NISSAN LATIO 2009 Service Repair Manual

Manufacturer: NISSAN, Model Year: 2009, Model line: LATIO, Model: NISSAN LATIO 2009Pages: 4331, PDF Size: 58.04 MB

Page 461 of 4331

BCS

N

O P

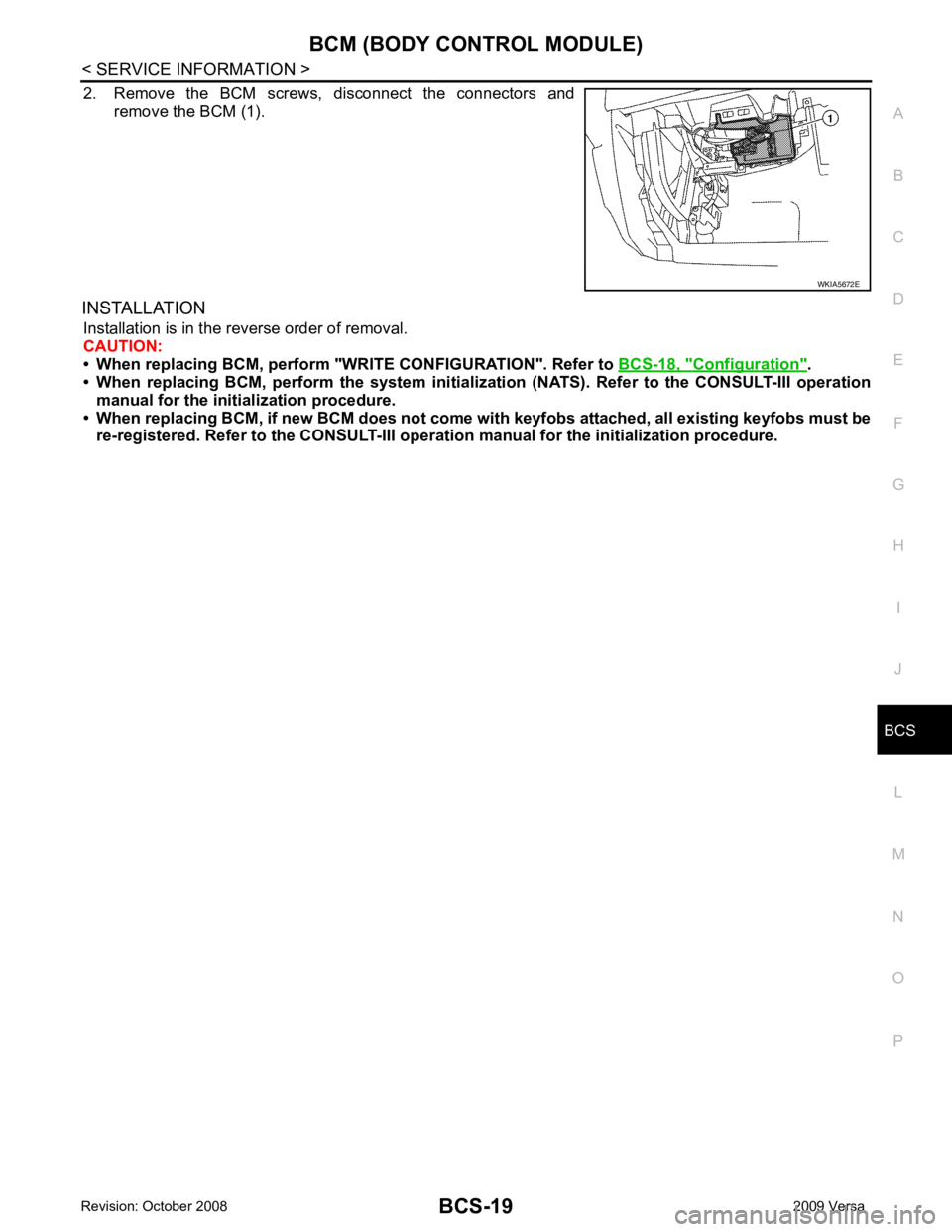

2. Remove the BCM screws, disconnect the connectors and

remove the BCM (1).

INSTALLATION Installation is in the reverse order of removal.

CAUTION:

• When replacing BCM, perform "WRI TE CONFIGURATION". Refer to BCS-18, " Configuration " .

