check engine NISSAN LATIO 2009 Service Manual PDF

[x] Cancel search | Manufacturer: NISSAN, Model Year: 2009, Model line: LATIO, Model: NISSAN LATIO 2009Pages: 4331, PDF Size: 58.04 MB

Page 721 of 4331

CAN Com-

munication Inspection Using CONSULT-III (Self-Diagnosis) " .

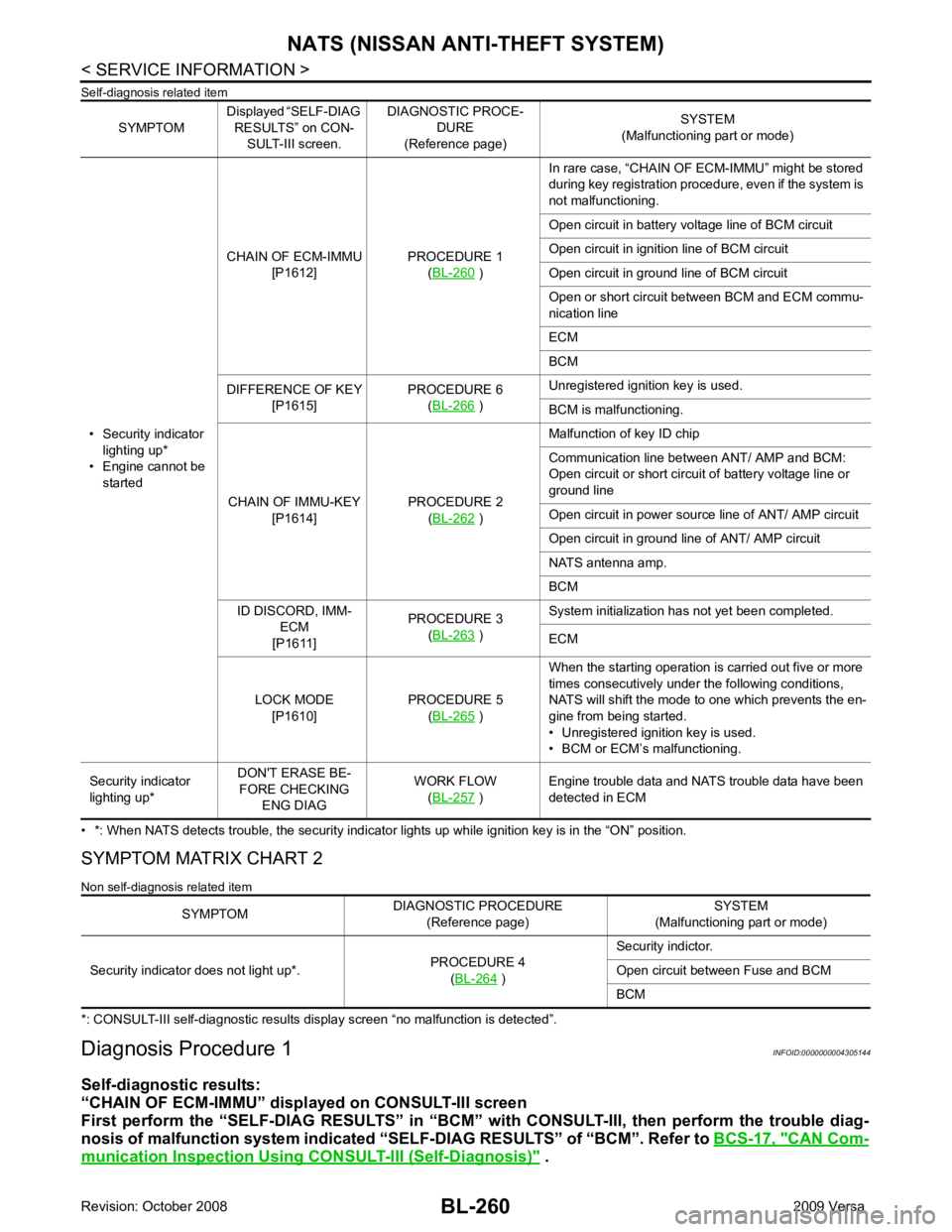

SYMPTOM

Displayed “SELF-DIAG

RESULTS” on CON- SULT-III screen. DIAGNOSTIC PROCE-

DURE

(Reference page) SYSTEM

(Malfunctioning part or mode)

• Security indicator lighting up*

• Engine cannot be started CHAIN OF ECM-IMMU

[P1612] PROCEDURE 1

(BL-260 )

In rare case, “CHAIN OF ECM-IMMU” might be stored

during key registration procedure, even if the system is

not malfunctioning.

Open circuit in battery voltage line of BCM circuit

Open circuit in ignition line of BCM circuit

Open circuit in ground line of BCM circuit

Open or short circuit between BCM and ECM commu-

nication line

ECM

BCM

DIFFERENCE OF KEY [P1615] PROCEDURE 6

(BL-266 )

Unregistered ignition key is used.

BCM is malfunctioning.

CHAIN OF IMMU-KEY [P1614] PROCEDURE 2

(BL-262 )

Malfunction of key ID chip

Communication line between ANT/ AMP and BCM:

Open circuit or short circuit of battery voltage line or

ground line

Open circuit in power source line of ANT/ AMP circuit

Open circuit in ground line of ANT/ AMP circuit

NATS antenna amp.

