engine NISSAN LATIO 2008 Service Repair Manual

[x] Cancel search | Manufacturer: NISSAN, Model Year: 2008, Model line: LATIO, Model: NISSAN LATIO 2008Pages: 2771, PDF Size: 60.61 MB

Page 1497 of 2771

DTC P1217 ENGINE OVER TEMPERATURE

EC-423

< SERVICE INFORMATION >

C

D

E

F

G

H

I

J

K

L

MA

EC

N

P O

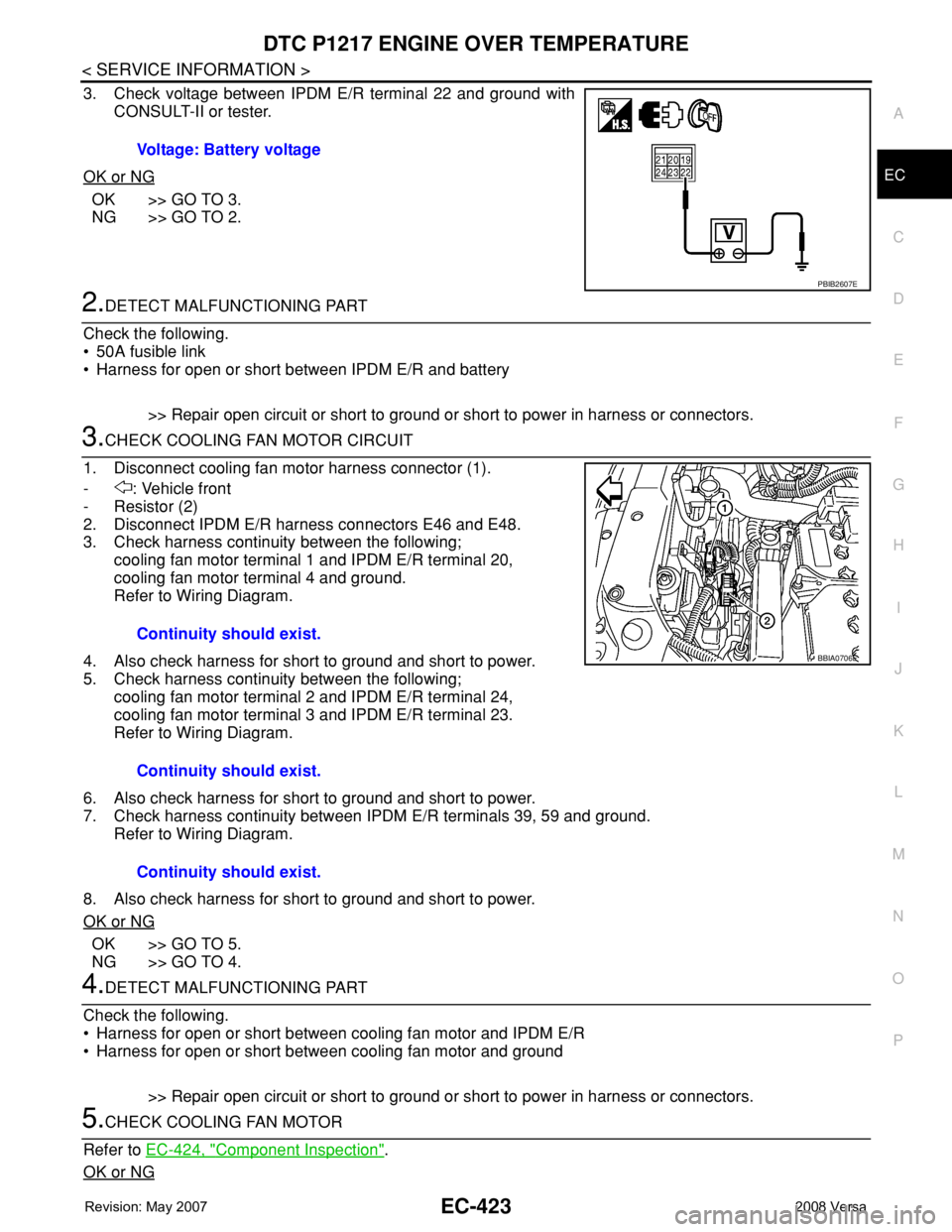

3. Check voltage between IPDM E/R terminal 22 and ground with

CONSULT-II or tester.

OK or NG

OK >> GO TO 3.

NG >> GO TO 2.

2.DETECT MALFUNCTIONING PART

Check the following.

• 50A fusible link

• Harness for open or short between IPDM E/R and battery

>> Repair open circuit or short to ground or short to power in harness or connectors.