• When replacing BCM, perform the syst em initialization (NATS). Refer to the CONSULT-III operation

manual for the initialization procedure.

• When replacing BCM, if new BCM does not come with keyfobs attached, all existing keyfobs must be

re-registered. Refer to the CONSULT-III opera tion manual for the initialization procedure.

Page 462 of 4331

BL

N

O P

CONTENTS

BODY, LOCK & SECURITY SYSTEM

SERVICE INFORMATION .. ..........................4

PRECAUTIONS .............................................. .....4

Precaution for Supplemental Restraint System

(SRS) "AIR BAG" and "SEAT BELT PRE-TEN-

SIONER" ............................................................. ......

4

Precaution Necessary fo r Steering Wheel Rota-

tion After Battery Disconnect ............................... ......

4

Precaution for Procedure without Cowl Top Cover ......5

Precaution for Work ............................................ ......5

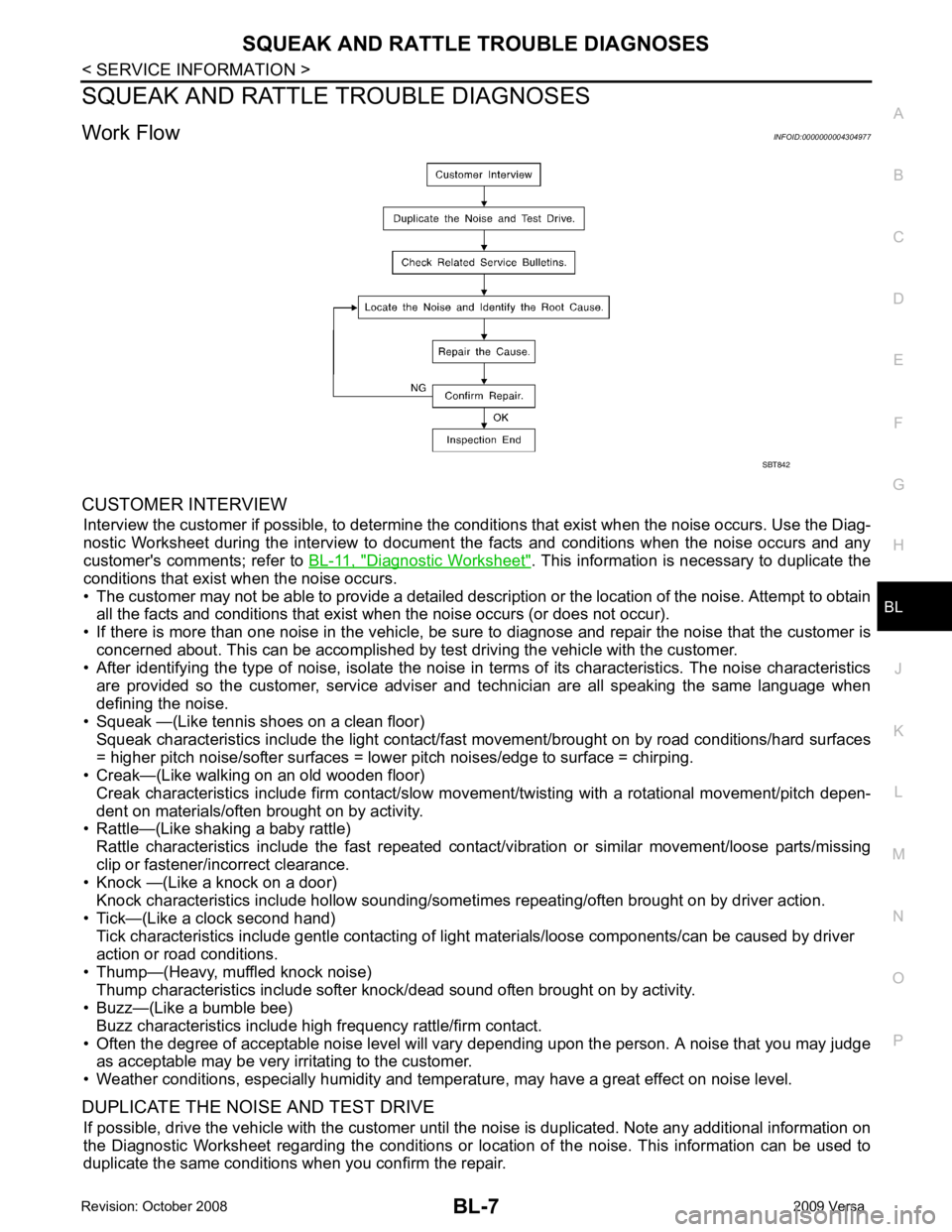

PREPARATION .............................................. .....6

Special Service Tool ........................................... ......6

Commercial Service Tool .................................... ......6

SQUEAK AND RATTLE TROUBLE DIAG-

NOSES ........................ ........................................7

Work Flow ........................................................... ......7

Generic Squeak and Rattle Troubleshooting ...... ......9

Diagnostic Worksheet ......................................... ....11

HOOD ............................................................. ....13

Fitting Adjustment ............................................... ....13

Removal and Installation .........................................14

Removal and Installation of Hood Lock Control .. ....15

Hood Lock Control Inspec tion .................................17

RADIATOR CORE SUPPORT ....................... ....19

Removal and Installation .........................................19

FRONT FENDER ............................................ ....21

Removal and Installation .........................................21

POWER DOOR LOCK SYSTEM .................... ....22

Component Parts and Harness Connector Loca-

tion ...................................................................... ....

22

System Description ............................................. ....23

CAN Communication System Description ........... ....25

Schematic ........................................................... ....26

Wiring Diagram - D/LOCK - ................................. ....27

Schematic ........................................................... ....31

Wiring Diagram - D/LOCK - ................................. ....32 Terminal and Reference

Value for BCM ..................37

Work Flow ............................................................ ....41

CONSULT-III Function (B CM) .................................41

Trouble Diagnosis Symptom Chart ...................... ....43

BCM Power Supply and Ground Circuit Inspection ....43

Door Switch Check (Hatchback) .......................... ....44

Door Switch Check (Sedan) ................................ ....47

