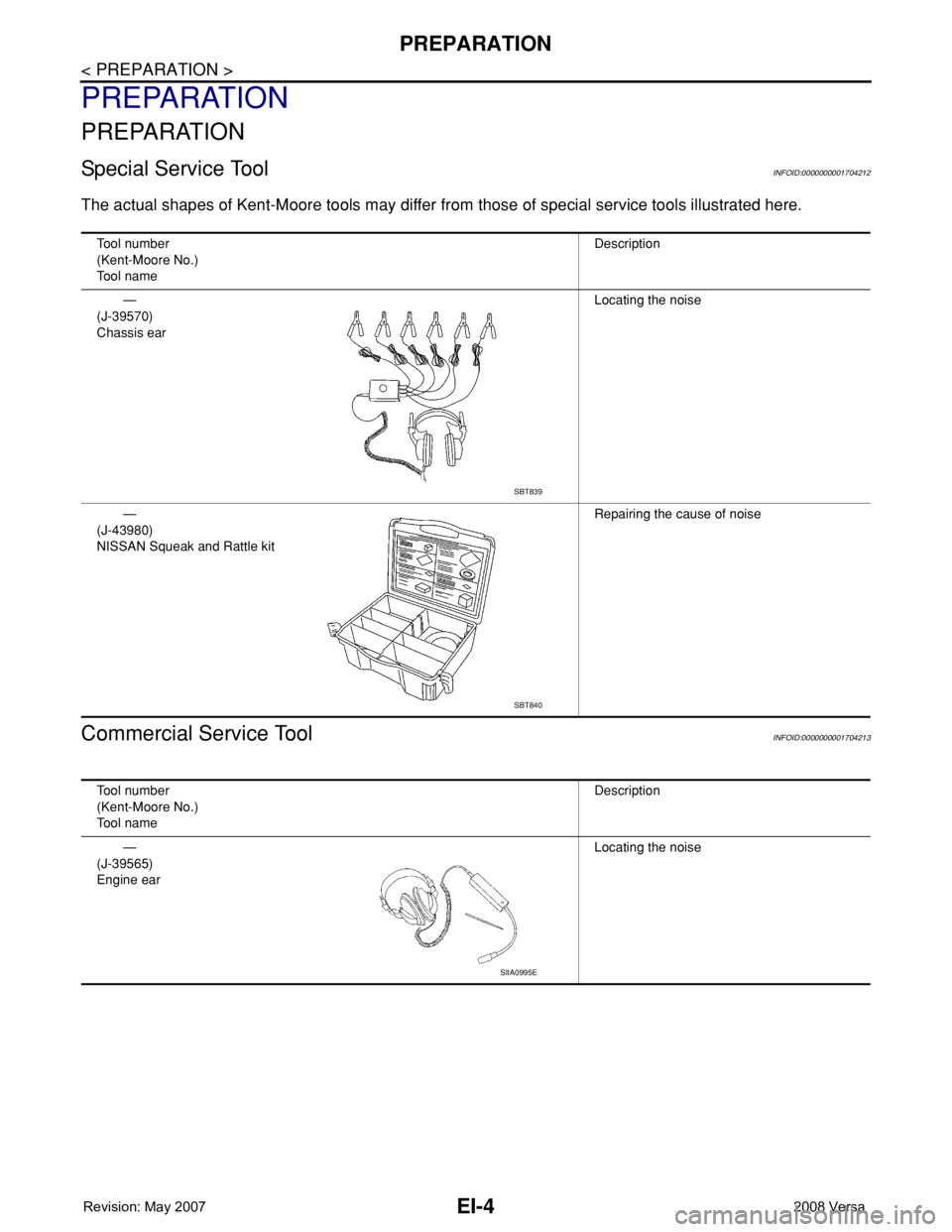

Special Service ToolINFOID:0000000001704212

The actual shapes of Kent-Moore tools may differ from those of special service tools illustrated here.

Commercial Service ToolINFOID:0000000001704213

Tool number

(Kent-Moore No.)

Tool nameDescription

—

(J-39570)

Chassis earLocating the noise

—

(J-43980)

NISSAN Squeak and Rattle kitRepairing the cause of noise

SBT839

SBT840

Tool number

(Kent-Moore No.)

Tool nameDescription

—

(J-39565)

Engine earLocating the noise

SIIA0995E

Page 1629 of 2771

EI-6

< SYMPTOM DIAGNOSIS >

SQUEAK AND RATTLE TROUBLE DIAGNOSIS

If possible, drive the vehicle with the customer until the noise is duplicated. Note any additional information on

the Diagnostic Worksheet regarding the conditions or location of the noise. This information can be used to

duplicate the same conditions when you confirm the repair.

