NISSAN LATIO 2009 Service Repair Manual

Manufacturer: NISSAN, Model Year: 2009, Model line: LATIO, Model: NISSAN LATIO 2009Pages: 4331, PDF Size: 58.04 MB

Page 921 of 4331

CO

NP

O

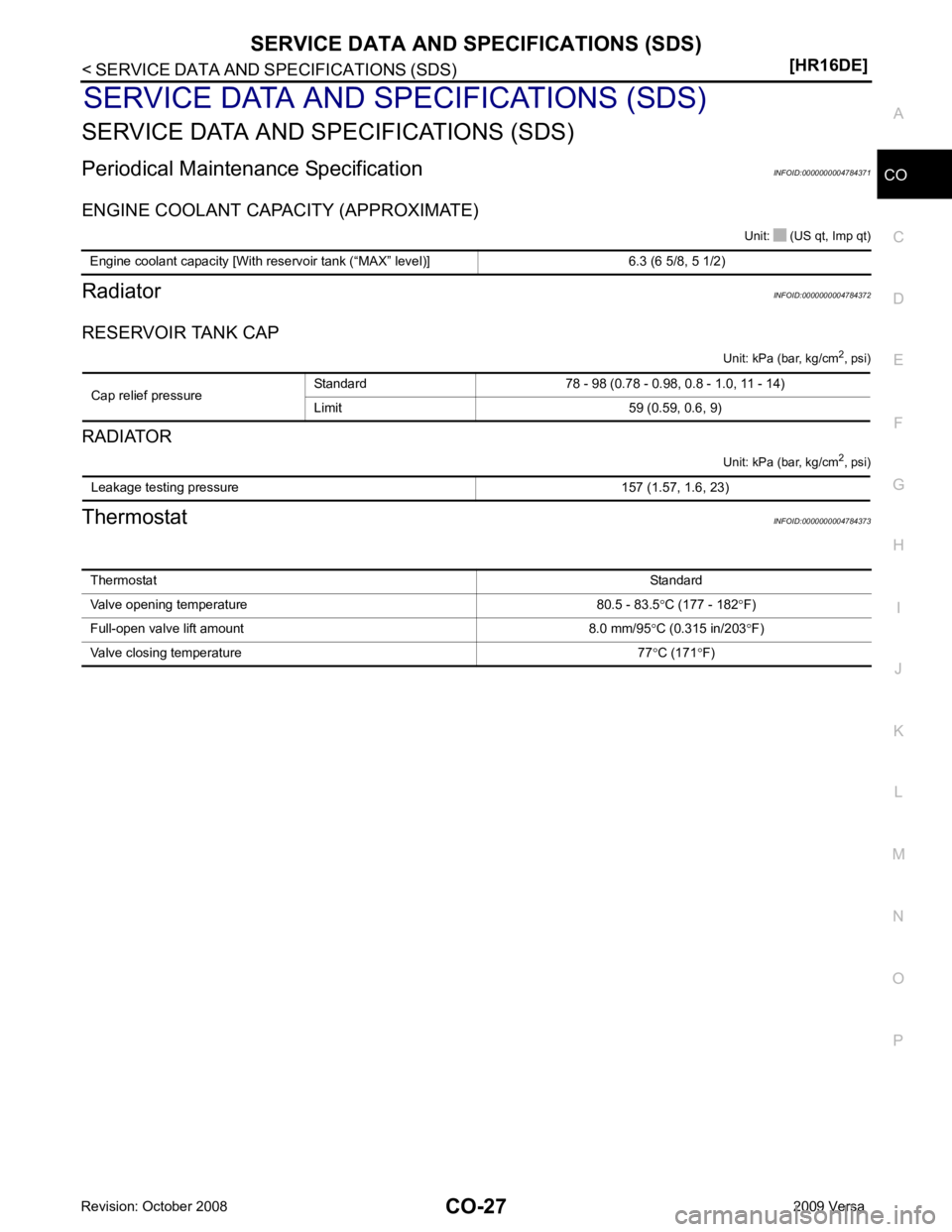

SERVICE DATA AND SPECIFICATIONS (SDS)

