NISSAN LATIO 2009 Service Repair Manual

Manufacturer: NISSAN, Model Year: 2009, Model line: LATIO, Model: NISSAN LATIO 2009Pages: 4331, PDF Size: 58.04 MB

Page 951 of 4331

CVT

N

O

P

N

Description ..........................................................

..

293

CONSULT-III Refe rence Value in Data Monitor

Mode ................................................................... ..

293

On Board Diagnosis Logic .................................. ..293

Possible Cause ................................................... ..293

DTC Confirmation Procedure .............................. ..293

Diagnosis Procedure ........................................... ..293

DTC P1701 TRANSMISSION CONTROL

MODULE (POWER SUPPLY) ........................ ..295

Description .......................................................... ..295

On Board Diagnosis Logic .................................. ..295

Possible Cause ................................................... ..295

DTC Confirmation Procedure .............................. ..295

Wiring Diagram - CVT - POWER ........................ ..296

Diagnosis Procedure ........................................... ..297

DTC P1705 THROTTLE POSITION SENSOR ..299

Description .......................................................... ..299

CONSULT-III Refe rence Value in Data Monitor

Mode ................................................................... ..

299

On Board Diagnosis Logic .................................. ..299

Possible Cause ................................................... ..299

DTC Confirmation Procedure .............................. ..299

Diagnosis Procedure ........................................... ..299

DTC P1722 ESTM VEHICLE SPEED SIGNAL ..301

Description .......................................................... ..301

CONSULT-III Refe rence Value in Data Monitor

Mode ................................................................... ..

301

On Board Diagnosis Logic .................................. ..301

Possible Cause ................................................... ..301

DTC Confirmation Procedure .............................. ..301

Diagnosis Procedure ........................................... ..301

DTC P1723 CVT SPEED SENSOR FUNC-

TION ............................................................... ..303

Description .......................................................... ..303

On Board Diagnosis Logic .................................. ..303

Possible Cause ................................................... ..303

DTC Confirmation Procedure .............................. ..303

Diagnosis Procedure ........................................... ..303

DTC P1726 ELECTRIC THROTTLE CON-

TROL SYSTEM .............................................. ..

305

Description .......................................................... ..305

On Board Diagnosis Logic .................................. ..305

Possible Cause ................................................... ..305

DTC Confirmation Procedure .............................. ..305

Diagnosis Procedure ........................................... ..305

DTC P1740 LOCK-UP SELECT SOLENOID

VALVE CIRCUIT ............................................ ..

306

Description .......................................................... ..306

CONSULT-III Refe rence Value in Data Monitor

Mode ................................................................... ..

306

On Board Diagnosis Logic .................................. ..306

Possible Cause ................................................... ..306

DTC Confirmation Procedure .............................. ..306

Wiring Diagram - CVT - L/USSV ......................... ..307 Diagnosis Procedure ...........................................

..308

Component Inspection ......................................... ..309

DTC P1745 LINE PRESSURE CONTROL ..... 310

Description ........................................................... ..310

On Board Diagnosis Logic ................................... ..310

Possible Cause .................................................... ..310

DTC Confirmation Procedure .............................. ..310

Diagnosis Procedure ........................................... ..310

DTC P1777 STEP MOTOR - CIRCUIT ........... 311

Description ........................................................... ..311

CONSULT-III Reference Va lue in Data Monitor

Mode .................................................................... ..

311

On Board Diagnosis Logic ................................... ..311

Possible Cause .................................................... ..311

DTC Confirmation Procedure .............................. ..311

Wiring Diagram - CVT - STM ............................... ..312

Diagnosis Procedure ........................................... ..313

Component Inspection ......................................... ..314

DTC P1778 STEP MOTOR - FUNCTION ....... 315

Description ........................................................... ..315

CONSULT-III Reference Va lue in Data Monitor

Mode .................................................................... ..

315

On Board Diagnosis Logic ................................... ..315

Possible Cause .................................................... ..315

DTC Confirmation Procedure .............................. ..315

Diagnosis Procedure ........................................... ..316

OVERDRIVE CONTROL SWITCH .................. 317

Description ........................................................... ..317

CONSULT-III Reference Va lue in Data Monitor

Mode .................................................................... ..