Key Switch (Insert) Check ................................... ....48

Door Lock and Unlock Switch Check .................. ....49

Front Door Lock Assembly LH (Actuator) Check .....52

Door Lock Actuator Check (Front RH and Rear

LH/RH) ................................................................. ....

53

Front Door Key Cylinder S witch LH Check ..............54

Passenger Select Unlock Relay Circuit Inspection

(With Intelligent Key) ........................................... ....

55

REMOTE KEYLESS ENTRY SYSTEM ............. 58

Component Parts and Harness Connector Loca-

tion ....................................................................... ....

58

System Description .............................................. ....58

CAN Communication System Description ........... ....60

Schematic ............................................................ ....61

Wiring Diagram - KEYLES - ................................ ....62

Terminal and Reference Value for BCM ..................65

How to Perform Trouble Diagnosis ...................... ....69

Preliminary Check ............................................... ....69

CONSULT-III Function (B CM) .................................69

Work Flow ............................................................ ....71

Trouble Diagnosis Symptom Chart ...................... ....71

Keyfob Battery and Function Check .................... ....72

ACC Switch Check .............................................. ....74

Door Switch Check (Hatchback) .......................... ....74

Door Switch Check (Sedan) ................................ ....76

Key Switch (Insert) Check ................................... ....78

Hazard Function Check ....................................... ....78

Horn Function Check ........................................... ....79

Interior Lamp and Ignition Keyhole Illumination

Function Check .................................................... ....

79

Remote Keyless Entry Rece iver Check ...................80

Keyfob Function (Lock) Check ............................ ....82

Page 463 of 4331

Page 464 of 4331

BL

N

O P

Check Trunk Lid Opener S

witch Circuit (With Intel-

ligent Key) ........................................................... ..

212

Check Trunk Release Solenoid Circuit ............... ..214

FUEL FILLER LID OPENER .......................... ..217

Removal and Installation of Fuel Filler Lid Opener ..217

VEHICLE SECURITY (THEFT WARNING)

SYSTEM ......................................................... ..

218

Component Parts and Harness Connector Loca-

tion ...................................................................... ..

218

System Description ............................................. ..219

CAN Communication System Description ........... ..221

Schematic ........................................................... ..222

Wiring Diagram - VEHSEC - ............................... ..223

Terminal and Reference Value for BCM ............. ..227

Terminal and Re ference Value for Intelligent Key

Unit ...................................................................... ..

