battery NISSAN LATIO 2010 Service User Guide

[x] Cancel search | Manufacturer: NISSAN, Model Year: 2010, Model line: LATIO, Model: NISSAN LATIO 2010Pages: 3745, PDF Size: 73.67 MB

Page 94 of 3745

TROUBLE DIAGNOSISAT-77

< SERVICE INFORMATION >

DE

F

G H

I

J

K L

M A

B

AT

N

O P

*1: These terminals are connected to the data link connector.

*2: These terminals are connected to the ECM.

CONSULT-III Function (TRANSMISSION)INFOID:0000000005397251

CONSULT-III can display each diagnostic item using the diagnostic test models shown following.

FUNCTION

CONSULT-III REFERENCE VALUE

NOTICE:

1. The CONSULT-III electrically displays shift timi ng and lock-up timing (that is, operation timing of each

solenoid).

34 LG Transmission range

switch “D” position

and When setting selector lever to “D” posi-

tion.

Battery voltage

When setting selector lever to other po-

sitions. 0 V

35 SB Transmission range

switch “R” position When setting selector lever to “R” posi-

tion.

Battery voltage

When setting selector lever to other po-

sitions. 0 V

36 R Transmission range

switch “N” or “P” position When setting selector

lever to “N” or “P”

position. Battery voltage

When setting selector lever to other po-

sitions. 0 V

38 G Input speed sensor When driving at 20 km/h (12 MPH) 360 Hz

39

*2L Engine speed signal and Refer to EC-454 (HR16DE),

EC-605 (MR18DE).

40 O Vehicle speed signal When driving vehicle at 2 to 3 km/h (1 to

2 MPH) for 1 m (3 ft) or more.Voltage varies

between less

than 0 V and

more than 4.5 V

42 B Sensor ground Always0 V

47 BR A/T fluid temperature

sensor

and When A/T fluid temperature is 20°

C

(68 °F). 1.5 V

When A/T fluid temperature is 80° C

(176 °F). 0.5 V

48 B Ground Always0 V

Te r m i n a l

Wire

color Item

ConditionJudgement stan-

dard (Approx.)

Diagnostic test mode Function

Work Support This mode enables a technician to adjust some devices faster and more accuratelyI.

Self Diagnostic Results Retrieve DTC from ECU and display diagnostic items.

Data Monitor Monitor the input/output signal of the control unit in real time.

CAN Diagnosis Support Monitor It monitors the status of CAN communication.

Function Test This mode can show results of self-diagnosis of ECU with either “OK” or “NG”. For engine, more

practical tests regarding sensors/switches and/or actuators are available.

DTC & SRT confirmation The status of system monitoring tests and the self-diagnosis status/result can be confirmed.

ECU Identification Display the ECU identification number (part number etc.) of the selected system.

Revision: January 20102010 Versa

Page 95 of 3745

AT-78

< SERVICE INFORMATION >

TROUBLE DIAGNOSIS

Check for time difference between actual shift timing and the CONSULT-III display. If the difference is

noticeable, mechanical parts (except solenoids, sens ors, etc.) may be malfunctioning. Check mechanical

parts using applicable diagnostic procedures.

2. Shift schedule (which implies gear position) display ed on CONSULT-III and that indicated in Service Man-

ual may differ slightly. This occurs because of the following reasons:

- Actual shift schedule has more or less tolerance or allowance,

- Shift schedule indicated in Service Manual refers to the point where shifts start, and

- Gear position displayed on CONSULT-III indicates the point where shifts are completed.

3. Shift solenoid valve “A” or “B” is displayed on CONSUL T-III at the start of shifting. Gear position is dis-

played upon completion of shifting (which is computed by TCM).

Item name Condition Display value (Approx.)

VHCL/S SE-A/T During driving Approximately matches the speedometer

reading.

VHCL/S SE-MTR

THROTTLE POSI Released accelerator pedal.

0.0/8

Fully depressed accelerator pedal. 8.0/8

FLUID TEMP SE When A/T fluid temperature is 20

°C (68 °F). 1.5 V

When A/T fluid temperature is 80 °C (176 °F). 0.5 V

BATTERY VOLT When turning ignition switch to “ON”. Battery voltage

ENGINE SPEED Engine running Approximately matches the tachometer

reading.

INPUT SPEED During driving (lock-up ON) Approximately matche s the engine speed.

OVERDRIVE SW When overdrive control switch is depressed. ON

When overdrive control switch is released. OFF

PN POSI SW When setting selector lever

to “N” or “P” position. ON

When setting selector lever to other positions. OFF

R POSITION SW When setting selector lever to “R” position. ON

When setting selector lever to other positions. OFF

D POSITION SW When setting selector lever to “D” position. ON

When setting selector lever to other positions. OFF

2 POSITION SW When setting selector lever to “2” position. ON

When setting selector lever to other positions. OFF

1 POSITION SW When setting selector lever to “1” position. ON

When setting selector lever to other positions. OFF

CLOSED THL/SW Released accelerator pedal.

