NISSAN LATIO 2009 Service Repair Manual

LATIO 2009

NISSAN

NISSAN

https://www.carmanualsonline.info/img/5/57359/w960_57359-0.png

NISSAN LATIO 2009 Service Repair Manual

Trending: ad blue, fuel consumption, check oil, oil temperature, fuse box, turn signal, brake

Page 1301 of 4331

CVT

N

O P

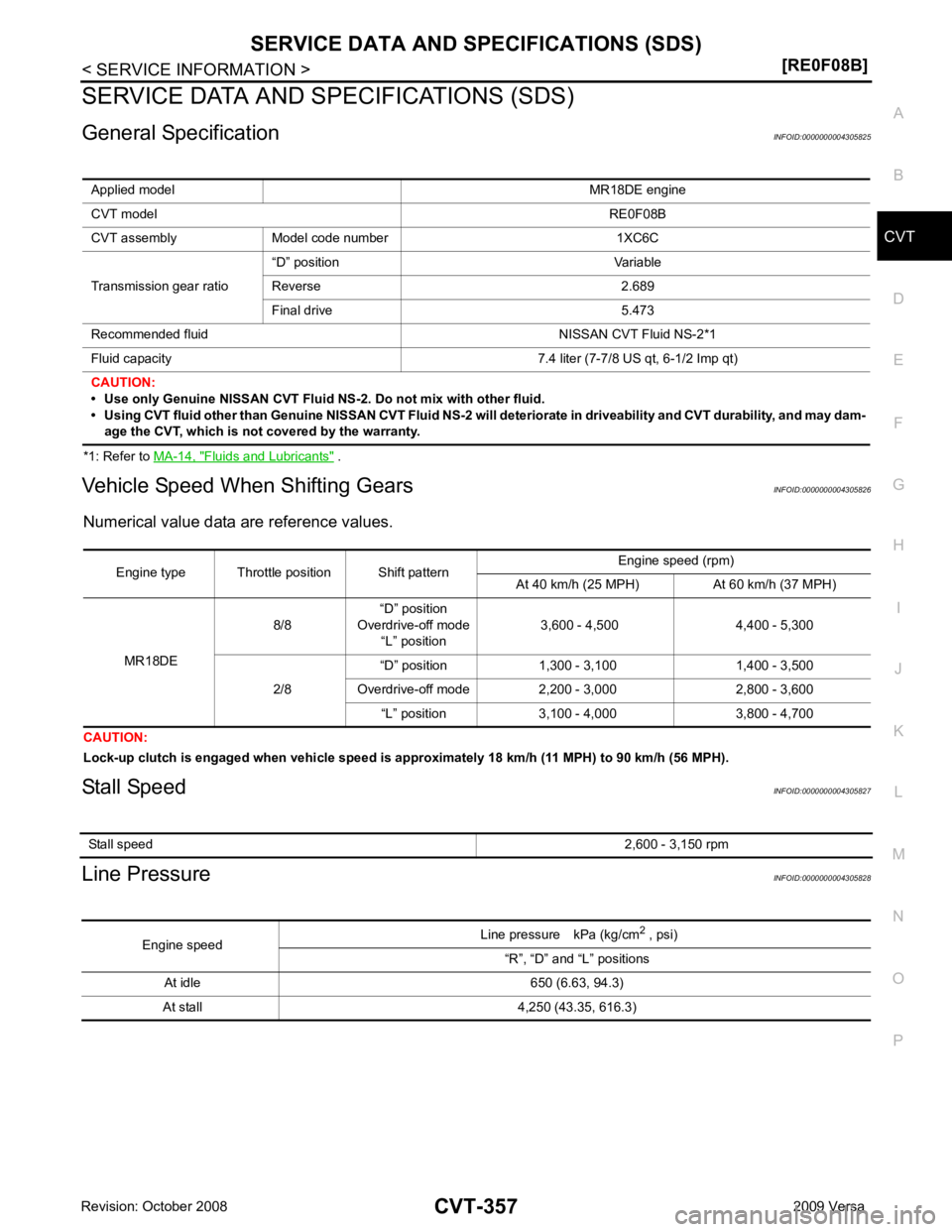

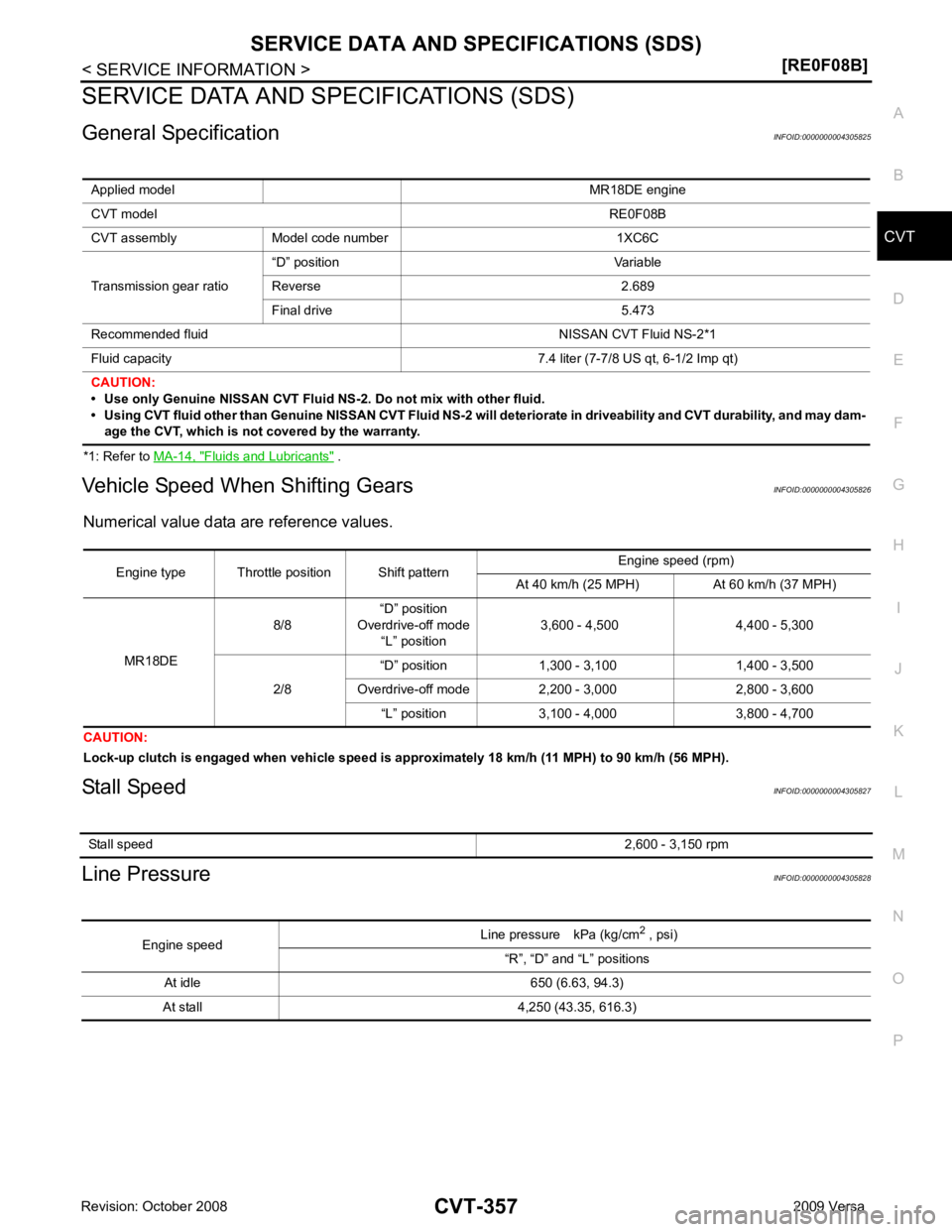

SERVICE DATA AND SPECIFICATIONS (SDS)

General Specification INFOID:0000000004305825

*1: Refer to MA-14, " Fluids and Lubricants " .

Vehicle Speed When Shifting Gears INFOID:0000000004305826

Numerical value data are reference values.

CAUTION:

Lock-up clutch is engaged when vehi cle speed is approximately 18 km/h (11 MPH) to 90 km/h (56 MPH).

Stall Speed INFOID:0000000004305827

Line Pressure INFOID:0000000004305828

Applied model

MR18DE engine

CVT model RE0F08B

CVT assembly Model code number 1XC6C

Transmission gear ratio “D” position Variable

Reverse 2.689

Final drive 5.473

Recommended fluid NISSAN CVT Fluid NS-2*1

Fluid capacity 7.4 liter (7-7/8 US qt, 6-1/2 Imp qt)

CAUTION:

• Use only Genuine NISSAN CVT Fluid NS-2. Do not mix with other fluid.

• Using CVT fluid other than Genuine NISSAN CVT Fluid NS-2 will deteriorate in driveability and CVT durability, and may dam- age the CVT, which is not covered by the warranty. Stall speed

2,600 - 3,150 rpmEngine speed

Line pressure kPa (kg/cm

2

, psi)

“R”, “D” and “L” positions

At idle 650 (6.63, 94.3)

At stall 4,250 (43.35, 616.3)

