NISSAN LATIO 2009 Service Repair Manual

Manufacturer: NISSAN, Model Year: 2009, Model line: LATIO, Model: NISSAN LATIO 2009Pages: 4331, PDF Size: 58.04 MB

Page 2381 of 4331

![NISSAN LATIO 2009 Service Repair Manual PREPARATION

EC-1025

< SERVICE INFOMATION >

[MR TYPE 2] C

D E

F

G H

I

J

K L

M A EC

NP

O

PREPARATION

Special Service Tool INFOID:0000000004499903

The actual shapes of Kent-Moore tools may differ fr om t NISSAN LATIO 2009 Service Repair Manual PREPARATION

EC-1025

< SERVICE INFOMATION >

[MR TYPE 2] C

D E

F

G H

I

J

K L

M A EC

NP

O

PREPARATION

Special Service Tool INFOID:0000000004499903

The actual shapes of Kent-Moore tools may differ fr om t](/img/5/57359/w960_57359-2380.png)

PREPARATION

EC-1025

< SERVICE INFOMATION >

[MR TYPE 2] C

D E

F

G H

I

J

K L

M A EC

NP

O

PREPARATION

Special Service Tool INFOID:0000000004499903

The actual shapes of Kent-Moore tools may differ fr om those of special service tools illustrated here.

Commercial Service Tool INFOID:0000000004499904

Tool number

(Kent-Moore No.)

Tool name Description

(J-44321)

Fuel pressure gauge

Kit Checking fuel pressure

(J-44321-6)

Fuel pressure adapter Connecting fuel pressure gauge to quick connec-

tor type fuel lines.

KV10118400

Fuel tube adapter Measuring fuel pressureLEC642

LBIA0376E

PBIB3043E

Tool number

(Kent-Moore No.)

Tool name Description

Leak detector

i.e.: (J-41416) Locating the EVAP leak

EVAP service port

adapter

i.e.: (J-41413-OBD) Applying positive pressure through EVAP service

port S-NT703

S-NT704

Page 2382 of 4331

![NISSAN LATIO 2009 Service Repair Manual EC-1026< SERVICE INFOMATION >

[MR TYPE 2]

PREPARATION

Fuel filler cap adapter

i.e.: (MLR-8382) Checking fuel tank vacuum relief valve opening

pressure

Socket wrench Removing and installing engine coo NISSAN LATIO 2009 Service Repair Manual EC-1026< SERVICE INFOMATION >

[MR TYPE 2]

PREPARATION

Fuel filler cap adapter

i.e.: (MLR-8382) Checking fuel tank vacuum relief valve opening

pressure

Socket wrench Removing and installing engine coo](/img/5/57359/w960_57359-2381.png)

EC-1026< SERVICE INFOMATION >

[MR TYPE 2]

PREPARATION

Fuel filler cap adapter

i.e.: (MLR-8382) Checking fuel tank vacuum relief valve opening

pressure

Socket wrench Removing and installing engine coolant tempera- ture sensor

Oxygen sensor thread

cleaner

i.e.: (J-43897-18)

(J-43897-12) Reconditioning the exhaust system threads before

installing a new oxygen sensor. Use with anti-

seize lubricant shown below.

a: 18 mm diameter with pitch 1.5 mm for Zirco-

nia Oxygen Sensor

b: 12 mm diameter with pitch 1.25 mm for Tita-

nia Oxygen Sensor

Anti-seize lubricant

i.e.: (Permatex TM

133AR or equivalent

meeting MIL specifica-

tion MIL-A-907) Lubricating oxygen sensor thread cleaning tool

when reconditioning exhaust system threads.

Tool number

(Kent-Moore No.)