SERVICE DATA AND SPECIFICATIONS (SDS)

Periodical Maintenance Specification INFOID:0000000004784371

ENGINE COOLANT CAPACITY (APPROXIMATE) Unit: (US qt, Imp qt)

Radiator INFOID:0000000004784372

RESERVOIR TANK CAP Unit: kPa (bar, kg/cm2

, psi)

RADIATOR Unit: kPa (bar, kg/cm2

, psi)

Thermostat INFOID:0000000004784373Cap relief pressure

Standard 78 - 98 (0.78 - 0.98, 0.8 - 1.0, 11 - 14)

Limit 59 (0.59, 0.6, 9) Leakage testing pressure 157 (1.57, 1.6, 23)

Thermostat

Standard

Valve opening temperature 80.5 - 83.5 °C (177 - 182 °F)

Full-open valve lift amount 8.0 mm/95 °C (0.315 in/203 °F)

Valve closing temperature 77°C (171 °F)

Page 922 of 4331

Page 923 of 4331

![NISSAN LATIO 2009 Service Repair Manual PRECAUTIONS

CO-29

< SERVICE INFORMATION >

[MR18DE] C

D E

F

G H

I

J

K L

M A CO

NP

O

Precaution for Liquid Gasket

INFOID:0000000004305229

REMOVAL OF LIQUID GASKET SEALING • After removing nuts and bol NISSAN LATIO 2009 Service Repair Manual PRECAUTIONS

CO-29

< SERVICE INFORMATION >

[MR18DE] C

D E

F

G H

I

J

K L

M A CO

NP

O

Precaution for Liquid Gasket

INFOID:0000000004305229

REMOVAL OF LIQUID GASKET SEALING • After removing nuts and bol](/img/5/57359/w960_57359-922.png)

