NISSAN LATIO 2010 Service Repair Manual

Manufacturer: NISSAN, Model Year: 2010, Model line: LATIO, Model: NISSAN LATIO 2010Pages: 3745, PDF Size: 73.67 MB

Page 181 of 3745

AT-164

< SERVICE INFORMATION >

INPUT SPEED SENSOR A

Diagnosis Procedure

INFOID:0000000005397377

1.CHECK INPUT SIGNAL

With CONSULT-III

1. Start engine.

2. Select “TCM INPUT SIGNALS” in “DATA MONITOR” mode for “TRANSMISSION” with CONSULT-III.

3. Read out the value of “INPUT SPEED” while driving. Check the value changes according to driving speed.

OK or NG

OK >> GO TO 8.

NG >> GO TO 2.

2. CHECK INPUT SPEED SENSOR

With CONSULT-III

1. Start engine.

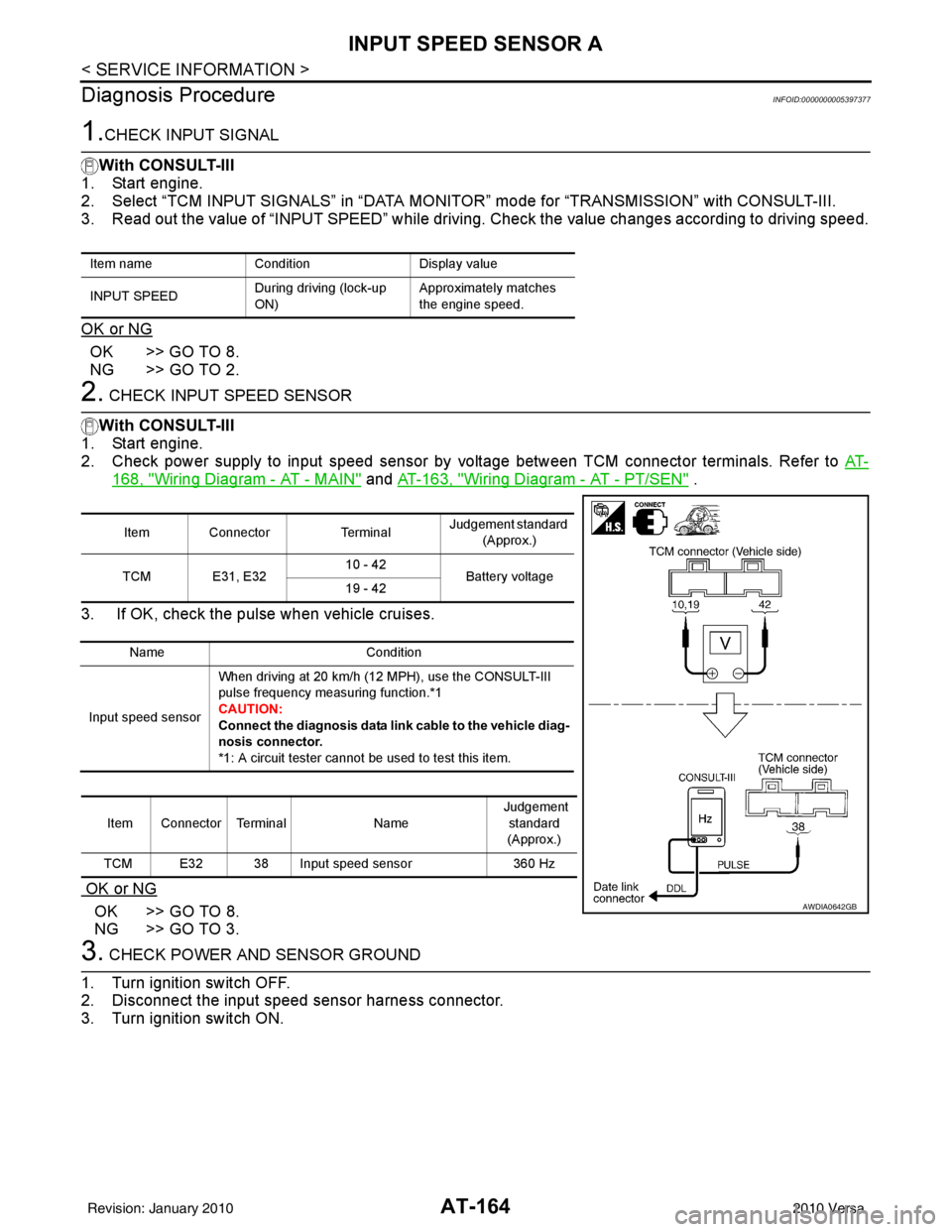

2. Check power supply to input speed sensor by voltage between TCM connector terminals. Refer to AT-

168, "Wiring Diagram - AT - MAIN" and AT-163, "Wiring Diagram - AT - PT/SEN" .

3. If OK, check the pulse when vehicle cruises.

OK or NG

OK >> GO TO 8.

NG >> GO TO 3.

3. CHECK POWER AND SENSOR GROUND

1. Turn ignition switch OFF.

2. Disconnect the input speed sensor harness connector.

3. Turn ignition switch ON.

Item name ConditionDisplay value

INPUT SPEED During driving (lock-up

ON)Approximately matches

the engine speed.

Item Connector

TerminalJudgement standard

(Approx.)

TCM E31, E32 10 - 42

Battery voltage

19 - 42

Name Condition

Input speed sensor When driving at 20 km/h (12 MPH), use the CONSULT-III

pulse frequency measuring function.*1

CAUTION:

Connect the diagnosis data link

cable to the vehicle diag-

nosis connector.

*1: A circuit tester cannot be used to test this item.

Item Connector Terminal Name Judgement

standard

(Approx.)

