coolant NISSAN NAVARA 2005 Repair Workshop Manual

[x] Cancel search | Manufacturer: NISSAN, Model Year: 2005, Model line: NAVARA, Model: NISSAN NAVARA 2005Pages: 3171, PDF Size: 49.59 MB

Page 2492 of 3171

HEATER & COOLING UNIT ASSEMBLY

MTC-105

C

D

E

F

G

H

I

K

L

MA

B

MTC

Removal and InstallationEJS005GY

REMOVAL

1. Discharge the refrigerant from the A/C system. Refer toMTC-118, "Discharging Refrigerant".

2. Drain the coolant from the engine cooling system. Refer toCO-8, "

DRAINING ENGINE COOLANT".

3. Remove the cowl top extension. Refer toEI-20, "

Removal and Installation".

4. Remove the exhaust system. Refer toEX-3, "

Removal and Installation".

5. Disconnect the heater hoses from the heater core.

6. Disconnect the high/low pressure pipes from the expansion valve.

7. Move the two front seats to the rearmost position on the seat track.

8. Remove the instrument panel and console panel. Refer toIP-10, "

Removal and Installation".

9. Remove the steering column. Refer toPS-11, "

Removal and Installation".

10. Disconnect the instrument panel wire harness at the RH and LH in-line connector brackets, and the fuse

block (J/B) electrical connectors. Refer toPG-38, "

Harness Layout".

11. Disconnect the steering member from each side of the vehicle body.

12. Remove the heater and cooling unit assembly with it attached to the steering member, from the vehicle.

CAUTION:

Use care not to damage the seats and interior trim panels when removing the heater and cooling

unit assembly with it attached to the steering member.

13. Remove the heater and cooling unit assembly from the steering member.

INSTALLATION

Installation is in the reverse order of removal.

CAUTION:

lReplace the O-ring of the low-pressure pipe and high-pressure pipe with a new one, and apply

compressor oil to it when installing it.

lAfter charging the refrigerant, check for leaks.

NOTE:

lFill the engine cooling system with the specified coolant mixture. Refer toCO-8, "REFILLING ENGINE

COOLANT".

lRecharge the A/C system. Refer toMTC-118, "Evacuating System and Charging Refrigerant".

