torque NISSAN LATIO 2011 Service Manual PDF

[x] Cancel search | Manufacturer: NISSAN, Model Year: 2011, Model line: LATIO, Model: NISSAN LATIO 2011Pages: 3787, PDF Size: 78.35 MB

Page 311 of 3787

AT-294

< SERVICE INFORMATION >

REPAIR FOR COMPONENT PARTS

• Wrap a small suitable tool (A) with vinyl tape and use it to insertvalves into their proper positions.

• Install retainer plates (1).

- While pushing plug or return spring, install retainer plate (1) using a suitable tool (A).

1-2 Accumulator Valve

• Install 1-2 accumulator valve (1), 1-2 accumulator valve spring and

plug. Align 1-2 accumulator retainer plate (2) from opposite side of

control valve body.

• Install 1-2 accumulator valve piston spring (3), 1-2 accumulator

piston (4), plug (5) and retainer plate (6).

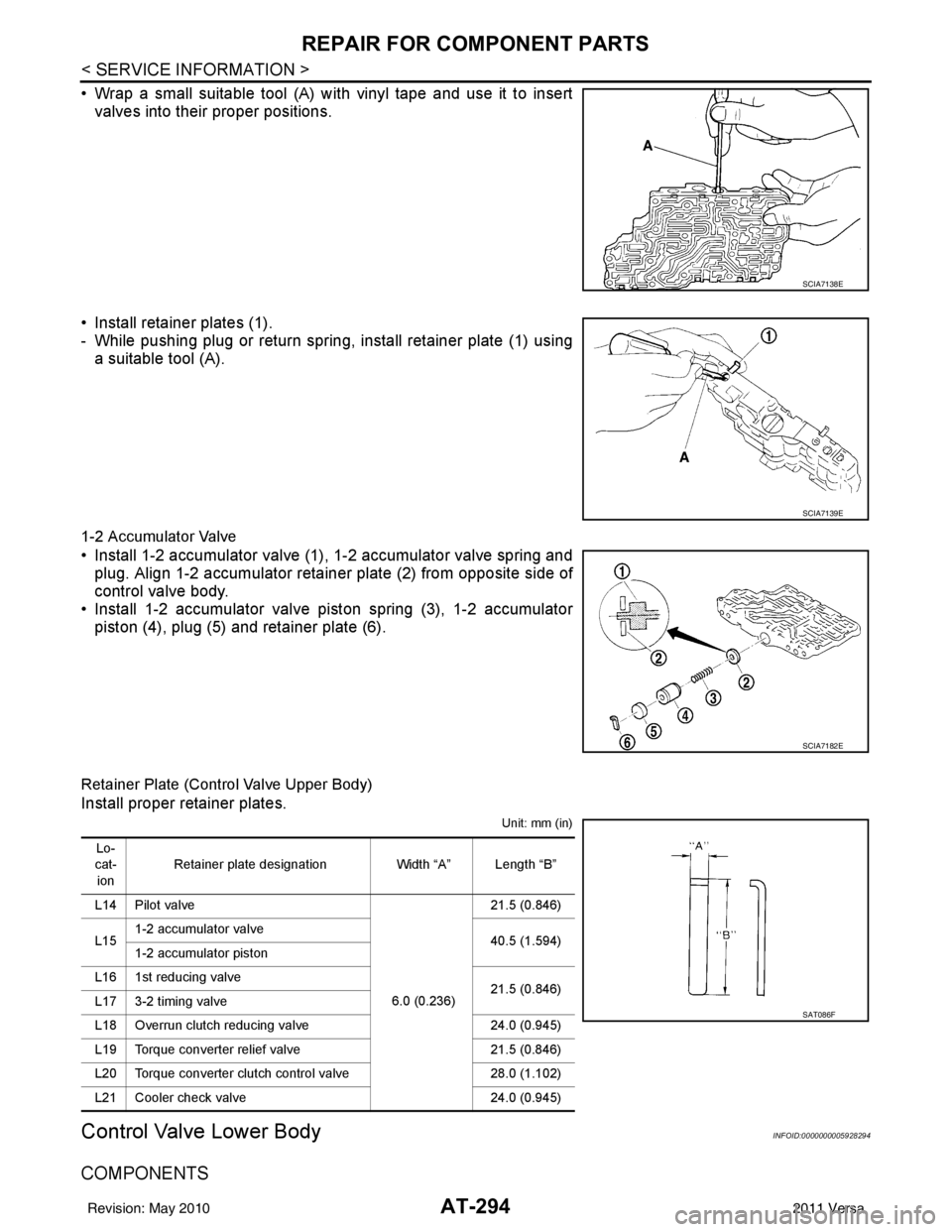

Retainer Plate (Control Valve Upper Body)

Install proper retainer plates.

Unit: mm (in)

Control Valve Lower BodyINFOID:0000000005928294

COMPONENTS

SCIA7138E

SCIA7139E

SCIA7182E

Lo-

cat-

ion Retainer plate designation

Width “A” Length “B”

L14 Pilot valve

6.0 (0.236)21.5 (0.846)

L15 1-2 accumulator valve

40.5 (1.594)

1-2 accumulator piston

L16 1st reducing valve 21.5 (0.846)

L17 3-2 timing valve

L18 Overrun clutch reducing valve 24.0 (0.945)

L19 Torque converter relief valve 21.5 (0.846)

L20 Torque converter clutch control valve 28.0 (1.102)

L21 Cooler check valve 24.0 (0.945)

SAT086F

Revision: May 2010 2011 Versa

Page 360 of 3787

REPAIR FOR COMPONENT PARTSAT-343

< SERVICE INFORMATION >

DE

F

G H

I

J

K L

M A

B

AT

N

O P

i. Set Tool (A) on differential side bearing (RH side) (1), and press differential side bearing (RH side) to differential case (2)

CAUTION:

Set Tool (A) on differential side bearing inner race.

Apply ATF to differential side bearings.

ii. Set Tool (A) on differential side bearing (LH side) (1), and press differential side bearing (LH side) to differential case (2)

CAUTION:

Set Tool (A) on differential side bearing inner race.

Apply ATF to differential side bearings.

b. MR18DE engine models

i. Set suitable tool (A) on differential side bearing inner race, and press differential side bearing inner race into differential case.

CAUTION:

Set Tool on differential side bearing inner race.

Apply ATF to differential side bearings.

