NISSAN LATIO 2009 Service Repair Manual

Manufacturer: NISSAN, Model Year: 2009, Model line: LATIO, Model: NISSAN LATIO 2009Pages: 4331, PDF Size: 58.04 MB

Page 941 of 4331

CO

NP

O

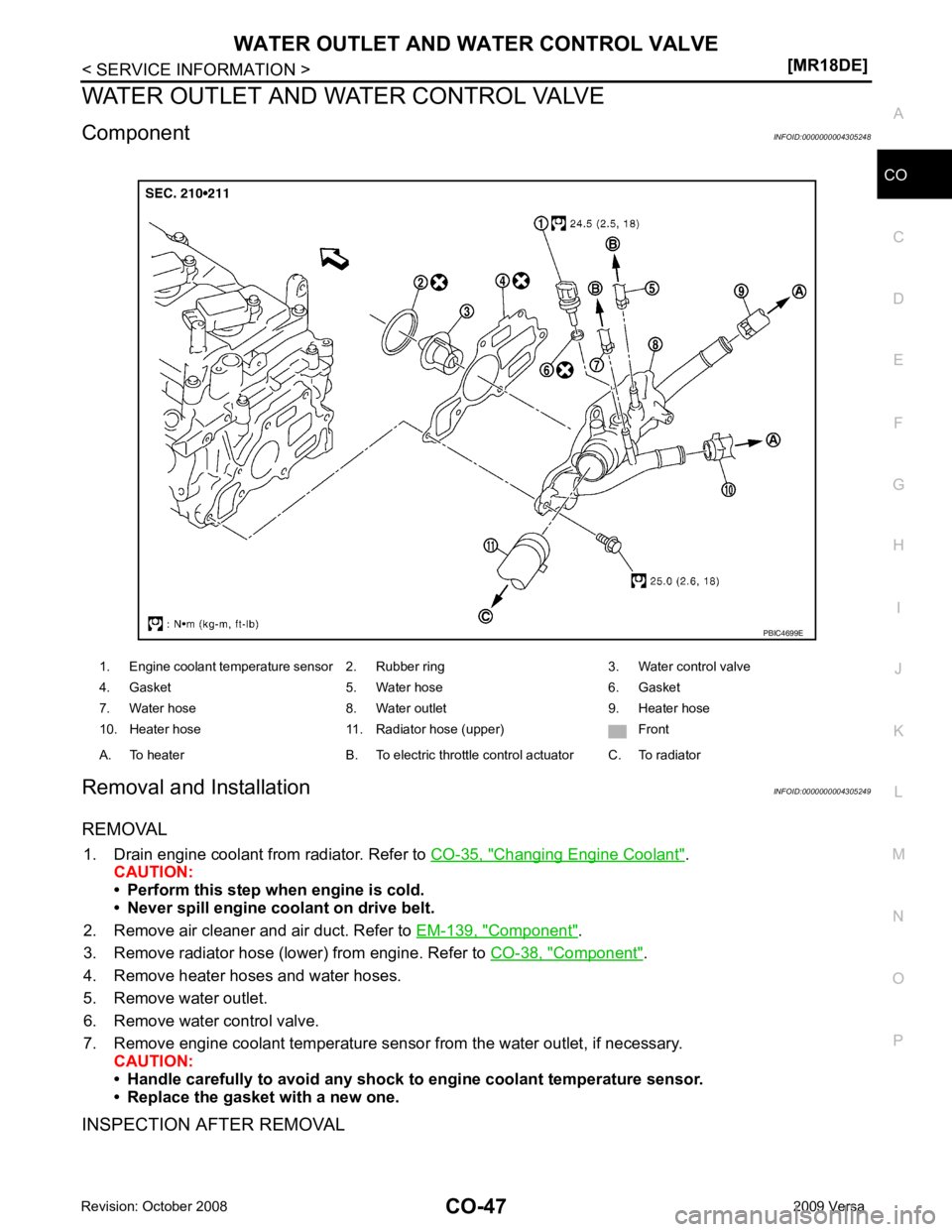

WATER OUTLET AND WATER CONTROL VALVE

Component INFOID:0000000004305248

Removal and Installation INFOID:0000000004305249

REMOVAL 1. Drain engine coolant from radiator. Refer to CO-35, " Changing Engine Coolant " .