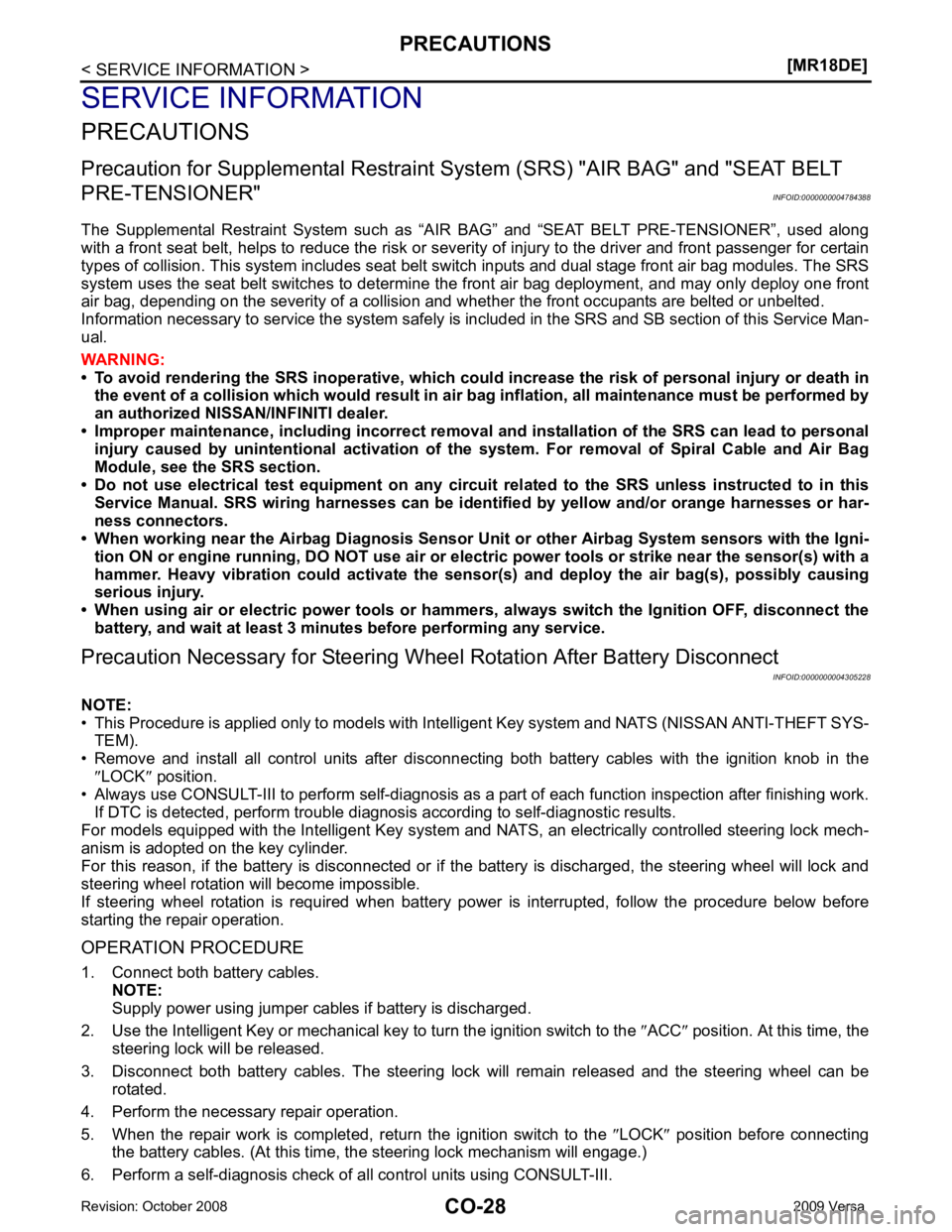

PRECAUTIONS

CO-29

< SERVICE INFORMATION >

[MR18DE] C

D E

F

G H

I

J

K L

M A CO

NP

O

Precaution for Liquid Gasket

INFOID:0000000004305229

REMOVAL OF LIQUID GASKET SEALING • After removing nuts and bolts, separate the mating surface, using Tool and remove old liquid gasket sealing.

CAUTION:

Be careful not to damage the mating surfaces.

• Tap Tool to insert it (1), and then slide it by tapping on the side (2)

as shown.

• In areas where Tool is difficult to use, use plastic hammer to lightly

tap the parts, to remove it.

CAUTION:

If for some unavoidable reason suitable tool such as screw-

driver is used, be careful not to damage the mating surfaces.

LIQUID GASKET APPLICATION PROCEDURE 1. Remove old liquid gasket adhering to the liquid gasket applica- tion surface and the mating surface, using scraper.

• Remove liquid gasket completely from the groove of the liquid gasket application surface, bolts, and bolt holes.

2. Thoroughly clean the mating surfaces and remove adhering moisture, grease and foreign materials.

3. Attach liquid gasket tube to Tool.

Use Genuine RTV Silicone Seal ant or equivalent. Refer to GI-42, " Recommended Chemical Prod-

uct and Sealant " .

4. Apply liquid gasket without breaks to the spec ified location with the specified dimensions.

• If there is a groove for the liquid gasket application, apply liquid gasket to the groove.

• As for the bolt holes, normally apply liquid gasket inside the holes. Occasionally, it should be applied outside the holes.

Make sure to read the text of service manual.

• Within five minutes of liquid gasket application, install the mat-

ing component.

• If liquid gasket protrudes, wipe it off immediately.

• Do not retighten nuts or bolts after the installation.

• After 30 minutes or more have passed from the installation, fill engine oil and engine coolant.

CAUTION:

If there are specific instructions in this manual, observe them.

Tool number : KV10111100 (J-37228)

WBIA0566E

Tool number : WS39930000 ( — )

PBIC0003E

WBIA0567E

SEM159F

Page 924 of 4331

![NISSAN LATIO 2009 Service Repair Manual CO-30< SERVICE INFORMATION >

[MR18DE]

PREPARATION

PREPARATION

Special Service Tool INFOID:0000000004673018

The actual shapes of Kent-Moore tools may from those of special service tools illustrated he NISSAN LATIO 2009 Service Repair Manual CO-30< SERVICE INFORMATION >

[MR18DE]

PREPARATION

PREPARATION

Special Service Tool INFOID:0000000004673018

The actual shapes of Kent-Moore tools may from those of special service tools illustrated he](/img/5/57359/w960_57359-923.png)

