sensor NISSAN LATIO 2009 Service Repair Manual

[x] Cancel search | Manufacturer: NISSAN, Model Year: 2009, Model line: LATIO, Model: NISSAN LATIO 2009Pages: 4331, PDF Size: 58.04 MB

Page 2740 of 4331

Diagnosis Procedure " .

WITH GST

NOTE:

Start from step 8, if it is possible to confirm that the fuel cannot be drained by 30 (7-7/8 US gal, 6-5/8

Imp gal) in advance.

1. Prepare a fuel container and a spare hose.

2. Release fuel pressure from fuel line, refer to EC-1086, " Fuel Pressure Check " .

3. Remove the fuel feed hose on the fuel level sensor unit.

4. Connect a spare fuel hose where the fuel feed hose was removed.

5. Turn ignition switch ON.

6. Drain fuel by 30 (7-7/8 US gal, 6-5/8 Imp gal) from the fuel tank using proper equipment.

7. Confirm that the fuel gauge indication varies.

8. Fill fuel into the fuel tank for 30 (7-7/8 US gal, 6-5/8 Imp gal).

9. Confirm that the fuel gauge indication varies.

10. If NG, go to EC-1384, " Diagnosis Procedure " .

Diagnosis Procedure INFOID:0000000004501202Self-Diagnosis Mode of Combination Meter " .

OK or NG OK >> GO TO 2.

NG >> Follow the instruction of DI-10, " Self-Diagnosis Mode of Combination Meter " .

Fuel Level Sensor Signal Inspection " .

OK or NG OK >> GO TO 3.

NG >> Repair or replace malfunctioning parts. .

>> INSPECTION END

Removal and Installation INFOID:0000000004501203

FUEL LEVEL SENSOR

Refer to FL-5 .

Page 2741 of 4331

![NISSAN LATIO 2009 Service Repair Manual DTC P0462, P0463 FUEL LEVEL SENSOR

EC-1385

< SERVICE INFOMATION >

[MR TYPE 2] C

D E

F

G H

I

J

K L

M A EC

NP

O

DTC P0462, P0463 FUEL LEVEL SENSOR

Component Description INFOID:0000000004501201

The fuel NISSAN LATIO 2009 Service Repair Manual DTC P0462, P0463 FUEL LEVEL SENSOR

EC-1385

< SERVICE INFOMATION >

[MR TYPE 2] C

D E

F

G H

I

J

K L

M A EC

NP

O

DTC P0462, P0463 FUEL LEVEL SENSOR

Component Description INFOID:0000000004501201

The fuel](/img/5/57359/w960_57359-2740.png)

DTC P0462, P0463 FUEL LEVEL SENSOR

EC-1385

< SERVICE INFOMATION >

[MR TYPE 2] C

D E

F

G H

I

J

K L

M A EC

NP

O

DTC P0462, P0463 FUEL LEVEL SENSOR

Component Description INFOID:0000000004501201

The fuel level sensor (3) is mounted in the fuel level sensor unit. The

sensor detects a fuel level in the fuel tank and transmits a signal to

the combination meter. The combination meter sends the fuel level

sensor signal to the ECM through CAN communication line.

It consists of two parts, one is mechanical float and the other is vari-

able resistor. Fuel level sensor output voltage changes depending on

the movement of the fuel mechanical float.

• Fuel level sensor unit and fuel pump (1)

• Fuel pressure regulator (2)

• Fuel tank temperature sensor (4)

On Board Diagnosis Logic INFOID:0000000004500246

NOTE:

• If DTC P0462 or P0463 is displayed with DTC UXXXX, first perform the trouble diagnosis for DTC

UXXXX.

• If DTC P0462 or P0463 is displayed with DTC P0607, first perform the trouble diagnosis for DTC

P0607. Refer to EC-1395 .

DTC Confirmation Procedure INFOID:0000000004500247

NOTE:

If DTC Confirmation Procedure has been previously conduc ted, always turn ignition switch OFF and wait at

least 10 seconds before conducting the next test.