TCM E32 38 Input speed sensor 360 Hz

AWDIA0642GB

Revision: January 20102010 Versa

Page 182 of 3745

INPUT SPEED SENSOR AAT-165

< SERVICE INFORMATION >

DE

F

G H

I

J

K L

M A

B

AT

N

O P

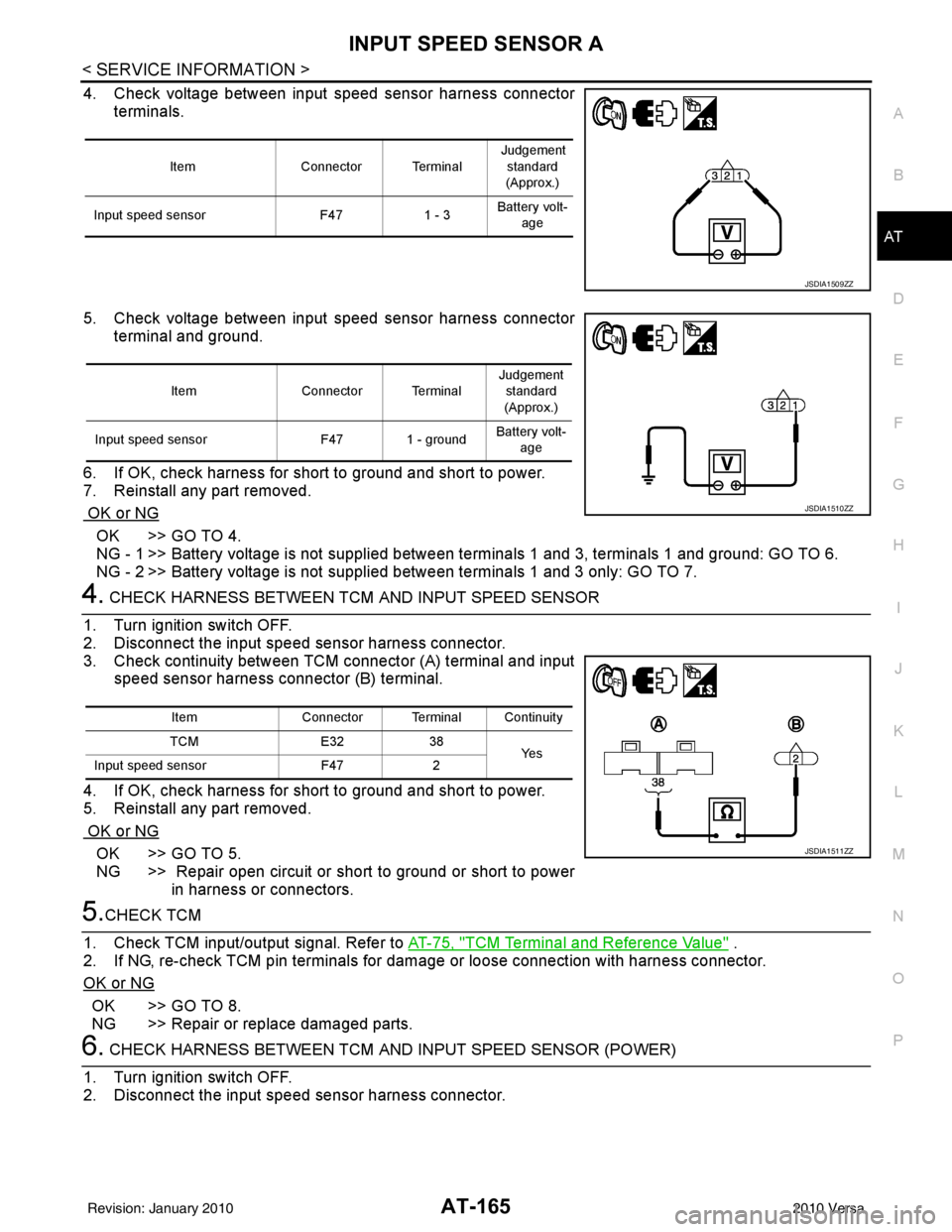

4. Check voltage between input speed sensor harness connector terminals.

5. Check voltage between input speed sensor harness connector terminal and ground.

6. If OK, check harness for short to ground and short to power.

7. Reinstall any part removed.

OK or NG

OK >> GO TO 4.

NG - 1 >> Battery voltage is not supplied between terminals 1 and 3, terminals 1 and ground: GO TO 6.

NG - 2 >> Battery voltage is not supplied between terminals 1 and 3 only: GO TO 7.

4. CHECK HARNESS BETWEEN TCM AND INPUT SPEED SENSOR

1. Turn ignition switch OFF.

2. Disconnect the input speed sensor harness connector.

3. Check continuity between TCM connector (A) terminal and input

speed sensor harness connector (B) terminal.

4. If OK, check harness for short to ground and short to power.

5. Reinstall any part removed.

OK or NG

OK >> GO TO 5.

NG >> Repair open circuit or short to ground or short to power in harness or connectors.

5.CHECK TCM

1. Check TCM input/output signal. Refer to AT-75, "

TCM Terminal and Reference Value" .

2. If NG, re-check TCM pin terminals for dam age or loose connection with harness connector.

OK or NG

OK >> GO TO 8.

NG >> Repair or replace damaged parts.

6. CHECK HARNESS BETWEEN TCM AND INPUT SPEED SENSOR (POWER)

1. Turn ignition switch OFF.

2. Disconnect the input speed sensor harness connector.

ItemConnector Terminal Judgement

standard

(Approx.)

Input speed sensor F471 - 3Battery volt-

age

JSDIA1509ZZ

Item Connector Terminal Judgement

standard

(Approx.)

