NISSAN LATIO 2009 Service Repair Manual

Manufacturer: NISSAN, Model Year: 2009, Model line: LATIO, Model: NISSAN LATIO 2009Pages: 4331, PDF Size: 58.04 MB

Page 2371 of 4331

EC

NP

O

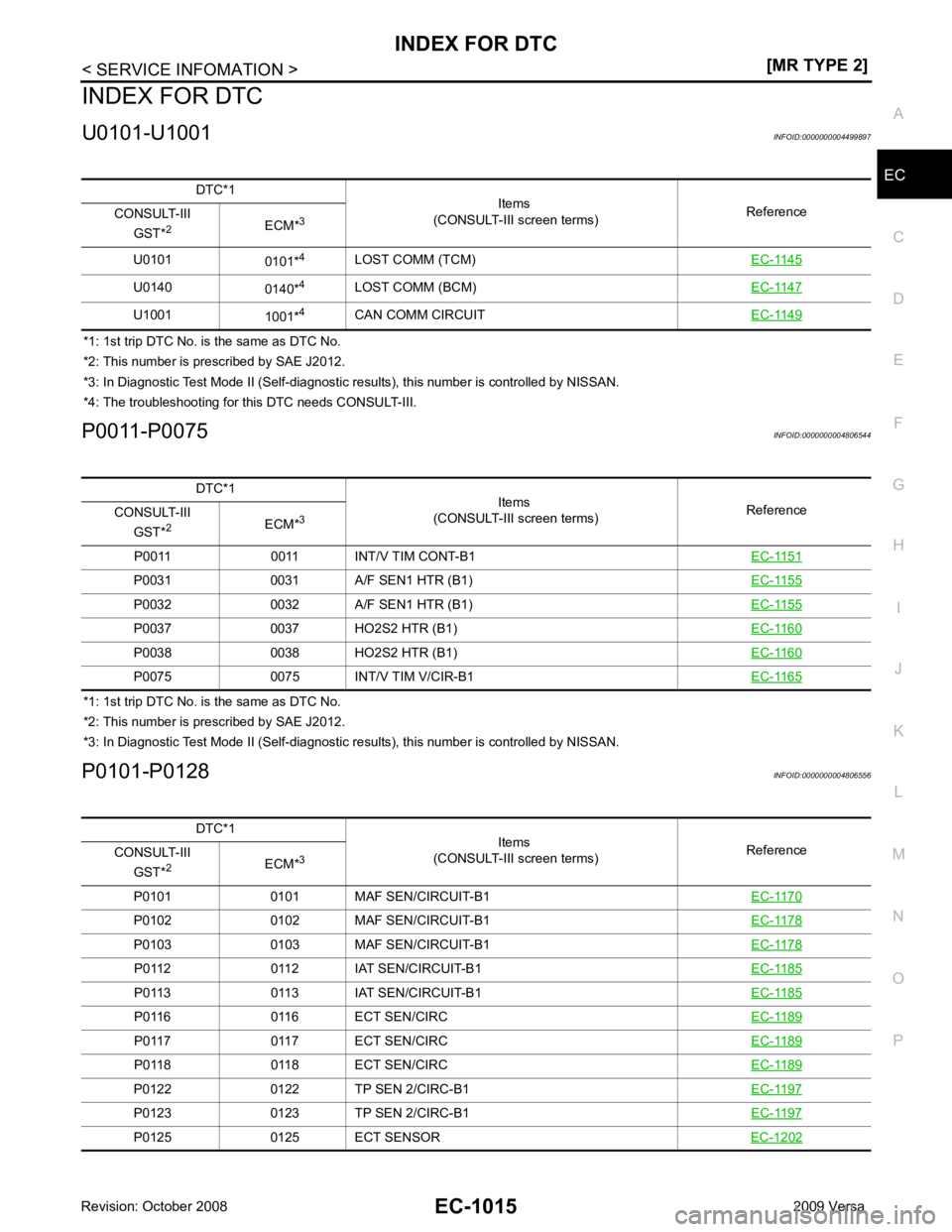

INDEX FOR DTC

U0101-U1001 INFOID:0000000004499897

*1: 1st trip DTC No. is the same as DTC No.

*2: This number is prescribed by SAE J2012.

*3: In Diagnostic Test Mode II (Self-diagnostic results), this number is controlled by NISSAN.

*4: The troubleshooting for this DTC needs CONSULT-III.

P0011-P0075 INFOID:0000000004806544

*1: 1st trip DTC No. is the same as DTC No.

*2: This number is prescribed by SAE J2012.

*3: In Diagnostic Test Mode II (Self-diagnostic results), this number is controlled by NISSAN.

