service NISSAN NAVARA 2005 Repair Owners Manual

[x] Cancel search | Manufacturer: NISSAN, Model Year: 2005, Model line: NAVARA, Model: NISSAN NAVARA 2005Pages: 3171, PDF Size: 49.59 MB

Page 825 of 3171

![NISSAN NAVARA 2005 Repair Owners Manual PRECAUTIONS

BRC-3

[ABS]

C

D

E

G

H

I

J

K

L

MA

B

BRC

[ABS]PRECAUTIONSPFP:00001

Precautions for Supplemental Restraint System (SRS) “AIR BAG” and “SEAT

BELT PRE-TENSIONER”

EFS006DM

The Supplement NISSAN NAVARA 2005 Repair Owners Manual PRECAUTIONS

BRC-3

[ABS]

C

D

E

G

H

I

J

K

L

MA

B

BRC

[ABS]PRECAUTIONSPFP:00001

Precautions for Supplemental Restraint System (SRS) “AIR BAG” and “SEAT

BELT PRE-TENSIONER”

EFS006DM

The Supplement](/img/5/57362/w960_57362-824.png)

PRECAUTIONS

BRC-3

[ABS]

C

D

E

G

H

I

J

K

L

MA

B

BRC

[ABS]PRECAUTIONSPFP:00001

Precautions for Supplemental Restraint System (SRS) “AIR BAG” and “SEAT

BELT PRE-TENSIONER”

EFS006DM

The Supplemental Restraint System such as “AIR BAG” and “SEAT BELT PRE-TENSIONER”, used along

with a front seat belt, helps to reduce the risk or severity of injury to the driver and front passenger for certain

types of collision. Information necessary to service the system safely is included in the SRS and SB section of

this Service Manual.

WARNING:

lTo avoid rendering the SRS inoperative, which could increase the risk of personal injury or death

in the event of a collision which would result in air bag inflation, all maintenance must be per-

formed by an authorized NISSAN/INFINITI dealer.

lImproper maintenance, including incorrect removal and installation of the SRS, can lead to per-

sonal injury caused by unintentional activation of the system. For removal of Spiral Cable and Air

Bag Module, see the SRS section.

lDo not use electrical test equipment on any circuit related to the SRS unless instructed to in this

Service Manual. SRS wiring harnesses can be identified by yellow and/or orange harnesses or

harness connectors.

Precautions for Brake SystemEFS005TG

lRecommended fluid is brake fluid “DOT 3” or “DOT 4”.

lNever reuse drained brake fluid.

lBe careful not to splash brake fluid on painted areas.If brake fluid is splashed, wipe it off and flush area

with water immediately.

lNever use mineral oils such as gasoline or kerosene. They will ruin rubber parts of the hydraulic system.

lUse flare nut wrench when removing flare nuts, and use a flare

nut torque wrench when tighten flare nuts.

lBrake system is an important safety part.If a brake fluid leak is

detected, always disassemble the affected part.If a malfunction

is detected, replace part with new one.

lBefore working, turn ignition switch OFF and disconnect con-

nector of ABS actuator and electric unit (control unit) or the bat-

tery cables.

lWhen installing brake tube and hose, be sure to torque.

WARNING:

Clean brake pads and shoes with a waster cloth, then wipe with

a dust collector.

Precautions for Brake ControlEFS005TH

lJust after starting vehicle after ignition switch ON, brake pedal may vibrate or motor operating noise may

be heard from engine room. This is a normal status of operation check.

lStopping distance may be longer than that of vehicles without ABS when vehicle drives on rough, gravel,

or snow-covered (fresh, deep snow) roads.

lWhen an error is indicated by ABS or another warning lamp, collect all necessary information from cus-

tomer (what symptoms are present under what conditions) and check for simple causes before starting

diagnostic servicing. Besides electrical system inspection, check brake booster operation, brake fluid

level, and fluid leaks.

lIf tyre size and type are used in an improper combination, or brake pads are not Genuine NISSAN parts,

stopping distance or steering stability may deteriorate.

lIf there is a radio, antenna, or antenna lead-in wire (including wiring) near control module, ABS function

may have a malfunction or error.

lIf aftermarket parts (car stereo, CD player, etc.) have been installed, check for incidents such as harness

pinches, open circuits, and improper wiring.

SBR820BA

Page 826 of 3171

![NISSAN NAVARA 2005 Repair Owners Manual BRC-4

[ABS]

PREPARATION

PREPARATION

PFP:00002

Special Service Tools (SST)EFS005TI

Tool number

Tool nameDescription

GG94310000

Flare nut torque wrench

a:10 mm (0.39 in)Installing brake tube and hose

ST NISSAN NAVARA 2005 Repair Owners Manual BRC-4

[ABS]

PREPARATION

PREPARATION

PFP:00002

Special Service Tools (SST)EFS005TI

Tool number

Tool nameDescription

GG94310000

Flare nut torque wrench

a:10 mm (0.39 in)Installing brake tube and hose

ST](/img/5/57362/w960_57362-825.png)

BRC-4

[ABS]

PREPARATION

PREPARATION

PFP:00002

Special Service Tools (SST)EFS005TI

Tool number

Tool nameDescription

GG94310000

Flare nut torque wrench

a:10 mm (0.39 in)Installing brake tube and hose

ST30720000

Drift

a: 77 mm (0.03 in) dia.

b: 55 mm (2.17 in) dia.