Tool name DescriptionS-NT815

S-NT705

AEM488

S-NT779

Page 2383 of 4331

EC

NP

O

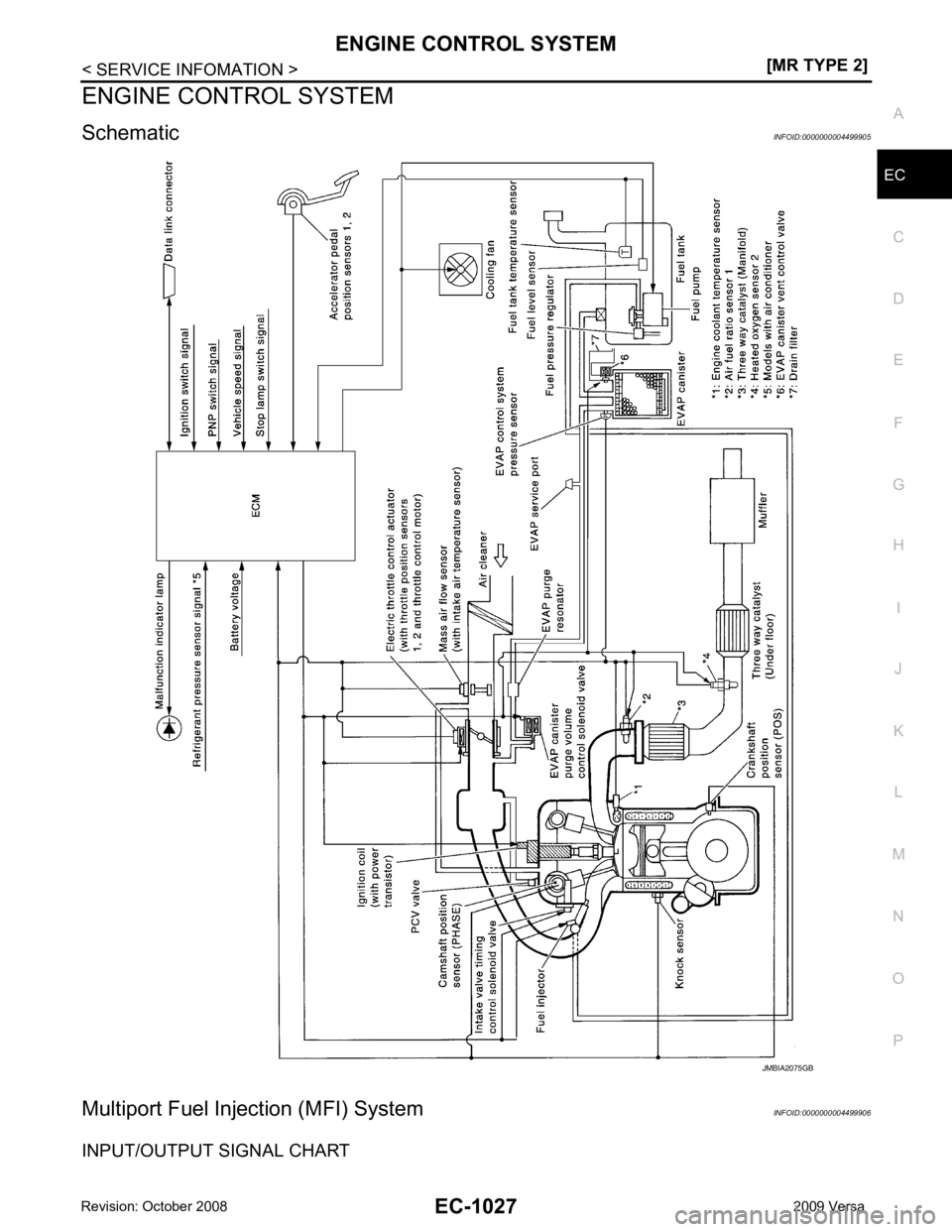

ENGINE CONTROL SYSTEM

Schematic INFOID:0000000004499905

Multiport Fuel Inje ction (MFI) System INFOID:0000000004499906

INPUT/OUTPUT SIGNAL CHART

Page 2384 of 4331

![NISSAN LATIO 2009 Service Repair Manual EC-1028< SERVICE INFOMATION >

[MR TYPE 2]

ENGINE CONTROL SYSTEM

*1: This sensor is not used to control the engine system under normal conditions.

*2: This signal is sent to the ECM through CAN communi NISSAN LATIO 2009 Service Repair Manual EC-1028< SERVICE INFOMATION >

[MR TYPE 2]

ENGINE CONTROL SYSTEM

*1: This sensor is not used to control the engine system under normal conditions.

