mirror NISSAN LATIO 2011 Service Owner's Manual

[x] Cancel search | Manufacturer: NISSAN, Model Year: 2011, Model line: LATIO, Model: NISSAN LATIO 2011Pages: 3787, PDF Size: 78.35 MB

Page 3034 of 3787

LT-2

System Description .................................................50

CAN Communication System Description ..............52

Schematic ............................................................ ...53

Wiring Diagram - TURN - ........................................54

Terminal and Reference Value for BCM .................57

How to Proceed with Trouble Diagnosis .................57

Preliminary Check ..................................................58

CONSULT-III Function (BCM) ................................58

Turn Signals Do Not Operate .................................58

Front Turn Signal Lamp Does Not Operate ............58

Rear Turn Signal Lamp Does Not Operate ............59

Hazard Warning Lamp Does Not Operate But

Turn Signal Lamp Operates ...................................

60

Turn Signal Indicator Lamp Does Not Operate ......61

Bulb Replacement for Front Turn Signal Lamp ......61

Bulb Replacement for Rear Turn Signal Lamp .......61

Removal and Installation of Front Turn Signal

Lamp .......................................................................

61

Removal and Installation of Rear Turn Signal

Lamp .......................................................................

61

LIGHTING AND TURN SIGNAL SWITCH .........62

Removal and Installation ..................................... ...62

HAZARD SWITCH .............................................63

Removal and Installation ..................................... ...63

COMBINATION SWITCH ..................................64

Wiring Diagram - COMBSW - .............................. ...64

Combination Switch Reading Function ...................64

Terminal and Reference Value for BCM .................65

CONSULT-III Function (BCM) ................................65

Combination Switch Inspection ..............................65

Removal and Installation ..................................... ...67

STOP LAMP ......................................................68

Wiring Diagram - STOP/L .................................... ...68

Wiring Diagram - STOP/L .......................................69

Bulb Replacement (High-Mounted Stop Lamp) ......69

Bulb Replacement (Rear Combination Lamp) ........70

Removal and Installation (High-Mounted Stop

Lamp) .....................................................................

70

Removal and Installation (Rear Combination

Lamp) .................................................................. ...

71

BACK-UP LAMP ................................................72

Wiring Diagram - BACK/L - .................................. ...72

Bulb Replacement ..................................................72

Removal and Installation ........................................73

PARKING, LICENSE PLATE AND TAIL

LAMPS ...............................................................

74

Component Parts and Harness Connector Loca-

tion ....................................................................... ...

74

System Description .................................................74

CAN Communication System Description ........... ...75

Schematic ...............................................................76

Wiring Diagram - TAIL/L - .......................................77

Terminal and Reference Value for BCM .............. ...80

Terminal and Reference Value for IPDM E/R .........80

How to Proceed with Trouble Diagnosis .................81

Preliminary Check ...................................................81

CONSULT-III Function (BCM) ............................. ...81

CONSULT-III Function (IPDM E/R) ........................81

Parking, License Plate and Tail Lamps Do Not Il-

luminate ..................................................................

81

Parking, License Plate and Tail Lamps Do Not

Turn OFF (After Approx. 10 Minutes) .....................

84

Bulb Replacement ................................................ ...84

Removal and Installation .........................................85

REAR COMBINATION LAMP ........................ ...87

Component .......................................................... ...87

Bulb Replacement ...................................................87

Removal and Installation .........................................88

Disassembly and Assembly ................................. ...88

INTERIOR LAMP ...............................................90

Map Lamp ............................................................ ...90

Luggage Room Lamp, Hatch Back .........................90

Trunk Room Lamp, Sedan ......................................91

Vanity Mirror Lamp ..................................................91

INTERIOR ROOM LAMP ...................................93

Component Parts and Harness Connector Loca-

tion ....................................................................... ...

93

System Description .................................................93

Schematic ...............................................................97

Wiring Diagram - INT/L - .........................................98

Terminal and Reference Value for BCM ...............102

How to Proceed with Trouble Diagnosis ...............102

Preliminary Check .................................................103

CONSULT-III Function (BCM) ............................. .103

Interior Room Lamp Control Does Not Operate

(With Map Lamp) ..................................................

104

Interior Room Lamp Control Does Not Operate

(Without Map Lamp) .............................................

106

Bulb Replacement .................................................107

Removal and Installation .......................................108

ILLUMINATION .............................................. ..109

System Description .............................................. .109

CAN Communication System Description ............110

Schematic .............................................................111

Wiring Diagram - ILL - ...........................................112

BULB SPECIFICATIONS ............................... ..116

Headlamp ............................................................. .116

Exterior Lamp ........................................................116

Interior Lamp/Illumination .....................................

