OBD port NISSAN LATIO 2011 Service Repair Manual

[x] Cancel search | Manufacturer: NISSAN, Model Year: 2011, Model line: LATIO, Model: NISSAN LATIO 2011Pages: 3787, PDF Size: 78.35 MB

Page 25 of 3787

AT-8

< SERVICE INFORMATION >

PRECAUTIONS

6. Perform a self-diagnosis check of all control units using CONSULT-III.

Precaution for On Board Diagnosis (OBD) System of A/T and EngineINFOID:0000000005928065

The ECM has an on board diagnostic system. It will light up the malfunction indicator lamp (MIL) to warn the

driver of a malfunction causing emission deterioration.

CAUTION:

• Be sure to turn the ignition switch OFF and disconnect battery negative cable from battery negative

terminal before any repair or inspection work. The open/short circuit of related switches, sensors,

solenoid valves, etc. will cause the MIL to light up.

• Be sure to connect and lock the connectors secure ly after work. A loose (unlocked) connector will

cause the MIL to light up due to an open circuit. (Be sure the connectors are free from water, grease,

dirt, bent terminals, etc.)

• Be sure to route and secure th e harnesses properly after work. Interference of the harness with a

bracket, etc. may cause the MIL to light up due to a short circuit.

• Be sure to erase the unnecessary malfunction informa tion (repairs completed) from the TCM and

ECM before returning the vehicle to the customer.

PrecautionINFOID:0000000005928066

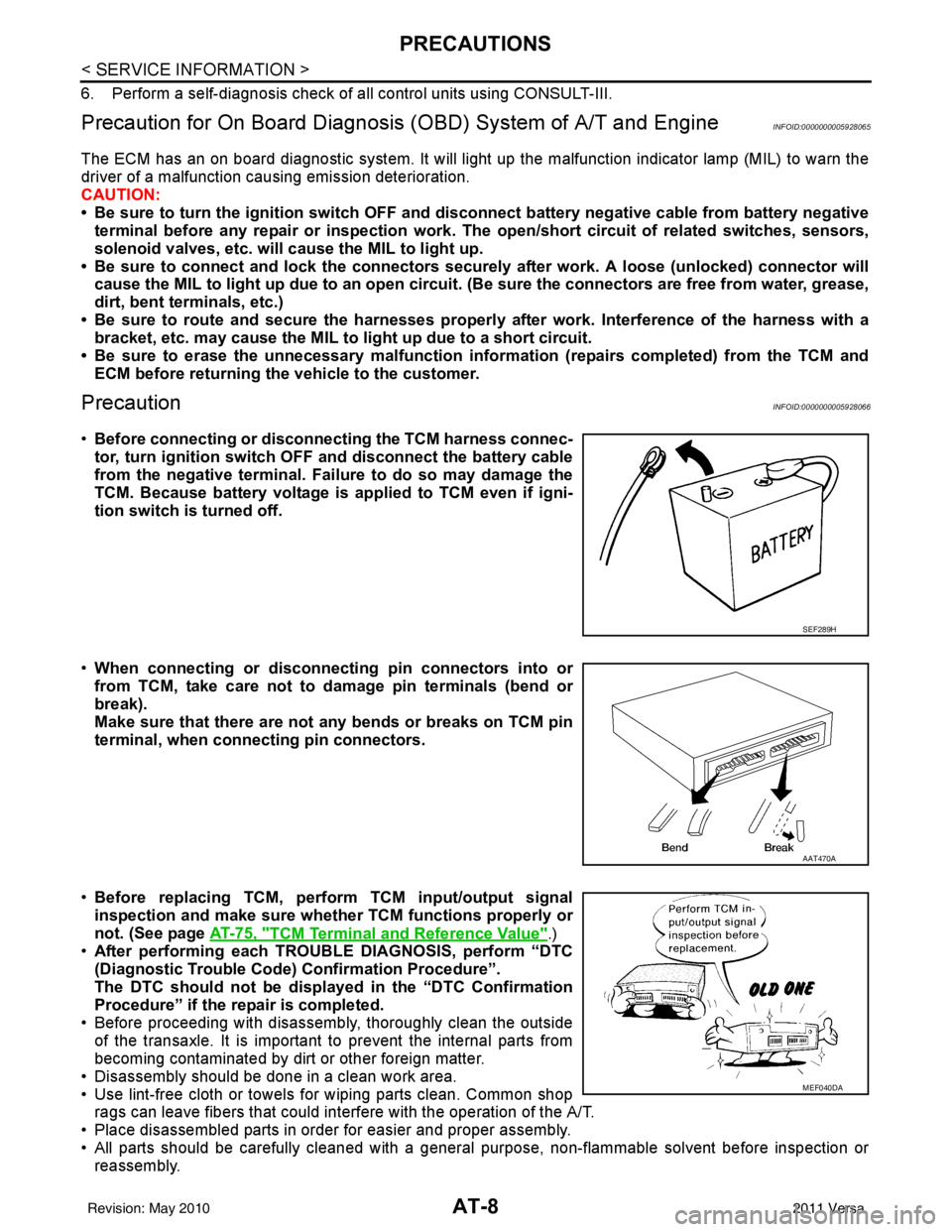

•Before connecting or disconn ecting the TCM harness connec-

tor, turn ignition switch OF F and disconnect the battery cable

from the negative terminal. Failure to do so may damage the

TCM. Because battery voltage is applied to TCM even if igni-

tion switch is turned off.