Installation rear sensor rotor ST27863000

Drift

a: 75 mm (2.95 in) dia.

b: 62 mm (2.44 in) dia.

KV40104710

Drift

a: 76 mm (2.99 in) dia.

b: 68.5 mm (2.697 in) dia.

NT406

ZZA0701D

ZZA0832D

ZZA0832D

Page 855 of 3171

![NISSAN NAVARA 2005 Repair Owners Manual TROUBLE DIAGNOSIS

BRC-33

[ABS]

C

D

E

G

H

I

J

K

L

MA

B

BRC

Inspection 8 Warning lamp systemEFS005U7

INSPECTION PROCEDURE

1.CHECK SELF-DIAGNOSTIC RESULTS

Perform self-diagnosis of ABS actuator and elect NISSAN NAVARA 2005 Repair Owners Manual TROUBLE DIAGNOSIS

BRC-33

[ABS]

C

D

E

G

H

I

J

K

L

MA

B

BRC

Inspection 8 Warning lamp systemEFS005U7

INSPECTION PROCEDURE

1.CHECK SELF-DIAGNOSTIC RESULTS

Perform self-diagnosis of ABS actuator and elect](/img/5/57362/w960_57362-854.png)

TROUBLE DIAGNOSIS

BRC-33

[ABS]

C

D

E

G

H

I

J

K

L

MA

B

BRC

Inspection 8 Warning lamp systemEFS005U7

INSPECTION PROCEDURE

1.CHECK SELF-DIAGNOSTIC RESULTS

Perform self-diagnosis of ABS actuator and electric unit (control unit). Refer toBRC-18, "

Self-Diagnosis".

OK or NG

OK >> GO TO 2.

NG >> Check items displayed by self-diagnosis. Refer toBRC-18, "

Display Item List".

2.CHECK COMBINATION METER

Check if the indication and operation of combination meter are normal. Refer toDI-13, "

Self-Diagnosis Mode

of Combination Meter".

OK or NG

OK >> INSPECTION END

NG >> Repair or replace combination meter. Refer toDI-27, "

Removal and Installation of Combination

Meter".

Symptom 1: Excessive ABS Function Operation FrequencyEFS005U8

1.CHECK START

Check longitudinal brake force distribution using a brake tester. Refer toBR-35, "

SERVICE DATA AND SPEC-

IFICATIONS (SDS)".

OK or NG

OK >> GO TO 2.

NG >> Check the following system. If any malfunction is found, repair or replace malfunctioning parts.

lBrake booster. Refer toBR-19, "BRAKE BOOSTER".

lHydraulic line. Refer toBR-12, "BRAKE TUBE AND HOSE".

lFront brake caliper. Refer toBR-24, "FRONT DISC BRAKE".

lRear wheel cylinder. Refer toBR-30, "REAR DRUM BRAKE".

2.CHECK FRONT AND REAR AXLE

Make sure that there is no excessive play in the front and rear axles. Refer to Front:FAX-5, "

WHEEL BEAR-

ING INSPECTION",Rear:RAX-6, "Rear Axle Bearing".

OK or NG

OK >> GO TO 3.

NG >> Repair.

3.CHECK WHEEL SENSOR AND SENSOR ROTOR

Check wheel sensor and sensor rotor for the following.

lWheel sensor installation for damage

lWheel sensor rotor installation for damage

lWheel sensor connector connection

lWheel sensor harness inspection

OK or NG

OK >> GO TO 4.

NG >>

lReplace wheel sensor or sensor rotor.

lRepair harness.

Page 865 of 3171

CL-1

CLUTCH

C TRANSMISSION/TRANSAXLE

CONTENTS

D

E

F

G

H

I

J

K

L

M

SECTIONCL

A

B

CL

CLUTCH

PRECAUTIONS .......................................................... 2

Service Notice or Precautions .................................. 2

PREPARATION ........................................................... 3

Special Service Tools ............................................... 3

Commercial Service Tools ........................................ 3

NOISE, VIBRATION AND HARSHNESS (NVH)

TROUBLESHOOTING ................................................ 5

NVH Troubleshooting Chart ..................................... 5

CLUTCH PEDAL ........................................................ 6

On-Vehicle Inspection and Adjustment .................... 6

Removal and Installation .......................................... 7

COMPONENTS .................................................... 7

REMOVAL ............................................................. 7

INSPECTION AFTER REMOVAL ......................... 7

INSTALLATION ..................................................... 7

CLUTCH FLUID .......................................................... 8

Air Bleeding Procedure ............................................ 8

CLUTCH MASTER CYLINDER .................................. 9

Components ............................................................. 9

Removal and Installation .......................................... 9

REMOVAL ............................................................. 9

INSTALLATION ..................................................... 9

Disassembly and Assembly ................................... 10

DISASSEMBLY ................................................... 10

INSPECTION AFTER DISASSEMBLY ............... 10

ASSEMBLY ......................................................... 10

OPERATING CYLINDER ...........................................11

Components ............................................................ 11

Removal and Installation ......................................... 11REMOVAL ........................................................... 11