Revision: May 2010 2011 Versa

Page 3123 of 3787

INTERIOR LAMPLT-91

< SERVICE INFORMATION >

C

DE

F

G H

I

J

L

M A

B

LT

N

O P

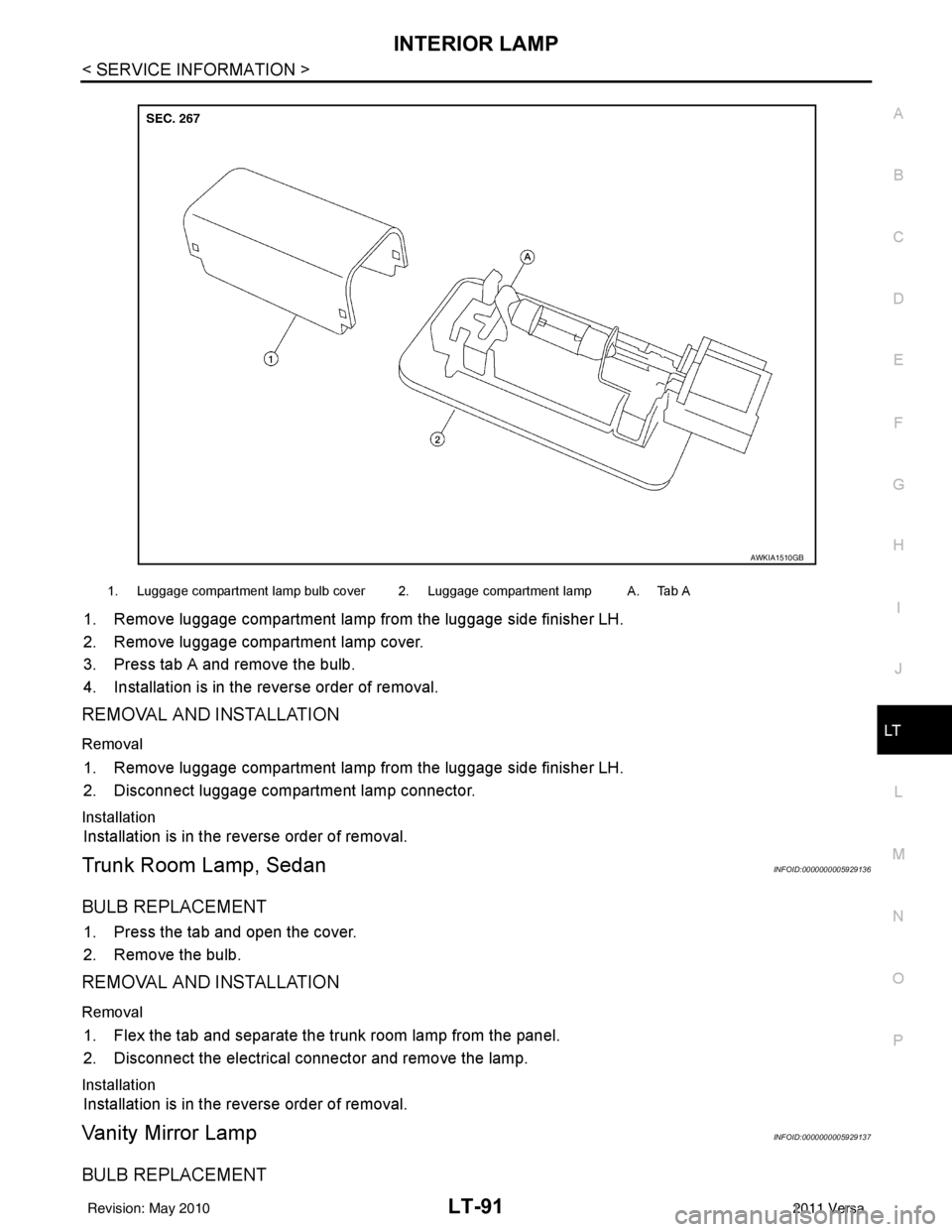

1. Remove luggage compartment lamp from the luggage side finisher LH.

2. Remove luggage compartment lamp cover.

3. Press tab A and remove the bulb.

4. Installation is in the reverse order of removal.

REMOVAL AND INSTALLATION

Removal

1. Remove luggage compartment lamp from the luggage side finisher LH.

2. Disconnect luggage compartment lamp connector.

Installation

Installation is in the reverse order of removal.

Trunk Room Lamp, SedanINFOID:0000000005929136

BULB REPLACEMENT

1. Press the tab and open the cover.

2. Remove the bulb.

REMOVAL AND INSTALLATION

Removal

1. Flex the tab and separate the trunk room lamp from the panel.

2. Disconnect the electrical connector and remove the lamp.

Installation

Installation is in the reverse order of removal.

Vanity Mirror LampINFOID:0000000005929137

BULB REPLACEMENT

1. Luggage compartment lamp bulb cover 2. Luggage compartment lamp A. Tab A

AWKIA1510GB

Revision: May 2010 2011 Versa

Page 3141 of 3787

ILLUMINATIONLT-109

< SERVICE INFORMATION >

C

DE

F

G H

I

J

L

M A

B

LT

N

O P

ILLUMINATION

System DescriptionINFOID:0000000005929150

The control of the illumination lamps operation is dependent upon the position of the lighting switch. When the

lighting switch is placed in the 1ST or 2ND position, the BCM (body control module) receives input signal

requesting the illumination lamps to illuminate. This input signal is communicated to IPDM E/R (intelligent

power distribution module engine room) across CAN communication lines. CPU (central processing unit)

located in the IPDM E/R controls the tail lamp relay coil . This relay, when energized, directs power to the illu-

mination lamps, which then illuminate.

Power is supplied at all times

• to ignition relay, located in IPDM E/R,

• to tail lamp relay, located in IPDM E/R,

• through 15A fuse (No. 52, located in IPDM E/R) and

• through 20A fuse (No. 53, located in IPDM E/R)

• to CPU located in IPDM E/R,

• through 40A fusible link (letter g, located in fuse and fusible link box)

• to BCM terminal 70, and

• through 10A fuse [No. 8, located in fuse block (J/B)]

• to BCM terminal 57.

With the ignition switch in the ON or START position, power is supplied

• to ignition relay, located in IPDM E/R, and

• through 10A fuse [No. 6, located in fuse block (J/B)]

• to BCM terminal 38.