Page 2494 of 3171

HEATER CORE

MTC-107

C

D

E

F

G

H

I

K

L

MA

B

MTC

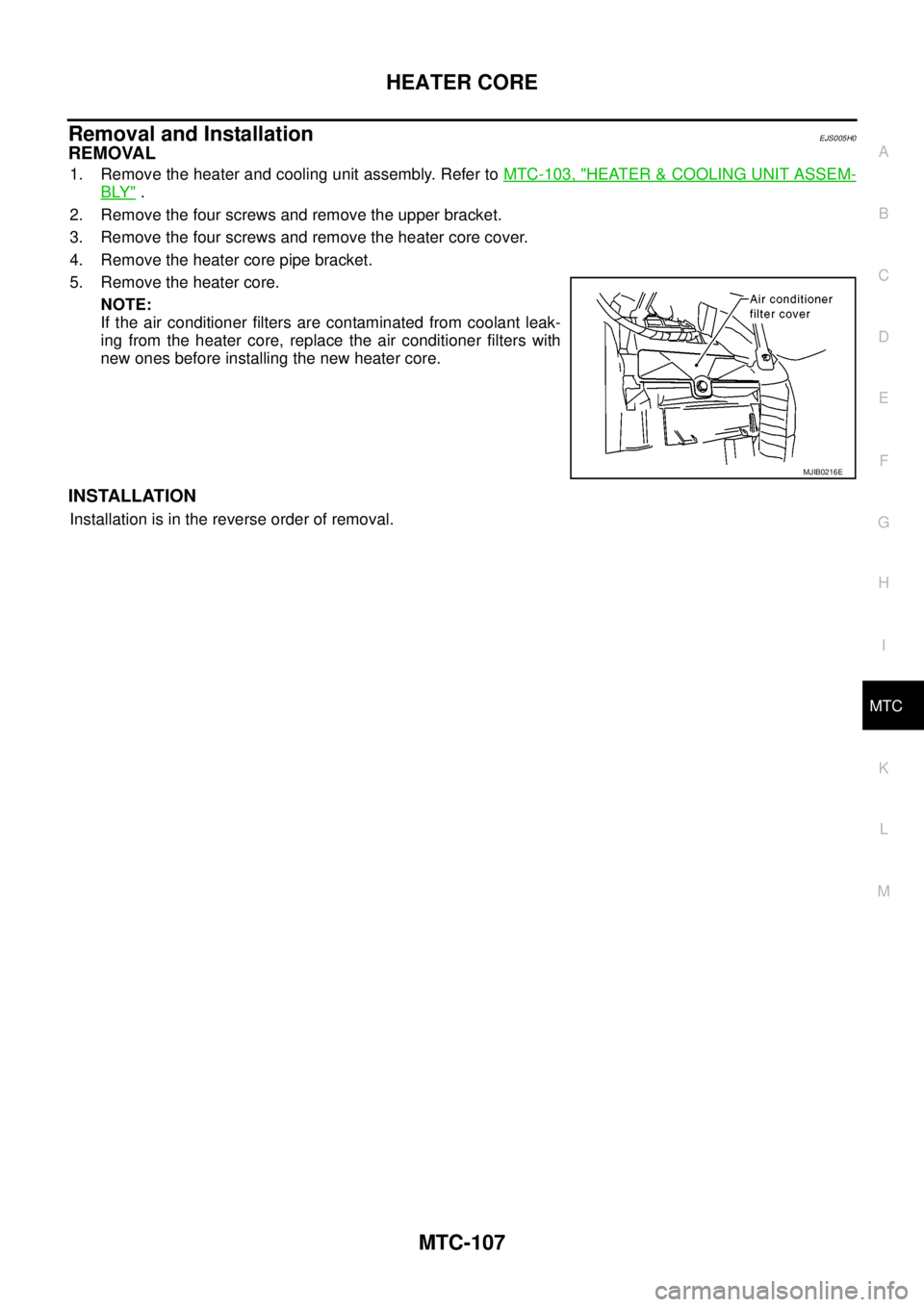

Removal and InstallationEJS005H0

REMOVAL

1. Remove the heater and cooling unit assembly. Refer toMTC-103, "HEATER&COOLING UNIT ASSEM-

BLY".

2. Remove the four screws and remove the upper bracket.

3. Remove the four screws and remove the heater core cover.

4. Remove the heater core pipe bracket.

5. Remove the heater core.

NOTE:

If the air conditioner filters are contaminated from coolant leak-

ing from the heater core, replace the air conditioner filters with

new ones before installing the new heater core.

INSTALLATION

Installation is in the reverse order of removal.

MJIB0216E

Page 2597 of 3171

PG-68

HARNESS

Wiring Diagram Codes (Cell Codes)