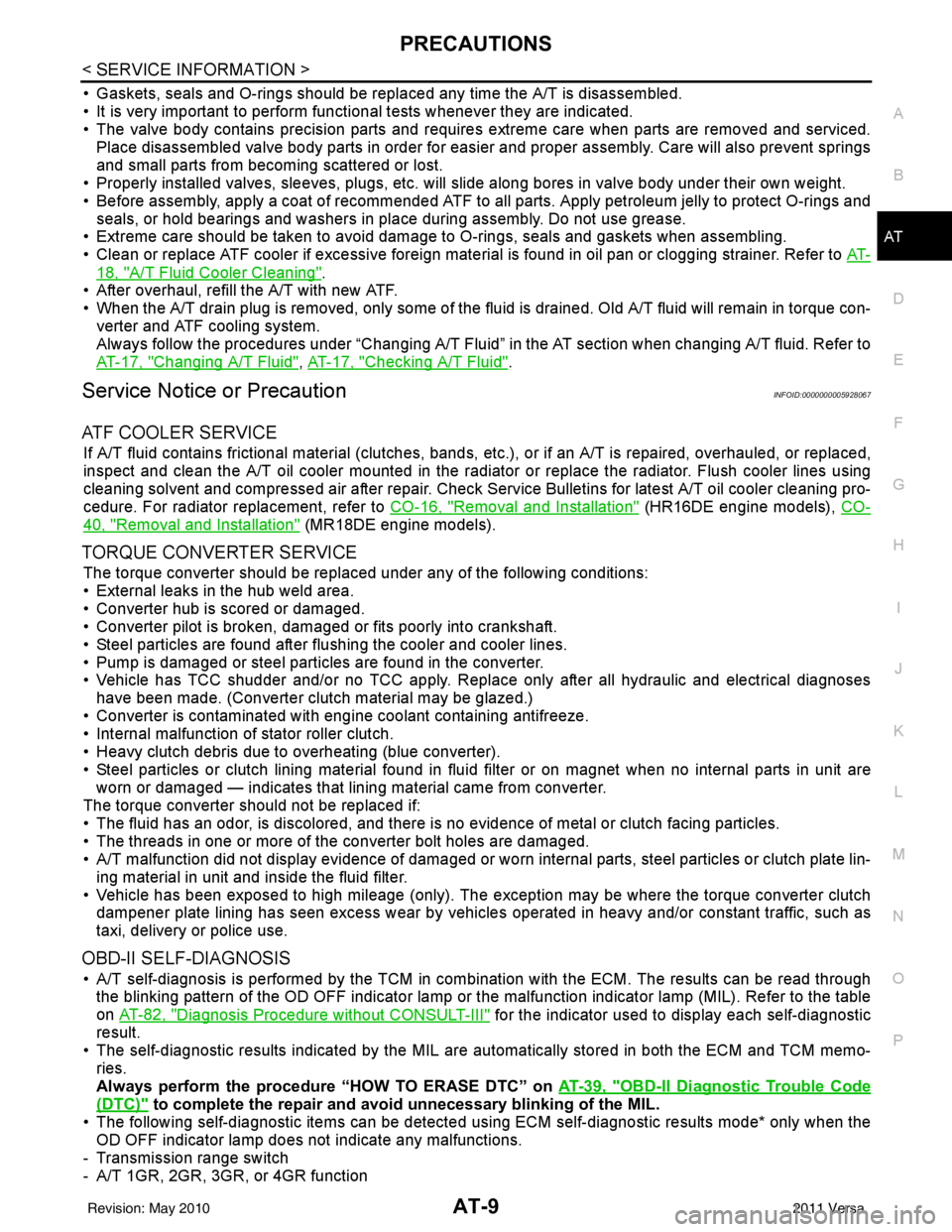

• When connecting or disconnect ing pin connectors into or

from TCM, take care not to damage pin terminals (bend or

break).

Make sure that there are not any bends or breaks on TCM pin

terminal, when connecting pin connectors.

• Before replacing TCM, perform TCM input/output signal

inspection and make sure whether TCM functions properly or

not. (See page AT-75, "

TCM Terminal and Reference Value".)

• After performing each TROUBLE DIAGNOSIS, perform “DTC

(Diagnostic Trouble Code) Confirmation Procedure”.

The DTC should not be displ ayed in the “DTC Confirmation

Procedure” if the repair is completed.