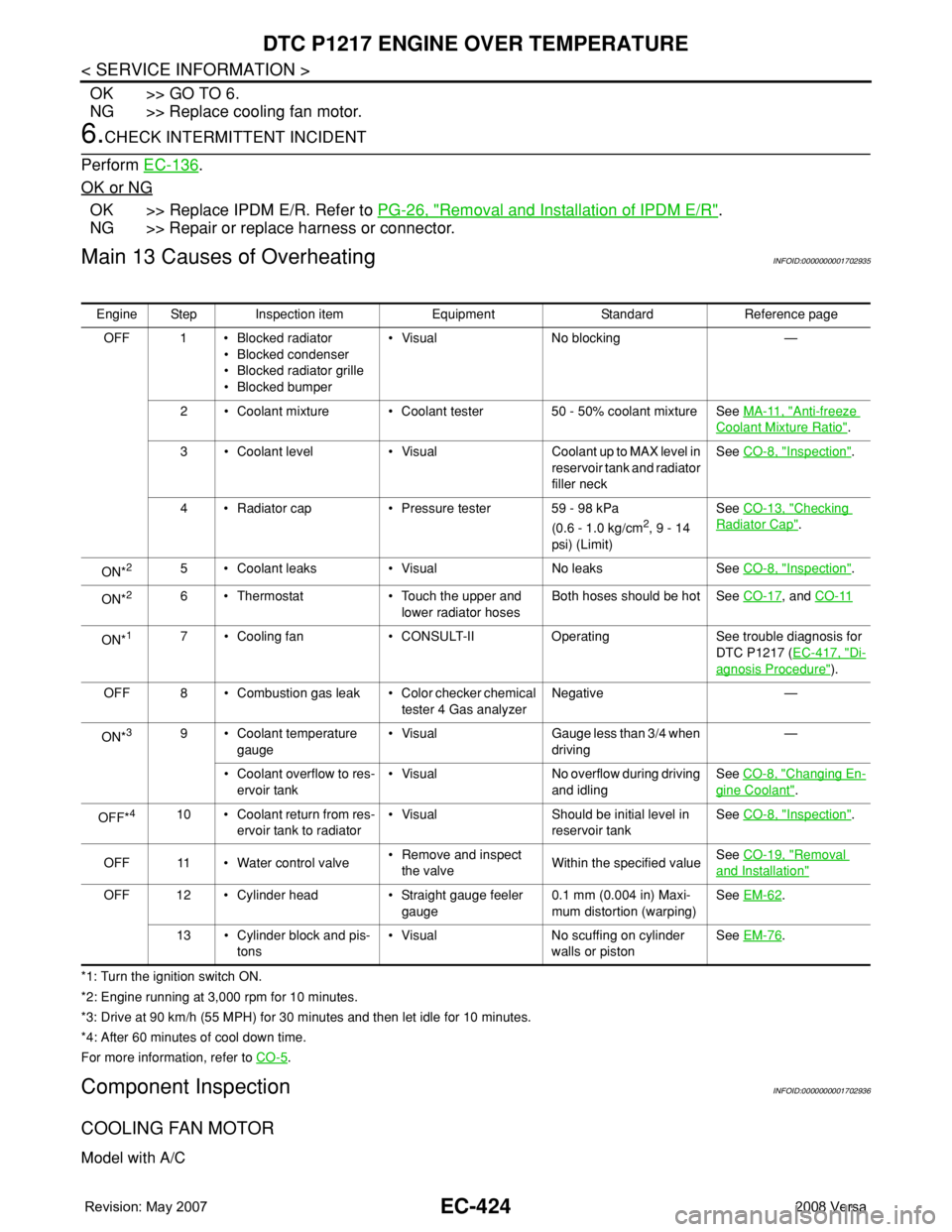

3.CHECK COOLING FAN MOTOR CIRCUIT

1. Disconnect cooling fan motor harness connector (1).

- : Vehicle front

-Resistor (2)

2. Disconnect IPDM E/R harness connectors E46 and E48.

3. Check harness continuity between the following;

cooling fan motor terminal 1 and IPDM E/R terminal 20,

cooling fan motor terminal 4 and ground.

Refer to Wiring Diagram.

4. Also check harness for short to ground and short to power.

5. Check harness continuity between the following;

cooling fan motor terminal 2 and IPDM E/R terminal 24,

cooling fan motor terminal 3 and IPDM E/R terminal 23.

Refer to Wiring Diagram.

6. Also check harness for short to ground and short to power.

7. Check harness continuity between IPDM E/R terminals 39, 59 and ground.

Refer to Wiring Diagram.

8. Also check harness for short to ground and short to power.

OK or NG

OK >> GO TO 5.

NG >> GO TO 4.

4.DETECT MALFUNCTIONING PART

Check the following.

• Harness for open or short between cooling fan motor and IPDM E/R

• Harness for open or short between cooling fan motor and ground

>> Repair open circuit or short to ground or short to power in harness or connectors.

5.CHECK COOLING FAN MOTOR

Refer to EC-424, "

Component Inspection".

OK or NG

Voltage: Battery voltage

PBIB2607E

Continuity should exist.

Continuity should exist.

Continuity should exist.

BBIA0706E

Page 1498 of 2771

EC-424

< SERVICE INFORMATION >

DTC P1217 ENGINE OVER TEMPERATURE

OK >> GO TO 6.

NG >> Replace cooling fan motor.

6.CHECK INTERMITTENT INCIDENT

Perform EC-136

.

OK or NG

OK >> Replace IPDM E/R. Refer to PG-26, "Removal and Installation of IPDM E/R".

NG >> Repair or replace harness or connector.

Main 13 Causes of OverheatingINFOID:0000000001702935

*1: Turn the ignition switch ON.

*2: Engine running at 3,000 rpm for 10 minutes.

*3: Drive at 90 km/h (55 MPH) for 30 minutes and then let idle for 10 minutes.

*4: After 60 minutes of cool down time.

For more information, refer to CO-5

.

Component InspectionINFOID:0000000001702936

COOLING FAN MOTOR

Model with A/C

Engine Step Inspection item Equipment Standard Reference page

OFF 1 • Blocked radiator

• Blocked condenser

• Blocked radiator grille

• Blocked bumper• Visual No blocking —

2 • Coolant mixture • Coolant tester 50 - 50% coolant mixture See MA-11, "

Anti-freeze

Coolant Mixture Ratio".

3 • Coolant level • Visual Coolant up to MAX level in

reservoir tank and radiator

filler neckSee CO-8, "

Inspection".

4 • Radiator cap • Pressure tester 59 - 98 kPa

(0.6 - 1.0 kg/cm

2, 9 - 14

psi) (Limit)See CO-13, "

Checking

Radiator Cap".

ON*

25 • Coolant leaks • Visual No leaks See CO-8, "Inspection".

ON*

26 • Thermostat • Touch the upper and

lower radiator hosesBoth hoses should be hot See CO-17, and CO-11

ON*17 • Cooling fan • CONSULT-II Operating See trouble diagnosis for

DTC P1217 (EC-417, "

Di-

agnosis Procedure").

OFF 8 • Combustion gas leak • Color checker chemical

tester 4 Gas analyzerNegative —

ON*

39 • Coolant temperature

gauge• Visual Gauge less than 3/4 when

driving—

• Coolant overflow to res-

ervoir tank• Visual No overflow during driving

and idlingSee CO-8, "

Changing En-

gine Coolant".

OFF*

410 • Coolant return from res-

ervoir tank to radiator• Visual Should be initial level in

reservoir tankSee CO-8, "Inspection".

OFF 11 • Water control valve• Remove and inspect

the valveWithin the specified valueSee CO-19, "

Removal

and Installation"

OFF 12 • Cylinder head • Straight gauge feeler

gauge0.1 mm (0.004 in) Maxi-

mum distortion (warping)See EM-62.

13 • Cylinder block and pis-

tons• Visual No scuffing on cylinder

walls or pistonSee EM-76

.

