coolant NISSAN NAVARA 2005 Repair Workshop Manual

[x] Cancel search | Manufacturer: NISSAN, Model Year: 2005, Model line: NAVARA, Model: NISSAN NAVARA 2005Pages: 3171, PDF Size: 49.59 MB

Page 2291 of 3171

MA-16

RECOMMENDED FLUIDS AND LUBRICANTS

Engine Coolant Mixture Ratio

ELS001JC

The engine cooling system is filled at the factory with a high-quality,

year-round and extended life engine coolant. The high quality engine

coolant contains the specific solutions effective for the anti-corrosion

and the anti-freeze function. Therefore, additional cooling system

additives are not necessary.

CAUTION:

lWhen adding or replacing coolant, be sure to use only Gen-

uine NISSAN Anti-freeze Coolant (L250) or equivalent in its

quality. Because L250 is premixed type coolant.

The use of other types of engine coolant may damage your

cooling system.

lWhen checking the engine coolant mixture ratio by the coolant

hydrometer, use the chart below to correct your hydrometer reading (specific gravity) according to coolant

temperature.

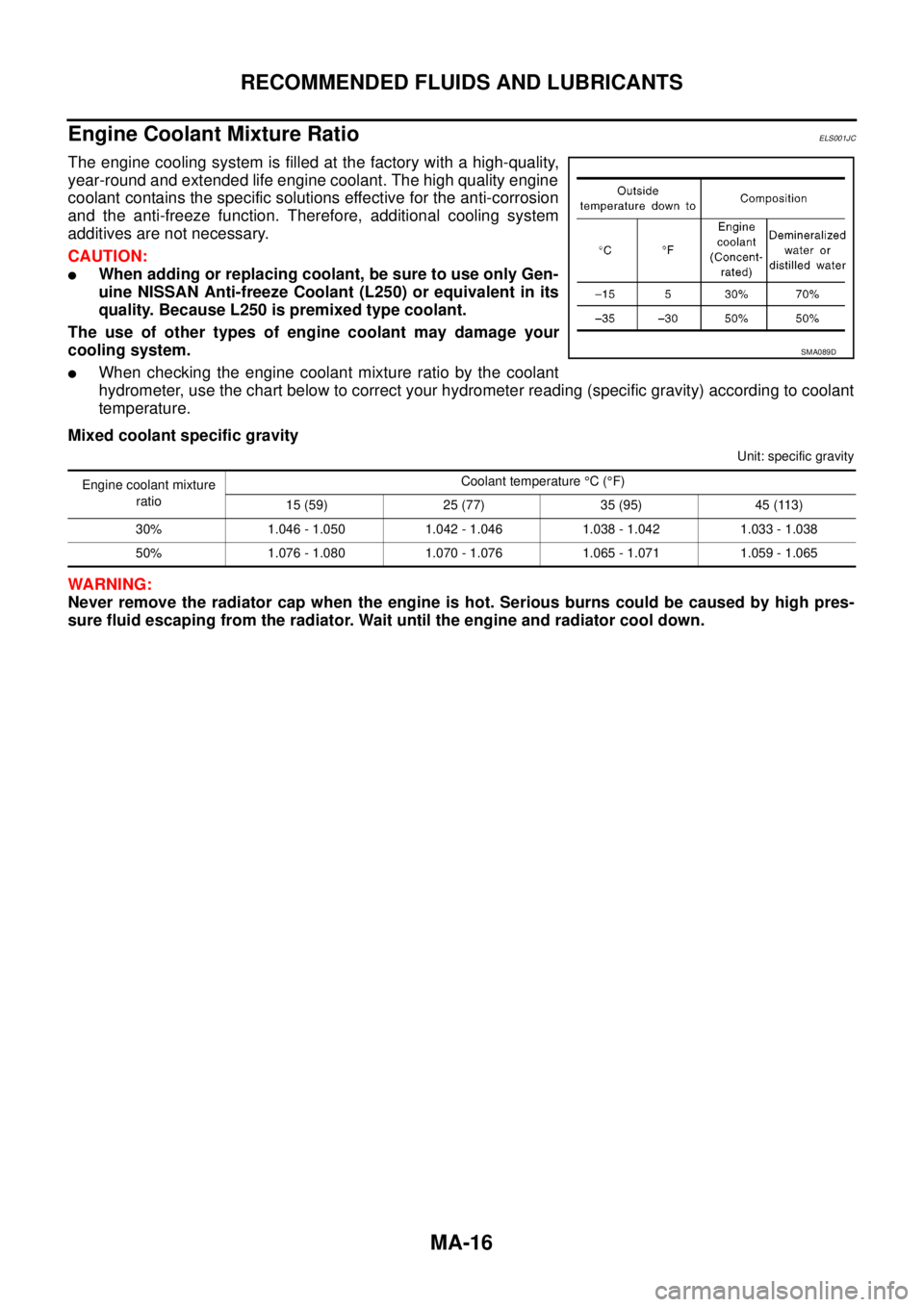

Mixed coolant specific gravity

Unit: specific gravity

WARNING:

Never remove the radiator cap when the engine is hot. Serious burns could be caused by high pres-

sure fluid escaping from the radiator. Wait until the engine and radiator cool down.

SMA089D

Engine coolant mixture

ratioCoolant temperature°C(°F)

15 (59) 25 (77) 35 (95) 45 (113)