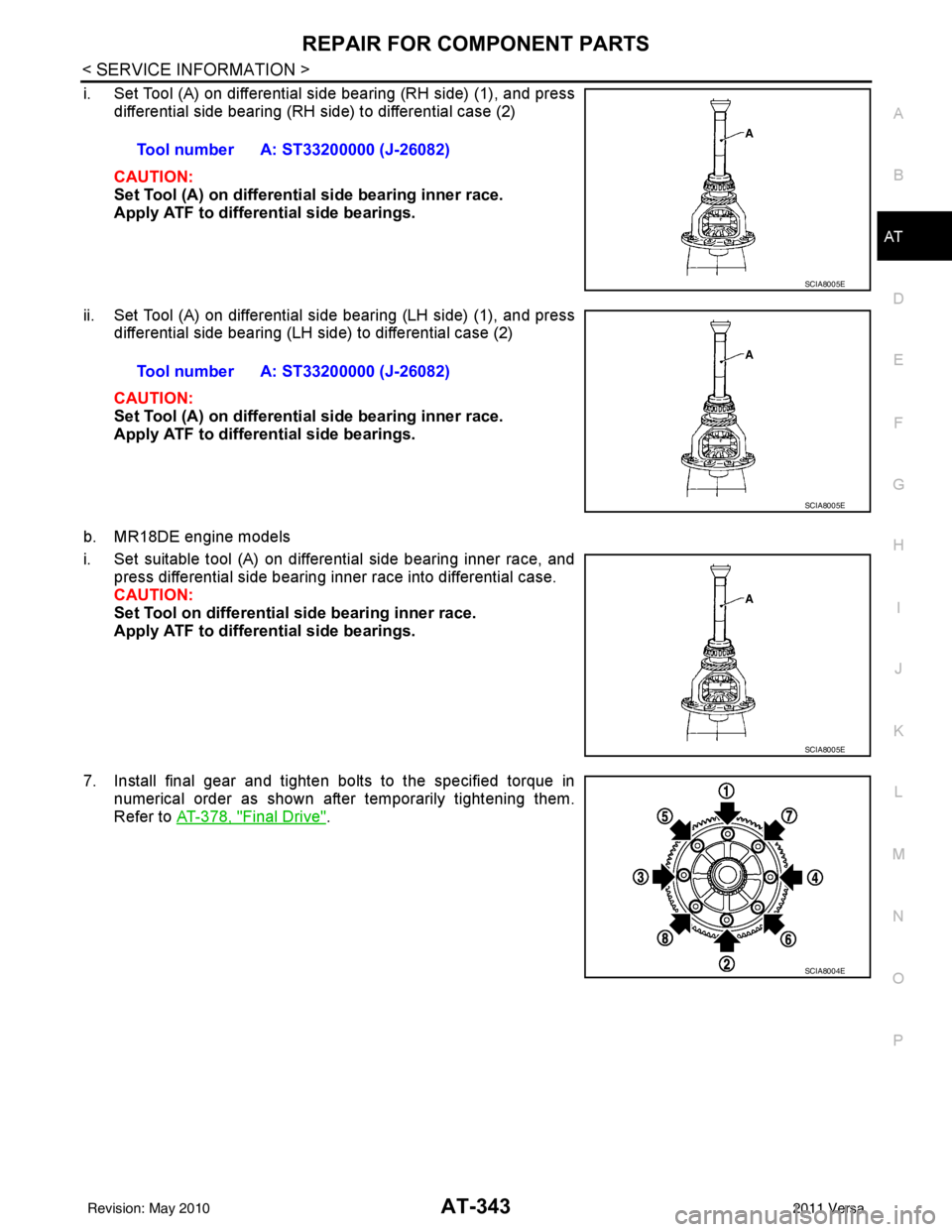

7. Install final gear and tighten bolts to the specified torque in numerical order as shown after temporarily tightening them.

Refer to AT-378, "

Final Drive".

Tool number A: ST33200000 (J-26082)

SCIA8005E

Tool number A: ST33200000 (J-26082)

