air bleeding NISSAN NAVARA 2005 Repair Workshop Manual

[x] Cancel search | Manufacturer: NISSAN, Model Year: 2005, Model line: NAVARA, Model: NISSAN NAVARA 2005Pages: 3171, PDF Size: 49.59 MB

Page 787 of 3171

BR-1

BRAKE SYSTEM

F BRAKES

CONTENTS

C

D

E

G

H

I

J

K

L

M

SECTIONBR

A

B

BR

BRAKE SYSTEM

PRECAUTIONS .......................................................... 3

Precautions for Supplemental Restraint System

(SRS)“AIRBAG”and“SEATBELTPRE-TEN-

SIONER” .................................................................. 3

Precautions for Brake System .................................. 3

PREPARATION ........................................................... 4

Special Service Tools ............................................... 4

Commercial Service Tools ........................................ 4

NOISE, VIBRATION AND HARSHNESS (NVH)

TROUBLESHOOTING ................................................ 5

NVH Troubleshooting Chart ..................................... 5

BRAKE PEDAL .......................................................... 6

Inspection and Adjustment ....................................... 6

ADJUSTMENT ...................................................... 7

Removal and Installation .......................................... 8

COMPONENTS .................................................... 8

REMOVAL ............................................................. 8

INSPECTION AFTER REMOVAL ......................... 9

INSTALLATION ..................................................... 9

BRAKE FLUID .......................................................... 10

On-board Inspection ............................................... 10

CHECKING BRAKE FLUID LEVEL .................... 10

Drain and Refill ....................................................... 10

Bleeding Brake System ........................................... 11

LHD MODEL ........................................................ 11

RHD MODEL ........................................................ 11

BRAKE TUBE AND HOSE ....................................... 12

Hydraulic Circuit ..................................................... 12

Removal and Installation of Front Brake Tube and

Brake Hose ............................................................ 13

REMOVAL ........................................................... 13

INSTALLATION ................................................... 13

Removal and Installation of Rear Brake Tube and

Brake Hose ............................................................ 13

REMOVAL ........................................................... 13

INSTALLATION ................................................... 13

Inspection after Installation .................................... 14

LOAD SENSING VALVE .......................................... 15

Removal and Installation ........................................ 15

REMOVAL ........................................................... 15INSTALLATION ................................................... 15