If the noise can be duplicated easily during the test drive, to help identify the source of the noise, try to dupli-

cate the noise with the vehicle stopped by doing one or all of the following:

• Close a door.

• Tap or push/pull around the area where the noise appears to be coming from.

• Rev the engine.

• Use a floor jack to recreate vehicle “twist”.

• At idle, apply engine load (electrical load, half-clutch on M/T model, drive position on A/T model).

• Raise the vehicle on a hoist and hit a tire with a rubber hammer.

• Drive the vehicle and attempt to duplicate the conditions the customer states exist when the noise occurs.

• If it is difficult to duplicate the noise, drive the vehicle slowly on an undulating or rough road to stress the

vehicle body.

CHECK RELATED SERVICE BULLETINS

After verifying the customer concern or symptom, check ASIST for Technical Service Bulletins (TSBs) related

to that concern or symptom.

If a TSB relates to the symptom, follow the procedure to repair the noise.

LOCATE THE NOISE AND IDENTIFY THE ROOT CAUSE

1. Narrow down the noise to a general area. To help pinpoint the source of the noise, use a listening tool

(Chassis Ear: J-39570, Engine Ear: J-39565 and mechanics stethoscope).

2. Narrow down the noise to a more specific area and identify the cause of the noise by:

• Removing the components in the area that you suspect the noise is coming from.

Do not use too much force when removing clips and fasteners, otherwise clips and fasteners

can be broken or lost during the repair, resulting in the creation of new noise.

• Tapping or pushing/pulling the component that you suspect is causing the noise.

Do not tap or push/pull the component with excessive force, otherwise the noise will be elimi-

nated only temporarily.

• Feeling for a vibration with your hand by touching the component(s) that you suspect is (are) causing

the noise.

• Placing a piece of paper between components that you suspect are causing the noise.

• Looking for loose components and contact marks.

Refer to EI-7, "

Generic Squeak and Rattle Troubleshooting".

REPAIR THE CAUSE

• If the cause is a loose component, tighten the component securely.

• If the cause is insufficient clearance between components:

- Separate components by repositioning or loosening and retightening the component, if possible.

- Insulate components with a suitable insulator such as urethane pads, foam blocks, felt cloth tape or ure-

thane tape. A NISSAN Squeak and Rattle Kit (J-43980) is available through your authorized NISSAN Parts

Department.

CAUTION:

Do not use excessive force as many components are constructed of plastic and may be damaged.

Always check with the Parts Department for the latest parts information.

The following materials are contained in the NISSAN Squeak and Rattle Kit (J-43980). Each item can be

ordered separately as needed.

URETHANE PADS [1.5 mm (0.059 in) thick]

Insulates connectors, harness, etc.

76268-9E005: 100 x 135 mm (3.94 x 5.31 in)/76884-71L01: 60 x 85 mm (2.36 x 3.35 in)/76884-71L02: 15 x 25

mm (0.59 x 0.98 in)

INSULATOR (Foam blocks)

Insulates components from contact. Can be used to fill space behind a panel.

73982-9E000: 45 mm (1.77 in) thick, 50 x 50 mm (1.97 x 1.97 in)/73982-50Y00: 10 mm (0.39 in) thick, 50 x 50

mm (1.97 x 1.97 in)

INSULATOR (Light foam block)

80845-71L00: 30 mm (1.18 in) thick, 30 x 50 mm (1.18 x 1.97 in)

FELT CLOTH TAPE

Used to insulate where movement does not occur. Ideal for instrument panel applications.

68370-4B000: 15 x 25 mm (0.59 x 0.98 in) pad/68239-13E00: 5 mm (0.20 in) wide tape roll

Page 1631 of 2771

EI-8

< SYMPTOM DIAGNOSIS >

SQUEAK AND RATTLE TROUBLE DIAGNOSIS

3. The trunk lid torsion bars knocking together

4. A loose license plate or bracket

Most of these incidents can be repaired by adjusting, securing or insulating the item(s) or component(s) caus-

ing the noise.

SUNROOF/HEADLINING

Noises in the sunroof/headlining area can often be traced to one of the following:

1. Sunroof lid, rail, linkage or seals making a rattle or light knocking noise

2. Sun visor shaft shaking in the holder

3. Front or rear windshield touching headliner and squeaking

Again, pressing on the components to stop the noise while duplicating the conditions can isolate most of these

incidents. Repairs usually consist of insulating with felt cloth tape.