SCIA8005E

SCIA8005E

SCIA8004E

Revision: May 2010

2011 Versa

Page 361 of 3787

AT-344

< SERVICE INFORMATION >

ASSEMBLY

ASSEMBLY

Assembly (1)INFOID:0000000005928303

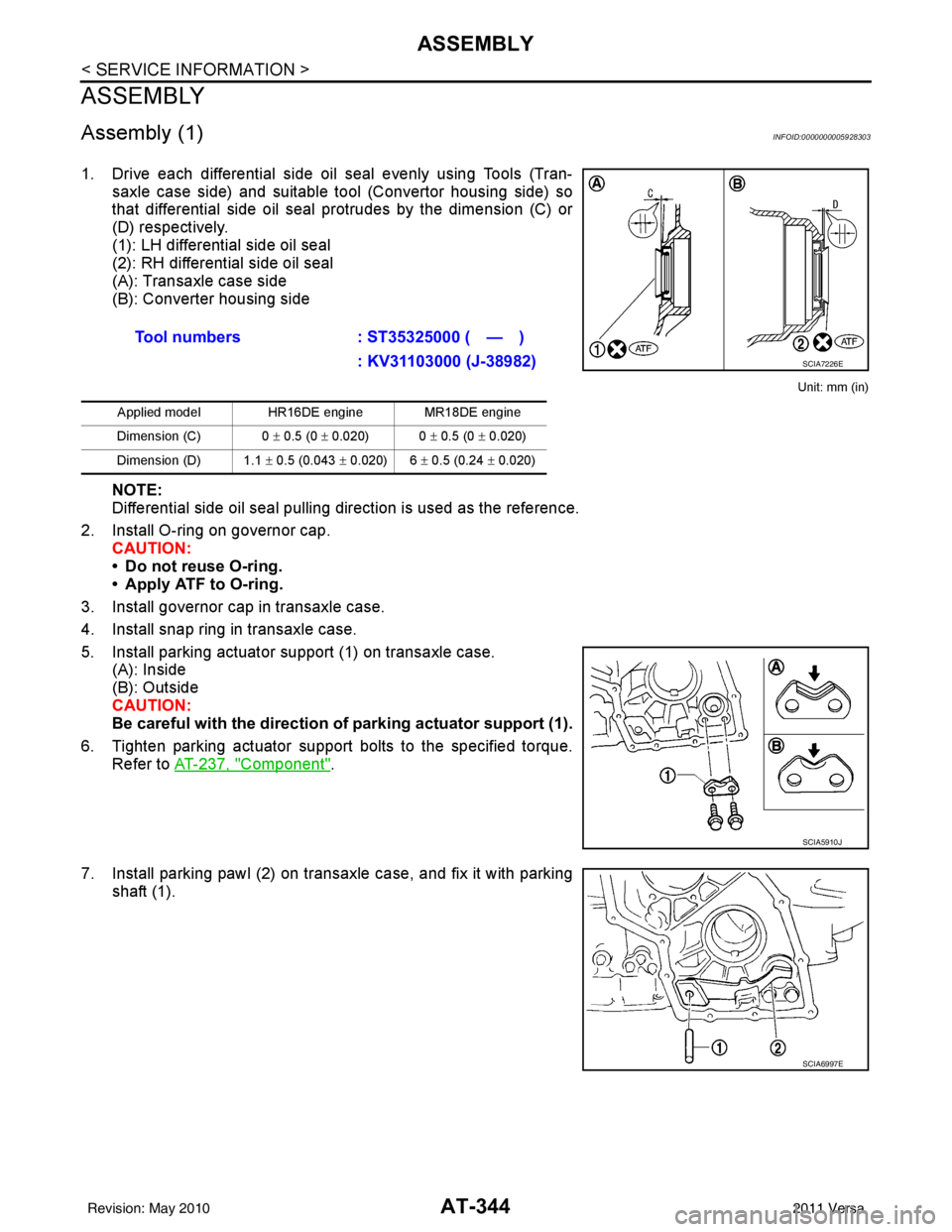

1. Drive each differential side oil seal evenly using Tools (Tran-saxle case side) and suitable tool (Convertor housing side) so

that differential side oil seal protrudes by the dimension (C) or

(D) respectively.

(1): LH differential side oil seal

(2): RH differential side oil seal

(A): Transaxle case side

(B): Converter housing side

Unit: mm (in)

NOTE:

Differential side oil seal pulling direction is used as the reference.

2. Install O-ring on governor cap. CAUTION:

• Do not reuse O-ring.

• Apply ATF to O-ring.

3. Install governor cap in transaxle case.

4. Install snap ring in transaxle case.

5. Install parking actuator support (1) on transaxle case. (A): Inside

(B): Outside

CAUTION:

Be careful with the direction of parking actuator support (1).

6. Tighten parking actuator support bolts to the specified torque. Refer to AT-237, "

Component".

7. Install parking pawl (2) on transaxle case, and fix it with parking shaft (1).Tool numbers

: ST35325000 ( — )

: KV31103000 (J-38982)

Applied model HR16DE engine MR18DE engine

Dimension (C) 0 ± 0.5 (0 ± 0.020) 0 ± 0.5 (0 ± 0.020)

Dimension (D) 1.1 ± 0.5 (0.043 ± 0.020) 6 ± 0.5 (0.24 ± 0.020)

SCIA7226E

SCIA5910J

SCIA6997E

Revision: May 2010 2011 Versa

Page 363 of 3787

AT-346

< SERVICE INFORMATION >

ASSEMBLY

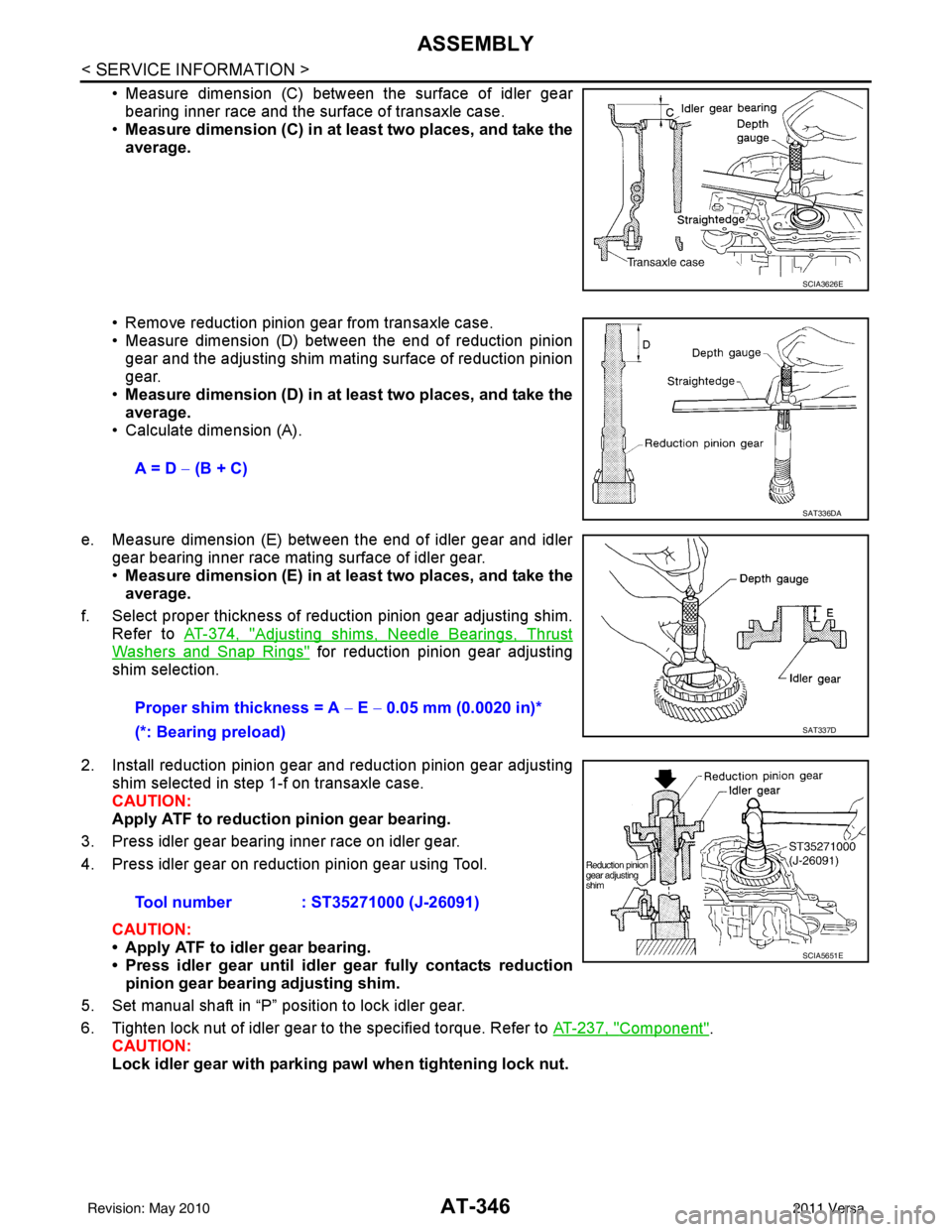

• Measure dimension (C) between the surface of idler gearbearing inner race and the surface of transaxle case.

• Measure dimension (C) in at least two places, and take the

average.

• Remove reduction pinion gear from transaxle case.

• Measure dimension (D) between the end of reduction pinion gear and the adjusting shim mating surface of reduction pinion

gear.

• Measure dimension (D) in at least two places, and take the

average.

• Calculate dimension (A).

e. Measure dimension (E) between the end of idler gear and idler gear bearing inner race mating surface of idler gear.