*2: This signal is sent to the ECM through CAN communi](/img/5/57359/w960_57359-2383.png)

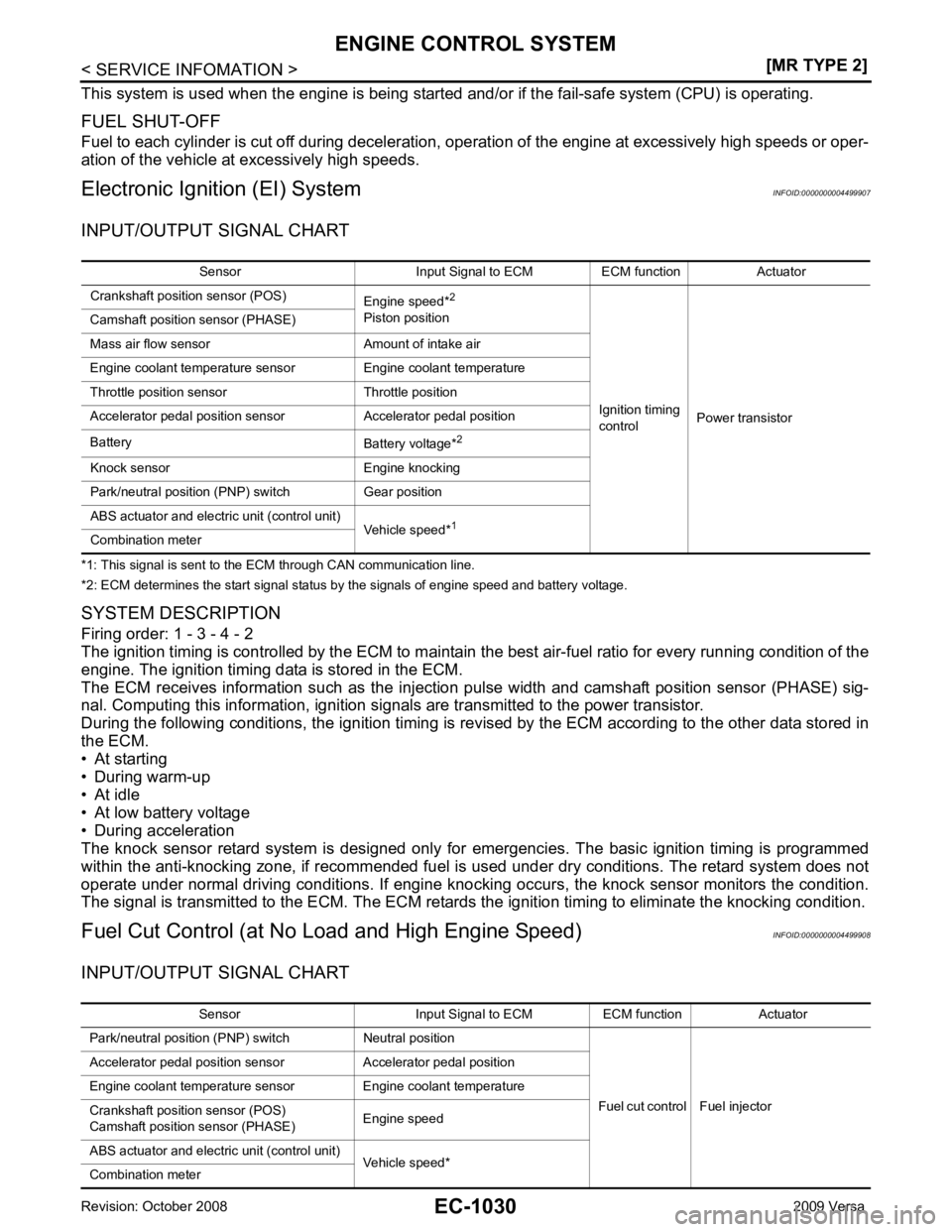

EC-1028< SERVICE INFOMATION >

[MR TYPE 2]

ENGINE CONTROL SYSTEM

*1: This sensor is not used to control the engine system under normal conditions.

*2: This signal is sent to the ECM through CAN communication line.

*3: ECM determines the start signal status by the signals of engine speed and battery voltage.

SYSTEM DESCRIPTION

The amount of fuel injected from the fuel injector is determined by the ECM. The ECM controls the length of

time the valve remains open (injection pulse duration). T he amount of fuel injected is a program value in the

ECM memory. The program value is preset by engi ne operating conditions. These conditions are determined

by input signals (for engine speed and intake air) from t he crankshaft position sensor (POS), camshaft position

sensor (PHASE) and the ma ss air flow sensor.