• Before proceeding with disassembly, thoroughly clean the outside of the transaxle. It is important to prevent the internal parts from

becoming contaminated by dirt or other foreign matter.

• Disassembly should be done in a clean work area.

• Use lint-free cloth or towels for wiping parts clean. Common shop rags can leave fibers that could in terfere with the operation of the A/T.

• Place disassembled parts in order for easier and proper assembly.

• All parts should be carefully cleaned with a general purpose, non-flammable solvent before inspection or reassembly.

SEF289H

AAT470A

MEF040DA

Revision: May 2010 2011 Versa

Page 26 of 3787

PRECAUTIONSAT-9

< SERVICE INFORMATION >

DE

F

G H

I

J

K L

M A

B

AT

N

O P

• Gaskets, seals and O-rings should be replaced any time the A/T is disassembled.

• It is very important to perform func tional tests whenever they are indicated.

• The valve body contains precision parts and requires extreme care when parts are removed and serviced.

Place disassembled valve body parts in order for easier and proper assembly. Care will also prevent springs

and small parts from becoming scattered or lost.

• Properly installed valves, sleeves, plugs, etc. will slide along bores in valve body under their own weight.

• Before assembly, apply a coat of recommended ATF to all parts. Apply petroleum jelly to protect O-rings and seals, or hold bearings and washers in pl ace during assembly. Do not use grease.

• Extreme care should be taken to avoid damage to O-rings, seals and gaskets when assembling.

• Clean or replace ATF cooler if excessive foreign material is found in oil pan or clogging strainer. Refer to AT-

18, "A/T Fluid Cooler Cleaning".

• After overhaul, refill the A/T with new ATF.

• When the A/T drain plug is removed, only some of the fluid is drained. Old A/T fluid will remain in torque con- verter and ATF cooling system.

Always follow the procedures under “Changing A/T Fluid” in the AT section when changing A/T fluid. Refer to

AT-17, "

Changing A/T Fluid", AT-17, "Checking A/T Fluid".

Service Notice or PrecautionINFOID:0000000005928067

ATF COOLER SERVICE

If A/T fluid contains frictional material (clutches, bands, etc.), or if an A/T is repaired, overhauled, or replaced,

inspect and clean the A/T oil cooler mounted in the radiator or replace the radiator. Flush cooler lines using

cleaning solvent and compressed air after repair. Check Service Bulletins for latest A/T oil cooler cleaning pro-

cedure. For radiator replacement, refer to CO-16, "

Removal and Installation" (HR16DE engine models), CO-

40, "Removal and Installation" (MR18DE engine models).

TORQUE CONVERTER SERVICE

The torque converter should be replaced under any of the following conditions:

• External leaks in the hub weld area.

• Converter hub is scored or damaged.

• Converter pilot is broken, damaged or fits poorly into crankshaft.

• Steel particles are found after flushing the cooler and cooler lines.

• Pump is damaged or steel particles are found in the converter.

• Vehicle has TCC shudder and/or no TCC apply. Replace only after all hydraulic and electrical diagnoses

have been made. (Converter clutch material may be glazed.)

• Converter is contaminated with engi ne coolant containing antifreeze.

• Internal malfunction of stator roller clutch.

• Heavy clutch debris due to overheating (blue converter).

• Steel particles or clutch lining material found in flui d filter or on magnet when no internal parts in unit are

worn or damaged — indicates that lining material came from converter.

The torque converter should not be replaced if:

• The fluid has an odor, is discolored, and there is no evidence of metal or clutch facing particles.

• The threads in one or more of the converter bolt holes are damaged.

• A/T malfunction did not display evidence of damaged or worn internal parts, steel particles or clutch plate lin-

ing material in unit and inside the fluid filter.

• Vehicle has been exposed to high mileage (only). The e xception may be where the torque converter clutch

dampener plate lining has seen excess wear by vehicles operated in heavy and/or constant traffic, such as

taxi, delivery or police use.

OBD-II SELF-DIAGNOSIS

• A/T self-diagnosis is performed by the TCM in combination with the ECM. The results can be read through the blinking pattern of the OD OFF indicator lamp or the malfunction indicator lamp (MIL). Refer to the table

on AT-82, "

Diagnosis Procedure without CONSULT-III" for the indicator used to display each self-diagnostic

result.

• The self-diagnostic results indicated by the MIL are automatically stored in both the ECM and TCM memo- ries.

Always perform the procedure “HOW TO ERASE DTC” on AT-39, "

OBD-II Diagnostic Trouble Code

(DTC)" to complete the repair and avoid unnecessary blinking of the MIL.

• The following self-diagnostic items can be detected us ing ECM self-diagnostic results mode* only when the

OD OFF indicator lamp does not indicate any malfunctions.