317

Wiring Diagram - CVT - ODSW ........................... ..318

Diagnosis Procedure ........................................... ..318

Component Inspection ......................................... ..320

SHIFT POSITION INDICATOR CIRCUIT ........ 322

Description ........................................................... ..322

CONSULT-III Reference Va lue in Data Monitor

Mode .................................................................... ..

322

Diagnosis Procedure ........................................... ..322

TROUBLE DIAGNOSIS FOR SYMPTOMS .... 323

Wiring Diagram - CVT - NONDTC ....................... ..323

O/D OFF Indicator Lamp Does Not Come On ..... ..325

Engine Cannot Be Started in "P" and "N" Position ..327

In "P" Position, Vehicle Moves Forward or Back-

ward When Pushed ............................................. ..

327

In "N" Position, Vehicle Moves ............................ ..328

Large Shock "N" → "R" Position .......................... ..328

Vehicle Does Not Creep Backward in "R" Position ..329

Vehicle Does Not Creep Forward in "D" or "L" Po-

sition .................................................................... ..

330

Vehicle Speed Does Not Change in "L" Position . ..331

Vehicle Speed Does Not Change in overdrive-off

mode .................................................................... ..

332

Vehicle Speed Does Not Change in "D" Position .. 333

Vehicle Does Not Decelerate by Engine Brake ... ..333

Page 952 of 4331

Page 953 of 4331

CVT

N

O P

SERVICE INFORMATION

INDEX FOR DTC

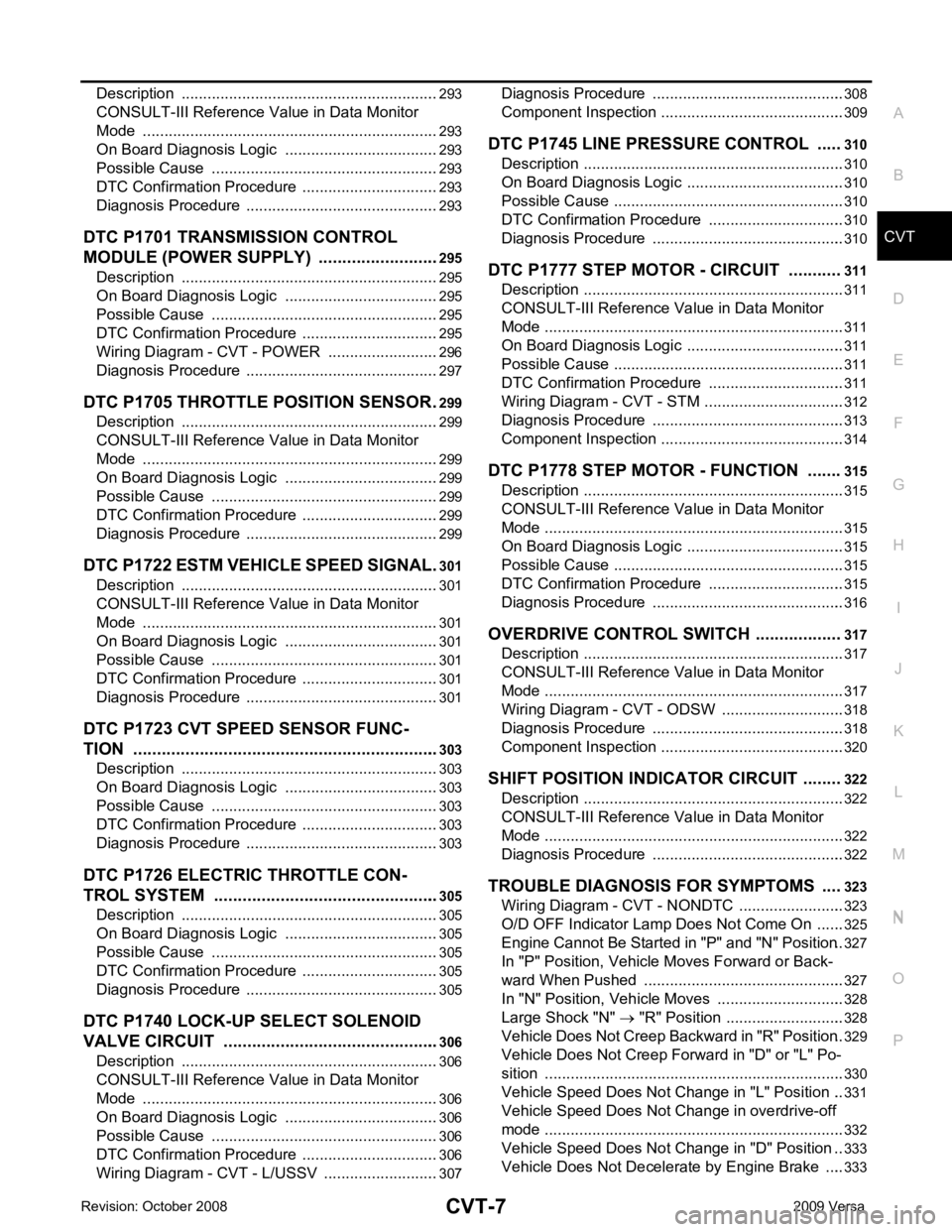

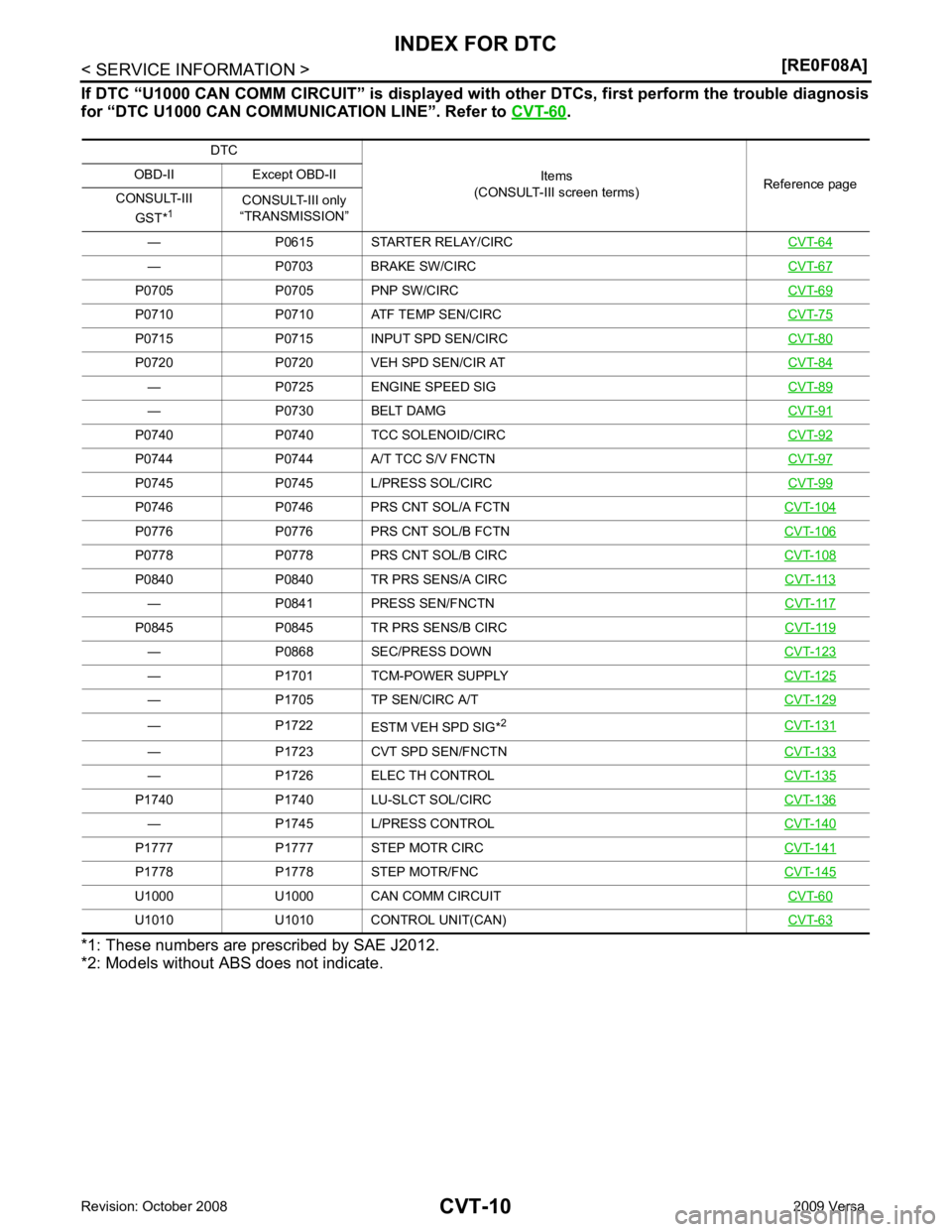

Alphabetical Index INFOID:0000000004666851

NOTE:

If DTC “U1000 CAN COMM CIRCUIT” is displayed with other DTCs, first perform the trouble diagnosis

for “DTC U1000 CAN COMMUNICATION LINE”. Refer to CVT-60 .

*1: These numbers are prescribed by SAE J2012.

*2: Models without ABS does not indicate.

DTC No. Index INFOID:0000000004666852

NOTE: Items

(CONSULT-III screen terms) DTC

Reference page

OBD-II Except OBD-II

CONSULT-III GST* 1 CONSULT-III only