OVERHEAD CONSOLE (FRONT AND REAR)

Overhead console noises are often caused by the console panel clips not being engaged correctly. Most of

these incidents are repaired by pushing up on the console at the clip locations until the clips engage.

In addition look for:

1. Loose harness or harness connectors.

2. Front console map/reading lamp lens loose.

3. Loose screws at console attachment points.

SEATS

When isolating seat noise it's important to note the position the seat is in and the load placed on the seat when

the noise is present. These conditions should be duplicated when verifying and isolating the cause of the

noise.

Cause of seat noise include:

1. Headrest rods and holder

2. A squeak between the seat pad cushion and frame

3. The rear seatback lock and bracket

These noises can be isolated by moving or pressing on the suspected components while duplicating the con-

ditions under which the noise occurs. Most of these incidents can be repaired by repositioning the component

or applying urethane tape to the contact area.

UNDERHOOD

Some interior noise may be caused by components under the hood or on the engine wall. The noise is then

transmitted into the passenger compartment.

Causes of transmitted underhood noise include:

1. Any component installed on the engine wall

2. Components that pass through the engine wall

3. Engine wall mounts and connectors

4. Loose radiator pins

5. Hood bumpers out of adjustment

6. Hood striker out of adjustment

These noises can be difficult to isolate since they cannot be reached from the interior of the vehicle. The best

method is to secure, move or insulate one component at a time and test drive the vehicle. Also, engine RPM

or load can be changed to isolate the noise. Repairs can usually be made by moving, adjusting, securing, or

insulating the component causing the noise.