Input speed sensor F47 1 - groundBattery volt-

age

JSDIA1510ZZ

Item Connector Terminal Continuity

TCM E3238

Ye s

Input speed sensor F472

JSDIA1511ZZ

Revision: January 20102010 Versa

Page 183 of 3745

AT-166

< SERVICE INFORMATION >

INPUT SPEED SENSOR A

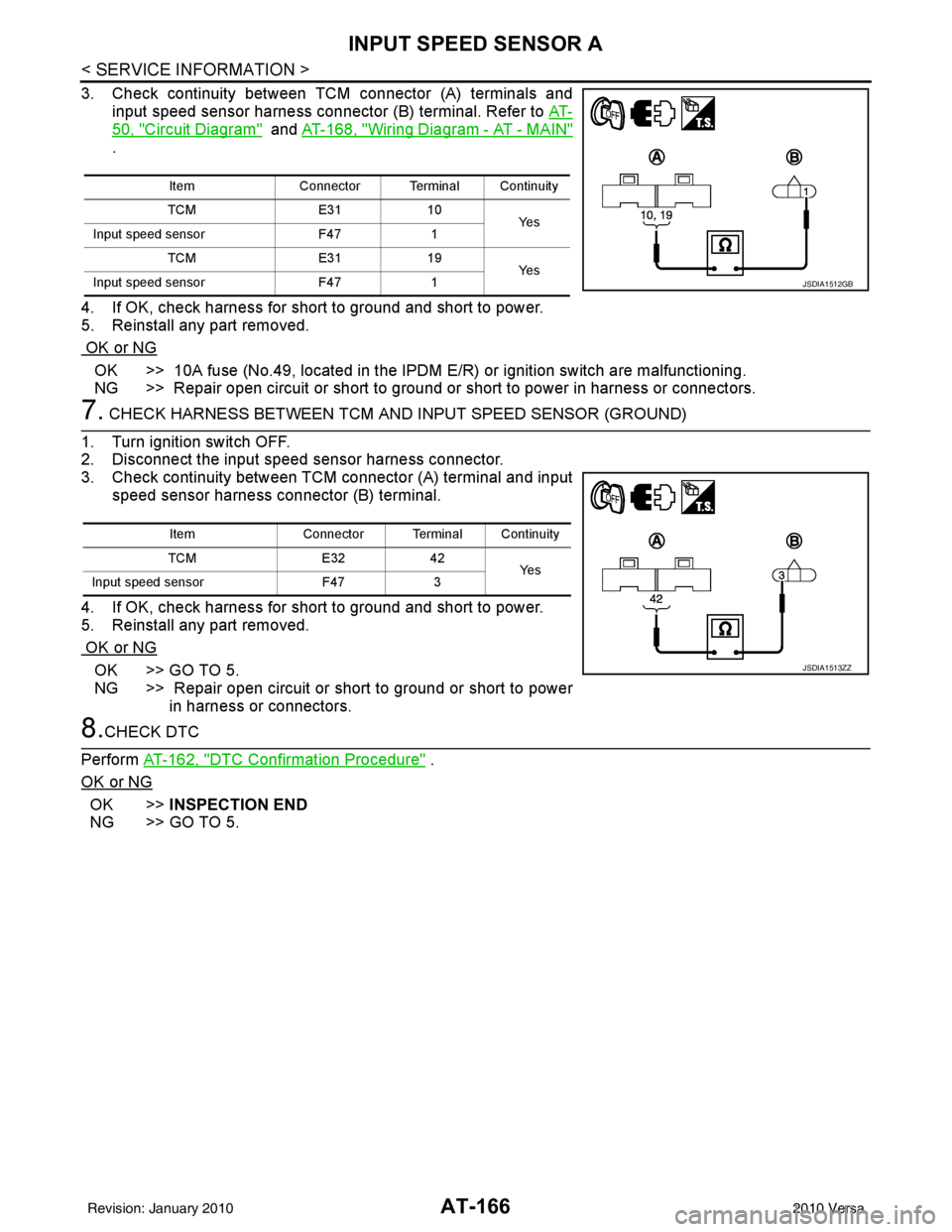

3. Check continuity between TCM connector (A) terminals and

input speed sensor harness connector (B) terminal. Refer to AT-

50, "Circuit Diagram" and AT-168, "Wiring Diagram - AT - MAIN"

.

4. If OK, check harness for short to ground and short to power.

5. Reinstall any part removed.

OK or NG

OK >> 10A fuse (No.49, located in the IPDM E/R) or ignition switch are malfunctioning.

NG >> Repair open circuit or short to ground or short to power in harness or connectors.

7. CHECK HARNESS BETWEEN TCM AND INPUT SPEED SENSOR (GROUND)

1. Turn ignition switch OFF.

2. Disconnect the input speed sensor harness connector.

3. Check continuity between TCM connector (A) terminal and input speed sensor harness connector (B) terminal.

4. If OK, check harness for short to ground and short to power.

5. Reinstall any part removed.

OK or NG

OK >> GO TO 5.

NG >> Repair open circuit or short to ground or short to power in harness or connectors.

8.CHECK DTC

Perform AT-162, "

DTC Confirmation Procedure" .

OK or NG

OK >> INSPECTION END

NG >> GO TO 5.

Item Connector Terminal Continuity

TCM E3110

Ye s

Input speed sensor F471

TCM E3119

Ye s

Input speed sensor F471

JSDIA1512GB

Item Connector Terminal Continuity

TCM E3242

Ye s

Input speed sensor F473

JSDIA1513ZZ

Revision: January 20102010 Versa

Page 184 of 3745

CONTROL UNIT (RAM), CONTROL UNIT (ROM)AT-167

< SERVICE INFORMATION >

DE

F

G H

I

J

K L

M A

B

AT

N

O P

CONTROL UNIT (RAM), CONTROL UNIT (ROM)