EKS00LJ9

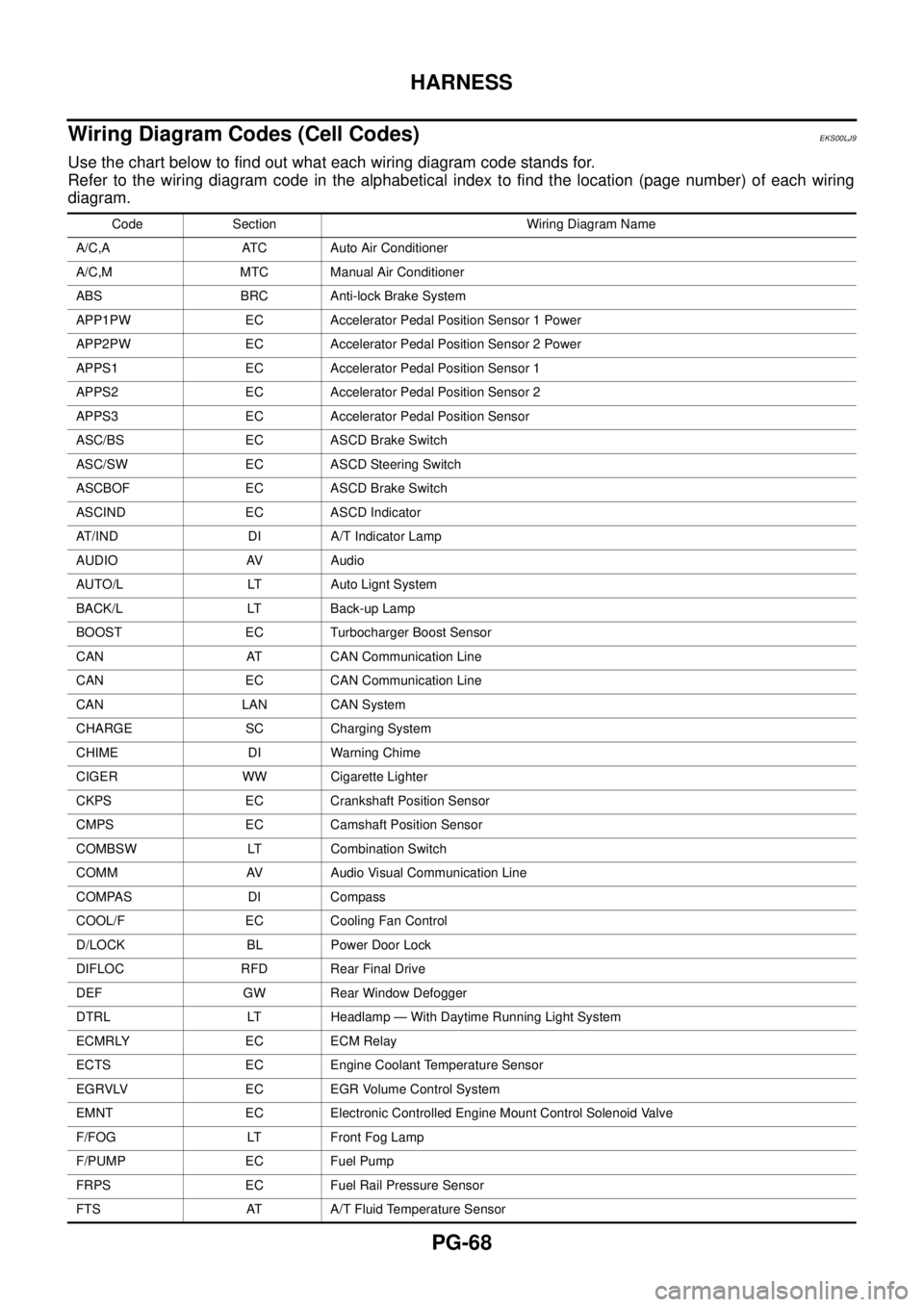

Use the chart below to find out what each wiring diagram code stands for.

Refer to the wiring diagram code in the alphabetical index to find the location (page number) of each wiring

diagram.

Code Section Wiring Diagram Name

A/C,A ATC Auto Air Conditioner

A/C,M MTC Manual Air Conditioner

ABS BRC Anti-lock Brake System

APP1PW EC Accelerator Pedal Position Sensor 1 Power

APP2PW EC Accelerator Pedal Position Sensor 2 Power

APPS1 EC Accelerator Pedal Position Sensor 1

APPS2 EC Accelerator Pedal Position Sensor 2

APPS3 EC Accelerator Pedal Position Sensor

ASC/BS EC ASCD Brake Switch

ASC/SW EC ASCD Steering Switch

ASCBOF EC ASCD Brake Switch

ASCIND EC ASCD Indicator

AT/IND DI A/T Indicator Lamp

AUDIO AV Audio

AUTO/L LT Auto Lignt System

BACK/L LT Back-up Lamp

BOOST EC Turbocharger Boost Sensor

CAN AT CAN Communication Line

CAN EC CAN Communication Line

CAN LAN CAN System

CHARGE SC Charging System

CHIME DI Warning Chime

CIGER WW Cigarette Lighter

CKPS EC Crankshaft Position Sensor

CMPS EC Camshaft Position Sensor

COMBSW LT Combination Switch

COMM AV Audio Visual Communication Line

COMPAS DI Compass

COOL/F EC Cooling Fan Control

D/LOCK BL Power Door Lock

DIFLOC RFD Rear Final Drive

DEF GW Rear Window Defogger

DTRL LT Headlamp — With Daytime Running Light System

ECMRLY EC ECM Relay

ECTS EC Engine Coolant Temperature Sensor

EGRVLV EC EGR Volume Control System

EMNT EC Electronic Controlled Engine Mount Control Solenoid Valve

F/FOG LT Front Fog Lamp

F/PUMP EC Fuel Pump

FRPS EC Fuel Rail Pressure Sensor

FTS AT A/T Fluid Temperature Sensor

Page 2665 of 3171

![NISSAN NAVARA 2005 Repair Workshop Manual RAX-2

[M226]