With the ignition switch in the ACC or ON position, power is supplied

• through 10A fuse [No. 20, located in fuse block (J/B)]

• to BCM terminal 11.

Ground is supplied

• to BCM terminal 67

• through grounds M57 and M61

• to IPDM E/R terminals 39 and 59, and

• through grounds E15 and E24.

ILLUMINATION OPERATION BY LIGHTING SWITCH

With the lighting switch in the 1ST or 2ND positi on, BCM receives input signal requesting the illumination

lamps to illuminate. This input signal is communicat ed to IPDM E/R across CAN communication lines. CPU

located in the IPDM E/R controls the tail lamp relay coil, which, when energized, directs power

• through 10A fuse (No. 37, located in IPDM E/R)

• through IPDM E/R terminal 29

• to illumination control switch terminal 1

• to VDC OFF switch terminal 3 (with VDC)

• to audio unit terminal 9

• to front air control terminal 5

• to A/T shift selector terminal 3 (with 4-speed A/T)

• to CVT shift selector terminal 3 (with CVT)

• to hazard switch terminal 3

• to combination meter terminal 12

• to door mirror remote control switch terminal 16

• to combination switch (spiral cable) terminal 26 (with steering wheel audio control switches)

• to steering wheel audio control switches through combinat ion switch (spiral cable) terminal 18 (with steering

wheel audio control switches).

Ground is supplied

• to VDC OFF switch terminal 4 (with VDC)

• to illumination control switch terminal 3, and

• through grounds M57 and M61.

The illumination control switch controls illuminat ion intensity by varying the ground to the following

• through illumination control switch terminal 2

• to audio unit terminal 8

• to front air control terminal 6

• to A/T shift selector terminal 4 (with 4-speed A/T)

• to CVT shift selector terminal 3 (with CVT)

Revision: May 2010 2011 Versa

Page 3142 of 3787

LT-110

< SERVICE INFORMATION >

ILLUMINATION

• to hazard switch terminal 4

• to combination meter terminal 13

• to door mirror remote control switch terminal 15

• to combination switch (spiral cable) terminal 27 (with steering wheel audio control switches)

• to steering wheel audio control switches through combination switch (spiral cable) terminal 21 (with steeringwheel audio control switches).

With power and ground supplied, illumination lamps illuminate.

EXTERIOR LAMP BATTERY SAVER CONTROL

Refer to LT-74, "System Description".

CAN Communication System DescriptionINFOID:0000000005929151

Refer to LAN-7, "System Description" .