Page 1637 of 2771

EI-14

< ON-VEHICLE REPAIR >

FRONT BUMPER

ON-VEHICLE REPAIR

FRONT BUMPER

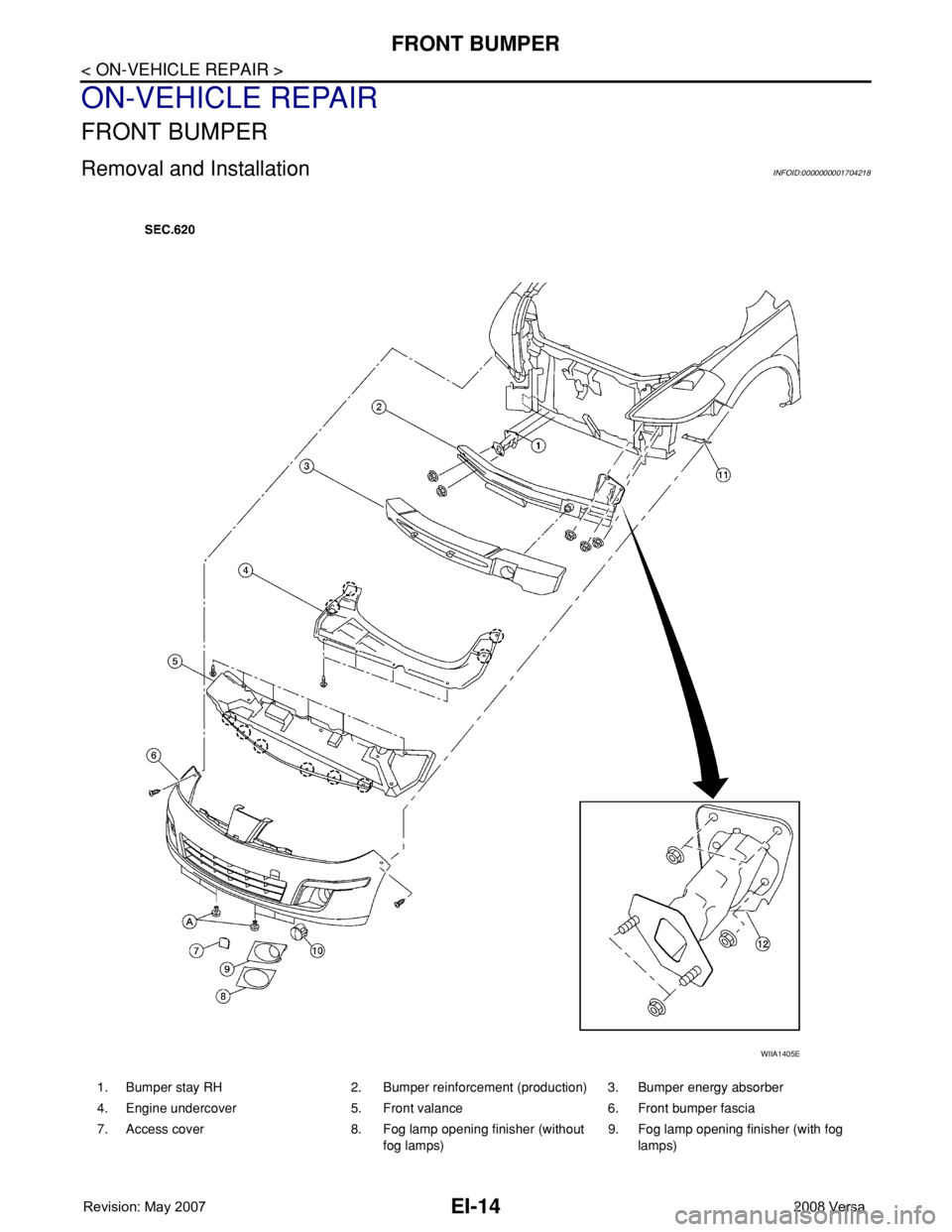

Removal and InstallationINFOID:0000000001704218

1. Bumper stay RH 2. Bumper reinforcement (production) 3. Bumper energy absorber

4. Engine undercover 5. Front valance 6. Front bumper fascia

7. Access cover 8. Fog lamp opening finisher (without

fog lamps)9. Fog lamp opening finisher (with fog

lamps)