30% 1.046 - 1.050 1.042 - 1.046 1.038 - 1.042 1.033 - 1.038

50% 1.076 - 1.080 1.070 - 1.076 1.065 - 1.071 1.059 - 1.065

Page 2293 of 3171

MA-18

ENGINE MAINTENANCE

Deflection Adjustment

ELS001JP

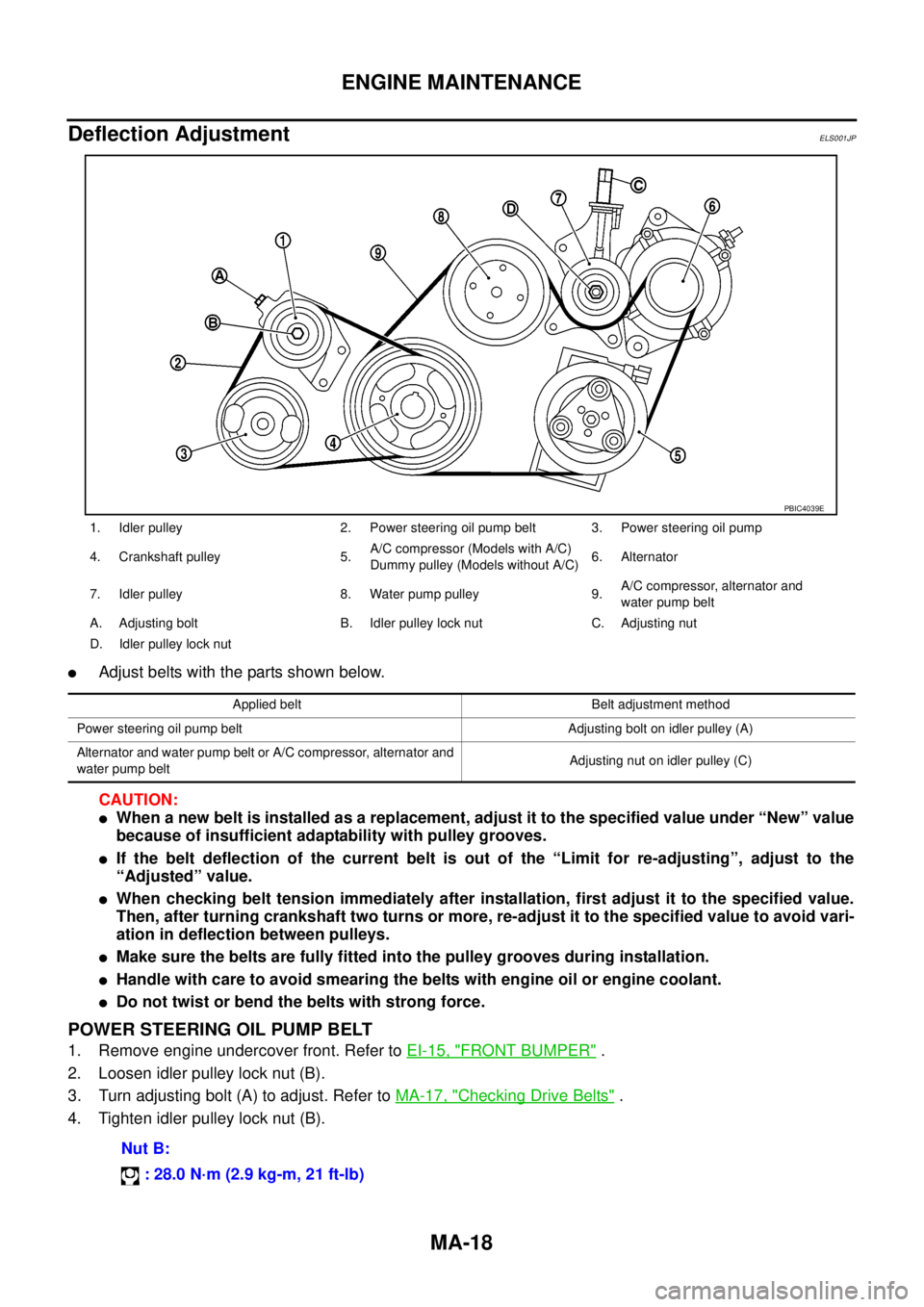

lAdjust belts with the parts shown below.

CAUTION:

lWhen a new belt is installed as a replacement, adjust it to the specified value under “New” value

because of insufficient adaptability with pulley grooves.

lIf the belt deflection of the current belt is out of the “Limit for re-adjusting”, adjust to the

“Adjusted” value.

lWhen checking belt tension immediately after installation, first adjust it to the specified value.

Then, after turning crankshaft two turns or more, re-adjust it to the specified value to avoid vari-

ation in deflection between pulleys.

lMake sure the belts are fully fitted into the pulley grooves during installation.

lHandle with care to avoid smearing the belts with engine oil or engine coolant.

lDo not twist or bend the belts with strong force.

POWER STEERING OIL PUMP BELT

1. Remove engine undercover front. Refer toEI-15, "FRONT BUMPER".

2. Loosen idler pulley lock nut (B).

3. Turn adjusting bolt (A) to adjust. Refer toMA-17, "

Checking Drive Belts".

4. Tighten idler pulley lock nut (B).

1. Idler pulley 2. Power steering oil pump belt 3. Power steering oil pump

4. Crankshaft pulley 5.A/C compressor (Models with A/C)

Dummypulley(ModelswithoutA/C)6. Alternator

7. Idler pulley 8. Water pump pulley 9.A/C compressor, alternator and

water pump belt

A. Adjusting bolt B. Idler pulley lock nut C. Adjusting nut

D. Idler pulley lock nut

PBIC4039E

Applied belt Belt adjustment method

Power steering oil pump belt Adjusting bolt on idler pulley (A)

Alternator and water pump belt or A/C compressor, alternator and

water pump beltAdjusting nut on idler pulley (C)

Nut B:

: 28.0 N·m (2.9 kg-m, 21 ft-lb)

Page 2294 of 3171

ENGINE MAINTENANCE

MA-19

C

D

E

F

G

H

I

J

K

MA

B

MA

A/C COMPRESSOR, ALTERNATOR AND WATER PUMP BELT

1. Loosen idler pulley lock nut (D).

2. Turn adjusting nut (C) to adjust. Refer toMA-18, "

Deflection Adjustment".

3. Tighten lock nut (D).

Changing Engine CoolantELS001JQ

WARNING:

lTo avoid being scalded, do not change engine coolant when engine is hot.

lWrap a thick cloth around cap and carefully remove radiator cap. First, turn radiator cap a quarter

of a turn to release built-up pressure. Then turn the cap all the way.