P0101-P0128 INFOID:0000000004806556

DTC*1

Items

(CONSULT-III screen terms) Reference

CONSULT-III

GST* 2

ECM*3

U0101 0101*4

LOST COMM (TCM) EC-1145U0140

0140*4

LOST COMM (BCM) EC-1147U1001

1001*4

CAN COMM CIRCUIT EC-1149DTC*1

Items

(CONSULT-III screen terms) Reference

CONSULT-III

GST* 2

ECM*3

P0011 0011 INT/V TIM CONT-B1 EC-1151P0031 0031 A/F SEN1 HTR (B1)

EC-1155P0032 0032 A/F SEN1 HTR (B1)

EC-1155P0037 0037 HO2S2 HTR (B1)

EC-1160P0038 0038 HO2S2 HTR (B1)

EC-1160P0075 0075 INT/V TIM V/CIR-B1

EC-1165DTC*1

Items

(CONSULT-III screen terms) Reference

CONSULT-III

GST* 2

ECM*3

P0101 0101 MAF SEN/CIRCUIT-B1 EC-1170P0102 0102 MAF SEN/CIRCUIT-B1

EC-1178P0103 0103 MAF SEN/CIRCUIT-B1

EC-1178P0112 0112 IAT SEN/CIRCUIT-B1

EC-1185P0113 0113 IAT SEN/CIRCUIT-B1

EC-1185P0116 0116 ECT SEN/CIRC

EC-1189P0117 0117 ECT SEN/CIRC

EC-1189P0118 0118 ECT SEN/CIRC

EC-1189P0122 0122 TP SEN 2/CIRC-B1

EC-1197P0123 0123 TP SEN 2/CIRC-B1

EC-1197P0125 0125 ECT SENSOR

EC-1202

Page 2372 of 4331

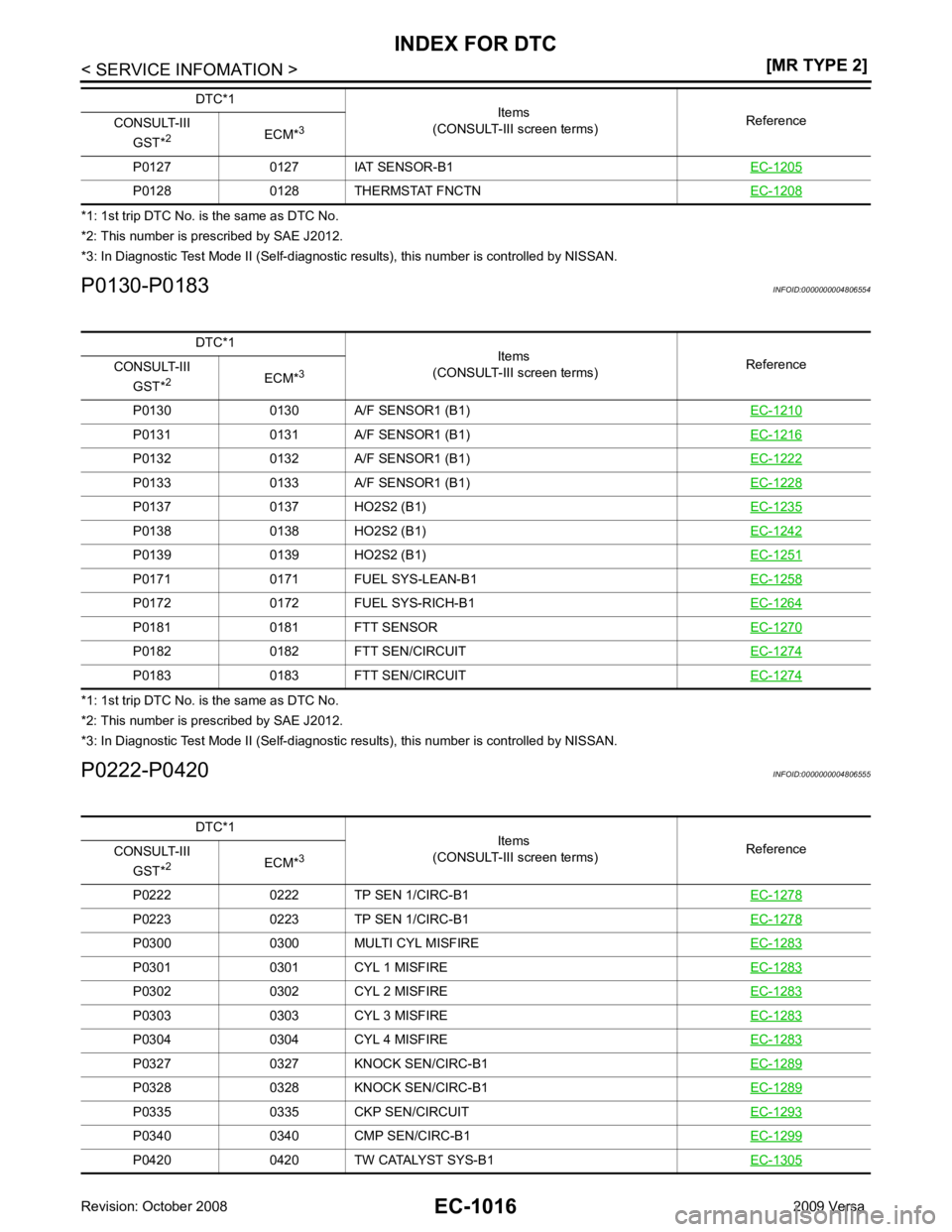

P0128 0128 THERMSTAT FNCTN

EC-1208DTC*1

Items

(CONSULT-III screen terms) Reference

CONSULT-III

GST* 2

ECM*3 P0131 0131 A/F SENSOR1 (B1)