TESTING CONDITION:

Before performing the following procedure, confirm th at battery voltage is more than 11V at ignition

switch ON.

1. Turn ignition switch ON and wait at least 5 seconds.

2. Check 1st trip DTC.

3. If 1st trip DTC is detected, go to EC-1385, " Diagnosis Procedure " .

Diagnosis Procedure INFOID:00000000045012041.

CHECK FUEL GAUGE OPERATION

Refer to DI-10, " Self-Diagnosis Mode of Combination Meter " .

OK or NG OK >> GO TO 2.

NG >> Follow the instruction of DI-10, " Self-Diagnosis Mode of Combination Meter " .

2.

CHECK FUEL LEVEL SENSOR AND CIRCUIT

Refer to DI-16, " Fuel Level Sensor Signal Inspection " .

OK or NG OK >> GO TO 3.

NG >> Repair or replace malfunctioning parts. BBIA0704E

DTC No. Trouble diagnosis name DTC detecting condition Possible cause

P0462

0462 Fuel level sensor circuit

low input An excessively low voltage from the sensor is

sent to ECM. • Harness or connectors

(CAN communication line is open or

shorted)

• Harness or connectors

(Fuel level sensor circuit is open or short-

ed)

• Combination meter

• Fuel level sensor

P0463

0463 Fuel level sensor circuit

high input An excessively high voltage from the sensor is

sent to ECM.

Page 2742 of 4331

.

>> INSPECTION END

Removal and Installation INFOID:0000000004501205

FUEL LEVEL SENSOR

Refer to FL-5 .

Page 2743 of 4331

EC

NP

O

DTC P0500 VSS

Description INFOID:0000000004500250

NOTE:

• If DTC P0500 is displayed with DTC UXXXX, first perform the tr ouble diagnosis for DTC UXXXX.

• If DTC P0500 is displayed with DT C P0607, first perform the trouble diagnosis for DTC P0607. Refer

to EC-1395 .

The vehicle speed signal is sent from “ABS actuator and electric unit (control unit)” or combination meter

through CAN communication line

On Board Diagnosis Logic INFOID:0000000004500251

FAIL-SAFE MODE When the malfunction is detect ed, ECM enters fail-safe mode.

DTC Confirmation Procedure INFOID:0000000004500252

CAUTION:

Always drive vehicle at a safe speed.

NOTE:

If DTC Confirmation Procedure has been previously conduc ted, always turn ignition switch OFF and wait at

least 10 seconds before conducting the next test.

TESTING CONDITION:

Steps 1 and 2 may be conducted with the drive wheels li fted in the shop or by driving the vehicle. If a

road test is expected to be easier, it is unnecessary to lift the vehicle.

WITH CONSULT-III

1. Start engine.

2. Read “VHCL SPEED SE” in “DATA MONITOR” m ode with CONSULT-III. The vehicle speed on CON-

SULT-III should exceed 10 km/h (6 MPH) when rotating wheels with suitable gear position.

If NG, go to EC-1388, " Diagnosis Procedure " .

If OK, go to following step.

3. Select “DATA MONITOR” mode with CONSULT-III.

4. Warm engine up to normal operating temperature.

5. Maintain the following conditions for at least 60 consecutive seconds.

6. Check 1st trip DTC.

7. If 1st trip DTC is detected, go to EC-1388, " Diagnosis Procedure " .

DTC No. Trouble diagnosis name DTC detecting condition Possible cause

P0500

0500 Vehicle speed sensor The vehicle speed signal sent to ECM is

almost km/h (0 MPH) even when vehicle

is being driven. • Harness or connectors

(CAN communication line is open or shorted.)