CAUTION:

• Perform this step when engine is cold.

• Never spill engine coolant on drive belt.

2. Remove air cleaner and air duct. Refer to EM-139, " Component " .

3. Remove radiator hose (lower) from engine. Refer to CO-38, " Component " .

4. Remove heater hoses and water hoses.

5. Remove water outlet.

6. Remove water control valve.

7. Remove engine coolant temperature sensor from the water outlet, if necessary. CAUTION:

• Handle carefully to avoid any shock to engine coolant temperature sensor.

• Replace the gasket with a new one.

INSPECTION AFTER REMOVAL 1. Engine coolant temperature sensor 2. Rubber ring 3. Water control valve

4. Gasket 5. Water hose 6. Gasket

7. Water hose 8. Water outlet 9. Heater hose

10. Heater hose 11. Radiator hose (upper) Front

A. To heater B. To electric throttle control actuator C. To radiator

Page 942 of 4331

![NISSAN LATIO 2009 Service Repair Manual CO-48< SERVICE INFORMATION >

[MR18DE]

WATER OUTLET AND WATER CONTROL VALVE

• Place a thread (A) so that it is c aught in the valves of water control

valve (1). Immerse fully in a container (B NISSAN LATIO 2009 Service Repair Manual CO-48< SERVICE INFORMATION >

[MR18DE]

WATER OUTLET AND WATER CONTROL VALVE

• Place a thread (A) so that it is c aught in the valves of water control

valve (1). Immerse fully in a container (B](/img/5/57359/w960_57359-941.png)

CO-48< SERVICE INFORMATION >

[MR18DE]

WATER OUTLET AND WATER CONTROL VALVE

• Place a thread (A) so that it is c aught in the valves of water control

valve (1). Immerse fully in a container (B) filled with water. Heat

while stirring.

• The valve opening temperature is the temperature at which the

valve opens and falls from the thread.

• Continue heating. Check the full-open valve lift amount.

NOTE:

The full-open valve lift amount standard temperature for water con-

trol valve is the reference value.

• After checking the full-open valve lift amount, lower the water tem- perature and check the valve closing temperature.

• If out of the specification, replace water control valve.

INSTALLATION

Installation is in the reverse order of removal.

• Use the following procedure to install the water control valve.

- Install water control valve while making rubber ring (1) groove fit to water control valve flange (A) around the whole circumference.

CAUTION:

Replace the rubber ring with a new one.

- While the mark (A) points to up, install water control valve (2) with frame center (B) facing straight upward into water outlet (1).

• Use the following procedure to install the water outlet.

- Install the water outlet to the cylinder head without disp lacing the water control valve from the valve position.

• Use the following procedure to install the water hoses. Valve opening temperature 93.5 - 96.5

°C (200 - 206 °F)

Full-open valve lift amount 8 mm/ 108 °C (0.315 in/ 226 °F)