Inspection ............................................................... 16

INSPECTION ...................................................... 16

BRAKE MASTER CYLINDER .................................. 17

On-Board Inspection ............................................... 17

LEAK INSPECTION ............................................ 17

Removal and Installation ........................................ 17

REMOVAL ........................................................... 17

INSTALLATION ................................................... 17

Components ........................................................... 17

Disassembly and Assembly .................................... 18

DISASSEMBLY ................................................... 18

ASSEMBLY ......................................................... 18

BRAKE BOOSTER ................................................... 19

On-Vehicle Service ................................................. 19

OPERATING CHECK .......................................... 19

AIRTIGHT CHECK .............................................. 19

Removal and Installation ........................................ 20

COMPONENTS ................................................... 20

REMOVAL ........................................................... 20

INSPECTION AFTER REMOVAL ....................... 20

INSTALLATION ................................................... 21

VACUUM LINES ....................................................... 22

Component ............................................................. 22

Removal and Installation ........................................ 23

Inspection ............................................................... 23

VISUAL INSPECTION ......................................... 23

CHECK VALVE INSPECTION ............................. 23

FRONT DISC BRAKE ............................................... 24

On-Board Inspection ............................................... 24

PAD WEAR INSPECTION ................................... 24

Components ........................................................... 24

Removal and Installation of Brake Pad .................. 25

REMOVAL ........................................................... 25

INSTALLATION ................................................... 25

Removal and Installation of Brake Caliper Assembly

... 26

REMOVAL ........................................................... 26

INSTALLATION ................................................... 26

Disassembly and Assembly of Brake Caliper

Page 796 of 3171

BR-10

BRAKE FLUID

BRAKE FLUID

PFP:KN100

On-board InspectionEFS005SI

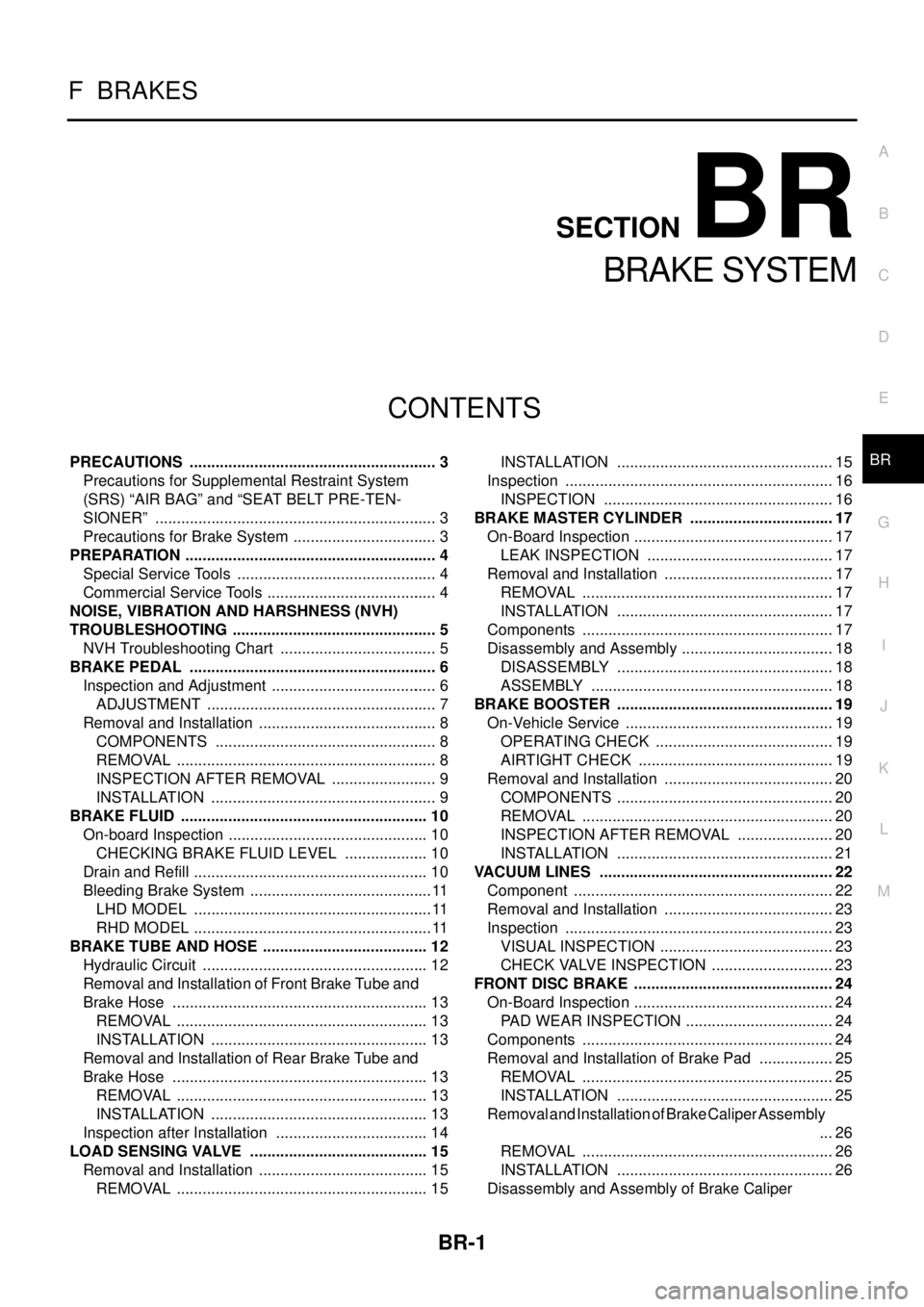

CHECKING BRAKE FLUID LEVEL

lMake sure the fluid level in the tank is within the standard

(between MAX and MIN lines).

lVisually check around the reservoir tank for fluid leakage.

lIf fluid level is excessively low, check brake system for fluid leak-

age.

lRelease parking brake lever and see if brake warning lamp goes

off. If not, check brake system for fluid leakage.

Drain and RefillEFS005SJ

CAUTION:

lRefill with new brake fluid “DOT 3” or “DOT 4”.

lNever reuse drained brake fluid.

lBe careful not to splash brake fluid on painted areas; it may cause paint damage. If brake fluid is

splashed on painted areas, immediately wipe off them and wash it away with water.

lBefore working, disconnect connector of ABS actuator and electric unit (control unit) or the bat-

tery cables.

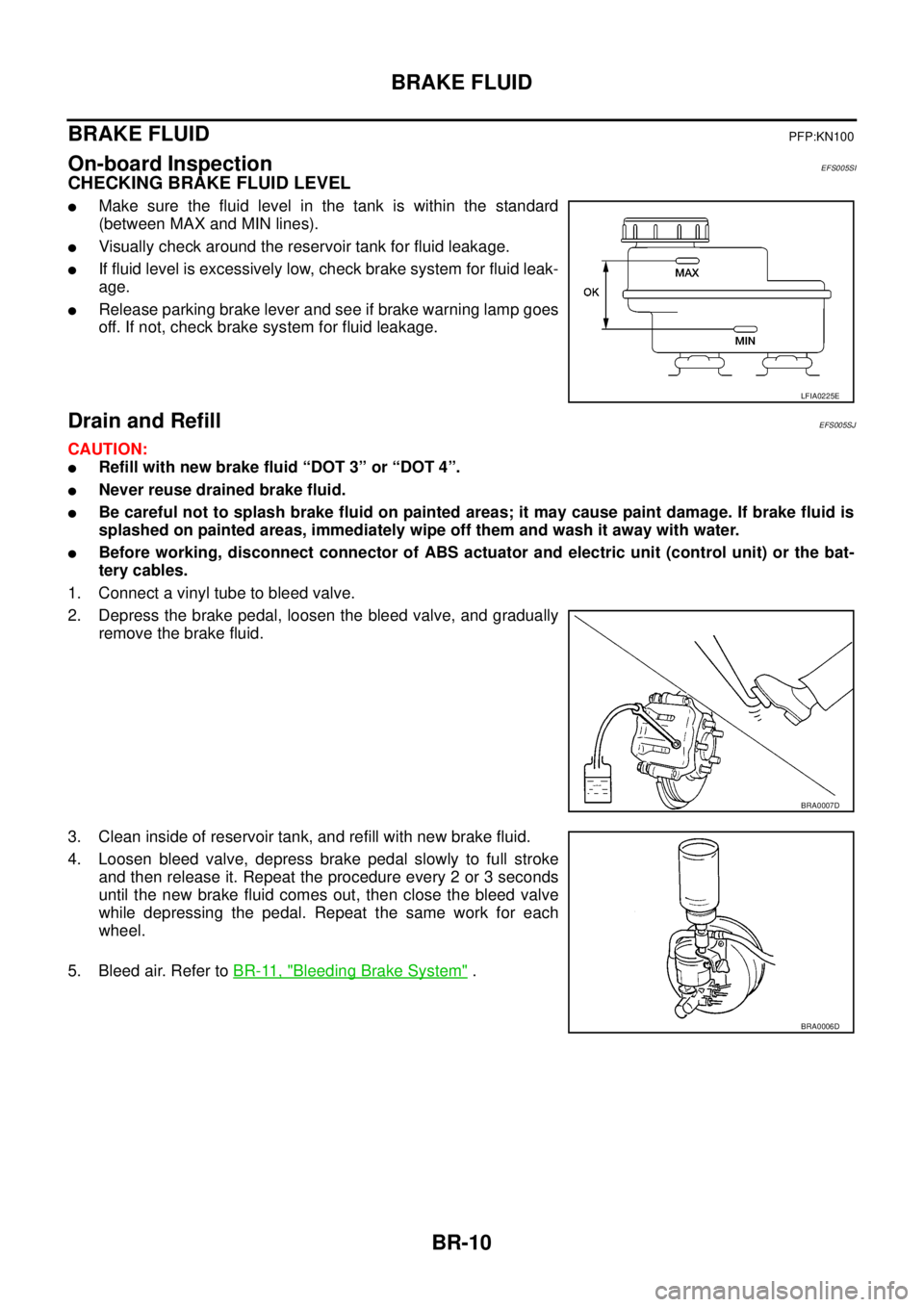

1. Connect a vinyl tube to bleed valve.

2. Depress the brake pedal, loosen the bleed valve, and gradually

remove the brake fluid.

3. Clean inside of reservoir tank, and refill with new brake fluid.

4. Loosen bleed valve, depress brake pedal slowly to full stroke

and then release it. Repeat the procedure every 2 or 3 seconds

until the new brake fluid comes out, then close the bleed valve

while depressing the pedal. Repeat the same work for each

wheel.

5. Bleed air. Refer toBR-11, "

Bleeding Brake System".

LFIA0225E

BRA0007D

BRA0006D

Page 797 of 3171

BRAKE FLUID

BR-11

C

D

E

G

H

I

J

K

L

MA

B

BR

Bleeding Brake SystemEFS005SK

CAUTION:

lWhile bleeding, pay attention to master cylinder fluid level.

lBefore working, disconnect electrical connector of ABS actuator and electric unit (control unit) or

the battery cable from the negative terminal.