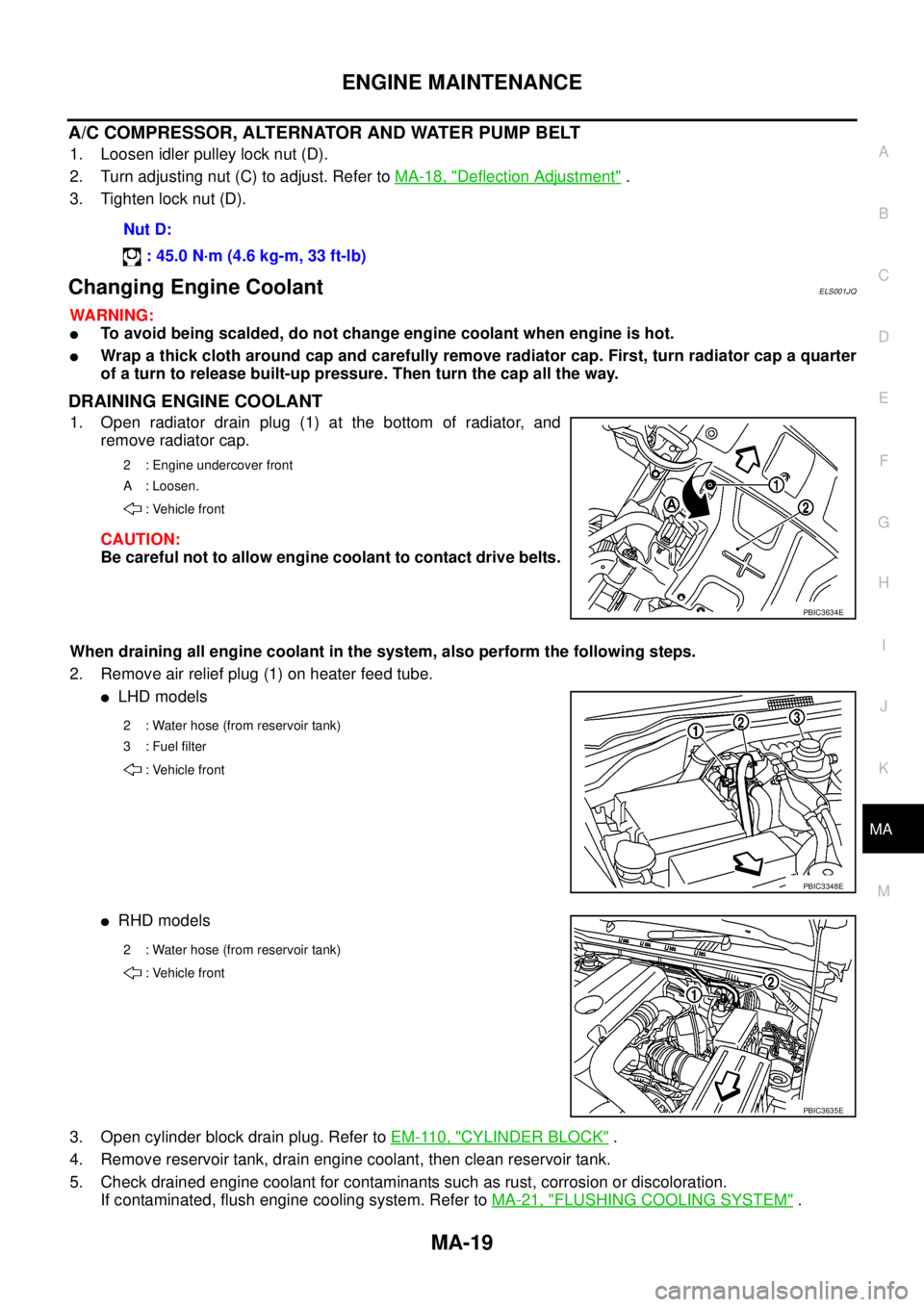

DRAINING ENGINE COOLANT

1. Open radiator drain plug (1) at the bottom of radiator, and

remove radiator cap.

CAUTION:

Be careful not to allow engine coolant to contact drive belts.

When draining all engine coolant in the system, also perform the following steps.

2. Remove air relief plug (1) on heater feed tube.

lLHD models

lRHD models

3. Open cylinder block drain plug. Refer toEM-110, "

CYLINDER BLOCK".

4. Remove reservoir tank, drain engine coolant, then clean reservoir tank.

5. Check drained engine coolant for contaminants such as rust, corrosion or discoloration.

If contaminated, flush engine cooling system. Refer toMA-21, "

FLUSHING COOLING SYSTEM". Nut D:

: 45.0 N·m (4.6 kg-m, 33 ft-lb)

2 : Engine undercover front

A : Loosen.

: Vehicle front

PBIC3634E

2 : Water hose (from reservoir tank)

3:Fuelfilter

: Vehicle front

PBIC3348E

2 : Water hose (from reservoir tank)