• Harness or connectors (Vehicle speed signal circuit is open or shorted)

• ABS actuator and electric unit (control unit)

• Combination meter Detected item Engine operating condition in fail-safe mode

Vehicle speed sensor The cooling fan operates (High) while engine is running. ENG SPEED More than 1,600 rpm

COOLAN TEMP/S More than 70 °C (158 °F)

B/FUEL SCHDL 5.5 - 31.8 msec

Shift lever Suitable position

PW/ST SIGNAL OFF

Page 2745 of 4331

EC

NP

O

DTC P0506 ISC SYSTEM

Description INFOID:0000000004500255

NOTE:

If DTC P0506 is displayed with ot her DTC, first perform the trouble diagnosis for the other DTC.

The ECM controls the engine idle speed to a specified leve l through the fine adjustment of the air, which is let

into the intake manifold, by operating the electric thrott le control actuator. The operating of the throttle valve is

varied to allow for optimum control of the engine id ling speed. The ECM calculates the actual engine speed

from signals of crankshaft position sensor (POS) and camshaft position sensor (PHASE).

The ECM controls the electric throttle control actuator so that the engine speed coincides with the target value

memorized in the ECM. The target engine speed is t he lowest speed at which the engine can operate steadily.

The optimum value stored in the ECM is determined by taking into consideration various engine conditions,

such as during warming up, deceleration, and engine load (air conditioner, power steering and cooling fan

operation, etc.).

On Board Diagnosis Logic INFOID:0000000004500256

DTC Confirmation Procedure INFOID:0000000004500257

NOTE:

• If DTC Confirmation Procedure has been previously conduc ted, always turn ignition switch OFF and wait at

least 10 seconds before conducting the next test.

• If the target idle speed is out of the specified value, perform EC-1084, " Idle Air Volume Learning " ,

before conducting DTC Confirmation Procedure. For the target idle speed, refer to the EC-1534 .

TESTING CONDITION:

• Before performing the following procedure, confirm that battery voltage is more than 11V at idle.

• Always perform the test at a temperature above −10 °C (14 °F).

1. Open engine hood.

2. Start engine and warm it up to normal operating temperature.

3. Turn ignition switch OFF and wait at least 10 seconds.

4. Start engine and run it for at least 1 minute at idle speed.

5. Check 1st trip DTC.

6. If 1st trip DTC is detected, go to EC-1389, " Diagnosis Procedure " .

Diagnosis Procedure INFOID:0000000004500258OK >> GO TO 2.

NG >> Discover air leak location and repair. ECM Re-communicating Function " .