Valve closing temperature 90 °C (194 °F) PBIC3314J

PBIC3317J

PBIC4700E

Page 943 of 4331

CO

NP

O

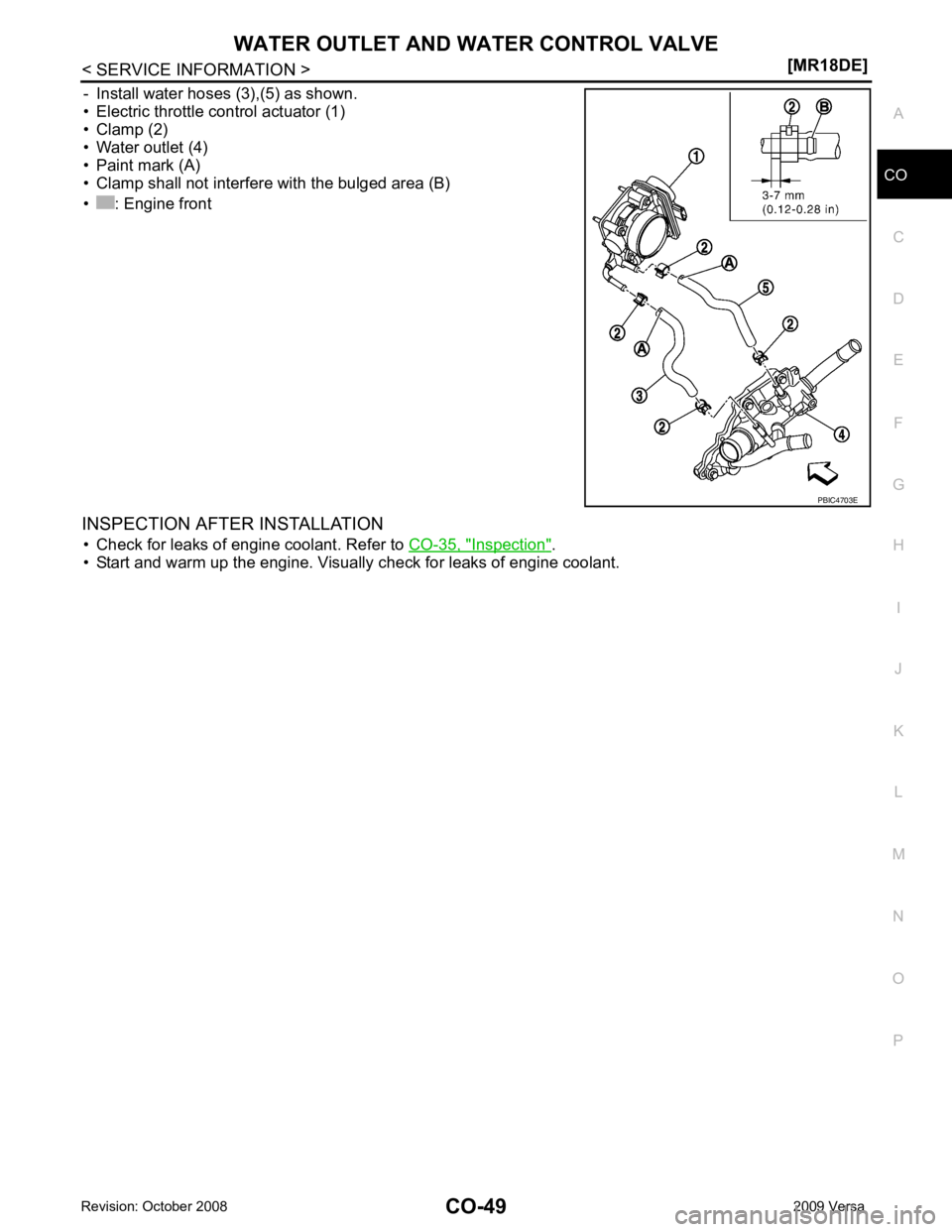

- Install water hoses (3),(5) as shown.

• Electric throttle control actuator (1)

• Clamp (2)

• Water outlet (4)

• Paint mark (A)

• Clamp shall not interfere with the bulged area (B)

• : Engine front

INSPECTION AFTER INSTALLATION • Check for leaks of engine coolant. Refer to CO-35, " Inspection " .

• Start and warm up the engine. Visually check for leaks of engine coolant.

