torque NISSAN LATIO 2011 Service User Guide

[x] Cancel search | Manufacturer: NISSAN, Model Year: 2011, Model line: LATIO, Model: NISSAN LATIO 2011Pages: 3787, PDF Size: 78.35 MB

Page 49 of 3787

AT-32

< SERVICE INFORMATION >

A/T CONTROL SYSTEM

*1: Output speed sensor

*2: Spare for accelerator pedal position signal

*3: If these input and output signals are different, the TCM triggers the fail-safe function.

*4: Used as a condition for starting self-diagnostics; if self-diagnosis are not started, it is judged that there is some kind of error.

*5: Input by CAN communications.

*6: Output by CAN communications.

Line Pressure ControlINFOID:0000000005928078

• TCM has various line pressure control char acteristics to match the driving conditions.

• An ON-OFF duty signal is sent to the line pres sure solenoid valve based on TCM characteristics.

• Hydraulic pressure on the clutch and brake is electronically controlled through the line pressure solenoid valve to accommodate engine torque. This results in smooth shift operation.

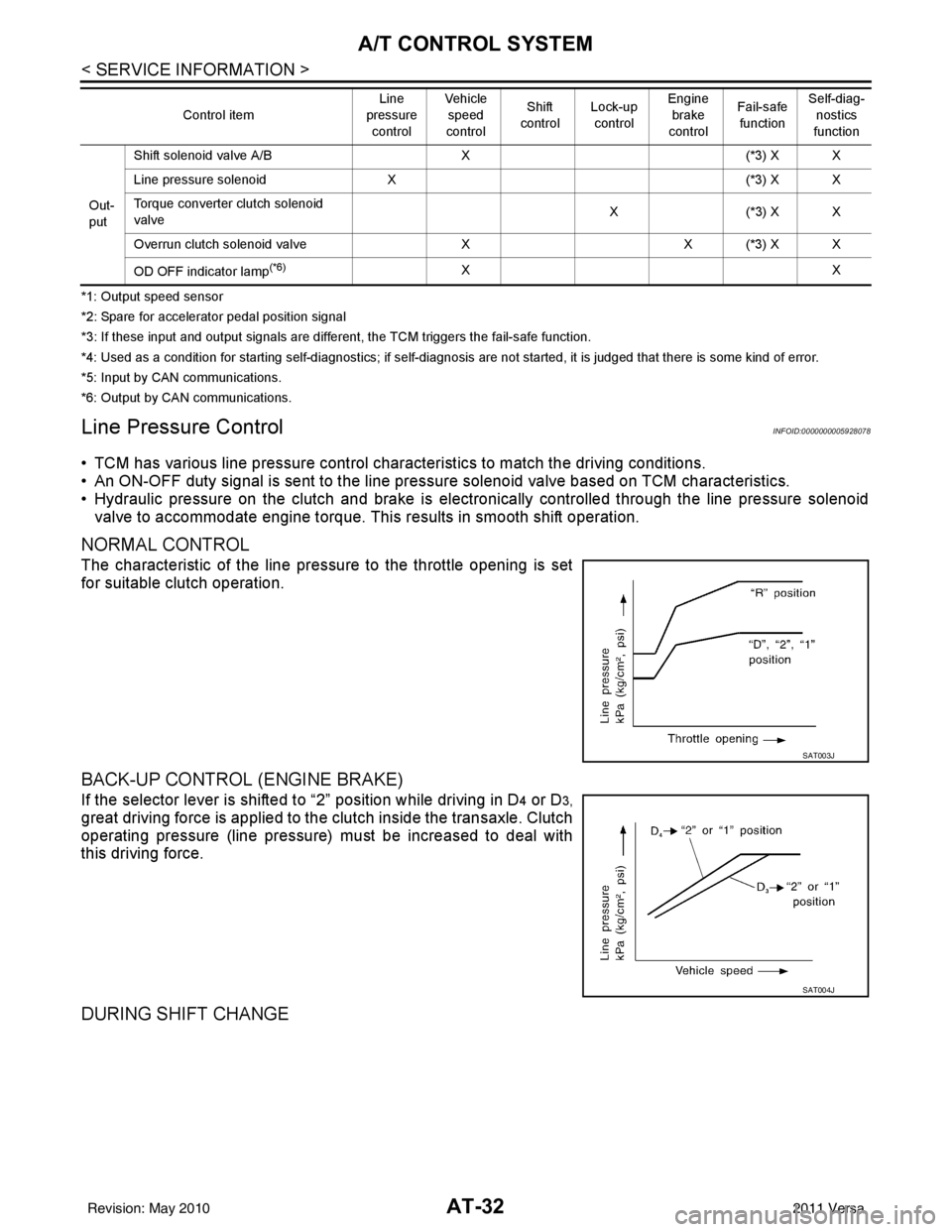

NORMAL CONTROL

The characteristic of the line pressure to the throttle opening is set

for suitable clutch operation.

BACK-UP CONTROL (ENGINE BRAKE)

If the selector lever is shifted to “2” position while driving in D4 or D3,

great driving force is applied to the clutch inside the transaxle. Clutch

operating pressure (line pressure) must be increased to deal with

this driving force.