CO-30< SERVICE INFORMATION >

[MR18DE]

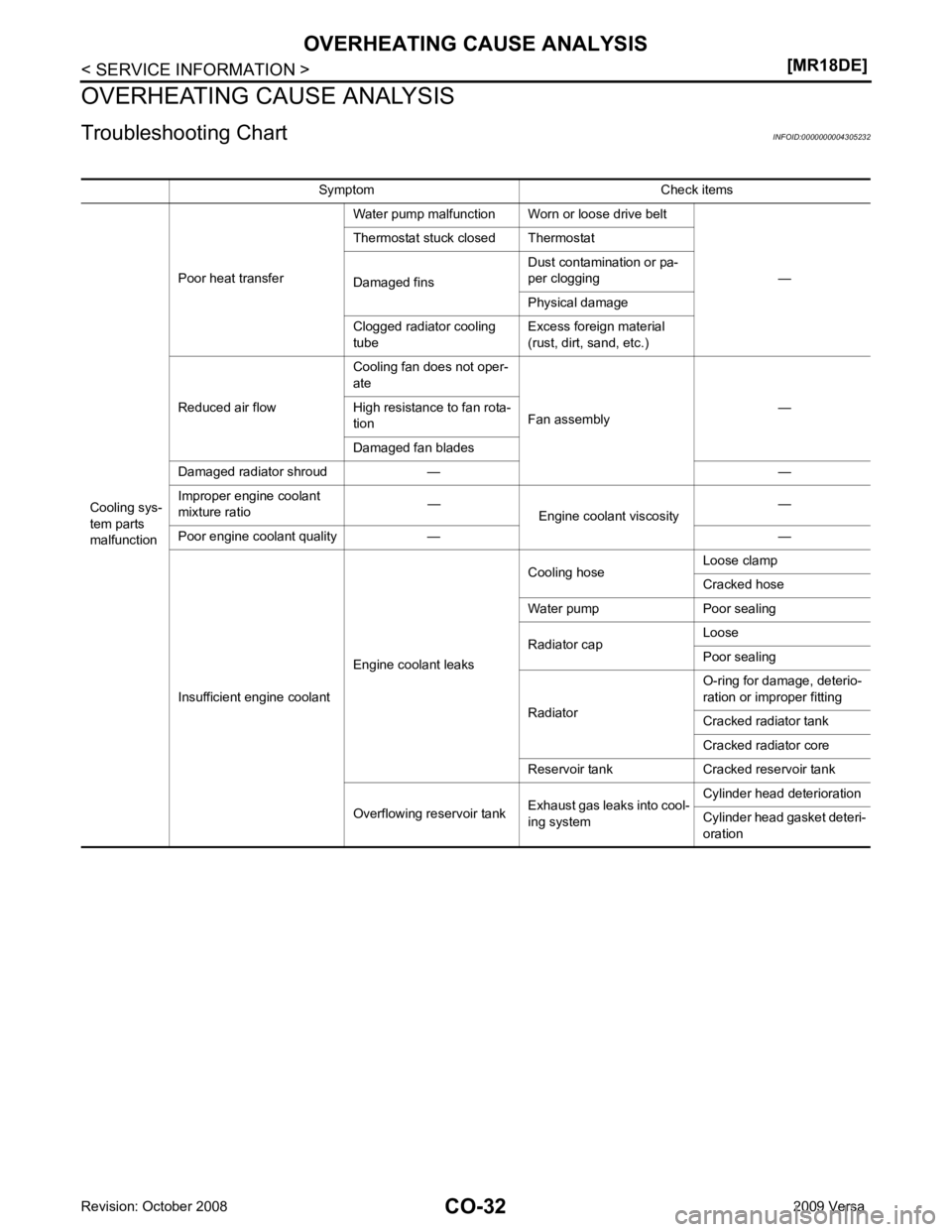

PREPARATION

PREPARATION

Special Service Tool INFOID:0000000004673018

The actual shapes of Kent-Moore tools may from those of special service tools illustrated here.

Commercial Service Tool INFOID:0000000004673019

Tool number

(Kent-Moore No.)