PRECAUTIONS

[M226]PRECAUTIONSPFP:00001

PrecautionsEDS003HT

lWhen installing the rubber bushings, the final tightening must be done under unladen condition and with

the tires on level grou NISSAN NAVARA 2005 Repair Workshop Manual RAX-2

[M226]

PRECAUTIONS

[M226]PRECAUTIONSPFP:00001

PrecautionsEDS003HT

lWhen installing the rubber bushings, the final tightening must be done under unladen condition and with

the tires on level grou](/img/5/57362/w960_57362-2664.png)

RAX-2

[M226]

PRECAUTIONS

[M226]PRECAUTIONSPFP:00001

PrecautionsEDS003HT

lWhen installing the rubber bushings, the final tightening must be done under unladen condition and with

the tires on level ground. Oil will shorten the life of the rubber bushings, so wipe off any spilled oil immedi-

ately.

lUnladen condition means the fuel tank, engine coolant and lubricants are at the full secification. The

spare tire, jack, hand tools, and mats are in their designated positions.

lLock nuts are not reusable. Always use new lock nuts for installation. New lock nuts are pre-oiled, do not

apply any additional lubrication.

Page 2807 of 3171

RSU-2

PRECAUTIONS

PRECAUTIONS

PFP:00001

PrecautionsEES002JD

lWhen installing rubber parts, final tightening must be carried out under unladen condition* with

tires on ground.

*Fuel, radiator coolant, and engine oil are full. Spare tire, jack, hand tools, and mats are in their

designated positions. Oil will shorten the life of rubber bushings, so wipe off any spilled oil imme-

diately.

lLock nuts are not reusable. Always use new lock nuts for installation. New lock nuts are pre-oiled,

do not apply any additional lubrication.

Page 2810 of 3171

REAR SUSPENSION ASSEMBLY

RSU-5

C

D

F

G

H

I

J

K

L

MA

B

RSU

CAUTION:

When installing the components with rubber bushings, the final tightening of the nuts and bolts must

be done with the vehicle in an unladen condition (the fuel, engine coolant, and engine oil full; the

spare tire, jack, hand tools and mats in their designated positions) with the tires on the ground.