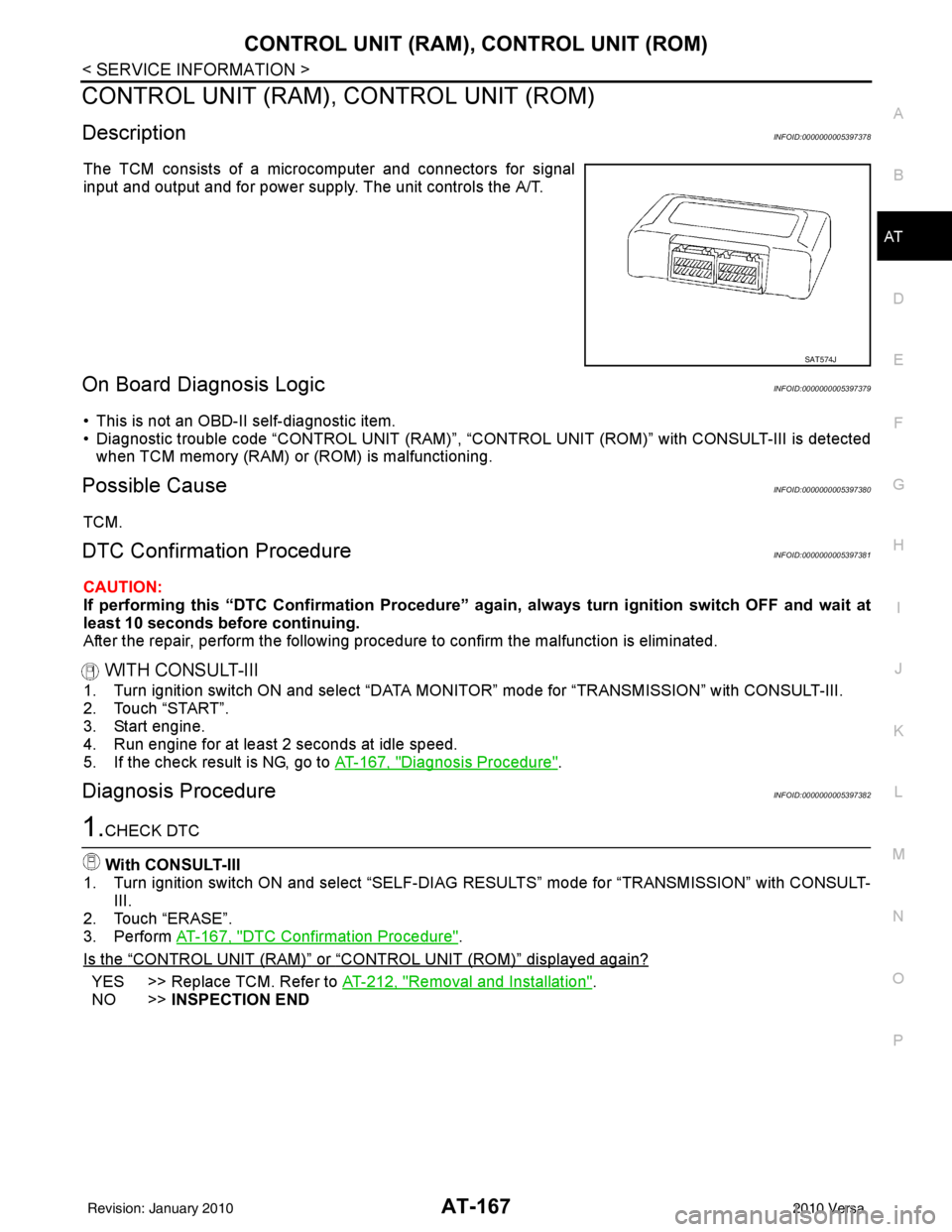

DescriptionINFOID:0000000005397378

The TCM consists of a microcomputer and connectors for signal

input and output and for power supply. The unit controls the A/T.

On Board Diagnosis LogicINFOID:0000000005397379

• This is not an OBD-II self-diagnostic item.

• Diagnostic trouble code “CONTROL UNIT (RAM)”, “CONTR OL UNIT (ROM)” with CONSULT-III is detected

when TCM memory (RAM) or (ROM) is malfunctioning.

Possible CauseINFOID:0000000005397380

TCM.

DTC Confirmation ProcedureINFOID:0000000005397381

CAUTION:

If performing this “DTC Confirmati on Procedure” again, always turn ignition switch OFF and wait at

least 10 seconds before continuing.

After the repair, perform the following procedure to confirm the malfunction is eliminated.

WITH CONSULT-III

1. Turn ignition switch ON and select “DATA MO NITOR” mode for “TRANSMISSION” with CONSULT-III.

2. Touch “START”.

3. Start engine.

4. Run engine for at least 2 seconds at idle speed.

5. If the check result is NG, go to AT-167, "

Diagnosis Procedure".

Diagnosis ProcedureINFOID:0000000005397382

1.CHECK DTC

With CONSULT-III

1. Turn ignition switch ON and select “SELF-DIAG RESULTS” mode for “TRANSMISSION” with CONSULT-

III.

2. Touch “ERASE”.

3. Perform AT-167, "

DTC Confirmation Procedure".

Is the

“CONTROL UNIT (RAM)” or “CONTROL UNIT (ROM)” displayed again?

YES >> Replace TCM. Refer to AT-212, "Removal and Installation".

