NISSAN LATIO 2009 Service Repair Manual

Manufacturer: NISSAN, Model Year: 2009, Model line: LATIO, Model: NISSAN LATIO 2009Pages: 4331, PDF Size: 58.04 MB

Page 2751 of 4331

EC

NP

O

DTC P0607 ECM

Description INFOID:0000000004501091

CAN (Controller Area Network) is a serial communication li ne for real time application. It is an on-vehicle mul-

tiplex communication line with high data communication speed and excellent error detection ability. Many elec-

tronic control units are equipped onto a vehicle, and each control unit shares information and links with other

control units during operation (not independent). In CAN communication, control units are connected with 2

communication lines (CAN H line, CAN L line) allowing a high rate of information transmission with less wiring.

Each control unit transmits/receives data but selectively reads required data only.

On Board Diagnosis Logic INFOID:0000000004306009

This self-diagnosis has the one trip detection logic (A/T and CVT).

The MIL will not light up for this self-diagnosis (M/T).

DTC Confirmation Procedure INFOID:0000000004306010

1. Turn ignition switch ON.

2. Check 1st trip DTC.

3. If 1st trip DTC is detected, go to EC-1395, " Diagnosis Procedure " .

Diagnosis Procedure INFOID:0000000004306011DTC Confirmation Procedure " .

3. Is the 1st trip DTC P0607 displayed again?

Yes or No Yes >> GO TO 2.

No >> INSPECTION END ECM Re-communicating Function " .

3. Perform EC-1084, " VIN Registration " .

4. Perform EC-1084, " Accelerator Pedal Released Position Learning " .

5. Perform EC-1084, " Throttle Valve Closed Position Learning " .

6. Perform EC-1084, " Idle Air Volume Learning " .

>> INSPECTION END

DTC No. Trouble diagnosis name DTC detecting condition Possible cause

P0607

0607 CAN communication bus

When detecting error during the initial diagno-

sis for CAN controller of each control unit. • ECM

Page 2752 of 4331

Diagnosis Procedure " .

DTC No.

Trouble diagnosis

name DTC detecting condition Possible cause

P0643

0643 Sensor power supply

circuit short ECM detects a voltage of power source for

sensor is excessively low or high. • Harness or connectors

(APP sensor 1 circuit is shorted.)

(Throttle position sensor circuit is shorted.)

[Camshaft position sensor (PHASE) circuit is

shorted.]

• Accelerator pedal position sensor

• Throttle position sensor

• Camshaft position sensor (PHASE) Engine operation condition in fail-safe mode

ECM stops the electric throttle control actuator control, throttle valve is maintained at a fixed opening (approx. 5 degrees) b y the return

spring.

Page 2753 of 4331

![NISSAN LATIO 2009 Service Repair Manual DTC P0643 SENSOR POWER SUPPLY

EC-1397

< SERVICE INFOMATION >

[MR TYPE 2] C

D E

F

G H

I

J

K L

M A EC

NP

O

Wiring Diagram

INFOID:0000000004500269

Specification data are reference values and are measure NISSAN LATIO 2009 Service Repair Manual DTC P0643 SENSOR POWER SUPPLY

EC-1397

< SERVICE INFOMATION >

[MR TYPE 2] C

D E

F

G H

I

J

K L

M A EC

NP

O

Wiring Diagram

INFOID:0000000004500269

Specification data are reference values and are measure](/img/5/57359/w960_57359-2752.png)

DTC P0643 SENSOR POWER SUPPLY

EC-1397

< SERVICE INFOMATION >

[MR TYPE 2] C

D E

F

G H

I

J

K L

M A EC

NP

O

Wiring Diagram

INFOID:0000000004500269

Specification data are reference values and are measured between each terminal and ground.

CAUTION:

Do not use ECM ground terminals wh en measuring input/output voltage. Doing so may result in dam-

age to the ECM's transistor. Use a ground ot her than ECM terminals, such as the ground. BBWA2649E

Page 2754 of 4331

![NISSAN LATIO 2009 Service Repair Manual EC-1398< SERVICE INFOMATION >

[MR TYPE 2]

DTC P0643 SENSOR POWER SUPPLY

Diagnosis Procedure INFOID:00000000045002701.