•Measure dimension (E) in at least two places, and take the

average.

f. Select proper thickness of reduction pinion gear adjusting shim. Refer to AT-374, "

Adjusting shims, Needle Bearings, Thrust

Washers and Snap Rings" for reduction pinion gear adjusting

shim selection.

2. Install reduction pinion gear and reduction pinion gear adjusting shim selected in step 1-f on transaxle case.

CAUTION:

Apply ATF to reduction pinion gear bearing.

3. Press idler gear bearing inner race on idler gear.

4. Press idler gear on reduction pinion gear using Tool.

CAUTION:

• Apply ATF to idler gear bearing.

• Press idler gear until idler gear fully contacts reduction

pinion gear bearing adjusting shim.

5. Set manual shaft in “P” position to lock idler gear.

6. Tighten lock nut of idler gear to the specified torque. Refer to AT-237, "

Component".

CAUTION:

Lock idler gear with parking pawl when tightening lock nut.

SCIA3626E

A = D − (B + C)

SAT336DA

Proper shim thickness = A − E − 0.05 mm (0.0020 in)*

(*: Bearing preload)

SAT337D

Tool number : ST35271000 (J-26091)

SCIA5651E

Revision: May 2010 2011 Versa

Page 364 of 3787

ASSEMBLYAT-347

< SERVICE INFORMATION >

DE

F

G H

I

J

K L

M A

B

AT

N

O P

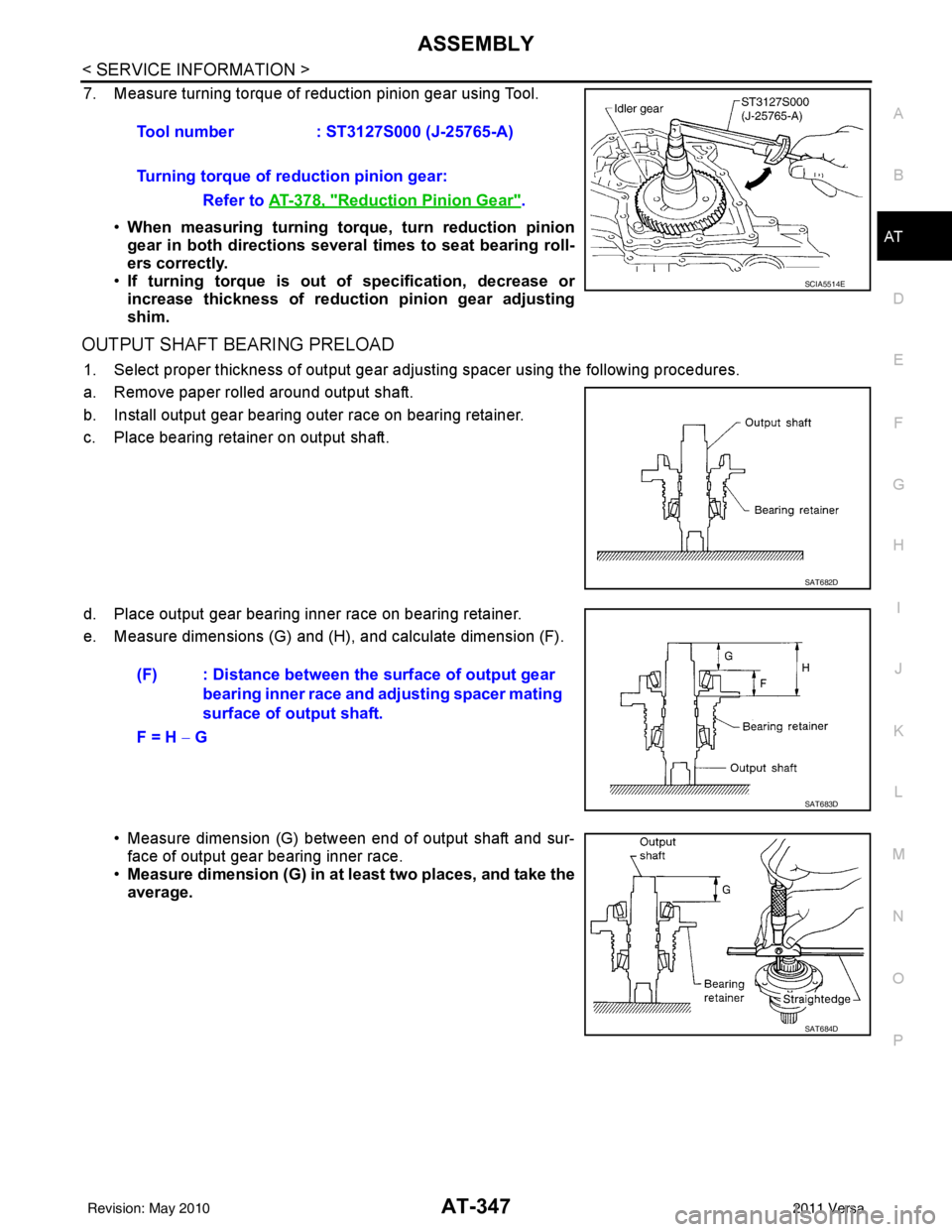

7. Measure turning torque of reduction pinion gear using Tool.

•When measuring turning torq ue, turn reduction pinion

gear in both directions several times to seat bearing roll-

ers correctly.

• If turning torque is out of specification, decrease or

increase thickness of reductio n pinion gear adjusting

shim.