ON

Depressed accelerator pedal. OFF

W/O THRL/P-SW Fully depressed accelerator pedal.

ON

Released accelerator pedal. OFF

SHIFT S/V A When shift solenoid valve A operates.

(When driving in “D

1” or “D4”.)

ON

When shift solenoid valve A does not operate.

(When driving in “D

2” or “D3”.) OFF

SHIFT S/V B When shift solenoid valve B operates.

(When driving in “D

1” or “D2”.)

ON

When shift solenoid valve B does not operate.

(When driving in “D

3” or “D4”.) OFF

Revision: January 20102010 Versa

Page 97 of 3745

AT-80

< SERVICE INFORMATION >

TROUBLE DIAGNOSIS

*1: Refer to AT- 4 1 , "Malfunction Indicator Lamp (MIL)" .

*2: These malfunctions cannot be displayed MIL if another malfunction is assigned to MIL.

DATA MONITOR MODE

Display Items List

X: Standard, —: Not applicable, : Option

SHIFT SOLENOID A • TCM detects an improper voltage drop when it tries to operate the so-

lenoid valve. P0750

AT- 1 3 8

SHIFT SOLENOID B • TCM detects an improper voltage drop when it tries to operate the so-

lenoid valve. P0755

AT- 1 4 3

OVER CLUTCH SOLE-

NOID • TCM detects an improper voltage drop when it tries to operate the so-

lenoid valve. P1760

AT- 1 4 8

VHCL SPEED SEN-

MTR • TCM does not receive the proper voltage signal from the sensor.

—AT- 1 5 3

BATT/FLUID TEMP

SEN • TCM receives an excessively low or high voltage from the sensor.

—AT- 1 5 6

INPUT SPEED SEN-

SOR A • TCM does not receive proper voltage signal from sensor.

—AT- 1 6 2

CONTROL UNIT (RAM) • TCM memory (RAM) is malfunctioning. —AT- 1 6 7

CONTROL UNIT (ROM) • TCM memory (ROM) is malfunctioning. —AT- 1 6 7

No failure

(NO SELF DIAGNOS-

TIC FAILURE INDICAT-

ED FURTHER

TESTING MAY BE RE-

QUIRED) • No failure has been detected.

——

Items (CONSULT-III

screen terms) Malfunction is detected when... OBD-II (DTC)

Reference page

MIL indicator

lamp*1, “EN-

GINE” with

CONSULT-III or GST

Monitored item (Unit) Monitor Item Selection

Remarks

TCM INPUT

SIGNALS MAIN SIG-

NALS SELEC-

TION FROM MENU

VHCL/S SE-A/T (km/h) X— Output speed sensor

VHCL/S SE-MTR (km/h) X— Vehicle speed display may not be accu-

rate under approx. 10 km/h (6 mph). It

may not indicate 0 km/h (0 mph) when

vehicle is stationary.