LHD MODEL

1. Connect a vinyl tube to the rear right bleed valve.

2. Fully depress brake pedal 4 to 5 times.

3. With brake pedal depressed, loosen bleed valve to let the air out, and then tighten it immediately.

4. Repeat steps 3, 4 until no more air comes out.

5. Tighten bleed valve to specified torque. Refer toBR-24, "

Components"(front disc brake),BR-30, "Com-

ponents"(rear drum brake).

6. From the steps 1 to 5 above, with master cylinder reservoir tank filled at least half way, bleed air from the

front left, rear left, and front right brake, in that order.

RHD MODEL

1. Connect a vinyl tube to the rear left bleed valve.

2. Fully depress brake pedal 4 to 5 times.

3. With brake pedal depressed, loosen bleed valve to let the air out, and then tighten it immediately.

4. Repeat steps 3, 4 until no more air comes out.

5. Tighten bleed valve to specified torque. Refer toBR-24, "

Components"(front disc brake),BR-30, "Com-

ponents"(rear drum brake).

6. From the steps 1 to 5 above, with master cylinder reservoir tank filled at least half way, bleed air from the

front right, rear right, and front left brake, in that order.

Page 799 of 3171

BRAKE TUBE AND HOSE

BR-13

C

D

E

G

H

I

J

K

L

MA

B

BR

CAUTION:

lAll brake tubes and hoses must be free from excessive bending, twisting and pulling.

lMake sure that there is no interference with other parts when turning steering both clockwise and

counterclockwise.

lBrake tube and hose is an important safety part. Always disassemble the parts and retighten their

fittings, if a brake fluid leak is detected. Replace applicable part with a new one, if damaged part is

detected.

lBe careful not to splash brake fluid on painted areas; it may cause paint damage. If brake fluid is

splashed on painted surfaces of body, immediately wipe off them and wash it away with water.

lDo not bend or twist brake hose sharply, or strongly pull it.

lCover the open end of brake tube and hoses when disconnecting to prevent entrance of dirt.

lRefill with new brake fluid “DOT 3” or “DOT 4”.

lNever reuse drained brake fluid.

Removal and Installation of Front Brake Tube and Brake HoseEFS005SM

REMOVAL

1. Drain brake fluid. Refer toBR-10, "Drain and Refill".

2. Using a flare nut wrench, disconnect brake tube from brake hose.

3. Remove union bolt and remove brake hose from caliper assembly.

4. Remove lock plate and remove brake hose from vehicle.

INSTALLATION

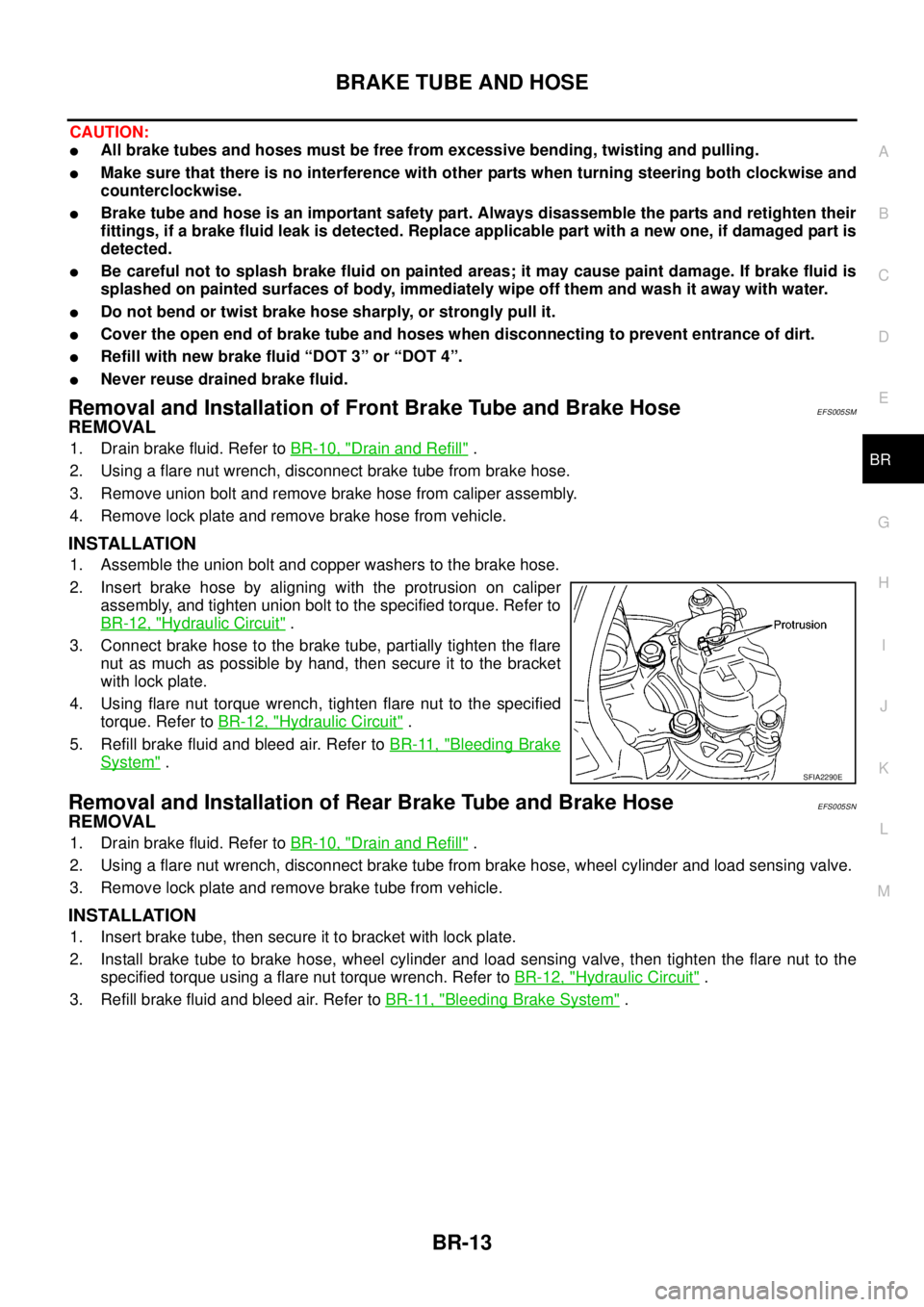

1. Assemble the union bolt and copper washers to the brake hose.

2. Insert brake hose by aligning with the protrusion on caliper

assembly, and tighten union bolt to the specified torque. Refer to

BR-12, "

Hydraulic Circuit".

3. Connect brake hose to the brake tube, partially tighten the flare

nut as much as possible by hand, then secure it to the bracket

with lock plate.