DURING SHIFT CHANGE

Out-

put Shift solenoid valve A/B

X(*3) X X

Line pressure solenoid X (*3) X X

Torque converter clutch solenoid

valve X(

*3 ) X X

Overrun clutch solenoid valve XX (*3) X X

OD OFF indicator lamp

(*6)XX

Control item

Line

pressure

control Vehicle

speed

control Shift

control Lock-up

control Engine

brake

control Fail-safe

function Self-diag-

nostics

function

SAT003J

SAT004J

Revision: May 2010 2011 Versa

Page 50 of 3787

A/T CONTROL SYSTEMAT-33

< SERVICE INFORMATION >

DE

F

G H

I

J

K L

M A

B

AT

N

O P

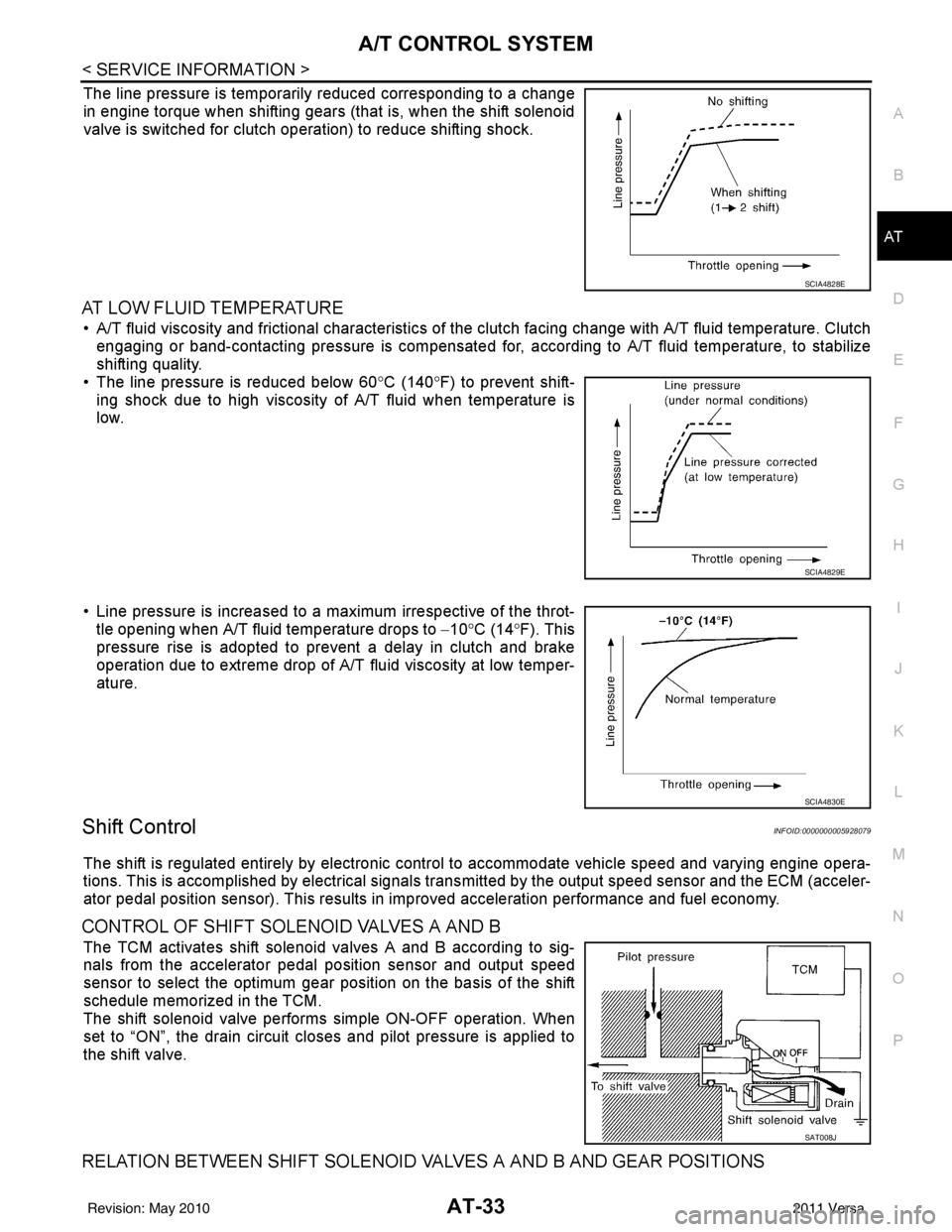

The line pressure is temporarily reduced corresponding to a change

in engine torque when shifting gears (that is, when the shift solenoid

valve is switched for clutch operation) to reduce shifting shock.

AT LOW FLUID TEMPERATURE

• A/T fluid viscosity and frictional characteristics of t he clutch facing change with A/T fluid temperature. Clutch

engaging or band-contacting pressure is compensated for, according to A/T fluid temperature, to stabilize

shifting quality.

• The line pressure is reduced below 60 °C (140° F) to prevent shift-

ing shock due to high viscosity of A/T fluid when temperature is

low.

• Line pressure is increased to a maximum irrespective of the throt- tle opening when A/T fluid temperature drops to −10° C (14° F). This

pressure rise is adopted to prevent a delay in clutch and brake

operation due to extreme drop of A/T fluid viscosity at low temper-

ature.

Shift ControlINFOID:0000000005928079

The shift is regulated entirely by electronic cont rol to accommodate vehicle speed and varying engine opera-

tions. This is accomplished by electrical signals trans mitted by the output speed sensor and the ECM (acceler-

ator pedal position sensor). This results in improved acceleration performance and fuel economy.

CONTROL OF SHIFT SOLENOID VALVES A AND B

The TCM activates shift solenoid valves A and B according to sig-

nals from the accelerator pedal position sensor and output speed

sensor to select the optimum gear position on the basis of the shift

schedule memorized in the TCM.

The shift solenoid valve performs simple ON-OFF operation. When

set to “ON”, the drain circuit closes and pilot pressure is applied to

the shift valve.