231

CONSULT-III Function (BCM) ............................. ..233

Trouble Diagnosis ............................................... ..235

Preliminary Check ............................................... ..235

Symptom Chart ................................................... ..237

Diagnosis Procedure 1 ........................................ ..238

Diagnosis Procedure 2 ........................................ ..241

Diagnosis Procedure 3 ........................................ ..242

Diagnosis Procedure 4 ........................................ ..242

Diagnosis Procedure 5 ........................................ ..242

Diagnosis Procedure 6 ........................................ ..242

Diagnosis Procedure 7 ........................................ ..242

Diagnosis Procedure 8 ........................................ ..244

Diagnosis Procedure 9 ........................................ ..245 NATS (Nissan Anti-Theft System) ................

248

Component Parts and Harness Connector Loca-

tion ....................................................................... ..

248

System Description .............................................. ..248

System Composition ............................................ ..249

ECM Re-communicating Function ....................... ..249

Wiring Diagram - NATS - ..................................... ..251

Terminal and Reference Value for BCM ................252

CONSULT-III Function ........................................ ..256

Trouble Diagnosis Procedure .............................. ..257

Trouble Diagnosis ................................................ ..259

Diagnosis Procedure 1 ........................................ ..260

Diagnosis Procedure 2 ........................................ ..262

Diagnosis Procedure 3 ........................................ ..263

Diagnosis Procedure 4 ........................................ ..264

Diagnosis Procedure 5 ........................................ ..265

Diagnosis Procedure 6 ........................................ ..266

How to Replace NATS Antenna Amp .................. ..266

BODY REPAIR ................................................ 267

Body Exterior Paint Color .................................... ..267

Body Component Parts ....................................... ..269

Corrosion Protection ............................................ ..274

Body Sealing ....................................................... ..278

Body Construction ............................................... ..284

Body Alignment ................................................... ..286

Handling Precaution for Plastics .......................... ..303

Precaution in Repairing High Strength Steel ....... ..307

Foam Repair ........................................................ ..310

Replacement Operation ....................................... ..313

Page 465 of 4331

Page 466 of 4331

BL

N

O P

Precaution for Procedur

e without Cowl Top Cover INFOID:0000000004304973

When performing the procedure after removing cowl top cover, cover

the lower end of windshield.

Precaution for Work INFOID:0000000004304974

• After removing and installing the opening/closing parts, be sure to carry out fitting adjustments to check their

operation.

• Check the lubrication level, damage, and wear of each part. If necessary, grease or replace it.