INSTALLATION ................................................... 12

Disassembly and Assembly .................................... 12

DISASSEMBLY ................................................... 12

INSPECTION AFTER DISASSEMBLY ................ 12

ASSEMBLY ......................................................... 12

CLUTCH PIPING ....................................................... 13

Removal and Installation ........................................ 13

CLUTCH RELEASE MECHANISM ........................... 14

Removal and Installation ........................................ 14

COMPONENTS ................................................... 14

REMOVAL ........................................................... 14

INSPECTION AFTER REMOVAL ....................... 15

INSTALLATION ................................................... 15

CLUTCH DISC, CLUTCH COVER AND FLYWHEEL... 17

Removal and Installation ........................................ 17

COMPONENTS ................................................... 17

REMOVAL ........................................................... 17

INSPECTION AND ADJUSTMENT AFTER

REMOVAL ........................................................... 17

INSTALLATION ................................................... 18

SERVICE DATA AND SPECIFICATIONS (SDS) ...... 20

Clutch Control System ............................................ 20

Clutch Master Cylinder ........................................... 20

Clutch Operating Cylinder ...................................... 20

Clutch Disc ............................................................. 20

Clutch Cover ........................................................... 20

Clutch Pedal ........................................................... 20

Page 866 of 3171

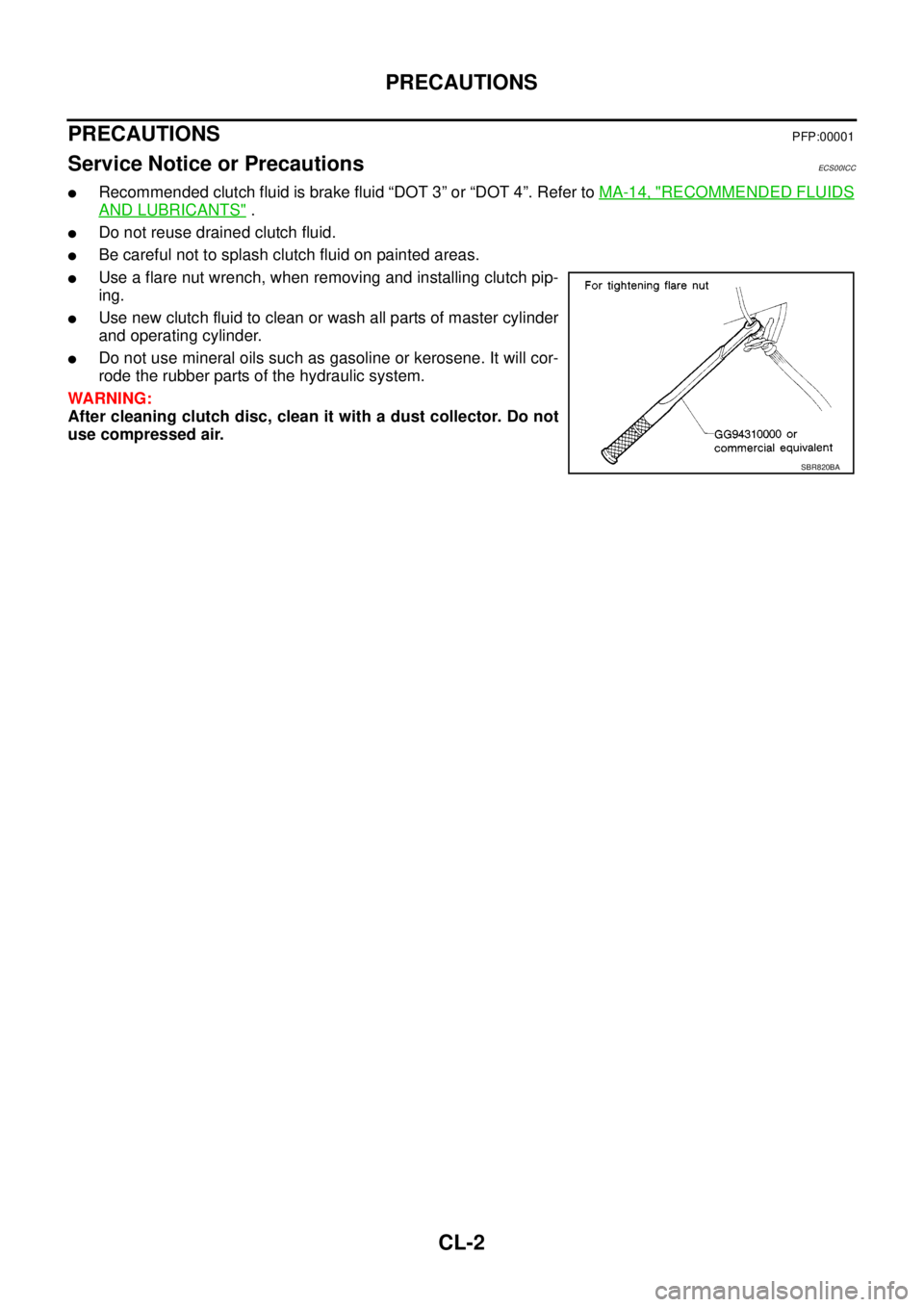

CL-2

PRECAUTIONS

PRECAUTIONS

PFP:00001

ServiceNoticeorPrecautionsECS00ICC

lRecommended clutch fluid is brake fluid “DOT 3” or “DOT 4”. Refer toMA-14, "RECOMMENDED FLUIDS

AND LUBRICANTS".

lDo not reuse drained clutch fluid.

lBe careful not to splash clutch fluid on painted areas.

lUse a flare nut wrench, when removing and installing clutch pip-

ing.

lUse new clutch fluid to clean or wash all parts of master cylinder

and operating cylinder.

lDo not use mineral oils such as gasoline or kerosene. It will cor-

rode the rubber parts of the hydraulic system.

WARNING:

After cleaning clutch disc, clean it with a dust collector. Do not

use compressed air.

SBR820BA

Page 867 of 3171

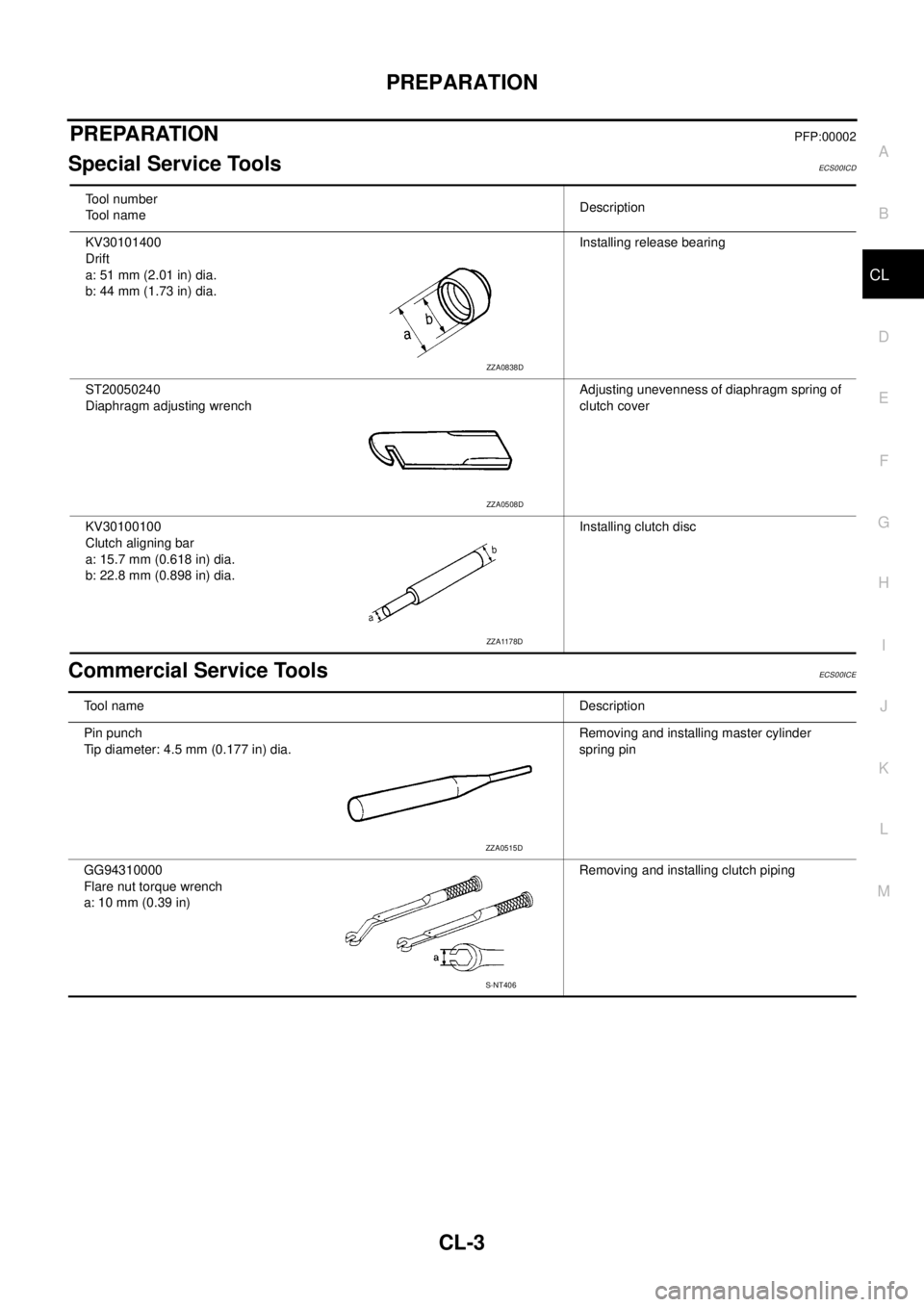

PREPARATION

CL-3

D

E

F

G

H

I

J

K

L

MA

B

CL

PREPARATIONPFP:00002

Special Service ToolsECS00ICD

Commercial Service ToolsECS00ICE

Tool number

Tool nameDescription

KV30101400

Drift

a: 51 mm (2.01 in) dia.