4. Using flare nut torque wrench, tighten flare nut to the specified

torque. Refer toBR-12, "

Hydraulic Circuit".

5. Refill brake fluid and bleed air. Refer toBR-11, "

Bleeding Brake

System".

Removal and Installation of Rear Brake Tube and Brake HoseEFS005SN

REMOVAL

1. Drain brake fluid. Refer toBR-10, "Drain and Refill".

2. Using a flare nut wrench, disconnect brake tube from brake hose, wheel cylinder and load sensing valve.

3. Remove lock plate and remove brake tube from vehicle.

INSTALLATION

1. Insert brake tube, then secure it to bracket with lock plate.

2. Install brake tube to brake hose, wheel cylinder and load sensing valve, then tighten the flare nut to the

specified torque using a flare nut torque wrench. Refer toBR-12, "

Hydraulic Circuit".

3. Refill brake fluid and bleed air. Refer toBR-11, "

Bleeding Brake System".

SFIA2290E

Page 801 of 3171

LOAD SENSING VALVE

BR-15

C

D

E

G

H

I

J

K

L

MA

B

BR

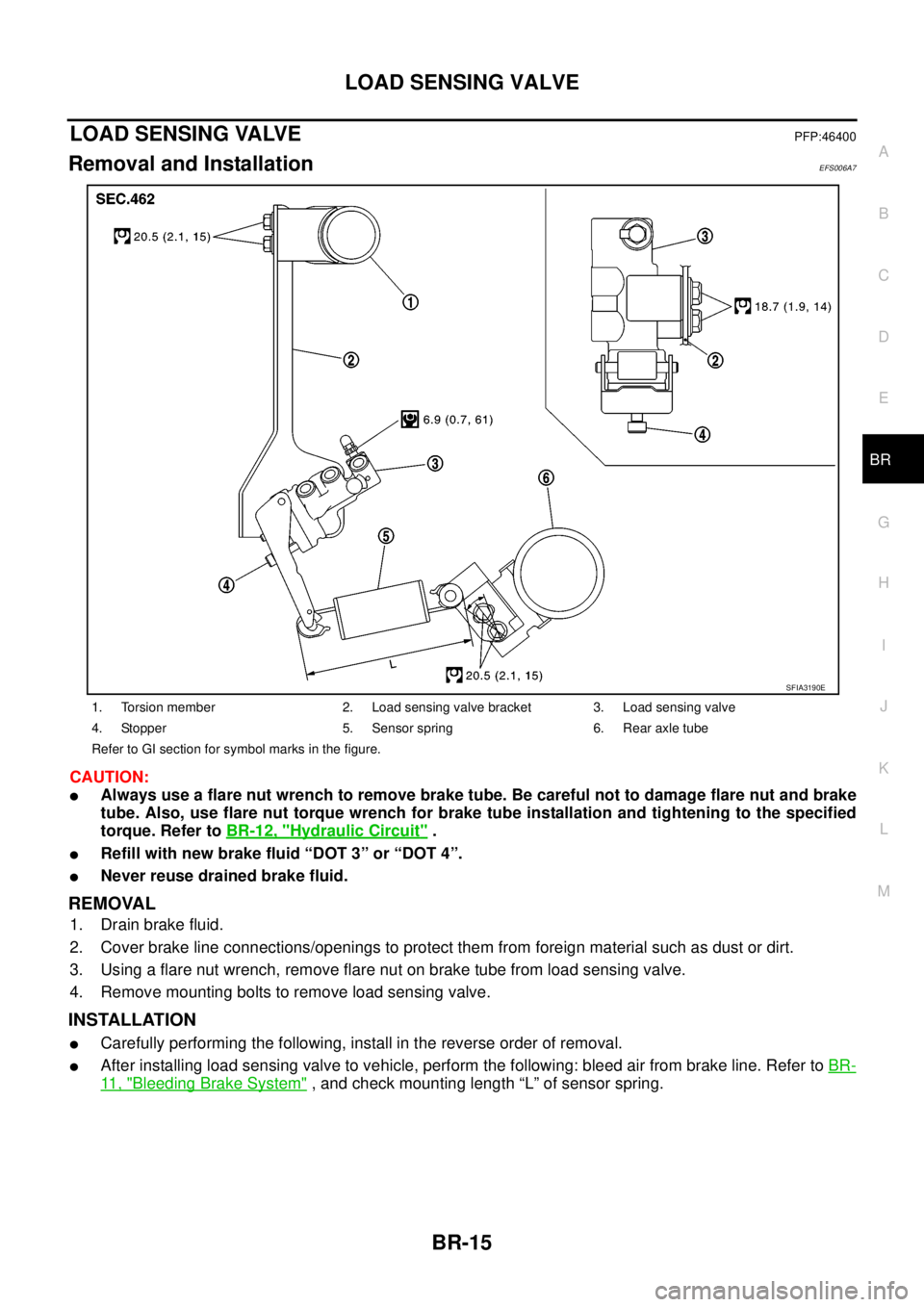

LOAD SENSING VALVEPFP:46400

Removal and InstallationEFS006A7

CAUTION:

lAlways use a flare nut wrench to remove brake tube. Be careful not to damage flare nut and brake

tube. Also, use flare nut torque wrench for brake tube installation and tightening to the specified

torque. Refer toBR-12, "

Hydraulic Circuit".

lRefill with new brake fluid “DOT 3” or “DOT 4”.

lNever reuse drained brake fluid.

REMOVAL

1. Drain brake fluid.

2. Cover brake line connections/openings to protect them from foreign material such as dust or dirt.

3. Using a flare nut wrench, remove flare nut on brake tube from load sensing valve.

4. Remove mounting bolts to remove load sensing valve.

INSTALLATION

lCarefully performing the following, install in the reverse order of removal.

lAfter installing load sensing valve to vehicle, perform the following: bleed air from brake line. Refer toBR-

11 , "Bleeding Brake System", and check mounting length “L” of sensor spring.

1. Torsion member 2. Load sensing valve bracket 3. Load sensing valve

4. Stopper 5. Sensor spring 6. Rear axle tube

Refer to GI section for symbol marks in the figure.