THRTL POS SEN (V) X—

FLUID TEMP SE (V) X—

BATTERY VOLT (V) X—

ENGINE SPEED (rpm) XX

INPUT SPEED (rpm) X—

OVERDRIVE SW (ON/OFF) X—

PN POSI SW (ON/OFF) X—

R POSITION SW (ON/OFF) X—

D POSITION SW (ON/OFF) X—

Revision: January 20102010 Versa

Page 109 of 3745

AT-92

< SERVICE INFORMATION >

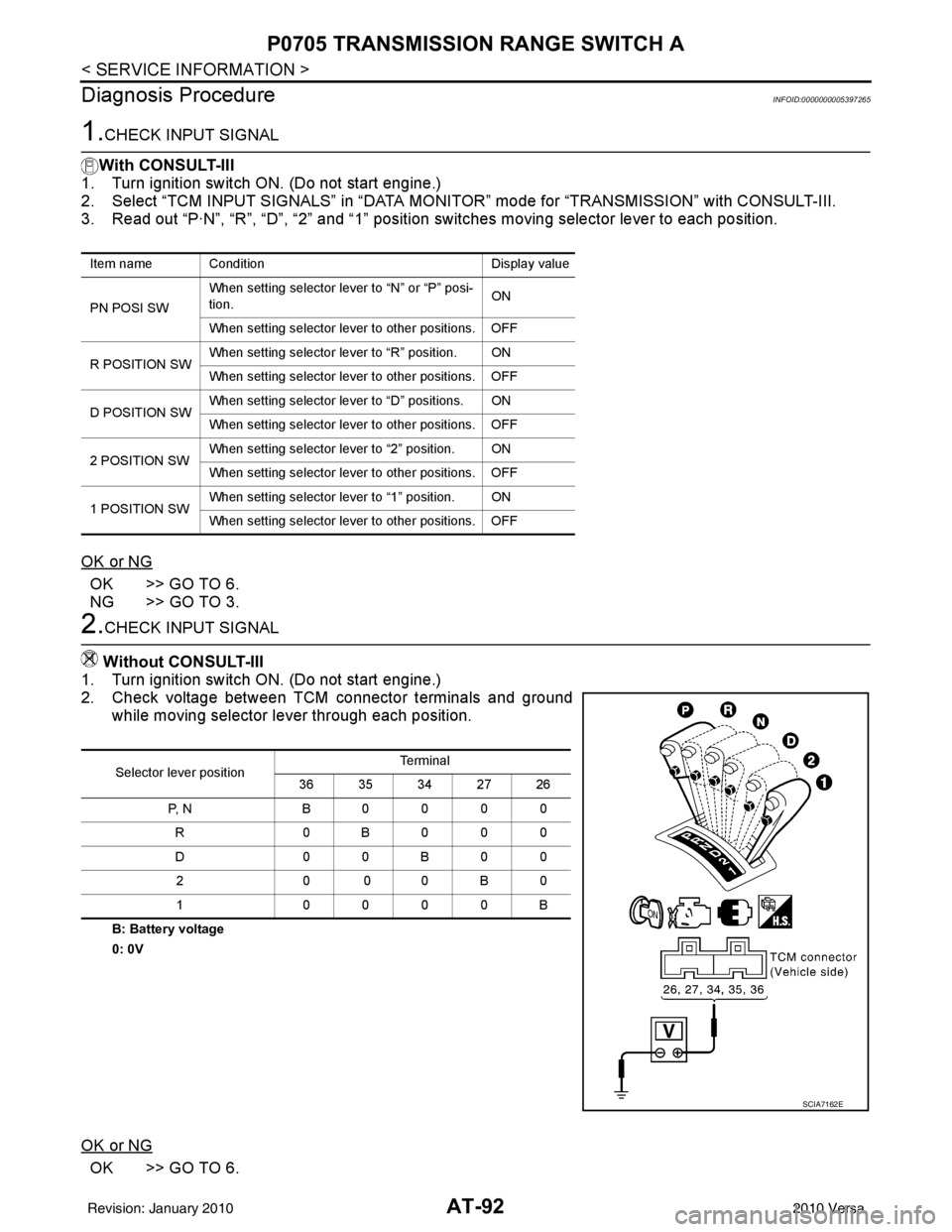

P0705 TRANSMISSION RANGE SWITCH A

Diagnosis Procedure

INFOID:0000000005397265

1.CHECK INPUT SIGNAL

With CONSULT-III

1. Turn ignition switch ON. (Do not start engine.)

2. Select “TCM INPUT SIGNALS” in “DATA MONITOR” mode for “TRANSMISSION” with CONSULT-III.

3. Read out “P·N”, “R”, “D”, “2” and “1” position switches moving selector lever to each position.

OK or NG

OK >> GO TO 6.

NG >> GO TO 3.

2.CHECK INPUT SIGNAL

Without CONSULT-III

1. Turn ignition switch ON. (Do not start engine.)

2. Check voltage between TCM connector terminals and ground while moving selector lever through each position.

B: Battery voltage

0: 0V

OK or NG

OK >> GO TO 6.

Item name Condition Display value

PN POSI SW When setting selector le

ver to “N” or “P” posi-

tion. ON

When setting selector lever to other positions. OFF

R POSITION SW When setting selector lever to “R” position. ON

When setting selector lever to other positions. OFF

D POSITION SW When setting selector lever to “D” positions. ON

When setting selector lever to other positions. OFF

2 POSITION SW When setting selector lever to “2” position. ON

When setting selector lever to other positions. OFF

1 POSITION SW When setting selector lever to “1” position. ON

When setting selector lever to other positions. OFF

Selector lever position Te r m i n a l

36 35 34 27 26

P, N B0000 R 0B000

D0 0B 00

20 00B 0

1 0000B

SCIA7162E

Revision: January 20102010 Versa

Page 119 of 3745

AT-102

< SERVICE INFORMATION >

P0720 OUTPUT SPEED SENSOR

TCM TERMINALS AND REFERENCE VALUES

Refer to AT-75, "TCM Terminal and Reference Value".

Diagnosis ProcedureINFOID:0000000005397281

1.CHECK INPUT SIGNAL

With CONSULT-III

1. Start engine.

2. Select “TCM INPUT SIGNALS” in “DATA MONITOR” mode for “TRANSMISSION” with CONSULT-III.

3. Read out the value of “VHCL/S SE-A/T” while driving. Check the value changes according to driving speed.

OK or NG

OK >> GO TO 8.

NG >> GO TO 2.