“TRANSMISSION”

A/T TCC S/V FNCTN P0744 P0744 CVT-97ATF TEMP SEN/CIRC P0710 P0710

CVT-75BELT DAMG — P0730

CVT-91BRAKE SW/CIRC — P0703

CVT-67CAN COMM CIRCU

IT U1000 U1000 CVT-60CONTROL UNIT(CAN) U1010 U1010

CVT-63CVT SPD SEN/FNCTN — P1723

CVT-133ENGINE SPEED SIG — P0725

CVT-89ELEC TH CONTROL — P1726

CVT-135ESTM VEH SPD SIG*

2

— P1722CVT-131INPUT SPD SEN/CIRC P0715 P0715

CVT-80L/PRESS CONTROL — P1745

CVT-140L/PRESS SOL/CIRC P0745 P0745

CVT-99LU-SLCT SOL/CIRC P1740 P1740

CVT-136PNP SW/CIRC P0705 P0705

CVT-69PRESS SEN/FNCTN — P0841

CVT-117PRS CNT SOL/A FCTN P0746 P0746

CVT-104PRS CNT SOL/B CIRC P0778 P0778

CVT-108PRS CNT SOL/B FCTN P0776 P0776

CVT-106SEC/PRESS DOWN — P0868

CVT-123STARTER RELAY/CIRC — P0615

CVT-64STEP MOTR CIRC P1777 P1777

CVT-141STEP MOTR/FNC P1778 P1778

CVT-145TCC SOLENOID/CIRC P0740 P0740

CVT-92TCM-POWER SUPPLY — P1701

CVT-125TP SEN/CIRC A/T — P1705

CVT-129TR PRS SENS/A CIRC P0840 P0840

CVT-113TR PRS SENS/B CIRC P0845 P0845

CVT-119VEH SPD SEN/CIR AT P0720 P0720

CVT-84

Page 954 of 4331

.