SFIA3190E

Page 802 of 3171

BR-16

LOAD SENSING VALVE

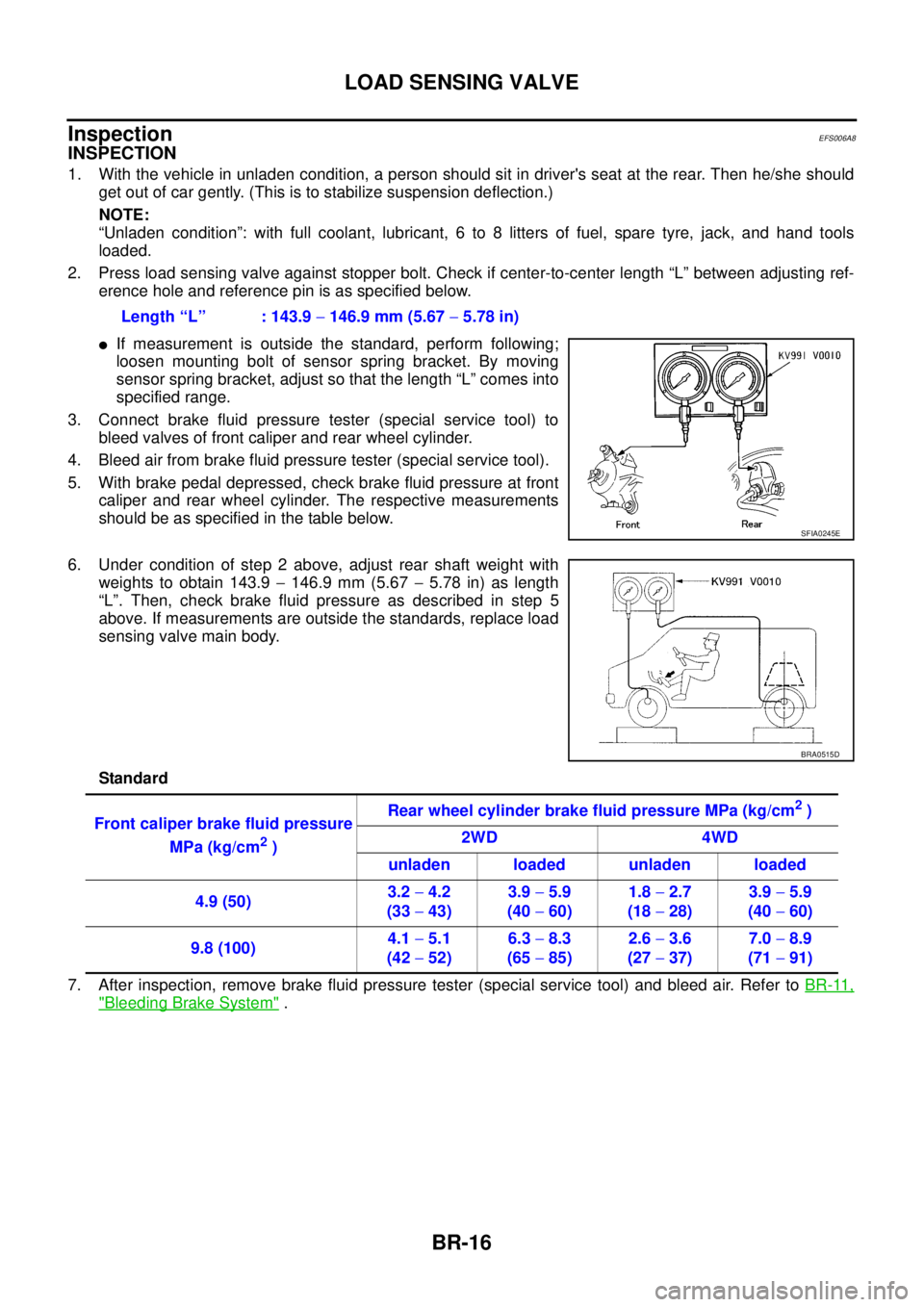

Inspection

EFS006A8

INSPECTION

1. With the vehicle in unladen condition, a person should sit in driver's seat at the rear. Then he/she should

get out of car gently. (This is to stabilize suspension deflection.)

NOTE:

“Unladen condition”: with full coolant, lubricant, 6 to 8 litters of fuel, spare tyre, jack, and hand tools

loaded.

2. Press load sensing valve against stopper bolt. Check if center-to-center length “L” between adjusting ref-

erence hole and reference pin is as specified below.

lIf measurement is outside the standard, perform following;

loosen mounting bolt of sensor spring bracket. By moving

sensor spring bracket, adjust so that the length “L” comes into

specified range.

3. Connect brake fluid pressure tester (special service tool) to

bleed valves of front caliper and rear wheel cylinder.

4. Bleed air from brake fluid pressure tester (special service tool).

5. With brake pedal depressed, check brake fluid pressure at front

caliper and rear wheel cylinder. The respective measurements

should be as specified in the table below.

6. Under condition of step 2 above, adjust rear shaft weight with

weights to obtain 143.9-146.9 mm (5.67-5.78 in) as length

“L”. Then, check brake fluid pressure as described in step 5

above. If measurements are outside the standards, replace load

sensing valve main body.

Standard

7. After inspection, remove brake fluid pressure tester (special service tool) and bleed air. Refer toBR-11,

"Bleeding Brake System". Length “L” : 143.9-146.9 mm (5.67-5.78 in)

SFIA0245E

BRA0515D

Front caliper brake fluid pressure

MPa (kg/cm

2)Rear wheel cylinder brake fluid pressure MPa (kg/cm

2)

2WD 4WD

unladen loaded unladen loaded

4.9 (50)3.2-4.2

(33-43)3.9-5.9

(40-60)1.8-2.7

(18-28)3.9-5.9

(40-60)

9.8 (100)4.1-5.1

(42-52)6.3-8.3

(65-85)2.6-3.6

(27-37)7.0-8.9

(71-91)