Page 467 of 4331

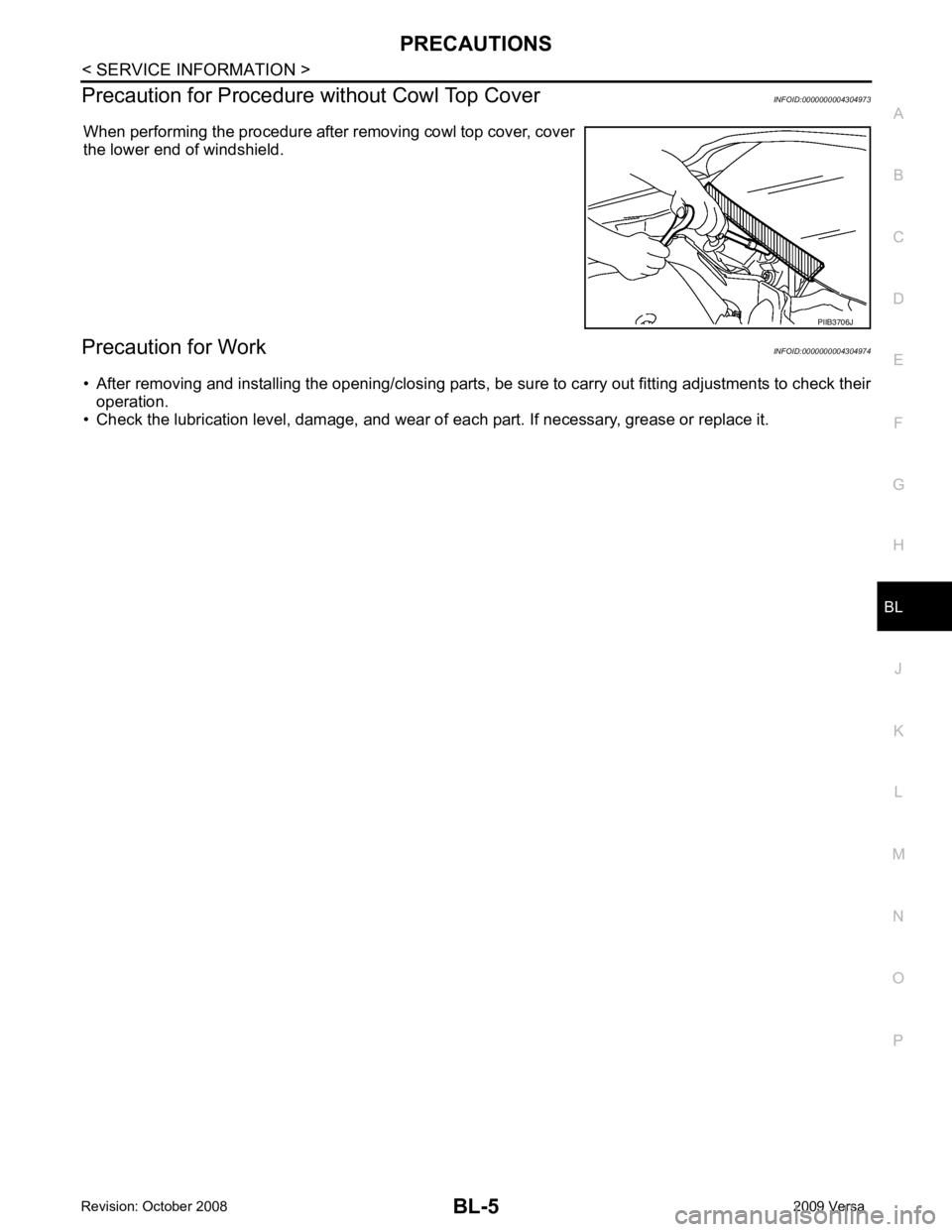

SIIA0994E

Page 468 of 4331

BL

N

O P

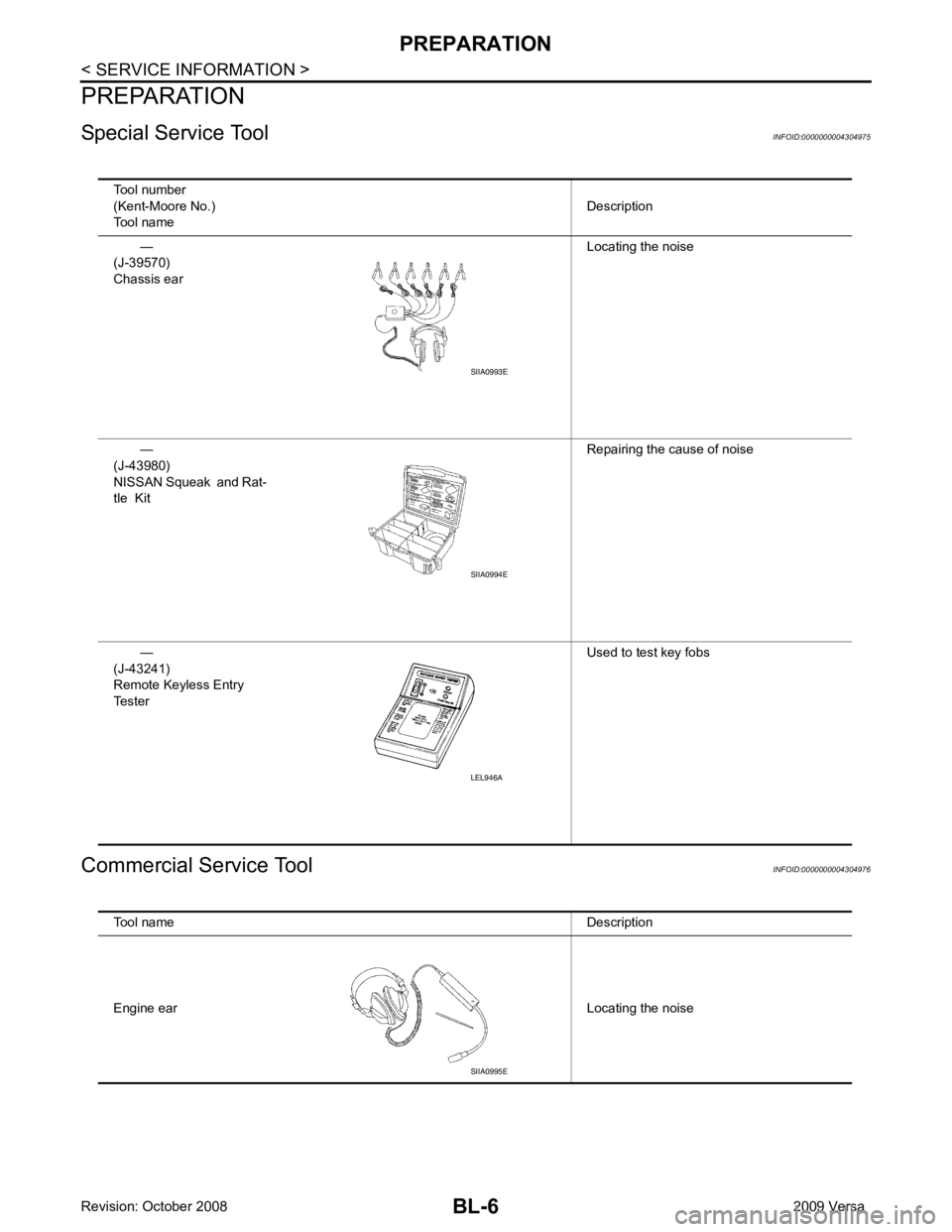

SQUEAK AND RATTLE TROUBLE DIAGNOSES

Work Flow INFOID:0000000004304977

CUSTOMER INTERVIEW Interview the customer if possible, to determine the c onditions that exist when the noise occurs. Use the Diag-

nostic Worksheet during the interv iew to document the facts and conditions when the noise occurs and any

customer's comments; refer to BL-11, " Diagnostic Worksheet " . This information is necessary to duplicate the

conditions that exist when the noise occurs.

• The customer may not be able to provide a detailed descr iption or the location of the noise. Attempt to obtain

all the facts and conditions that exist when the noise occurs (or does not occur).

• If there is more than one noise in the vehicle, be sure to diagnose and repair the noise that the customer is

concerned about. This can be accomplished by test driving the vehicle with the customer.

• After identifying the type of noise, isolate the noise in terms of its characteristics. The noise characteristics

are provided so the customer, service adviser and technician are all speaking the same language when

defining the noise.

• Squeak —(Like tennis shoes on a clean floor)

Squeak characteristics include the light contact/fast movement/brought on by road conditions/hard surfaces

= higher pitch noise/softer surfaces = lower pitch noises/edge to surface = chirping.

• Creak—(Like walking on an old wooden floor)