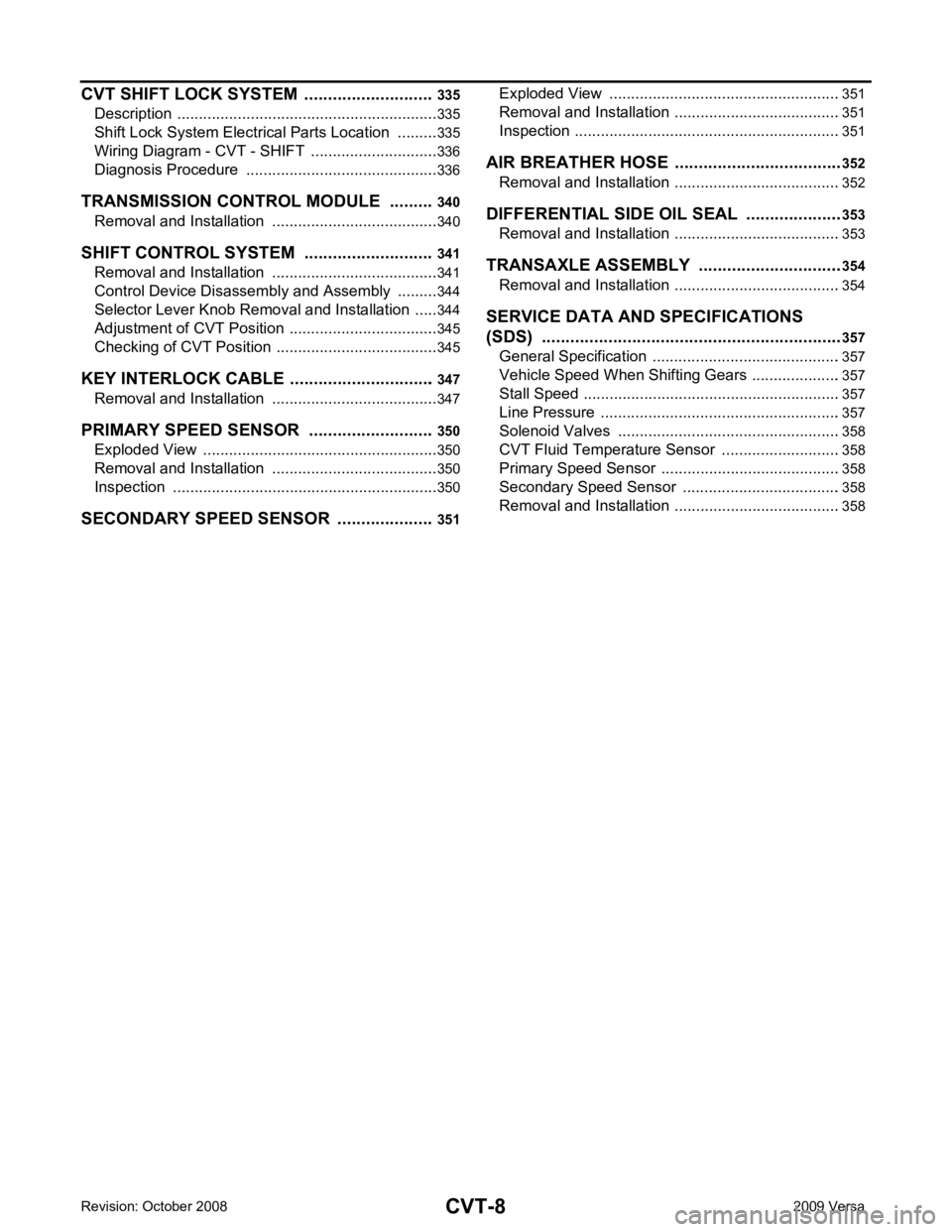

*1: These numbers are pr escribed by SAE J2012.

*2: Models without ABS does not indicate. DTC

Items

(CONSULT-III screen terms) Reference page

OBD-II Except OBD-II

CONSULT-III GST* 1 CONSULT-III only

“TRANSMISSION”

— P0615 STARTER RELAY/CIRC CVT-64— P0703 BRAKE SW/CIRC

CVT-67P0705 P0705 PNP SW/CIRC

CVT-69P0710 P0710 ATF TEMP SEN/CIRC

CVT-75P0715 P0715 INPUT SPD SEN/CIRC

CVT-80P0720 P0720 VEH SPD SEN/CIR AT

CVT-84— P0725 ENGINE SPEED SIG

CVT-89— P0730 BELT DAMG

CVT-91P0740 P0740 TCC SOLENOID/CIRC

CVT-92P0744 P0744 A/T TCC S/V FNCTN

CVT-97P0745 P0745 L/PRESS SOL/CIRC

CVT-99P0746 P0746 PRS CNT SOL/A FCTN

CVT-104P0776 P0776 PRS CNT SOL/B FCTN

CVT-106P0778 P0778 PRS CNT SOL/B CIRC

CVT-108P0840 P0840 TR PRS SENS/A CIRC

CVT-113— P0841 PRESS SEN/FNCTN

CVT-117P0845 P0845 TR PRS SENS/B CIRC

CVT-119— P0868 SEC/PRESS DOWN

CVT-123— P1701 TCM-POWER SUPPLY

CVT-125— P1705 TP SEN/CIRC A/T

CVT-129— P1722

ESTM VEH SPD SIG*2

CVT-131— P1723 CVT SPD SEN/FNCTN

CVT-133— P1726 ELEC TH CONTROL

CVT-135P1740 P1740 LU-SLCT SOL/CIRC

CVT-136— P1745 L/PRESS CONTROL

CVT-140P1777 P1777 STEP MOTR CIRC

CVT-141P1778 P1778 STEP MOTR/FNC

CVT-145U1000 U1000 CAN COMM CIRCUIT

CVT-60U1010 U1010 CONTROL UNIT(CAN)