OUTPUT SHAFT BEARING PRELOAD

1. Select proper thickness of output gear adjusting spacer using the following procedures.

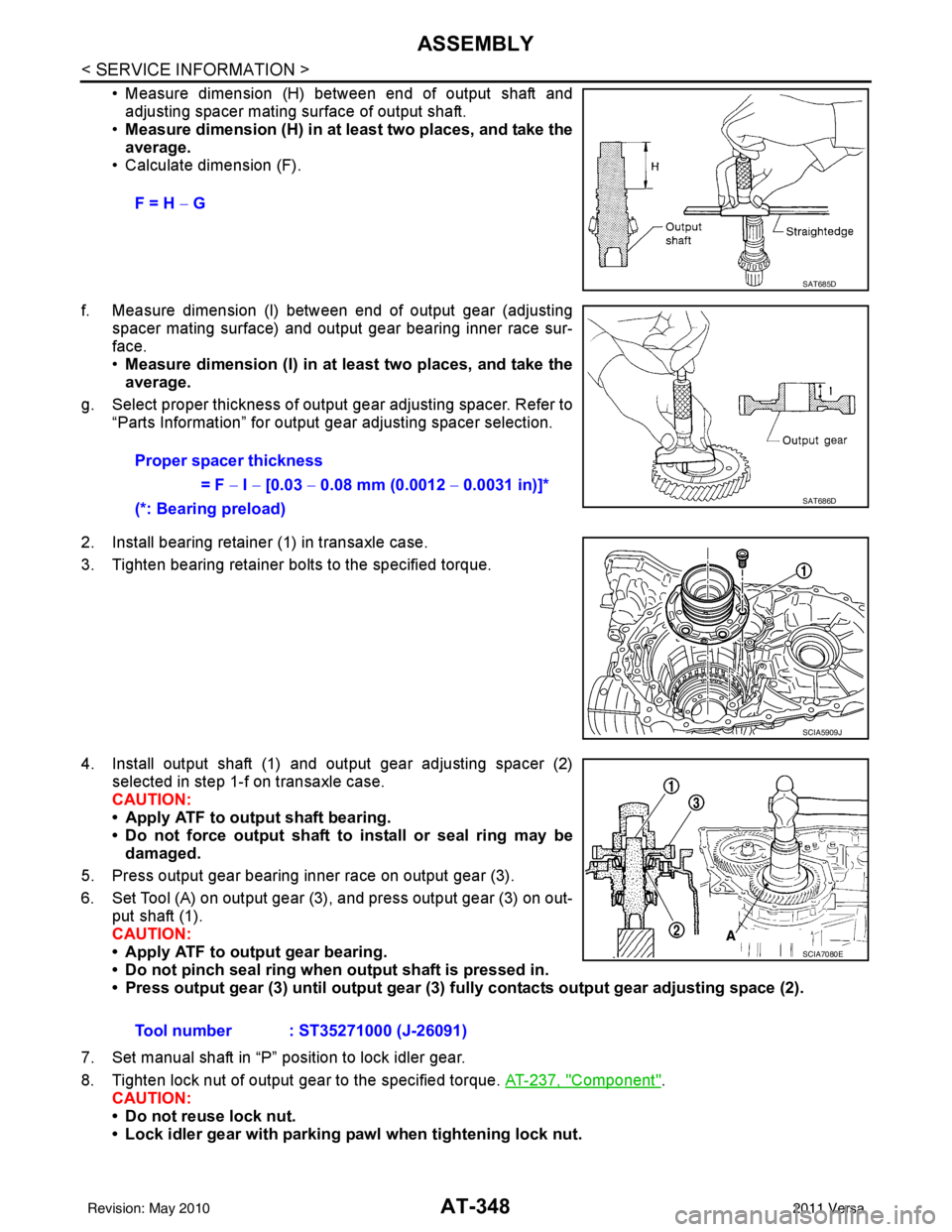

a. Remove paper rolled around output shaft.

b. Install output gear bearing outer race on bearing retainer.

c. Place bearing retainer on output shaft.

d. Place output gear bearing inner race on bearing retainer.

e. Measure dimensions (G) and (H ), and calculate dimension (F).

• Measure dimension (G) betw een end of output shaft and sur-

face of output gear bearing inner race.

• Measure dimension (G) in at least two places, and take the

average.Tool number

: ST3127S000 (J-25765-A)

Turning torque of reduction pinion gear: Refer to AT-378, "

Reduction Pinion Gear".

SCIA5514E

SAT682D

(F) : Distance between the surface of output gear bearing inner race and adjusting spacer mating

surface of output shaft.

F = H − G

SAT683D

SAT684D

Revision: May 2010 2011 Versa

Page 365 of 3787

AT-348

< SERVICE INFORMATION >

ASSEMBLY

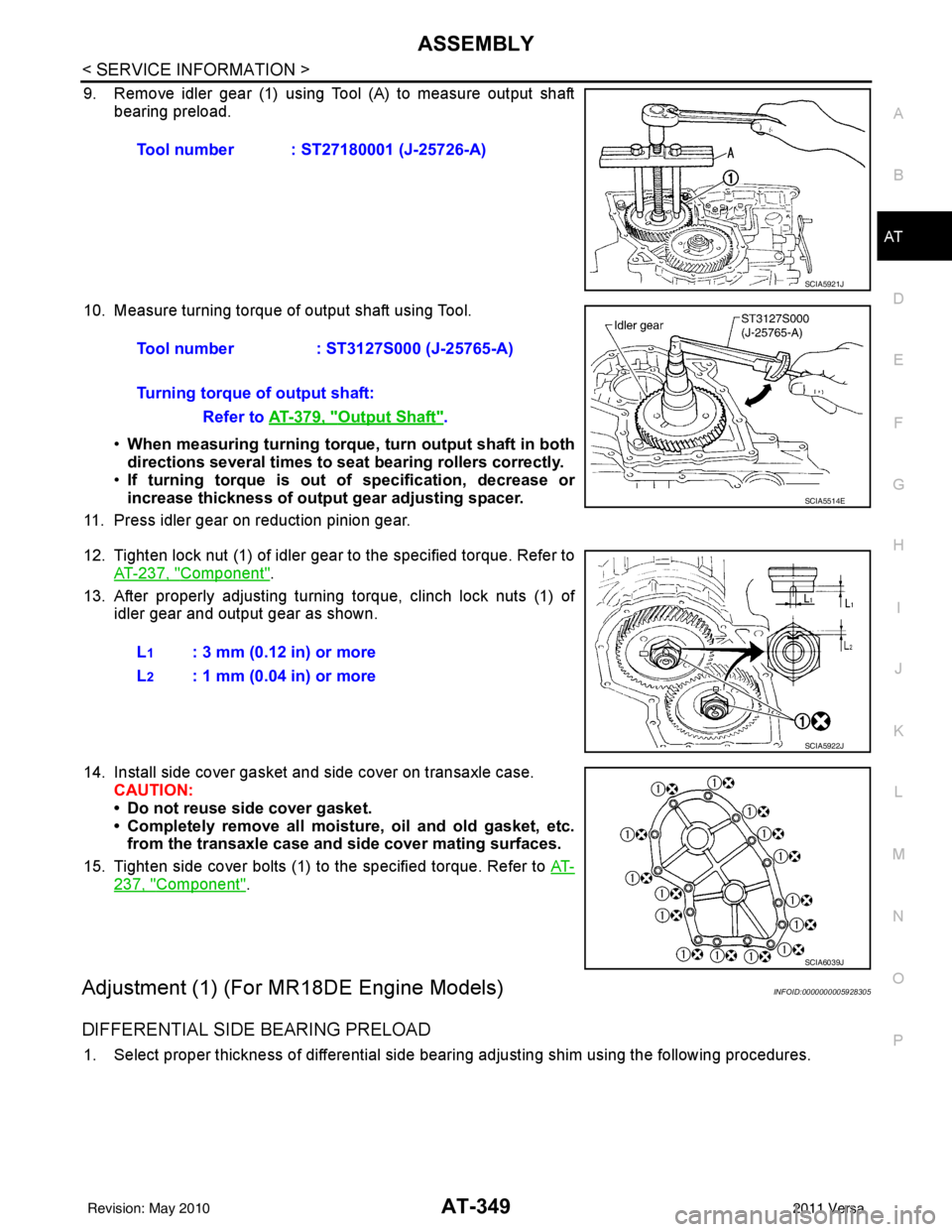

• Measure dimension (H) between end of output shaft andadjusting spacer mating surface of output shaft.