RELATION BETWEEN SHIFT SOLENOID VALVES A AND B AND GEAR POSITIONS

SCIA4828E

SCIA4829E

SCIA4830E

SAT008J

Revision: May 2010 2011 Versa

Page 51 of 3787

AT-34

< SERVICE INFORMATION >

A/T CONTROL SYSTEM

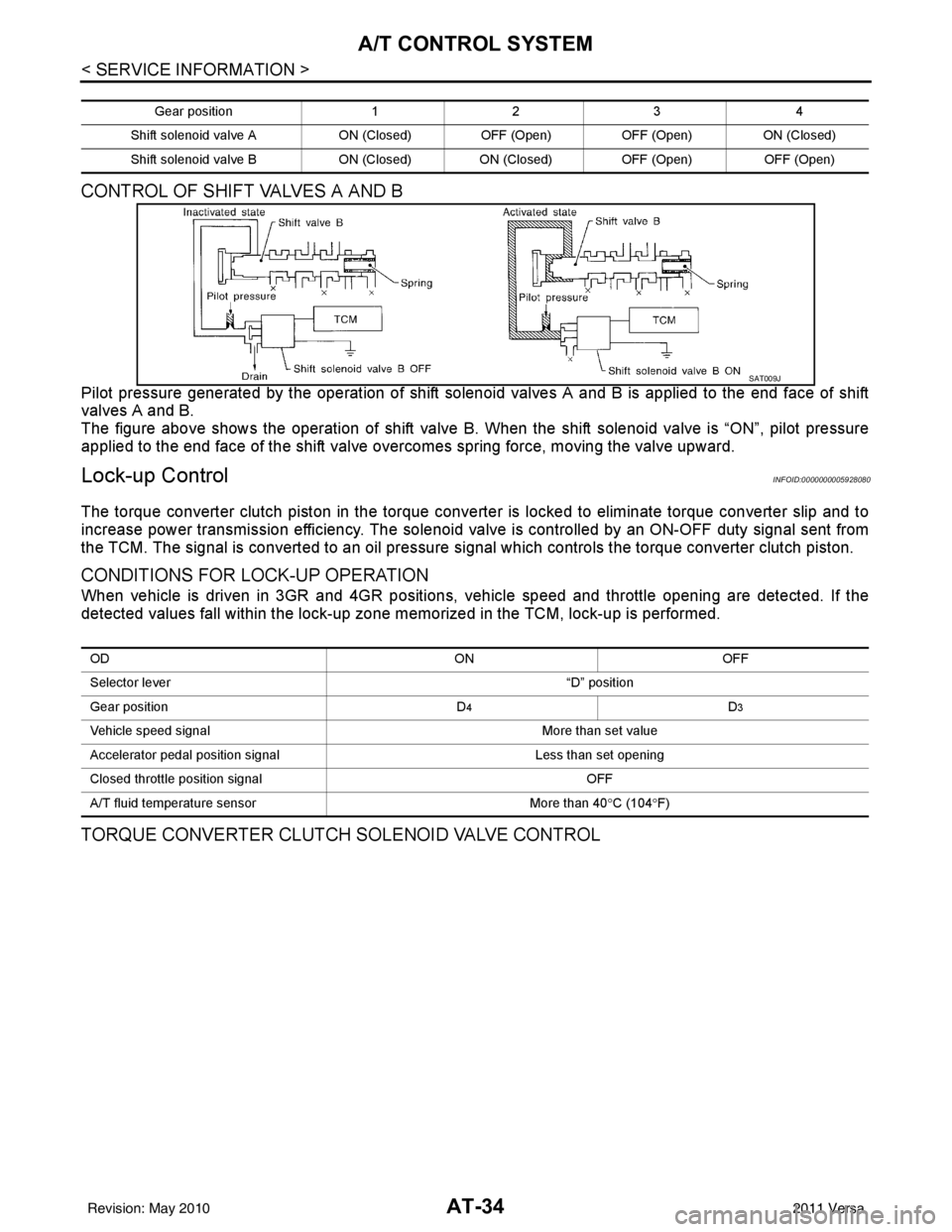

CONTROL OF SHIFT VALVES A AND B

Pilot pressure generated by the operation of shift solenoid valves A and B is applied to the end face of shift

valves A and B.

The figure above shows the operation of shift valve B. When the shift solenoid valve is “ON”, pilot pressure

applied to the end face of the shift valve overcomes spring force, moving the valve upward.

Lock-up ControlINFOID:0000000005928080

The torque converter clutch piston in the torque conver ter is locked to eliminate torque converter slip and to

increase power transmission efficiency. The solenoid va lve is controlled by an ON-OFF duty signal sent from

the TCM. The signal is converted to an oil pressure si gnal which controls the torque converter clutch piston.

CONDITIONS FOR LOCK-UP OPERATION

When vehicle is driven in 3GR and 4GR positions, v ehicle speed and throttle opening are detected. If the

detected values fall within the lock-up zone me morized in the TCM, lock-up is performed.

TORQUE CONVERTER CLUTCH SOLENOID VALVE CONTROL

Gear position123 4

Shift solenoid valve A ON (Closed)OFF (Open)OFF (Open) ON (Closed)

Shift solenoid valve B ON (Closed)ON (Closed) OFF (Open) OFF (Open)

SAT009J

OD ONOFF

Selector lever “D” position

Gear position D

4D3

Vehicle speed signal More than set value

Accelerator pedal position signal Less than set opening

Closed throttle position signal OFF

A/T fluid temperature sensor More than 40°C (104 °F)

Revision: May 2010 2011 Versa

Page 52 of 3787

A/T CONTROL SYSTEMAT-35

< SERVICE INFORMATION >

DE

F

G H

I

J

K L

M A

B

AT

N

O P

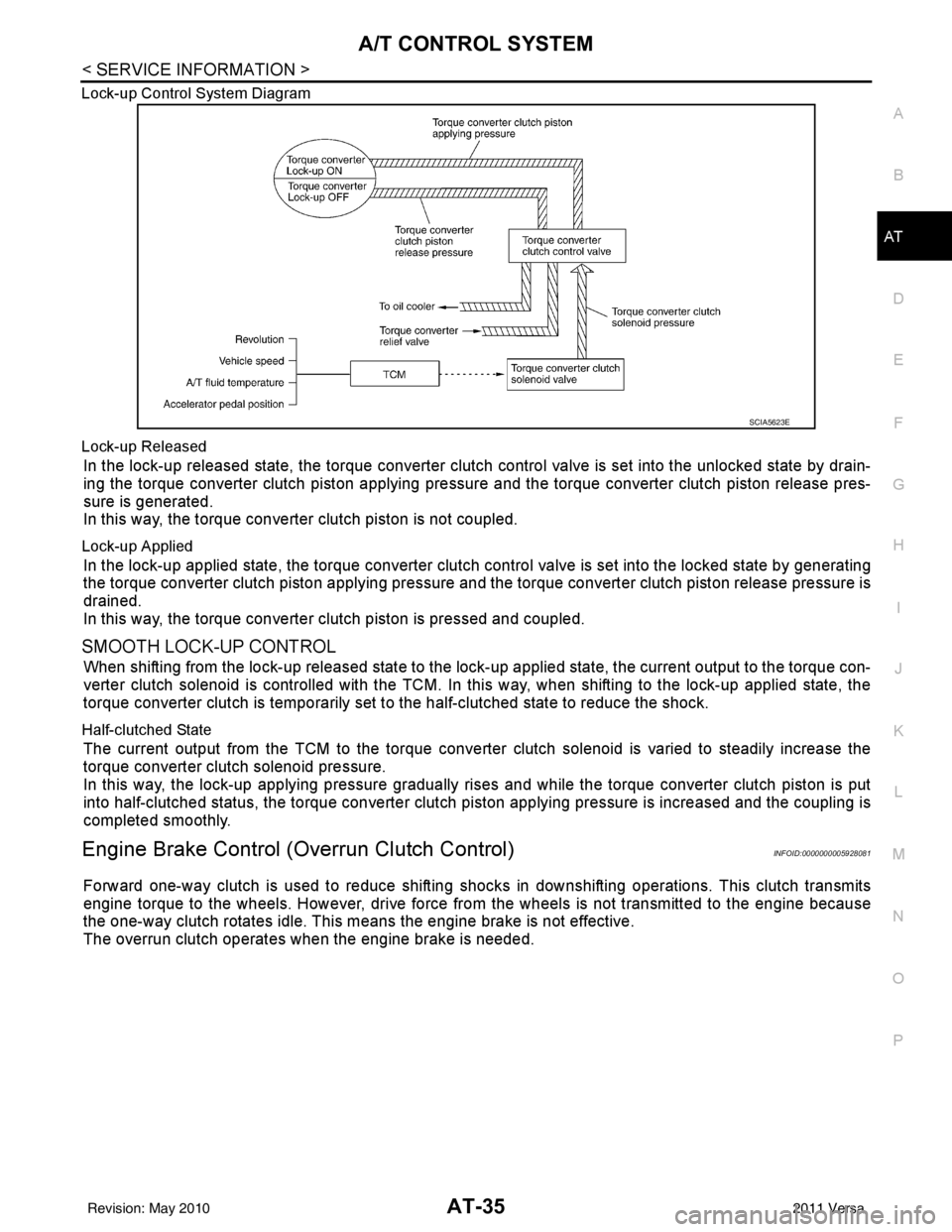

Lock-up Control System Diagram

Lock-up Released

In the lock-up released state, the torque converter clutch control valve is set into the unlocked state by drain-

ing the torque converter clutch piston applying pressure and the torque converter clutch piston release pres-

sure is generated.