b: 44 mm (1.73 in) dia.Installing release bearing

ST20050240

Diaphragm adjusting wrenchAdjusting unevenness of diaphragm spring of

clutch cover

KV30100100

Clutch aligning bar

a: 15.7 mm (0.618 in) dia.

b: 22.8 mm (0.898 in) dia.Installing clutch disc

ZZA0838D

ZZA0508D

ZZA1178D

Tool nameDescription

Pin punch

Tip diameter: 4.5 mm (0.177 in) dia.Removing and installing master cylinder

spring pin

GG94310000

Flare nut torque wrench

a: 10 mm (0.39 in)Removing and installing clutch piping

ZZA0515D

S-NT406

Page 884 of 3171

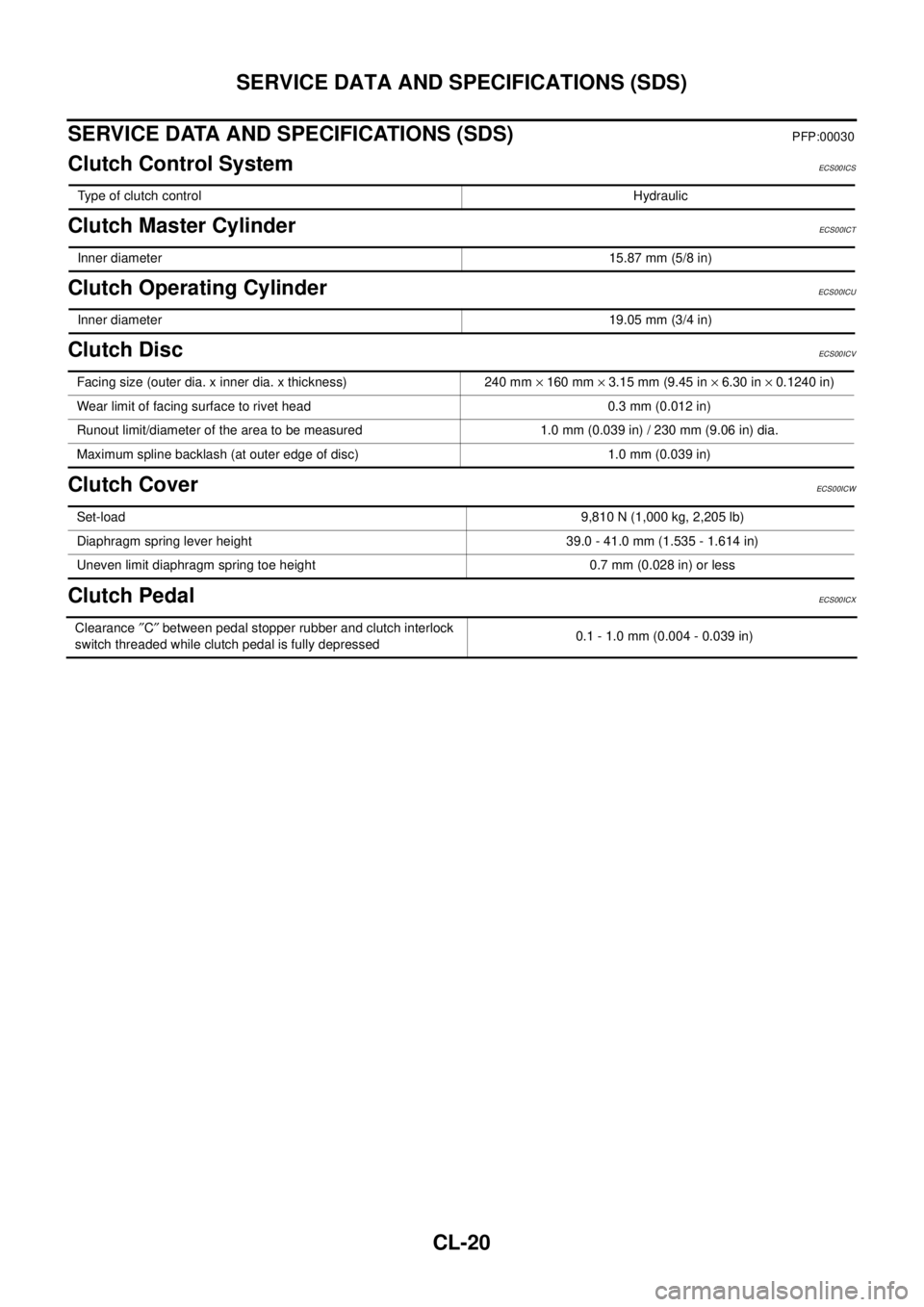

CL-20

SERVICE DATA AND SPECIFICATIONS (SDS)