4. Perform EC-1084, " VIN Registration " .

5. Perform EC-1084, " Accelerator Pedal Released Position Learning " .

6. Perform EC-1084, " Throttle Valve Closed Position Learning " .

DTC No. Trouble diagnosis name DTC detecting condition Possible cause

P0506

0506 Idle speed control sys-

tem RPM lower than ex-

pected The idle speed is less than the target idle speed

by 100 rpm or more. • Electric throttle control actuator

• Intake air leak

Page 2747 of 4331

EC

NP

O

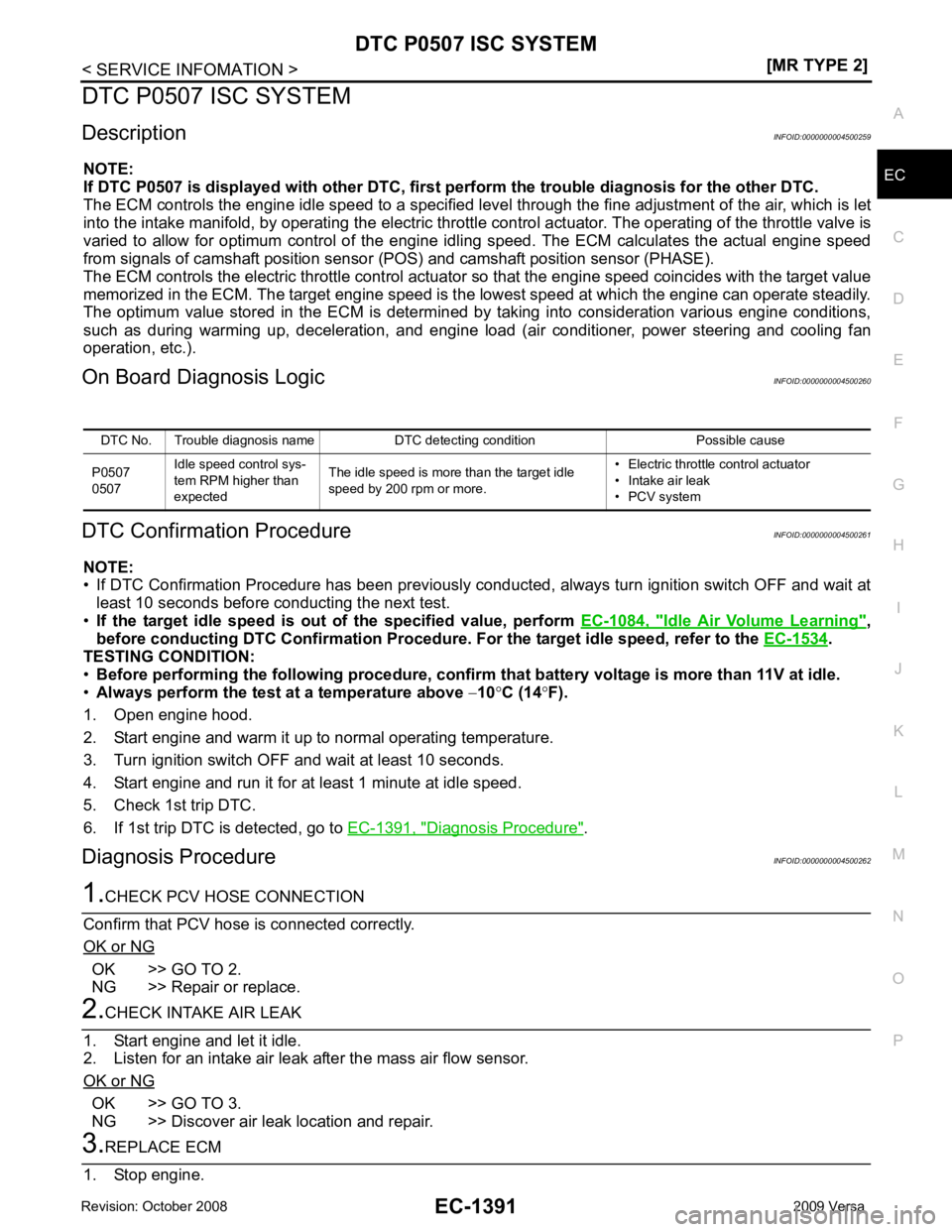

DTC P0507 ISC SYSTEM

Description INFOID:0000000004500259

NOTE:

If DTC P0507 is displayed with ot her DTC, first perform the trouble diagnosis for the other DTC.

The ECM controls the engine idle speed to a specified leve l through the fine adjustment of the air, which is let

into the intake manifold, by operating the electric thrott le control actuator. The operating of the throttle valve is

varied to allow for optimum control of the engine id ling speed. The ECM calculates the actual engine speed

from signals of camshaft position sensor (POS) and camshaft position sensor (PHASE).

The ECM controls the electric throttle control actuator so that the engine speed coincides with the target value

memorized in the ECM. The target engine speed is t he lowest speed at which the engine can operate steadily.

The optimum value stored in the ECM is determined by taking into consideration various engine conditions,

such as during warming up, deceleration, and engine load (air conditioner, power steering and cooling fan

operation, etc.).

On Board Diagnosis Logic INFOID:0000000004500260

DTC Confirmation Procedure INFOID:0000000004500261

NOTE:

• If DTC Confirmation Procedure has been previously conduc ted, always turn ignition switch OFF and wait at

least 10 seconds before conducting the next test.

• If the target idle speed is out of the specified value, perform EC-1084, " Idle Air Volume Learning " ,

before conducting DTC Confirmation Procedure. For the target idle speed, refer to the EC-1534 .

TESTING CONDITION:

• Before performing the following procedure, confirm that battery voltage is more than 11V at idle.