Revision: May 2010 2011 Versa

Page 3148 of 3787

LT-116

< SERVICE INFORMATION >

BULB SPECIFICATIONS

BULB SPECIFICATIONS

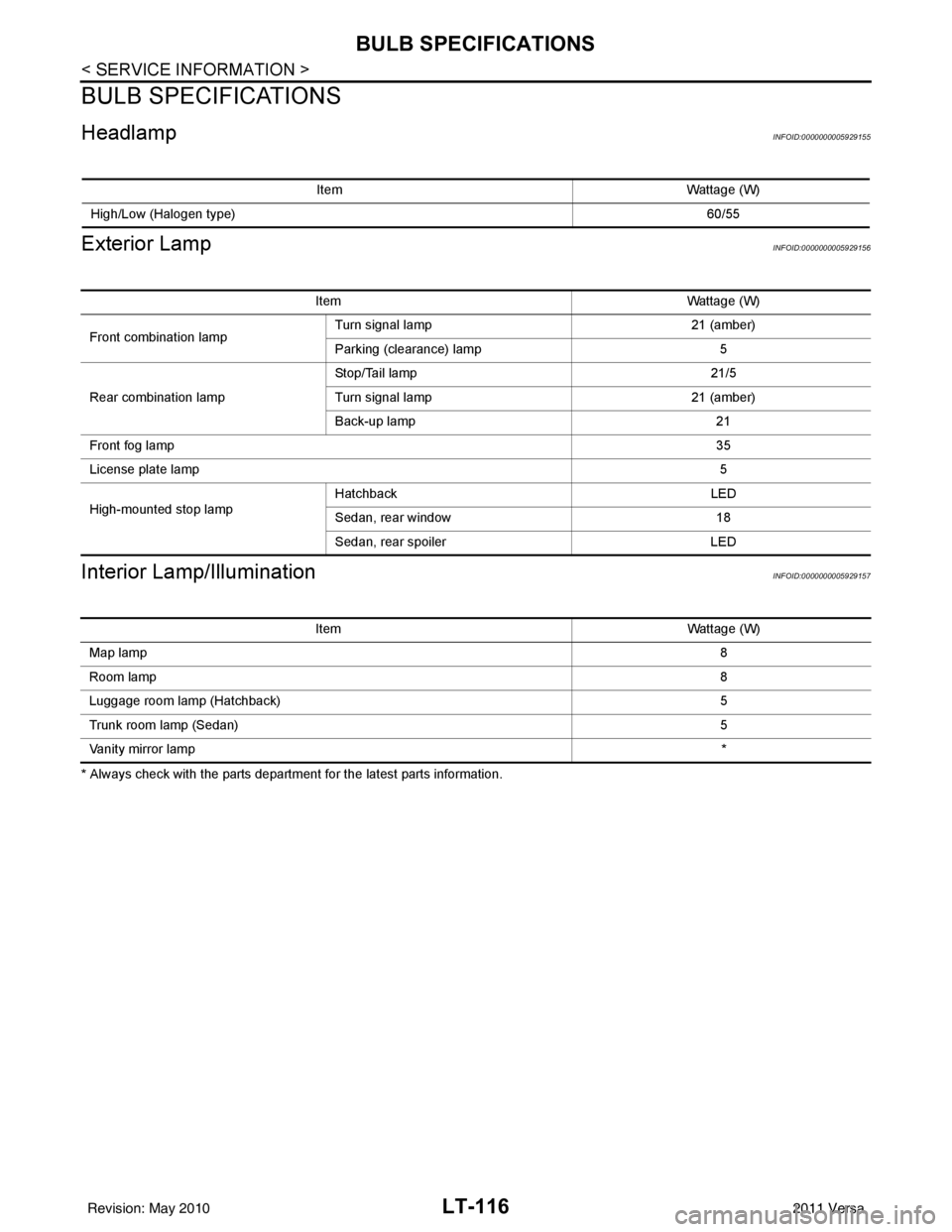

HeadlampINFOID:0000000005929155

Exterior LampINFOID:0000000005929156

Interior Lamp/IlluminationINFOID:0000000005929157

* Always check with the parts department for the latest parts information.Item

Wattage (W)

High/Low (Halogen type) 60/55

ItemWattage (W)

Front combination lamp Turn signal lamp

21 (amber)

Parking (clearance) lamp 5

Rear combination lamp Stop/Tail lamp

21/5

Turn signal lamp 21 (amber)

Back-up lamp 21

Front fog lamp 35

License plate lamp 5

High-mounted stop lamp Hatchback

LED

Sedan, rear window 18

Sedan, rear spoiler LED

ItemWattage (W)

Map lamp 8

Room lamp 8

Luggage room lamp (Hatchback) 5

Trunk room lamp (Sedan) 5

Vanity mirror lamp *

Revision: May 2010 2011 Versa

Page 3408 of 3787

MTC-92

< SERVICE INFORMATION >

REFRIGERANT LINES

• If reusing the evaporator, install the thermo control amp. at the position marked when removing the

thermo control amp., if equipped (MR18DE - TYPE 2 systems).

• When recharging refrigerant, check for leaks.

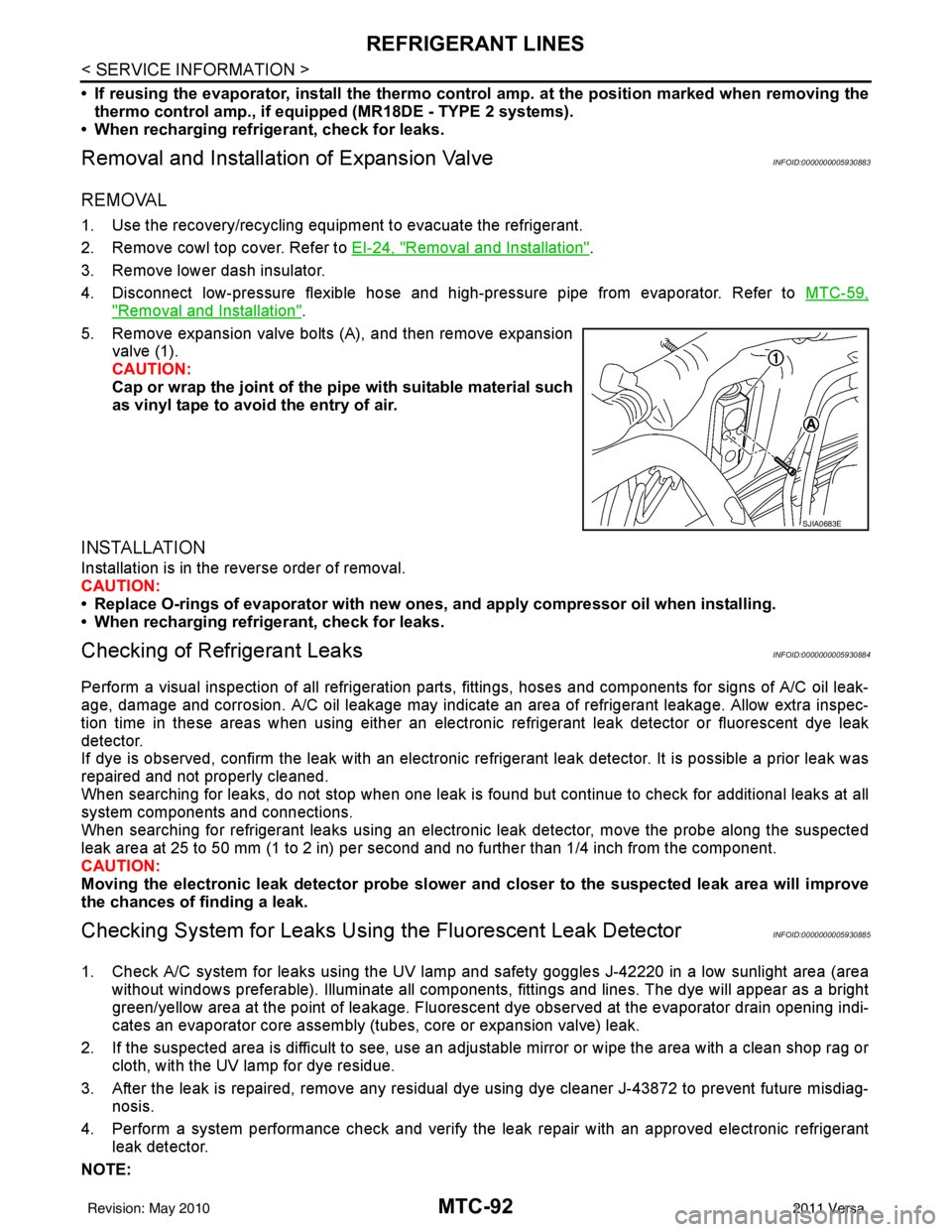

Removal and Installation of Expansion ValveINFOID:0000000005930883

REMOVAL

1. Use the recovery/recycling equipment to evacuate the refrigerant.

2. Remove cowl top cover. Refer to EI-24, "

Removal and Installation".