On-Vehicle Inspection and ServiceEES002JH

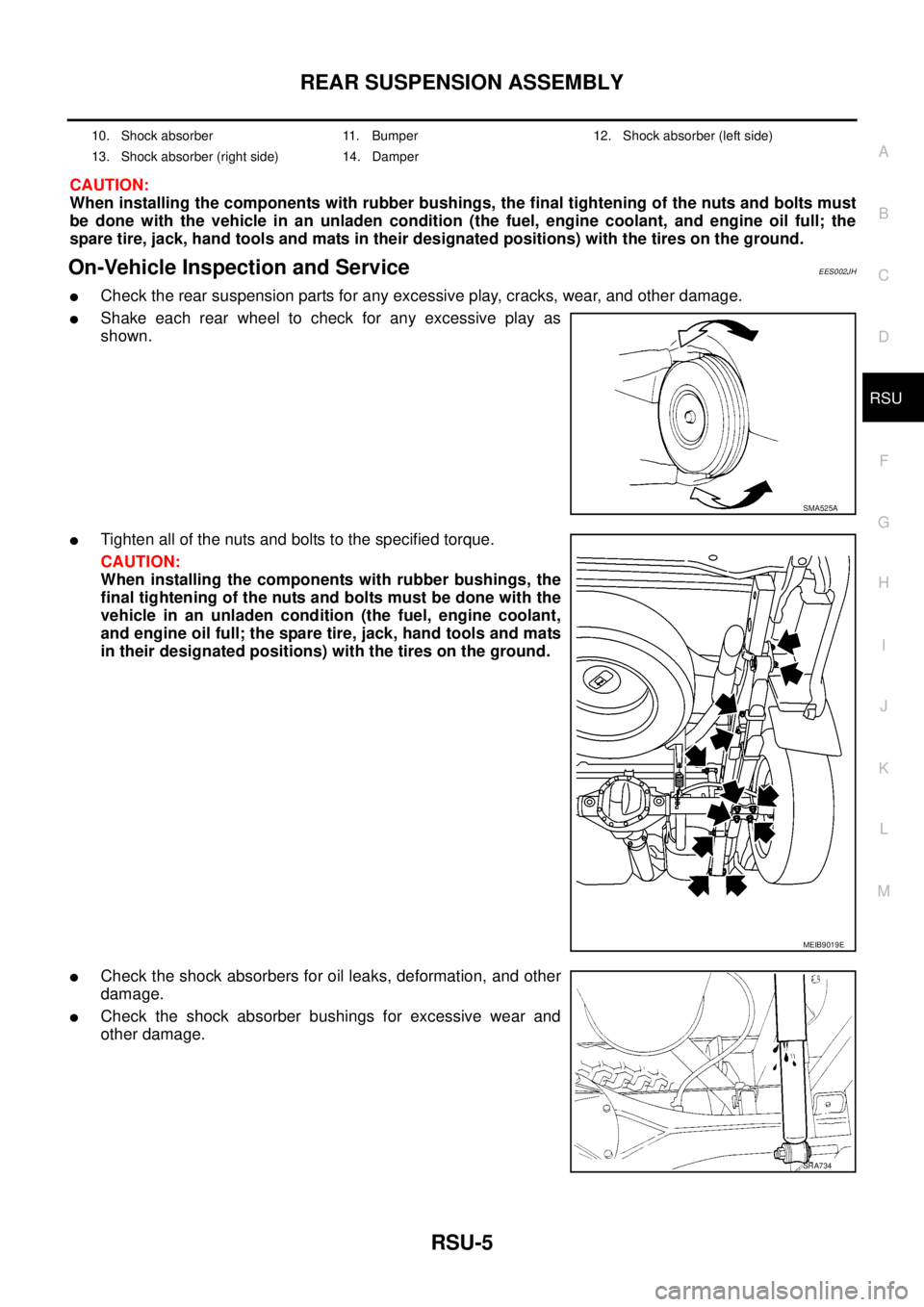

lCheck the rear suspension parts for any excessive play, cracks, wear, and other damage.

lShake each rear wheel to check for any excessive play as

shown.