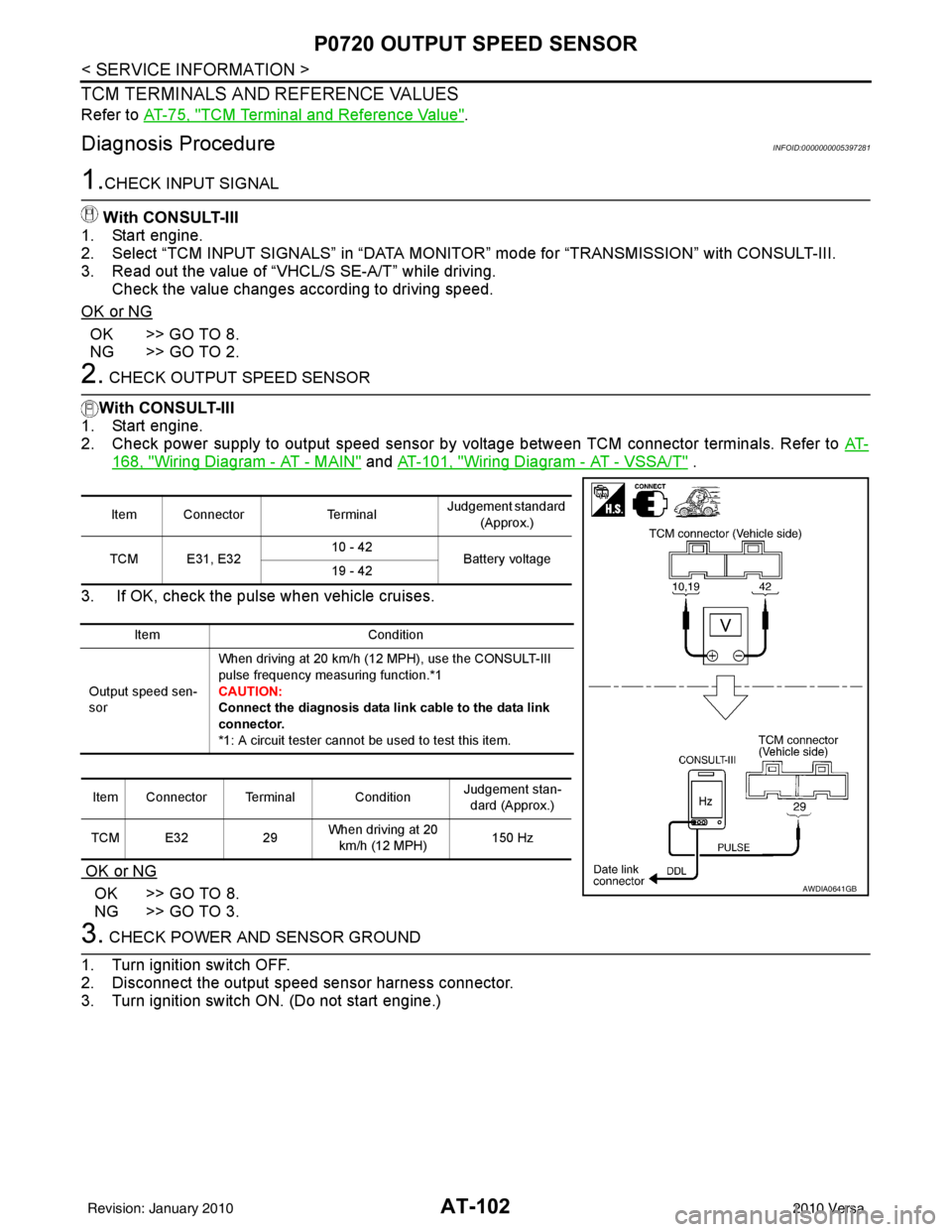

2. CHECK OUTPUT SPEED SENSOR

With CONSULT-III

1. Start engine.

2. Check power supply to output speed sensor by voltage between TCM connector terminals. Refer to AT-

168, "Wiring Diagram - AT - MAIN" and AT-101, "Wiring Diagram - AT - VSSA/T" .

3. If OK, check the pulse when vehicle cruises.

OK or NG

OK >> GO TO 8.

NG >> GO TO 3.

3. CHECK POWER AND SENSOR GROUND

1. Turn ignition switch OFF.

2. Disconnect the output speed sensor harness connector.

3. Turn ignition switch ON. (Do not start engine.)

Item Connector TerminalJudgement standard

(Approx.)

TCM E31, E32 10 - 42

Battery voltage

19 - 42

Item Condition

Output speed sen-

sor When driving at 20 km/h (12 MPH), use the CONSULT-III

pulse frequency measuring function.*1

CAUTION:

Connect the diagnosis

data link cable to the data link

connector.

*1: A circuit tester cannot be used to test this item.

Item Connector Terminal Condition Judgement stan-

dard (Approx.)

TCM E32 29When driving at 20

km/h (12 MPH) 150 Hz

AWDIA0641GB

Revision: January 20102010 Versa

Page 120 of 3745

P0720 OUTPUT SPEED SENSORAT-103

< SERVICE INFORMATION >

DE

F

G H

I

J

K L

M A

B

AT

N

O P

4. Check voltage between output speed sensor harness connector terminals.

5. Check voltage between output speed sensor harness connector terminal and ground.

6. If OK, check harness for short to ground and short to power.

7. Reinstall any part removed.

OK or NG

OK >> GO TO 4.

NG - 1 >> Battery voltage is not supplied between terminals 1 and 3, terminals 1 and ground: GO TO 6.

NG - 2 >> Battery voltage is not supplied between terminals 1 and 3 only: GO TO 7.