Tool name Description

WS39930000

( — )

Tube pressure Pressing the tube of liquid gasket

KV991J0070

(J-45695)

Coolant Refill Tool Refilling engine cooling system

EG17650301

(J-33984-A)

Radiator cap tester adapter Adapting radiator cap tester to radiator cap

and radiator filler neck

a: 28 (1.10) dia.

b: 31.4 (1.236) dia.

c: 41.3 (1.626) dia.

Unit: mm (in)

KV10111100

(J-37228)

Seal cutter Removing chain tensioner cover and water

pump cover

—

(J-23688)

Engine coolant refractometer Checking concentration of ethylene glycol in

engine coolant S-NT052

LMA053

S-NT564

NT046

WBIA0539E

Page 925 of 4331

![NISSAN LATIO 2009 Service Repair Manual PREPARATION

CO-31

< SERVICE INFORMATION >

[MR18DE] C

D E

F

G H

I

J

K L

M A CO

NP

O

Tool name

Description

Power tool Loosening bolts and nuts

Radiator cap tester Checking radiator and radiator cap PBIC NISSAN LATIO 2009 Service Repair Manual PREPARATION

CO-31

< SERVICE INFORMATION >

[MR18DE] C

D E

F

G H

I

J

K L

M A CO

NP

O

Tool name

Description

Power tool Loosening bolts and nuts

Radiator cap tester Checking radiator and radiator cap PBIC](/img/5/57359/w960_57359-924.png)