: Vehicle front

PBIC3635E

Page 2295 of 3171

MA-20

ENGINE MAINTENANCE

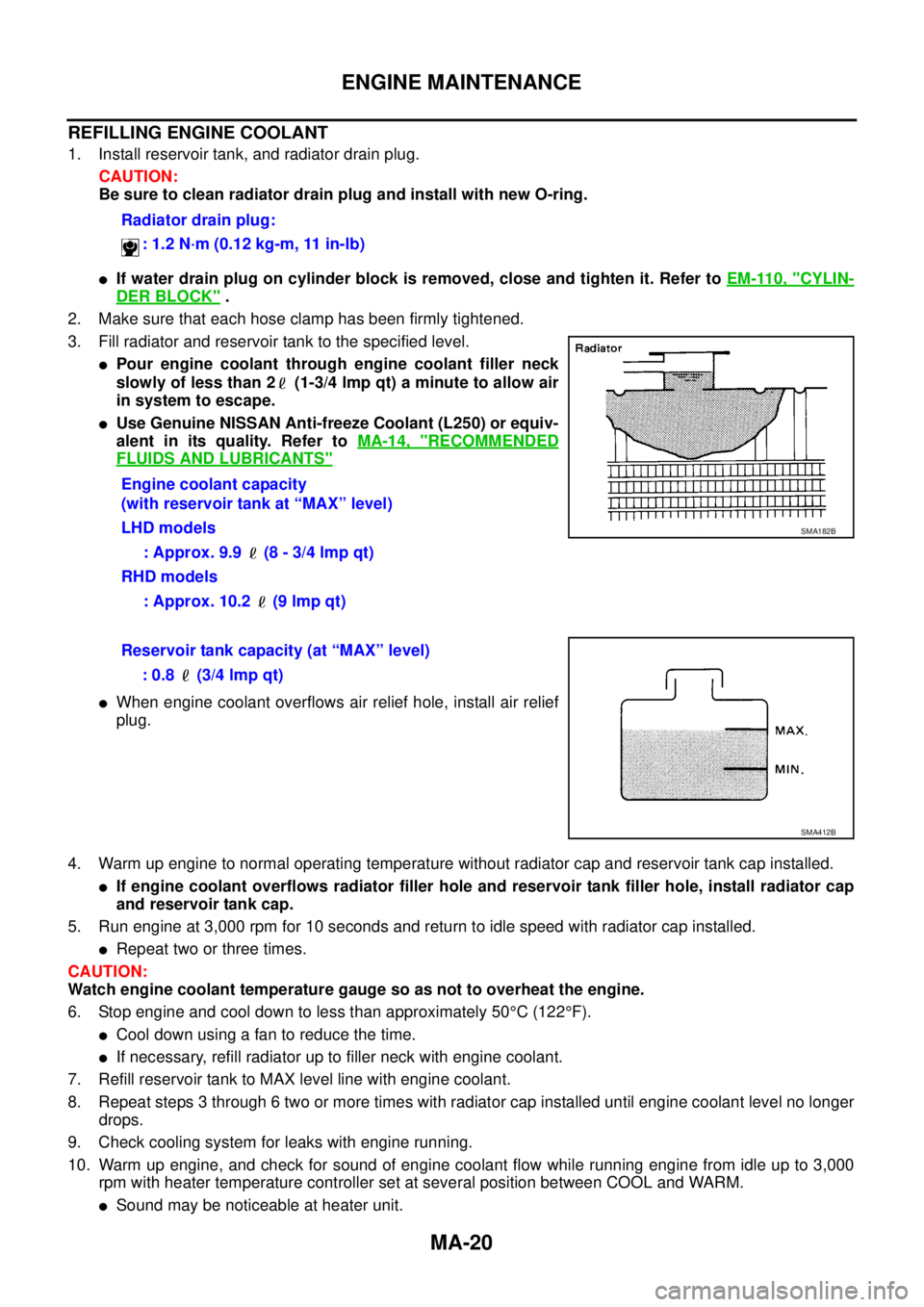

REFILLING ENGINE COOLANT

1. Install reservoir tank, and radiator drain plug.

CAUTION:

Be sure to clean radiator drain plug and install with new O-ring.

lIf water drain plug on cylinder block is removed, close and tighten it. Refer toEM-110, "CYLIN-

DER BLOCK".

2. Make sure that each hose clamp has been firmly tightened.

3. Fill radiator and reservoir tank to the specified level.

lPour engine coolant through engine coolant filler neck

slowly of less than 2 (1-3/4 lmp qt) a minute to allow air

in system to escape.

lUse Genuine NISSAN Anti-freeze Coolant (L250) or equiv-

alent in its quality. Refer toMA-14, "

RECOMMENDED

FLUIDS AND LUBRICANTS"

lWhen engine coolant overflows air relief hole, install air relief

plug.

4. Warm up engine to normal operating temperature without radiator cap and reservoir tank cap installed.

lIf engine coolant overflows radiator filler hole and reservoir tank filler hole, install radiator cap

and reservoir tank cap.

5. Run engine at 3,000 rpm for 10 seconds and return to idle speed with radiator cap installed.

lRepeat two or three times.

CAUTION:

Watch engine coolant temperature gauge so as not to overheat the engine.

6. Stop engine and cool down to less than approximately 50°C(122°F).

lCool down using a fan to reduce the time.

lIf necessary, refill radiator up to filler neck with engine coolant.

7. Refill reservoir tank to MAX level line with engine coolant.

8. Repeat steps 3 through 6 two or more times with radiator cap installed until engine coolant level no longer

drops.

9. Check cooling system for leaks with engine running.

10. Warm up engine, and check for sound of engine coolant flow while running engine from idle up to 3,000

rpm with heater temperature controller set at several position between COOL and WARM.

lSound may be noticeable at heater unit.Radiator drain plug:

: 1.2 N·m (0.12 kg-m, 11 in-lb)

Engine coolant capacity

(with reservoir tank at “MAX” level)

LHD models

: Approx. 9.9 (8 - 3/4 lmp qt)

RHD models

: Approx. 10.2 (9 lmp qt)

SMA182B

Reservoir tank capacity (at “MAX” level)

: 0.8 (3/4 lmp qt)

SMA412B

Page 2296 of 3171

ENGINE MAINTENANCE

MA-21

C

D

E

F

G

H

I

J

K

MA

B

MA

11. Repeat step 10 three times.

12. If sound is heard, bleed air from cooling system by repeating steps 3 through 6 until engine coolant level

no longer drops.

FLUSHING COOLING SYSTEM

1. Fill radiator with water until water spills from the air relief hole, then close air relief plug. Fill radiator and

reservoir tank with water and reinstall radiator cap and reservoir tank cap.

2. Run engine and warm it up to normal operating temperature.

3. Rev engine two or three times under no-load.

4. Stop engine and wait until it cools down.

5. Drain water from the system. Refer toMA-19, "

DRAINING ENGINE COOLANT".

6. Repeat steps 1 through 5 until clear water begins to drain from radiator.

Checking Cooling SystemELS001JR

WARNING:

Never remove the radiator cap and reservoir tank cap when the engine is hot. Serious burns could

occur from high pressure engine coolant escaping from the radiator and the reservoir tank. Wrap a

thick cloth around the cap. Slowly turn it a quarter turn to allow built-up pressure to escape. Carefully

remove the cap by turning it all the way.

CHECKING COOLING SYSTEM HOSES

Check hoses for improper attachment, leaks, cracks, damage, loose connections, chafing and deterioration.

CHECKING RADIATOR

Check radiator for mud or clogging. If necessary, clean radiator as follows.

lBe careful not to bend or damage the radiator fins.

lWhen radiator is cleaned without removal, remove all surrounding parts such as cooling fan, radiator

shroud and horns. Then tape the harness and connectors to prevent water from entering.

1. Apply water by hose to the back side of the radiator core vertically downwards.

2. Apply water again to all radiator core surface once per minute.

3. Stop washing if any stains no longer flow out from the radiator.

4. Blow air into the back side of radiator core vertically downwards.

lUse compressed air lower than 490 kpa (4.9 bar, 5 kg/cm2, 71psi) and keep distance more than 30

cm(11.8 in).