BCM

ID DISCORD, IMM- ECM

[P1611] PROCEDURE 3

(BL-263 )

System initialization has not yet been completed.

ECM

LOCK MODE [P1610] PROCEDURE 5

(BL-265 )

When the starting operation is carried out five or more

times consecutively under the following conditions,

NATS will shift the mode to one which prevents the en-

gine from being started.

• Unregistered ignition key is used.

• BCM or ECM’s malfunctioning.

Security indicator

lighting up* DON'T ERASE BE-

FORE CHECKING ENG DIAG WORK FLOW

(BL-257 )

Engine trouble data and NATS trouble data have been

detected in ECM SYMPTOM

DIAGNOSTIC PROCEDURE

(Reference page) SYSTEM

(Malfunctioning part or mode)

Security indicator does not light up*. PROCEDURE 4

(BL-264 )

Security indictor.

Open circuit between Fuse and BCM

BCM

Page 723 of 4331

Removal and Installation of BCM " .

2. Perform initialization with CONSULT-III.

For initialization, refer to “CONSULT-III Operation Manual NATS”.

Does the engine start? Yes >> BCM is malfunctioning.

• Replace BCM. Refer to BCS-18, " Removal and Installation of BCM " .

• Perform initialization with CONSULT-III

• For initialization, refer to “CONSULT-III Operation Manual NATS”

No >> ECM is malfunctioning. • Replace ECM.

• Perform initialization or re-communicating function

• For initialization, refer to “CONSULT-III Operation Manual NATS”

• For re-communicating function, refer to BL-249, " ECM Re-communicating Function "

“ CHAIN OF IMMU-KEY ” displayed?

Yes >> GO TO 2

No >> GO TO BL-259, " Trouble Diagnosis " .

How to Replace NATS Antenna Amp " .

OK or NG OK >> GO TO 3

NG >> Reinstall NATS antenna amp. correctly. Yes >> Ignition key ID chip is malfunctioning.

• Replace the ignition key

• Perform initialization with CONSULT-III For initialization, refer to “CONSULT-III Operation Manual NATS”

No >> GO TO 4 OK >> GO TO 5

NG >> Check the following. • 20A fuse [No. 53, located in IPDM E/R]

• Harness for open or short between fuse and NATS

antenna amp.

Page 725 of 4331

“ ID DISCORD IMM-ECM ” displayed?

Yes >> GO TO 2

No >> GO TO BL-259, " Trouble Diagnosis " .

Yes >> • Start engine. (END)

• (System initialization had not been completed.)

No >> ECM is malfunctioning. • Replace ECM.

• Perform initialization with CONSULT-III For initialization, refer to “CONSULT-III Operation Manual NATS”

Diagnosis Procedure 4 INFOID:0000000004305147

“COMBINATION METER (SECURITY) DOES NOT LIGHT UP” OK >> GO TO 2

NG >> Replace fuse. OK >> Inspection End.

NG >> GO TO 3 OK >> GO TO 4

NG >> Check harness for open or short between fuse and com- bination meter (security).