VARIOUS FUEL INJECTION I NCREASE/DECREASE COMPENSATION

In addition, the amount of fuel injected is compens ated to improve engine performance under various operat-

ing conditions as listed below.

• During warm-up

• When starting the engine

• During acceleration

• Hot-engine operation

• When selector lever is changed from N to D (A/T and CVT models)

• High-load, high-speed operation

• During deceleration

• During high engine speed operation

MIXTURE RATIO FEEDBACK CONTROL (CLOSED LOOP CONTROL) Sensor Input Signal to ECM ECM function Actuator

Crankshaft position sensor (POS) Engine speed*3

Piston position

Fuel injection

& mixture ratio

control Fuel injector

Camshaft position sensor (PHASE)

Mass air flow sensor Amount of intake air

Engine coolant temperature sensor Engine coolant temperature

Air fuel ratio (A/F) sensor 1 Density of oxygen in exhaust gas

Throttle position sensor Throttle position

Accelerator pedal position sensor Accelerator pedal position

Park/neutral position (PNP) switch Gear position

Battery Battery voltage*3

Knock sensor Engine knocking condition

EPS control unit Power steering operation*2

Heated oxygen sensor 2* 1

Density of oxygen in exhaust gas

Air conditioner switch Air conditioner operation*2

ABS actuator and electric unit (control unit)

Vehicle speed*2

Combination meter PBIB3020E

Page 2385 of 4331

![NISSAN LATIO 2009 Service Repair Manual ENGINE CONTROL SYSTEM

EC-1029

< SERVICE INFOMATION >

[MR TYPE 2] C

D E

F

G H

I

J

K L

M A EC

NP

O

The mixture ratio feedback system provides the best air/

fuel mixture ratio for drivability and emissio NISSAN LATIO 2009 Service Repair Manual ENGINE CONTROL SYSTEM

EC-1029

< SERVICE INFOMATION >

[MR TYPE 2] C

D E

F

G H

I

J

K L

M A EC

NP

O

The mixture ratio feedback system provides the best air/

fuel mixture ratio for drivability and emissio](/img/5/57359/w960_57359-2384.png)