Page 1499 of 2771

DTC P1217 ENGINE OVER TEMPERATURE

EC-425

< SERVICE INFORMATION >

C

D

E

F

G

H

I

J

K

L

MA

EC

N

P O

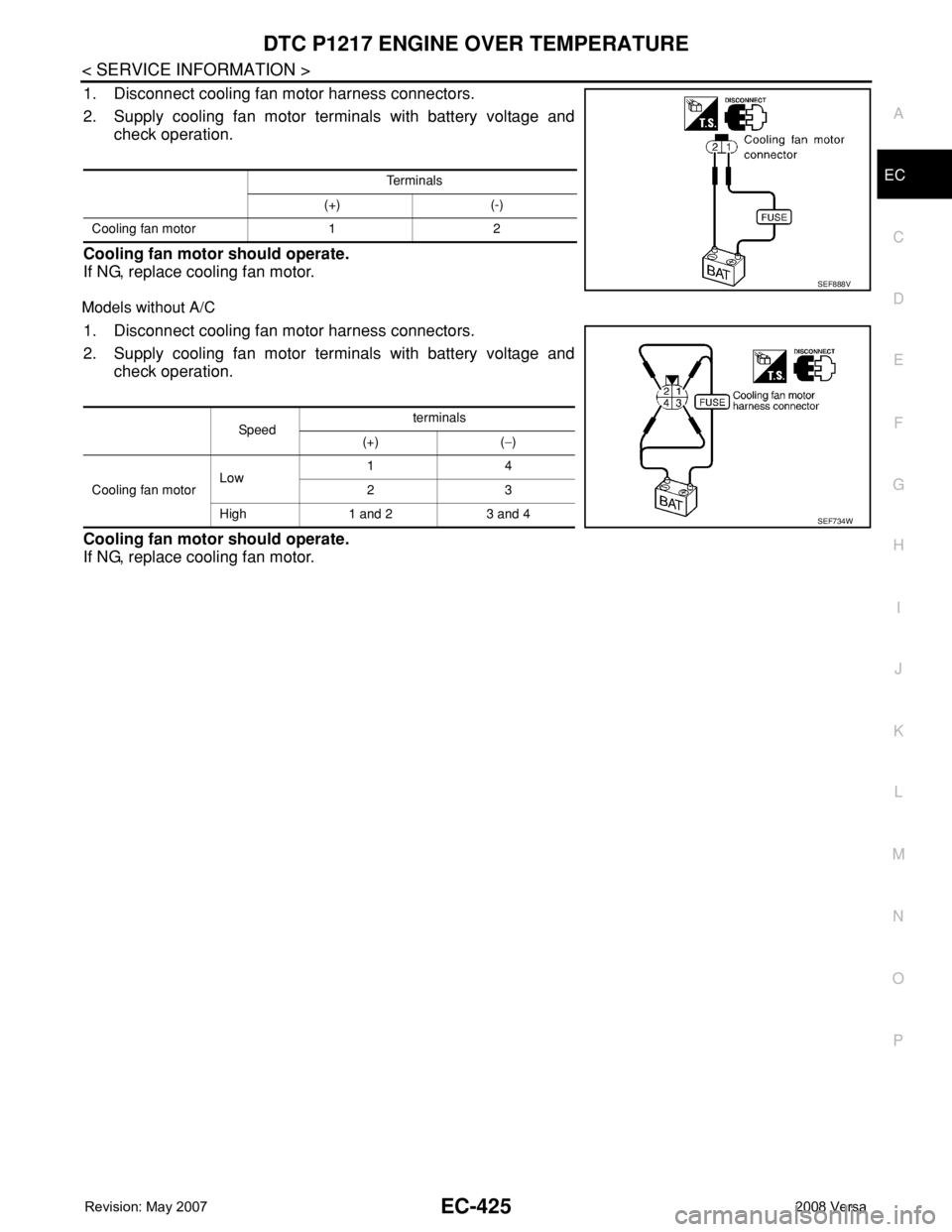

1. Disconnect cooling fan motor harness connectors.

2. Supply cooling fan motor terminals with battery voltage and

check operation.

Cooling fan motor should operate.

If NG, replace cooling fan motor.

Models without A/C

1. Disconnect cooling fan motor harness connectors.

2. Supply cooling fan motor terminals with battery voltage and

check operation.

Cooling fan motor should operate.

If NG, replace cooling fan motor.

Te r m i n a l s

(+) (-)

Cooling fan motor 1 2

SEF888V

Sp ee dterminals

(+) (−)

Cooling fan motorLow 14

23

High 1 and 2 3 and 4

SEF734W

Page 1504 of 2771

EC-430

< SERVICE INFORMATION >

DTC P1421 COLD START CONTROL

DTC P1421 COLD START CONTROL

DescriptionINFOID:0000000001702947

ECM controls ignition timing and engine idle speed when engine is started with prewarming up condition.

This control promotes the activation of three way catalyst by heating the catalyst and reduces emissions.

On Board Diagnosis LogicINFOID:0000000001702948

DTC Confirmation ProcedureINFOID:0000000001702949

NOTE:

• If DTC Confirmation Procedure has been previously conducted, always turn ignition switch OFF and wait at

least 10 seconds before conducting the next test.

•If DTC P1421 is displayed with other DTC, first perform the trouble diagnosis for other DTC.

TESTING CONDITION:

Before performing the following procedure, confirm that battery voltage is more than 11V at idle.