4. CHECK HARNESS BETWEEN TCM AND OUTPUT SPEED SENSOR

1. Turn ignition switch OFF.

2. Disconnect the TCM connector and output speed sensor harness connector.

3. Check continuity between TCM connector (A) terminal and out- put speed sensor harness connector (B) terminal.

4. If OK, check harness for short to ground and short to power.

5. Reinstall any part removed.

OK or NG

OK >> GO TO 5.

NG >> Repair open circuit or short to ground or short to power in harness or connectors.

5.CHECK TCM

1. Check TCM input/output signal. Refer to AT-75, "

TCM Terminal and Reference Value" .

2. If NG, re-check TCM pin terminals for dam age or loose connection with harness connector.

OK or NG

OK >> GO TO 8.

NG >> Repair or replace damaged parts.

6. CHECK HARNESS BETWEEN TCM AND OUTPUT SPEED SENSOR (POWER)

1. Turn ignition switch OFF.

2. Disconnect the TCM connector and output speed sensor harness connector.

Item Connector Terminal Judgement standard

(Approx.)

Output speed sen- sor F38

1 - 3Battery voltage

JSDIA1504ZZ

Item Connector Terminal Judgement standard

(Approx.)

Output speed sen- sor F38

1 - ground Battery voltage

JSDIA1505ZZ

Item Connector Terminal Continuity

TCM E3229

Ye s

Output speed sensor F382

JSDIA1506ZZ

Revision: January 20102010 Versa

Page 128 of 3745

P0731 1GR INCORRECT RATIOAT-111

< SERVICE INFORMATION >

DE

F

G H

I

J

K L

M A

B

AT

N

O P

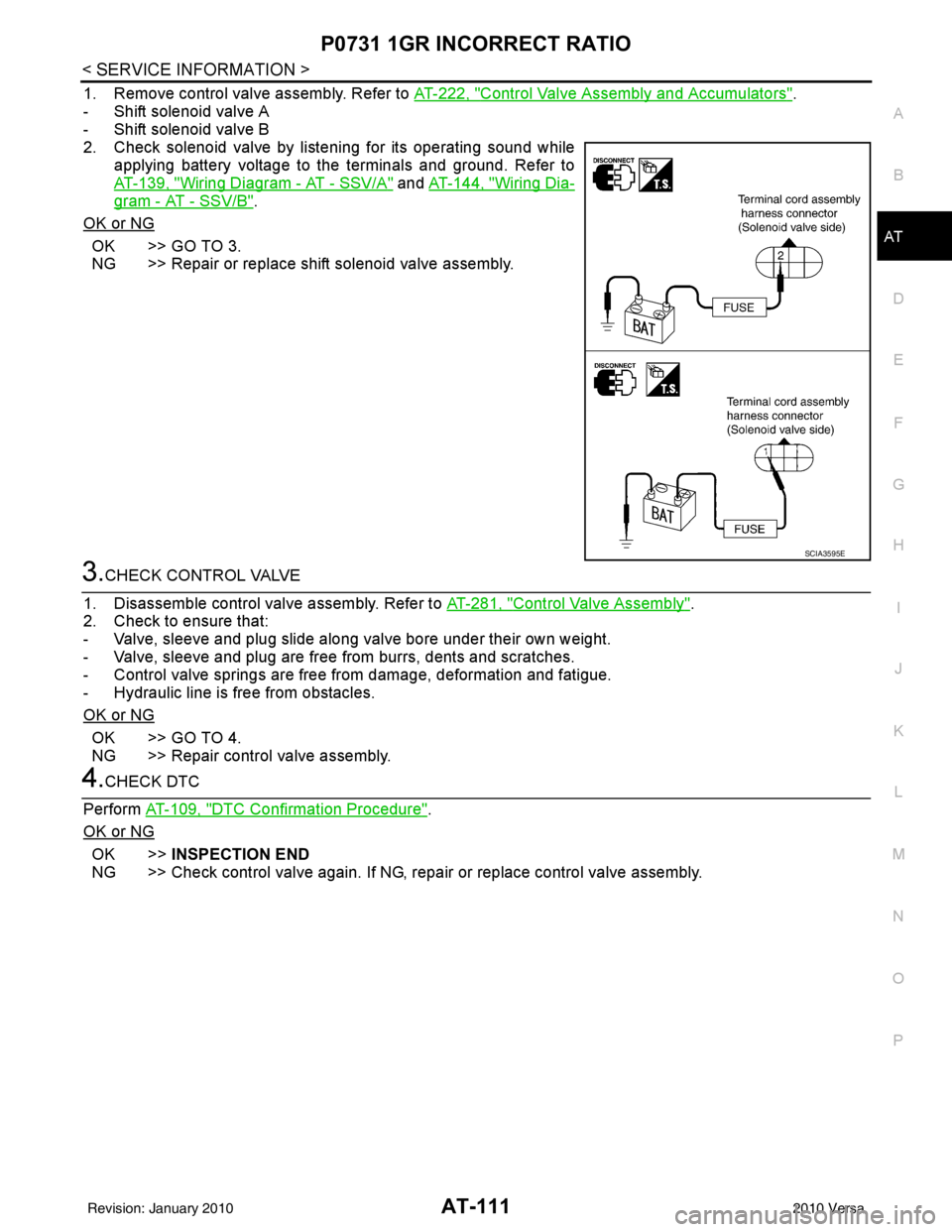

1. Remove control valve assembly. Refer to AT-222, "Control Valve Assembly and Accumulators".

- Shift solenoid valve A

- Shift solenoid valve B

2. Check solenoid valve by listening for its operating sound while applying battery voltage to the terminals and ground. Refer to

AT-139, "

Wiring Diagram - AT - SSV/A" and AT-144, "Wiring Dia-

gram - AT - SSV/B".