In this way, the torque converter clutch piston is not coupled.

Lock-up Applied

In the lock-up applied state, the torque converter clutch

control valve is set into the locked state by generating

the torque converter clutch piston applying pressure and t he torque converter clutch piston release pressure is

drained.

In this way, the torque converter clutch piston is pressed and coupled.

SMOOTH LOCK-UP CONTROL

When shifting from the lock-up released state to the lock-up applied state, the current output to the torque con-

verter clutch solenoid is controlled with the TCM. In this way, when shifting to the lock-up applied state, the

torque converter clutch is temporarily set to the half-clutched state to reduce the shock.

Half-clutched State

The current output from the TCM to the torque converte r clutch solenoid is varied to steadily increase the

torque converter clutch solenoid pressure.

In this way, the lock-up applying pressure gradually rises and while the torque converter clutch piston is put

into half-clutched status, the torque converter clutch piston applying pressure is increased and the coupling is

completed smoothly.

Engine Brake Control (Overrun Clutch Control)INFOID:0000000005928081

Forward one-way clutch is used to reduce shifting shoc ks in downshifting operations. This clutch transmits

engine torque to the wheels. However, drive force fr om the wheels is not transmitted to the engine because

the one-way clutch rotates idle. This means the engine brake is not effective.

The overrun clutch operates when the engine brake is needed.

SCIA5623E

Revision: May 2010 2011 Versa

Page 54 of 3787

A/T CONTROL SYSTEMAT-37

< SERVICE INFORMATION >

DE

F

G H

I

J

K L

M A

B

AT

N

O P

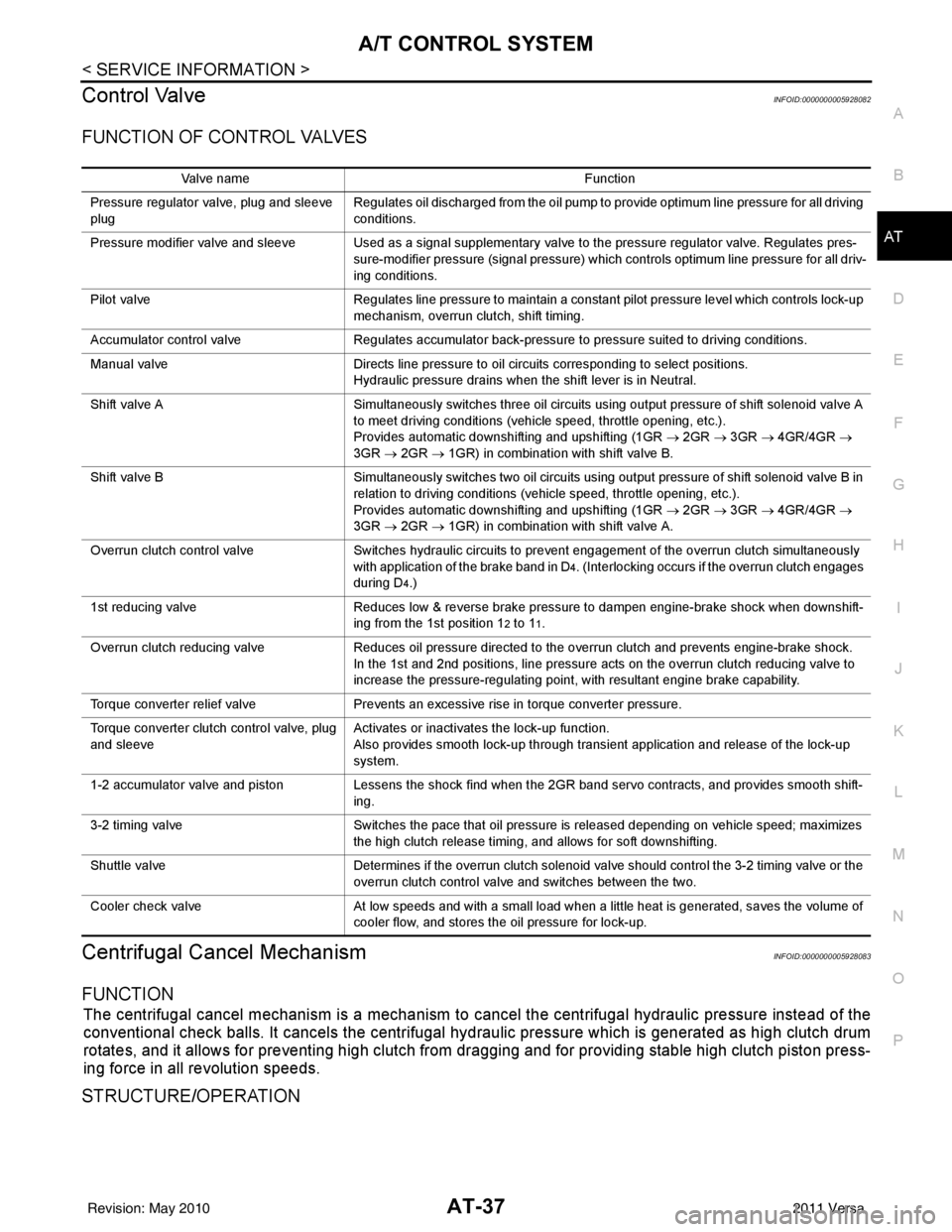

Control ValveINFOID:0000000005928082

FUNCTION OF CONTROL VALVES

Centrifugal Cancel MechanismINFOID:0000000005928083

FUNCTION

The centrifugal cancel mechanism is a mechanism to c ancel the centrifugal hydraulic pressure instead of the

conventional check balls. It cancels the centrifugal hy draulic pressure which is generated as high clutch drum

rotates, and it allows for preventing high clutch from dragging and for providing stable high clutch piston press-

ing force in all revolution speeds.

STRUCTURE/OPERATION

Valve name Function

Pressure regulator valve, plug and sleeve

plug Regulates oil discharged from the oil pump to provide optimum line pressure for all driving

conditions.