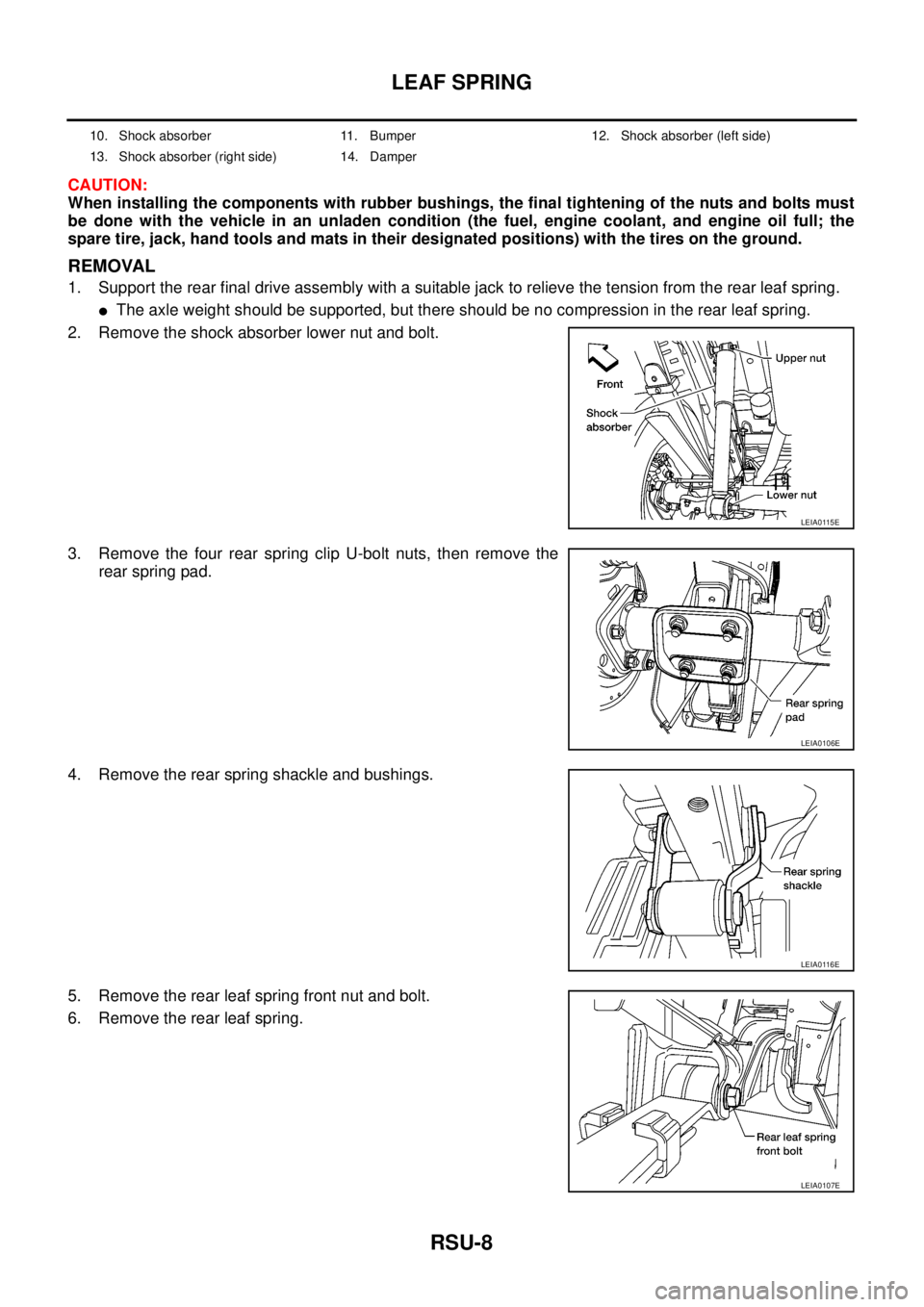

lTighten all of the nuts and bolts to the specified torque.

CAUTION:

When installing the components with rubber bushings, the

final tightening of the nuts and bolts must be done with the

vehicle in an unladen condition (the fuel, engine coolant,

and engine oil full; the spare tire, jack, hand tools and mats

in their designated positions) with the tires on the ground.

lCheck the shock absorbers for oil leaks, deformation, and other

damage.

lCheck the shock absorber bushings for excessive wear and

other damage.

10. Shock absorber 11. Bumper 12. Shock absorber (left side)

13. Shock absorber (right side) 14. Damper

SMA525A

MEIB9019E

SRA734

Page 2813 of 3171

RSU-8

LEAF SPRING

CAUTION:

When installing the components with rubber bushings, the final tightening of the nuts and bolts must

be done with the vehicle in an unladen condition (the fuel, engine coolant, and engine oil full; the

spare tire, jack, hand tools and mats in their designated positions) with the tires on the ground.

REMOVAL

1. Support the rear final drive assembly with a suitable jack to relieve the tension from the rear leaf spring.

lThe axle weight should be supported, but there should be no compression in the rear leaf spring.

2. Remove the shock absorber lower nut and bolt.

3. Remove the four rear spring clip U-bolt nuts, then remove the

rear spring pad.