- Transmission range switch

- A/T 1GR, 2GR, 3GR, or 4GR function

Revision: May 2010 2011 Versa

Page 1086 of 3787

![NISSAN LATIO 2011 Service Repair Manual TROUBLE DIAGNOSISCVT-31

< SERVICE INFORMATION > [RE0F08B]

D

E

F

G H

I

J

K L

M A

B

CVT

N

O P

TCM Power Supply (Memory Back-up)

Transaxle assembly is protected by limiting the engine torque when the mem NISSAN LATIO 2011 Service Repair Manual TROUBLE DIAGNOSISCVT-31

< SERVICE INFORMATION > [RE0F08B]

D

E

F

G H

I

J

K L

M A

B

CVT

N

O P

TCM Power Supply (Memory Back-up)

Transaxle assembly is protected by limiting the engine torque when the mem](/img/5/57357/w960_57357-1085.png)

TROUBLE DIAGNOSISCVT-31

< SERVICE INFORMATION > [RE0F08B]

D

E

F

G H

I

J

K L

M A

B

CVT

N

O P

TCM Power Supply (Memory Back-up)

Transaxle assembly is protected by limiting the engine torque when the memory back-up power supply (for

controlling) from the battery is not supplied to TCM.

Normal statues is restored when turning the ignition switch

OFF to ON after the normal power supply.

How to Perform Trouble Diagnosis for Quick and Accurate RepairINFOID:0000000005928750

INTRODUCTION

The TCM receives a signal from the vehicle speed sensor, transmission range switch and provides shift con-

trol or lock-up control via CVT solenoid valves.

The TCM also communicates with the ECM by means of a signal

sent from sensing elements used wit h the OBD-related parts of the

CVT system for malfunction-diagnos tic purposes. The TCM is capa-

ble of diagnosing malfunctioning parts while the ECM can store mal-

functions in its memory.

Input and output signals must always be correct and stable in the

operation of the CVT system. The CVT system must be in good

operating condition and be free of valve seizure, solenoid valve mal-

function, etc.

It is much more difficult to diagnose an error that occurs intermit-

tently rather than continuously. Most intermittent errors are caused

by poor electric connections or impr oper wiring. In this case, careful

checking of suspected circuits may help prevent the replacement of

good parts.

A visual check only may not find t he cause of the errors. A road test

with CONSULT-III (or GST) or a circuit tester connected should be

performed. Follow the "WORK FLOW" .

Before undertaking actual checks, take a few minutes to talk with a

customer who approaches with a driveability complaint. The cus-

tomer can supply good information about such errors, especially

intermittent ones. Find out what symptoms are present and under

what conditions they occur. A “DIAGNOSTIC WORKSHEET” as

shown on the example (Refer to "Diagnostic Worksheet Chart" )

should be used.

Start your diagnosis by looking for “conventional” errors first. This will

help troubleshoot driveability errors on an electronically controlled

engine vehicle.

Also check related Service bulletins.

WORK FLOW

A good understanding of the malfunction conditions can make troubleshooting faster and more accurate.

In general, each customer feels differently about a malf unction. It is important to fully understand the symp-

toms or conditions for a customer complaint.

Make good use of the two sheets provided, "Information From Customer" and "Diagnostic Worksheet Chart" ,

to perform the best troubleshooting possible.

Work Flow Chart

SAT631IB

SAT632I

SEF234G

Revision: May 2010 2011 Versa

Page 1105 of 3787

![NISSAN LATIO 2011 Service Repair Manual CVT-50

< SERVICE INFORMATION >[RE0F08B]

TROUBLE DIAGNOSIS

*: Models without ABS

does not indicate.

WORK SUPPORT MODE

Display Item List

Engine Brake Adjustment

CAUTION:

Mode of “+1”“0”“-1” NISSAN LATIO 2011 Service Repair Manual CVT-50

< SERVICE INFORMATION >[RE0F08B]

TROUBLE DIAGNOSIS

*: Models without ABS

does not indicate.

WORK SUPPORT MODE

Display Item List

Engine Brake Adjustment

CAUTION:

Mode of “+1”“0”“-1”](/img/5/57357/w960_57357-1104.png)

CVT-50

< SERVICE INFORMATION >[RE0F08B]

TROUBLE DIAGNOSIS

*: Models without ABS

does not indicate.

WORK SUPPORT MODE

Display Item List

Engine Brake Adjustment

CAUTION:

Mode of “+1”“0”“-1”“-2”“OFF” can be selected by pressing the “UP”“DOWN” on CONSULT-III screen.

However, do not select mode other th an “0” and “OFF”. If the “+1” or “-1” or “-2” is selected, that

might cause the irregular driveability.

Check CVT Fluid Deterioration Date

CAUTION:

Touch “CLEAR” after changing CVT fluid, and then erase “CVTF DETERIORATION DATE”.

SELF-DIAGNOSTIC RESULT MODE

After performing self-diagnosis, place check marks for results on the CVT-31, "How to Perform Trouble Diag-

nosis for Quick and Accurate Repair" . Reference pages are provided following the items.