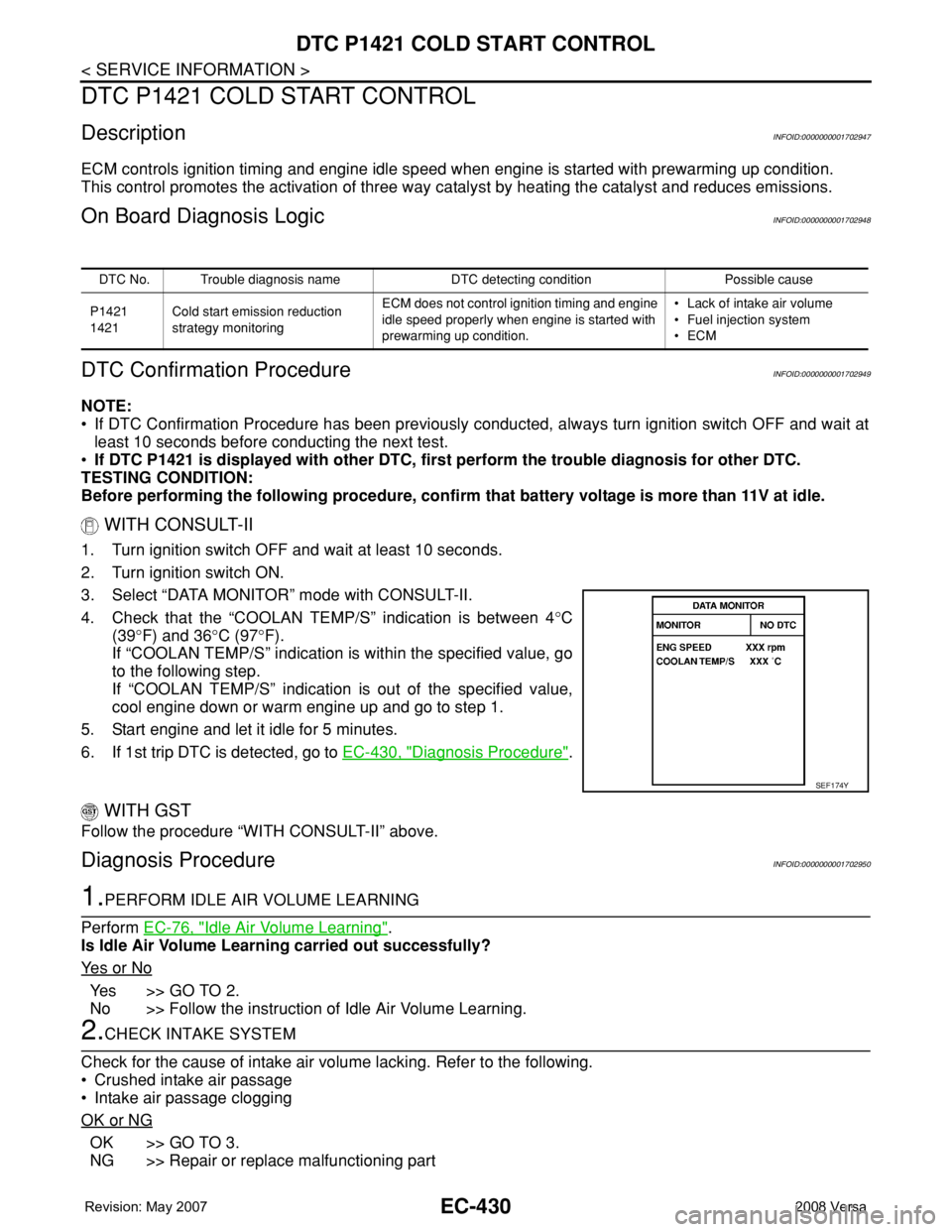

WITH CONSULT-II

1. Turn ignition switch OFF and wait at least 10 seconds.

2. Turn ignition switch ON.

3. Select “DATA MONITOR” mode with CONSULT-II.

4. Check that the “COOLAN TEMP/S” indication is between 4°C

(39°F) and 36°C (97°F).

If “COOLAN TEMP/S” indication is within the specified value, go

to the following step.

If “COOLAN TEMP/S” indication is out of the specified value,

cool engine down or warm engine up and go to step 1.

5. Start engine and let it idle for 5 minutes.

6. If 1st trip DTC is detected, go to EC-430, "

Diagnosis Procedure".

WITH GST

Follow the procedure “WITH CONSULT-II” above.

Diagnosis ProcedureINFOID:0000000001702950

1.PERFORM IDLE AIR VOLUME LEARNING

Perform EC-76, "

Idle Air Volume Learning".

Is Idle Air Volume Learning carried out successfully?

Ye s o r N o

Ye s > > G O T O 2 .

No >> Follow the instruction of Idle Air Volume Learning.

2.CHECK INTAKE SYSTEM

Check for the cause of intake air volume lacking. Refer to the following.

• Crushed intake air passage

• Intake air passage clogging

OK or NG

OK >> GO TO 3.

NG >> Repair or replace malfunctioning part

DTC No. Trouble diagnosis name DTC detecting condition Possible cause

P1421

1421Cold start emission reduction

strategy monitoringECM does not control ignition timing and engine

idle speed properly when engine is started with

prewarming up condition.• Lack of intake air volume

• Fuel injection system

•ECM

SEF174Y

Page 1509 of 2771

DTC P1564 ASCD STEERING SWITCH

EC-435

< SERVICE INFORMATION >

C

D

E

F

G

H

I

J

K

L

MA

EC

N

P O

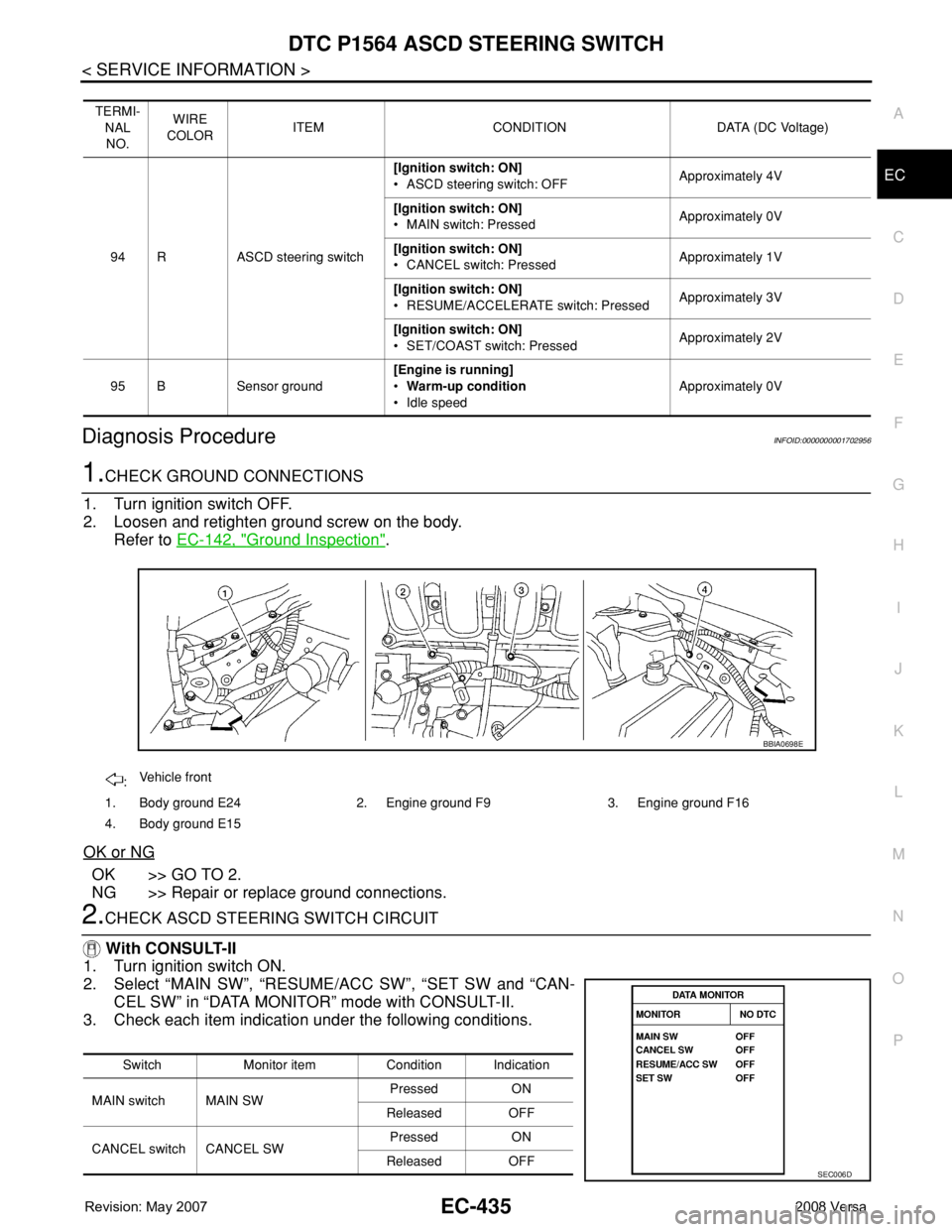

Diagnosis ProcedureINFOID:0000000001702956

1.CHECK GROUND CONNECTIONS

1. Turn ignition switch OFF.

2. Loosen and retighten ground screw on the body.

Refer to EC-142, "

Ground Inspection".