4. Remove the rear spring shackle and bushings.

5. Remove the rear leaf spring front nut and bolt.

6. Remove the rear leaf spring.

10. Shock absorber 11. Bumper 12. Shock absorber (left side)

13. Shock absorber (right side) 14. Damper

LEIA0115E

LEIA0106E

LEIA0116E

LEIA0107E

Page 2815 of 3171

RSU-10

LEAF SPRING

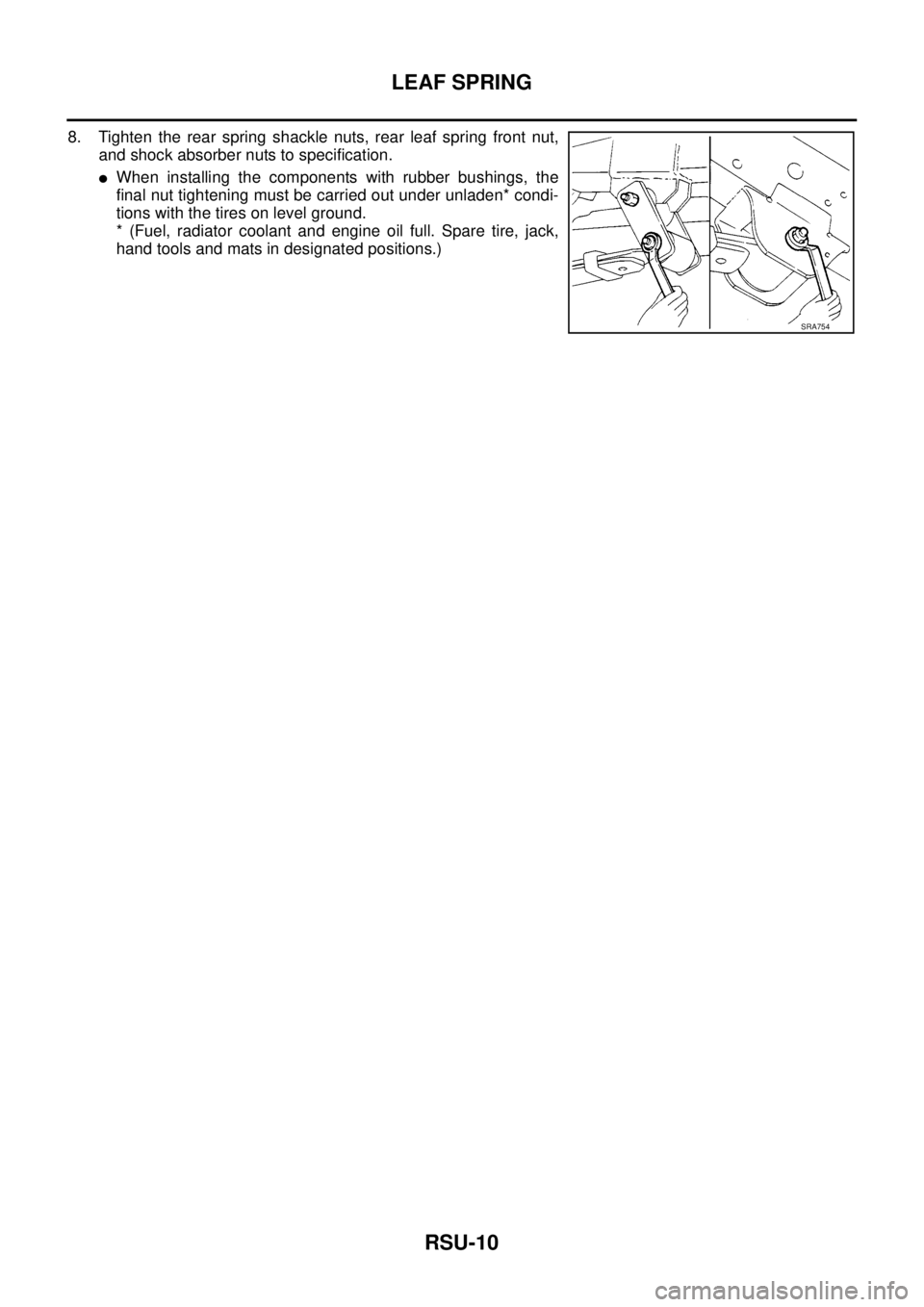

8. Tighten the rear spring shackle nuts, rear leaf spring front nut,

and shock absorber nuts to specification.

lWhen installing the components with rubber bushings, the

final nut tightening must be carried out under unladen* condi-

tions with the tires on level ground.

* (Fuel, radiator coolant and engine oil full. Spare tire, jack,

hand tools and mats in designated positions.)

SRA754

Page 2816 of 3171

SERVICE DATA AND SPECIFICATIONS (SDS)