NO >> INSPECTION END

SAT574J

Revision: January 20102010 Versa

Page 185 of 3745

AT-168

< SERVICE INFORMATION >

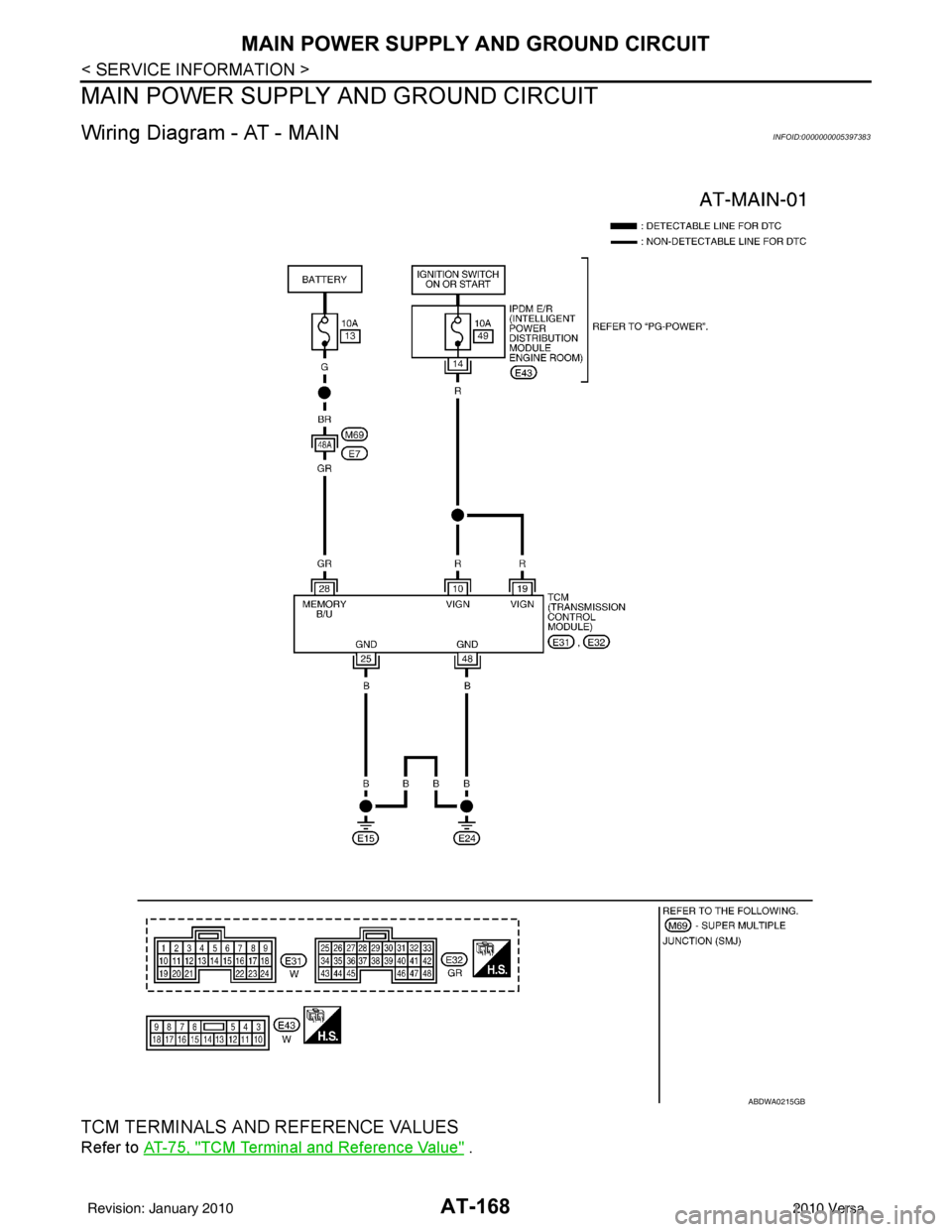

MAIN POWER SUPPLY AND GROUND CIRCUIT

MAIN POWER SUPPLY AND GROUND CIRCUIT

Wiring Diagram - AT - MAININFOID:0000000005397383

TCM TERMINALS AND REFERENCE VALUES

Refer to AT-75, "TCM Terminal and Reference Value" .

ABDWA0215GB

Revision: January 20102010 Versa

Page 186 of 3745

MAIN POWER SUPPLY AND GROUND CIRCUITAT-169

< SERVICE INFORMATION >

DE

F

G H

I

J

K L

M A

B

AT

N

O P

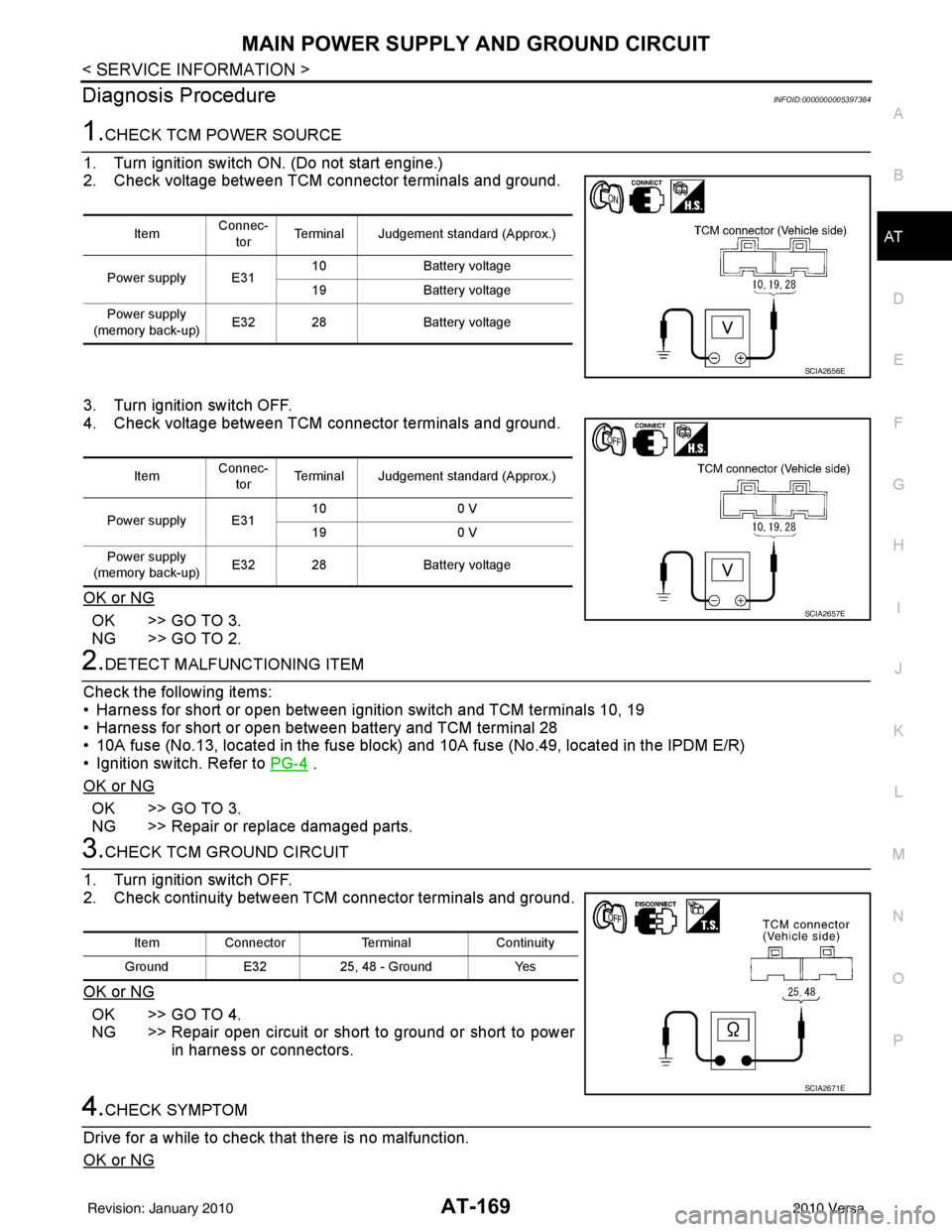

Diagnosis ProcedureINFOID:0000000005397384

1.CHECK TCM POWER SOURCE

1. Turn ignition switch ON. (Do not start engine.)

2. Check voltage between TCM connector terminals and ground.

3. Turn ignition switch OFF.

4. Check voltage between TCM connector terminals and ground.

OK or NG

OK >> GO TO 3.

NG >> GO TO 2.

2.DETECT MALFUNCTIONING ITEM

Check the following items:

• Harness for short or open between ignition switch and TCM terminals 10, 19

• Harness for short or open between battery and TCM terminal 28

• 10A fuse (No.13, located in the fuse block) and 10A fuse (No.49, located in the IPDM E/R)

• Ignition switch. Refer to PG-4

.

OK or NG

OK >> GO TO 3.

NG >> Repair or replace damaged parts.

3.CHECK TCM GROUND CIRCUIT

1. Turn ignition switch OFF.

2. Check continuity between TCM connector terminals and ground.

OK or NG

OK >> GO TO 4.

NG >> Repair open circuit or short to ground or short to power in harness or connectors.

4.CHECK SYMPTOM

Drive for a while to check that there is no malfunction.

OK or NG

Item Connec-

tor Terminal Judgement standard (Approx.)

Power supply E31 10

Battery voltage

19 Battery voltage

Power supply

(memory back-up) E32 28

Battery voltage

SCIA2656E

ItemConnec-

tor Terminal Judgement standard (Approx.)