3. Remove lower dash insulator.

4. Disconnect low-pressure flexible hose and high-pressure pipe from evaporator. Refer to MTC-59,

"Removal and Installation".

5. Remove expansion valve bolts (A), and then remove expansion valve (1).

CAUTION:

Cap or wrap the joint of the pi pe with suitable material such

as vinyl tape to avoid the entry of air.

INSTALLATION

Installation is in the reverse order of removal.

CAUTION:

• Replace O-rings of evaporator with new ones, and apply compressor oil when installing.

• When recharging refrigerant, check for leaks.

Checking of Refrigerant LeaksINFOID:0000000005930884

Perform a visual inspection of all refrigeration parts, fittings, hoses and components for signs of A/C oil leak-

age, damage and corrosion. A/C oil leakage may indicate an area of refrigerant leakage. Allow extra inspec-

tion time in these areas when using either an electronic refrigerant leak detector or fluorescent dye leak

detector.

If dye is observed, confirm the leak with an electronic refrigerant leak detector. It is possible a prior leak was

repaired and not properly cleaned.

When searching for leaks, do not stop when one leak is found but continue to check for additional leaks at all

system components and connections.

When searching for refrigerant leaks using an electronic leak detector, move the probe along the suspected

leak area at 25 to 50 mm (1 to 2 in) per second and no further than 1/4 inch from the component.

CAUTION:

Moving the electronic leak detector probe slower an d closer to the suspected leak area will improve

the chances of finding a leak.

Checking System for Leaks Using the Fluorescent Leak DetectorINFOID:0000000005930885

1. Check A/C system for leaks using the UV lamp and safety goggles J-42220 in a low sunlight area (area

without windows preferable). Illuminate all components, fittings and lines. The dye will appear as a bright

green/yellow area at the point of leakage. Fluoresce nt dye observed at the evaporator drain opening indi-

cates an evaporator core assembly (tubes, core or expansion valve) leak.

2. If the suspected area is difficult to see, use an adjustable mirror or wipe the area with a clean shop rag or cloth, with the UV lamp for dye residue.

3. After the leak is repaired, remove any residual dye using dye cleaner J-43872 to prevent future misdiag- nosis.

4. Perform a system performance chec k and verify the leak repair with an approved electronic refrigerant

leak detector.

NOTE:

SJIA0683E

Revision: May 2010 2011 Versa

Page 3461 of 3787

HARNESSPG-41

< SERVICE INFORMATION >

C

DE

F

G H

I

J

L

M A

B

PG

N

O P

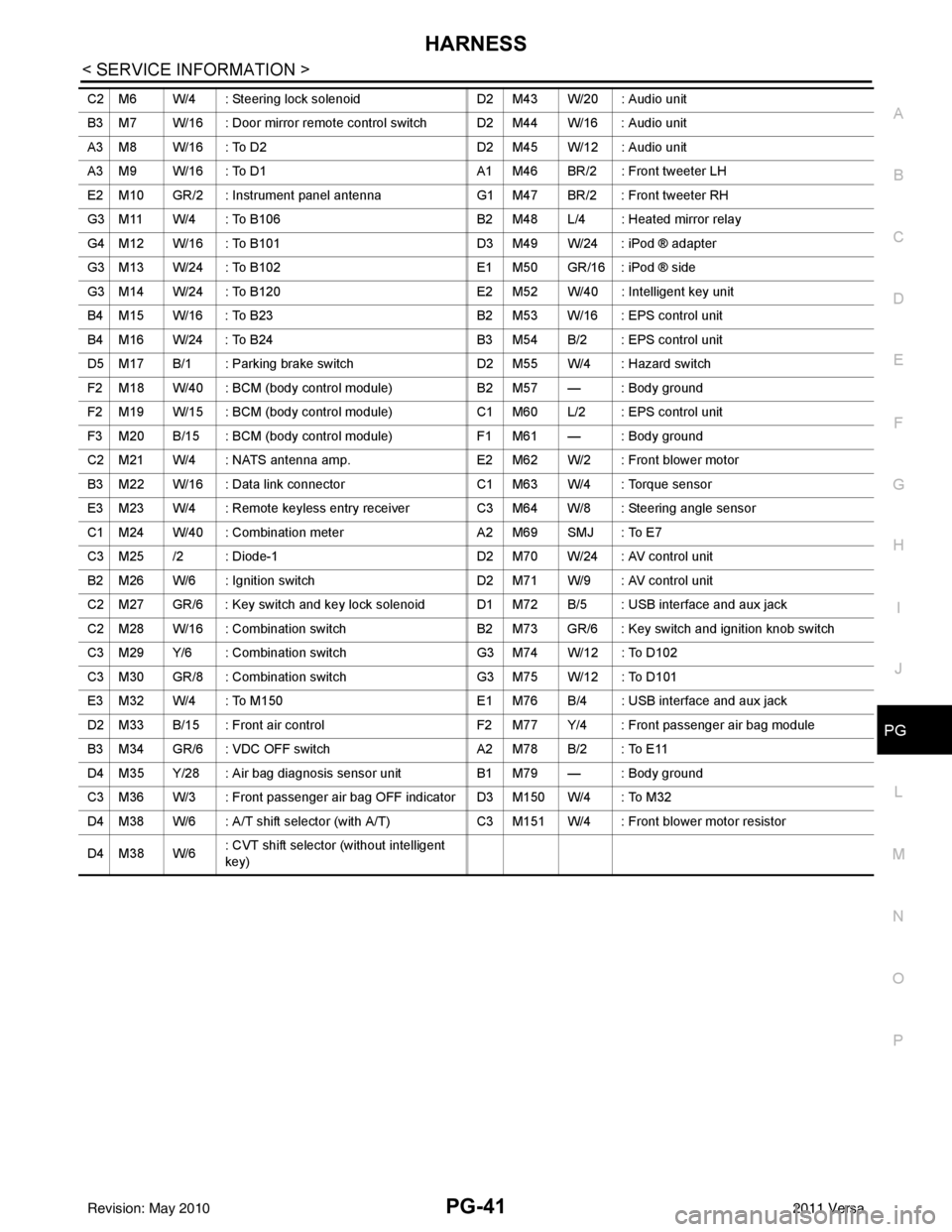

C2 M6 W/4 : Steering lock solenoid D2 M43 W/20 : Audio unit

B3 M7 W/16 : Door mirror re mote control switch D2 M44 W/16 : Audio unit

A3 M8 W/16 : To D2 D2 M45 W/12 : Audio unit

A3 M9 W/16 : To D1 A1 M46 BR/2 : Front tweeter LH

E2 M10 GR/2 : Instrument panel antenna G1 M47 BR/2 : Front tweeter RH

G3 M11 W/4 : To B106 B2 M48 L/4 : Heated mirror relay

G4 M12 W/16 : To B101 D3 M49 W/24 : iPod ® adapter

G3 M13 W/24 : To B102 E1 M50 GR/16 : iPod ® side

G3 M14 W/24 : To B120 E2 M52 W/40 : Intelligent key unit

B4 M15 W/16 : To B23 B2 M53 W/16 : EPS control unit

B4 M16 W/24 : To B24 B3 M54 B/2 : EPS control unit

D5 M17 B/1 : Parking brake switch D2 M55 W/4 : Hazard switch

F2 M18 W/40 : BCM (body control module) B2 M57 — : Body ground

F2 M19 W/15 : BCM (body control module) C1 M60 L/2 : EPS control unit

F3 M20 B/15 : BCM (body control module) F1 M61 — : Body ground

C2 M21 W/4 : NATS antenna amp. E2 M62 W/2 : Front blower motor

B3 M22 W/16 : Data link connector C1 M63 W/4 : Torque sensor

E3 M23 W/4 : Remote keyless entry receiver C3 M64 W/8 : Steering angle sensor

C1 M24 W/40 : Combination meter A2 M69 SMJ : To E7

C3 M25 /2 : Diode-1 D2 M70 W/24 : AV control unit

B2 M26 W/6 : Ignition switch D2 M71 W/9 : AV control unit

C2 M27 GR/6 : Key switch and key lock solenoid D1 M72 B/5 : USB interface and aux jack

C2 M28 W/16 : Combination switch B2 M73 GR/6 : Key switch and ignition knob switch

C3 M29 Y/6 : Combination switch G3 M74 W/12 : To D102

C3 M30 GR/8 : Combination switch G3 M75 W/12 : To D101

E3 M32 W/4 : To M150 E1 M76 B/4 : USB interface and aux jack

D2 M33 B/15 : Front air control F2 M77 Y/4 : Front passenger air bag module

B3 M34 GR/6 : VDC OFF switch A2 M78 B/2 : To E11

D4 M35 Y/28 : Air bag diagnosis sensor unit B1 M79 — : Body ground

C3 M36 W/3 : Front passenger air bag OFF indicator D3 M150 W/4 : To M32

D4 M38 W/6 : A/T shift selector (with A/T) C3 M151 W/4 : Front blower motor resistor

D4 M38 W/6 : CVT shift selector (without intelligent

key)