SERVICE DATA AND SPECIFICATIONS (SDS)

PFP:00030

Clutch Control SystemECS00ICS

Clutch Master CylinderECS00ICT

Clutch Operating CylinderECS00ICU

Clutch DiscECS00ICV

Clutch CoverECS00ICW

Clutch PedalECS00ICX

Type of clutch controlHydraulic

Inner diameter15.87 mm (5/8 in)

Inner diameter19.05 mm (3/4 in)

Facing size (outer dia. x inner dia. x thickness) 240 mm´160 mm´3.15 mm (9.45 in´6.30 in´0.1240 in)

Wear limit of facing surface to rivet head 0.3 mm (0.012 in)

Runout limit/diameter of the area to be measured 1.0 mm (0.039 in) / 230 mm (9.06 in) dia.

Maximum spline backlash (at outer edge of disc) 1.0 mm (0.039 in)

Set-load9,810 N (1,000 kg, 2,205 lb)

Diaphragm spring lever height 39.0 - 41.0 mm (1.535 - 1.614 in)

Uneven limit diaphragm spring toe height 0.7 mm (0.028 in) or less

Clearance²C²between pedal stopper rubber and clutch interlock

switch threaded while clutch pedal is fully depressed0.1 - 1.0 mm (0.004 - 0.039 in)

Page 885 of 3171

CO-1

ENGINE COOLING SYSTEM

B ENGINE

CONTENTS

C

D

E

F

G

H

I

J

K

L

M

SECTIONCO

A

CO

ENGINE COOLING SYSTEM

PRECAUTIONS .......................................................... 2

Precautions For Liquid Gasket ................................. 2

LIQUID GASKET APPLICATION PROCEDURE..... 2

PREPARATION ........................................................... 3

Special Service Tools ............................................... 3

Commercial Service Tools ........................................ 3

OVERHEATING CAUSE ANALYSIS .......................... 4

Troubleshooting Chart .............................................. 4

COOLING SYSTEM .................................................... 6

Cooling Circuit .......................................................... 6

ENGINE COOLANT .................................................... 7

Inspection ................................................................. 7

LEVEL CHECK ..................................................... 7

CHECKING RADIATOR SYSTEM FOR LEAKS..... 7

Changing Engine Coolant ........................................ 7

DRAINING ENGINE COOLANT ........................... 8

REFILLING ENGINE COOLANT .......................... 8

FLUSHING COOLING SYSTEM ........................... 9

RADIATOR .................................................................11

Components ............................................................ 11

Removal and Installation ......................................... 11

REMOVAL ............................................................ 11

INSPECTION AFTER REMOVAL ....................... 13

INSTALLATION ................................................... 14

INSPECTION AFTER INSTALLATION ............... 14

RADIATOR (ALUMINUM TYPE) .............................. 15

Components ........................................................... 15

Disassembly and Assembly ................................... 15

PREPARATION ................................................... 15

DISASSEMBLY ................................................... 15

ASSEMBLY ......................................................... 16

INSPECTION ...................................................... 18COOLING FAN .......................................................... 19

Components (Crankshaft Driven Type) .................. 19

Removal and Installation ........................................ 19

REMOVAL ........................................................... 19

INSPECTION AFTER REMOVAL ....................... 19

INSTALLATION ................................................... 19

Removal and Installation (Motor Driven Type) (Mod-

els with A/C) ........................................................... 19

REMOVAL ........................................................... 19

INSTALLATION ................................................... 20

WATER PUMP .......................................................... 21

Components ........................................................... 21

Removal and Installation ........................................ 21

REMOVAL ........................................................... 21

INSPECTION AFTER REMOVAL ....................... 22

INSTALLATION ................................................... 22

INSPECTION AFTER INSTALLATION ................ 22

THERMOSTAT AND WATER PIPING ...................... 23

Components ........................................................... 23

Removal and Installation ........................................ 24

REMOVAL ........................................................... 24

INSPECTION AFTER REMOVAL ....................... 24

INSTALLATION ................................................... 24

INSPECTION AFTER INSTALLATION ................ 25

SERVICE DATA AND SPECIFICATIONS (SDS) ...... 26

Standard and Limit .................................................. 26

ENGINE COOLANT CAPACITY .......................... 26

THERMOSTAT .................................................... 26

RESERVOIR TANK ............................................. 26

Page 887 of 3171

PREPARATION

CO-3

C

D

E

F

G

H

I

J

K

L

MA

CO

PREPARATIONPFP:00002

Special Service ToolsEBS01E6K

Commercial Service ToolsEBS01E6L

Tool number

Tool nameDescription

WS39930000

Tube presserPressing the tube of liquid gasket

EG17650301

Radiator cap tester adapterAdapting radiator cap tester to radiator cap

and radiator filler neck

a: 28 (1.10) dia.

b: 31.4 (1.236) dia.

c: 41.3 (1.626) dia.