Display Items List

X: Applicable —: Not applicable

LUSEL SOL OUTSelector lever in “P

” and “N” positions on

Wait at least for 5 seconds with the selector lever

in “R”, “D” and “L” positions off

RANGE Selector lever in “N

” or “P” position. N·P

Selector lever in “R” position. R

Selector lever in “D” position. D

Selector lever in “L” position. L

Item name

Condition Display value (Approx.)

Item name Description

ENGINE BRAKE ADJ. The engine brake level setting can be canceled.

CONFORM CVTF DETERIORTN The CVT fluid deterioration level can be checked.

“ENGINE BRAKE LEVEL”

0: Initial set value (Engine brake level control is ac-

tivated)

OFF: Engine brake level control is deactivated.

“CVTF DETERIORATION DATE”

More than 210000: It is necessary to change CVT fluid.

Less than 210000: It is not necessary to change CVT fluid.

Items (CONSULT-

III screen terms) Malfunction is detected when... TCM self-di-

agnosis OBD-III (DTC)

Reference page

“TRANSMIS-

SION” with

CONSULT-III MIL indicator

lamp*1, “EN-

GINE” with

CONSULT-III or GST

CAN COMM CIR-

CUIT When TCM is not transmitting or receiving CAN communica-

tion signal for 2 seconds or more

U1000 U1000

CVT-56

CONTROL

UNIT(CAN)When detecting error during the initial diagnosis of CAN con-

troller of TCM

U1010 U1010

CVT-59

Revision: May 2010 2011 Versa

Page 1301 of 3787

EC-7

C

DE

F

G H

I

J

K L

M

EC A

N

O P

Description ..........................................................

..

492

PRECAUTION ............................................493

PRECAUTIONS .............................................. ..493

Precaution for Supplemental Restraint System

(SRS) "AIR BAG" and "SEAT BELT PRE-TEN-

SIONER" ............................................................. ..

493

Precaution for Procedure without Cowl Top Cover ..493

On Board Diagnosis (OBD) System of Engine and

A/T .........................................................................

493

General Precautions .............................................494

PREPARATION .........................................497

PREPARATION .............................................. ..497

Special Service Tools .......................................... ..497

Commercial Service Tools ....................................497

ON-VEHICLE MAINTENANCE ..................499

FUEL PRESSURE .......................................... ..499

Inspection ............................................................ ..499

EVAP LEAK CHECK ........................................501

Inspection ............................................................ ..501

SERVICE DATA AND SPECIFICATIONS

(SDS) ......... ................................. ................

503

SERVICE DATA AND SPECIFICATIONS

(SDS) .............................................................. ..

503

Idle Speed ........................................................... ..503

Ignition Timing .......................................................503

Calculated Load Value ..........................................503

Mass Air Flow Sensor ...........................................503

MR18DE

SERVICE INFORMATION .. .......................

504

INDEX FOR DTC ............................................ ..504

U0101-U1001 ...................................................... ..504

P0011-P0075 ........................................................504

P0101-P0128 ........................................................504

P0130-P0183 ........................................................505

P0222-P0420 ........................................................505

P0441-P0463 ........................................................506

P0500-P0643 ........................................................506

P0705-P0734 ........................................................507

P0740-P0840 ........................................................507

P0850-P1574 ........................................................508

P1610-P1615 ........................................................508

P1715-P1805 ........................................................508

P2100-P2A00 ........................................................509

PRECAUTIONS ................................................510

Precaution for Supplemental Restraint System

(SRS) "AIR BAG" and "SEAT BELT PRE-TEN-

SIONER" ............................................................. ..

510

Precaution Necessary for Steering Wheel Rota-

tion After Battery Disconnect ............................... ..

510

Precaution for Procedure without Cowl Top Cover ..511

On Board Diagnosis (OBD) System of Engine and

A/T, CVT ................................................................

511

Precaution .............................................................511

PREPARATION ...............................................515

Special Service Tool ..............................................515

Commercial Service Tool ......................................515

ENGINE CONTROL SYSTEM ........................517

Schematic ............................................................ ..517

Multiport Fuel Injection (MFI) System ....................517

Electronic Ignition (EI) System ..............................520

Fuel Cut Control (at No Load and High Engine

Speed) ...................................................................

520

AIR CONDITIONING CUT CONTROL ............522

Input/Output Signal Chart ......................................522

System Description ................................................522

AUTOMATIC SPEED CONTROL DEVICE

(ASCD) ............................................................

523

System Description ................................................523

Component Description .........................................524

CAN COMMUNICATION .................................525

System Description ................................................525

EVAPORATIVE EMISSION SYSTEM .............526

Description .............................................................526

Component Inspection ...........................................528

How to Detect Fuel Vapor Leakage .......................530

ON BOARD REFUELING VAPOR RECOV-

ERY (ORVR) ....................................................

532

System Description ................................................532

Diagnosis Procedure .............................................532

Component Inspection ...........................................535

POSITIVE CRANKCASE VENTILATION .......538

Description .............................................................538

Component Inspection ...........................................538

NVIS (NISSAN VEHICLE IMMOBILIZER SYS-

TEM-NATS) .....................................................