Page 807 of 4331

BR

N

O P

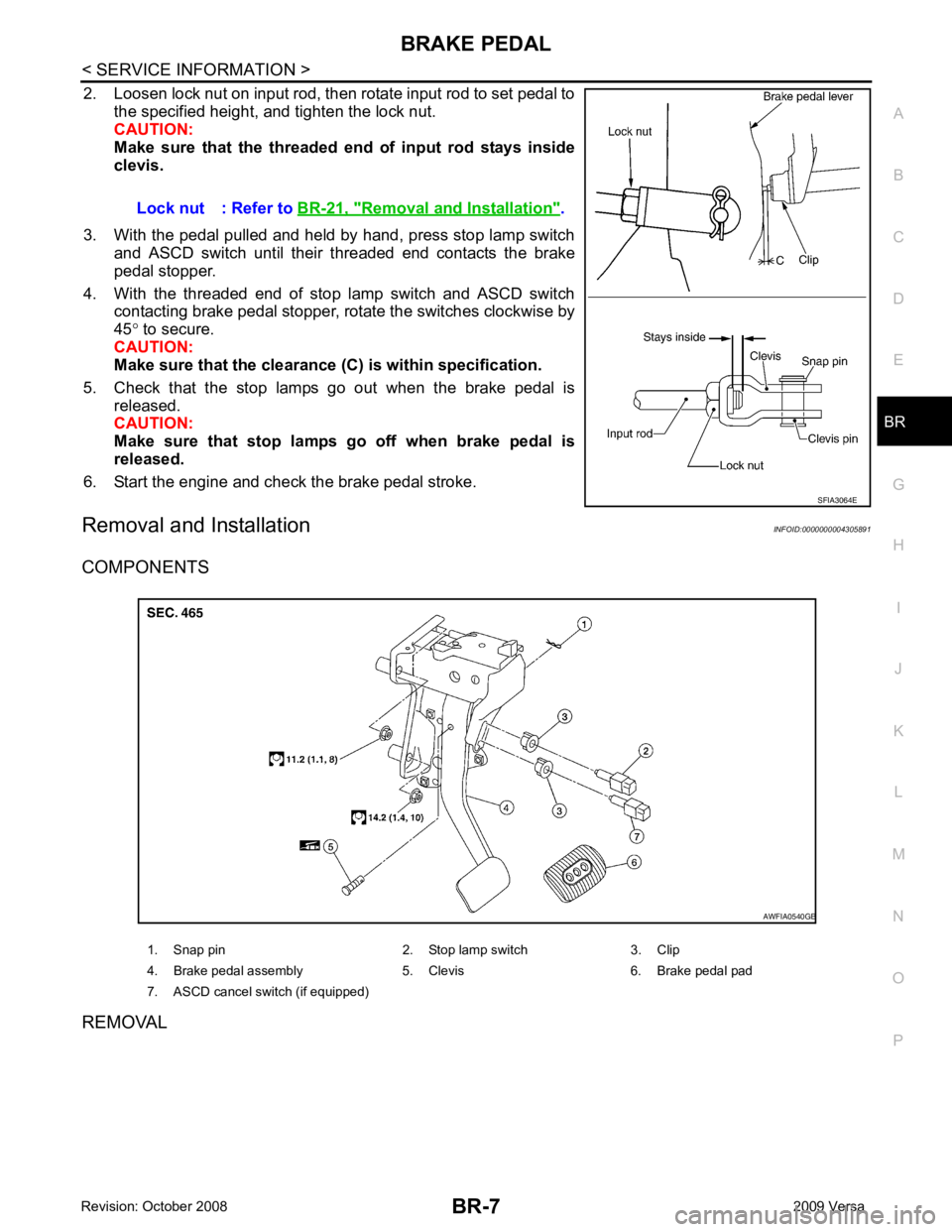

2. Loosen lock nut on input rod, then rotate input rod to set pedal to

the specified height, and tighten the lock nut.

CAUTION:

Make sure that the threaded end of input rod stays inside

clevis.

3. With the pedal pulled and held by hand, press stop lamp switch and ASCD switch until their threaded end contacts the brake

pedal stopper.

4. With the threaded end of stop lamp switch and ASCD switch contacting brake pedal stopper, rotate the switches clockwise by

45 ° to secure.

CAUTION:

Make sure that the clearance (C) is within specification.

5. Check that the stop lamps go out when the brake pedal is released.

CAUTION:

Make sure that stop lamps go off when brake pedal is

released.

6. Start the engine and check the brake pedal stroke.

Removal and Installation INFOID:0000000004305891

COMPONENTS

REMOVAL Lock nut : Refer to

BR-21, " Removal and Installation " .

Page 813 of 4331

BR

N

O P

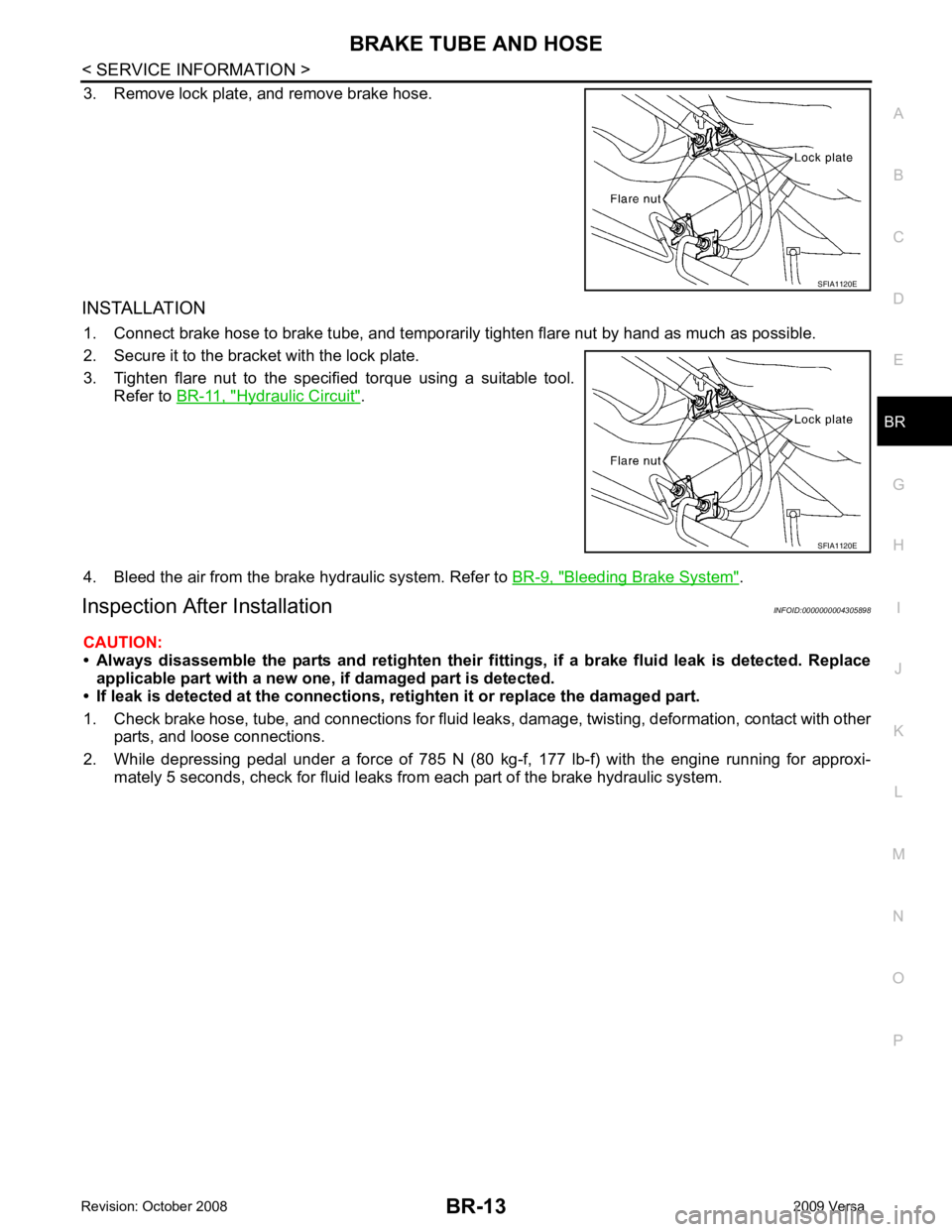

3. Remove lock plate, and remove brake hose.

INSTALLATION 1. Connect brake hose to brake tube, and temporaril y tighten flare nut by hand as much as possible.