RSU-11

C

D

F

G

H

I

J

K

L

MA

B

RSU

SERVICE DATA AND SPECIFICATIONS (SDS)PFP:00030

General Specifications (Rear)EES002JK

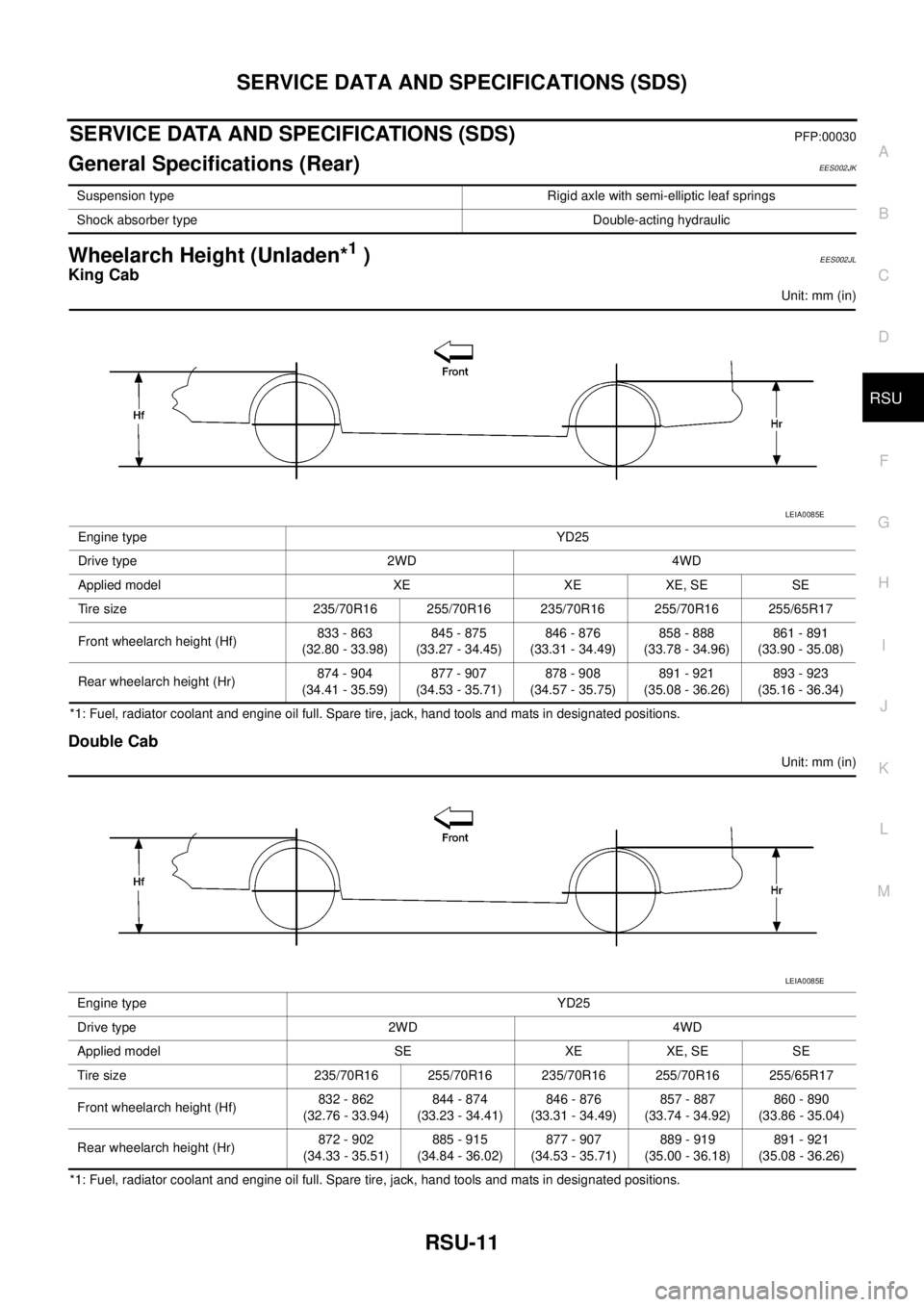

Wheelarch Height (Unladen*1)EES002JL

King Cab

Unit: mm (in)

*1: Fuel, radiator coolant and engine oil full. Spare tire, jack, hand tools and mats in designated positions.

Double Cab

Unit: mm (in)

*1: Fuel, radiator coolant and engine oil full. Spare tire, jack, hand tools and mats in designated positions.Suspension type Rigid axle with semi-elliptic leaf springs

Shock absorber type Double-acting hydraulic

Engine type YD25

Drive type 2WD 4WD

Applied model XE XE XE, SE SE

Tire size 235/70R16 255/70R16 235/70R16 255/70R16 255/65R17

Front wheelarch height (Hf)833 - 863

(32.80 - 33.98)845 - 875

(33.27 - 34.45)846 - 876

(33.31 - 34.49)858 - 888

(33.78 - 34.96)861 - 891

(33.90 - 35.08)

Rear wheelarch height (Hr)874 - 904

(34.41 - 35.59)877 - 907

(34.53 - 35.71)878 - 908

(34.57 - 35.75)891 - 921

(35.08 - 36.26)893 - 923

(35.16 - 36.34)

LEIA0085E

Engine type YD25

Drive type 2WD 4WD

Applied model SE XE XE, SE SE

Tire size 235/70R16 255/70R16 235/70R16 255/70R16 255/65R17

Front wheelarch height (Hf)832 - 862

(32.76 - 33.94)844 - 874

(33.23 - 34.41)846 - 876

(33.31 - 34.49)857 - 887

(33.74 - 34.92)860 - 890

(33.86 - 35.04)

Rear wheelarch height (Hr)872 - 902

(34.33 - 35.51)885 - 915

(34.84 - 36.02)877 - 907

(34.53 - 35.71)889 - 919

(35.00 - 36.18)891 - 921

(35.08 - 36.26)

LEIA0085E