Creak characteristics include firm contact/slow mo vement/twisting with a rotational movement/pitch depen-

dent on materials/often brought on by activity.

• Rattle—(Like shaking a baby rattle)

Rattle characteristics include the fast repeated contac t/vibration or similar movement/loose parts/missing

clip or fastener/incorrect clearance.

• Knock —(Like a knock on a door)

Knock characteristics include hollow sounding/someti mes repeating/often brought on by driver action.

• Tick—(Like a clock second hand) Tick characteristics include gentle contacting of li ght materials/loose components/can be caused by driver

action or road conditions.

• Thump—(Heavy, muffled knock noise) Thump characteristics include softer k nock/dead sound often brought on by activity.

• Buzz—(Like a bumble bee)

Buzz characteristics include high frequency rattle/firm contact.

• Often the degree of acceptable noise level will vary depending upon the person. A noise that you may judge as acceptable may be very irritating to the customer.

• Weather conditions, especially humidity and temperature, may have a great effect on noise level.

DUPLICATE THE NOISE AND TEST DRIVE If possible, drive the vehicle with the customer until the noise is duplicated. Note any additional information on

the Diagnostic Worksheet regarding the conditions or lo cation of the noise. This information can be used to

duplicate the same conditions when you confirm the repair.

Page 469 of 4331

Generic Squeak and Rattle Troubleshooting " .

REPAIR THE CAUSE

• If the cause is a loose component, tighten the component securely.