5. Blow air again into all the radiator core surface once per minute until no water sprays out.

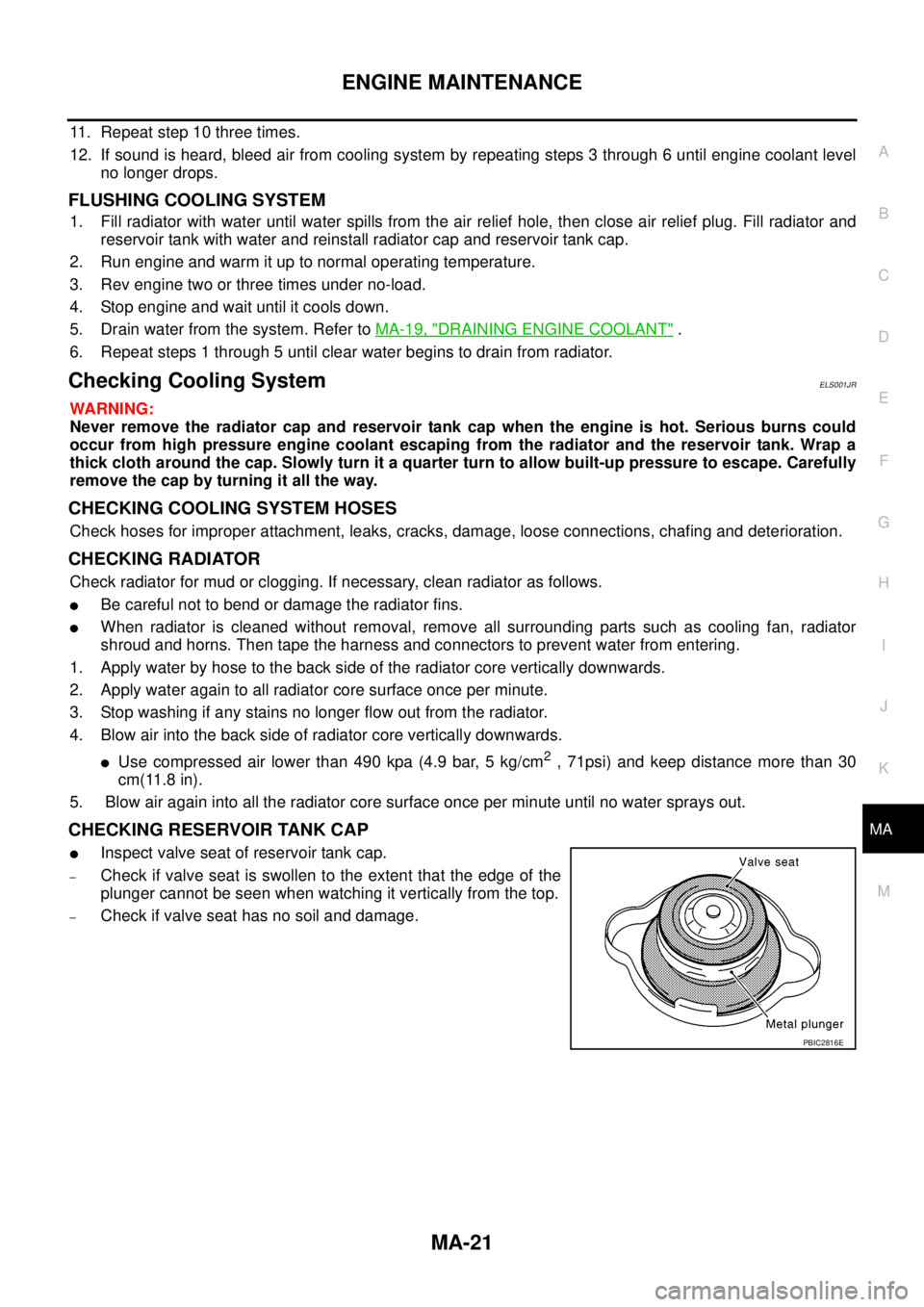

CHECKING RESERVOIR TANK CAP

lInspect valve seat of reservoir tank cap.

–Check if valve seat is swollen to the extent that the edge of the

plunger cannot be seen when watching it vertically from the top.

–Check if valve seat has no soil and damage.