OK or NG

OK >> GO TO 2.

NG >> Repair or replace ground connections.

2.CHECK ASCD STEERING SWITCH CIRCUIT

With CONSULT-II

1. Turn ignition switch ON.

2. Select “MAIN SW”, “RESUME/ACC SW”, “SET SW and “CAN-

CEL SW” in “DATA MONITOR” mode with CONSULT-II.

3. Check each item indication under the following conditions.

TERMI-

NAL

NO.WIRE

COLORITEM CONDITION DATA (DC Voltage)

94 R ASCD steering switch[Ignition switch: ON]

• ASCD steering switch: OFFApproximately 4V

[Ignition switch: ON]

• MAIN switch: PressedApproximately 0V

[Ignition switch: ON]

• CANCEL switch: PressedApproximately 1V

[Ignition switch: ON]

• RESUME/ACCELERATE switch: PressedApproximately 3V

[Ignition switch: ON]

• SET/COAST switch: PressedApproximately 2V

95 B Sensor ground[Engine is running]

•Warm-up condition

• Idle speedApproximately 0V

:Vehicle front

1. Body ground E24 2. Engine ground F9 3. Engine ground F16

4. Body ground E15

BBIA0698E

Switch Monitor item Condition Indication

MAIN switch MAIN SWPressed ON

Released OFF

CANCEL switch CANCEL SWPressed ON

Released OFF

SEC006D

Page 1513 of 2771

DTC P1572 ASCD BRAKE SWITCH

EC-439

< SERVICE INFORMATION >

C

D

E

F

G

H

I

J

K

L

MA

EC

N

P O

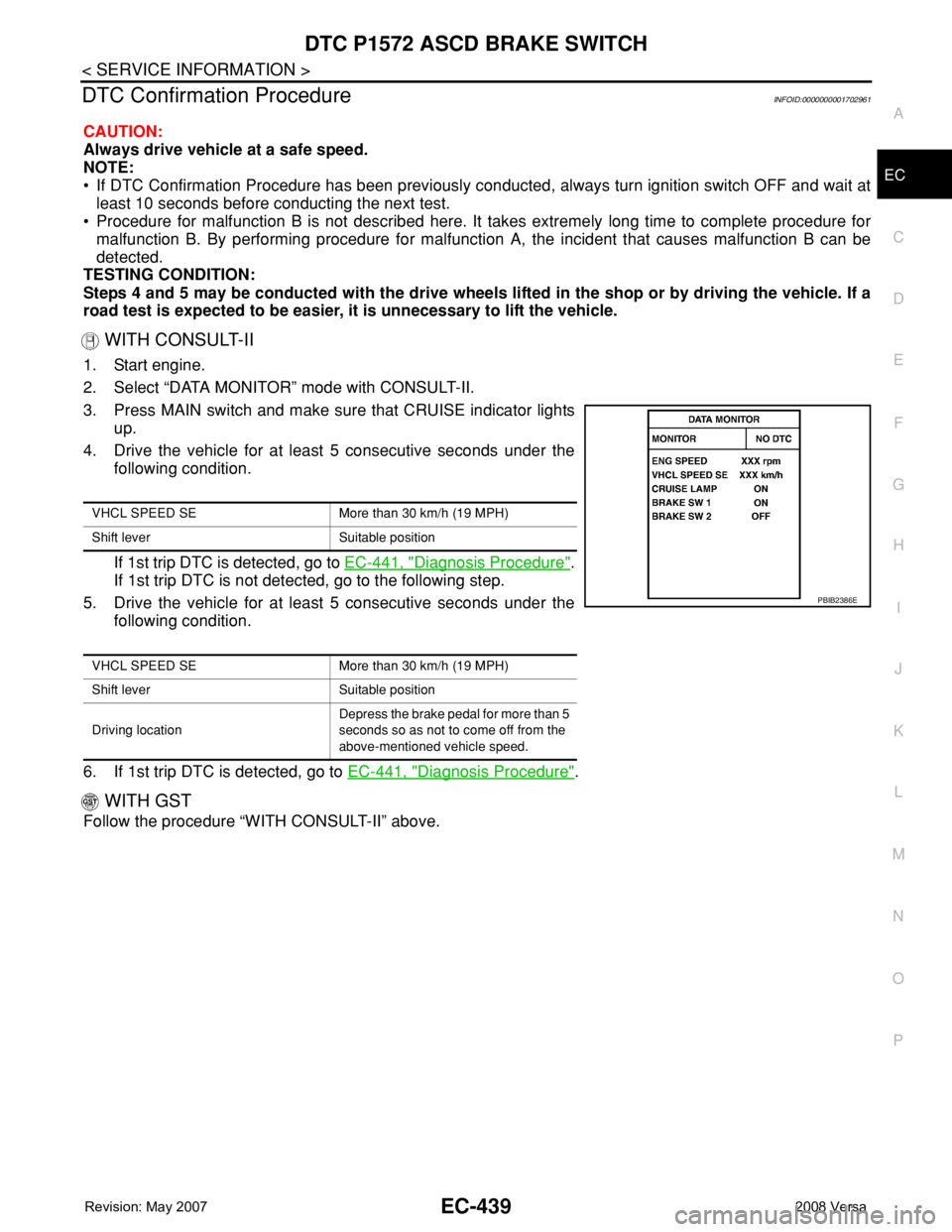

DTC Confirmation ProcedureINFOID:0000000001702961

CAUTION:

Always drive vehicle at a safe speed.

NOTE:

• If DTC Confirmation Procedure has been previously conducted, always turn ignition switch OFF and wait at

least 10 seconds before conducting the next test.

• Procedure for malfunction B is not described here. It takes extremely long time to complete procedure for

malfunction B. By performing procedure for malfunction A, the incident that causes malfunction B can be

detected.

TESTING CONDITION:

Steps 4 and 5 may be conducted with the drive wheels lifted in the shop or by driving the vehicle. If a

road test is expected to be easier, it is unnecessary to lift the vehicle.

WITH CONSULT-II

1. Start engine.

2. Select “DATA MONITOR” mode with CONSULT-II.

3. Press MAIN switch and make sure that CRUISE indicator lights

up.

4. Drive the vehicle for at least 5 consecutive seconds under the

following condition.

If 1st trip DTC is detected, go to EC-441, "

Diagnosis Procedure".

If 1st trip DTC is not detected, go to the following step.

5. Drive the vehicle for at least 5 consecutive seconds under the

following condition.

6. If 1st trip DTC is detected, go to EC-441, "

Diagnosis Procedure".

WITH GST

Follow the procedure “WITH CONSULT-II” above.

VHCL SPEED SE More than 30 km/h (19 MPH)

Shift lever Suitable position

VHCL SPEED SE More than 30 km/h (19 MPH)

Shift lever Suitable position

Driving locationDepress the brake pedal for more than 5

seconds so as not to come off from the

above-mentioned vehicle speed.