Page 944 of 4331

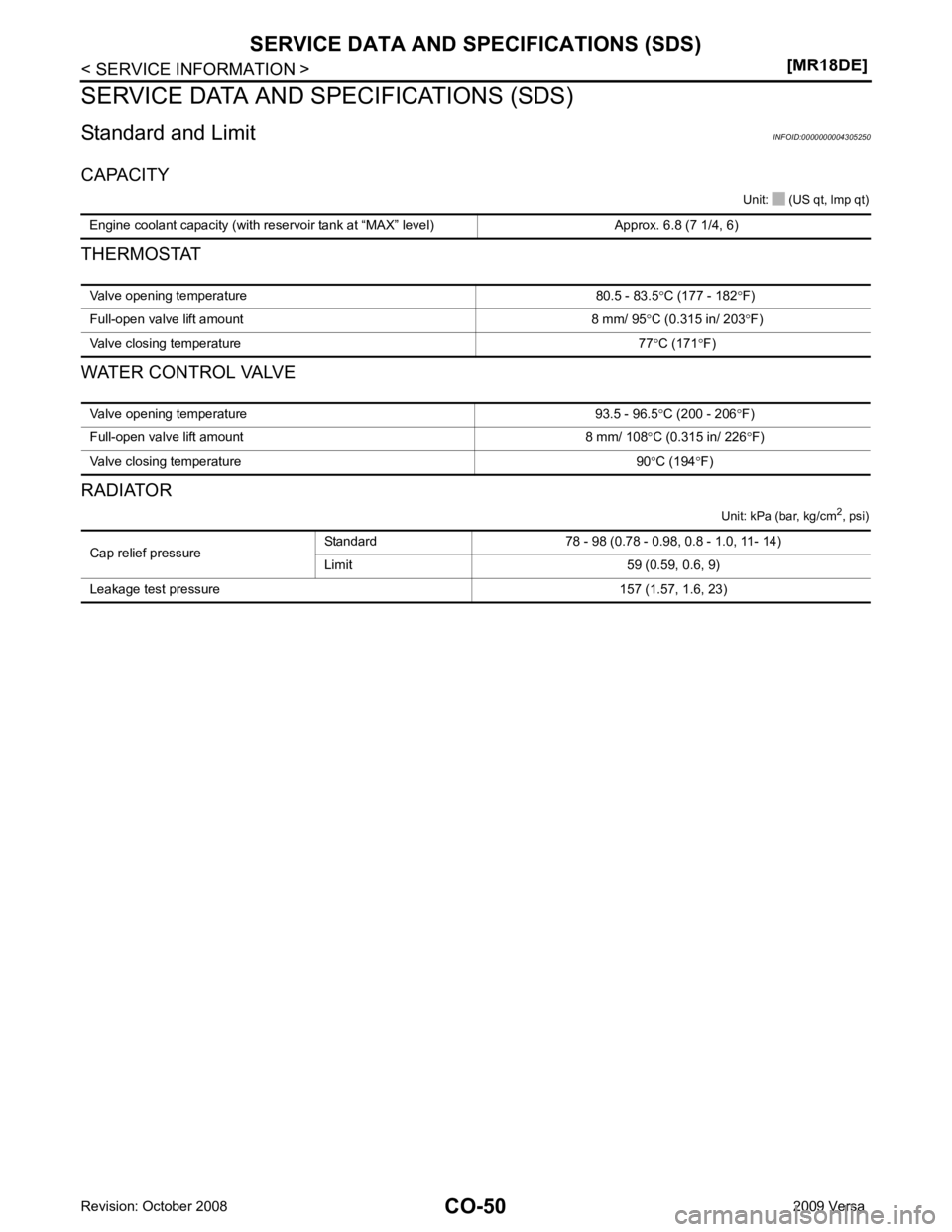

Valve opening temperature 80.5 - 83.5

°C (177 - 182 °F)

Full-open valve lift amount 8 mm/ 95 °C (0.315 in/ 203 °F)

Valve closing temperature 77 °C (171 °F) Valve opening temperature 93.5 - 96.5

°C (200 - 206 °F)

Full-open valve lift amount 8 mm/ 108 °C (0.315 in/ 226 °F)

Valve closing temperature 90°C (194 °F) Cap relief pressure

Standard 78 - 98 (0.78 - 0.98, 0.8 - 1.0, 11- 14)

Limit 59 (0.59, 0.6, 9)

Leakage test pressure 157 (1.57, 1.6, 23)

Page 945 of 4331

CVT

N

O P

CONTENTS

CVT

RE0F08A

SERVICE INFORMATION .. ..........................

9

INDEX FOR DTC ............................................ .....9

Alphabetical Index ............................................... ......9

DTC No. Index .................................................... ......9

PRECAUTIONS .............................................. ....11

Precaution for Supplemental Restraint System

(SRS) "AIR BAG" and "SEAT BELT PRE-TEN-

SIONER" ............................................................. ....

11

Precaution Necessary fo r Steering Wheel Rota-

tion After Battery Disconnect ............................... ....

11

Precaution for On Board Diagnosis (OBD) System

of CVT and Engine .............................................. ....

12

Service After Replacing TCM and Transaxle As-

sembly ................................................................. ....

12

Removal and Installation Procedure for CVT Unit

Connector ............................................................ ....