Pressure modifier valve and sleeve Used as a signal supplementary valve to the pressure regulator valve. Regulates pres- sure-modifier pressure (signal pressure) which controls optimum line pressure for all driv-

ing conditions.

Pilot valve Regulates line pressure to maintain a constant pilot pressure level which controls lock-up

mechanism, overrun clutch, shift timing.

Accumulator control valve Regulates accumulator back-pressure to pressure suited to driving conditions.

Manual valve Directs line pressure to oil circuits corresponding to select positions.

Hydraulic pressure drains when the shift lever is in Neutral.

Shift valve A Simultaneously switches three oil circuits using output pressure of shift solenoid valve A

to meet driving conditions (vehicle speed, throttle opening, etc.).

Provides automatic downshifting and upshifting (1GR → 2GR → 3GR → 4GR/4GR →

3GR → 2GR → 1GR) in combination with shift valve B.

Shift valve B Simultaneously switches two oil circuits using output pressure of shift solenoid valve B in

relation to driving conditions (vehicle speed, throttle opening, etc.).

Provides automatic downshifting and upshifting (1GR → 2GR → 3GR → 4GR/4GR →

3GR → 2GR → 1GR) in combination with shift valve A.

Overrun clutch control valve Switches hydraulic circuits to prevent engagement of the overrun clutch simultaneously

with application of the brake band in D

4. (Interlocking occurs if the overrun clutch engages

during D

4.)

1st reducing valve Reduces low & reverse brake pressure to dampen engine-brake shock when downshift-

ing from the 1st position 1

2 to 11.

Overrun clutch reducing valve Reduces oil pressure directed to the overrun clutch and prevents engine-brake shock.

In the 1st and 2nd positions, line pressure acts on the overrun clutch reducing valve to

increase the pressure-regulating point, with resultant engine brake capability.

Torque converter relief valve Prevents an excessive rise in torque converter pressure.

Torque converter clutch control valve, plug

and sleeve Activates or inactivates the lock-up function.

Also provides smooth lock-up through transient application and release of the lock-up

system.

1-2 accumulator valve and piston Lessens the shock find when the 2GR band servo contracts, and provides smooth shift-

ing.

3-2 timing valve Switches the pace that oil pressure is released depending on vehicle speed; maximizes

the high clutch release timing, and allows for soft downshifting.

Shuttle valve Determines if the overrun clutch solenoid valve should control the 3-2 timing valve or the

overrun clutch control valve and switches between the two.

Cooler check valve At low speeds and with a small load when a little heat is generated, saves the volume of

cooler flow, and stores the oil pressure for lock-up.

Revision: May 2010 2011 Versa

Page 60 of 3787

TROUBLE DIAGNOSISAT-43

< SERVICE INFORMATION >

DE

F

G H

I

J

K L

M A

B

AT

N

O P

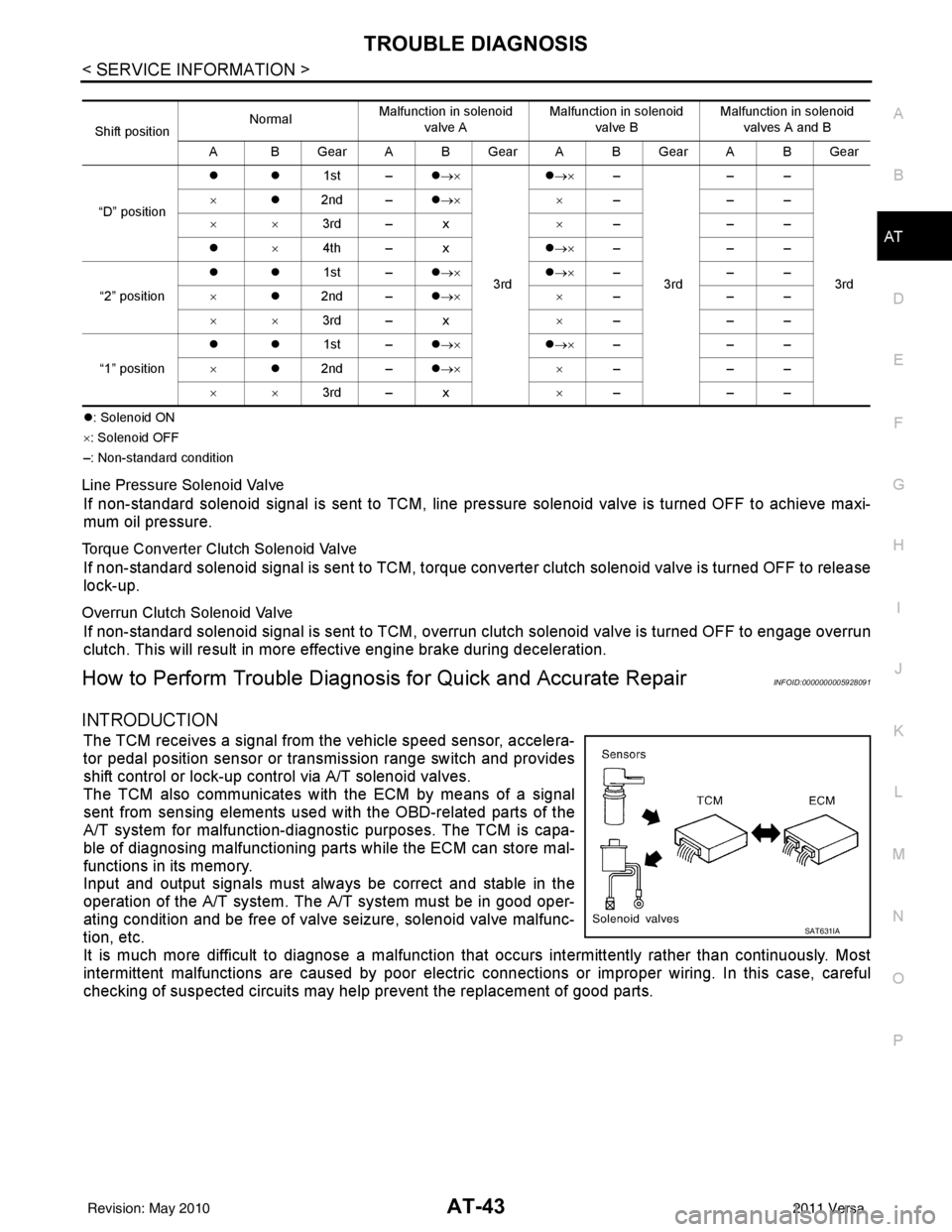

�z : Solenoid ON

× : Solenoid OFF

–: Non-standard condition

Line Pressure Solenoid Valve

If non-standard solenoid signal is sent to TCM, line pre ssure solenoid valve is turned OFF to achieve maxi-

mum oil pressure.