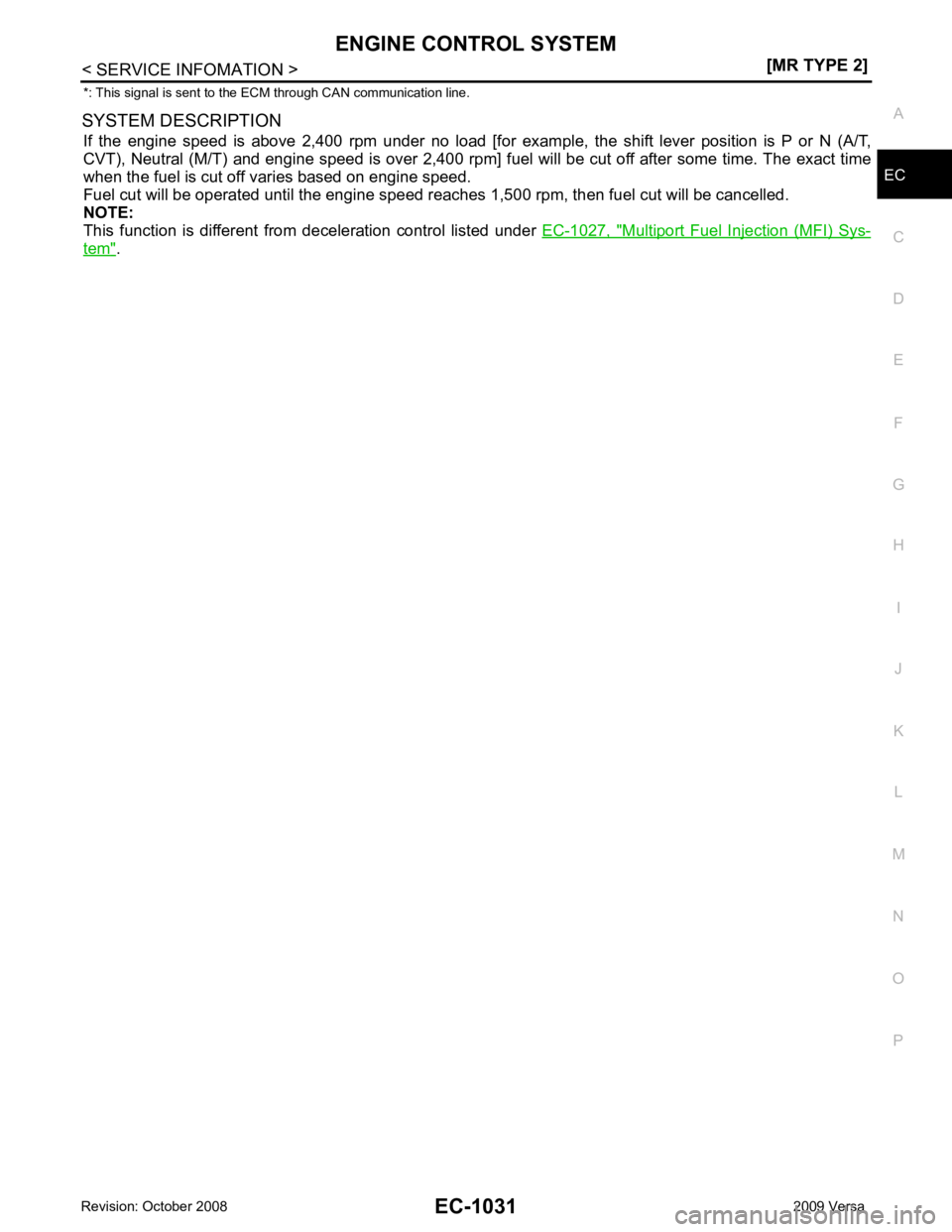

ENGINE CONTROL SYSTEM

EC-1029

< SERVICE INFOMATION >

[MR TYPE 2] C

D E

F

G H

I

J

K L

M A EC

NP

O

The mixture ratio feedback system provides the best air/

fuel mixture ratio for drivability and emission control.

The three way catalyst (manifold) can then better r educe CO, HC and NOx emissions. This system uses air

fuel ratio (A/F) sensor 1 in the exhaust manifold to monitor whether the engine operation is rich or lean. The

ECM adjusts the injection pulse width according to the sensor voltage signal. For more information about air

fuel ratio (A/F) sensor 1, refer to EC-1210 . This maintains the mixture ratio within the range of stoichiometric

(ideal air/fuel mixture).

This stage is referred to as the closed loop control condition.

Heated oxygen sensor 2 is located downstream of the th ree way catalyst (manifold). Even if the switching

characteristics of air fuel ratio (A/F) sensor 1 shift, the air/fuel ratio is controlled to stoichiometric by the signal

from heated oxygen sensor 2.

Open Loop Control The open loop system condition refers to when the ECM detects any of the following conditions. Feedback

control stops in order to maintain stabilized fuel combustion.

• Deceleration and acceleration

• High-load, high-speed operation

• Malfunction of air fuel ratio (A/F) sensor 1 or its circuit

• Insufficient activation of air fuel ratio (A /F) sensor 1 at low engine coolant temperature

• High engine coolant temperature

• During warm-up

• After shifting from N to D (A/T and CVT models)

• When starting the engine

MIXTURE RATIO SELF-LEARNING CONTROL The mixture ratio feedback control system monitors the mixture ratio signal transmitted from air fuel ratio (A/F)

sensor 1. This feedback signal is then sent to the ECM. The ECM controls the basic mixture ratio as close to

the theoretical mixture ratio as possible. However, the bas ic mixture ratio is not necessarily controlled as orig-

inally designed. Both manufacturing differences (i.e., mass air flow sensor hot wire) and characteristic

changes during operation (i.e., fuel injector clogging) directly affect mixture ratio.

Accordingly, the difference between the basic and theoretical mixture ratios is monitored in this system. This is

then computed in terms of “injection pulse duration” to automatically compensate for the difference between

the two ratios.

“Fuel trim” refers to the feedback compensation value co mpared against the basic injection duration. Fuel trim

includes short term fuel trim and long term fuel trim.

“Short term fuel trim” is the short-term fuel compensati on used to maintain the mixture ratio at its theoretical

value. The signal from air fuel ratio (A/F) sensor 1 i ndicates whether the mixture ratio is RICH or LEAN com-

pared to the theoretical value. The signal then triggers a r eduction in fuel volume if the mixture ratio is rich, and

an increase in fuel volume if it is lean.