Page 803 of 3171

BRAKE MASTER CYLINDER

BR-17

C

D

E

G

H

I

J

K

L

MA

B

BR

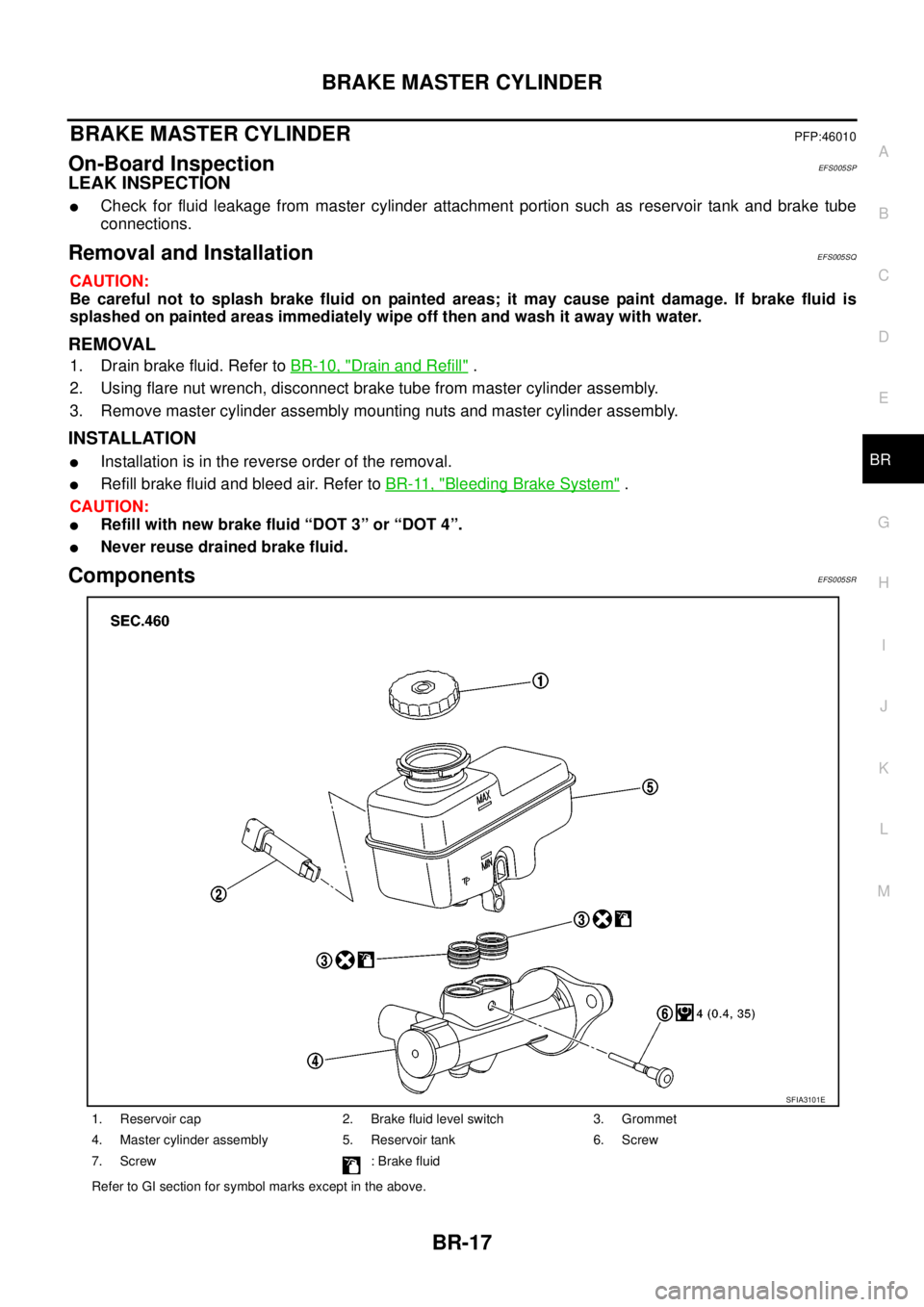

BRAKE MASTER CYLINDERPFP:46010

On-Board InspectionEFS005SP

LEAK INSPECTION

lCheck for fluid leakage from master cylinder attachment portion such as reservoir tank and brake tube

connections.

Removal and InstallationEFS005SQ

CAUTION:

Be careful not to splash brake fluid on painted areas; it may cause paint damage. If brake fluid is

splashed on painted areas immediately wipe off then and wash it away with water.

REMOVAL

1. Drain brake fluid. Refer toBR-10, "Drain and Refill".

2. Using flare nut wrench, disconnect brake tube from master cylinder assembly.

3. Remove master cylinder assembly mounting nuts and master cylinder assembly.

INSTALLATION

lInstallation is in the reverse order of the removal.

lRefill brake fluid and bleed air. Refer toBR-11, "Bleeding Brake System".

CAUTION:

lRefill with new brake fluid “DOT 3” or “DOT 4”.

lNever reuse drained brake fluid.

ComponentsEFS005SR

1. Reservoir cap 2. Brake fluid level switch 3. Grommet

4. Master cylinder assembly 5. Reservoir tank 6. Screw

7. Screw : Brake fluid

Refer to GI section for symbol marks except in the above.