EC-1216P0132 0132 A/F SENSOR1 (B1)

EC-1222P0133 0133 A/F SENSOR1 (B1)

EC-1228P0137 0137 HO2S2 (B1)

EC-1235P0138 0138 HO2S2 (B1)

EC-1242P0139 0139 HO2S2 (B1)

EC-1251P0171 0171 FUEL SYS-LEAN-B1

EC-1258P0172 0172 FUEL SYS-RICH-B1

EC-1264P0181 0181 FTT SENSOR

EC-1270P0182 0182 FTT SEN/CIRCUIT

EC-1274P0183 0183 FTT SEN/CIRCUIT

EC-1274DTC*1

Items

(CONSULT-III screen terms) Reference

CONSULT-III

GST* 2

ECM*3

P0222 0222 TP SEN 1/CIRC-B1 EC-1278P0223 0223 TP SEN 1/CIRC-B1

EC-1278P0300 0300 MULTI CYL MISFIRE

EC-1283P0301 0301 CYL 1 MISFIRE

EC-1283P0302 0302 CYL 2 MISFIRE

EC-1283P0303 0303 CYL 3 MISFIRE

EC-1283P0304 0304 CYL 4 MISFIRE

EC-1283P0327 0327 KNOCK SEN/CIRC-B1

EC-1289P0328 0328 KNOCK SEN/CIRC-B1

EC-1289P0335 0335 CKP SEN/CIRCUIT

EC-1293P0340 0340 CMP SEN/CIRC-B1

EC-1299P0420 0420 TW CATALYST SYS-B1

EC-1305

Page 2373 of 4331

EC

NP

O

*1: 1st trip DTC No. is

the same as DTC No.

*2: This number is prescribed by SAE J2012.

*3: In Diagnostic Test Mode II (Self-diagnostic results), this number is controlled by NISSAN.

P0441-P0463 INFOID:0000000004806553

*1: 1st trip DTC No. is the same as DTC No.

*2: This number is prescribed by SAE J2012.

*3: In Diagnostic Test Mode II (Self-diagnostic results), this number is controlled by NISSAN.

P0500-P0643 INFOID:0000000004806552

*1: 1st trip DTC No. is the same as DTC No.

*2: This number is prescribed by SAE J2012.

*3: In Diagnostic Test Mode II (Self-diagnostic results), this number is controlled by NISSAN.