“Long term fuel trim” is overall fuel compensation ca rried out long-term to compensate for continual deviation

of the short term fuel trim from the central value. Such deviation will occur due to individual engine differences,

wear over time and changes in the usage environment.

FUEL INJECTION TIMING

Two types of systems are used.

Sequential Multiport Fuel Injection System

Fuel is injected into each cylinder during each engine cycl e according to the firing order. This system is used

when the engine is running.

Simultaneous Multiport Fuel Injection System Fuel is injected simultaneously into all four cylinders twice each engine cycle. In other words, pulse signals of

the same width are simultaneously transmitted from the ECM.

The four fuel injectors will then receive the signals two times for each engine cycle. SEF337W

Page 2386 of 4331

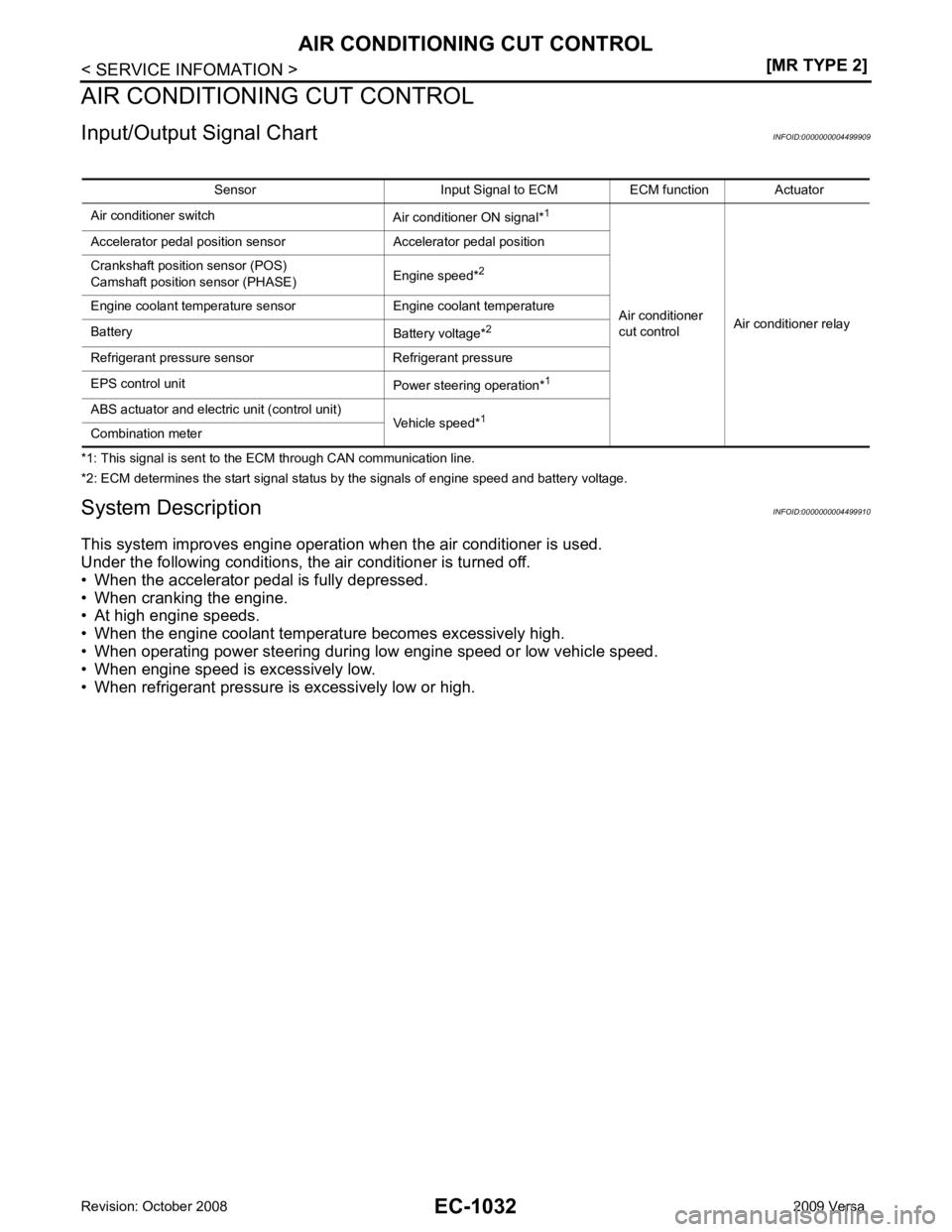

Sensor Input Signal to ECM ECM function Actuator

Park/neutral position (P NP) switch Neutral position

Fuel cut control Fuel injector

Accelerator pedal position sensor Accelerator pedal position

Engine coolant temperature sensor Engine coolant temperature

Crankshaft position sensor (POS)