13

Precaution ........................................................... ....14

Service Notice or Precaution ............................... ....15

PREPARATION .............................................. ....16

Special Service Tool ........................................... ....16

Commercial Service Tool .................................... ....16

CVT FLUID ..................................................... ....17

Checking CVT Fluid ............................................ ....17

Changing CVT Fluid ............................................ ....18

CVT Fluid Cooler Cleanin g .....................................18

CVT SYSTEM ... .............................................. ....22

Cross-Sectional View - RE0F08A ....................... ....22

Control System .................................................... ....23

Hydraulic Control System ........................................24

TCM Function ...................................................... ....24

CAN Communication ........................................... ....25

Input/Output Signal of TCM ................................. ....26

Line Pressure and Secondary Pressure Control . ....26

Shift Control ........................................................ ....27

Lock-up and Select Control ................................. ....28 Control Valve .......................................................

....29

ON BOARD DIAGNOSTIC (OBD) SYSTEM .... 30

Introduction .......................................................... ....30

OBD-II Function for CVT System ........................ ....30

One or Two Trip Detection Logic of OBD-II ......... ....30

OBD-II Diagnostic Trouble Code (DTC) .............. ....30

Malfunction Indicator Lamp (MIL) ............................31

TROUBLE DIAGNOSIS .................................... 33

DTC Inspection Priority Chart .............................. ....33

Fail-Safe .............................................................. ....33

How to Perform Trouble Diagnosis for Quick and

Accurate Repair ................................................... ....

34

CVT Electrical Parts Location .............................. ....39

Circuit Diagram .................................................... ....40

Inspections before Trouble Diagnosis ................. ....40

Road Test ............................................................ ....44

Check before Engine Is Started ........................... ....45

Check at Idle ........................................................ ....45

Cruise Test .......................................................... ....47

Vehicle Speed When Shifting Gears ................... ....49

TCM Terminal and Refere nce Value .......................49

CONSULT-III Function (TRANSMISSION) .......... ....51

Diagnosis Procedure withou t CONSULT-III ............59

DTC U1000 CAN COMMUNICATION LINE ..... 60

Description ........................................................... ....60

On Board Diagnosis Logic ................................... ....60

Possible Cause .................................................... ....60

DTC Confirmation Procedure .............................. ....60

Wiring Diagram - CVT - CAN ............................... ....61

Diagnosis Procedure ........................................... ....62

DTC U1010 TRANSMISSION CONTROL

MODULE (CAN) ................................................ 63

Description ........................................................... ....63

On Board Diagnosis Logic ................................... ....63

Possible Cause .................................................... ....63

DTC Confirmation Procedure .............................. ....63

Diagnosis Procedure ........................................... ....63

Page 946 of 4331

Page 947 of 4331

CVT

N

O

P

N

Description ..........................................................

..

104

CONSULT-III Refe rence Value in Data Monitor

Mode ................................................................... ..

104

On Board Diagnosis Logic .................................. ..104

Possible Cause ................................................... ..104

DTC Confirmation Procedure .............................. ..104

Diagnosis Procedure ........................................... ..104

DTC P0776 PRESSURE CONTROL SOLE-

NOID B PERFORMANCE (SEC PRESSURE

SOLENOID VALVE) ....................................... ..106

Description .......................................................... ..106

CONSULT-III Refe rence Value in Data Monitor

Mode ................................................................... ..

106

On Board Diagnosis Logic .................................. ..106

Possible Cause ................................................... ..106

DTC Confirmation Procedure .............................. ..106

Diagnosis Procedure ........................................... ..106

DTC P0778 PRESSURE CONTROL SOLE-

NOID B ELECTRICAL (SEC PRESSURE SO-

LENOID VALVE) ............................................ ..

108

Description .......................................................... ..108

CONSULT-III Refe rence Value in Data Monitor

Mode ................................................................... ..

108

On Board Diagnosis Logic .................................. ..108

Possible Cause ................................................... ..108

DTC Confirmation Procedure .............................. ..108

Wiring Diagram - CVT - SECPSV .........................109

Diagnosis Procedure ........................................... ..110

Component Inspection ........................................ ..111

DTC P0840 TRANSMISSION FLUID PRES-

SURE SENSOR A CIRCUIT (SEC PRES-

SURE SENSOR) ............................................. ..