• Measure dimension (H) in at least two places, and take the

average.

• Calculate dimension (F).

f. Measure dimension (I) between end of output gear (adjusting spacer mating surface) and output gear bearing inner race sur-

face.

•Measure dimension (I) in at least two places, and take the

average.

g. Select proper thickness of output gear adjusting spacer. Refer to “Parts Information” for output gear adjusting spacer selection.

2. Install bearing retainer (1) in transaxle case.

3. Tighten bearing retainer bolts to the specified torque.

4. Install output shaft (1) and output gear adjusting spacer (2) selected in step 1-f on transaxle case.

CAUTION:

• Apply ATF to output shaft bearing.

• Do not force output shaft to install or seal ring may be

damaged.

5. Press output gear bearing inner race on output gear (3).

6. Set Tool (A) on output gear (3), and press output gear (3) on out- put shaft (1).

CAUTION:

• Apply ATF to output gear bearing.

• Do not pinch seal ring when output shaft is pressed in.

• Press output gear (3) until output gear (3) fully contacts output gear adjusting space (2).

7. Set manual shaft in “P” position to lock idler gear.

8. Tighten lock nut of output gear to the specified torque. AT-237, "

Component".

CAUTION:

• Do not reuse lock nut.

• Lock idler gear with parking pawl when tightening lock nut. F = H −

G

SAT685D

Proper spacer thickness

= F − I − [0.03 − 0.08 mm (0.0012 − 0.0031 in)]*

(*: Bearing preload)

SAT686D

SCIA5909J

Tool number : ST35271000 (J-26091)

SCIA7080E

Revision: May 2010 2011 Versa

Page 366 of 3787

ASSEMBLYAT-349

< SERVICE INFORMATION >

DE

F

G H

I

J

K L

M A

B

AT

N

O P

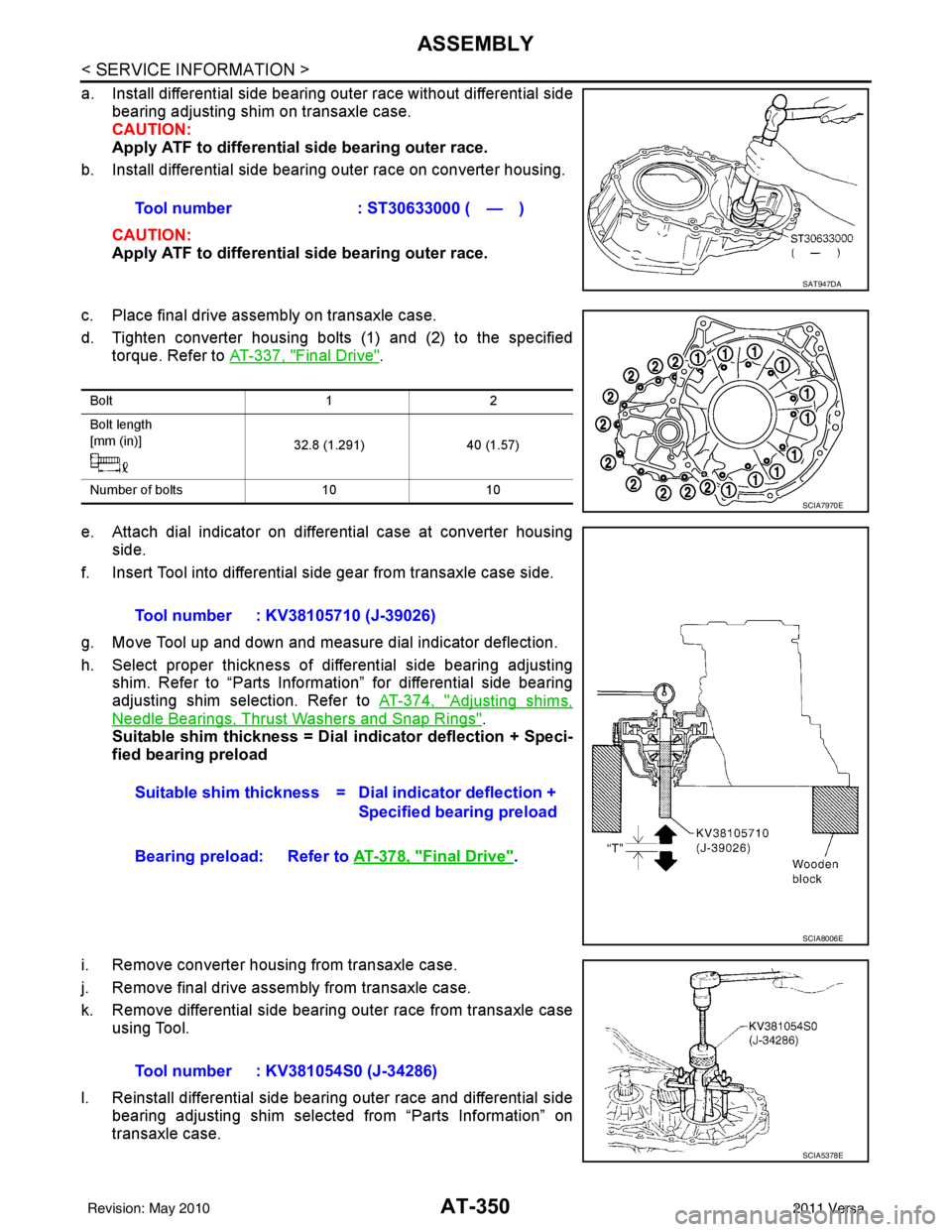

9. Remove idler gear (1) using Tool (A) to measure output shaft bearing preload.

10. Measure turning torque of output shaft using Tool. •When measuring turning torque , turn output shaft in both

directions several times to seat bearing rollers correctly.

• If turning torque is out of specification, decrease or

increase thickness of output gear adjusting spacer.

11. Press idler gear on reduction pinion gear.

12. Tighten lock nut (1) of idler gear to the specified torque. Refer to AT-237, "

Component".

13. After properly adjusting turning torque, clinch lock nuts (1) of idler gear and output gear as shown.

14. Install side cover gasket and side cover on transaxle case. CAUTION:

• Do not reuse side cover gasket.

• Completely remove all moistu re, oil and old gasket, etc.

from the transaxle case and side cover mating surfaces.