• Always perform the test at a temperature above −10 °C (14 °F).

1. Open engine hood.

2. Start engine and warm it up to normal operating temperature.

3. Turn ignition switch OFF and wait at least 10 seconds.

4. Start engine and run it for at least 1 minute at idle speed.

5. Check 1st trip DTC.

6. If 1st trip DTC is detected, go to EC-1391, " Diagnosis Procedure " .

Diagnosis Procedure INFOID:0000000004500262OK >> GO TO 2.

NG >> Repair or replace. OK >> GO TO 3.

NG >> Discover air leak location and repair.

Page 2752 of 4331

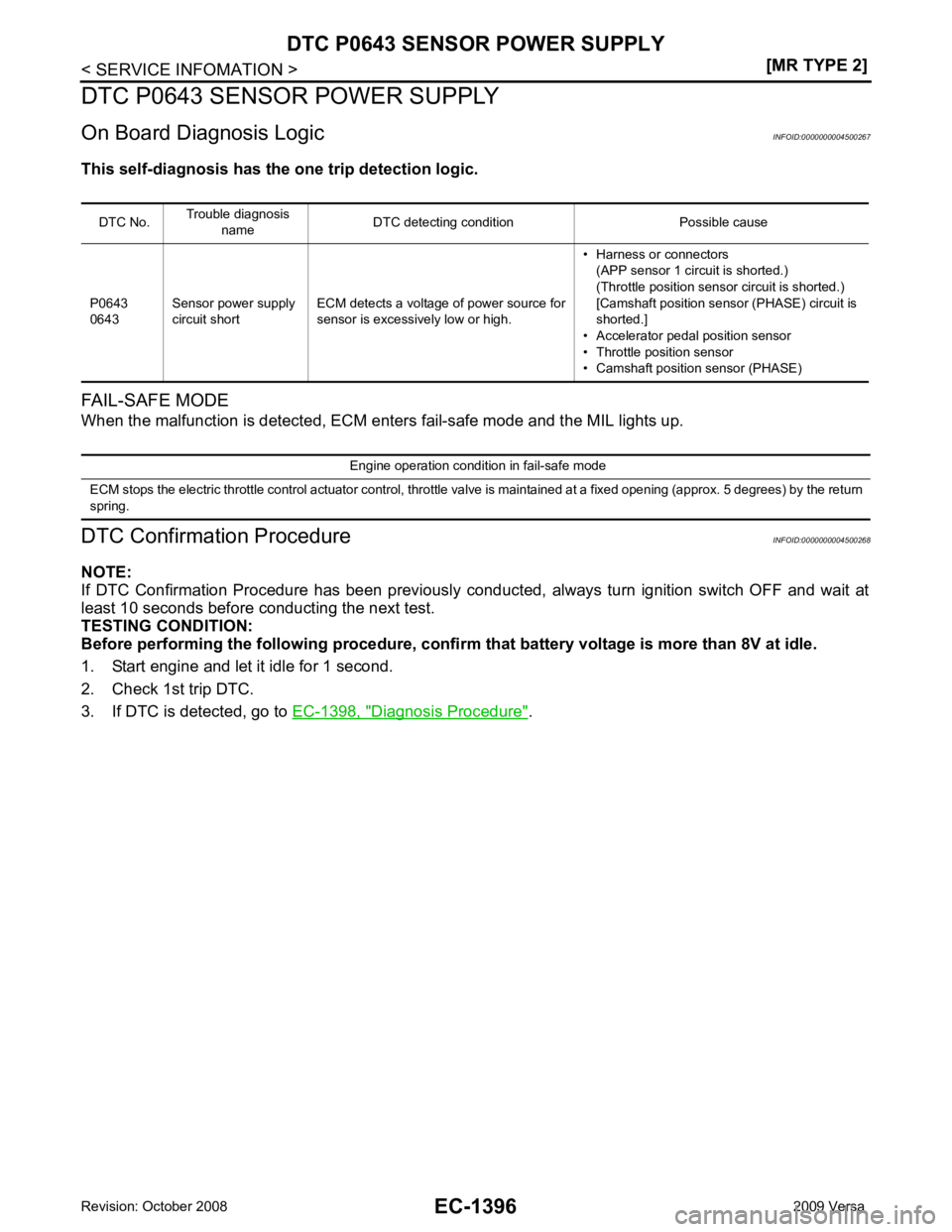

Diagnosis Procedure " .