DTC*1

Items

(CONSULT-III screen terms) Reference

CONSULT-III

GST* 2

ECM*3

P0441 0441 EVAP PURG FLOW/MON EC-1310P0442 0442 EVAP SMALL LEAK

EC-1315P0443 0443 PURG VOLUME CONT/V

EC-1322P0444 0444 PURG VOLUME CONT/V

EC-1330P0445 0445 PURG VOLUME CONT/V

EC-1330P0447 0447 VENT CONTROL VALVE

EC-1336P0448 0448 VENT CONTROL VALVE

EC-1342P0451 0451 EVAP SYS PRES SEN

EC-1348P0452 0452 EVAP SYS PRES SEN

EC-1351P0453 0453 EVAP SYS PRES SEN

EC-1358P0455 0455 EVAP GROSS LEAK

EC-1366P0456 0456 EVAP VERY SML LEAK

EC-1373P0460 0460 FUEL LEV SEN SLOSH

EC-1381P0461 0461 FUEL LEVEL SENSOR

EC-1383P0462 0462 FUEL LEVL SEN/CIRC

EC-1385P0463 0463 FUEL LEVL SEN/CIRC

EC-1385DTC*1

Items

(CONSULT-III screen terms) Reference

CONSULT-III

GST* 2

ECM*3

P0500 0500 VEH SPEED SEN/CIRC EC-1387P0506 0506 ISC SYSTEM

EC-1389P0507 0507 ISC SYSTEM

EC-1391P0605 0605 ECM

EC-1393P0607 0607 ECM

EC-1395P0643 0643 SENSOR POWER/CIRC

EC-1396

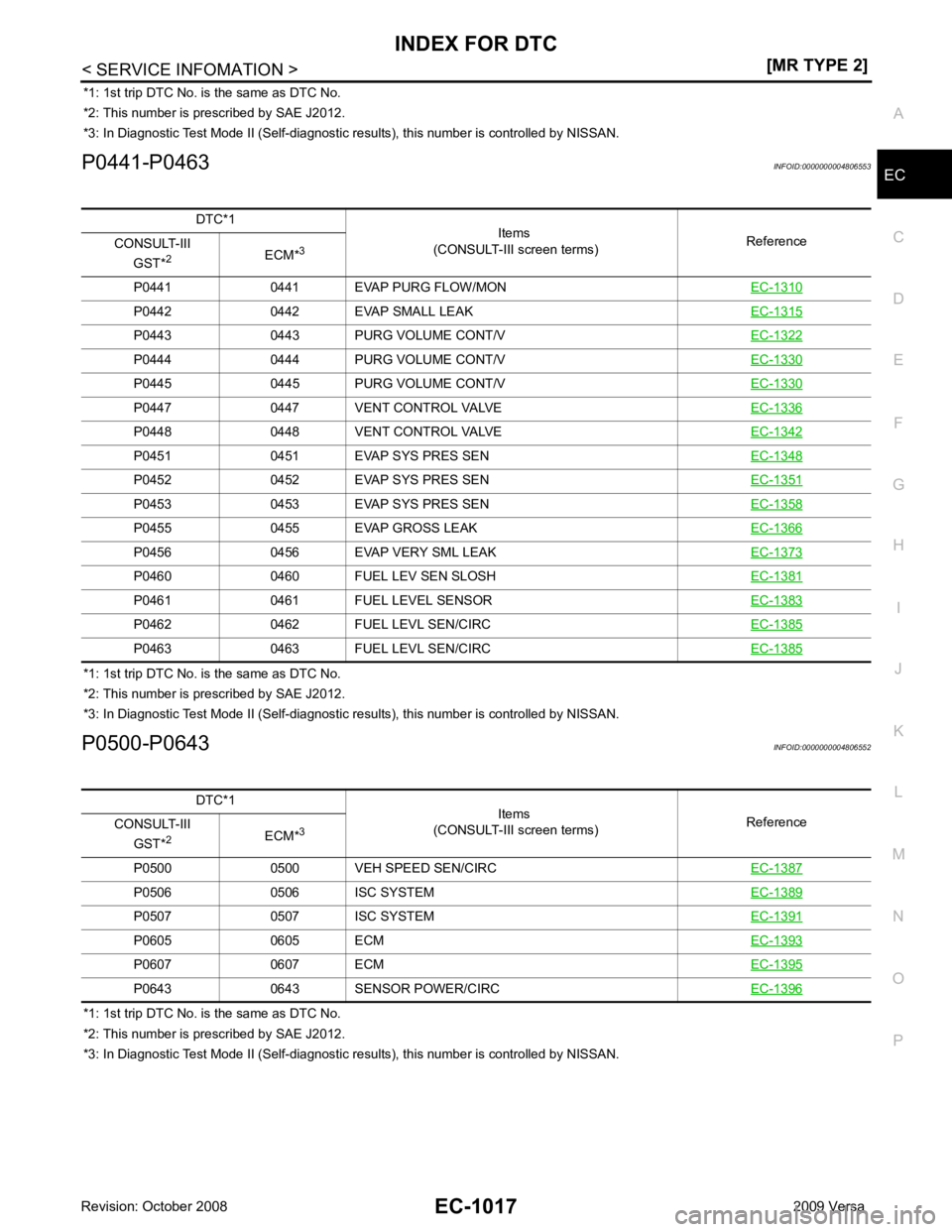

Page 2374 of 4331

(A/T)

CVT-244 (CVT)

P0710 0710 ATF TEMP SEN/CIRC*4

AT-96 (A/T)

CVT-249 (CVT)

P0715 0715 INPUT SPD SEN/CIRC CVT-254P0720 0720 VEH SPD SEN/CIR AT

AT-101 (A/T)

CVT-258 (CVT)

P0725 0725 ENGINE SPEED SIG AT-106P0731 0731

A/T 1ST GR FNCTN*4

AT-110P0732 0732

A/T 2ND GR FNCTN*4

AT-113P0733 0733

A/T 3RD GR FNCTN*4

AT-116P0734 0734

A/T 4TH GR FNCTN*4

AT-119DTC*1

Items

(CONSULT-III screen terms) Reference

CONSULT-III

GST* 2

ECM*3

P0740 0740 TCC SOLENOID/CIRC AT-124 (A/T)

CVT-266 (CVT)

P0744 0744 A/T TCC S/V FNCTN AT-129 (A/T)

CVT-271 (CVT)

P0745 0745 L/PRESS SOL/CIRC AT-134 (A/T)

CVT-273 (CVT)