Torque Converter Clutch Solenoid Valve

If non-standard solenoid signal is sent to TCM, torque conv erter clutch solenoid valve is turned OFF to release

lock-up.

Overrun Clutch Solenoid Valve

If non-standard solenoid signal is sent to TCM, overr un clutch solenoid valve is turned OFF to engage overrun

clutch. This will result in more effective engine brake during deceleration.

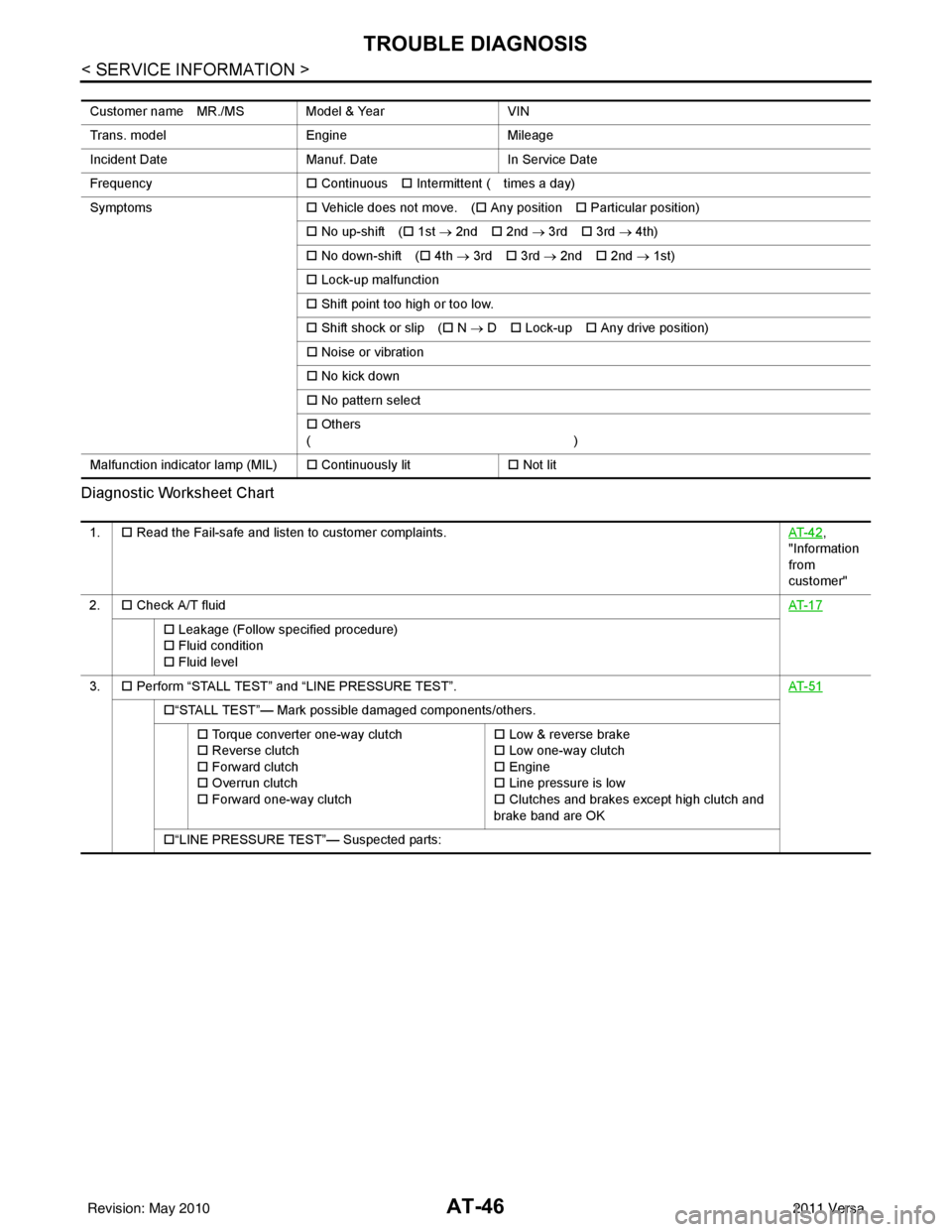

How to Perform Trouble Diagnosis for Quick and Accurate RepairINFOID:0000000005928091

INTRODUCTION

The TCM receives a signal from the vehicle speed sensor, accelera-

tor pedal position sensor or transmission range switch and provides

shift control or lock-up control via A/T solenoid valves.

The TCM also communicates with the ECM by means of a signal

sent from sensing elements used wit h the OBD-related parts of the

A/T system for malfunction-diagnostic purposes. The TCM is capa-

ble of diagnosing malfunctioning parts while the ECM can store mal-

functions in its memory.

Input and output signals must always be correct and stable in the

operation of the A/T system. T he A/T system must be in good oper-

ating condition and be free of valve seizure, solenoid valve malfunc-

tion, etc.

It is much more difficult to diagnose a malfunction that occurs intermittently rather than continuously. Most

intermittent malfunctions are caused by poor electric c onnections or improper wiring. In this case, careful

checking of suspected circuits may hel p prevent the replacement of good parts.

Shift positionNormal

Malfunction in solenoid

valve A Malfunction in solenoid

valve B Malfunction in solenoid

valves A and B

A BGearABGearABGearABGear

“D” position �z�z

1st –�z→×

3rd �z

→× –

3rd ––

3rd

×

�z2nd – �z→× ×–––

×× 3rd – x ×–––

�z ×4th – x �z→× –––

“2” position �z�z

1st –�z→× �z→× –––

× �z2nd – �z→× ×–––

×× 3rd – x ×–––

“1” position �z�z

1st –�z→× �z→× –––

× �z2nd – �z→× ×–––

×× 3rd – x ×–––

SAT631IA

Revision: May 2010 2011 Versa

Page 63 of 3787

AT-46

< SERVICE INFORMATION >

TROUBLE DIAGNOSIS

Diagnostic Worksheet Chart

Customer name MR./MS Model & YearVIN

Trans. model EngineMileage

Incident Date Manuf. DateIn Service Date

Frequency �† Continuous �† Intermittent ( times a day)

Symptoms �† Vehicle does not move. ( �† Any position �† Particular position)

�† No up-shift ( �† 1st → 2nd �† 2nd → 3rd �† 3rd → 4th)

�† No down-shift ( �† 4th → 3rd �† 3rd → 2nd�† 2nd → 1st)

�† Lock-up malfunction

�† Shift point too high or too low.