WIIA1405E

Page 1638 of 2771

FRONT BUMPER

EI-15

< ON-VEHICLE REPAIR >

C

D

E

F

G

H

J

K

L

MA

B

EI

N

O

P

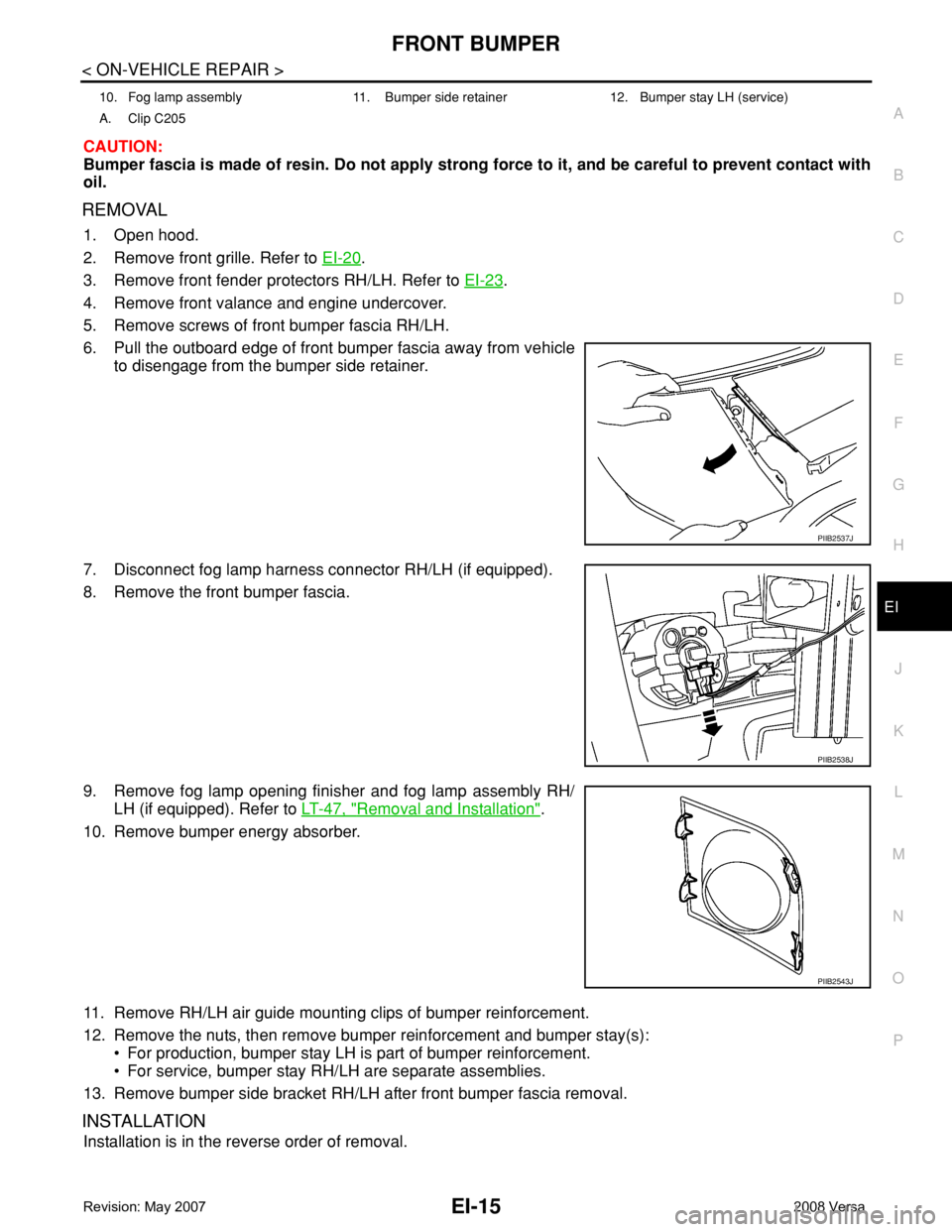

CAUTION:

Bumper fascia is made of resin. Do not apply strong force to it, and be careful to prevent contact with

oil.

REMOVAL

1. Open hood.

2. Remove front grille. Refer to EI-20

.

3. Remove front fender protectors RH/LH. Refer to EI-23

.

4. Remove front valance and engine undercover.

5. Remove screws of front bumper fascia RH/LH.

6. Pull the outboard edge of front bumper fascia away from vehicle

to disengage from the bumper side retainer.

7. Disconnect fog lamp harness connector RH/LH (if equipped).

8. Remove the front bumper fascia.

9. Remove fog lamp opening finisher and fog lamp assembly RH/

LH (if equipped). Refer to LT-47, "

Removal and Installation".

10. Remove bumper energy absorber.

11. Remove RH/LH air guide mounting clips of bumper reinforcement.

12. Remove the nuts, then remove bumper reinforcement and bumper stay(s):

• For production, bumper stay LH is part of bumper reinforcement.

• For service, bumper stay RH/LH are separate assemblies.

13. Remove bumper side bracket RH/LH after front bumper fascia removal.

INSTALLATION

Installation is in the reverse order of removal.