PREPARATION

CO-31

< SERVICE INFORMATION >

[MR18DE] C

D E

F

G H

I

J

K L

M A CO

NP

O

Tool name

Description

Power tool Loosening bolts and nuts

Radiator cap tester Checking radiator and radiator cap PBIC0190E

PBIC1982E

Page 926 of 4331

Page 927 of 4331

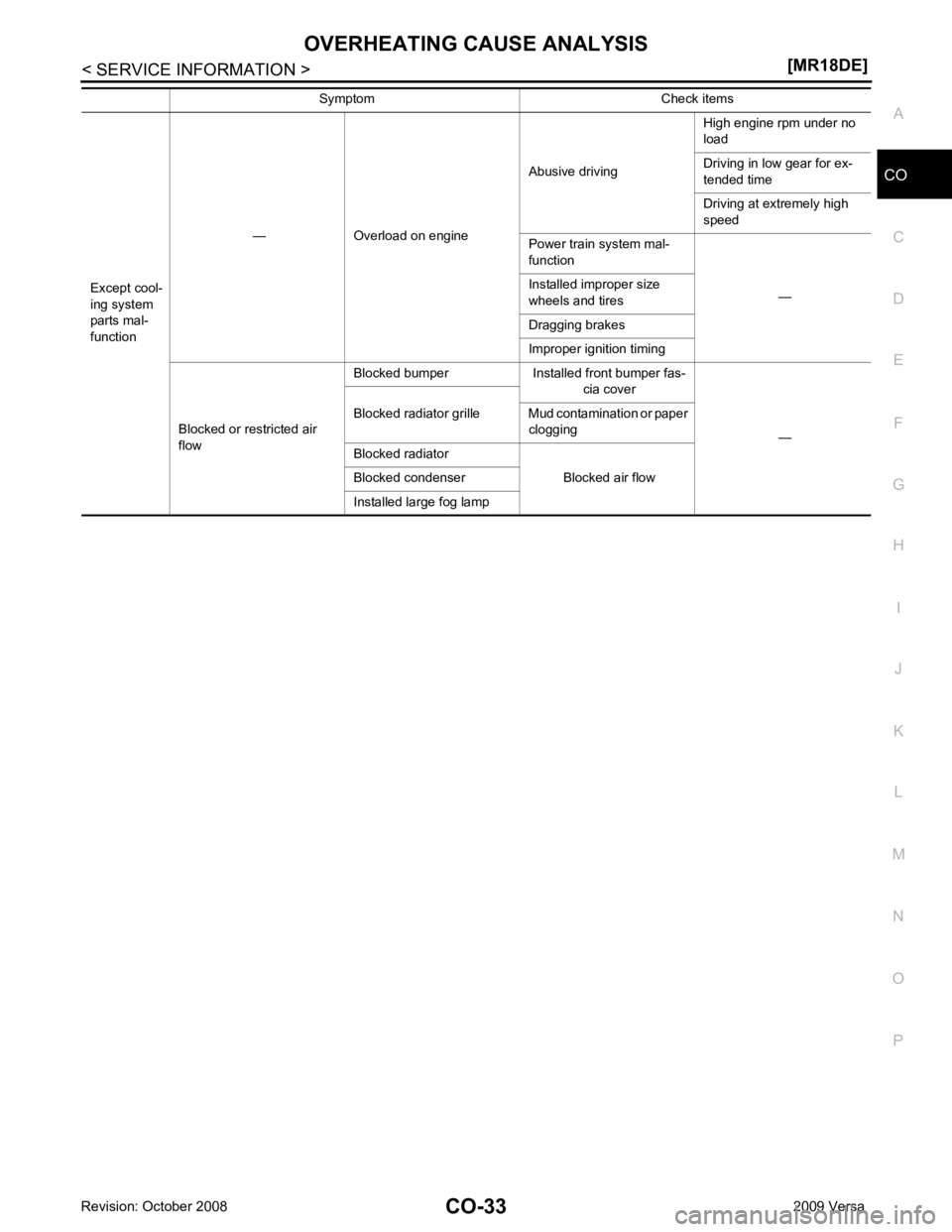

CO

NP

O

Except cool-

ing system

parts mal-

function — Overload on engine

Abusive driving

High engine rpm under no

load

Driving in low gear for ex-

tended time

Driving at extremely high

speed

Power train system mal-

function

—

Installed improper size

wheels and tires

Dragging brakes

Improper ignition timing

Blocked or restricted air

flow Blocked bumper Installed front bumper fas-

cia cover

—

Blocked radiator grille Mud contamination or paper

clogging

Blocked radiator Blocked air flow

Blocked condenser

Installed large fog lamp

Symptom Check items

Page 928 of 4331

Page 929 of 4331

![NISSAN LATIO 2009 Service Repair Manual ENGINE COOLANT

CO-35

< SERVICE INFORMATION >

[MR18DE] C

D E

F

G H

I

J

K L

M A CO

NP

O

ENGINE COOLANT

Inspection INFOID:0000000004305234

LEVEL CHECK • Check if the reservoir tank engine coolant level NISSAN LATIO 2009 Service Repair Manual ENGINE COOLANT

CO-35

< SERVICE INFORMATION >

[MR18DE] C

D E

F

G H

I

J

K L

M A CO

NP

O

ENGINE COOLANT

Inspection INFOID:0000000004305234

LEVEL CHECK • Check if the reservoir tank engine coolant level](/img/5/57359/w960_57359-928.png)

ENGINE COOLANT

CO-35

< SERVICE INFORMATION >

[MR18DE] C

D E

F

G H

I

J

K L

M A CO

NP

O

ENGINE COOLANT

Inspection INFOID:0000000004305234

LEVEL CHECK • Check if the reservoir tank engine coolant level is within the “MIN” to “MAX” range when engine is cool.

• Adjust the engine coolant level as necessary.

CHECKING COOLING SYSTEM FOR LEAKS To check for leaks, apply pressure to the cooling system using suit-

able tool and Tool.

WARNING:

Never remove the radiator cap wh en the engine is hot. Serious

burns could occur from high pressure coolant escaping from

the radiator.

CAUTION:

Higher pressure than specified may cause radiator damage.

Changing Engine Coolant INFOID:0000000004673021

WARNING:

• To avoid being scalded, do not change engine coolant when engine is hot.

• Wrap a thick cloth around radiator cap and carefully remove the cap. First, turn the cap a quarter of a

turn to release built-up pressure. Then turn the cap all the way.

CAUTION:

• Do not spill engine coolant on drive belt.

DRAINING ENGINE COOLANT 1. Open radiator drain plug (1) at the bottom of radiator, and then remove radiator cap.

• Front

When draining all of engine coolant in the system, open

water drain plug on cylinder block. Refer to EM-200 .