2. Secure it to the bracket with the lock plate.

3. Tighten flare nut to the specified torque using a suitable tool. Refer to BR-11, " Hydraulic Circuit " .

4. Bleed the air from the brake hydraulic system. Refer to BR-9, " Bleeding Brake System " .

Inspection After Installation INFOID:0000000004305898

CAUTION:

• Always disassemble the parts and retighten their fitti ngs, if a brake fluid leak is detected. Replace

applicable part with a new one, if damaged part is detected.

• If leak is detected at the connections, retighten it or replace the damaged part.

1. Check brake hose, tube, and connections for fluid leak s, damage, twisting, deformation, contact with other

parts, and loose connections.

2. While depressing pedal under a force of 785 N (80 kg-f, 177 lb-f) with the engine running for approxi- mately 5 seconds, check for fluid leaks from each part of the brake hydraulic system. SFIA1120E

Page 823 of 4331

BR

N

O P

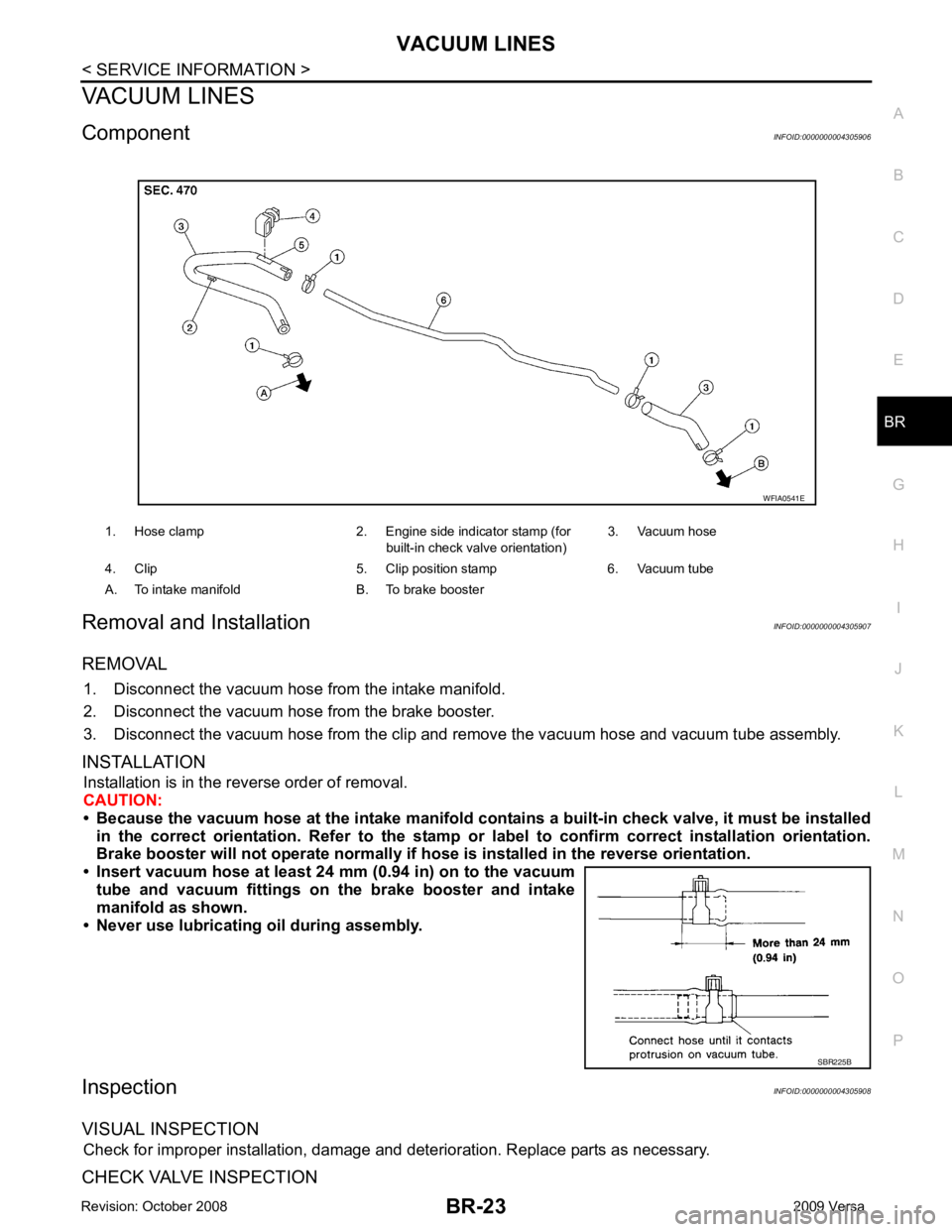

VACUUM LINES

Component INFOID:0000000004305906

Removal and Installation INFOID:0000000004305907

REMOVAL 1. Disconnect the vacuum hose from the intake manifold.