Page 1302 of 4331

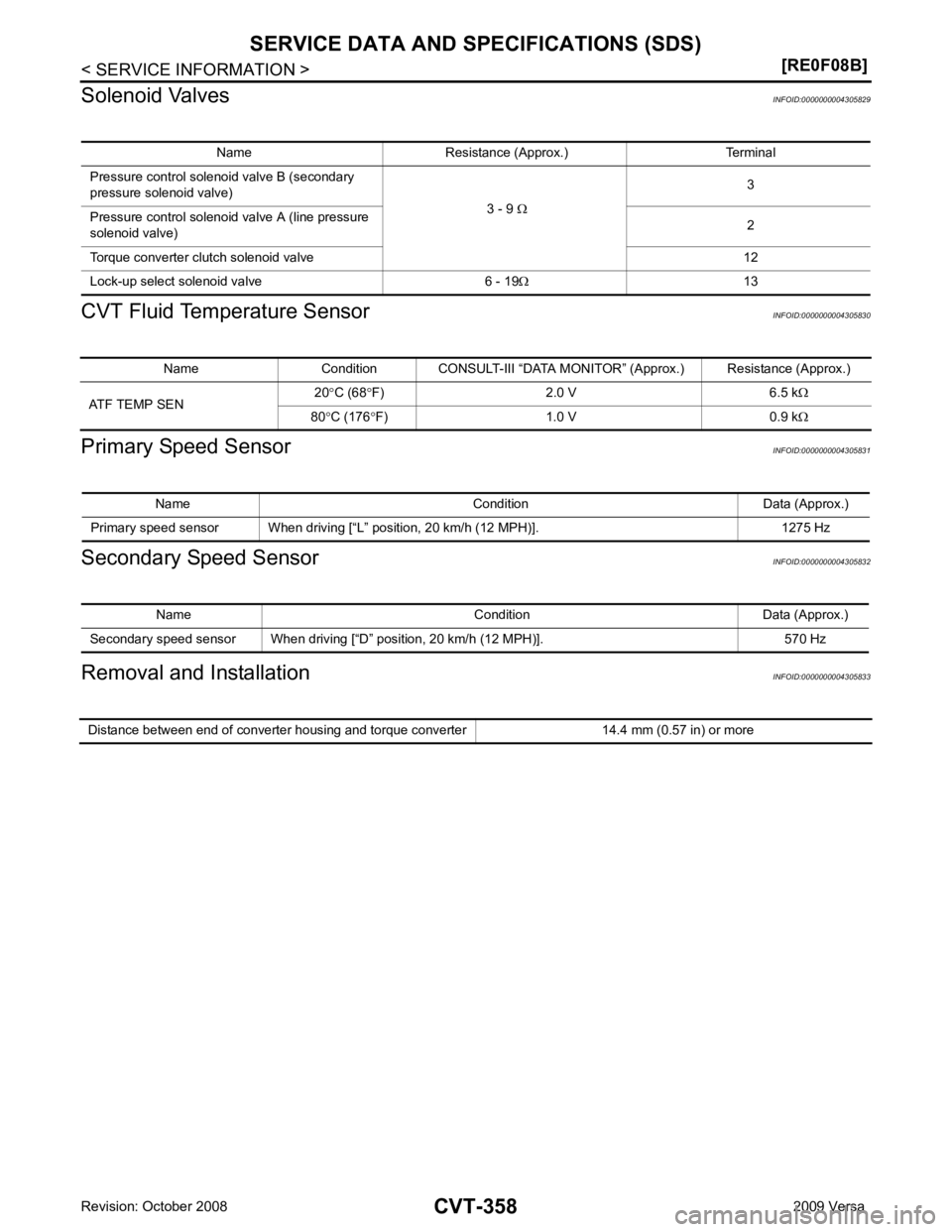

Name Condition CONSULT-III “DATA MONI

TOR” (Approx.) Resistance (Approx.)

ATF TEMP SEN 20

°C (68 °F) 2.0 V 6.5 k Ω

80 °C (176 °F) 1.0 V 0.9 k ΩName Condition Data (Approx.)

Secondary speed sensor When driving [

Page 1303 of 4331

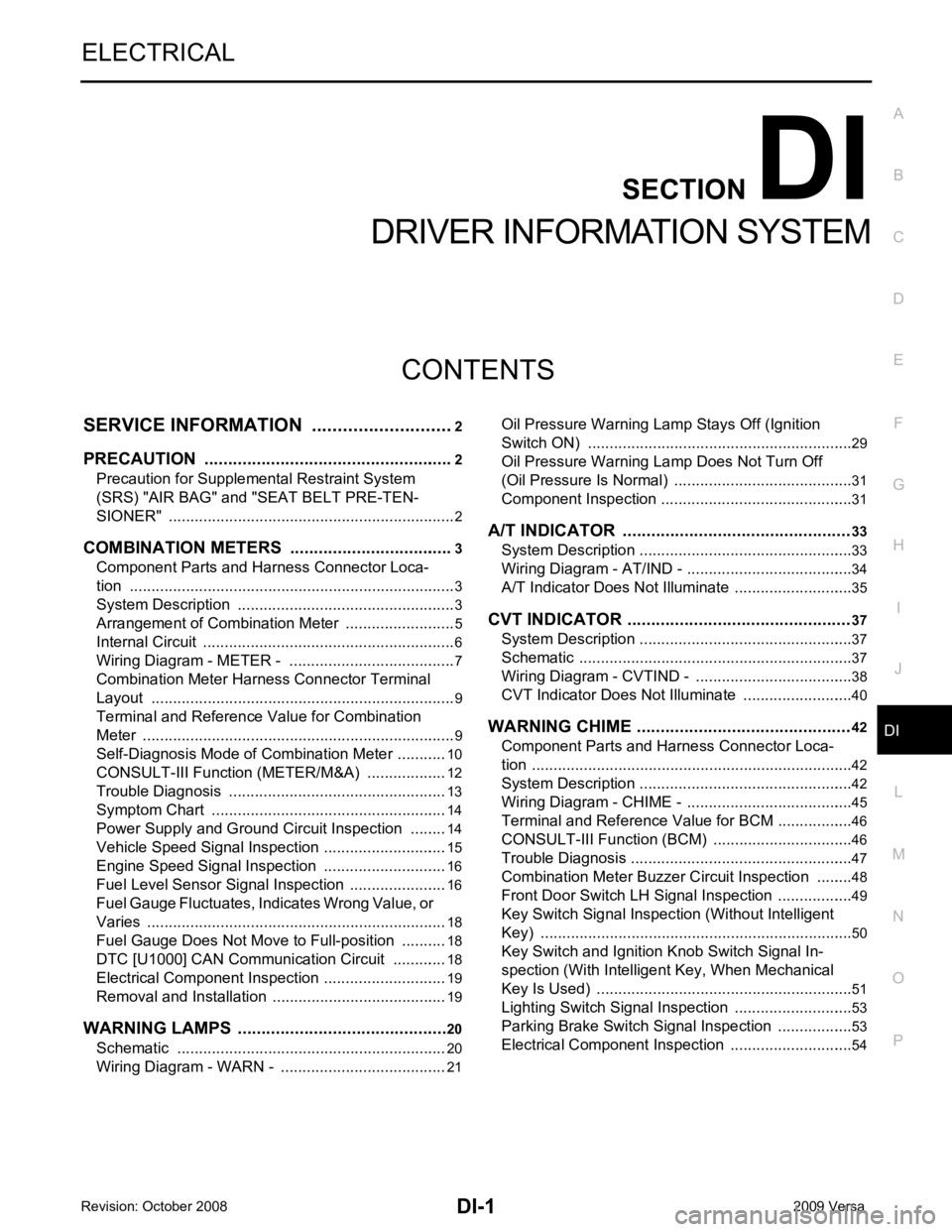

DI

N

O P

CONTENTS

DRIVER INFORMATION SYSTEM

SERVICE INFORMATION .. ..........................2

PRECAUTION ................................................ .....2

Precaution for Supplemental Restraint System

(SRS) "AIR BAG" and "SEAT BELT PRE-TEN-

SIONER" ............................................................. ......

2

COMBINATION METERS .............................. .....3

Component Parts and Harness Connector Loca-

tion ...................................................................... ......