DTC No.

Trouble diagnosis

name DTC detecting condition Possible cause

P0643

0643 Sensor power supply

circuit short ECM detects a voltage of power source for

sensor is excessively low or high. • Harness or connectors

(APP sensor 1 circuit is shorted.)

(Throttle position sensor circuit is shorted.)

[Camshaft position sensor (PHASE) circuit is

shorted.]

• Accelerator pedal position sensor

• Throttle position sensor

• Camshaft position sensor (PHASE) Engine operation condition in fail-safe mode

ECM stops the electric throttle control actuator control, throttle valve is maintained at a fixed opening (approx. 5 degrees) b y the return

spring.

Page 2753 of 4331

![NISSAN LATIO 2009 Service Repair Manual DTC P0643 SENSOR POWER SUPPLY

EC-1397

< SERVICE INFOMATION >

[MR TYPE 2] C

D E

F

G H

I

J

K L

M A EC

NP

O

Wiring Diagram

INFOID:0000000004500269

Specification data are reference values and are measure NISSAN LATIO 2009 Service Repair Manual DTC P0643 SENSOR POWER SUPPLY

EC-1397

< SERVICE INFOMATION >

[MR TYPE 2] C

D E

F

G H

I

J

K L

M A EC

NP

O

Wiring Diagram

INFOID:0000000004500269

Specification data are reference values and are measure](/img/5/57359/w960_57359-2752.png)

DTC P0643 SENSOR POWER SUPPLY

EC-1397

< SERVICE INFOMATION >

[MR TYPE 2] C

D E

F

G H

I

J

K L

M A EC

NP

O

Wiring Diagram

INFOID:0000000004500269

Specification data are reference values and are measured between each terminal and ground.

CAUTION:

Do not use ECM ground terminals wh en measuring input/output voltage. Doing so may result in dam-

age to the ECM's transistor. Use a ground ot her than ECM terminals, such as the ground. BBWA2649E

Page 2754 of 4331

![NISSAN LATIO 2009 Service Repair Manual EC-1398< SERVICE INFOMATION >

[MR TYPE 2]

DTC P0643 SENSOR POWER SUPPLY

Diagnosis Procedure INFOID:00000000045002701.

CHECK GROUND CONNECTIONS

1. Turn ignition switch OFF.

2. Loosen and retighten grou NISSAN LATIO 2009 Service Repair Manual EC-1398< SERVICE INFOMATION >

[MR TYPE 2]

DTC P0643 SENSOR POWER SUPPLY

Diagnosis Procedure INFOID:00000000045002701.

CHECK GROUND CONNECTIONS

1. Turn ignition switch OFF.

2. Loosen and retighten grou](/img/5/57359/w960_57359-2753.png)

EC-1398< SERVICE INFOMATION >

[MR TYPE 2]

DTC P0643 SENSOR POWER SUPPLY

Diagnosis Procedure INFOID:00000000045002701.

CHECK GROUND CONNECTIONS

1. Turn ignition switch OFF.

2. Loosen and retighten ground screws on the body.

Refer to EC-1144, " Ground Inspection " .

OK or NG OK >> GO TO 2.