CHECK GROUND CONNECTIONS

1. Turn ignition switch OFF.

2. Loosen and retighten grou NISSAN LATIO 2009 Service Repair Manual EC-1398< SERVICE INFOMATION >

[MR TYPE 2]

DTC P0643 SENSOR POWER SUPPLY

Diagnosis Procedure INFOID:00000000045002701.

CHECK GROUND CONNECTIONS

1. Turn ignition switch OFF.

2. Loosen and retighten grou](/img/5/57359/w960_57359-2753.png)

EC-1398< SERVICE INFOMATION >

[MR TYPE 2]

DTC P0643 SENSOR POWER SUPPLY

Diagnosis Procedure INFOID:00000000045002701.

CHECK GROUND CONNECTIONS

1. Turn ignition switch OFF.

2. Loosen and retighten ground screws on the body.

Refer to EC-1144, " Ground Inspection " .

OK or NG OK >> GO TO 2.

NG >> Repair or replace ground connections. TER-

MI-

NAL

NO. WIRE

COLOR ITEM CONDITION DATA (DC Voltage)

72 V Sensor power supply

(Throttle position sensor) [Ignition switch: ON]

Approximately 5V

78 O Sensor power supply

[Camshaft position sensor

(PHASE)] [Ignition switch: ON]

Approximately 5V

102 SB Sensor power supply

(APP sensor 2) [Ignition switch: ON]

Approximately 5V

103 GR Accelerator pe

dal position

sensor 2 [Ignition switch: ON]

• Engine stopped

• Accelerator pedal: Fully released 0.3 - 0.6V

[Ignition switch: ON]

• Engine stopped

• Accelerator pedal: Fully depressed 1.95 - 2.4V

104 Y Sensor ground

(APP sensor 2) [Engine is running]

• Warm-up condition

• Idle speed Approximately 0V

106 P Sensor power supply

(APP sensor 1) [Ignition switch: ON]

Approximately 5V

110 G Accelerator pe

dal position

sensor 1 [Ignition switch: ON]

• Engine stopped

• Accelerator pedal: Fully released 0.6 - 0.9V

[Ignition switch: ON]

• Engine stopped

• Accelerator pedal: Fully depressed 3.9 - 4.7V

111 R Sensor ground

(APP sensor 1) [Engine is running]

• Warm-up condition

• Idle speed Approximately 0V:

Vehicle front

1. Body ground E24 2. Engine ground F9 3. Engine ground F16

4. Body ground E15 BBIA0698E

Page 2755 of 4331

![NISSAN LATIO 2009 Service Repair Manual DTC P0643 SENSOR POWER SUPPLY

EC-1399

< SERVICE INFOMATION >

[MR TYPE 2] C

D E

F

G H

I

J

K L

M A EC

NP

O 2.

CHECK ACCELERATOR PEDAL POSITION SENSOR 1 POWER SUPPLY CIRCUIT

1. Disconnect accelerator pe NISSAN LATIO 2009 Service Repair Manual DTC P0643 SENSOR POWER SUPPLY

EC-1399

< SERVICE INFOMATION >

[MR TYPE 2] C

D E

F

G H

I

J

K L

M A EC

NP

O 2.

CHECK ACCELERATOR PEDAL POSITION SENSOR 1 POWER SUPPLY CIRCUIT

1. Disconnect accelerator pe](/img/5/57359/w960_57359-2754.png)

DTC P0643 SENSOR POWER SUPPLY

EC-1399

< SERVICE INFOMATION >

[MR TYPE 2] C

D E

F

G H

I

J

K L

M A EC

NP

O 2.

CHECK ACCELERATOR PEDAL POSITION SENSOR 1 POWER SUPPLY CIRCUIT

1. Disconnect accelerator pedal position (APP) sensor (1) harness connector.

2. Turn ignition switch ON.

3. Check voltage between APP sensor terminal 4 and ground with CONSULT-III or tester.

OK or NG OK >> GO TO 8.

NG >> GO TO 3. 3.

CHECK ACCELERATOR PEDAL POSITION SENSOR 1 POWER SUPPLY CIRCUIT-II

1. Turn ignition switch OFF.

2. Disconnect ECM harness connector.

3. Check harness continuity between APP sensor terminal 4 and ECM terminal 106.

Refer to Wiring Diagram.