PBIB2386E

Page 1521 of 2771

DTC P1574 ASCD VEHICLE SPEED SENSOR

EC-447

< SERVICE INFORMATION >

C

D

E

F

G

H

I

J

K

L

MA

EC

N

P O

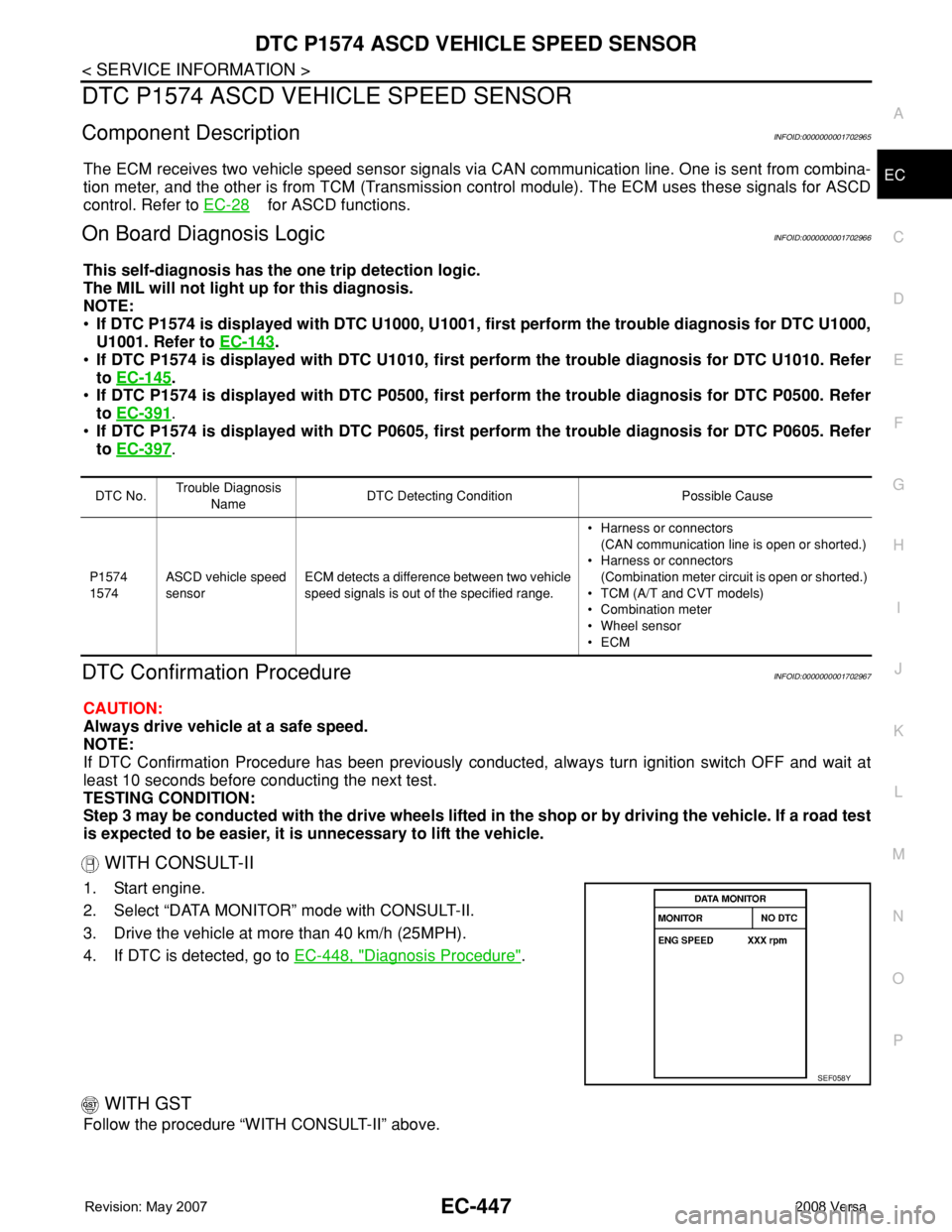

DTC P1574 ASCD VEHICLE SPEED SENSOR

Component DescriptionINFOID:0000000001702965

The ECM receives two vehicle speed sensor signals via CAN communication line. One is sent from combina-

tion meter, and the other is from TCM (Transmission control module). The ECM uses these signals for ASCD

control. Refer to EC-28

for ASCD functions.

On Board Diagnosis LogicINFOID:0000000001702966

This self-diagnosis has the one trip detection logic.

The MIL will not light up for this diagnosis.

NOTE:

•If DTC P1574 is displayed with DTC U1000, U1001, first perform the trouble diagnosis for DTC U1000,

U1001. Refer to EC-143

.

•If DTC P1574 is displayed with DTC U1010, first perform the trouble diagnosis for DTC U1010. Refer

to EC-145

.

•If DTC P1574 is displayed with DTC P0500, first perform the trouble diagnosis for DTC P0500. Refer

to EC-391

.

•If DTC P1574 is displayed with DTC P0605, first perform the trouble diagnosis for DTC P0605. Refer

to EC-397

.

DTC Confirmation ProcedureINFOID:0000000001702967

CAUTION:

Always drive vehicle at a safe speed.

NOTE:

If DTC Confirmation Procedure has been previously conducted, always turn ignition switch OFF and wait at

least 10 seconds before conducting the next test.

TESTING CONDITION:

Step 3 may be conducted with the drive wheels lifted in the shop or by driving the vehicle. If a road test

is expected to be easier, it is unnecessary to lift the vehicle.

WITH CONSULT-II

1. Start engine.

2. Select “DATA MONITOR” mode with CONSULT-II.

3. Drive the vehicle at more than 40 km/h (25MPH).

4. If DTC is detected, go to EC-448, "

Diagnosis Procedure".

WITH GST

Follow the procedure “WITH CONSULT-II” above.

DTC No.Trouble Diagnosis

NameDTC Detecting Condition Possible Cause

P1574

1574ASCD vehicle speed

sensorECM detects a difference between two vehicle

speed signals is out of the specified range.• Harness or connectors

(CAN communication line is open or shorted.)

• Harness or connectors

(Combination meter circuit is open or shorted.)

• TCM (A/T and CVT models)

• Combination meter

• Wheel sensor

•ECM

SEF058Y

Page 1523 of 2771

DTC P1715 INPUT SPEED SENSOR (TURBINE REVOLUTION SENSOR)

EC-449

< SERVICE INFORMATION >

C

D

E

F

G

H

I

J

K

L

MA

EC

N

P O

DTC P1715 INPUT SPEED SENSOR (TURBINE REVOLUTION SENSOR)

DescriptionINFOID:0000000001702969

ECM receives turbine revolution sensor signal from TCM through CAN communication line. ECM uses this

signal for engine control.

CONSULT-II Reference Value in Data Monitor ModeINFOID:0000000001702970

Specification data are reference values.