15. Tighten side cover bolts (1) to the specified torque. Refer to AT-

237, "Component".

Adjustment (1) (For MR18DE Engine Models)INFOID:0000000005928305

DIFFERENTIAL SIDE BEARING PRELOAD

1. Select proper thickness of differential side bearing adjusting shim using the following procedures.Tool number : ST27180001 (J-25726-A)

SCIA5921J

Tool number

: ST3127S000 (J-25765-A)

Turning torque of output shaft: Refer to AT-379, "

Output Shaft".

SCIA5514E

L1: 3 mm (0.12 in) or more

L

2: 1 mm (0.04 in) or more

SCIA5922J

SCIA6039J

Revision: May 2010 2011 Versa

Page 367 of 3787

AT-350

< SERVICE INFORMATION >

ASSEMBLY

a. Install differential side bearing outer race without differential sidebearing adjusting shim on transaxle case.

CAUTION:

Apply ATF to differential side bearing outer race.

b. Install differential side bearing outer race on converter housing.

CAUTION:

Apply ATF to differential side bearing outer race.

c. Place final drive assembly on transaxle case.

d. Tighten converter housing bolts (1) and (2) to the specified torque. Refer to AT-337, "

Final Drive".

e. Attach dial indicator on differential case at converter housing side.

f. Insert Tool into differential side gear from transaxle case side.

g. Move Tool up and down and measure dial indicator deflection.

h. Select proper thickness of differential side bearing adjusting shim. Refer to “Parts Information” for differential side bearing

adjusting shim selection. Refer to AT-374, "

Adjusting shims,

Needle Bearings, Thrust Washers and Snap Rings".

Suitable shim thickness = Dial indicator deflection + Speci-

fied bearing preload

i. Remove converter housing from transaxle case.

j. Remove final drive assembly from transaxle case.

k. Remove differential side bearing outer race from transaxle case using Tool.

l. Reinstall differential side bearing outer race and differential side bearing adjusting shim selected from “Parts Information” on

transaxle case.Tool number : ST30633000 ( — )

SAT947DA

Bolt

12

Bolt length

[mm (in)] 32.8 (1.291)40 (1.57)

Number of bolts 1010

SCIA7970E

Tool number : KV38105710 (J-39026)

Suitable shim thickness = D ial indicator deflection +

Specified bearing preload

Bearing preload: Refer to AT-378, "

Final Drive".

SCIA8006E

Tool number : KV381054S0 (J-34286)

SCIA5378E

Revision: May 2010 2011 Versa

Page 368 of 3787

ASSEMBLYAT-351

< SERVICE INFORMATION >

DE

F

G H

I

J

K L

M A

B

AT

N

O P

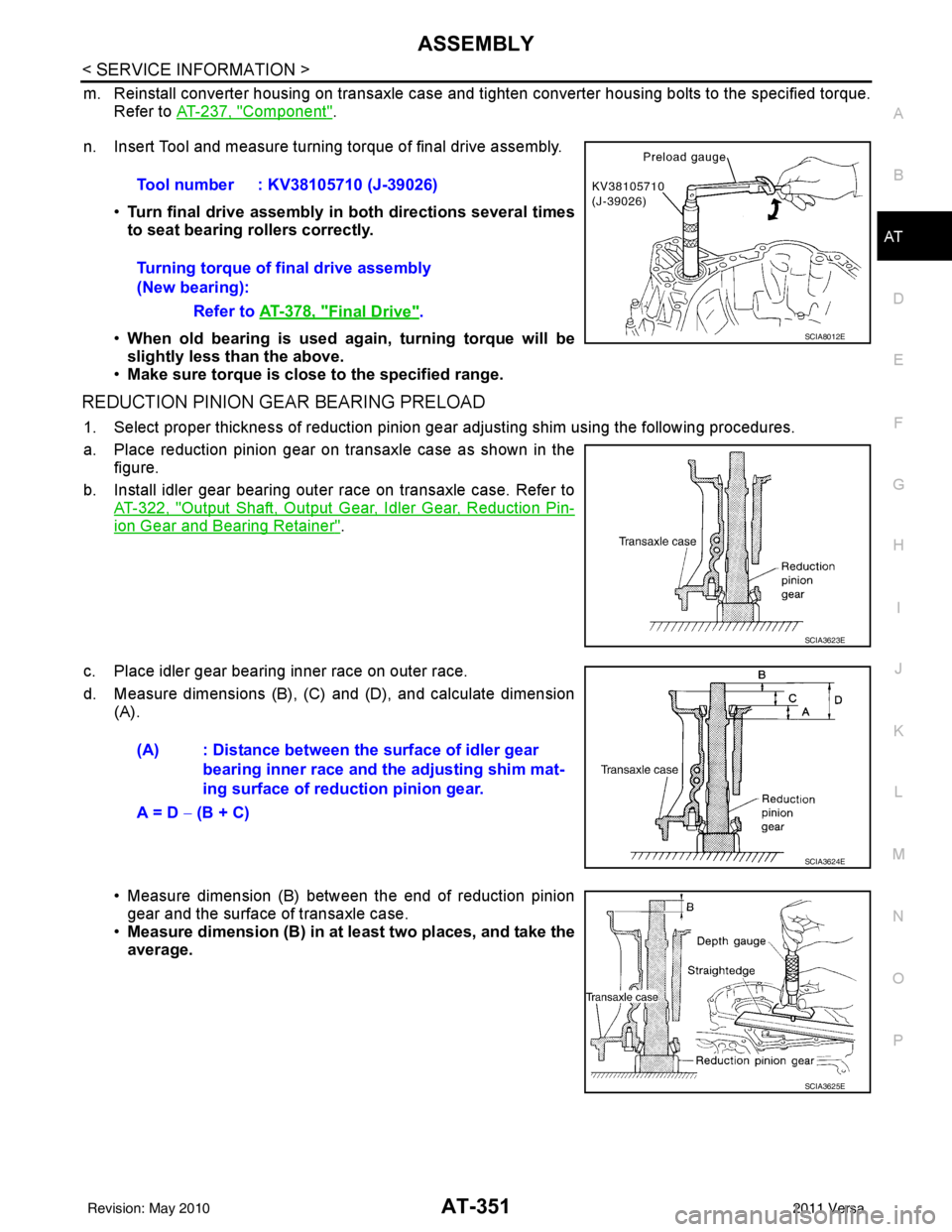

m. Reinstall converter housing on transaxle case and ti ghten converter housing bolts to the specified torque.

Refer to AT-237, "

Component".

n. Insert Tool and measure turning torque of final drive assembly.

•Turn final drive assembly in both directions several times

to seat bearing rollers correctly.

• When old bearing is used ag ain, turning torque will be

slightly less than the above.