PBIC2816E

Page 2297 of 3171

MA-22

ENGINE MAINTENANCE

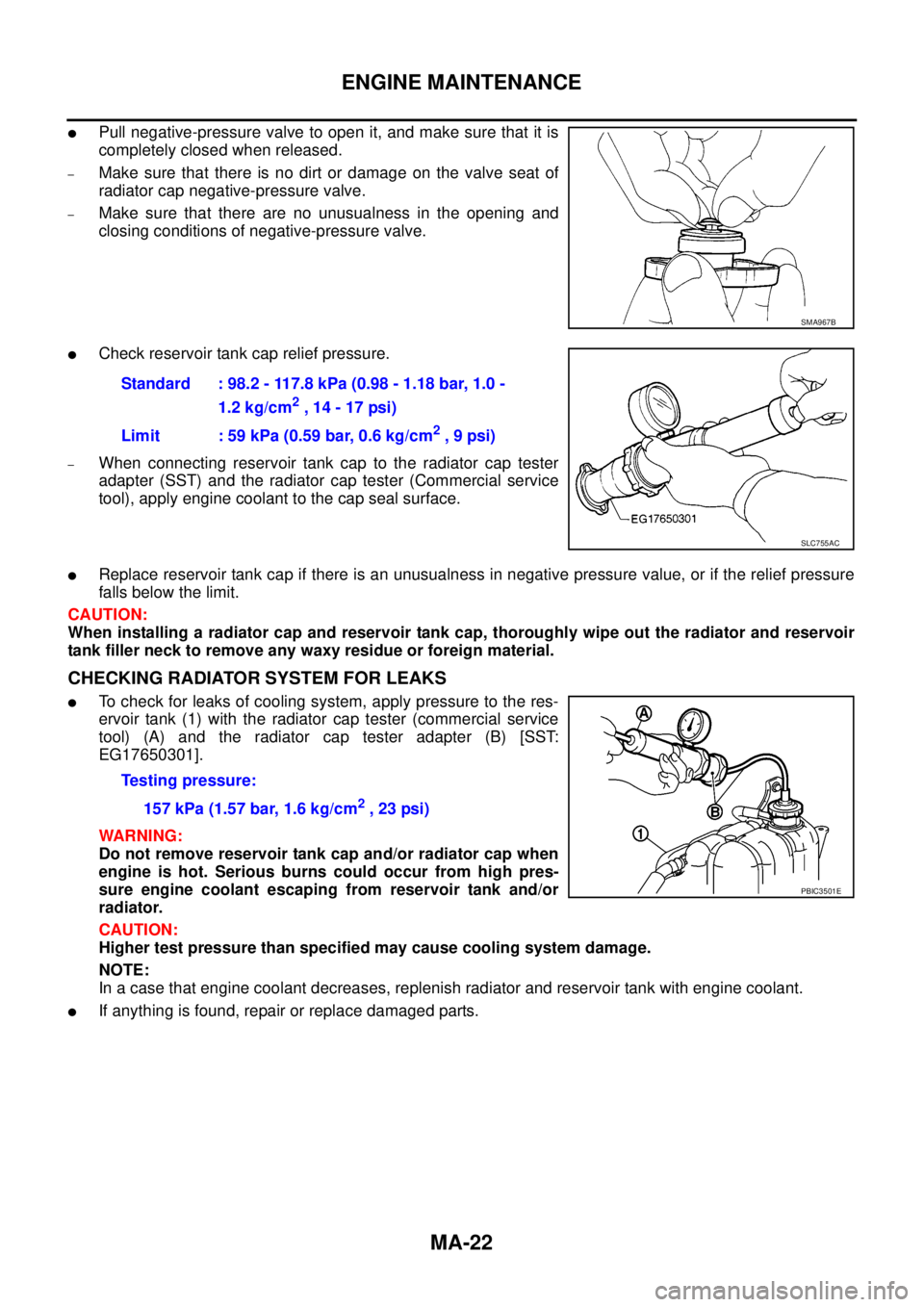

lPull negative-pressure valve to open it, and make sure that it is

completely closed when released.

–Makesurethatthereisnodirtordamageonthevalveseatof

radiator cap negative-pressure valve.

–Make sure that there are no unusualness in the opening and

closing conditions of negative-pressure valve.

lCheck reservoir tank cap relief pressure.

–When connecting reservoir tank cap to the radiator cap tester

adapter (SST) and the radiator cap tester (Commercial service

tool), apply engine coolant to the cap seal surface.

lReplace reservoir tank cap if there is an unusualness in negative pressure value, or if the relief pressure

falls below the limit.

CAUTION:

When installing a radiator cap and reservoir tank cap, thoroughly wipe out the radiator and reservoir

tank filler neck to remove any waxy residue or foreign material.

CHECKING RADIATOR SYSTEM FOR LEAKS

lTo check for leaks of cooling system, apply pressure to the res-

ervoir tank (1) with the radiator cap tester (commercial service

tool) (A) and the radiator cap tester adapter (B) [SST:

EG17650301].

WARNING:

Do not remove reservoir tank cap and/or radiator cap when

engine is hot. Serious burns could occur from high pres-

sure engine coolant escaping from reservoir tank and/or

radiator.

CAUTION:

Higher test pressure than specified may cause cooling system damage.

NOTE:

In a case that engine coolant decreases, replenish radiator and reservoir tank with engine coolant.

lIf anything is found, repair or replace damaged parts.

SMA967B

Standard : 98.2 - 117.8 kPa (0.98 - 1.18 bar, 1.0 -

1.2 kg/cm

2,14-17psi)

Limit : 59 kPa (0.59 bar, 0.6 kg/cm

2,9psi)

SLC755AC

Testing pressure:

157 kPa (1.57 bar, 1.6 kg/cm

2,23psi)

PBIC3501E

Page 2316 of 3171

SERVICE DATA AND SPECIFICATIONS (SDS)

MA-41

C

D

E

F

G

H

I

J

K

MA

B

MA

SERVICE DATA AND SPECIFICATIONS (SDS)PFP:00030

Standard and LimitELS001J8

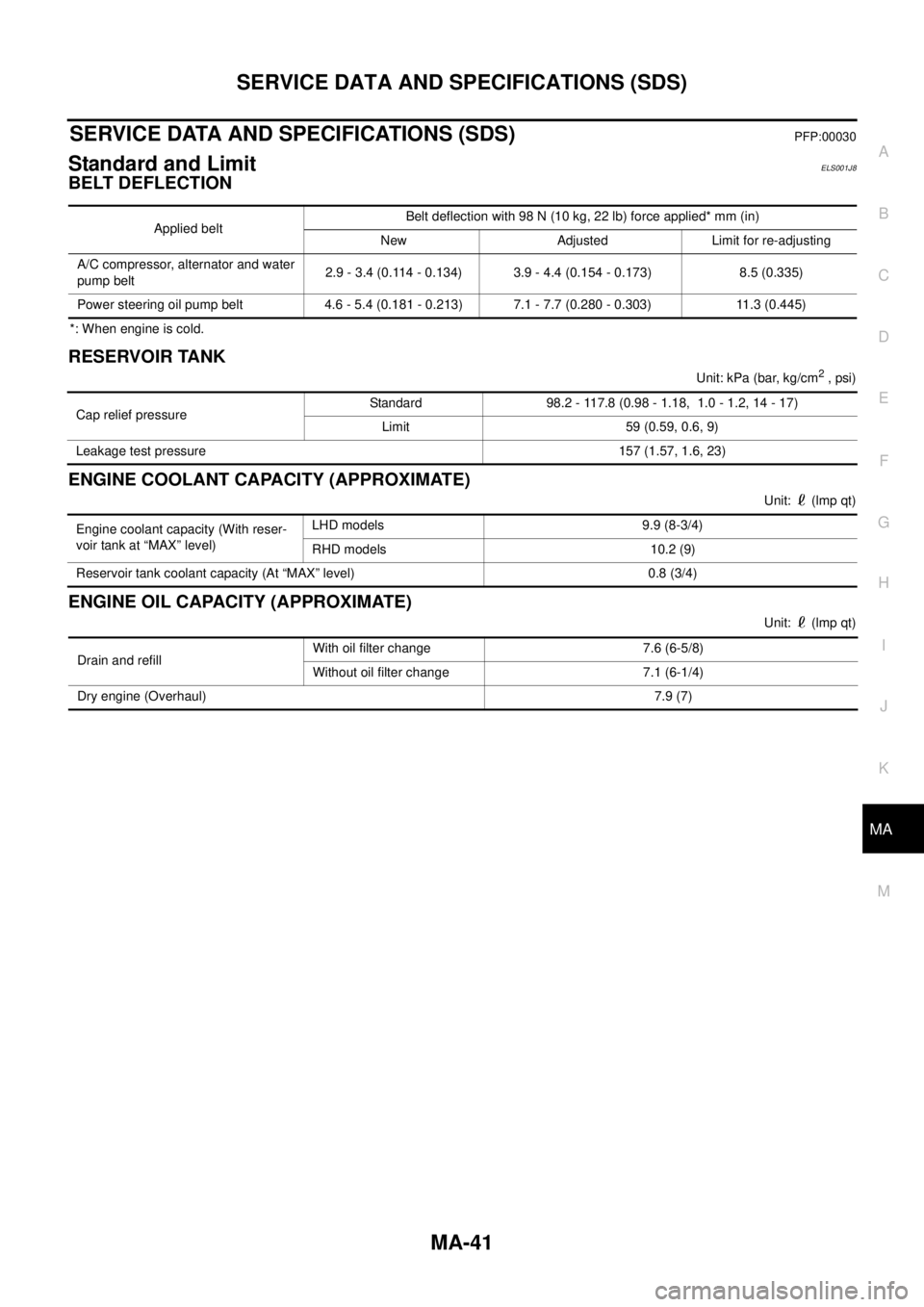

BELT DEFLECTION

*: When engine is cold.