OK or NG OK >> GO TO 4.

NG >> Repair open circuit or short to ground or short to power in harness or connectors. 4.

CHECK SENSOR POWER SUPPLY CIRCUITS

Check harness for short to power and short to ground, between the following terminals.

OK or NG OK >> GO TO 5.

NG >> Repair short to ground or short to power in harness or connectors. 5.

CHECK CAMSHAFT POSITI ON SENSOR (PHASE)

Refer to EC-1303, " Component Inspection " .

OK or NG OK >> GO TO 6.

NG >> Replace camshaft position sensor (PHASE). 6.

CHECK THROTTLE POSITION SENSOR

Refer to EC-1201, " Component Inspection " . BBIA0705E

Voltage: Approximately 5V

PBIA9606J

Continuity should exist.

ECM terminal Sensor terminal Reference Wiring Diagram 72 Throttle position sensor terminal 1 EC-1477, " Wiring Diagram "

78 Camshaft position sensor (PHASE) terminal 1

EC-1300, " Wiring Diagram "

106 APP sensor terminal 4

EC-1397, " Wiring Diagram "

Page 2756 of 4331

OK >> GO TO 8.

NG >> GO TO 7. Throttle Valve Closed Position Learning " .

3. Perform EC-1084, " Idle Air Volume Learning " .

>> INSPECTION END Component Inspection " .

OK or NG OK >> GO TO 10.

NG >> GO TO 9. Accelerator Pedal Released Position Learning " .

3. Perform EC-1084, " Throttle Valve Closed Position Learning " .

4. Perform EC-1084, " Idle Air Volume Learning " .

>> INSPECTION END .