3

System Description ............................................. ......3

Arrangement of Combination Meter .................... ......5

Internal Circuit ..................................................... ......6

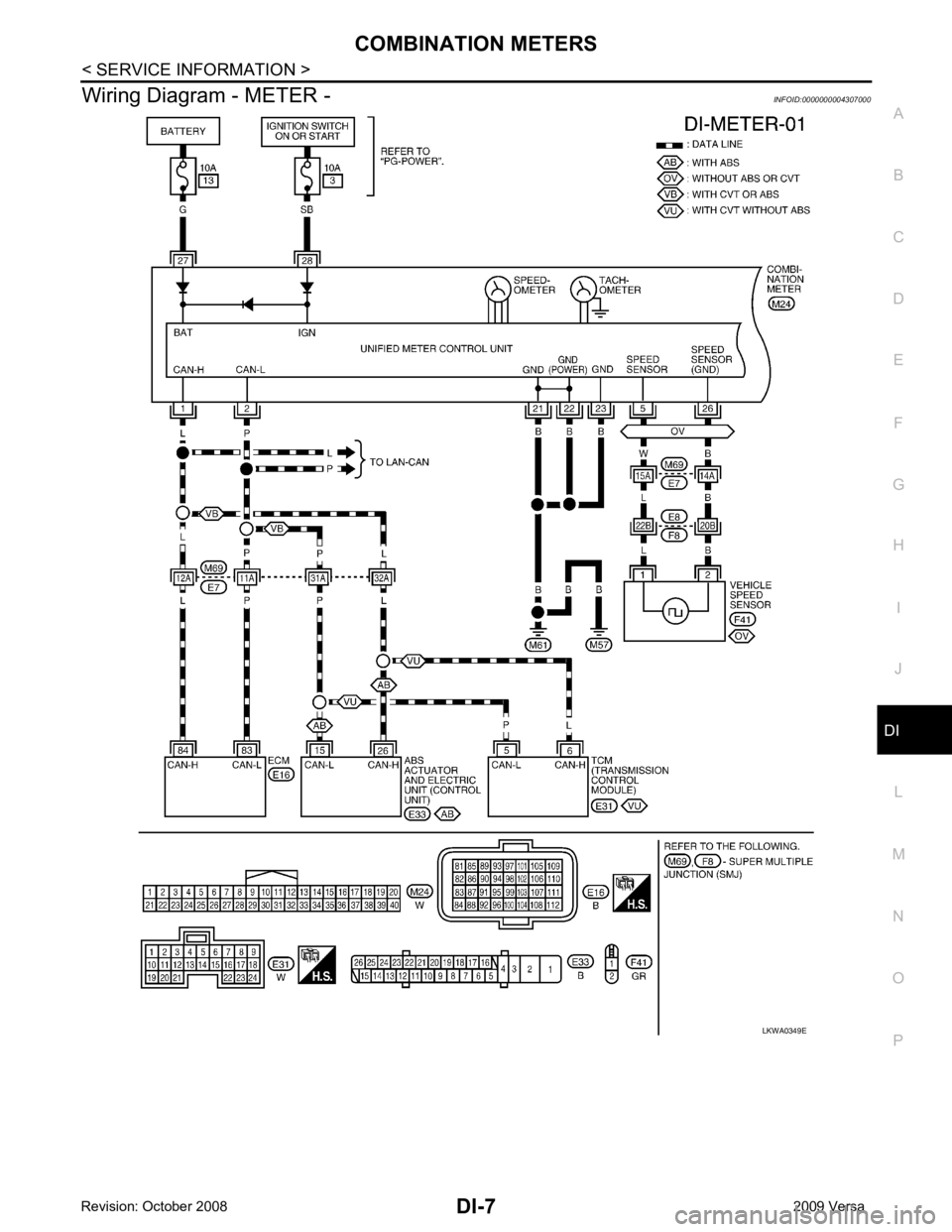

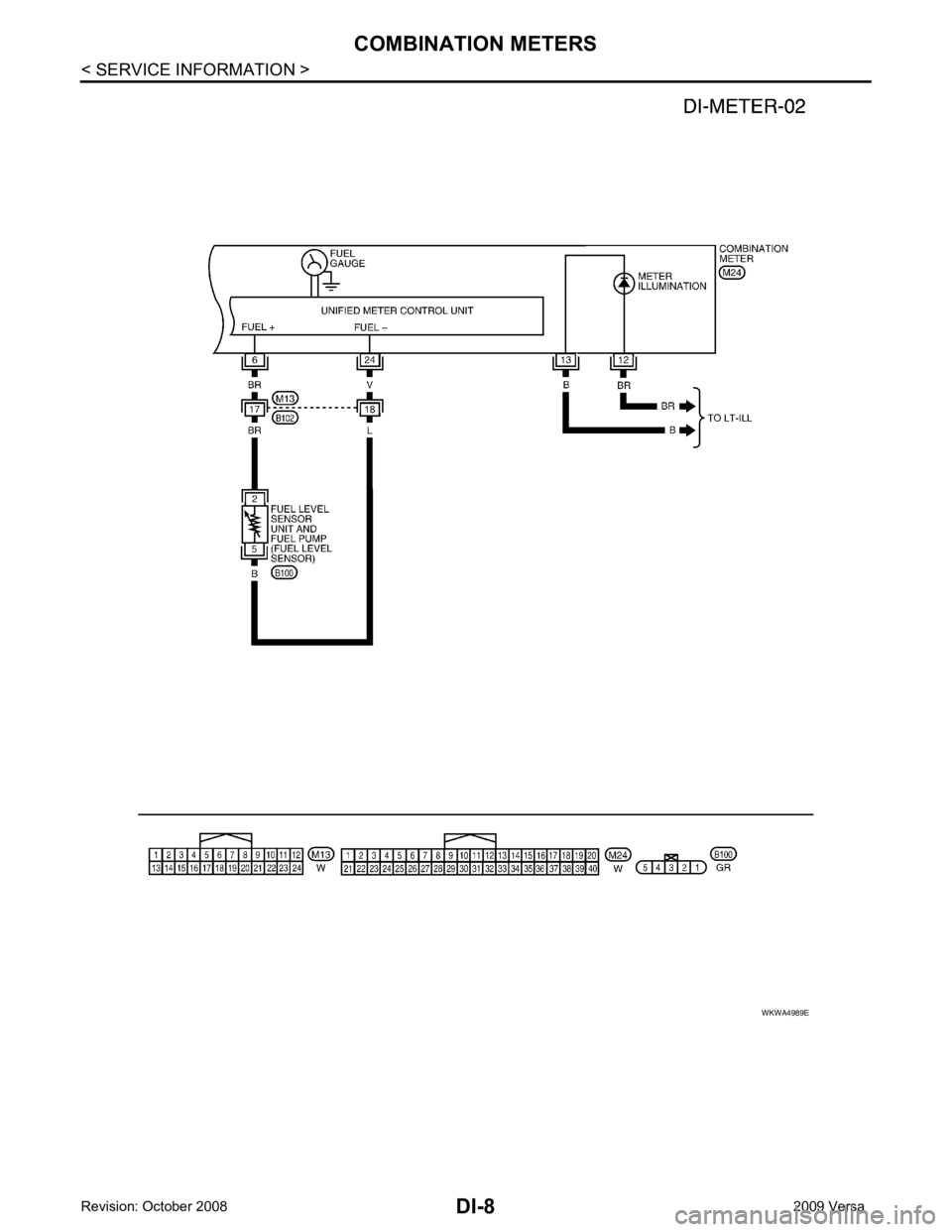

Wiring Diagram - METER - ................................. ......7

Combination Meter Harness Connector Terminal

Layout ................................................................. ......

9

Terminal and Reference Value for Combination

Meter ................................................................... ......

9

Self-Diagnosis Mode of Combination Meter ........ ....10

CONSULT-III Function (METER/M&A) ............... ....12

Trouble Diagnosis ............................................... ....13

Symptom Chart ................................................... ....14

Power Supply and Ground Circuit Inspection ..... ....14

Vehicle Speed Signal Inspection ......................... ....15

Engine Speed Signal Inspection ......................... ....16

Fuel Level Sensor Signal Inspection ................... ....16

Fuel Gauge Fluctuates, Indicates Wrong Value, or

Varies .................................................................. ....

18

Fuel Gauge Does Not Move to Full-position ...........18

DTC [U1000] CAN Communication Circuit ......... ....18

Electrical Component Inspection ......................... ....19

Removal and Installation .........................................19

WARNING LAMPS ......................................... ....20

Schematic ........................................................... ....20

Wiring Diagram - WARN - ................................... ....21 Oil Pressure Wa

rning Lamp Stays Off (Ignition

Switch ON) .......................................................... ....