Power supply E31 10

0 V

19 0 V

Power supply

(memory back-up) E32 28

Battery voltage

SCIA2657E

Item Connector TerminalContinuity

Ground E3225, 48 - Ground Yes

SCIA2671E

Revision: January 20102010 Versa

Page 187 of 3745

AT-170

< SERVICE INFORMATION >

MAIN POWER SUPPLY AND GROUND CIRCUIT

OK >>INSPECTION END

NG >> GO TO 5.

5.CHECK TCM

1. Check TCM input/output signal. Refer to AT-75, "

TCM Terminal and Reference Value" .

2. If NG, recheck TCM pin terminals for damage or loose connection with harness connector.

OK or NG

OK >> INSPECTION END

NG >> Repair or replace damaged parts.

Revision: January 20102010 Versa

Page 188 of 3745

TR SW, OD SW AND CLOSED THROTTLE, WIDE OPEN THROTTLE POSITION

SIGNAL CIRCUIT

AT-171

< SERVICE INFORMATION >

DE

F

G H

I

J

K L

M A

B

AT

N

O P

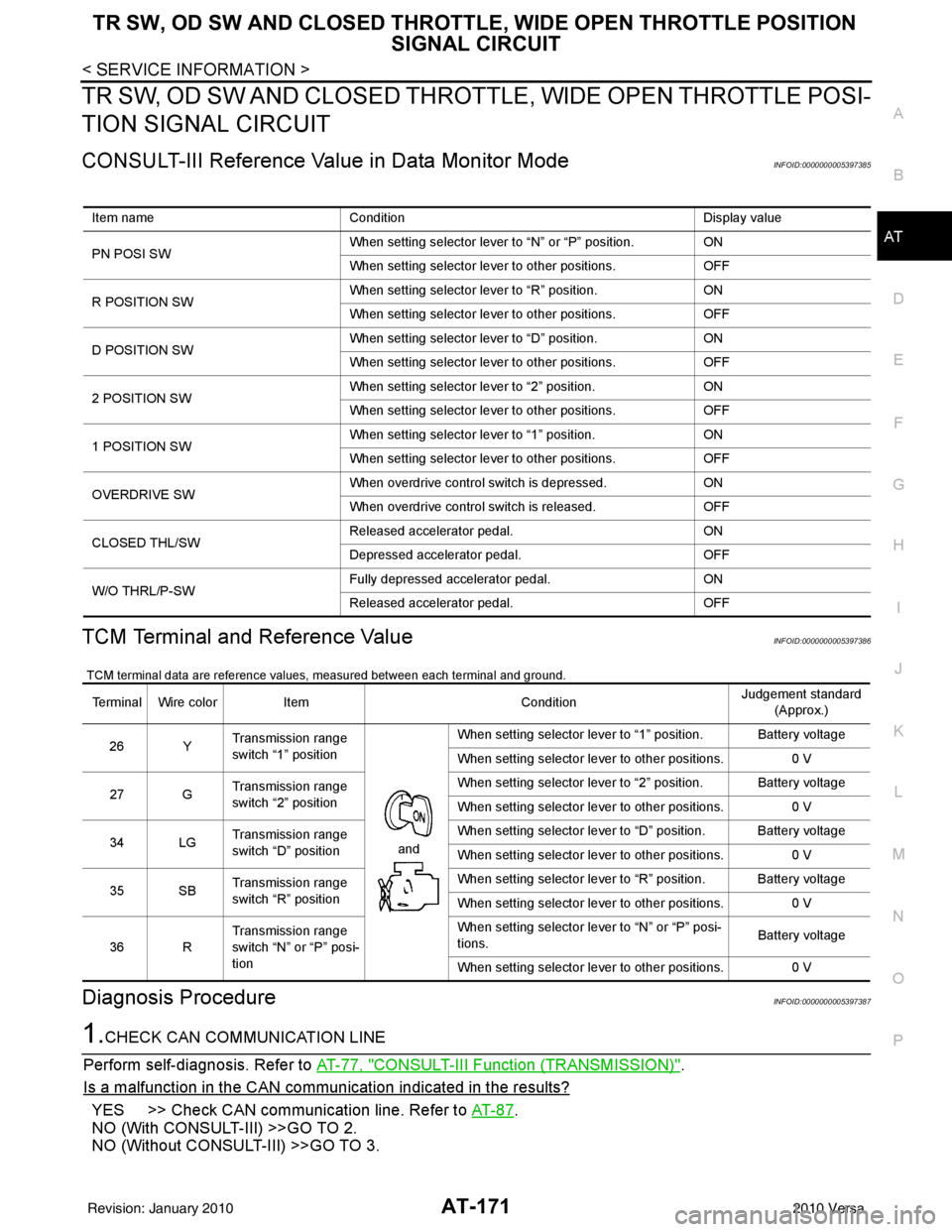

TR SW, OD SW AND CLOSED THROTTL E, WIDE OPEN THROTTLE POSI-

TION SIGNAL CIRCUIT

CONSULT-III Reference Val ue in Data Monitor ModeINFOID:0000000005397385

TCM Terminal and Reference ValueINFOID:0000000005397386

TCM terminal data are reference values, measured between each terminal and ground.

Diagnosis ProcedureINFOID:0000000005397387

1.CHECK CAN COMMUNICATION LINE

Perform self-diagnosis. Refer to AT-77, "

CONSULT-III Function (TRANSMISSION)".

Is a malfunction in the CAN communication indicated in the results?

YES >> Check CAN communication line. Refer to AT- 8 7.

NO (With CONSULT-III) >>GO TO 2.

NO (Without CONSULT-III) >>GO TO 3.

Item name Condition Display value

PN POSI SW When setting selector lever

to “N” or “P” position. ON

When setting selector lever to other positions. OFF

R POSITION SW When setting selector lever to “R” position.

ON

When setting selector lever to other positions. OFF

D POSITION SW When setting selector lever to “D” position.

ON

When setting selector lever to other positions. OFF

2 POSITION SW When setting selector lever to “2” position.

ON

When setting selector lever to other positions. OFF

1 POSITION SW When setting selector lever to “1” position.

ON

When setting selector lever to other positions. OFF

OVERDRIVE SW When overdrive control switch is depressed.

ON

When overdrive control switch is released. OFF

CLOSED THL/SW Released accelerator pedal.

ON

Depressed accelerator pedal. OFF

W/O THRL/P-SW Fully depressed accelerator pedal.