• If the cause is insufficient clearance between components:

- separate components by repositioning or loos ening and retightening the component, if possible.

- insulate components with a suitable insulator such as urethane pads, foam blocks, felt cloth tape or urethane

tape. A NISSAN Squeak and Rattle Kit (J-43980) is av ailable through your authorized NISSAN Parts Depart-

ment.

CAUTION:

Do not use excessive force as many components are constructed of plastic and may be damaged.

Always check with the Parts Department for the latest parts information.

The following materials are contained in the NISS AN Squeak and Rattle Kit (J-43980). Each item can be

ordered separately as needed.

URETHANE PADS [1.5 mm (0.059 in) thick]

Insulates connectors, harness, etc.

76268-9E005: 100 ×135 mm (3.94 ×5.31 in)/76884-71L01: 60 ×85 mm (2.36 ×3.35 in)/76884-71L02: 15 ×25

mm (0.59 ×0.98 in)

INSULATOR (Foam blocks)

Insulates components from contact. Can be used to fill space behind a panel.

73982-9E000: 45 mm (1.77 in) thick, 50 ×50 mm (1.97 ×1.97 in)/73982-50Y00: 10 mm (0.39 in) thick,

50 ×50 mm (1.97 ×1.97 in)

INSULATOR (Light foam block)

80845-71L00: 30 mm (1.18 in) thick, 30 ×50 mm (1.18 ×1.97 in)

FELT CLOTH TAPE

Used to insulate where movemen t does not occur. Ideal for instrument panel applications.

68370-4B000: 15 ×25 mm (0.59 ×0.98 in) pad/68239-13E00: 5 mm (0.20 in ) wide tape roll. The following

materials not found in the kit can also be used to repair squeaks and rattles.

UHMW (TEFLON) TAPE

Insulates where slight movemen t is present. Ideal for instrument panel applications.

Page 470 of 4331

BL

N

O P

SILICONE GREASE

Used instead of UHMW tape that will be visible or not fit.

Note: Will only last a few months.

SILICONE SPRAY

Use when grease cannot be applied.

DUCT TAPE

Use to eliminate movement.

CONFIRM THE REPAIR Confirm that the cause of a noise is repaired by test driving the vehicle. Operate the vehicle under the same

conditions as when the noise originally occurred. Refer to the notes on the Diagnostic Worksheet.

Generic Squeak and Rattle Troubleshooting INFOID:0000000004304978

Refer to Table of Contents for specific component removal and installation information.

INSTRUMENT PANEL Most incidents are caused by contact and movement between:

1. The cluster lid A and instrument panel

2. Acrylic lens and combination meter housing

3. Instrument panel to front pillar garnish

4. Instrument panel to windshield

5. Instrument panel mounting pins

6. Wiring harnesses behind the combination meter

7. A/C defroster duct and duct joint

These incidents can usually be located by tapping or moving the components to duplicate the noise or by

pressing on the components while driving to stop the noi se. Most of these incidents can be repaired by apply-

ing felt cloth tape or silicone spray (in hard to reach areas). Urethane pads can be used to insulate wiring har-

ness.

CAUTION:

Do not use silicone spray to isolate a squeak or ra ttle. If you saturate the area with silicone, you will

not be able to recheck the repair.

CENTER CONSOLE Components to pay attention to include:

1. Shifter assembly cover to finisher

2. A/C control unit and cluster lid C

3. Wiring harnesses behind audio and A/C control unit

The instrument panel repair and isolation pr ocedures also apply to the center console.

DOORS Pay attention to the:

1. Finisher and inner panel making a slapping noise

2. Inside handle escutcheon to door finisher

3. Wiring harnesses tapping

4. Door striker out of alignment causing a popping noise on starts and stops

Tapping or moving the components or pressing on them wh ile driving to duplicate the conditions can isolate

many of these incidents. You can usually insulate the ar eas with felt cloth tape or insulator foam blocks from

the NISSAN Squeak and Rattle Kit (J-43980) to repair the noise.

TRUNK Trunk noises are often caused by a loose jack or loose items put into the trunk by the owner.

In addition look for:

1. Trunk lid bumpers out of adjustment

2. Trunk lid striker out of adjustment

3. The trunk lid torsion bars knocking together

4. A loose license plate or bracket