540

Description .............................................................540

ON BOARD DIAGNOSTIC (OBD) SYSTEM ..541

Introduction ............................................................541

Two Trip Detection Logic .......................................541

Emission-related Diagnostic Information ...............542

Malfunction Indicator Lamp (MIL) ..........................565

OBD System Operation Chart ...............................568

BASIC SERVICE PROCEDURE .....................574

Basic Inspection ....................................................574

Idle Speed and Ignition Timing Check ...................578

Procedure After Replacing ECM ...........................579

VIN Registration ....................................................580

Accelerator Pedal Released Position Learning .....580

Throttle Valve Closed Position Learning ...............580

Revision: May 2010 2011 Versa

Page 1791 of 3787

![NISSAN LATIO 2011 Service Repair Manual PREPARATIONEC-497

< PREPARATION > [HR16DE]

C

D

E

F

G H

I

J

K L

M A

EC

NP

O

PREPARATION

PREPARATION

Special Service ToolsINFOID:0000000005930164

NOTE:

The actual shapes of Kent-Moore tools may differ f NISSAN LATIO 2011 Service Repair Manual PREPARATIONEC-497

< PREPARATION > [HR16DE]

C

D

E

F

G H

I

J

K L

M A

EC

NP

O

PREPARATION

PREPARATION

Special Service ToolsINFOID:0000000005930164

NOTE:

The actual shapes of Kent-Moore tools may differ f](/img/5/57357/w960_57357-1790.png)

PREPARATIONEC-497

< PREPARATION > [HR16DE]

C

D

E

F

G H

I

J

K L

M A

EC

NP

O

PREPARATION

PREPARATION

Special Service ToolsINFOID:0000000005930164

NOTE:

The actual shapes of Kent-Moore tools may differ from those of special service tools illustrated here.

Commercial Service ToolsINFOID:0000000005930165

Tool number

(Kent-Moore No.)

Tool name

Description

(J-44321)

Fuel pressure gauge

kit Checks fuel pressure

(J-44321-6)

Fuel pressure adapter Connects fuel pressure gauge to quick connector

type fuel lines.

KV10118400

Fuel tube adapter Measures fuel pressure

LEC642

LBIA0376E

PBIB3043E

Tool name

(Kent-Moore No.)

Description

Leak detector

i.e.: (J-41416) Locates the EVAP leak

EVAP service port

adapter

i.e.: (J-41413-OBD) Applies positive pressure through EVAP service

port

S-NT703

S-NT704

Revision: May 2010

2011 Versa

Page 1795 of 3787

![NISSAN LATIO 2011 Service Repair Manual EVAP LEAK CHECKEC-501

< ON-VEHICLE MAINTENANCE > [HR16DE]

C

D

E

F

G H

I

J

K L

M A

EC

NP

O

EVAP LEAK CHECK

InspectionINFOID:0000000005930167

CAUTION:

• Do not use compressed air or a high pressure pu NISSAN LATIO 2011 Service Repair Manual EVAP LEAK CHECKEC-501

< ON-VEHICLE MAINTENANCE > [HR16DE]

C

D

E

F

G H

I

J

K L

M A

EC

NP

O

EVAP LEAK CHECK

InspectionINFOID:0000000005930167

CAUTION:

• Do not use compressed air or a high pressure pu](/img/5/57357/w960_57357-1794.png)

EVAP LEAK CHECKEC-501

< ON-VEHICLE MAINTENANCE > [HR16DE]

C

D

E

F

G H

I

J

K L

M A

EC

NP

O

EVAP LEAK CHECK

InspectionINFOID:0000000005930167

CAUTION:

• Do not use compressed air or a high pressure pump.

• Do not exceed 4.12 kPa (0.042 kg/cm

2, 0.6 psi) of pressure in EVAP system.

NOTE:

• Do not start engine.

• Improper installation of EVAP service port adapter [commercial service tool: (J-41413-OBD)] to the EVAP service port may cause a leak.

WITH CONSULT-III

1. Install EVAP service port adapter [commercial service tool: (J- 41413-OBD)] and pressure pump to EVAP service port.

2. Turn ignition switch ON.

3. Select the “EVAP SYSTEM CLOSE” of “WORK SUPPORT” mode with CONSULT-III.

4. Touch “START”. A bar graph (Pressure indicating display) will appear on the screen.

5. Apply positive pressure to the EVAP system until the pressure indicator reaches the middle of the bar graph.

6. Remove EVAP service port adapter [commercial service tool: (J- 41413-OBD)] and hose with pressure pump.

7. Locate the leak using a leak detector [commercial service tool: (J-41416)]. Refer to EC-79, "

System Description".

WITHOUT CONSULT-III

1. Install EVAP service port adapter [commercial service tool: (J-

41413-OBD)] and pressure pump to EVAP service port.