OK or NG

OK >> GO TO 3.

NG >> Repair or replace shift solenoid valve assembly.

3.CHECK CONTROL VALVE

1. Disassemble control valve assembly. Refer to AT-281, "

Control Valve Assembly".

2. Check to ensure that:

- Valve, sleeve and plug slide along valve bore under their own weight.

- Valve, sleeve and plug are free from burrs, dents and scratches.

- Control valve springs are free from damage, deformation and fatigue.

- Hydraulic line is free from obstacles.

OK or NG

OK >> GO TO 4.

NG >> Repair control valve assembly.

4.CHECK DTC

Perform AT-109, "

DTC Confirmation Procedure".

OK or NG

OK >> INSPECTION END

NG >> Check control valve again. If NG, repa ir or replace control valve assembly.

SCIA3595E

Revision: January 20102010 Versa

Page 130 of 3745

P0732 2GR INCORRECT RATIOAT-113

< SERVICE INFORMATION >

DE

F

G H

I

J

K L

M A

B

AT

N

O P

- Make sure that “GEAR” shows “3” or “4” after releasing pedal.

6. Depress accelerator pedal to WOT (more than 7.0/8 of “THROTTLE POSI”) quickly from a speed of 45 to 50 km/h (28 to 31 MPH) until “TESTING” changes to “STOP VEHICLE” or “COMPLETE”. (It will take

approximately 3 seconds.)

If the check result NG appears on CONSULT-III screen, go to AT-113, "

Diagnosis Procedure".

If “STOP VEHICLE” appears on CONSULT-III screen, go to following step.

- Make sure that “GEAR” shows “2” when depressing accelerator pedal to WOT.

- If “TESTING” does not appear on CONSULT-III fo r a long time, select “SELF-DIAG RESULTS” for

“TRANSMISSION”. In case a DTC other than “P0732 2GR INCORRECT RATIO” is shown, refer to

AT-77, "

CONSULT-III Function (TRANSMISSION)".

7. Stop vehicle.

8. Follow the instruction displayed. (Check for normal shifting referring to the table below.)

9. Make sure that “OK” is disp layed. (If “NG” is displayed, refer to “Diagnostic Procedure”.)

Refer to AT-113, "

Diagnosis Procedure".

Refer to AT-64, "

Vehicle Speed at Which Gear Shifting Occurs".

WITH GST

Follow the procedure “WITH CONSULT-III”.