>> INSPECTION END

Page 2757 of 4331

EC

NP

O

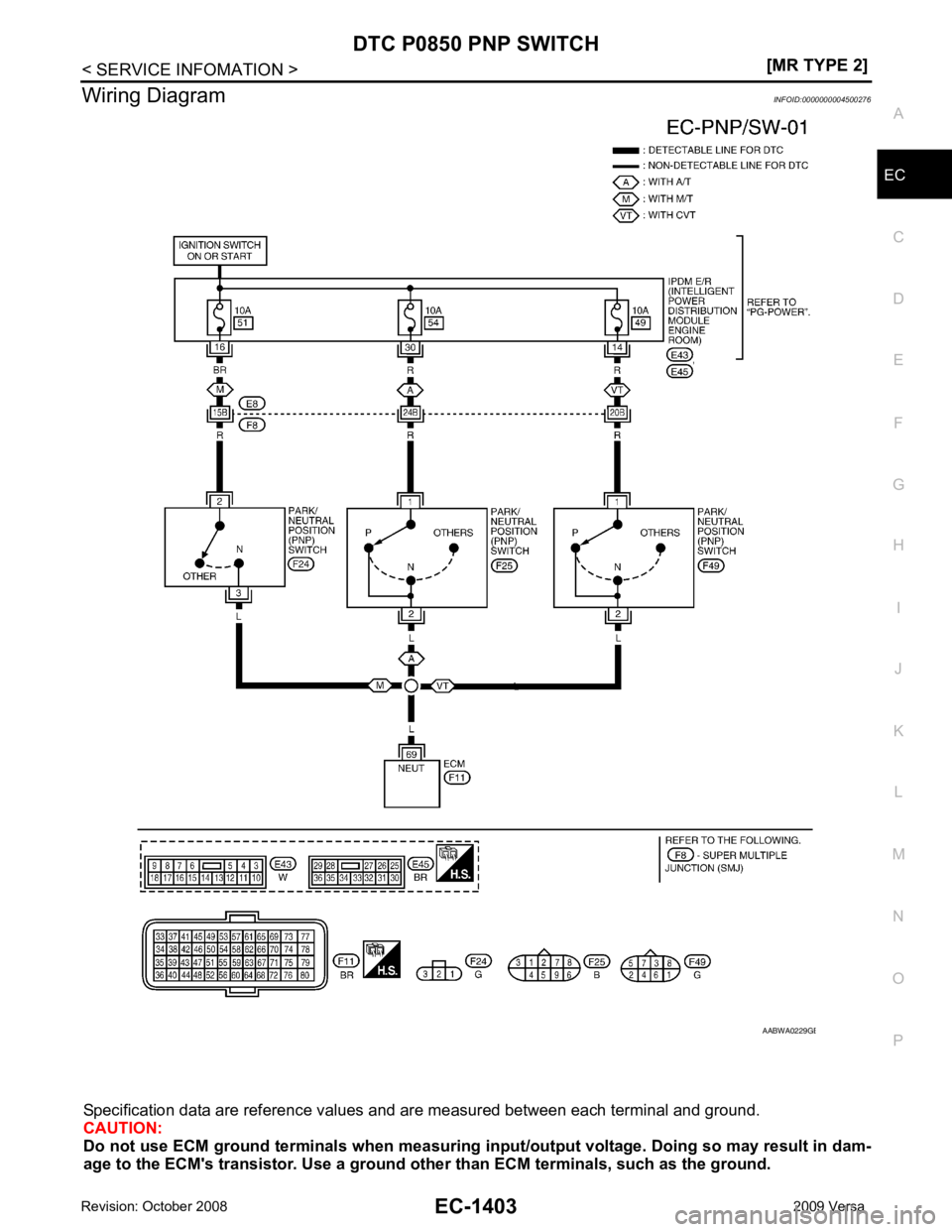

DTC P0850 PNP SWITCH

Component Description INFOID:0000000004500271

When the shift lever position is P or N (A/T, CVT), Neut ral (M/T), park/neutral position (PNP) switch is ON.

ECM detects the position because the continuity of the line (the ON signal) exists.

CONSULT-III Reference Val ue in Data Monitor Mode INFOID:0000000004500272

Specification data are reference values.

On Board Diagnosis Logic INFOID:0000000004500273

DTC Confirmation Procedure INFOID:0000000004500274

CAUTION:

Always drive vehicle at a safe speed.

NOTE:

If DTC Confirmation Procedure has been previously conduc ted, always turn ignition switch OFF and wait at

least 10 seconds before conducting the next test.

WITH CONSULT-III

1. Turn ignition switch ON.

2. Select “P/N POSI SW” in “DATA MONITOR” mode wit h CONSULT-III. Then check the “P/N POSI SW” sig-

nal under the following conditions.

If NG, go to EC-1404, " Diagnosis Procedure " .

If OK, go to following step.

3. Select “DATA MONITOR” mode with CONSULT-III.

4. Start engine and warm it up to normal operating temperature.

5. Maintain the following conditions for at least 60 consecutive seconds. MONITOR ITEM CONDITION SPECIFICATION

P/N POSI SW • Ignition switch: ON Shift lever: P or N (A/T, CVT),

Neutral (M/T) ON

Shift lever: Except above OFF DTC No. Trouble diagnosis name DTC detecting condition Possible cause

P0850

0850 Park/neutral position switch The signal of the park/neutral position (PNP)

switch is not changed in the process of en-

gine starting and driving. • Harness or connectors

[Park/neutral position (PNP) switch circuit

is open or shorted.]

• Park/neutral position (PNP) switch

• TCM (CVT models) Position (Shift lever) Known-good signal

N or P position (A/T, CVT)

Neutral position (M/T) ON

Except above OFF

ENG SPEED More than 1,200 rpm (CVT) More than 1,450 rpm (A/T)

More than 1,900 rpm (M/T)

COOLAN TEMP/S More than 70 °C (158 °F)

B/FUEL SCHDL 2.4 - 31.8 msec (CVT) 1.4 - 31.8 msec (A/T)

1.7 - 31.8 msec (M/T)

Page 2758 of 4331

![NISSAN LATIO 2009 Service Repair Manual EC-1402< SERVICE INFOMATION >

[MR TYPE 2]

DTC P0850 PNP SWITCH

6. Check 1st trip DTC.

7. If 1st trip DTC is detected, go to EC-1404, " Diagnosis Procedure " .

Overall Function Check INFOID:0000000004 NISSAN LATIO 2009 Service Repair Manual EC-1402< SERVICE INFOMATION >