113

Description .......................................................... ..113

CONSULT-III Refe rence Value in Data Monitor

Mode ................................................................... ..

113

On Board Diagnosis Logic .................................. ..113

Possible Cause ................................................... ..113

DTC Confirmation Procedure .............................. ..113

Wiring Diagram - CVT - SECPS .......................... ..114

Diagnosis Procedure ........................................... ..115

DTC P0841 PRESSURE SENSOR FUNC-

TION ............................................................... ..

117

Description .......................................................... ..117

CONSULT-III Refe rence Value in Data Monitor

Mode ................................................................... ..

117

On Board Diagnosis Logic .................................. ..117

Possible Cause ................................................... ..117

DTC Confirmation Procedure .............................. ..117

Diagnosis Procedure ........................................... ..117

DTC P0845 TRANSMISSION FLUID PRES-

SURE SENSOR B CIRCUIT (PRI PRESSURE

SENSOR) ........................................................ ..119

Description .......................................................... ..119 CONSULT-III Reference Va

lue in Data Monitor

Mode .................................................................... ..

119

On Board Diagnosis Logic ................................... ..119

Possible Cause .................................................... ..119

DTC Confirmation Procedure .............................. ..119

Wiring Diagram - CVT - PRIPS ........................... ..120

Diagnosis Procedure ........................................... ..121

DTC P0868 SECONDARY PRESSURE

DOWN ............................................................. 123

Description ........................................................... ..123

CONSULT-III Reference Va lue in Data Monitor

Mode .................................................................... ..

123

On Board Diagnosis Logic ................................... ..123

Possible Cause .................................................... ..123

DTC Confirmation Procedure .............................. ..123

Diagnosis Procedure ........................................... ..123

DTC P1701 TRANSMISSION CONTROL

MODULE (POWER SUPPLY) ......................... 125

Description ........................................................... ..125

On Board Diagnosis Logic ................................... ..125

Possible Cause .................................................... ..125

DTC Confirmation Procedure .............................. ..125

Wiring Diagram - CVT - POWER ......................... ..126

Diagnosis Procedure ........................................... ..127

DTC P1705 THROTTLE POSITION SENSOR .129

Description ........................................................... ..129

CONSULT-III Reference Va lue in Data Monitor

Mode .................................................................... ..

129

On Board Diagnosis Logic ................................... ..129

Possible Cause .................................................... ..129

DTC Confirmation Procedure .............................. ..129

Diagnosis Procedure ........................................... ..129

DTC P1722 ESTM VEHICLE SPEED SIGNAL .131

Description ........................................................... ..131

CONSULT-III Reference Va lue in Data Monitor

Mode .................................................................... ..