P0746 0746 PRS CNT SOL/A FCTN CVT-278P0750 0750 SFT SOL A/CIRC

AT-139P0755 0755 SFT SOL B/CIRC

AT-144P0776 0776 PRS CNT SOL/B FCTN

CVT-280P0778 0778 PRS CNT SOL/B CIRC

CVT-282P0840 0840 TR PRS SENS/A CIRC

CVT-287

Page 2375 of 4331

EC

NP

O

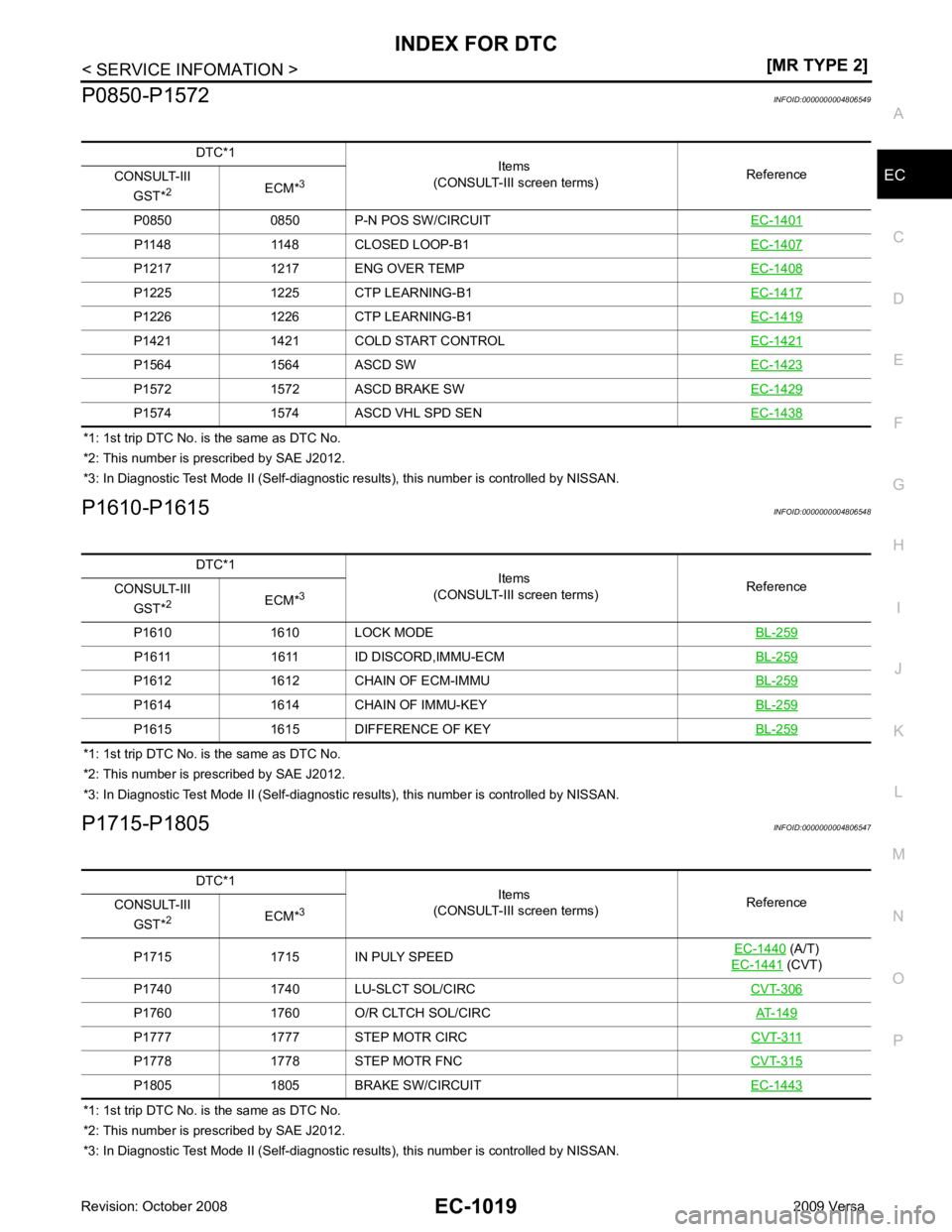

P0850-P1572

INFOID:0000000004806549

*1: 1st trip DTC No. is the same as DTC No.

*2: This number is prescribed by SAE J2012.

*3: In Diagnostic Test Mode II (Self-diagnostic results), this number is controlled by NISSAN.

P1610-P1615 INFOID:0000000004806548

*1: 1st trip DTC No. is the same as DTC No.

*2: This number is prescribed by SAE J2012.

*3: In Diagnostic Test Mode II (Self-diagnostic results), this number is controlled by NISSAN.

P1715-P1805 INFOID:0000000004806547

*1: 1st trip DTC No. is the same as DTC No.

*2: This number is prescribed by SAE J2012.

*3: In Diagnostic Test Mode II (Self-diagnostic results), this number is controlled by NISSAN.

DTC*1

Items

(CONSULT-III screen terms) Reference

CONSULT-III

GST* 2

ECM*3

P0850 0850 P-N POS SW/CIRCUIT EC-1401P1148 1148 CLOSED LOOP-B1

EC-1407P1217 1217 ENG OVER TEMP

EC-1408P1225 1225 CTP LEARNING-B1

EC-1417P1226 1226 CTP LEARNING-B1

EC-1419P1421 1421 COLD START CONTROL

EC-1421P1564 1564 ASCD SW

EC-1423P1572 1572 ASCD BRAKE SW

EC-1429P1574 1574 ASCD VHL SPD SEN

EC-1438DTC*1

Items

(CONSULT-III screen terms) Reference

CONSULT-III

GST* 2

ECM*3

P1610 1610 LOCK MODE BL-259P1611 1611 ID DISCORD,IMMU-ECM

BL-259P1612 1612 CHAIN OF ECM-IMMU

BL-259P1614 1614 CHAIN OF IMMU-KEY

BL-259P1615 1615 DIFFERENCE OF KEY

BL-259DTC*1

Items

(CONSULT-III screen terms) Reference

CONSULT-III

GST* 2

ECM*3

P1715 1715 IN PULY SPEED EC-1440 (A/T)

EC-1441 (CVT)