2. Apply battery voltage between the terminals of EVAP canister vent control valve to make a closed EVAP system.

3. To locate the leak, deliver positive pressure to the EVAP system until pressure gauge points reach 1.38 to 2.76 kPa (0.014 to

0.028 kg/cm

2, 0.2 to 0.4 psi).

4. Remove EVAP service port adapter [commercial service tool: (J- 41413-OBD)] and hose with pressure pump.

SEF462UA

SEF200U

SEF462UA

Revision: May 2010 2011 Versa

Page 1809 of 3787

![NISSAN LATIO 2011 Service Repair Manual PREPARATIONEC-515

< SERVICE INFORMATION > [MR18DE]

C

D

E

F

G H

I

J

K L

M A

EC

NP

O

PREPARATION

Special Service ToolINFOID:0000000006341695

The actual shapes of Kent-Moore tools may differ from those o NISSAN LATIO 2011 Service Repair Manual PREPARATIONEC-515

< SERVICE INFORMATION > [MR18DE]

C

D

E

F

G H

I

J

K L

M A

EC

NP

O

PREPARATION

Special Service ToolINFOID:0000000006341695

The actual shapes of Kent-Moore tools may differ from those o](/img/5/57357/w960_57357-1808.png)

PREPARATIONEC-515

< SERVICE INFORMATION > [MR18DE]

C

D

E

F

G H

I

J

K L

M A

EC

NP

O

PREPARATION

Special Service ToolINFOID:0000000006341695

The actual shapes of Kent-Moore tools may differ from those of special service tools illustrated here.

Commercial Service ToolINFOID:0000000006341696

Tool number

(Kent-Moore No.)

Tool name

Description

(J-44321)

Fuel pressure gauge

Kit Checking fuel pressure

(J-44321-6)

Fuel pressure adapter Connecting fuel pressure gauge to quick connec-

tor type fuel lines.

KV10118400

Fuel tube adapter Measuring fuel pressure

LEC642

LBIA0376E

PBIB3043E

Tool number

(Kent-Moore No.)

Tool name Description

Leak detector

i.e.: (J-41416) Locating the EVAP leak

EVAP service port

adapter

i.e.: (J-41413-OBD) Applying positive pressure through EVAP service

port

S-NT703

S-NT704

Revision: May 2010

2011 Versa

Page 1841 of 3787

![NISSAN LATIO 2011 Service Repair Manual ON BOARD DIAGNOSTIC (OBD) SYSTEMEC-547

< SERVICE INFORMATION > [MR18DE]

C

D

E

F

G H

I

J

K L

M A

EC

NP

O

Both 1st trip freeze frame data and freeze frame dat

a (along with the DTCs) are cleared when th NISSAN LATIO 2011 Service Repair Manual ON BOARD DIAGNOSTIC (OBD) SYSTEMEC-547

< SERVICE INFORMATION > [MR18DE]

C

D

E

F

G H

I

J

K L

M A

EC

NP

O

Both 1st trip freeze frame data and freeze frame dat

a (along with the DTCs) are cleared when th](/img/5/57357/w960_57357-1840.png)

ON BOARD DIAGNOSTIC (OBD) SYSTEMEC-547

< SERVICE INFORMATION > [MR18DE]

C

D

E

F

G H

I

J

K L

M A

EC

NP

O

Both 1st trip freeze frame data and freeze frame dat

a (along with the DTCs) are cleared when the ECM mem-

ory is erased. Procedures for clearing the ECM me mory are described in "EMISSION-RELATED DIAGNOS-

TIC INFORMATION ITEMS".

SYSTEM READINESS TEST (SRT) CODE

System Readiness Test (SRT) code is specified in Service $01 of SAE J1979/ISO 15031-5.

As part of an enhanced emissions test for Inspection & Ma intenance (I/M), certain states require the status of

SRT be used to indicate whether the ECM has comple ted self-diagnosis of major emission systems and com-

ponents. Completion must be verified in order for the emissions inspection to proceed.

If a vehicle is rejected for a State emissions inspection due to one or more SRT items indicating “INCMP”, use

the information in this Service Manual to set the SRT to “CMPLT”.

In most cases the ECM will automatically complete its self-diagnosis cycle during normal usage, and the SRT

status will indicate “CMPLT” for each application system. Once set as “CMPLT”, the SRT status remains

“CMPLT” until the self-diagnosis memory is erased.

Occasionally, certain portions of the self-diagnostic test may not be completed as a result of the customer's

normal driving pattern; the SRT will indicate “INCMP” for these items.

NOTE:

The SRT will also indicate “INCMP” if the self-diagnosis memory is erased for any reason or if the ECM mem-

ory power supply is interrupted for several hours.

If, during the state emissions inspection, the SRT indicates “CMPLT” for all test items, the inspector will con-

tinue with the emissions test. However, if the SRT i ndicates “INCMP” for one or more of the SRT items the

vehicle is returned to the customer untested.