Unit: mm (in)

KV99103510

Radiator plate pliers AInstalling radiator upper and lower tanks

KV99103520

Radiator plate pliers BRemoving radiator upper and lower tanks

S-NT052

S-NT564

S-NT224

S-NT225

Tool nameDescription

Radiator cap tester Checking radiator and reservoir tank cap

PBIC1982E

Page 891 of 3171

ENGINE COOLANT

CO-7

C

D

E

F

G

H

I

J

K

L

MA

CO

ENGINE COOLANTPFP:KQ100

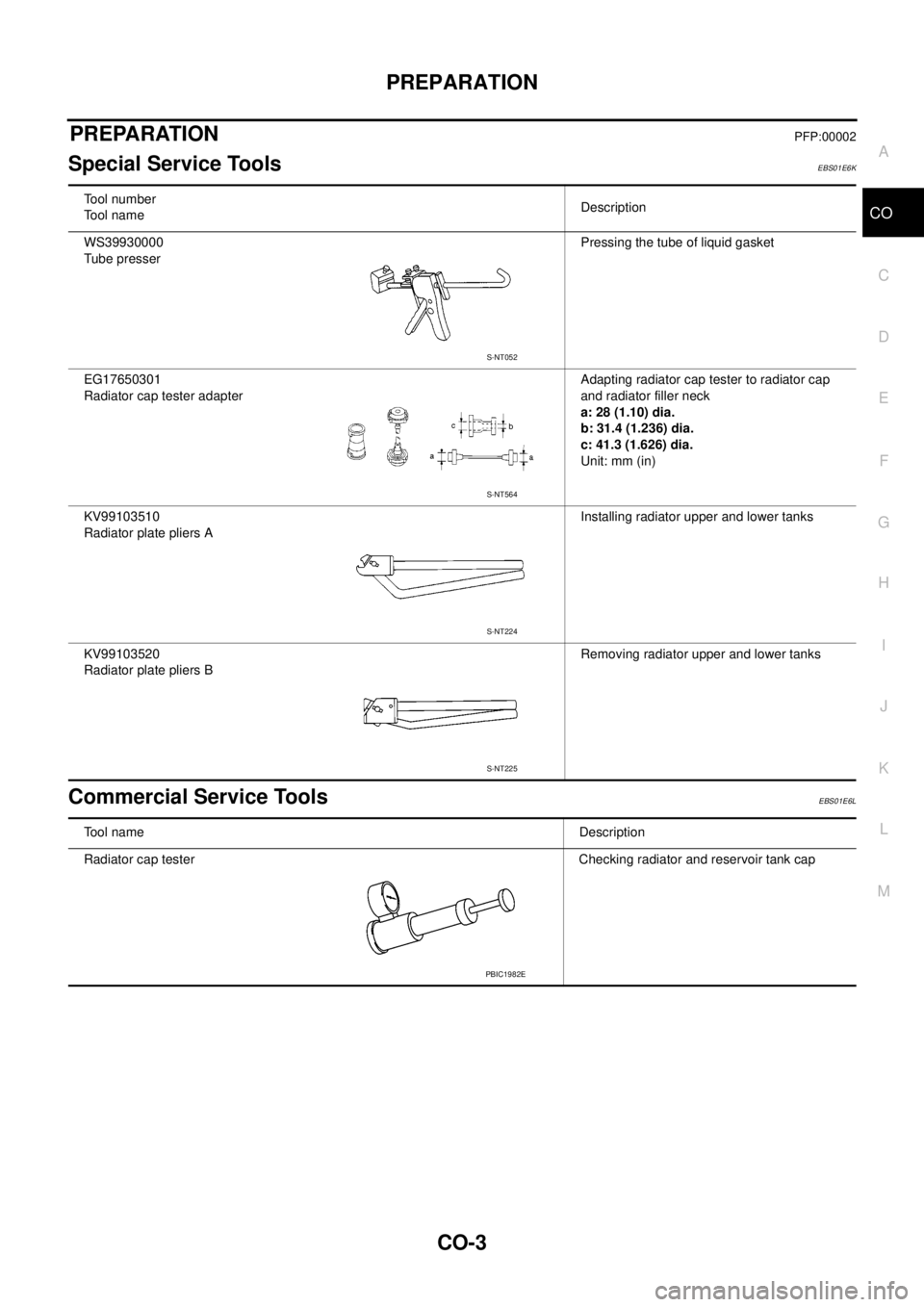

InspectionEBS01E6P

LEVEL CHECK

lCheck if the reservoir tank engine coolant level within MIN to

MAX when engine is cool.

lAdjust engine coolant level as necessary.