Diagnosis ProcedureINFOID:0000000005397298

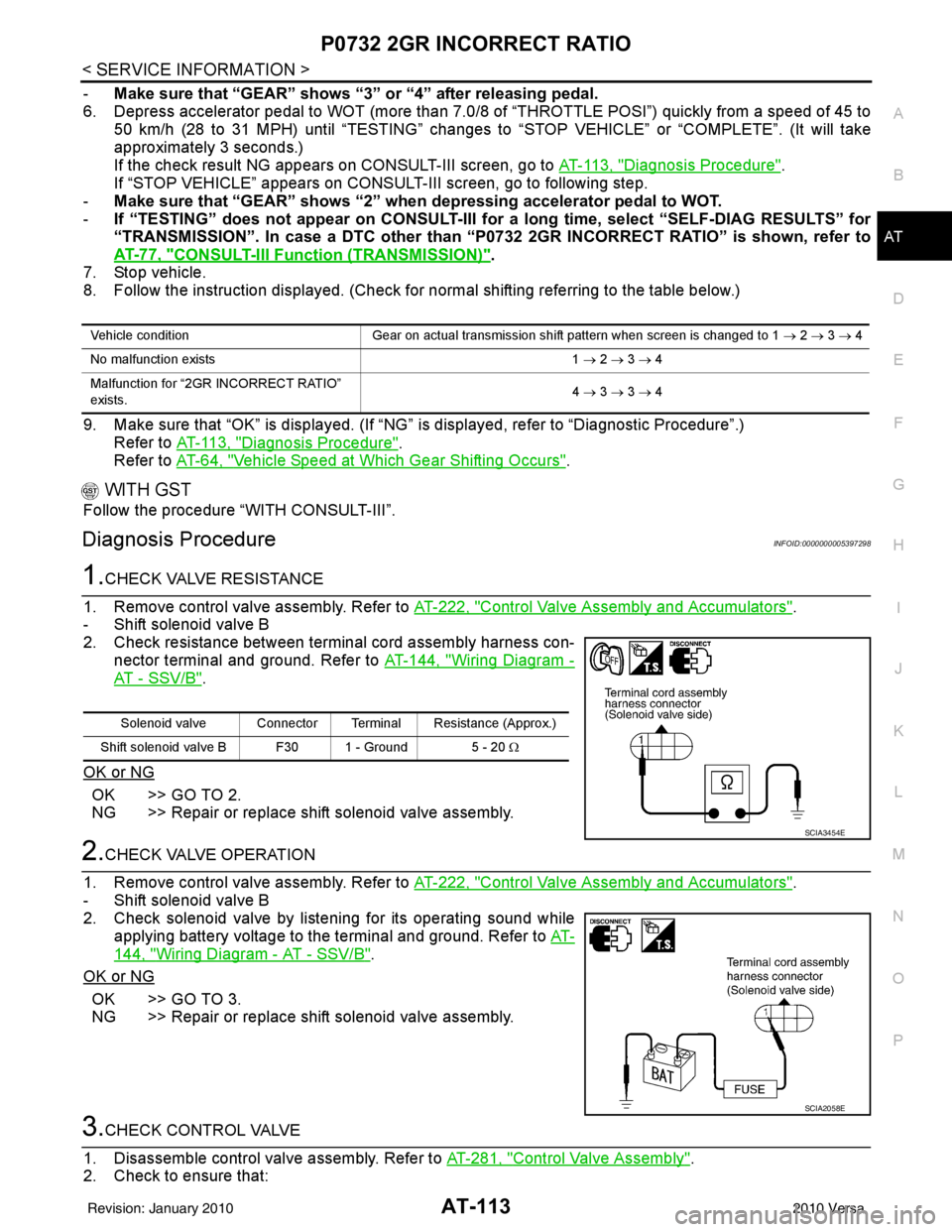

1.CHECK VALVE RESISTANCE

1. Remove control valve assembly. Refer to AT-222, "

Control Valve Assembly and Accumulators".

- Shift solenoid valve B

2. Check resistance between terminal cord assembly harness con- nector terminal and ground. Refer to AT-144, "

Wiring Diagram -

AT - SSV/B".

OK or NG

OK >> GO TO 2.

NG >> Repair or replace shift solenoid valve assembly.

2.CHECK VALVE OPERATION

1. Remove control valve assembly. Refer to AT-222, "

Control Valve Assembly and Accumulators".

- Shift solenoid valve B

2. Check solenoid valve by listening for its operating sound while applying battery voltage to the terminal and ground. Refer to AT-

144, "Wiring Diagram - AT - SSV/B".

OK or NG

OK >> GO TO 3.

NG >> Repair or replace shift solenoid valve assembly.

3.CHECK CONTROL VALVE

1. Disassemble control valve assembly. Refer to AT-281, "

Control Valve Assembly".

2. Check to ensure that:

Vehicle condition Gear on actual transmission shift pattern when screen is changed to 1 → 2 → 3 → 4

No malfunction exists 1 → 2 → 3 → 4

Malfunction for “2GR INCORRECT RATIO”

exists. 4

→ 3 → 3 → 4

Solenoid valve Connector Terminal Resistance (Approx.)

Shift solenoid valve B F30 1 - Ground 5 - 20 Ω

SCIA3454E

SCIA2058E

Revision: January 20102010 Versa

Page 134 of 3745

P0733 3GR INCORRECT RATIOAT-117

< SERVICE INFORMATION >

DE

F

G H

I

J

K L

M A

B

AT

N

O P

2. Check solenoid valve by listening for its operating sound while applying battery voltage to the terminals and ground. Refer to

AT-139, "

Wiring Diagram - AT - SSV/A" and AT-144, "Wiring Dia-

gram - AT - SSV/B".

OK or NG

OK >> GO TO 3.

NG >> Repair or replace shift solenoid valve assembly.

3.CHECK CONTROL VALVE

1. Disassemble control valve assembly. Refer to AT-281, "

Control Valve Assembly".

2. Check to ensure that:

- Valve, sleeve and plug slide along valve bore under their own weight.

- Valve, sleeve and plug are free from burrs, dents and scratches.

- Control valve springs are free from damage, deformation and fatigue.

- Hydraulic line is free from obstacles.

OK or NG

OK >> GO TO 4.

NG >> Repair control valve assembly.

4.CHECK DTC

Perform AT-115, "

DTC Confirmation Procedure".

OK or NG

OK >> INSPECTION END

NG >> Check control valve again. If NG, repair or replace control valve assembly.