29

Oil Pressure Wa rning Lamp Does Not Turn Off

(Oil Pressure Is Normal) ...................................... ....

31

Component Inspection ......................................... ....31

A/T INDICATOR ................................................ 33

System Description .............................................. ....33

Wiring Diagram - AT/IND - ................................... ....34

A/T Indicator Does Not Illuminate ........................ ....35

CVT INDICATOR ............................................... 37

System Description .............................................. ....37

Schematic ............................................................ ....37

Wiring Diagram - CVTIND - ................................. ....38

CVT Indicator Does Not Illuminate ...................... ....40

WARNING CHIME ............................................. 42

Component Parts and Harness Connector Loca-

tion ....................................................................... ....

42

System Description .............................................. ....42

Wiring Diagram - CHIME - ................................... ....45

Terminal and Reference Value for BCM ..................46

CONSULT-III Function (B CM) .................................46

Trouble Diagnosis ................................................ ....47

Combination Meter Buzzer Cir cuit Inspection .........48

Front Door Switch LH Signal Inspection .............. ....49

Key Switch Signal Inspec tion (Without Intelligent

Key) ..................................................................... ....

50

Key Switch and Ignition Knob Switch Signal In-

spection (With Intelligent Key, When Mechanical

Key Is Used) ........................................................ ....