2. Disconnect the vacuum hose from the brake booster.

3. Disconnect the vacuum hose from the clip and re move the vacuum hose and vacuum tube assembly.

INSTALLATION Installation is in the reverse order of removal.

CAUTION:

• Because the vacuum hose at the intake manifold contai ns a built-in check valve, it must be installed

in the correct orientation. Refer to the stamp or label to confirm correct installation orientation.

Brake booster will not operate normally if ho se is installed in the reverse orientation.

• Insert vacuum hose at least 24 mm (0.94 in) on to the vacuum tube and vacuum fittings on the brake booster and intake

manifold as shown.

• Never use lubricating oil during assembly.

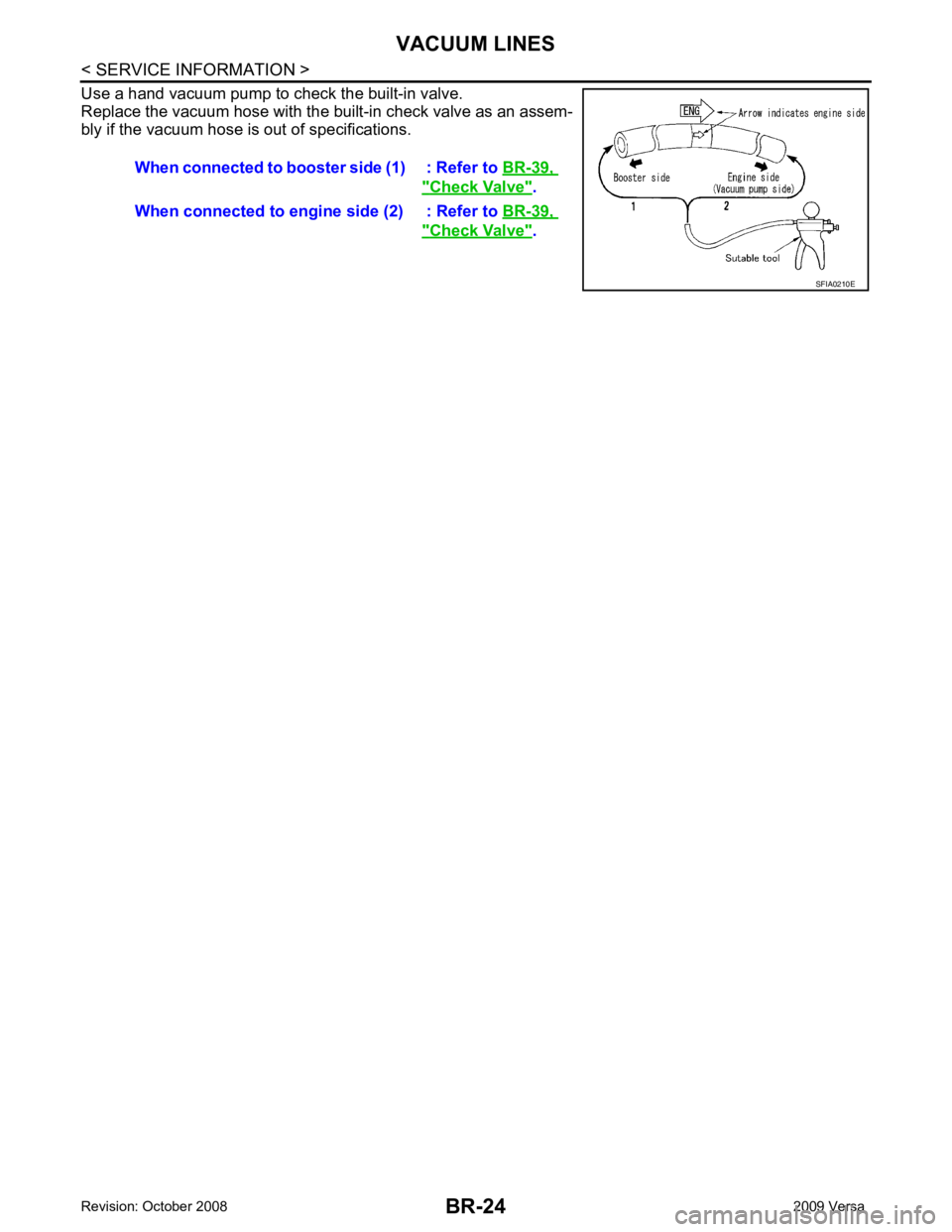

Inspection INFOID:0000000004305908

VISUAL INSPECTION Check for improper installation, damage and deterioration. Replace parts as necessary.

CHECK VALVE INSPECTION 1. Hose clamp 2. Engine side indicator stamp (for

built-in check valve orientation)3. Vacuum hose

4. Clip 5. Clip position stamp 6. Vacuum tube

A. To intake manifold B. To brake booster SBR225B

Page 824 of 4331

" Check Valve " .

When connected to engine side (2) : Refer to BR-39, " Check Valve " .