Camshaft position sensor (PHASE) Engine speed

ABS actuator and electric unit (control unit) Vehicle speed*

Combination meter

Page 2387 of 4331

EC

NP

O

*: This signal is sent to the ECM through CAN communication line.

SYSTEM DESCRIPTION If the engine speed is above 2,400 rpm under no load [for ex ample, the shift lever position is P or N (A/T,

CVT), Neutral (M/T) and engine speed is over 2,400 rpm] f uel will be cut off after some time. The exact time

when the fuel is cut off varies based on engine speed.

Fuel cut will be operated until the engine speed reaches 1,500 rpm, then fuel cut will be cancelled.

NOTE:

This function is different from deceleration control listed under EC-1027, " Multiport Fuel Injection (MFI) Sys-

tem " .

Page 2388 of 4331

Page 2389 of 4331

EC

NP

O

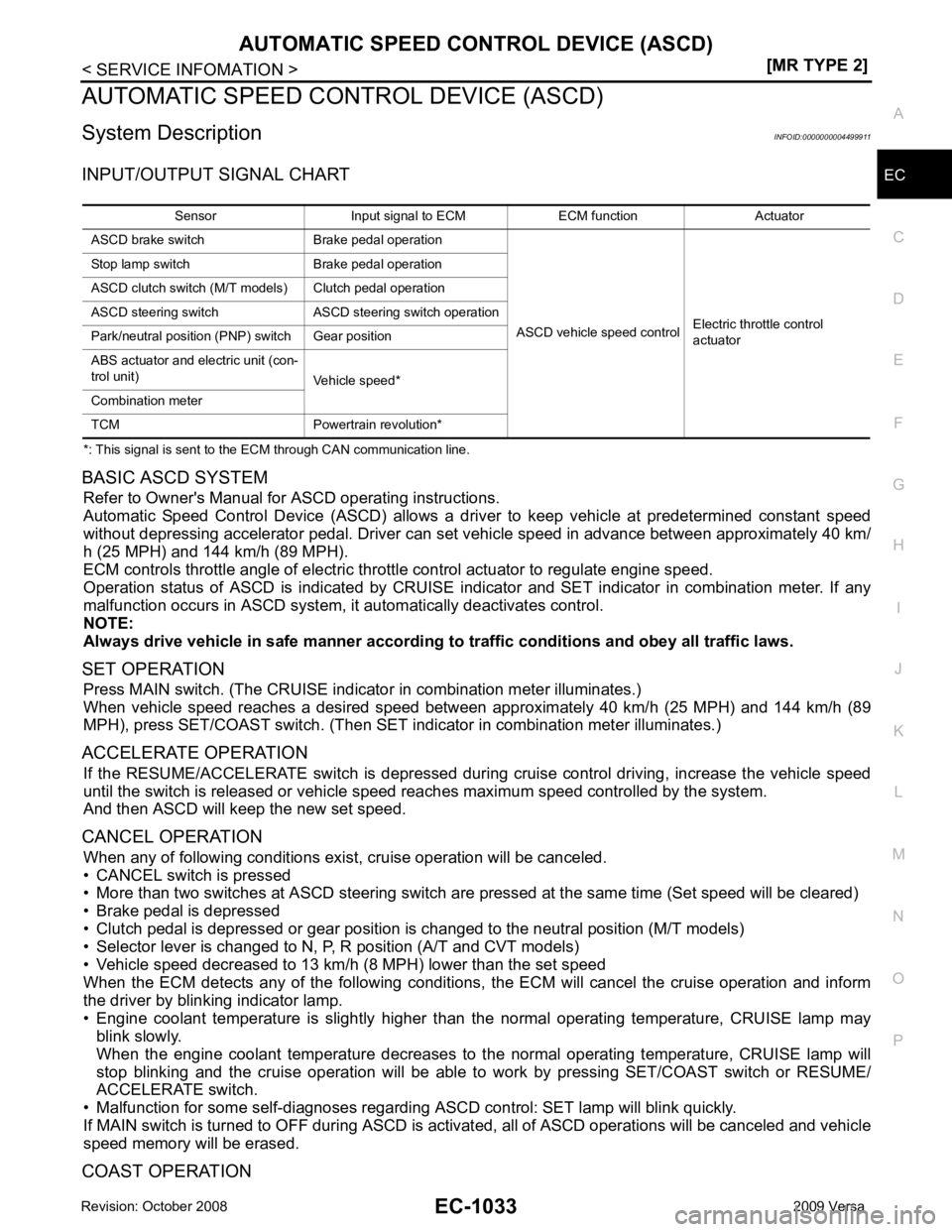

AUTOMATIC SPEED CONTROL DEVICE (ASCD)

System Description INFOID:0000000004499911

INPUT/OUTPUT SIGNAL CHART

*: This signal is sent to the ECM through CAN communication line.

BASIC ASCD SYSTEM Refer to Owner's Manual for ASCD operating instructions.

Automatic Speed Control Device (ASCD) allows a driver to keep vehicle at predetermined constant speed

without depressing accelerator pedal. Driver can set vehicle speed in advance between approximately 40 km/

h (25 MPH) and 144 km/h (89 MPH).

ECM controls throttle angle of electric thro ttle control actuator to regulate engine speed.

Operation status of ASCD is indicated by CRUISE i ndicator and SET indicator in combination meter. If any

malfunction occurs in ASCD system, it automatically deactivates control.

NOTE:

Always drive vehicle in safe manner according to traffic conditions and obey all traffic laws.

SET OPERATION Press MAIN switch. (The CRUISE indicato r in combination meter illuminates.)

When vehicle speed reaches a desired speed between appr oximately 40 km/h (25 MPH) and 144 km/h (89

MPH), press SET/COAST switch. (Then SET indi cator in combination meter illuminates.)

ACCELERATE OPERATION If the RESUME/ACCELERATE switch is depressed during cruise control driving, increase the vehicle speed