51

Lighting Switch Signal Inspection ........................ ....53

Parking Brake Switch Signal Inspection .............. ....53

Electrical Component Inspection ......................... ....54

Page 1304 of 4331

Page 1305 of 4331

DI

N

O P

COMBINATION METERS

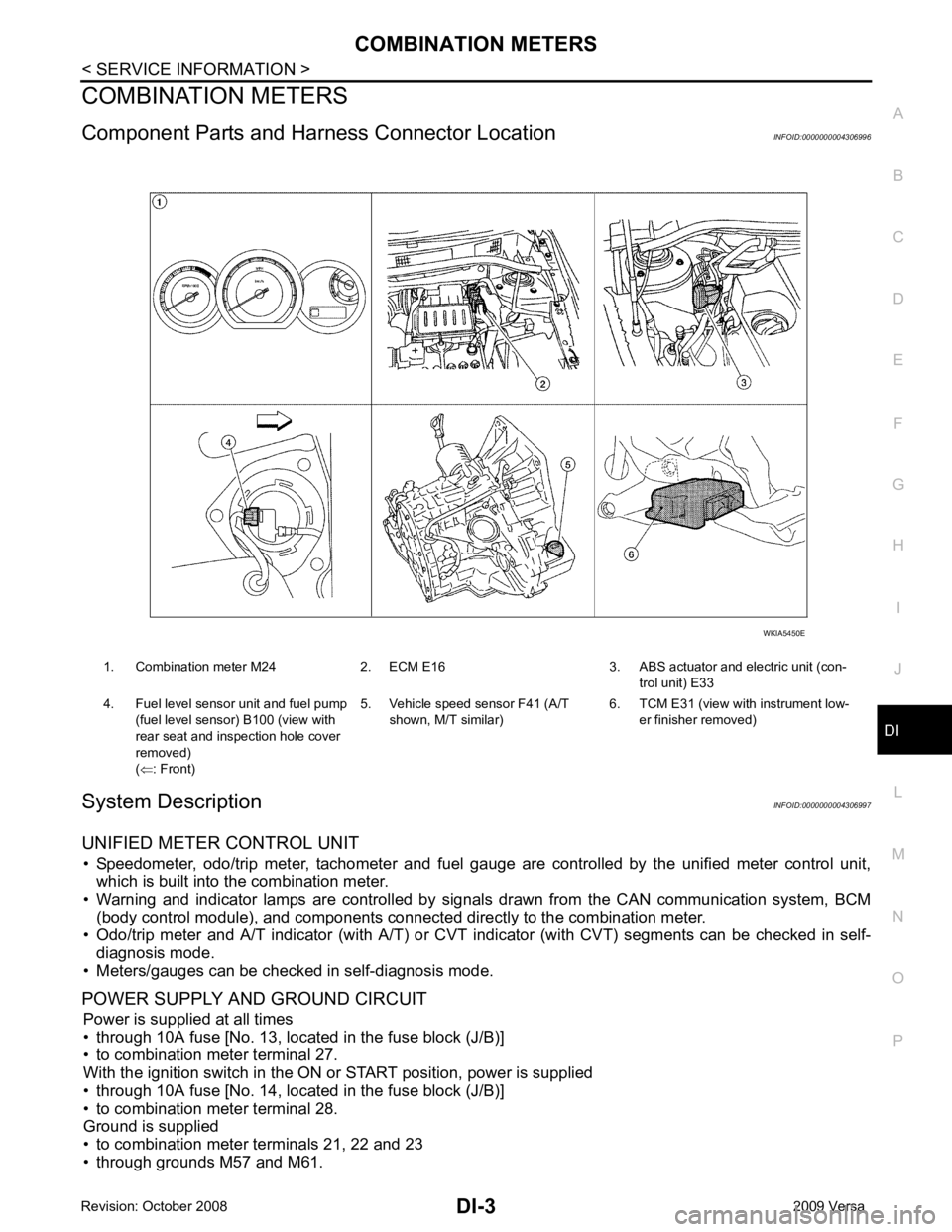

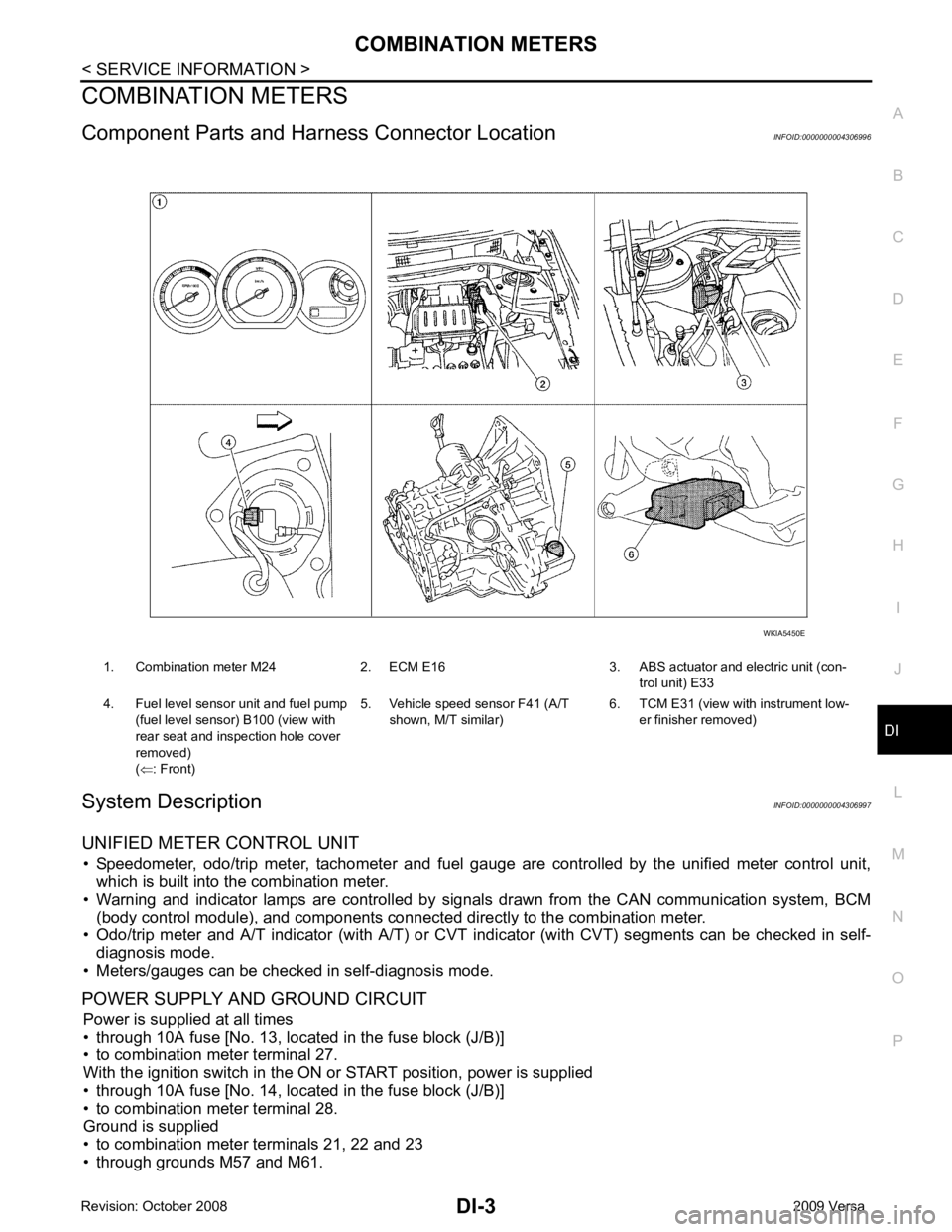

Component Parts and Har ness Connector Location INFOID:0000000004306996

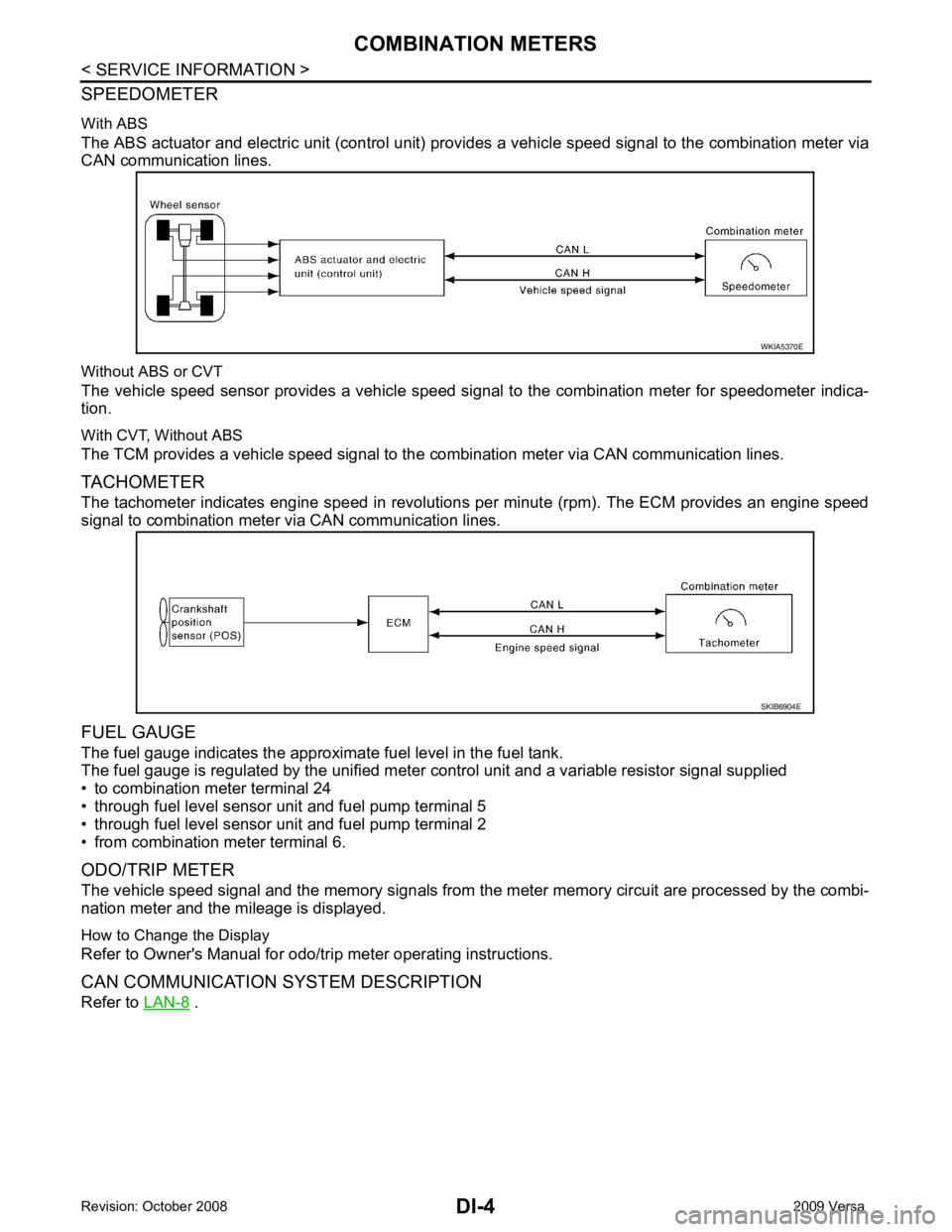

System Description INFOID:0000000004306997

UNIFIED METER CONTROL UNIT • Speedometer, odo/trip meter, tachometer and fuel gauge are controlled by the unified meter control unit,

which is built into the combination meter.

• Warning and indicator lamps are controlled by signal s drawn from the CAN communication system, BCM

(body control module), and components connected directly to the combination meter.

• Odo/trip meter and A/T indicator (with A/T) or CVT i ndicator (with CVT) segments can be checked in self-

diagnosis mode.

• Meters/gauges can be checked in self-diagnosis mode.

POWER SUPPLY AND GROUND CIRCUIT Power is supplied at all times

• through 10A fuse [No. 13, located in the fuse block (J/B)]

• to combination meter terminal 27.

With the ignition switch in the ON or START position, power is supplied

• through 10A fuse [No. 14, located in the fuse block (J/B)]

• to combination meter terminal 28.

Ground is supplied

• to combination meter terminals 21, 22 and 23

• through grounds M57 and M61. 1. Combination meter M24 2. ECM E16 3. ABS actuator and electric unit (con-

trol unit) E33

4. Fuel level sensor unit and fuel pump (fuel level sensor) B100 (view with

rear seat and inspection hole cover

removed)

( ⇐ : Front) 5. Vehicle speed sensor F41 (A/T

shown, M/T similar) 6. TCM E31 (view with

instrument low-

er finisher removed)