CVT-63

Page 955 of 4331

CVT

N

O P

PRECAUTIONS

Precaution for Supplemental Restraint System (SRS) "AIR BAG" and "SEAT BELT

PRE-TENSIONER" INFOID:0000000004800719

The Supplemental Restraint System such as “A IR BAG” and “SEAT BELT PRE-TENSIONER”, used along

with a front seat belt, helps to reduce the risk or severi ty of injury to the driver and front passenger for certain

types of collision. This system includes seat belt switch inputs and dual stage front air bag modules. The SRS

system uses the seat belt switches to determine the front air bag deployment, and may only deploy one front

air bag, depending on the severity of a collision and w hether the front occupants are belted or unbelted.

Information necessary to service the system safely is included in the SRS and SB section of this Service Man-

ual.

WARNING:

• To avoid rendering the SRS inoper ative, which could increase the risk of personal injury or death in

the event of a collision which would result in air bag inflation, all maintenance must be performed by

an authorized NISSAN/INFINITI dealer.

• Improper maintenance, including in correct removal and installation of the SRS can lead to personal

injury caused by unintentional act ivation of the system. For removal of Spiral Cable and Air Bag

Module, see the SRS section.

• Do not use electrical test equipm ent on any circuit related to the SRS unless instructed to in this

Service Manual. SRS wiring harnesses can be identi fied by yellow and/or orange harnesses or har-

ness connectors.

• When working near the Airbag Diagnosis Sensor Un it or other Airbag System sensors with the Igni-

tion ON or engine running, DO NOT use air or el ectric power tools or strike near the sensor(s) with a

hammer. Heavy vibration could activate the sensor( s) and deploy the air bag(s), possibly causing

serious injury.

• When using air or electric power tools or hammers , always switch the Ignition OFF, disconnect the

battery, and wait at least 3 minutes before performing any service.

Precaution Necessary for Steering Wh eel Rotation After Battery Disconnect

INFOID:0000000004666854

NOTE:

• This Procedure is applied only to models with Intell igent Key system and NVIS/IVIS (NISSAN/INFINITI

VEHICLE IMMOBILIZER SYSTEM - NATS).

• Remove and install all control units after disconnecti ng both battery cables with the ignition knob in the

″ LOCK ″ position.

• Always use CONSULT-III to perform self-diagnosis as a part of each function inspection after finishing work.

If DTC is detected, perform trouble diagnosis according to self-diagnostic results.

For models equipped with the Intelligent Key system and NVIS/IVIS, an electrically controlled steering lock

mechanism is adopted on the key cylinder.

For this reason, if the battery is disconnected or if the battery is discharged, the steering wheel will lock and

steering wheel rotation will become impossible.

If steering wheel rotation is required when battery pow er is interrupted, follow the procedure below before

starting the repair operation.

OPERATION PROCEDURE 1. Connect both battery cables. NOTE:

Supply power using jumper cables if battery is discharged.

2. Use the Intelligent Key or mechanical key to turn the ignition switch to the ″ACC ″ position. At this time, the

steering lock will be released.

3. Disconnect both battery cables. The steering lock will remain released and the steering wheel can be

rotated.

4. Perform the necessary repair operation.

5. When the repair work is completed, return the ignition switch to the ″LOCK ″ position before connecting

the battery cables. (At this time, the steering lock mechanism will engage.)

6. Perform a self-diagnosis check of al l control units using CONSULT-III.

Page 956 of 4331

Page 957 of 4331

CVT

N

O P

Do not start engine.