Revision: May 2010

2011 Versa

Page 3473 of 3787

HARNESSPG-53

< SERVICE INFORMATION >

C

DE

F

G H

I

J

L

M A

B

PG

N

O P

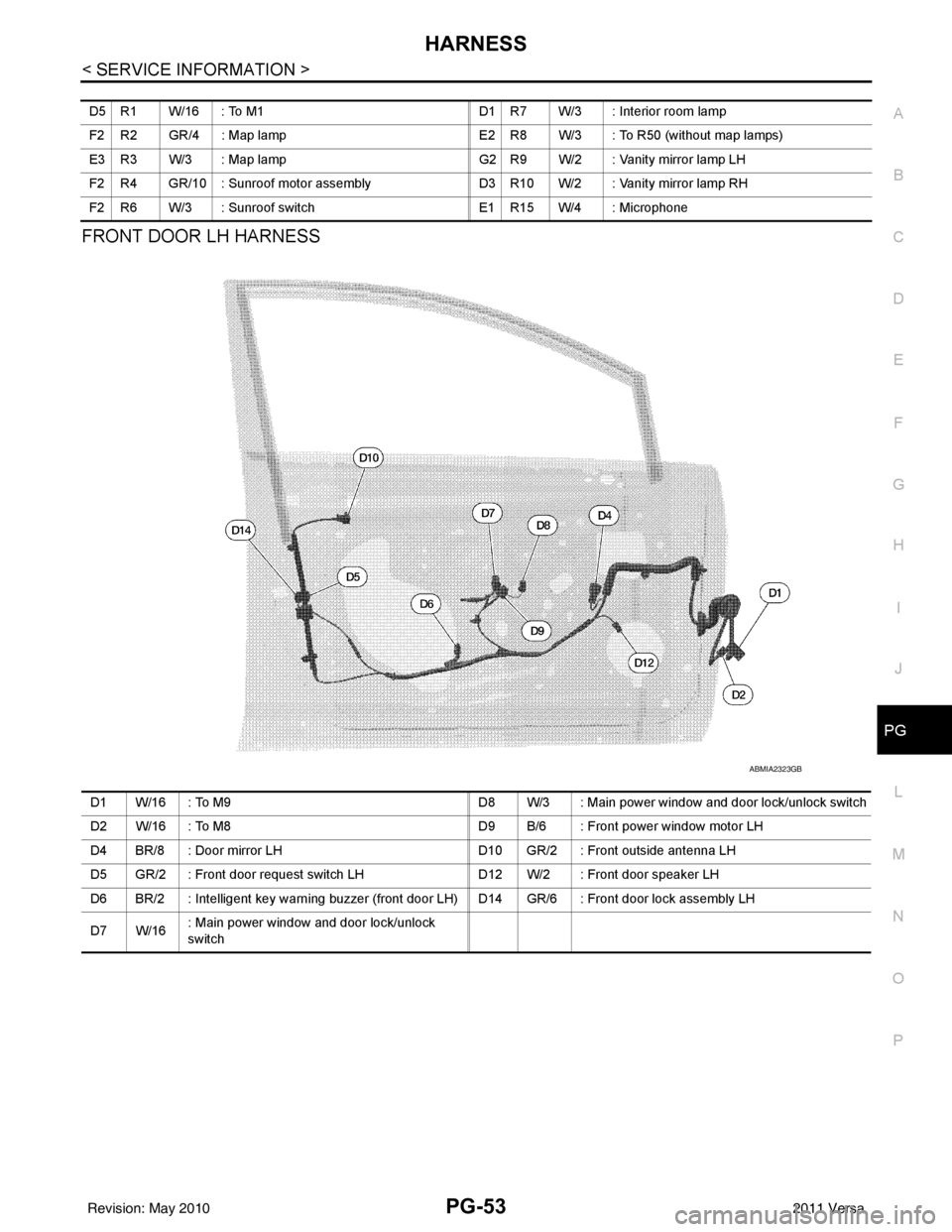

FRONT DOOR LH HARNESS

D5 R1 W/16 : To M1 D1 R7 W/3 : Interior room lamp

F2 R2 GR/4 : Map lamp E2 R8 W/3 : To R50 (without map lamps)

E3 R3 W/3 : Map lamp G2 R9 W/2 : Vanity mirror lamp LH

F2 R4 GR/10 : Sunroof motor assembly D3 R10 W/2 : Vanity mirror lamp RH

F2 R6 W/3 : Sunroof switch E1 R15 W/4 : Microphone

ABMIA2323GB

D1 W/16 : To M9D8 W/3 : Main power window and door lock/unlock switch

D2 W/16 : To M8 D9 B/6 : Front power window motor LH

D4 BR/8 : Door mirror LH D10 GR/2 : Front outside antenna LH

D5 GR/2 : Front door request switch LH D12 W/2 : Front door speaker LH

D6 BR/2 : Intelligent key warning buzzer (front door LH) D14 GR/6 : Front door lock assembly LH