131

On Board Diagnosis Logic ................................... ..131

Possible Cause .................................................... ..131

DTC Confirmation Procedure .............................. ..131

Diagnosis Procedure ........................................... ..131

DTC P1723 CVT SPEED SENSOR FUNC-

TION ................................................................ 133

Description ........................................................... ..133

On Board Diagnosis Logic ................................... ..133

Possible Cause .................................................... ..133

DTC Confirmation Procedure .............................. ..133

Diagnosis Procedure ........................................... ..133

DTC P1726 ELECTRIC THROTTLE CON-

TROL SYSTEM ............................................... 135

Description ........................................................... ..135

On Board Diagnosis Logic ................................... ..135

Possible Cause .................................................... ..135

DTC Confirmation Procedure .............................. ..135

Diagnosis Procedure ........................................... ..135

Page 948 of 4331

Page 949 of 4331

CVT

N

O

P

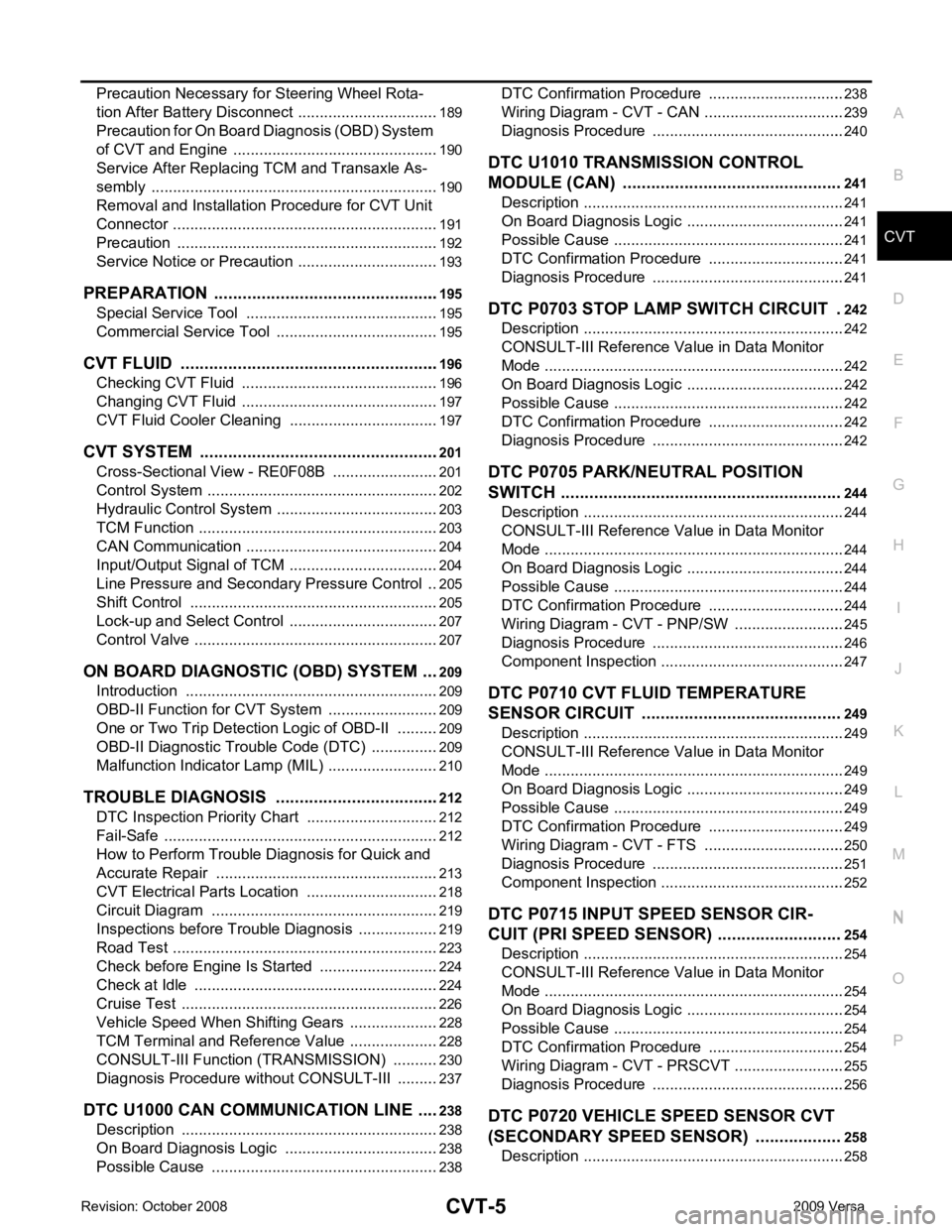

N

Precaution Necessary fo

r Steering Wheel Rota-

tion After Battery Disconnect ............................... ..

189

Precaution for On Board Diagnosis (OBD) System

of CVT and Engine .............................................. ..

190

Service After Replacing TCM and Transaxle As-

sembly ................................................................. ..

190

Removal and Installation Procedure for CVT Unit

Connector ............................................................ ..