CAUTION:

• Perform this step when engine is cold.

• Do not spill engine coolant on drive belt.

2. Remove reservoir tank as necessary, and drain engi ne coolant and clean reservoir tank before installing.

Refer to CO-38, " Component " .

3. Check drained engine coolant for contaminants such as rust, corrosion or discoloration. If contaminated, flush the engine cooling system. SMA412B

Tool number : EG17650301 (J-33984-A)

Testing pressure : 157 kPa (1.6 kg/cm 2

, 23 psi) WBIA0568E

PBIC3799E

Page 930 of 4331

![NISSAN LATIO 2009 Service Repair Manual CO-36< SERVICE INFORMATION >

[MR18DE]

ENGINE COOLANT

REFILLING ENGINE COOLANT

1. Install the radiator drain plug. Install the reservoir tank and cylinder block drain plug, if removed for a total

syst NISSAN LATIO 2009 Service Repair Manual CO-36< SERVICE INFORMATION >

[MR18DE]

ENGINE COOLANT

REFILLING ENGINE COOLANT

1. Install the radiator drain plug. Install the reservoir tank and cylinder block drain plug, if removed for a total

syst](/img/5/57359/w960_57359-929.png)

CO-36< SERVICE INFORMATION >

[MR18DE]

ENGINE COOLANT

REFILLING ENGINE COOLANT

1. Install the radiator drain plug. Install the reservoir tank and cylinder block drain plug, if removed for a total

system drain or for engine removal or repair.

• The radiator must be complete ly empty of coolant and water.

• Apply sealant to the threads of the cylinder bl ock drain plugs. Use Genuine High Performance

Thread Sealant or equivalent. Refer to GI-42, " Recommended Chemical Product and Sealant " .

2. If disconnected, reattach the upper radiator hose at the engine side.

3. Set the vehicle heater controls to the full HOT and heat er ON position. Turn the vehicle ignition ON with

the engine OFF as necessary to activate the heater mode.

4. Install the Tool by installing the radiator cap adapter onto the radiator neck opening. Then attach the gauge body assembly

with the refill tube and the venturi assembly to the radiator cap

adapter.

5. Insert the refill hose into the coolant mixture container that is placed at floor level. Make sure the ball valve is in the closed

position.

• Use Genuine NISSAN Long Life Anti-freeze coolant or

equivalent, mixed with distil led water or demineralized

water.

Refer to MA-15, " Anti-freeze Coolant Mixture Ratio " .

6. Install an air hose to the venturi assembly, the air pressure must be within specification.

CAUTION:

The compressed air supply must be equipped with an air dryer.

7. The vacuum gauge will begin to rise and there will be an audible hissing noise. During this process open the ball valve on the refill hose slightly. Coolant will be vi sible rising in the refill hose. Once the refill hose is

full of coolant, close the ball valve. This will purge any air trapped in the refill hose.

8. Continue to draw the vacuum until the gauge reaches 28 inches of vacuum. The gauge may not reach 28 inches in high altitude

locations, use the vacuum specifications based on the altitude

above sea level.

9. When the vacuum gauge has reached the specifi ed amount, disconnect the air hose and wait 20 seconds

to see if the system loses any vacuum. If the vacuum level drops, perform any necessary repairs to the

system and repeat steps 6 - 8 to bring the vacuum to the specified amount. Recheck for any leaks.

Radiator drain plug : Refer to

CO-38, " Component " .

Cylinder block drain plug : Refer to EM-200, " Disassembly and Assembly " .

Tool number : KV991J0070 (J-45695)

Engine coolant capacity

(with reservoir tank) : Refer to

MA-14, " Fluids

and Lubricants " .

Compressed air

supply pressure : 5.7 - 8.5 kPa (5.6 - 8.4 kg/cm

2

,

80 - 120 psi) LLIA0058E

Altitude above sea level Vacuum gauge reading

0 - 100 m (328 ft) : 28 inches of vacuum

300 m (984 ft) : 27 inches of vacuum

500 m (1,641 ft) : 26 inches of vacuum

1,000 m (3,281 ft) : 24 - 25 inches of vacuum LLIA0057E