P1740 1740 LU-SLCT SOL/CIRC CVT-306P1760 1760 O/R CLTCH SOL/CIRC

AT-149P1777 1777 STEP MOTR CIRC

CVT-311P1778 1778 STEP MOTR FNC

CVT-315P1805 1805 BRAKE SW/CIRCUIT

EC-1443

Page 2376 of 4331

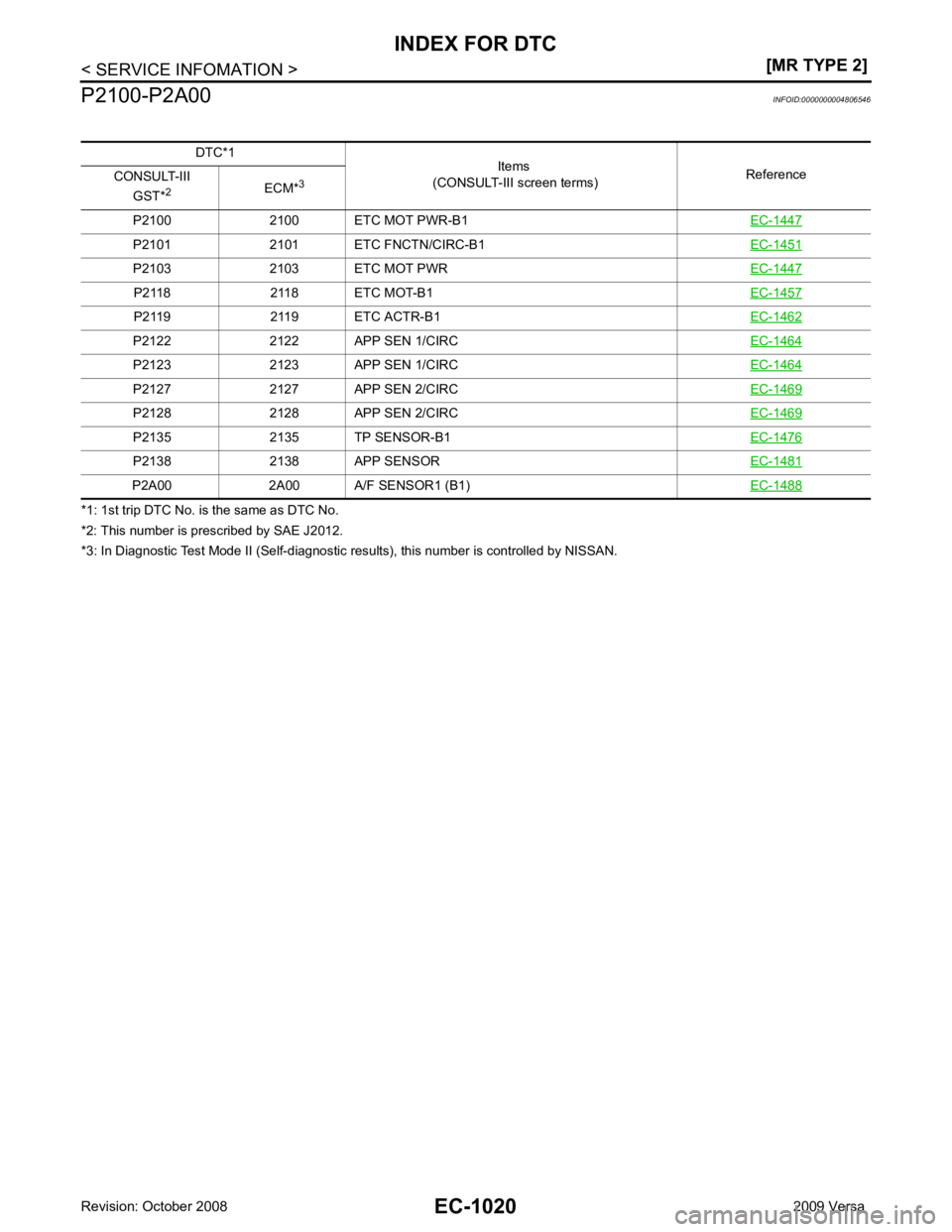

P2101 2101 ETC FNCTN/CIRC-B1

EC-1451P2103 2103 ETC MOT PWR

EC-1447P2118 2118 ETC MOT-B1

EC-1457P2119 2119 ETC ACTR-B1

EC-1462P2122 2122 APP SEN 1/CIRC

EC-1464P2123 2123 APP SEN 1/CIRC

EC-1464P2127 2127 APP SEN 2/CIRC

EC-1469P2128 2128 APP SEN 2/CIRC

EC-1469P2135 2135 TP SENSOR-B1

EC-1476P2138 2138 APP SENSOR

EC-1481P2A00 2A00 A/F SENSOR1 (B1)

EC-1488

Page 2377 of 4331

![NISSAN LATIO 2009 Service Repair Manual PRECAUTIONS

EC-1021

< SERVICE INFOMATION >

[MR TYPE 2] C

D E

F

G H

I

J

K L

M A EC

NP

O

PRECAUTIONS

Precaution for Supplemental Restraint System (SRS) "AIR BAG" and "SEAT BELT

PRE-TENSIONER" INFOID:0 NISSAN LATIO 2009 Service Repair Manual PRECAUTIONS

EC-1021

< SERVICE INFOMATION >

[MR TYPE 2] C

D E

F

G H

I

J

K L

M A EC

NP

O

PRECAUTIONS

Precaution for Supplemental Restraint System (SRS) "AIR BAG" and "SEAT BELT

PRE-TENSIONER" INFOID:0](/img/5/57359/w960_57359-2376.png)