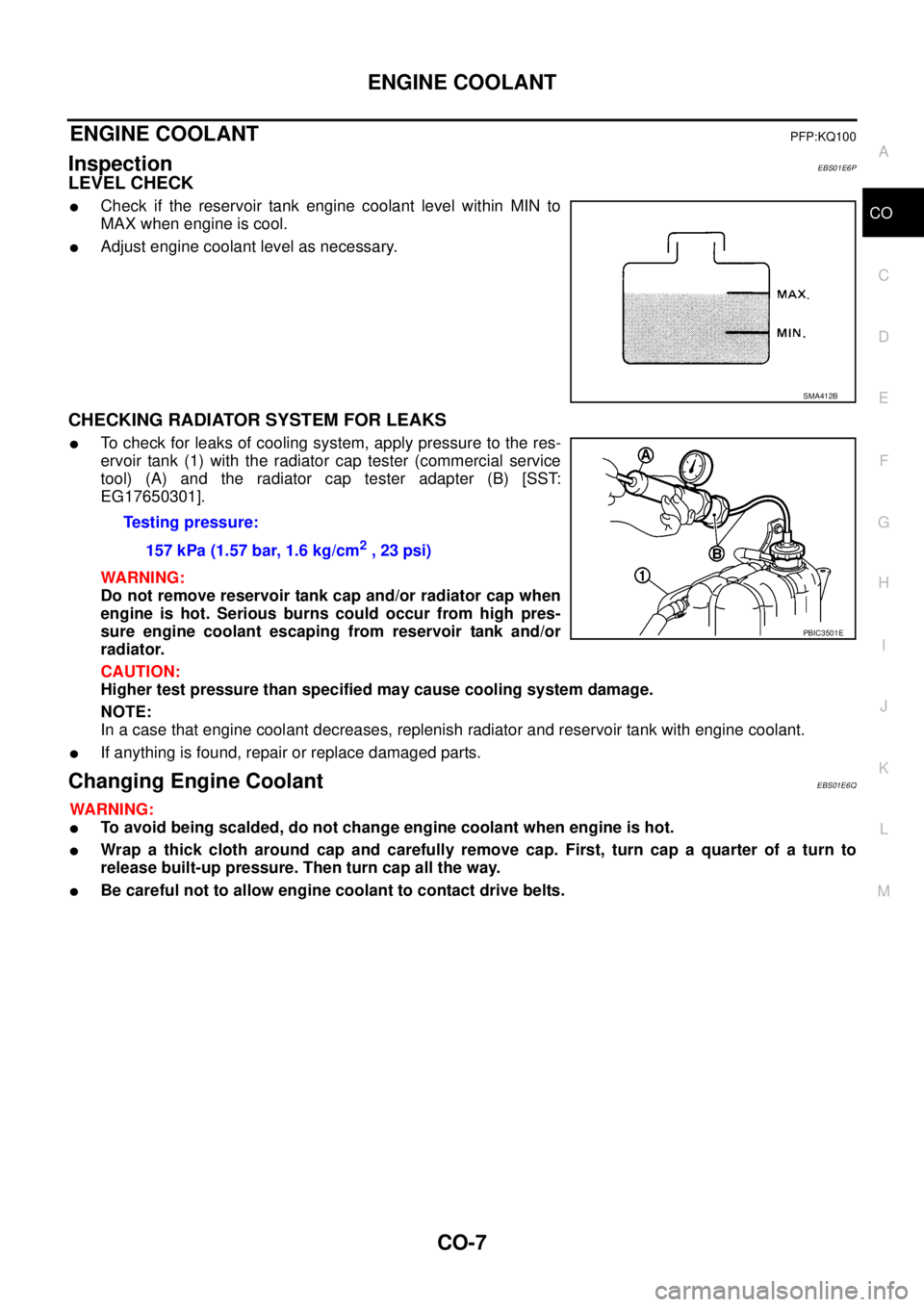

CHECKING RADIATOR SYSTEM FOR LEAKS

lTo check for leaks of cooling system, apply pressure to the res-

ervoir tank (1) with the radiator cap tester (commercial service

tool) (A) and the radiator cap tester adapter (B) [SST:

EG17650301].

WARNING:

Do not remove reservoir tank cap and/or radiator cap when

engine is hot. Serious burns could occur from high pres-

sure engine coolant escaping from reservoir tank and/or

radiator.

CAUTION:

Higher test pressure than specified may cause cooling system damage.

NOTE:

In a case that engine coolant decreases, replenish radiator and reservoir tank with engine coolant.

lIf anything is found, repair or replace damaged parts.

Changing Engine CoolantEBS01E6Q

WARNING:

lTo avoid being scalded, do not change engine coolant when engine is hot.

lWrap a thick cloth around cap and carefully remove cap. First, turn cap a quarter of a turn to

release built-up pressure. Then turn cap all the way.

lBe careful not to allow engine coolant to contact drive belts.

SMA412B

Testing pressure:

157 kPa (1.57 bar, 1.6 kg/cm

2,23psi)

PBIC3501E