until the switch is released or vehicle speed reaches maximum speed controlled by the system.

And then ASCD will keep the new set speed.

CANCEL OPERATION When any of following conditions exis t, cruise operation will be canceled.

• CANCEL switch is pressed

• More than two switches at ASCD steering switch are pressed at the same time (Set speed will be cleared)

• Brake pedal is depressed

• Clutch pedal is depressed or gear position is changed to the neutral position (M/T models)

• Selector lever is changed to N, P, R position (A/T and CVT models)

• Vehicle speed decreased to 13 km/h (8 MPH) lower than the set speed

When the ECM detects any of the following conditions, the ECM will cancel the cruise operation and inform

the driver by blinking indicator lamp.

• Engine coolant temperature is slightly higher than the normal operating temperature, CRUISE lamp may

blink slowly.

When the engine coolant temperature decreases to t he normal operating temperature, CRUISE lamp will

stop blinking and the cruise operation will be able to work by pressing SET/COAST switch or RESUME/

ACCELERATE switch.

• Malfunction for some self-diagnoses regarding ASCD control: SET lamp will blink quickly.

If MAIN switch is turned to OFF during ASCD is activated, all of ASCD operations will be canceled and vehicle

speed memory will be erased.

COAST OPERATION Sensor Input signal to ECM ECM function Actuator

ASCD brake switch Brake pedal operation

ASCD vehicle speed controlElectric throttle control

actuator

Stop lamp switch Brake pedal operation

ASCD clutch switch (M/T models) Clutch pedal operation

ASCD steering switch ASCD steering switch operation

Park/neutral position (PNP) switch Gear position

ABS actuator and electric unit (con-

trol unit) Vehicle speed*

Combination meter

TCM Powertrain revolution*

Page 2390 of 4331

.

ASCD BRAKE SWITCH

Refer to EC-1429 and

EC-1495 .

ASCD CLUTCH SWITCH

Refer to EC-1429 and

EC-1495 .

STOP LAMP SWITCH

Refer to EC-1429 ,

EC-1443 and

EC-1495 .

ELECTRIC THROTTLE CONTROL ACTUATOR

Refer to EC-1447 ,

EC-1451 ,

EC-1457 and

EC-1462 .

ASCD INDICATOR

Refer to EC-1503 .