D7 W/16 : Main power window and door lock/unlock

switch

Revision: May 2010

2011 Versa

Page 3474 of 3787

PG-54

< SERVICE INFORMATION >

HARNESS

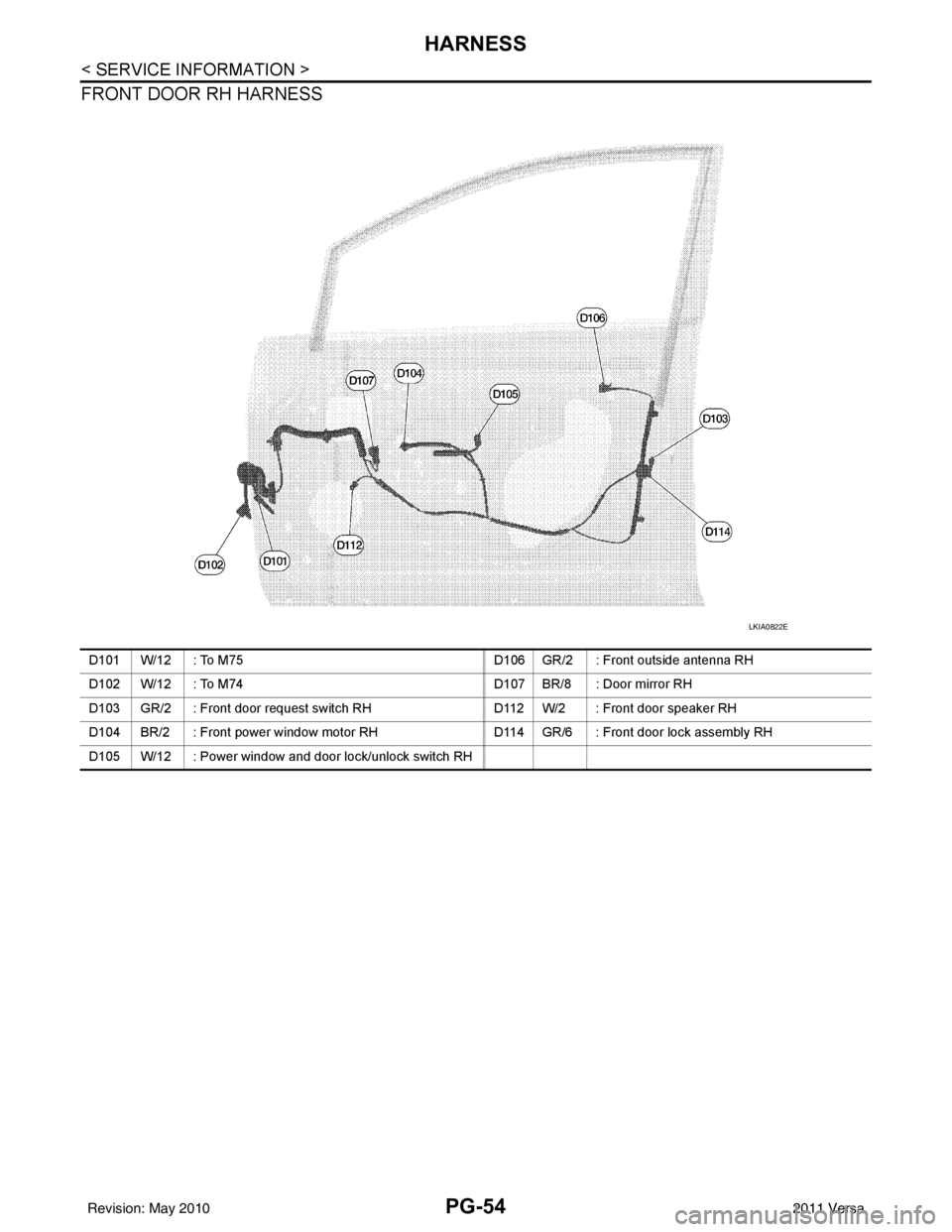

FRONT DOOR RH HARNESS

LKIA0822E

D101 W/12 : To M75D106 GR/2 : Front outside antenna RH

D102 W/12 : To M74 D107 BR/8 : Door mirror RH

D103 GR/2 : Front door request switch RH D112 W/2 : Front door speaker RH

D104 BR/2 : Front power window motor RH D114 GR/6 : Front door lock assembly RH

D105 W/12 : Power window and door lock/unlock switch RH

Revision: May 2010 2011 Versa

Page 3479 of 3787

HARNESSPG-59

< SERVICE INFORMATION >

C

DE

F

G H

I

J

L

M A

B

PG

N

O P

H/LAMP LT Headlamp

H/PHON AV Hands Free Telephone

HORN WW Horn

HO2S2 EC Heated Oxygen Sensor 2

HO2S2H EC Heated Oxygen Sensor 2 Heater

IATS EC Intake Air Temperature Sensor

IGNSYS EC Ignition System

I/KEY BL Intelligent Key System

ILL LT Illumination

INJECT EC Injector

INT/L LT Room/Map, Vanity and Luggage Lamps

IVC EC Intake Valve Timing Control Solenoid Valve

KEYLES BL Remote Keyless Entry System

KS EC Knock Sensor

LPSV AT Line Pressure Solenoid Valve

LPSV CVT Line Pressure Solenoid Valve

L/USSV CVT Lock-up Select Solenoid Valve

MAFS EC Mass Air Flow Sensor

MAIN AT Main Power Supply and Ground Circuit

MAIN EC Main Power Supply and Ground Circuit

METER DI Speedometer, Tachometer, Temp. and Fuel Gauges

MIL/DL EC Malfunction Indicator Lamp

MIRROR GW Door Mirror

NATS BL Nissan Anti-Theft System

NONDTC AT Non-detectable Item

NONDTC CVT Non-detectable Item

ODSW CVT Overdrive Control Switch

OVRCSV AT Over Run Clutch Solenoid Valve

P/SCKT WW Power Socket

PGC/V EC EVAP Canister Purge Vo lume Control Solenoid Valve

PHASE EC Camshaft Position Sensor (PHASE)

PNP/SW EC Park/Neutral Position Switch

POS EC Crankshaft Position Sensor (POS)

POWER CVT Transmission Control Module (Power Supply)

PRE/SE EC EVAP Control System Pressure Sensor

PRIPS CVT Primary Pressure Sensor

PRSCVT CVT Primary Speed Sensor CVT (Input Speed Sensor)

PT/SEN AT Powertrain Revolution Sensor

RP/SEN EC Refrigerant Pressure Sensor

SECPS CVT Secondary Pressure Sensor

SECPSV CVT Secondary Speed Sensor CVT (Input Speed Sensor)

SEN/PW EC Sensor Power Supply

SESCVT CVT Secondary Pressure Sensor Solenoid Valve

SHIFT AT A/T Shift Lock System

SHIFT CVT CVT Shift Lock System

SROOF RF Sunroof

SRS SRS Supplemental Restraint System

SSV/A AT Shift Solenoid Valve A

SSV/B AT Shift Solenoid Valve B

START SC Starting System

STM CVT Step Motor

STOP/L LT Stop Lamp

Revision: May 2010 2011 Versa