SFIA3101E

Page 807 of 3171

BRAKE BOOSTER

BR-21

C

D

E

G

H

I

J

K

L

MA

B

BR

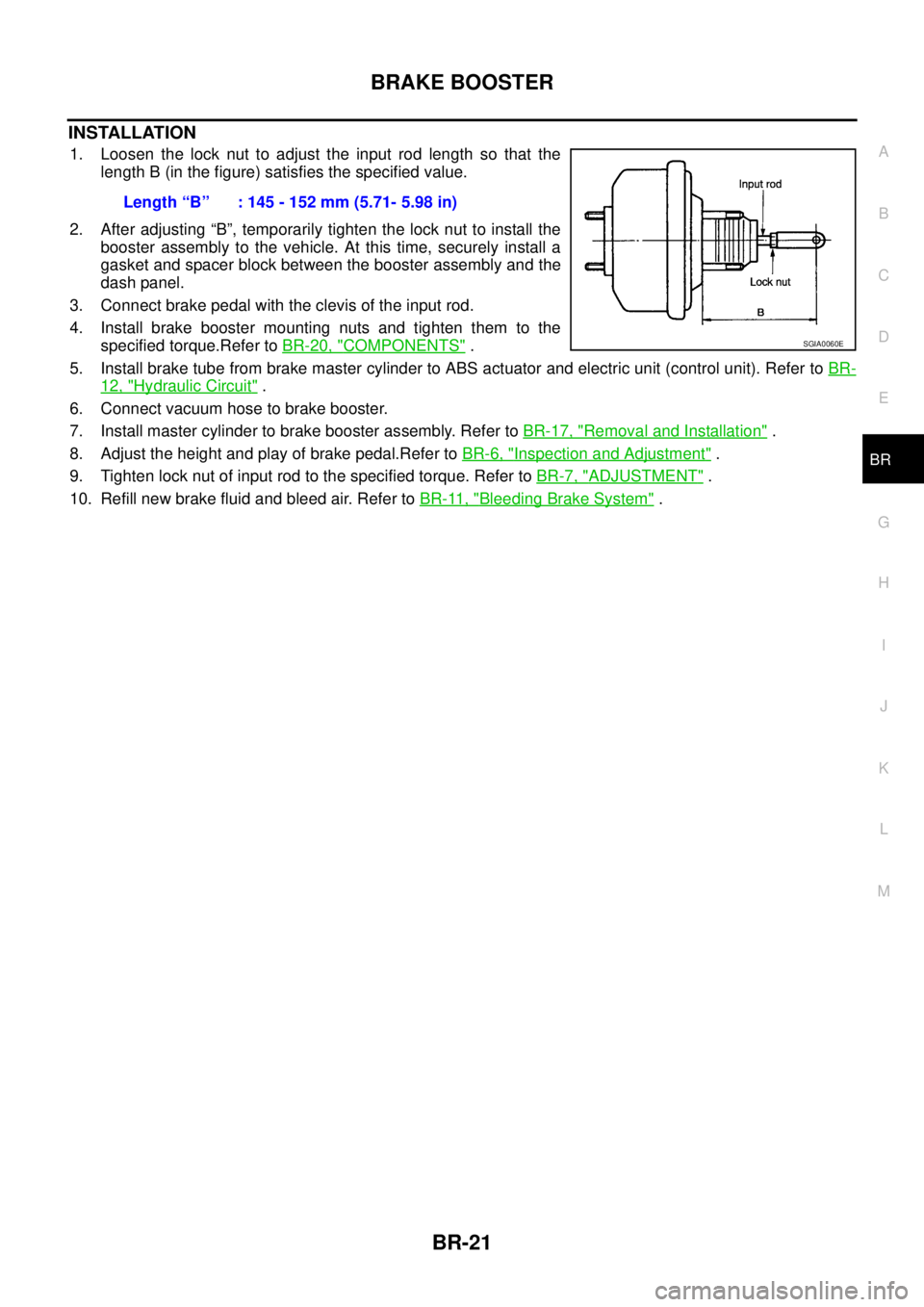

INSTALLATION

1. Loosen the lock nut to adjust the input rod length so that the

length B (in the figure) satisfies the specified value.

2. After adjusting “B”, temporarily tighten the lock nut to install the

booster assembly to the vehicle. At this time, securely install a

gasket and spacer block between the booster assembly and the

dash panel.

3. Connect brake pedal with the clevis of the input rod.

4. Install brake booster mounting nuts and tighten them to the

specified torque.Refer toBR-20, "

COMPONENTS".

5. Install brake tube from brake master cylinder to ABS actuator and electric unit (control unit). Refer toBR-

12, "Hydraulic Circuit".

6. Connect vacuum hose to brake booster.

7. Install master cylinder to brake booster assembly. Refer toBR-17, "

Removal and Installation".

8. Adjust the height and play of brake pedal.Refer toBR-6, "

Inspection and Adjustment".

9. Tighten lock nut of input rod to the specified torque. Refer toBR-7, "

ADJUSTMENT".

10. Refill new brake fluid and bleed air. Refer toBR-11, "

Bleeding Brake System". Length“B” :145-152mm(5.71-5.98in)

SGIA0060E

Page 812 of 3171

BR-26

FRONT DISC BRAKE

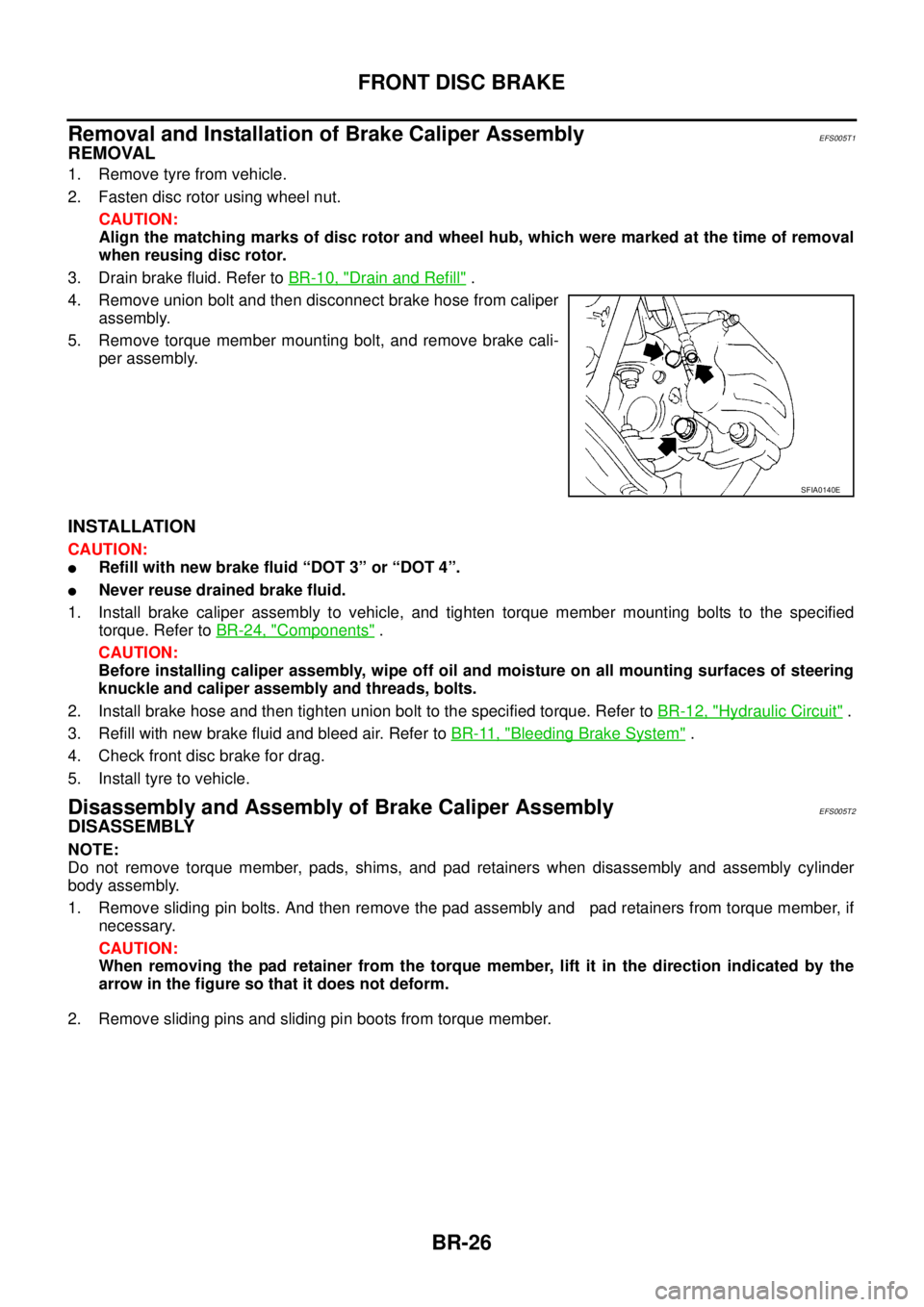

Removal and Installation of Brake Caliper Assembly

EFS005T1

REMOVAL

1. Remove tyre from vehicle.

2. Fasten disc rotor using wheel nut.

CAUTION:

Align the matching marks of disc rotor and wheel hub, which were marked at the time of removal

when reusing disc rotor.

3. Drain brake fluid. Refer toBR-10, "

Drain and Refill".