�† Shift shock or slip ( �† N → D �† Lock-up �† Any drive position)

�† Noise or vibration

�† No kick down

�† No pattern select

�† Others

()

Malfunction indicator lamp (MIL) �† Continuously lit �† Not lit

1. �† Read the Fail-safe and listen to customer complaints. AT- 4 2,

"Information

from

customer"

2. �† Check A/T fluid AT- 1 7

�† Leakage (Follow specified procedure)

�† Fluid condition

�† Fluid level

3. �† Perform “STALL TEST” and “LINE PRESSURE TEST”. AT- 5 1

�†“STALL TEST”— Mark possible damaged components/others.

�† Torque converter one-way clutch

�† Reverse clutch

�† Forward clutch

�† Overrun clutch

�† Forward one-way clutch �†

Low & reverse brake

�† Low one-way clutch

�† Engine

�† Line pressure is low

�† Clutches and brakes except high clutch and

brake band are OK

�† “LINE PRESSURE TEST”— Suspected parts:

Revision: May 2010 2011 Versa

Page 64 of 3787

TROUBLE DIAGNOSISAT-47

< SERVICE INFORMATION >

DE

F

G H

I

J

K L

M A

B

AT

N

O P

4. �† Perform “Road Test”. AT- 5 5

4-1. “Check Before Engine is Started” AT- 5 6

�†AT- 1 8 0 , "OD OFF Indicator Lamp Does Not Come On"

�† Perform self-diagnosis. Enter checks for detected items. AT- 7 7 , AT- 8 2 .

�† CAN COMM CIRCUIT AT- 8 7

.

�† TRANSMISSION RANGE SWITCH A AT- 9 0

.

�† TRANSMISSION FLUID TEMPERATURE SENSOR A AT- 9 5

.

�† OUTPUT SPEED SENSOR AT- 1 0 0

.

�† ENGINE SPEED AT- 1 0 5

.

�† 1GR INCORRECT RATIO AT- 1 0 9

�† 2GR INCORRECT RATIO AT- 11 2 .

�† 3GR INCORRECT RATIO AT- 11 5

.

�† 4GR INCORRECT RATIO AT- 11 8

.

�† TORQUE CONVERTER AT- 1 2 3

.

�† TORQUE CONVERTER AT- 1 2 8

.

�† PRESSURE CONTROL SOLENOID A AT- 1 3 3

.

�† SHIFT SOLENOID A AT- 1 3 8

.

�† SHIFT SOLENOID B AT- 1 4 3

.

�† OVERRUN CLUTCH SOLENOID AT- 1 4 8

.

�† VEHICLE SPEED SIGNAL AT- 1 5 3

.

�† BATT/FLUID TEMP SEN AT- 1 5 6

.

�† INPUT SPEED SENSOR A AT- 1 6 2

.

�† CONTROL UNIT (RAM), CONTROL UNIT (ROM) AT- 1 6 7

.

�† MAIN POWER SUPPLY AND GROUND CIRCUIT AT- 1 6 8

.

4-2. “Check at Idle” AT- 5 6

�†AT- 1 8 2 , "Engine Cannot Be Started in "P" and "N" Position" .

�† AT- 1 8 3 , "

In "P" Position, Vehicle Moves Forward or Backward When Pushed" .

�† AT- 1 8 3 , "

In "N" Position, Vehicle Moves" .

�† AT- 1 8 4 , "

Large Shock "N" → "R" Position" .

�† AT- 1 8 5 , "

Vehicle Does Not Creep Backward in "R" Position" .

�† AT- 1 8 6 , "

Vehicle Does Not Creep Forward in "D", "2" or "1" Position" .

Revision: May 2010 2011 Versa

Page 65 of 3787

AT-48

< SERVICE INFORMATION >

TROUBLE DIAGNOSIS

4. 4-3. “Cruise Test”AT- 5 8

Part 1

�†AT- 1 8 7 , "

Vehicle Cannot Be Started from D1" .

�† AT- 1 8 9 , "

A/T Does Not Shift: D1→ D2or Does Not Kickdown: D4→ D2" .

�† AT- 1 9 0 , "

A/T Does Not Shift: D2→ D3" .

�† AT- 1 9 2 , "

A/T Does Not Shift: D3→ D4" .

�† AT- 1 9 3 , "

A/T Does Not Perform Lock-up" .

�† AT- 1 9 4 , "

A/T Does Not Hold Lock-up Condition" .

�† AT- 1 9 5 , "

Lock-up Is Not Released" .

�† AT- 1 9 6 , "

Engine Speed Does Not Return to Idle (Light Braking D4→ D3)" .

Part 2 AT- 6 1

�†AT- 1 8 7 , "Vehicle Cannot Be Started from D1" .

�† AT- 1 8 9 , "

A/T Does Not Shift: D1→ D2or Does Not Kickdown: D4→ D2" .

�† AT- 1 9 0 , "

A/T Does Not Shift: D2→ D3" .

�† AT- 1 9 2 , "

A/T Does Not Shift: D3→ D4" .

Part 3 AT- 6 2

�†AT- 1 9 7 , "A/T Does Not Shift: D4→ D3, When OD OFF" .

�† AT- 1 9 8 , "

A/T Does Not Shift: D3→ 22, When Selector Lever "D" → "2" Position" .

�† AT- 1 9 9 , "

A/T Does Not Shift: 22→ 11, When Selector Lever "2" → "1" Position" .

�† AT- 2 0 1 , "

Vehicle Does Not Decelerate by Engine Brake" .

�† Perform self-diagnosis. Enter checks for detected items. AT- 7 7

, AT- 8 2 .

�† CAN COMM CIRCUIT AT- 8 7

.

�† TRANSMISSION RANGE SWITCH A AT- 9 0

.

�† TRANSMISSION FLUID TEMPERATURE SENSOR A AT- 9 5

.

�† OUTPUT SPEED SENSOR AT- 1 0 0

.

�† ENGINE SPEED AT- 1 0 5

.

�† 1GR INCORRECT RATIO AT- 1 0 9

�† 2GR INCORRECT RATIO AT- 11 2 .

�† 3GR INCORRECT RATIO AT- 11 5

.

�† 4GR INCORRECT RATIO AT- 11 8

.

�† TORQUE CONVERTER AT-123

.

�† TORQUE CONVERTER AT-128

.

�† PRESSURE CONTROL SOLENOID A AT- 1 3 3

.

�† SHIFT SOLENOID A AT- 1 3 8

.

�† SHIFT SOLENOID B AT- 1 4 3

.

�† OVERRUN CLUTCH SOLENOID AT- 1 4 8

.

�† VEHICLE SPEED SIGNAL AT- 1 5 3

.

�† BATT/FLUID TEMP SEN AT-156

.

�† INPUT SPEED SENSOR A AT- 1 6 2

.

�† CONTROL UNIT (RAM), CONTROL UNIT (ROM) AT-167

.