PRECAUTIONS

EC-1021

< SERVICE INFOMATION >

[MR TYPE 2] C

D E

F

G H

I

J

K L

M A EC

NP

O

PRECAUTIONS

Precaution for Supplemental Restraint System (SRS) "AIR BAG" and "SEAT BELT

PRE-TENSIONER" INFOID:0000000004499899

The Supplemental Restraint System such as “A IR BAG” and “SEAT BELT PRE-TENSIONER”, used along

with a front seat belt, helps to reduce the risk or severi ty of injury to the driver and front passenger for certain

types of collision. This system includes seat belt switch inputs and dual stage front air bag modules. The SRS

system uses the seat belt switches to determine the front air bag deployment, and may only deploy one front

air bag, depending on the severity of a collision and w hether the front occupants are belted or unbelted.

Information necessary to service the system safely is included in the “SUPPLEMENTAL RESTRAINT SYS-

TEM” and “SEAT BELTS” of this Service Manual.

WARNING:

• To avoid rendering the SRS inoper ative, which could increase the risk of personal injury or death in

the event of a collision which would result in air bag inflation, all maintenance must be performed by

an authorized NISSAN/INFINITI dealer.

• Improper maintenance, including in correct removal and installation of the SRS, can lead to personal

injury caused by unintentional act ivation of the system. For removal of Spiral Cable and Air Bag

Module, see the “SUPPLEMEN TAL RESTRAINT SYSTEM”.

• Do not use electrical test equipm ent on any circuit related to the SRS unless instructed to in this

Service Manual. SRS wiring harnesses can be identi fied by yellow and/or orange harnesses or har-

ness connectors.

PRECAUTIONS WHEN USING POWER TOOLS (AIR OR ELECTRIC) AND HAMMERS WARNING:

• When working near the Airbag Diagnosis Sensor Un it or other Airbag System sensors with the igni-

tion ON or engine running, DO NOT use air or el ectric power tools or strike near the sensor(s) with a

hammer. Heavy vibration could activate the sensor( s) and deploy the air bag(s), possibly causing

serious injury.

• When using air or electric power tools or hammers , always switch the ignition OFF, disconnect the

battery, and wait at least 3 minutes before performing any service.

Precaution for Procedur e without Cowl Top Cover INFOID:0000000004499900

When performing the procedure after removing cowl top cover, cover

the lower end of windshield with urethane, etc.

On Board Diagnosis (OBD) Syst em of Engine and A/T, CVT INFOID:0000000004499901

The ECM has an on board diagnostic system . It will light up the malfunction indicator lamp (MIL) to warn the

driver of a malfunction causing emission deterioration.

CAUTION:

• Be sure to turn the ignition sw itch OFF and disconnect the battery ground cable before any repair or

inspection work. The open/short circuit of relate d switches, sensors, solenoid valves, etc. will cause

the MIL to light up.

• Be sure to connect and lock the connectors secure ly after work. A loose (unlocked) connector will

cause the MIL to light up due to the open circuit. (Be sure the connector is free from water, grease,

dirt, bent terminals, etc.)

• Certain systems and components, especially those related to OBD, may use a new style slide-lock-

ing type harness connector. For descripti on and how to disconnect, refer to PG-64 .

• Be sure to route and secure the harnesses properly after work. The interference of the harness with

a bracket, etc. may cause the MIL to li ght up due to the short circuit. PIIB3706J

Page 2378 of 4331

![NISSAN LATIO 2009 Service Repair Manual EC-1022< SERVICE INFOMATION >

[MR TYPE 2]

PRECAUTIONS

• Be sure to connect rubber tubes properly afte r work. A misconnected or disconnected rubber tube

may cause the MIL to light up d NISSAN LATIO 2009 Service Repair Manual EC-1022< SERVICE INFOMATION >

[MR TYPE 2]

PRECAUTIONS

• Be sure to connect rubber tubes properly afte r work. A misconnected or disconnected rubber tube

may cause the MIL to light up d](/img/5/57359/w960_57359-2377.png)

EC-1022< SERVICE INFOMATION >

[MR TYPE 2]

PRECAUTIONS

• Be sure to connect rubber tubes properly afte r work. A misconnected or disconnected rubber tube

may cause the MIL to light up due to the malfunction of the fuel injection system, etc.

• Be sure to erase the unnecessary malfunction info rmation (repairs completed) from the ECM and

TCM (Transmission control module) before returning the vehicle to the customer.

Precaution INFOID:0000000004499902

• Always use a 12 volt battery as power source.

• Do not attempt to disconnect battery cables while engine is

running.

• Before connecting or disconnecting the ECM harness con-

nector, turn ignition switch OFF and disconnect negative bat-

tery cable. Failure to do so may damage the ECM because

battery voltage is applied to ECM even if ignition switch is

turned OFF.

• Before removing parts, turn ig nition switch OFF and then dis-

connect negative battery cable.

• Do not disassemble ECM.