ON

Released accelerator pedal. OFF

Terminal Wire colorItem ConditionJudgement standard

(Approx.)

26 Y Transmission range

switch “1” position

andWhen setting selector lever to “1” position. Battery voltage

When setting selector lever to other positions.

0 V

27 G Transmission range

switch “2” position When setting selector lever to “2” position. Battery voltage

When setting selector lever to other positions.

0 V

34 LG Transmission range

switch “D” position When setting selector lever to “D” position. Battery voltage

When setting selector lever to other positions.

0 V

35 SB Transmission range

switch “R” position When setting selector lever to “R” position. Battery voltage

When setting selector lever to other positions.

0 V

36 R Transmission range

switch “N” or “P” posi-

tion When setting selector le

ver to “N” or “P” posi-

tions. Battery voltage

When setting selector lever to other positions. 0 V

Revision: January 20102010 Versa

Page 189 of 3745

AT-172

< SERVICE INFORMATION >

TR SW, OD SW AND CLOSED THROTTLE, WIDE OPEN THROTTLE POSITION

SIGNAL CIRCUIT

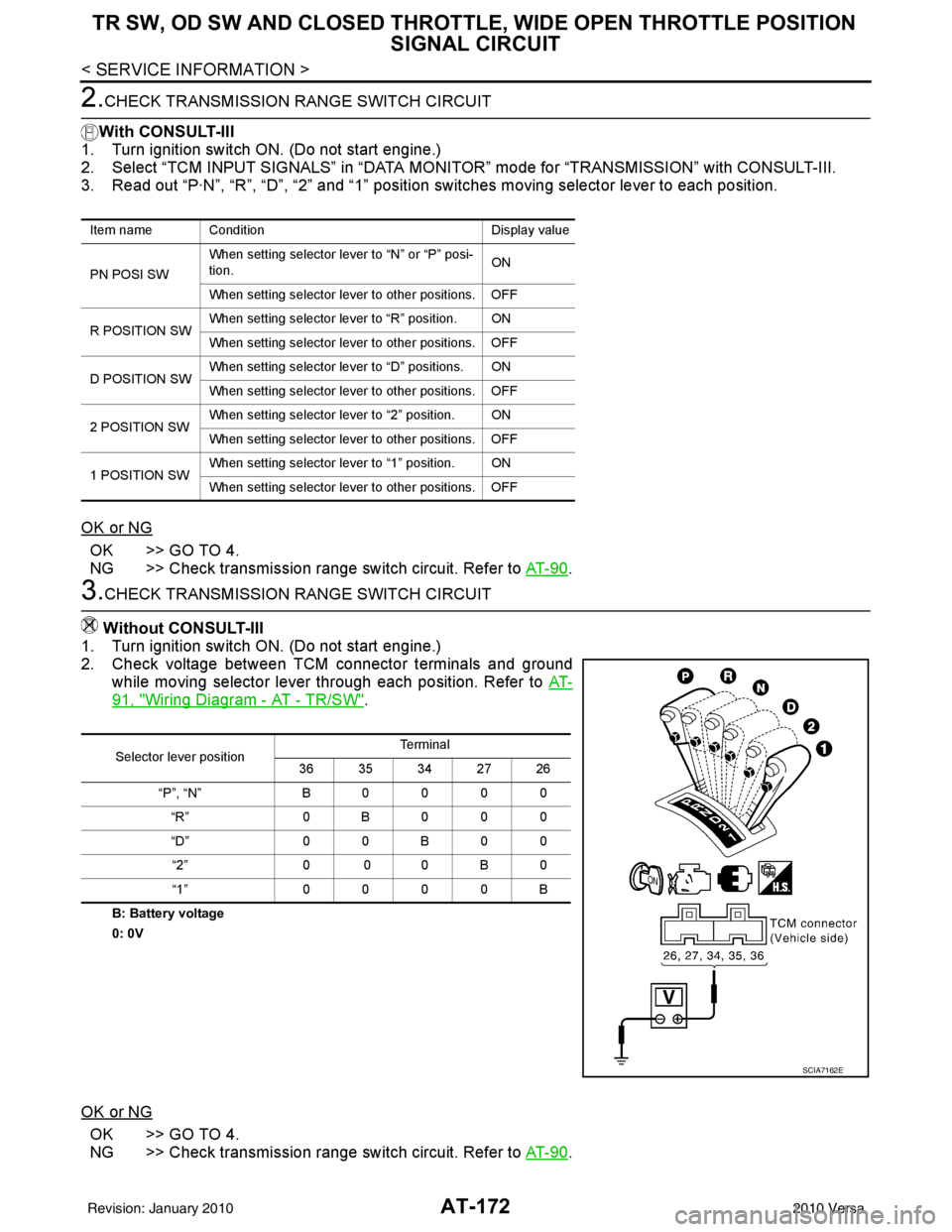

2.CHECK TRANSMISSION RANGE SWITCH CIRCUIT

With CONSULT-III

1. Turn ignition switch ON. (Do not start engine.)

2. Select “TCM INPUT SIGNALS” in “DATA MONITOR” mode for “TRANSMISSION” with CONSULT-III.

3. Read out “P·N”, “R”, “D”, “2” and “1” position switches moving selector lever to each position.

OK or NG

OK >> GO TO 4.

NG >> Check transmission range switch circuit. Refer to AT- 9 0

.

3.CHECK TRANSMISSION RANGE SWITCH CIRCUIT

Without CONSULT-III

1. Turn ignition switch ON. (Do not start engine.)

2. Check voltage between TCM connector terminals and ground while moving selector lever through each position. Refer to AT-

91, "Wiring Diagram - AT - TR/SW".

B: Battery voltage

0: 0V

OK or NG

OK >> GO TO 4.

NG >> Check transmission range switch circuit. Refer to AT- 9 0

.