On Board Diagnosis LogicINFOID:0000000001702971

NOTE:

•If DTC P1715 is displayed with DTC U1000, U1001 first perform the trouble diagnosis for DTC U1000,

U1001. Refer to EC-143

.

•If DTC P1715 is displayed with DTC U1010, first perform the trouble diagnosis for DTC U1010. Refer

to EC-145

.

•If DTC P1715 is displayed with DTC P0335, first perform the trouble diagnosis for DTC P0335. Refer

to EC-295

.

•If DTC P1715 is displayed with DTC P0340 first perform the trouble diagnosis for DTC P0340.

Refer to EC-302

.

•If DTC P1715 is displayed with DTC P0605, first perform the trouble diagnosis for DTC P0605. Refer

to EC-397

.

The MIL will not lights up for this diagnosis.

Diagnosis ProcedureINFOID:0000000001702972

1.CHECK DTC WITH TCM

Check DTC with TCM. Refer to AT- 3 6

.

OK or NG

OK >> GO TO 2.

NG >> Perform trouble shooting relevant to DTC indicated.

2.REPLACE TCM

Replace TCM. Refer to AT- 3 9

.

>>INSPECTION END

MONITOR ITEM CONDITION SPECIFICATION

I/P PULLY SPD • Vehicle speed: More than 20 km/h (12MPH)Almost the same speed as the

tachometer indication

DTC No. Trouble diagnosis name DTC detecting condition Possible cause

P1715

1715Input speed sensor

(Turbine revolution sen-

sor)

(TCM output)Turbine revolution sensor signal is differ-

ent from the theoretical value calculated

by ECM from revolution sensor signal and

engine rpm signal.• Harness or connectors

(CAN communication line is open or shorted)

• Harness or connectors

(Turbine revolution sensor circuit is open or

shorted)

•TCM

Page 1524 of 2771

EC-450

< SERVICE INFORMATION >

DTC P1715 INPUT SPEED SENSOR (PRIMARY SPEED SENSOR)

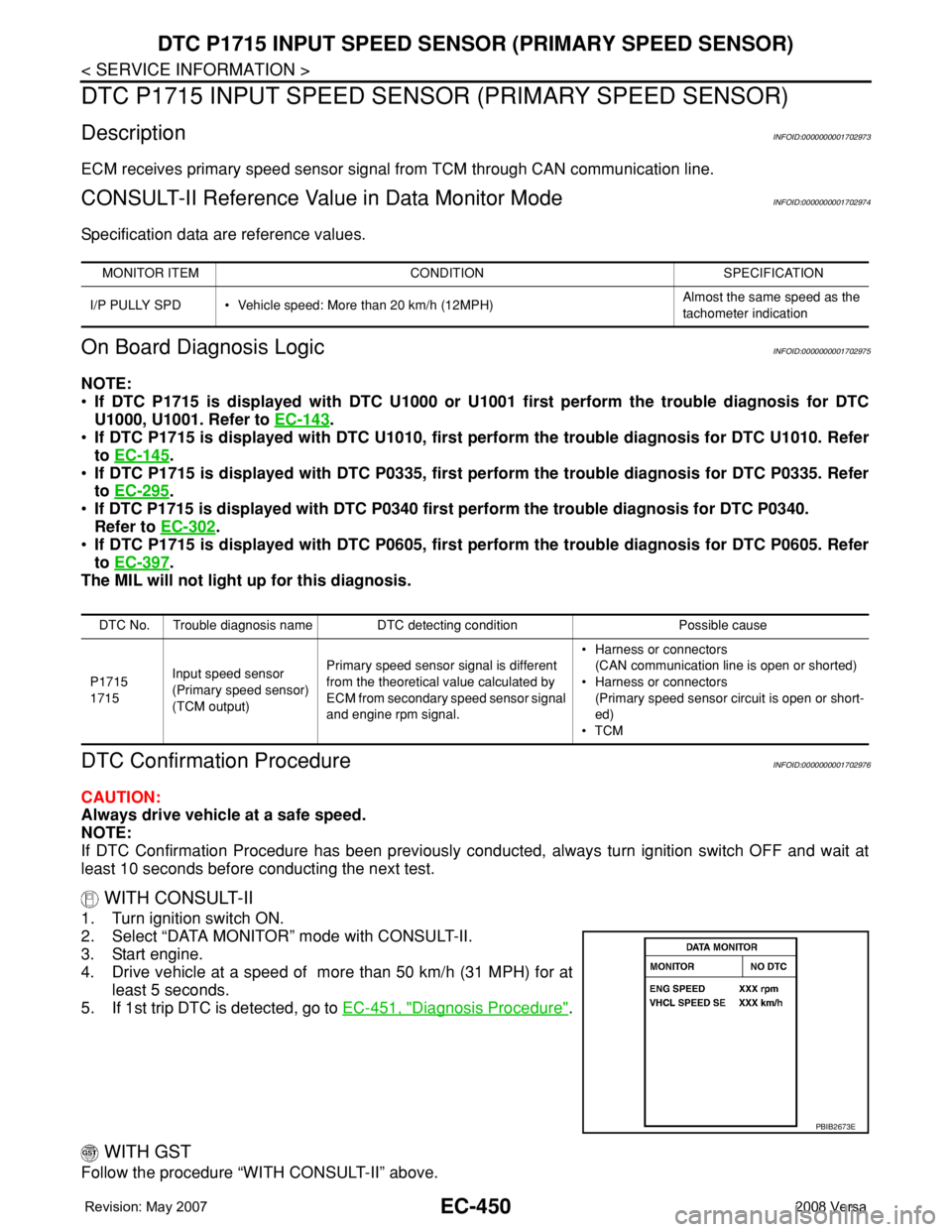

DTC P1715 INPUT SPEED SENSOR (PRIMARY SPEED SENSOR)

DescriptionINFOID:0000000001702973

ECM receives primary speed sensor signal from TCM through CAN communication line.

CONSULT-II Reference Value in Data Monitor ModeINFOID:0000000001702974

Specification data are reference values.

On Board Diagnosis LogicINFOID:0000000001702975

NOTE:

•If DTC P1715 is displayed with DTC U1000 or U1001 first perform the trouble diagnosis for DTC

U1000, U1001. Refer to EC-143

.

•If DTC P1715 is displayed with DTC U1010, first perform the trouble diagnosis for DTC U1010. Refer

to EC-145

.

•If DTC P1715 is displayed with DTC P0335, first perform the trouble diagnosis for DTC P0335. Refer

to EC-295

.

•If DTC P1715 is displayed with DTC P0340 first perform the trouble diagnosis for DTC P0340.

Refer to EC-302

.

•If DTC P1715 is displayed with DTC P0605, first perform the trouble diagnosis for DTC P0605. Refer

to EC-397

.

The MIL will not light up for this diagnosis.