6. Select “SELF-DIAG RESULTS”.

7. Shift the selector lever to “R” position.

8. Depress slightly the accelerator pedal (Pedal angle: 2/8) while depressing the brake pedal.

9. Perform “ERASE”.

10. Shift the selector lever to “R” position afte r replacing TCM. Turn the ignition switch OFF.

11. Wait approximately 10 minutes after turning the ignition switch OFF.

12. Turn the ignition switch ON while shifting the selector lever to “R” position. CAUTION:

Do not start engine.

13. Select “CALIBRATION DATA”.

14. Check that the value on “CALIBRATION DATA” is same as the data after erasing "Calibration Data". • Restart the procedure from step 3 if the values are not same.

15. Shift the selector lever to “P” position.

16. Check that the shift position indicator in the combi nation meter turns ON (It indicates approximately 1 or 2

seconds after shifting the selector lever to “P” position.)

• Check the following items if the shift position indicato r does not turn ON. Repair or replace the shift posi-

tion indicator if necessary.

- The harness between TCM and ROM ASSY in the transaxle assembly is open or short.

- Cable disconnected, loosen, or bent from the connector housing.

- Power supply and ground of TCM. Refer to CVT-125, " Description " .

PATTERN C 1. Replace the transaxle assembly first, and then replace TCM.