Page 1306 of 4331

Page 1307 of 4331

DI

N

O P

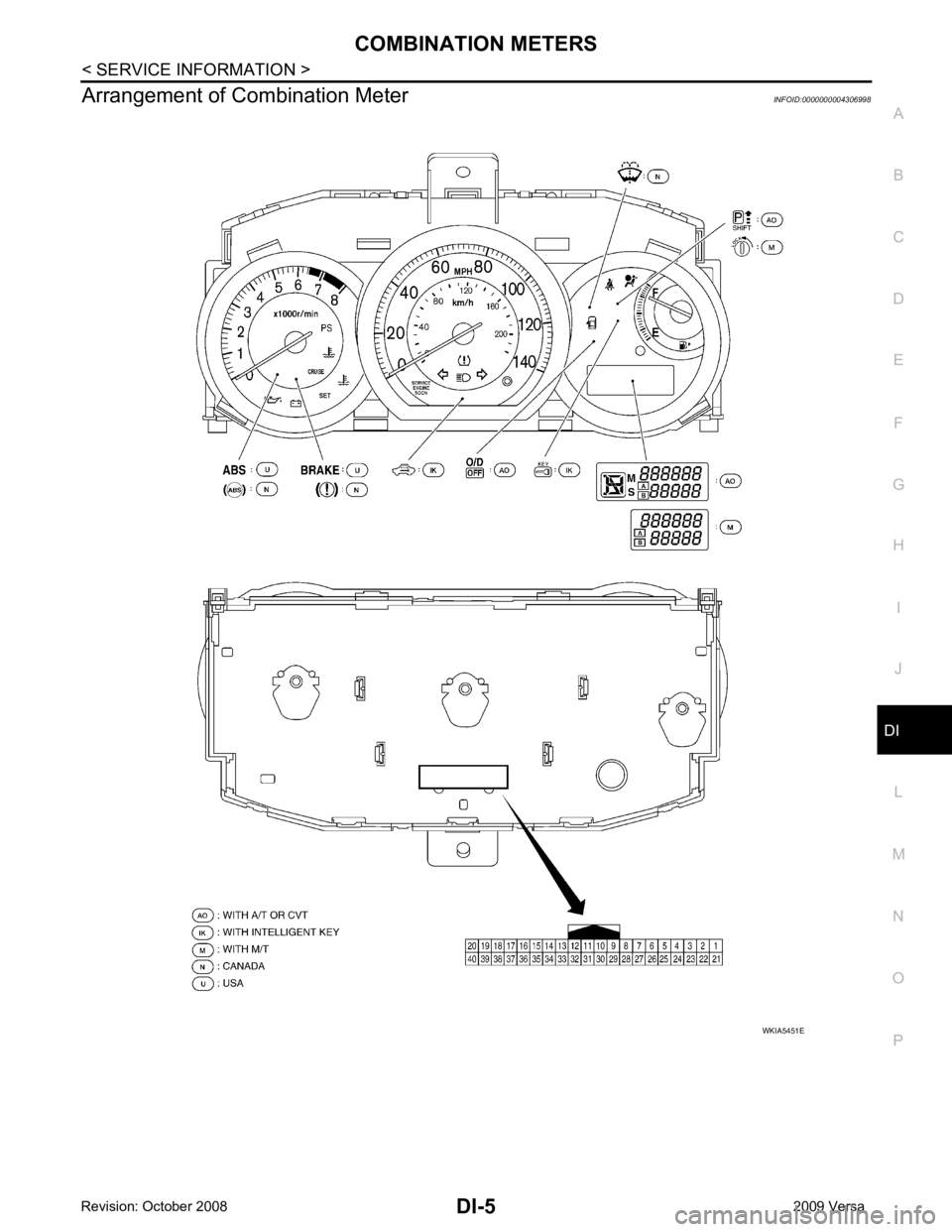

Arrangement of Combination Meter

INFOID:0000000004306998

Page 1308 of 4331

Page 1309 of 4331

DI

N

O P

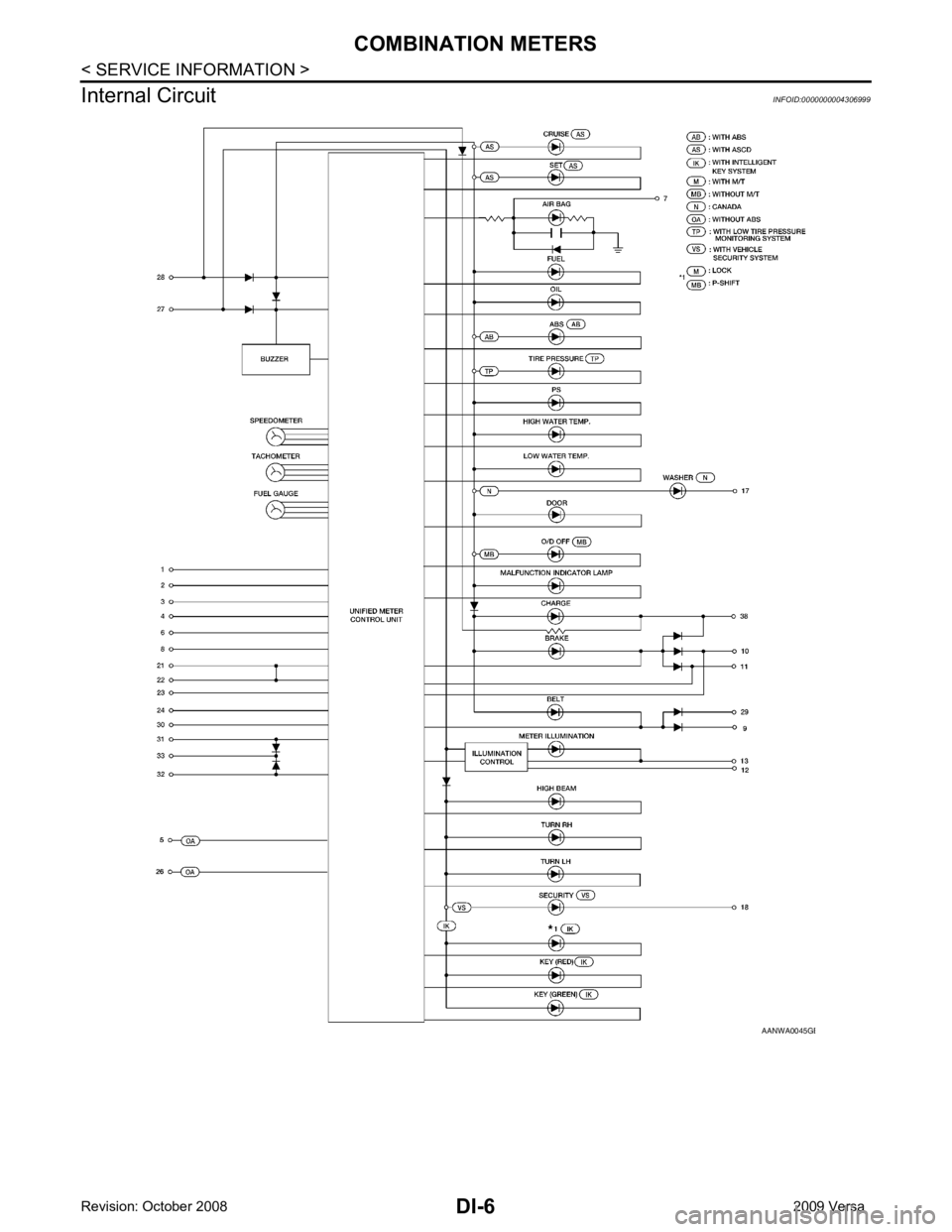

Wiring Diagram - METER -

INFOID:0000000004307000

Page 1310 of 4331

Trending: turn signal bulb, wheel bolt torque, tire pressure, service indicator, automatic transmission fluid, fuse box, overheating