Page 839 of 4331

SERVICE DATA AND SPECIFICATIONS (SDS)

BR-39

< SERVICE INFORMATION >

C

D E

G H

I

J

K L

M A

B BR

N

O P

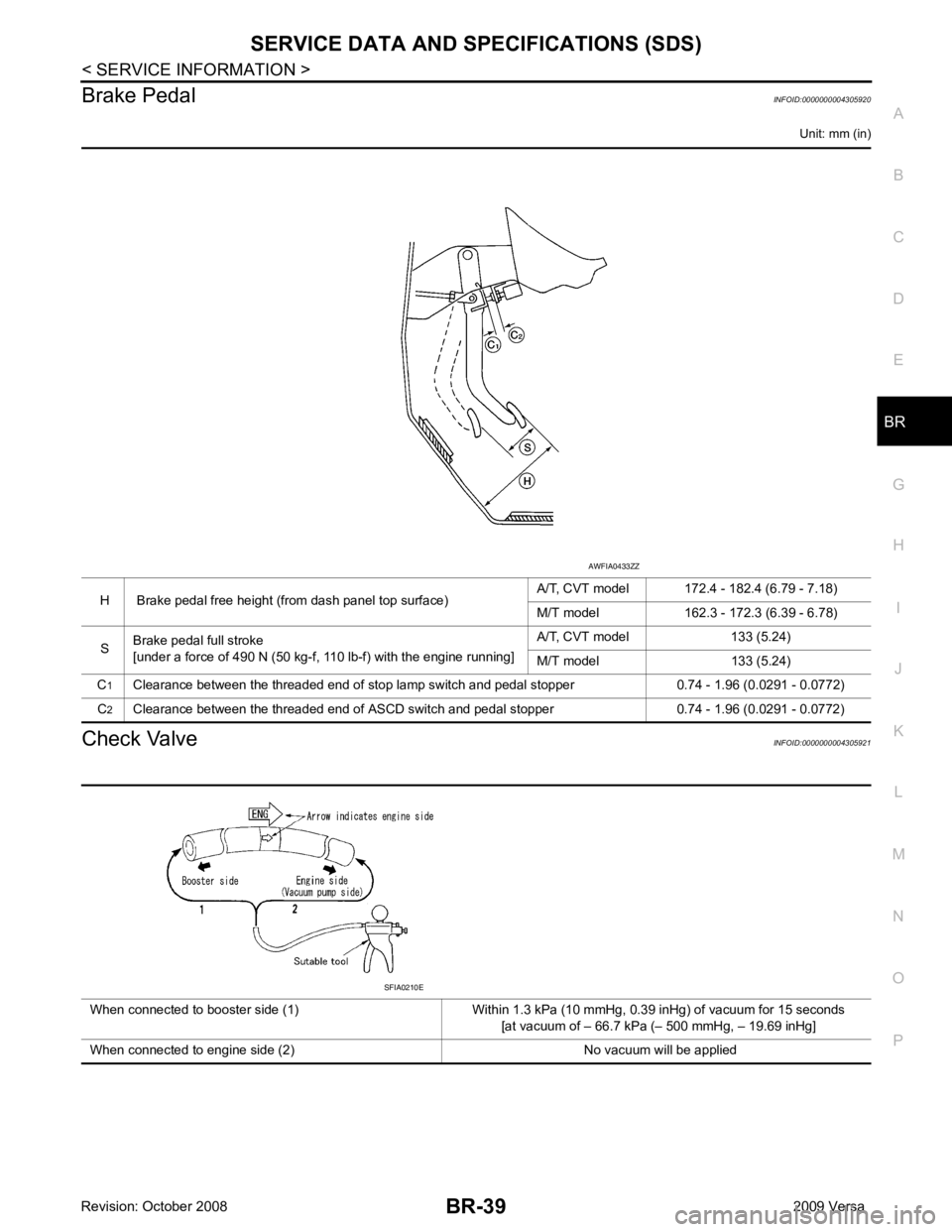

Brake Pedal

INFOID:0000000004305920

Unit: mm (in)

Check Valve INFOID:0000000004305921

H Brake pedal free height (from dash panel top surface)

A/T, CVT model 172.4 - 182.4 (6.79 - 7.18)

M/T model 162.3 - 172.3 (6.39 - 6.78)

S Brake pedal full stroke

[under a force of 490 N (50 kg-f, 110 lb-f) with the engine running] A/T, CVT model 133 (5.24)

M/T model 133 (5.24)

C 1

Clearance between the threaded end of stop lamp switch and pedal stopper 0.74 - 1.96 (0.0291 - 0.0772)

C 2

Clearance between the threaded end of ASCD switch and pedal stopper 0.74 - 1.96 (0.0291 - 0.0772) AWFIA0433ZZ

When connected to booster side (1) Within 1.3 kPa (10 mmHg, 0.39 inHg) of vacuum for 15 seconds [at vacuum of – 66.7 kPa (– 500 mmHg, – 19.69 inHg]

When connected to engine side (2) No vacuum will be applied SFIA0210E

Page 843 of 4331

BRC

N

O P

Precaution for Brake Control

INFOID:0000000004307252

• During ABS operation, the brake pedal may vibrate lightly and a mechanical noise may be heard. This is normal.

• Just after starting the vehicle, the brake pedal may vibrate or motor operating noises may be heard from

engine compartment. This is normal due to the self check operation.

• Stopping distance may be longer than that of vehicles without ABS when vehicle drives on rough, gravel, or

snow-covered (fresh, deep snow) roads.

• When an error is indicated by ABS or another warning lamp, collect all necessary information from customer

(what symptoms are present under what conditions) and check for simple causes before starting diagnosis.