NOTE:

If permanent DTC is stored or MIL illuminates during the state emissions inspection, the vehicle is also

returned to the customer untested even though the SRT indicates “CMPLT” for all test items. Therefore, it is

important to check SRT (“CMPLT ”), DTC (No DTCs) and permanent DT C (No permanent DTCs) before the

inspection.

SRT Item

The table below shows required self-diagnostic items to set the SRT to “CMPLT”.

*: If completion of several SRTs is required, perform driving patterns (DTC confirmation procedure), one by one based on the pr iority for

models with CONSULT-III.

SRT Set Timing

SRT is set as “CMPLT” after self-diagnosis has been performed one or more times. Completion of SRT is

done regardless of whether the result is OK or NG. T he set timing is different between OK and NG results and

is shown in the table below.

SRT item

(CONSULT-III indica- tion) Perfor-

mance

Priority* Required self-diagnostic items to set the SRT to “CMPLT” Corresponding DTC No.

CATALYST 2 Three way catalyst function P0420

EVAP SYSTEM 2 EVAP control system purge flow monitoring P0441

1 EVAP control system P0442

2 EVAP control system P0456

HO2S 2 Air fuel ratio (A/F) sensor 1 —

Heated oxygen sensor 2 P0137

Heated oxygen sensor 2 P0138

Heated oxygen sensor 2 P0139

EGR/VVT SYSTEM 3 Intake value timing control function P0011

Self-diagnosis resultExample

Diagnosis Ignition cycle

← ON → OFF ← ON → OFF ← ON → OFF ← ON →

Revision: May 2010 2011 Versa

Page 1847 of 3787

![NISSAN LATIO 2011 Service Repair Manual ON BOARD DIAGNOSTIC (OBD) SYSTEMEC-553

< SERVICE INFORMATION > [MR18DE]

C

D

E

F

G H

I

J

K L

M A

EC

NP

O

Suggested Maximum Speed in Each Gear

Downshift to a lower gear if the engine is not running smoo NISSAN LATIO 2011 Service Repair Manual ON BOARD DIAGNOSTIC (OBD) SYSTEMEC-553

< SERVICE INFORMATION > [MR18DE]

C

D

E

F

G H

I

J

K L

M A

EC

NP

O

Suggested Maximum Speed in Each Gear

Downshift to a lower gear if the engine is not running smoo](/img/5/57357/w960_57357-1846.png)

ON BOARD DIAGNOSTIC (OBD) SYSTEMEC-553

< SERVICE INFORMATION > [MR18DE]

C

D

E

F

G H

I

J

K L

M A

EC

NP

O

Suggested Maximum Speed in Each Gear

Downshift to a lower gear if the engine is not running smoothly, or if you need to accelerate.

Do not exceed the maximum suggested speed (shown below) in any gear. For level road driving, use the high-

est gear suggested for that speed. Always observe post

ed speed limits and drive according to the road condi-

tions to ensure safe operation. Do not over-rev t he engine when shifting to a lower gear as it may cause

engine damage or loss of vehicle control.

PERMANENT DIAGNOSTIC TROU BLE CODE (PERMANENT DTC)

Permanent DTC is defined in SAE J1979/ISO 15031-5 Service $0A.

ECM stores a DTC issuing a command of turning on MIL as a permanent DTC and keeps storing the DTC as

a permanent DTC until ECM judges that there is no presence of malfunction.

Permanent DTCs cannot be erased by using the Erase function of CONSULT-III or Generic Scan Tool (GST)

and by disconnecting the battery to shut off power to EC M. This prevents a vehicle from passing the state

emission inspection without repairing a malfunctioning part.

When not passing the state emission inspection due to more than one permanent DTC, permanent DTCs

should be erased, referring to this manual.

NOTE:

• The important items in state emission inspection are t hat MIL is not ON, SRT test items are set, and perma-

nent DTCs are not included.

• Permanent DTCs do not apply for regions that permanent DTCs are not regulated by law.

Permanent DTC Item

For permanent DTC items, MIL turns ON. Refer to EC-542, "Emission-related Diagnostic Information", “EMIS-

SION-RELATED DIAGNOSTIC INFORMATION ITEMS”.

Permanent DTC Set Timing

The setting timing of permanent DTC is stored in ECM with the lighting of MIL when a DTC is confirmed.

Permanent DTC Service Procedure

For normal acceleration in low alti-

tude areas

[less than 1,219 m (4,000 ft)]: For quick acceleration in low alti-

tude areas For high attitude areas

[over 1,219m (4,000 ft)]:

Gear change ACCEL shift point km/h (MPH) km/h (MPH)km/h (MPH)

1st to 2nd 13 (8)24 (15) 24 (15)

2nd to 3rd 27 (17)40 (25)40 (25)

3rd to 4th 40 (25)53 (33)65 (40)

4th to 5th 58 (36)71 (44)72 (45)

5th to 6th 82 (51)82 (51)82 (51)

Gear km/h (MPH)

1st 50 (30)

2nd 90 (55)

3rd —

4th —

5th —

6th —

Revision: May 2010 2011 Versa