[MR TYPE 2]

DTC P0850 PNP SWITCH

6. Check 1st trip DTC.

7. If 1st trip DTC is detected, go to EC-1404, " Diagnosis Procedure " .

Overall Function Check INFOID:0000000004](/img/5/57359/w960_57359-2757.png)

EC-1402< SERVICE INFOMATION >

[MR TYPE 2]

DTC P0850 PNP SWITCH

6. Check 1st trip DTC.

7. If 1st trip DTC is detected, go to EC-1404, " Diagnosis Procedure " .

Overall Function Check INFOID:0000000004500275

Use this procedure to check the overall function of the park/neutral position (PNP) switch circuit. During this

check, a 1st trip DTC might not be confirmed.

WITH GST

1. Turn ignition switch ON.

2. Check voltage between ECM terminal 69 (PNP switch signal) and ground under the following conditions.

3. If NG, go to EC-1404, " Diagnosis Procedure " .

VHCL SPEED SE More than 64km/h (29 MPH)

Shift lever Suitable position Condition (Shift lever) Voltage V (Known-good data)

P or N position (A/T, CVT)

Neutral position (M/T) BATTERY VOLTAGE

(11 - 14V)

Except above Approx. 0 SEC910C

Page 2759 of 4331

EC

NP

O

Wiring Diagram

INFOID:0000000004500276

Specification data are reference values and are measured between each terminal and ground.

CAUTION:

Do not use ECM ground terminals wh en measuring input/output voltage. Doing so may result in dam-

age to the ECM's transistor. Use a ground ot her than ECM terminals, such as the ground. B

Page 2760 of 4331

![NISSAN LATIO 2009 Service Repair Manual EC-1404< SERVICE INFOMATION >

[MR TYPE 2]

DTC P0850 PNP SWITCH

Diagnosis Procedure INFOID:0000000004500277

A/T MODELS AND CVT MODELS 1.

CHECK PNP SWITCH POWER SUPPLY CIRCUIT

1. Turn ignition switch OF NISSAN LATIO 2009 Service Repair Manual EC-1404< SERVICE INFOMATION >

[MR TYPE 2]

DTC P0850 PNP SWITCH

Diagnosis Procedure INFOID:0000000004500277

A/T MODELS AND CVT MODELS 1.

CHECK PNP SWITCH POWER SUPPLY CIRCUIT

1. Turn ignition switch OF](/img/5/57359/w960_57359-2759.png)

EC-1404< SERVICE INFOMATION >

[MR TYPE 2]

DTC P0850 PNP SWITCH

Diagnosis Procedure INFOID:0000000004500277

A/T MODELS AND CVT MODELS 1.

CHECK PNP SWITCH POWER SUPPLY CIRCUIT

1. Turn ignition switch OFF.

2. Disconnect PNP switch harness connector.

3. Turn ignition switch ON.

4. Check voltage between PNP switch terminal 1 and ground with CONSULT-III or tester.

OK or NG OK >> GO TO 3.

NG >> GO TO 2. 2.

DETECT MALFUNCTIONING PART

Check the following.

• Harness connectors E8, F8

• Harness for open or short between PNP switch and fuse

>> Repair open circuit or short to ground or short to power in harness or connectors. 3.

CHECK PNP SWITCH INPUT SIGNAL CIRCUIT FOR OPEN AND SHORT

1. Turn ignition switch OFF.

2. Disconnect ECM harness connector.

3. Check harness continuity between PNP switch terminal 2 and ECM terminal 69. Refer to Wiring Diagram.

4. Also check harness for short to ground and short to power.

OK or NG OK >> GO TO 4.

NG >> Repair open circuit or short to ground or short to power in harness or connectors. TERMI-

NAL NO. WIRE

COLOR ITEM CONDITION DATA (DC Voltage)

69 L Park/neutral position

(PNP) switch [Ignition switch: ON]

• Shift lever: P or N (A/T, CVT), Neutral (M/T) BATTERY VOLTAGE

(11 - 14V)

[Ignition switch: ON]

• Except above Approximately 0V A/T CVT

Voltage: Battery voltage PBIB3002E JMBIA2080ZZ

Continuity should exist.