Besides electrical system inspection, check brake booster operation, brake fluid level, and fluid leaks.

• If incorrect tire sizes or types are installed on the vehicle or brake pads are not Genuine NISSAN parts, stop-

ping distance or steering stability may deteriorate.

• If there is a radio, antenna or related wiring near t he control module, ABS function may have a malfunction

or error.

• If aftermarket parts (car stereo, CD player, etc.) have been installed, check for incidents such as harness pinches, open circuits or improper wiring.

Precaution for CAN System INFOID:0000000004307253

• Do not apply voltage of 7.0V or higher to terminal to be measured.

• Maximum open terminal voltage of tester in use must be less than 7.0V.

• Before checking harnesses, turn ignition switch OFF and disconnect battery negative cable.

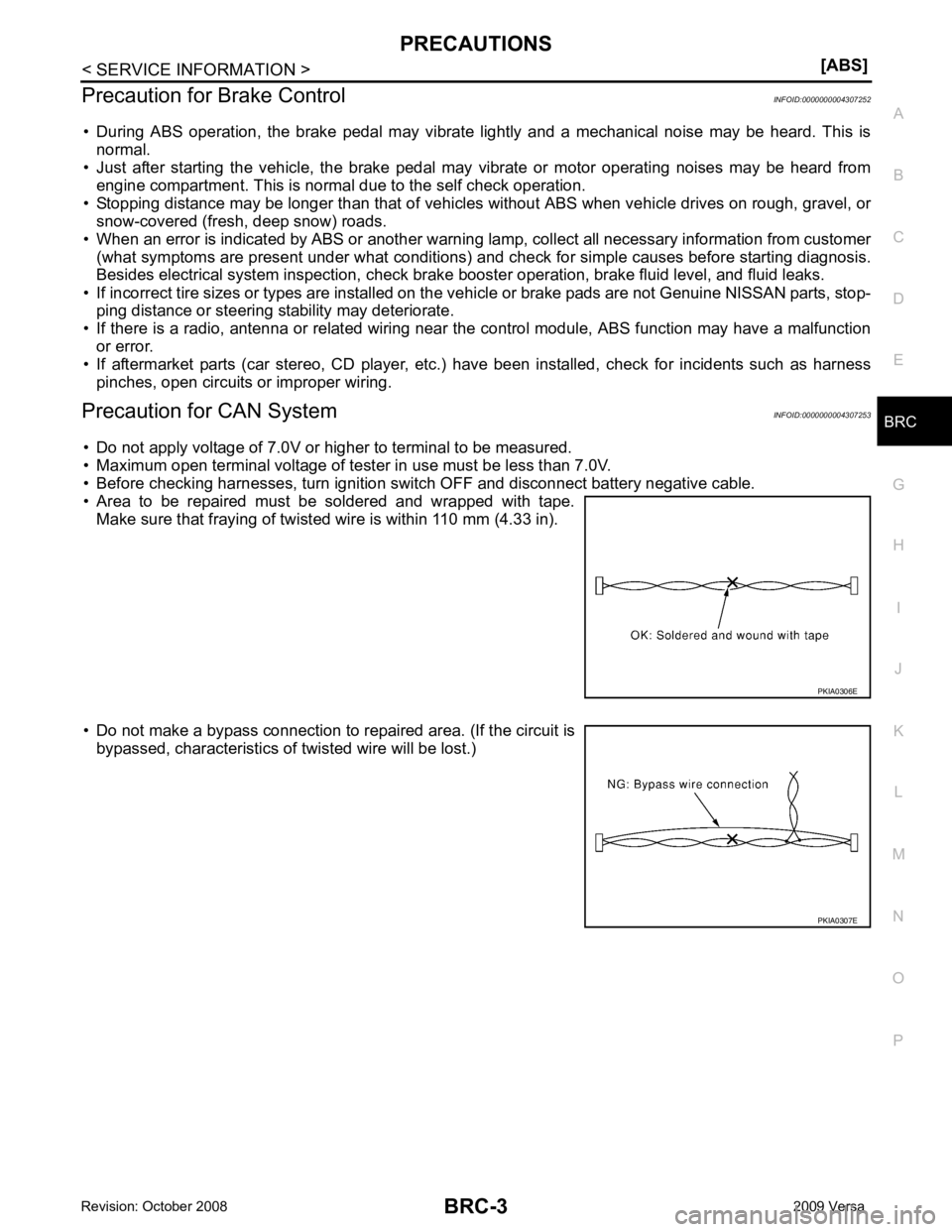

• Area to be repaired must be soldered and wrapped with tape. Make sure that fraying of twisted wire is within 110 mm (4.33 in).

• Do not make a bypass connection to repaired area. (If the circuit is bypassed, characteristics of twisted wire will be lost.)