RESERVOIR TANK

Unit:kPa(bar,kg/cm2, psi)

ENGINE COOLANT CAPACITY (APPROXIMATE)

Unit: (lmp qt)

ENGINE OIL CAPACITY (APPROXIMATE)

Unit: (lmp qt) Applied beltBelt deflection with 98 N (10 kg, 22 lb) force applied* mm (in)

New Adjusted Limit for re-adjusting

A/C compressor, alternator and water

pump belt2.9 - 3.4 (0.114 - 0.134) 3.9 - 4.4 (0.154 - 0.173) 8.5 (0.335)

Power steering oil pump belt 4.6 - 5.4 (0.181 - 0.213) 7.1 - 7.7 (0.280 - 0.303) 11.3 (0.445)

Cap relief pressureStandard 98.2 - 117.8 (0.98 - 1.18, 1.0 - 1.2, 14 - 17)

Limit 59 (0.59, 0.6, 9)

Leakage test pressure 157 (1.57, 1.6, 23)

Engine coolant capacity (With reser-

voir tank at “MAX” level)LHD models 9.9 (8-3/4)

RHD models 10.2 (9)

Reservoir tank coolant capacity (At “MAX” level) 0.8 (3/4)

Drain and refillWith oil filter change 7.6 (6-5/8)

Without oil filter change 7.1 (6-1/4)

Dry engine (Overhaul)7.9 (7)

Page 2413 of 3171

MTC-26

AIR CONDITIONER CONTROL

AIR CONDITIONER CONTROL

PFP:27500

DescriptionEJS005FW

The front air control provides regulation of the vehicle's interior temperature. The system is based on the posi-

tion of the front air controls temperature switch selected by the driver. This is done by utilizing a microcom-

puter, also referred to as the front air control, which receives input signals from the following three sensors:

lIntake sensor

lPBR (Position Balanced Resistor).

The front air control uses these signals (including the set position of the temperature switch) to control:

lOutlet air volume

lAir temperature

lAir distribution

The front air control is used to select:

lOutlet air volume

lAir temperature/distribution

OperationEJS005FX

AIR MIX DOOR CONTROL

The air mix door is controlled so that in-vehicle temperature changed based on the position of the temperature

switch.

BLOWER SPEED CONTROL

Blower speed is controlled based on front blower switch settings.

When blower switch is turned, the blower motor starts and increases air flow volume each time the blower

switch is turned counterclockwise, and decreases air flow volume each time the blower switch is turned coun-

terclockwise.

When engine coolant temperature is low, the blower motor operation is delayed to prevent cool air from flow-

ing.

INTAKE DOORS CONTROL

The intake doors are controlled by the recirculation switch setting, and the mode (defroster) switch setting.

MODE DOOR CONTROL

The mode door is controlled by the position of the mode switch.

DEFROSTER DOOR CONTROL

The defroster door is controlled by: Turning the defroster dial to front defroster.