DTC Confirmation ProcedureINFOID:0000000001702976

CAUTION:

Always drive vehicle at a safe speed.

NOTE:

If DTC Confirmation Procedure has been previously conducted, always turn ignition switch OFF and wait at

least 10 seconds before conducting the next test.

WITH CONSULT-II

1. Turn ignition switch ON.

2. Select “DATA MONITOR” mode with CONSULT-II.

3. Start engine.

4. Drive vehicle at a speed of more than 50 km/h (31 MPH) for at

least 5 seconds.

5. If 1st trip DTC is detected, go to EC-451, "

Diagnosis Procedure".

WITH GST

Follow the procedure “WITH CONSULT-II” above.

MONITOR ITEM CONDITION SPECIFICATION

I/P PULLY SPD • Vehicle speed: More than 20 km/h (12MPH)Almost the same speed as the

tachometer indication

DTC No. Trouble diagnosis name DTC detecting condition Possible cause

P1715

1715Input speed sensor

(Primary speed sensor)

(TCM output)Primary speed sensor signal is different

from the theoretical value calculated by

ECM from secondary speed sensor signal

and engine rpm signal.• Harness or connectors

(CAN communication line is open or shorted)

• Harness or connectors

(Primary speed sensor circuit is open or short-

ed)

•TCM

PBIB2673E

Page 1526 of 2771

EC-452

< SERVICE INFORMATION >

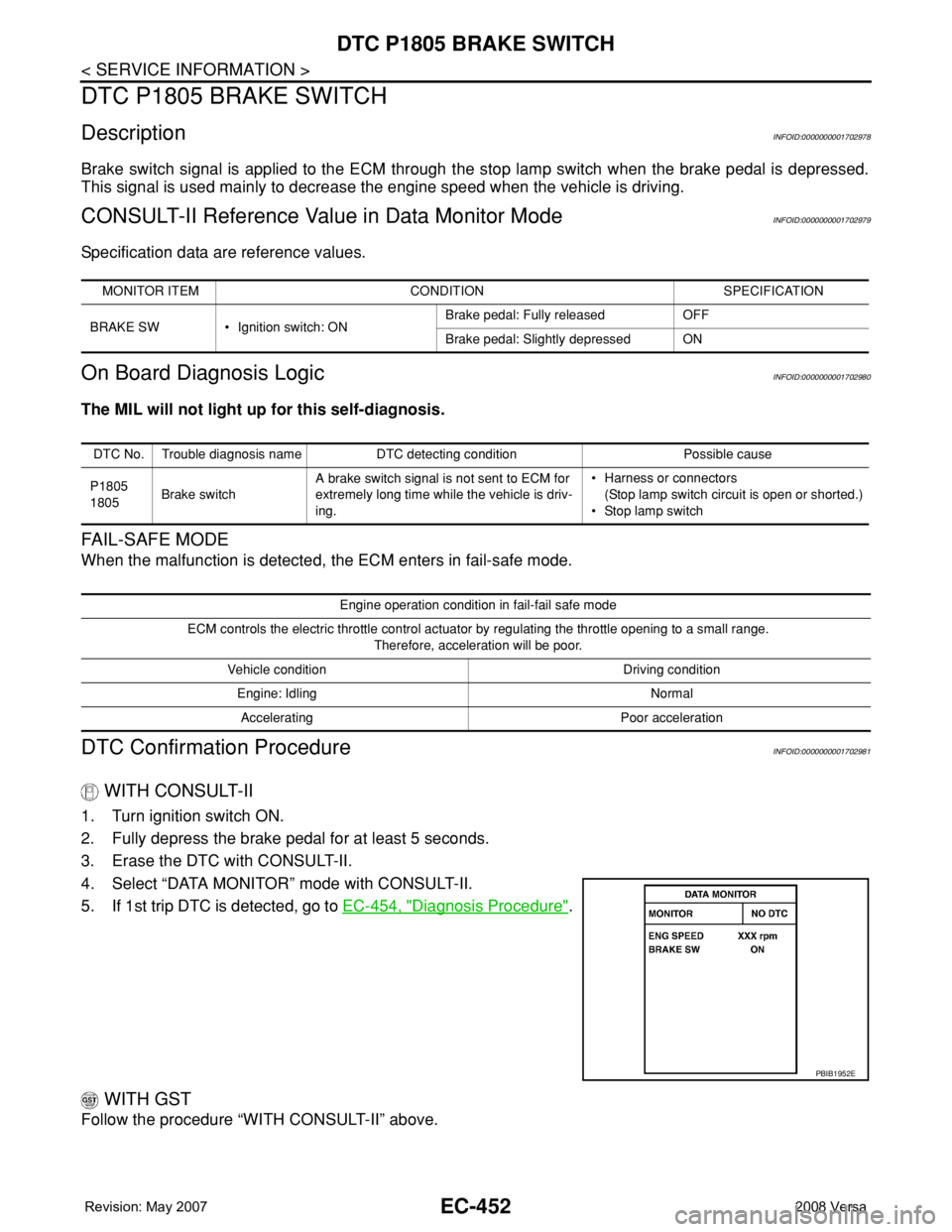

DTC P1805 BRAKE SWITCH

DTC P1805 BRAKE SWITCH

DescriptionINFOID:0000000001702978

Brake switch signal is applied to the ECM through the stop lamp switch when the brake pedal is depressed.

This signal is used mainly to decrease the engine speed when the vehicle is driving.

CONSULT-II Reference Value in Data Monitor ModeINFOID:0000000001702979

Specification data are reference values.

On Board Diagnosis LogicINFOID:0000000001702980

The MIL will not light up for this self-diagnosis.

FAIL-SAFE MODE

When the malfunction is detected, the ECM enters in fail-safe mode.

DTC Confirmation ProcedureINFOID:0000000001702981

WITH CONSULT-II

1. Turn ignition switch ON.

2. Fully depress the brake pedal for at least 5 seconds.

3. Erase the DTC with CONSULT-II.

4. Select “DATA MONITOR” mode with CONSULT-II.

5. If 1st trip DTC is detected, go to EC-454, "

Diagnosis Procedure".

WITH GST

Follow the procedure “WITH CONSULT-II” above.

MONITOR ITEM CONDITION SPECIFICATION

BRAKE SW • Ignition switch: ONBrake pedal: Fully released OFF

Brake pedal: Slightly depressed ON

DTC No. Trouble diagnosis name DTC detecting condition Possible cause

P1805

1805Brake switchA brake switch signal is not sent to ECM for

extremely long time while the vehicle is driv-

ing.• Harness or connectors

(Stop lamp switch circuit is open or shorted.)

• Stop lamp switch

Engine operation condition in fail-fail safe mode

ECM controls the electric throttle control actuator by regulating the throttle opening to a small range.

Therefore, acceleration will be poor.

Vehicle condition Driving condition

Engine: Idling Normal

Accelerating Poor acceleration

PBIB1952E