Page 845 of 4331

BRC

N

O P

SYSTEM DESCRIPTION

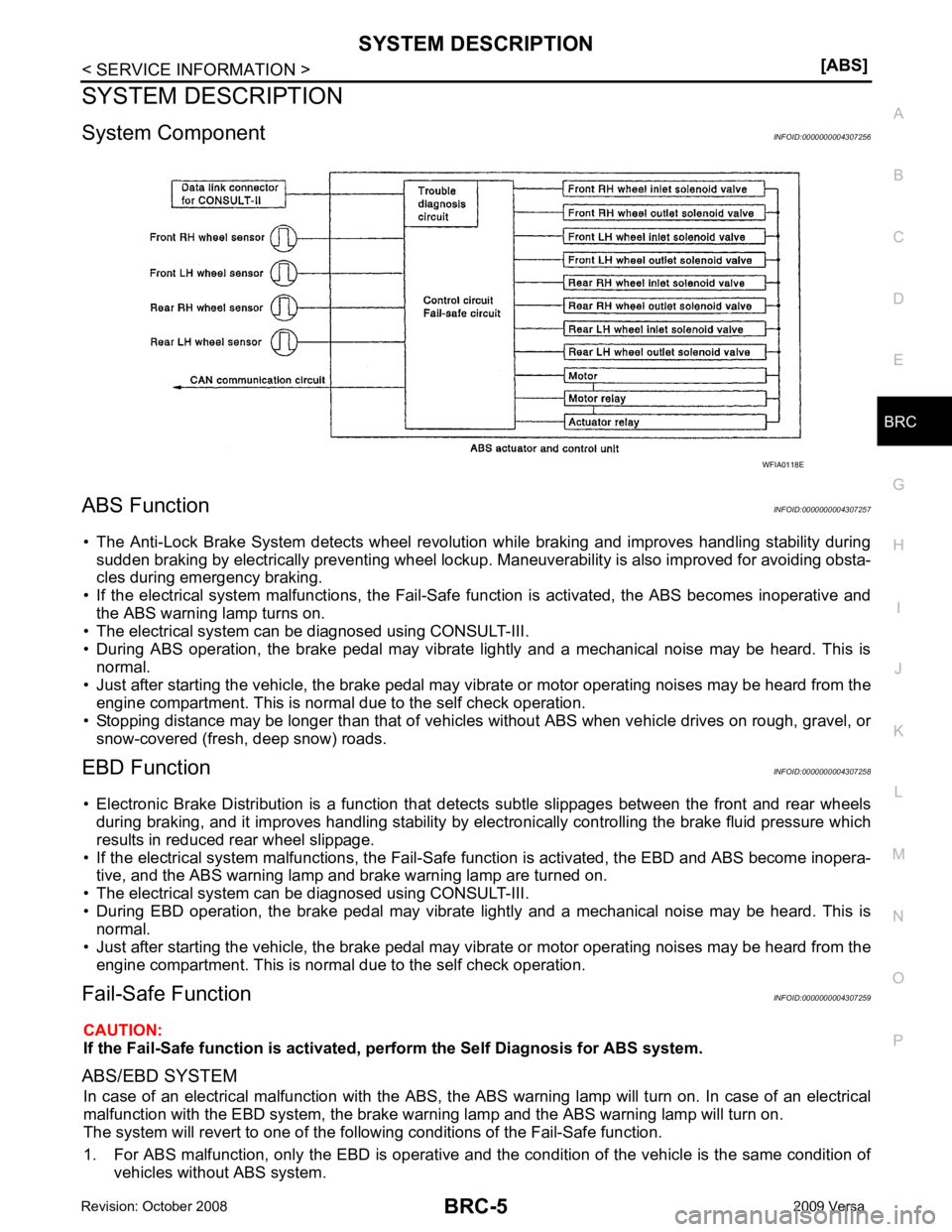

System Component INFOID:0000000004307256

ABS Function INFOID:0000000004307257

• The Anti-Lock Brake System detects wheel revolution while braking and improves handling stability during sudden braking by electrically preventing wheel lockup. Maneuverability is also improved for avoiding obsta-

cles during emergency braking.

• If the electrical system malfunctions, the Fail-Safe function is activated, the ABS becomes inoperative and

the ABS warning lamp turns on.

• The electrical system can be diagnosed using CONSULT-III.

• During ABS operation, the brake pedal may vibrate lightly and a mechanical noise may be heard. This is

normal.

• Just after starting the vehicle, the brake pedal may vibrate or motor operating noises may be heard from the

engine compartment. This is normal due to the self check operation.

• Stopping distance may be longer than that of vehicles without ABS when vehicle drives on rough, gravel, or

snow-covered (fresh, deep snow) roads.

EBD Function INFOID:0000000004307258

• Electronic Brake Distribution is a function that detec ts subtle slippages between the front and rear wheels

during braking, and it improves handling stability by elec tronically controlling the brake fluid pressure which

results in reduced rear wheel slippage.

• If the electrical system malfunctions, the Fail-Safe function is activated, the EBD and ABS become inopera-

tive, and the ABS warning lamp and brake warning lamp are turned on.

• The electrical system can be diagnosed using CONSULT-III.

• During EBD operation, the brake pedal may vibrate lightly and a mechanical noise may be heard. This is

normal.

• Just after starting the vehicle, the brake pedal may vibrate or motor operating noises may be heard from the

engine compartment. This is normal due to the self check operation.

Fail-Safe Function INFOID:0000000004307259

CAUTION:

If the Fail-Safe function is activated, perform the Self Diagnosis for ABS system.

ABS/EBD SYSTEM In case of an electrical malfunction with the ABS, the ABS warning lamp wi ll turn on. In case of an electrical

malfunction with the EBD system, the brake warni ng lamp and the ABS warning lamp will turn on.

The system will revert to one of the follo wing conditions of the Fail-Safe function.

1. For ABS malfunction, only the EBD is operative and t he condition of the vehicle is the same condition of

vehicles without ABS system.