• Make sure torque is close to the specified range.

REDUCTION PINION GEAR BEARING PRELOAD

1. Select proper thickness of reduction pinion gear adjusting shim using the following procedures.

a. Place reduction pinion gear on transaxle case as shown in the figure.

b. Install idler gear bearing outer race on transaxle case. Refer to AT-322, "

Output Shaft, Output Gear, Idler Gear, Reduction Pin-

ion Gear and Bearing Retainer".

c. Place idler gear bearing inner race on outer race.

d. Measure dimensions (B), (C) and (D), and calculate dimension (A).

• Measure dimension (B) between the end of reduction pinion

gear and the surface of transaxle case.

• Measure dimension (B) in at least two places, and take the

average.Tool number : KV38105710 (J-39026)

Turning torque of final drive assembly

(New bearing):

Refer to AT-378, "

Final Drive".

SCIA8012E

SCIA3623E

(A) : Distance between the surface of idler gear

bearing inner race and th e adjusting shim mat-

ing surface of reduction pinion gear.

A = D − (B + C)

SCIA3624E

SCIA3625E

Revision: May 2010 2011 Versa

Page 369 of 3787

AT-352

< SERVICE INFORMATION >

ASSEMBLY

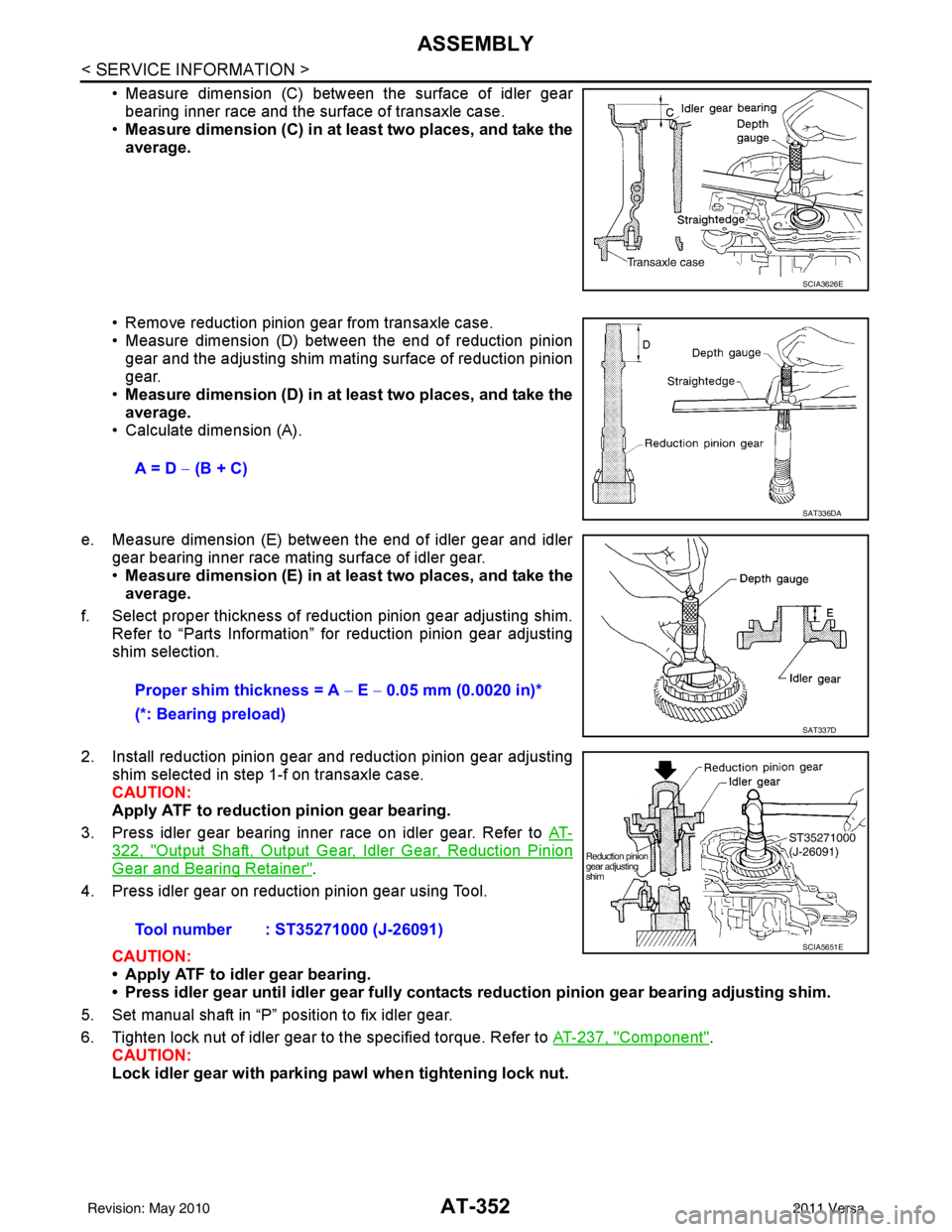

• Measure dimension (C) between the surface of idler gearbearing inner race and the surface of transaxle case.

• Measure dimension (C) in at least two places, and take the

average.

• Remove reduction pinion gear from transaxle case.

• Measure dimension (D) between the end of reduction pinion gear and the adjusting shim mating surface of reduction pinion

gear.

• Measure dimension (D) in at least two places, and take the

average.

• Calculate dimension (A).

e. Measure dimension (E) between the end of idler gear and idler gear bearing inner race mating surface of idler gear.

•Measure dimension (E) in at least two places, and take the

average.

f. Select proper thickness of reduction pinion gear adjusting shim. Refer to “Parts Information” for reduction pinion gear adjusting

shim selection.

2. Install reduction pinion gear and reduction pinion gear adjusting shim selected in step 1-f on transaxle case.

CAUTION:

Apply ATF to reduction pinion gear bearing.

3. Press idler gear bearing inner race on idler gear. Refer to AT-

322, "Output Shaft, Output Gear, Idler Gear, Reduction Pinion

Gear and Bearing Retainer".

4. Press idler gear on reduction pinion gear using Tool.

CAUTION:

• Apply ATF to idler gear bearing.

• Press idler gear until idler gear fully contacts reduction pinion gear bearing adjusting shim.

5. Set manual shaft in “P” position to fix idler gear.

6. Tighten lock nut of idler gear to the specified torque. Refer to AT-237, "

Component".

CAUTION:

Lock idler gear with parking pawl when tightening lock nut.

SCIA3626E

A = D − (B + C)

SAT336DA

Proper shim thickness = A − E − 0.05 mm (0.0020 in)*

(*: Bearing preload)

SAT337D

Tool number : ST35271000 (J-26091)SCIA5651E

Revision: May 2010 2011 Versa