2. Perform the service of “PATTERN A”. (Perform the service of “Pattern B” if TCM is replaced first.)

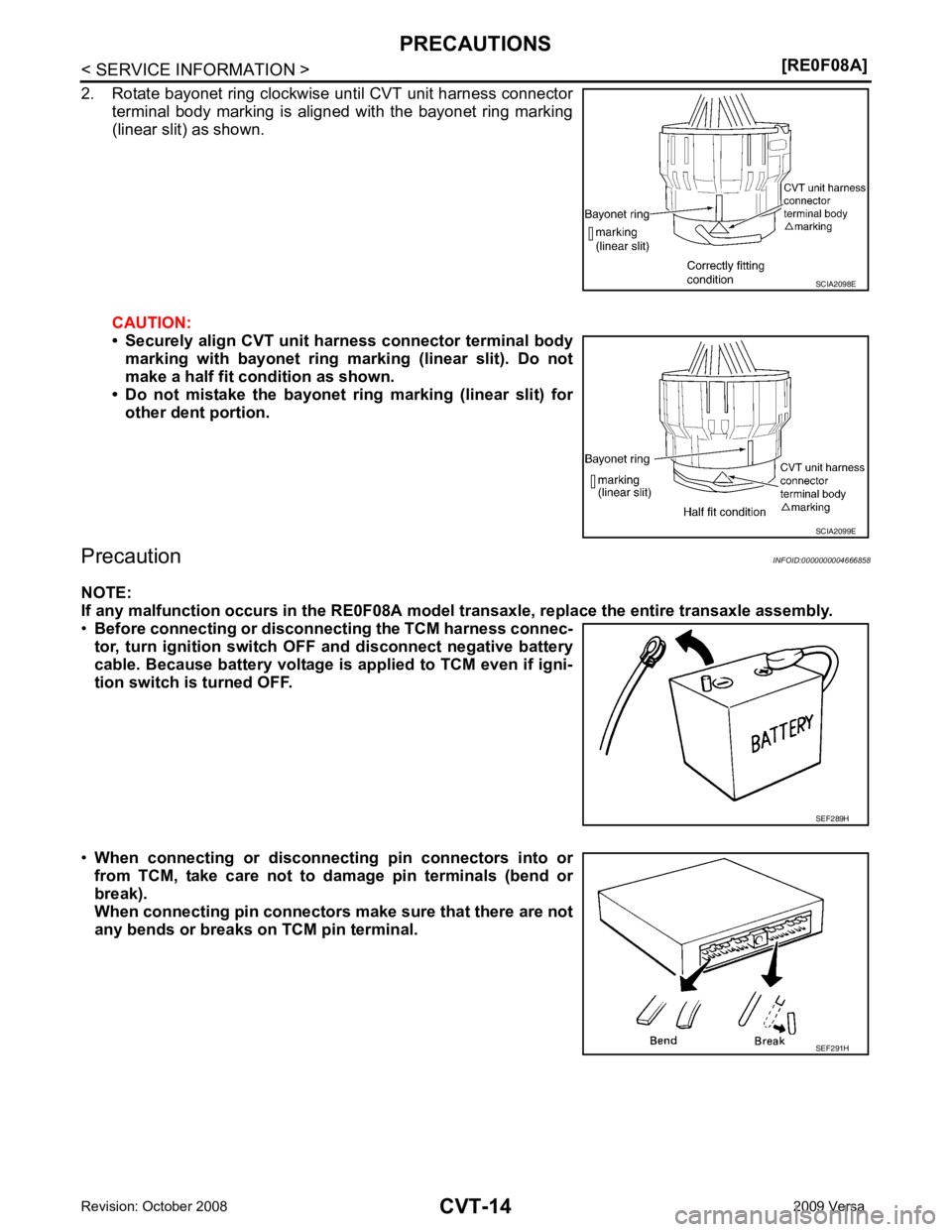

Removal and Installation Proc edure for CVT Unit Connector INFOID:0000000004666857

REMOVAL Rotate bayonet ring counterclockwise, pull out CVT unit harness

connector upward and disconnect it.

INSTALLATION 1. Align CVT unit harness connector terminal body marking with bayonet ring marking, insert CVT unit harness connector, and

then rotate bayonet ring clockwise.

Page 958 of 4331

SCIA2099E

SEF291H

Page 959 of 4331

![NISSAN LATIO 2009 Service Repair Manual PRECAUTIONS

CVT-15

< SERVICE INFORMATION >

[RE0F08A] D

E

F

G H

I

J

K L

M A

B CVT

N

O P

•

Before replacing TCM, perform TCM input/output signal

inspection and make sure whether TCM functions pr NISSAN LATIO 2009 Service Repair Manual PRECAUTIONS

CVT-15

< SERVICE INFORMATION >

[RE0F08A] D

E

F

G H

I

J

K L

M A

B CVT

N

O P

•

Before replacing TCM, perform TCM input/output signal

inspection and make sure whether TCM functions pr](/img/5/57359/w960_57359-958.png)

PRECAUTIONS

CVT-15

< SERVICE INFORMATION >

[RE0F08A] D

E

F

G H

I

J

K L

M A

B CVT

N

O P

•

Before replacing TCM, perform TCM input/output signal

inspection and make sure whether TCM functions properly or

not. CVT-49, " TCM Terminal and Reference Value " .

• After performing each TROUBL E DIAGNOSIS, perform “DTC

Confirmation Procedure”.

If the repair is completed the DTC should not be displayed in

the “DTC Confirmation Procedure”.

• Always use the specified br and of CVT fluid. Refer to MA-14, " Flu-

ids and Lubricants " .

• Use lint-free paper, not cloth rags, during work.

• After replacing the CVT fluid, dispose of the waste oil using the methods prescribed by law, ordinance, etc.

Service Notice or Precaution INFOID:0000000004666859

CVT FLUID COOLER SERVICE If CVT fluid contains friction material (clutches, brakes , etc.), or if an CVT is replaced, inspect and clean the

CVT fluid cooler mounted in the radiator or replace t he radiator. Flush cooler lines using cleaning solvent and

compressed air after repair. For CVT fluid cooler cleaning procedure, refer to CVT-18, " CVT Fluid Cooler

Cleaning " . For radiator replacement, refer to

CO-38 .

OBD-II SELF-DIAGNOSIS • CVT self-diagnosis is performed by the TCM in comb ination with the ECM. The results can be read through

the blinking pattern of the malfunction indi cator lamp (MIL). Refer to the table on CVT-51, " CONSULT-III

Function (TRANSMISSION) " for the indicator used to display each self-diagnostic result.

• The self-diagnostic results indicated by the MIL ar e automatically stored in both the ECM and TCM memo-

ries.

Always perform the procedure on CVT-30, " OBD-II Diagnostic Trouble Code (DTC) " to complete the

repair and avoid unnecessary blinking of the MIL.

For details of OBD-II, refer to EC-541, " Introduction " .

• Certain systems and components, especially those re lated to OBD, may use the new style slide-lock-

ing type harness connector. For descripti on and how to disconnect, refer to PG-64 . MEF040DA

SEF217U

Page 960 of 4331