• If battery cable is disconnected, the memory will return to the

initial ECM values.

The ECM will now start to self-c ontrol at its initial values.

Engine operation can vary slight ly in this case. However, this

is not an indication of a malf unction. Do not replace parts

because of a slight variation.

• If the battery is disconnected, the following emission-related

diagnostic information will be lost within 24 hours.

- Diagnostic trouble codes

- 1st trip diagnostic trouble codes

- Freeze frame data

- 1st trip freeze frame data

- System readiness test (SRT) codes

- Test values

• When connecting ECM harness connector, fasten (B) it

securely with a lever (1) as far as it will go as shown in the fig-

ure.

- ECM (2)

- Loosen (A)

• When connecting or disconnect ing pin connectors into or

from ECM, take care not to damage pin terminals (bend or

break).

Make sure that there are not any bends or breaks on ECM pin

terminal, when connecting pin connectors.

• Securely connect ECM harness connectors.

A poor connection can cause an extremely high (surge) volt-

age to develop in coil and co ndenser, thus resulting in dam-

age to ICs.

• Keep engine control system harness at least 10 cm (4 in) away

from adjacent harness, to preven t engine control system mal-

functions due to receiving exter nal noise, degraded operation

of ICs, etc. SEF289H

PBIA9222J

PBIB2947E

PBIB0090E

Page 2379 of 4331

![NISSAN LATIO 2009 Service Repair Manual PRECAUTIONS

EC-1023

< SERVICE INFOMATION >

[MR TYPE 2] C

D E

F

G H

I

J

K L

M A EC

NP

O

•

Keep engine control system parts and harness dry.

• Before replacing ECM, perform “ECM Terminals an NISSAN LATIO 2009 Service Repair Manual PRECAUTIONS

EC-1023

< SERVICE INFOMATION >

[MR TYPE 2] C

D E

F

G H

I

J

K L

M A EC

NP

O

•

Keep engine control system parts and harness dry.

• Before replacing ECM, perform “ECM Terminals an](/img/5/57359/w960_57359-2378.png)

PRECAUTIONS

EC-1023

< SERVICE INFOMATION >

[MR TYPE 2] C

D E

F

G H

I

J

K L

M A EC

NP

O

•

Keep engine control system parts and harness dry.

• Before replacing ECM, perform “ECM Terminals and Refer-

ence Value” inspection and m ake sure ECM functions prop-

erly. Refer to EC-1109, " ECM Terminal and Reference Value " .

• Handle mass air flow sensor carefully to avoid damage.

• Do not disassemble mass air flow sensor.

• Do not clean mass air flow senso r with any type of detergent.

• Do not disassemble electric th rottle control actuator.

• Even a slight leak in the air intake system can cause serious

incidents.

• Do not shock or jar the camsh aft position sensor (PHASE),

crankshaft position sensor (POS).

• After performing each TROUBL E DIAGNOSIS, perform DTC

Confirmation Procedure or Overall Function Check.

The DTC should not be displ ayed in the DTC Confirmation

Procedure if the repair is completed. The Overall Function

Check should be a good result if the repair is completed.

• When measuring ECM signals with a circuit tester, never allow

the two tester probes to contact.

Accidental contact of probes will cause a short circuit and

damage the ECM power transistor.

• Do not use ECM ground termina ls when measuring input/out-

put voltage. Doing so may result in damage to the ECM's tran-

sistor. Use a ground other than ECM terminals, such as the

ground. MEF040D

SEF217U

SEF348N

Page 2380 of 4331

![NISSAN LATIO 2009 Service Repair Manual EC-1024< SERVICE INFOMATION >

[MR TYPE 2]

PRECAUTIONS

• Do not operate fuel pump when there is no fuel in lines.

• Tighten fuel hose clamps to the specified torque.

- Fuel level sensor unit and NISSAN LATIO 2009 Service Repair Manual EC-1024< SERVICE INFOMATION >

[MR TYPE 2]

PRECAUTIONS

• Do not operate fuel pump when there is no fuel in lines.

• Tighten fuel hose clamps to the specified torque.

- Fuel level sensor unit and](/img/5/57359/w960_57359-2379.png)

EC-1024< SERVICE INFOMATION >

[MR TYPE 2]

PRECAUTIONS

• Do not operate fuel pump when there is no fuel in lines.

• Tighten fuel hose clamps to the specified torque.

- Fuel level sensor unit and fuel pump (1)

- Fuel pressure regulator (2)

- Fuel level sensor (3)

- Fuel tank temperature sensor (4)

• Do not depress accelerator pedal when starting.

• Immediately after starting, do not rev up engine unnecessar-

ily.

• Do not rev up engine just prior to shutdown.

• When installing C.B. ham radio or a mobile phone, be sure to

observe the following as it m ay adversely affect electronic

control systems depending on installation location.

- Keep the antenna as far as possi ble from the electronic con-

trol units.

- Keep the antenna feeder line more than 20 cm (8 in) away

from the harness of electronic controls.

Do not let them run parallel for a long distance.

- Adjust the antenna and feeder line so that the standing-wave

radio can be kept smaller.

- Be sure to ground the radio to vehicle body. BBIA0704E

SEF709Y

SEF708Y