�† MAIN POWER SUPPLY AND GROUND CIRCUIT AT- 1 6 8

.

5. �† For self-diagnosis NG items, inspect each component. Repair or replace the damaged parts. AT- 7 7

,

AT- 8 2

6. �† Perform “Road Test”. AT- 5 5

7.�† Perform the Diagnostic Procedures for all remaining items marked NG. Repair or replace the damaged parts.

Refer to the Symptom Chart when you perform the procedures. (The chart also shows some other possible symp-

toms and the component inspection orders.) AT- 6 5

8.

�† Erase DTC from TCM and ECM memories. AT- 3 9,

AT- 8 2

Revision: May 2010 2011 Versa

Page 69 of 3787

AT-52

< SERVICE INFORMATION >

TROUBLE DIAGNOSIS

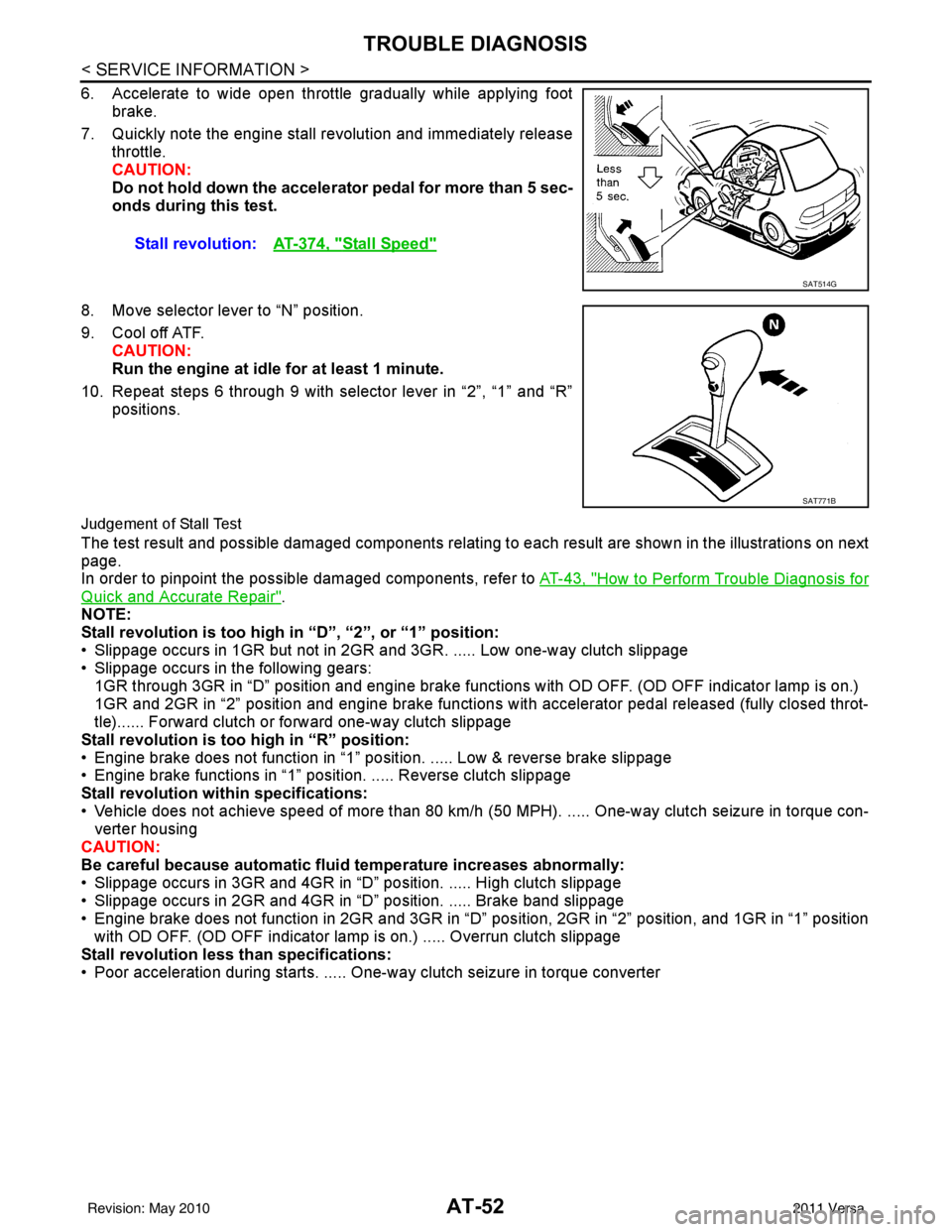

6. Accelerate to wide open throttle gradually while applying footbrake.

7. Quickly note the engine stall revolution and immediately release throttle.

CAUTION:

Do not hold down the accelerator pedal for more than 5 sec-

onds during this test.

8. Move selector lever to “N” position.

9. Cool off ATF. CAUTION:

Run the engine at idle for at least 1 minute.

10. Repeat steps 6 through 9 with selector lever in “2”, “1” and “R” positions.

Judgement of Stall Test

The test result and possible damaged components relating to each result are shown in the illustrations on next

page.

In order to pinpoint the possible damaged components, refer to AT-43, "

How to Perform Trouble Diagnosis for

Quick and Accurate Repair".

NOTE:

Stall revolution is too high in “D”, “2”, or “1” position:

• Slippage occurs in 1GR but not in 2GR and 3GR. ..... Low one-way clutch slippage

• Slippage occurs in the following gears:

1GR through 3GR in “D” position and engine brake functions with OD OFF. (OD OFF indicator lamp is on.)

1GR and 2GR in “2” position and engine brake functions with accelerator pedal released (fully closed throt-

tle)...... Forward clutch or forward one-way clutch slippage

Stall revolution is too high in “R” position:

• Engine brake does not function in “1” posit ion. ..... Low & reverse brake slippage

• Engine brake functions in “1” position. ..... Reverse clutch slippage

Stall revolution within specifications:

• Vehicle does not achieve speed of more than 80 km/h ( 50 MPH). ..... One-way clutch seizure in torque con-

verter housing

CAUTION:

Be careful because automatic flui d temperature increases abnormally:

• Slippage occurs in 3GR and 4GR in “D” position. ..... High clutch slippage

• Slippage occurs in 2GR and 4GR in “D” position. ..... Brake band slippage

• Engine brake does not function in 2GR and 3GR in “D” pos ition, 2GR in “2” position, and 1GR in “1” position

with OD OFF. (OD OFF indicator lamp is on.) ..... Overrun clutch slippage

Stall revolution less than specifications:

• Poor acceleration during starts. ..... One-way clutch seizure in torque converter Stall revolution:

AT-374, "

Stall Speed"

SAT514G

SAT771B

Revision: May 2010 2011 Versa