SCIA3595E

Revision: January 20102010 Versa

Page 137 of 3745

AT-120

< SERVICE INFORMATION >

P0734 4GR INCORRECT RATIO

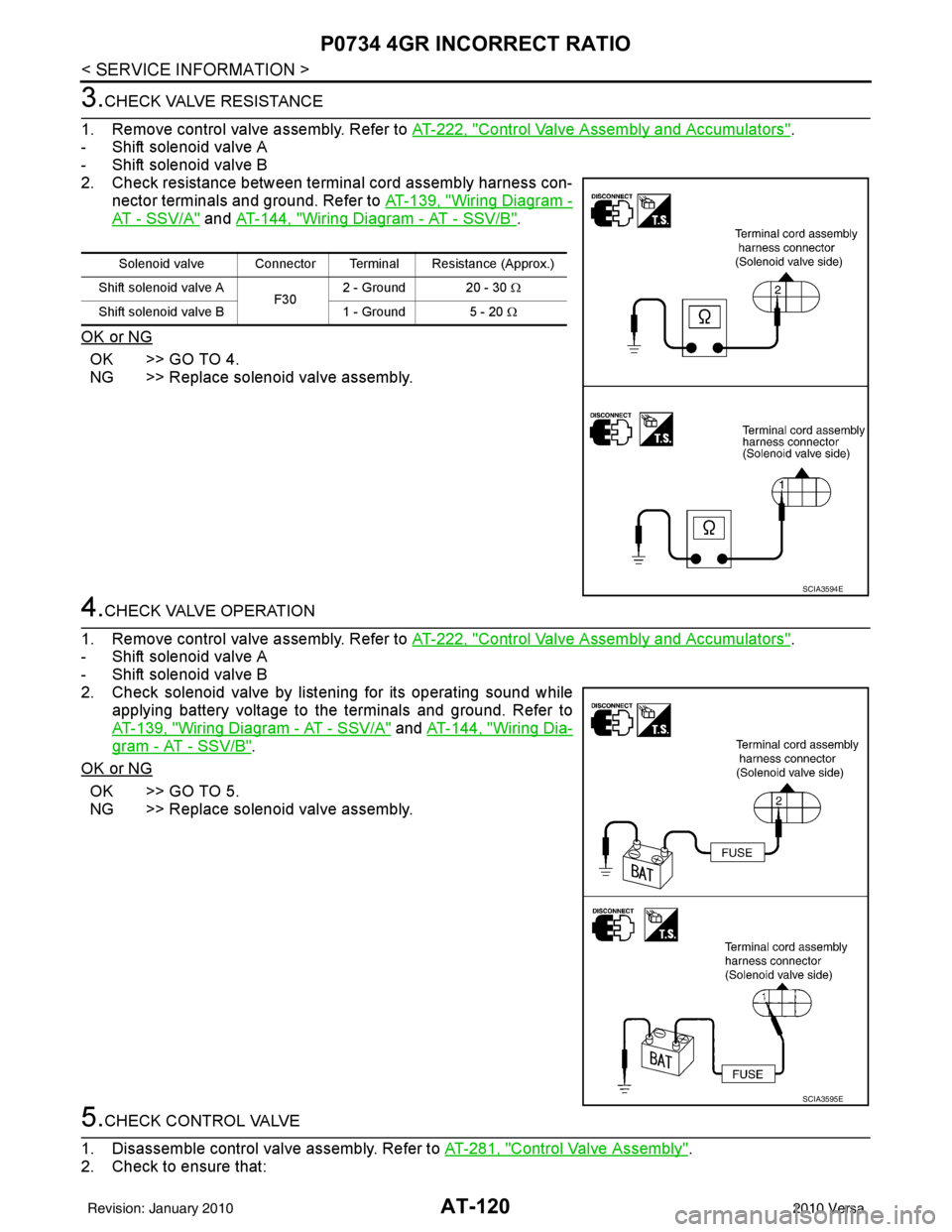

3.CHECK VALVE RESISTANCE

1. Remove control valve assembly. Refer to AT-222, "

Control Valve Assembly and Accumulators".

- Shift solenoid valve A

- Shift solenoid valve B

2. Check resistance between terminal cord assembly harness con- nector terminals and ground. Refer to AT-139, "

Wiring Diagram -

AT - SSV/A" and AT-144, "Wiring Diagram - AT - SSV/B".

OK or NG

OK >> GO TO 4.

NG >> Replace solenoid valve assembly.

4.CHECK VALVE OPERATION

1. Remove control valve assembly. Refer to AT-222, "

Control Valve Assembly and Accumulators".

- Shift solenoid valve A

- Shift solenoid valve B

2. Check solenoid valve by listening for its operating sound while applying battery voltage to the terminals and ground. Refer to

AT-139, "

Wiring Diagram - AT - SSV/A" and AT-144, "Wiring Dia-

gram - AT - SSV/B".

OK or NG

OK >> GO TO 5.

NG >> Replace solenoid valve assembly.

5.CHECK CONTROL VALVE

1. Disassemble control valve assembly. Refer to AT-281, "

Control Valve Assembly".

2. Check to ensure that:

Solenoid valve Connector Terminal Resistance (Approx.)

Shift solenoid valve A F302 - Ground 20 - 30

Ω

Shift solenoid valve B 1 - Ground 5 - 20 Ω

SCIA3594E

SCIA3595E

Revision: January 20102010 Versa