10. Fog lamp assembly 11. Bumper side retainer 12. Bumper stay LH (service)

A. Clip C205

PIIB2537J

PIIB2538J

PIIB2543J

Page 1678 of 2771

EM-1

ENGINE

C

D

E

F

G

H

I

J

K

L

M

SECTION EM

A

EM

N

O

P

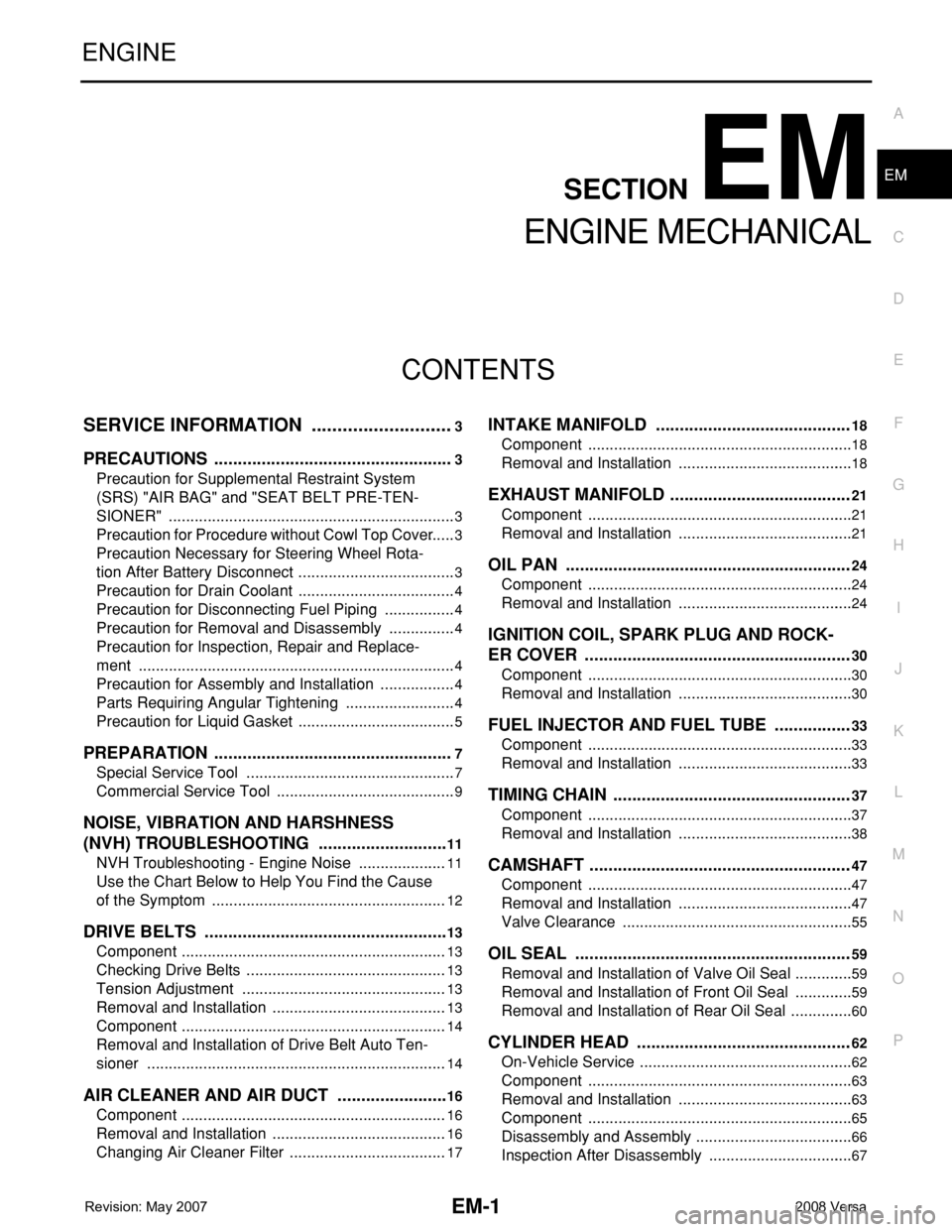

CONTENTS

ENGINE MECHANICAL

SERVICE INFORMATION ............................3

PRECAUTIONS ...................................................3

Precaution for Supplemental Restraint System

(SRS) "AIR BAG" and "SEAT BELT PRE-TEN-

SIONER" ...................................................................

3

Precaution for Procedure without Cowl Top Cover ......3

Precaution Necessary for Steering Wheel Rota-

tion After Battery Disconnect .....................................

3

Precaution for Drain Coolant .....................................4

Precaution for Disconnecting Fuel Piping .................4

Precaution for Removal and Disassembly ................4

Precaution for Inspection, Repair and Replace-

ment ..........................................................................

4

Precaution for Assembly and Installation ..................4

Parts Requiring Angular Tightening ..........................4

Precaution for Liquid Gasket .....................................5

PREPARATION ...................................................7

Special Service Tool .................................................7

Commercial Service Tool ..........................................9

NOISE, VIBRATION AND HARSHNESS

(NVH) TROUBLESHOOTING ............................

11

NVH Troubleshooting - Engine Noise .....................11

Use the Chart Below to Help You Find the Cause

of the Symptom .......................................................

12

DRIVE BELTS ....................................................13

Component ..............................................................13

Checking Drive Belts ...............................................13

Tension Adjustment ................................................13

Removal and Installation .........................................13

Component ..............................................................14

Removal and Installation of Drive Belt Auto Ten-

sioner ......................................................................

14

AIR CLEANER AND AIR DUCT ........................16

Component ..............................................................16

Removal and Installation .........................................16

Changing Air Cleaner Filter .....................................17

INTAKE MANIFOLD .........................................18

Component ..............................................................18

Removal and Installation .........................................18

EXHAUST MANIFOLD ......................................21

Component ..............................................................21

Removal and Installation .........................................21

OIL PAN ............................................................24

Component ..............................................................24

Removal and Installation .........................................24

IGNITION COIL, SPARK PLUG AND ROCK-

ER COVER ........................................................

30

Component ..............................................................30

Removal and Installation .........................................30

FUEL INJECTOR AND FUEL TUBE ................33

Component ..............................................................33

Removal and Installation .........................................33

TIMING CHAIN ..................................................37

Component ..............................................................37

Removal and Installation .........................................38

CAMSHAFT .......................................................47

Component ..............................................................47

Removal and Installation .........................................47

Valve Clearance ......................................................55

OIL SEAL ..........................................................59

Removal and Installation of Valve Oil Seal ..............59

Removal and Installation of Front Oil Seal ..............59

Removal and Installation of Rear Oil Seal ...............60

CYLINDER HEAD .............................................62

On-Vehicle Service ..................................................62

Component ..............................................................63

Removal and Installation .........................................63

Component ..............................................................65

Disassembly and Assembly .....................................66

Inspection After Disassembly ..................................67