Page 2480 of 3171

TROUBLE DIAGNOSIS

MTC-93

C

D

E

F

G

H

I

K

L

MA

B

MTC

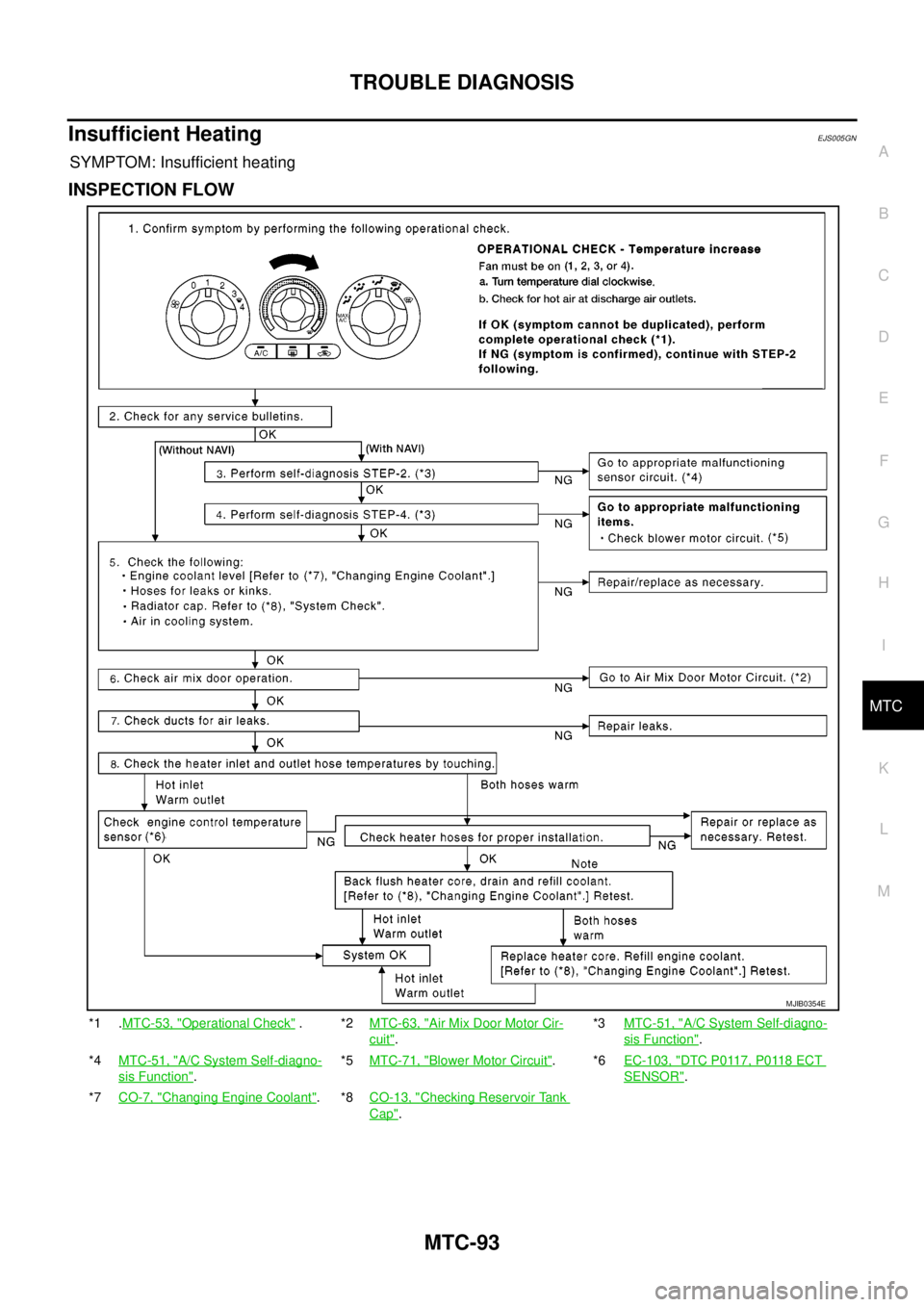

Insufficient HeatingEJS005GN

SYMPTOM: Insufficient heating

INSPECTION FLOW

*1 .MTC-53, "Operational Check".*2MTC-63, "Air Mix Door Motor Cir-

cuit".*3MTC-51, "

A/C System Self-diagno-

sis Function".

*4MTC-51, "

A/C System Self-diagno-

sis Function".*5MTC-71, "

Blower Motor Circuit".*6EC-103, "DTC P0117, P0118 ECT

SENSOR".

*7CO-7, "

Changing Engine Coolant".*8CO-13, "Checking Reservoir Tank

Cap".

MJIB0354E

Page 2490 of 3171

HEATER & COOLING UNIT ASSEMBLY

MTC-103

C

D

E

F

G

H

I

K

L

MA

B

MTC

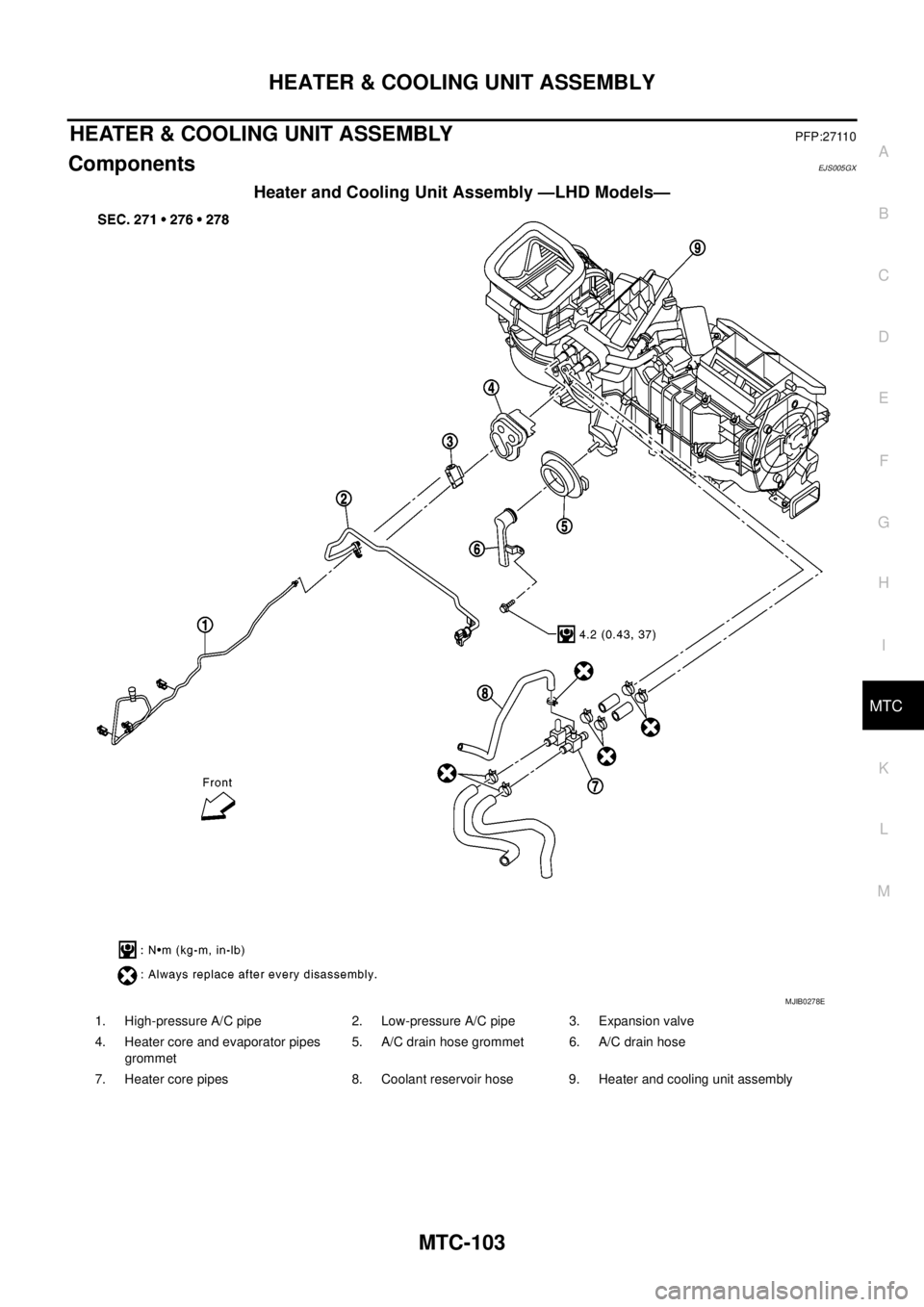

HEATER & COOLING UNIT ASSEMBLYPFP:27110

ComponentsEJS005GX

Heater and Cooling Unit Assembly —LHD Models—

MJIB0278E

1. High-pressure A/C pipe 2. Low-pressure A/C pipe 3. Expansion valve

4. Heater core and evaporator pipes

grommet5. A/C drain hose grommet 6. A/C drain hose

7. Heater core pipes 8. Coolant reservoir hose 9. Heater and cooling unit assembly