191

Precaution ........................................................... ..192

Service Notice or Precaution ............................... ..193

PREPARATION .............................................. ..195

Special Service Tool ........................................... ..195

Commercial Service Tool .................................... ..195

CVT FLUID ..................................................... ..196

Checking CVT Fluid ............................................ ..196

Changing CVT Fluid ............................................ ..197

CVT Fluid Cooler Cleanin g ...................................197

CVT SYSTEM ... .............................................. ..201

Cross-Sectional View - RE0F08B ....................... ..201

Control System .................................................... ..202

Hydraulic Control System ......................................203

TCM Function ...................................................... ..203

CAN Communication ........................................... ..204

Input/Output Signal of TCM ................................. ..204

Line Pressure and Secondary Pressure Control . ..205

Shift Control ........................................................ ..205

Lock-up and Select Control ................................. ..207

Control Valve ....................................................... ..207

ON BOARD DIAGNOSTIC (OBD) SYSTEM .. ..209

Introduction ......................................................... ..209

OBD-II Function for CVT System ........................ ..209

One or Two Trip Detection Logic of OBD-II ........ ..209

OBD-II Diagnostic Trouble Code (DTC) .............. ..209

Malfunction Indicator Lamp (MIL) ........................ ..210

TROUBLE DIAGNOSIS ................................. ..212

DTC Inspection Priority Chart ............................. ..212

Fail-Safe .............................................................. ..212

How to Perform Trouble Diagnosis for Quick and

Accurate Repair ........... .........................................

213

CVT Electrical Parts Location ............................. ..218

Circuit Diagram ................................................... ..219

Inspections before Trouble Diagnosis ................. ..219

Road Test ............................................................ ..223

Check before Engine Is Started ............................224

Check at Idle ....................................................... ..224

Cruise Test .......................................................... ..226

Vehicle Speed When Shifting Gears ................... ..228

TCM Terminal and Reference Value ................... ..228

CONSULT-III Function (TRANSMISSION) ......... ..230

Diagnosis Procedu re without CONSULT-III ........ ..237

DTC U1000 CAN COMMUNICATION LINE ... ..238

Description .......................................................... ..238

On Board Diagnosis Logic .................................. ..238

Possible Cause ................................................... ..238 DTC Confirmation Procedure ..............................

..238

Wiring Diagram - CVT - CAN ............................... ..239

Diagnosis Procedure ........................................... ..240

DTC U1010 TRANSMISSION CONTROL

MODULE (CAN) .............................................. 241

Description ........................................................... ..241

On Board Diagnosis Logic ................................... ..241

Possible Cause .................................................... ..241

DTC Confirmation Procedure .............................. ..241

Diagnosis Procedure ........................................... ..241

DTC P0703 STOP LAMP SWITCH CIRCUIT . 242

Description ........................................................... ..242

CONSULT-III Reference Va lue in Data Monitor

Mode .................................................................... ..

242

On Board Diagnosis Logic ................................... ..242

Possible Cause .................................................... ..242

DTC Confirmation Procedure .............................. ..242

Diagnosis Procedure ........................................... ..242

DTC P0705 PARK/NEUTRAL POSITION

SWITCH ........................................................... 244

Description ........................................................... ..244

CONSULT-III Reference Va lue in Data Monitor

Mode .................................................................... ..

244

On Board Diagnosis Logic ................................... ..244

Possible Cause .................................................... ..244

DTC Confirmation Procedure .............................. ..244

Wiring Diagram - CVT - PNP/SW ........................ ..245

Diagnosis Procedure ........................................... ..246

Component Inspection ......................................... ..247

DTC P0710 CVT FLUID TEMPERATURE

SENSOR CIRCUIT .......................................... 249

Description ........................................................... ..249

CONSULT-III Reference Va lue in Data Monitor

Mode .................................................................... ..

249

On Board Diagnosis Logic ................................... ..249

Possible Cause .................................................... ..249

DTC Confirmation Procedure .............................. ..249

Wiring Diagram - CVT - FTS ............................... ..250

Diagnosis Procedure ........................................... ..251

Component Inspection ......................................... ..252

DTC P0715 INPUT SPEED SENSOR CIR-

CUIT (PRI SPEED SENSOR) .......................... 254

Description ........................................................... ..254

CONSULT-III Reference Va lue in Data Monitor

Mode .................................................................... ..

254

On Board Diagnosis Logic ................................... ..254

Possible Cause .................................................... ..254

DTC Confirmation Procedure .............................. ..254

Wiring Diagram - CVT - PRSCVT ........................ ..255

Diagnosis Procedure ........................................... ..256

DTC P0720 VEHICLE SPEED SENSOR CVT

(SECONDARY SPEED SENSOR) .................. 258

Description ........................................................... ..258

Page 950 of 4331