NG >> Repair or replace ground connections. TER-

MI-

NAL

NO. WIRE

COLOR ITEM CONDITION DATA (DC Voltage)

72 V Sensor power supply

(Throttle position sensor) [Ignition switch: ON]

Approximately 5V

78 O Sensor power supply

[Camshaft position sensor

(PHASE)] [Ignition switch: ON]

Approximately 5V

102 SB Sensor power supply

(APP sensor 2) [Ignition switch: ON]

Approximately 5V

103 GR Accelerator pe

dal position

sensor 2 [Ignition switch: ON]

• Engine stopped

• Accelerator pedal: Fully released 0.3 - 0.6V

[Ignition switch: ON]

• Engine stopped

• Accelerator pedal: Fully depressed 1.95 - 2.4V

104 Y Sensor ground

(APP sensor 2) [Engine is running]

• Warm-up condition

• Idle speed Approximately 0V

106 P Sensor power supply

(APP sensor 1) [Ignition switch: ON]

Approximately 5V

110 G Accelerator pe

dal position

sensor 1 [Ignition switch: ON]

• Engine stopped

• Accelerator pedal: Fully released 0.6 - 0.9V

[Ignition switch: ON]

• Engine stopped

• Accelerator pedal: Fully depressed 3.9 - 4.7V

111 R Sensor ground

(APP sensor 1) [Engine is running]

• Warm-up condition

• Idle speed Approximately 0V:

Vehicle front

1. Body ground E24 2. Engine ground F9 3. Engine ground F16

4. Body ground E15 BBIA0698E

Page 2755 of 4331

![NISSAN LATIO 2009 Service Repair Manual DTC P0643 SENSOR POWER SUPPLY

EC-1399

< SERVICE INFOMATION >

[MR TYPE 2] C

D E

F

G H

I

J

K L

M A EC

NP

O 2.

CHECK ACCELERATOR PEDAL POSITION SENSOR 1 POWER SUPPLY CIRCUIT

1. Disconnect accelerator pe NISSAN LATIO 2009 Service Repair Manual DTC P0643 SENSOR POWER SUPPLY

EC-1399

< SERVICE INFOMATION >

[MR TYPE 2] C

D E

F

G H

I

J

K L

M A EC

NP

O 2.

CHECK ACCELERATOR PEDAL POSITION SENSOR 1 POWER SUPPLY CIRCUIT

1. Disconnect accelerator pe](/img/5/57359/w960_57359-2754.png)

DTC P0643 SENSOR POWER SUPPLY

EC-1399

< SERVICE INFOMATION >

[MR TYPE 2] C

D E

F

G H

I

J

K L

M A EC

NP

O 2.

CHECK ACCELERATOR PEDAL POSITION SENSOR 1 POWER SUPPLY CIRCUIT

1. Disconnect accelerator pedal position (APP) sensor (1) harness connector.

2. Turn ignition switch ON.

3. Check voltage between APP sensor terminal 4 and ground with CONSULT-III or tester.

OK or NG OK >> GO TO 8.

NG >> GO TO 3. 3.

CHECK ACCELERATOR PEDAL POSITION SENSOR 1 POWER SUPPLY CIRCUIT-II

1. Turn ignition switch OFF.

2. Disconnect ECM harness connector.

3. Check harness continuity between APP sensor terminal 4 and ECM terminal 106.

Refer to Wiring Diagram.

OK or NG OK >> GO TO 4.

NG >> Repair open circuit or short to ground or short to power in harness or connectors. 4.

CHECK SENSOR POWER SUPPLY CIRCUITS

Check harness for short to power and short to ground, between the following terminals.

OK or NG OK >> GO TO 5.

NG >> Repair short to ground or short to power in harness or connectors. 5.

CHECK CAMSHAFT POSITI ON SENSOR (PHASE)

Refer to EC-1303, " Component Inspection " .

OK or NG OK >> GO TO 6.

NG >> Replace camshaft position sensor (PHASE). 6.

CHECK THROTTLE POSITION SENSOR

Refer to EC-1201, " Component Inspection " . BBIA0705E

Voltage: Approximately 5V

PBIA9606J

Continuity should exist.

ECM terminal Sensor terminal Reference Wiring Diagram 72 Throttle position sensor terminal 1 EC-1477, " Wiring Diagram "

78 Camshaft position sensor (PHASE) terminal 1

EC-1300, " Wiring Diagram "

106 APP sensor terminal 4

EC-1397, " Wiring Diagram "