Item name Condition Display value

PN POSI SW When setting selector le

ver to “N” or “P” posi-

tion. ON

When setting selector lever to other positions. OFF

R POSITION SW When setting selector lever to “R” position. ON

When setting selector lever to other positions. OFF

D POSITION SW When setting selector lever to “D” positions. ON

When setting selector lever to other positions. OFF

2 POSITION SW When setting selector lever to “2” position. ON

When setting selector lever to other positions. OFF

1 POSITION SW When setting selector lever to “1” position. ON

When setting selector lever to other positions. OFF

Selector lever position Te r m i n a l

36 35 34 27 26

“P”, “N” B0000 “R” 0B000

“D” 0 0 B 0 0

“2” 0 0 0 B 0

“1” 0000B

SCIA7162E

Revision: January 20102010 Versa

Page 190 of 3745

TR SW, OD SW AND CLOSED THROTTLE, WIDE OPEN THROTTLE POSITION

SIGNAL CIRCUIT

AT-173

< SERVICE INFORMATION >

DE

F

G H

I

J

K L

M A

B

AT

N

O P

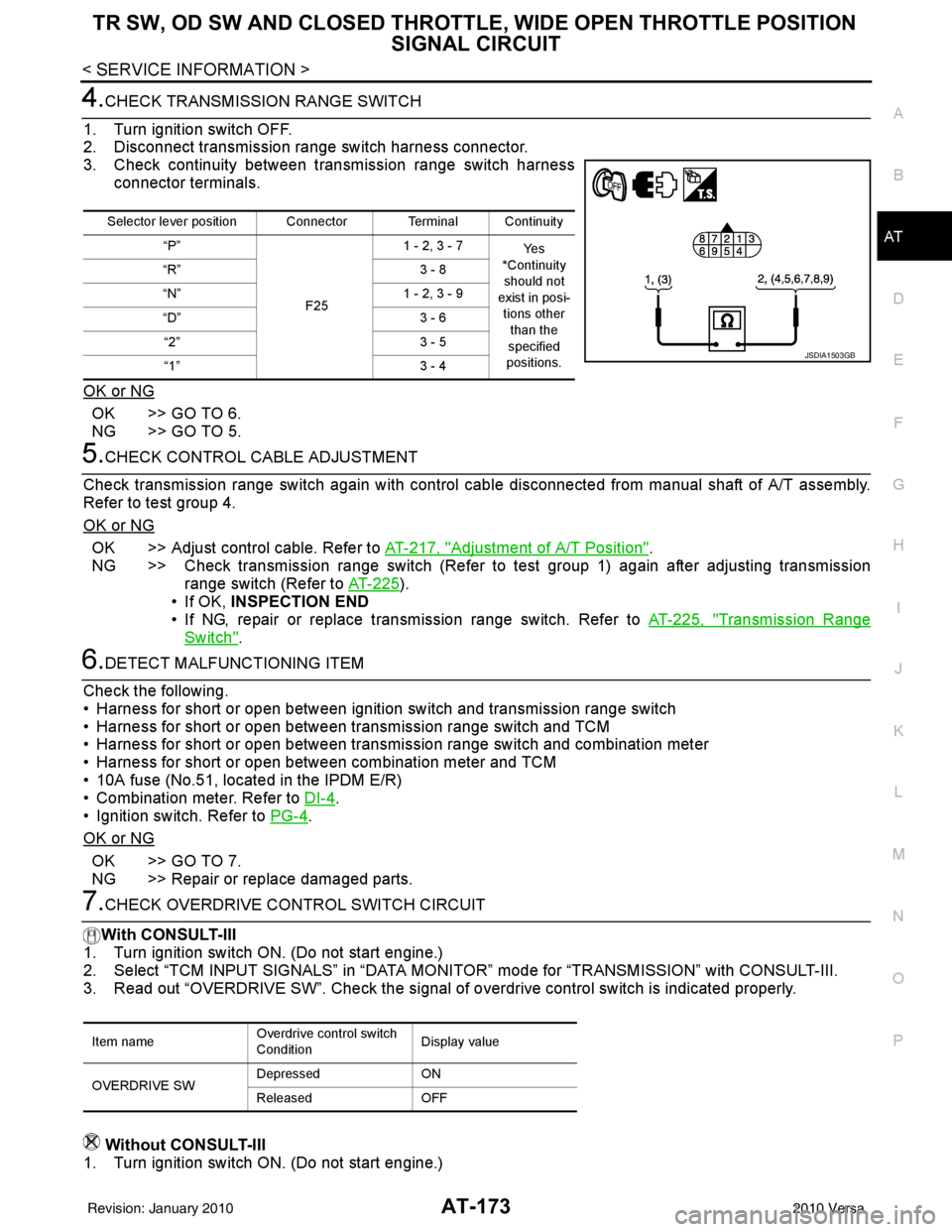

4.CHECK TRANSMISSION RANGE SWITCH

1. Turn ignition switch OFF.

2. Disconnect transmission range switch harness connector.

3. Check continuity between transmission range switch harness connector terminals.

OK or NG

OK >> GO TO 6.

NG >> GO TO 5.

5.CHECK CONTROL CABLE ADJUSTMENT

Check transmission range switch again with control cabl e disconnected from manual shaft of A/T assembly.

Refer to test group 4.

OK or NG

OK >> Adjust control cable. Refer to AT-217, "Adjustment of A/T Position".

NG >> Check transmission range switch (Refer to test group 1) again after adjusting transmission range switch (Refer to AT-225

).

• If OK, INSPECTION END

• If NG, repair or replace transmission range switch. Refer to AT-225, "

Transmission Range

Switch".

6.DETECT MALFUNCTIONING ITEM

Check the following.

• Harness for short or open between ignition switch and transmission range switch

• Harness for short or open between transmission range switch and TCM

• Harness for short or open between transmission range switch and combination meter

• Harness for short or open between combination meter and TCM

• 10A fuse (No.51, located in the IPDM E/R)

• Combination meter. Refer to DI-4

.

• Ignition switch. Refer to PG-4

.

OK or NG

OK >> GO TO 7.

NG >> Repair or replace damaged parts.

7.CHECK OVERDRIVE CO NTROL SWITCH CIRCUIT

With CONSULT-III

1. Turn ignition switch ON. (Do not start engine.)

2. Select “TCM INPUT SIGNALS” in “DATA MONI TOR” mode for “TRANSMISSION” with CONSULT-III.

3. Read out “OVERDRIVE SW”. Check the signal of ov erdrive control switch is indicated properly.

Without CONSULT-III

1. Turn ignition switch ON. (Do not start engine.)

Selector lever position Connector Terminal Continuity

“P”

F251 - 2, 3 - 7

Ye s

*Continuity should not

exist in posi-

tions other than the

specified

positions.

“R”

3 - 8

“N” 1 - 2, 3 - 9

“D” 3 - 6

“2” 3 - 5

“1” 3 - 4

JSDIA1503GB

Item nameOverdrive control switch

ConditionDisplay value

OVERDRIVE SW Depressed

ON

Released OFF

Revision: January 20102010 Versa