4. Remove union bolt and then disconnect brake hose from caliper

assembly.

5. Remove torque member mounting bolt, and remove brake cali-

per assembly.

INSTALLATION

CAUTION:

lRefill with new brake fluid “DOT 3” or “DOT 4”.

lNever reuse drained brake fluid.

1. Install brake caliper assembly to vehicle, and tighten torque member mounting bolts to the specified

torque. Refer toBR-24, "

Components".

CAUTION:

Before installing caliper assembly, wipe off oil and moisture on all mounting surfaces of steering

knuckle and caliper assembly and threads, bolts.

2. Install brake hose and then tighten union bolt to the specified torque. Refer toBR-12, "

Hydraulic Circuit".

3. Refill with new brake fluid and bleed air. Refer toBR-11, "

Bleeding Brake System".

4. Check front disc brake for drag.

5. Install tyre to vehicle.

Disassembly and Assembly of Brake Caliper AssemblyEFS005T2

DISASSEMBLY

NOTE:

Do not remove torque member, pads, shims, and pad retainers when disassembly and assembly cylinder

body assembly.

1. Remove sliding pin bolts. And then remove the pad assembly and pad retainers from torque member, if

necessary.

CAUTION:

When removing the pad retainer from the torque member, lift it in the direction indicated by the

arrow in the figure so that it does not deform.

2. Remove sliding pins and sliding pin boots from torque member.

SFIA0140E

Page 820 of 3171

BR-34

REAR DRUM BRAKE

Removal and Installation of Wheel Cylinder

EFS006AH

REMOVAL

1. Drain brake fluid. Refer toBR-10, "Drain and Refill".

2. Remove rear brake shoe assembly.

3. Remove brake tube from the wheel cylinder.

4. Remove bolts on the wheel cylinder, and then remove wheel cylinder from the back plate.

INSTALLATION

lInstallation is the reverse order of removal. Tighten bolts to the specified torque. Refer toBR-30, "Compo-

nents".

lRefill with new brake fluid and bleed air. Refer toBR-11, "Bleeding Brake System".

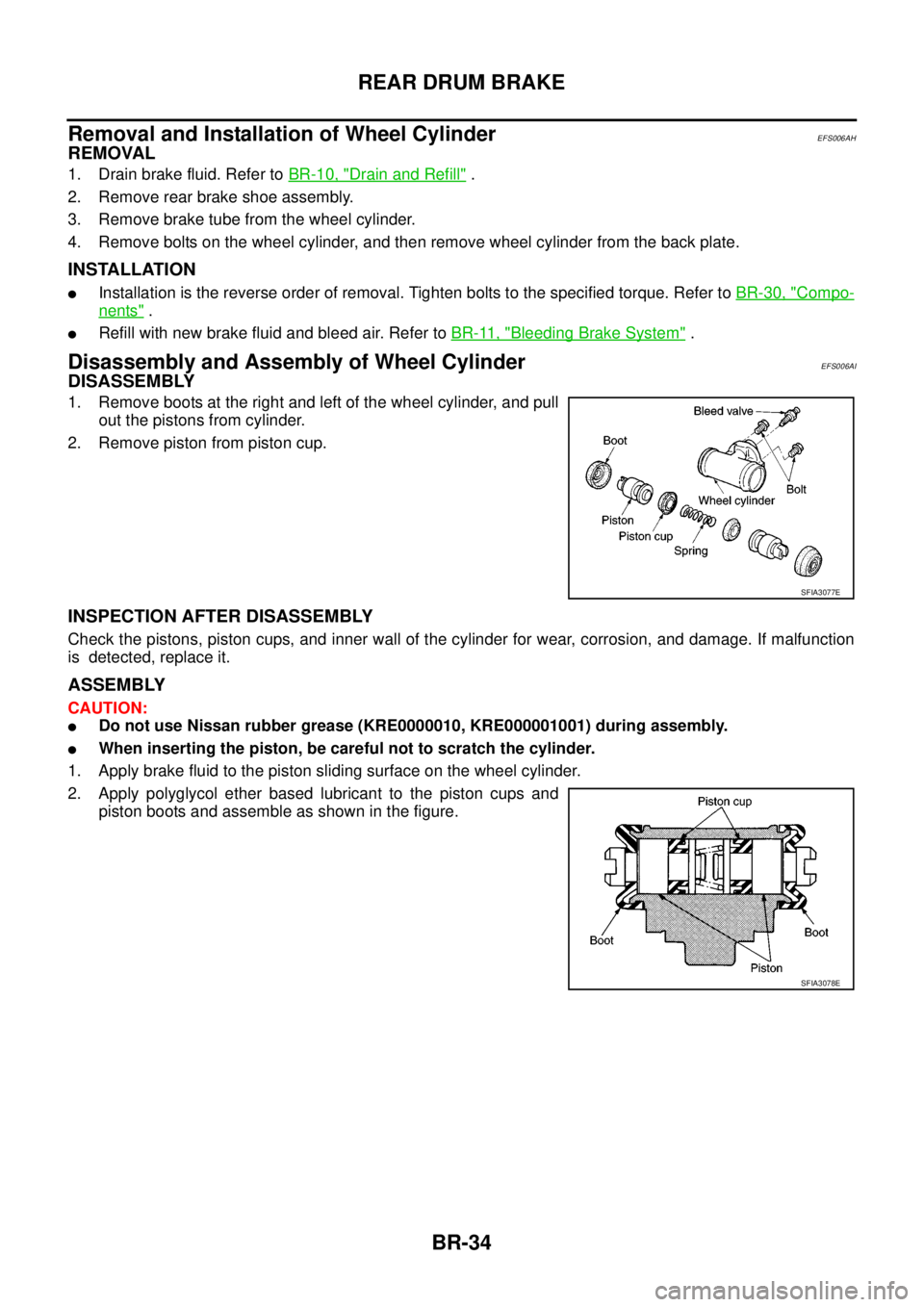

Disassembly and Assembly of Wheel CylinderEFS006AI

DISASSEMBLY

1. Remove boots at the right and left of the wheel cylinder, and pull

out the pistons from cylinder.

2. Remove piston from piston cup.

INSPECTION AFTER DISASSEMBLY

Check the pistons, piston cups, and inner wall of the cylinder for wear, corrosion, and damage. If malfunction

is detected, replace it.

ASSEMBLY

CAUTION:

lDo not use Nissan rubber grease (KRE0000010, KRE000001001) during assembly.

lWhen inserting the piston, be careful not to scratch the cylinder.

1. Apply brake fluid to the piston sliding surface on the wheel cylinder.

2. Apply polyglycol ether based lubricant to the piston cups and

piston boots and assemble as shown in the figure.

SFIA3077E

SFIA3078E