fuse NISSAN NAVARA 2005 Repair Workshop Manual

[x] Cancel search | Manufacturer: NISSAN, Model Year: 2005, Model line: NAVARA, Model: NISSAN NAVARA 2005Pages: 3171, PDF Size: 49.59 MB

Page 3060 of 3171

TROUBLE DIAGNOSIS FOR SYMPTOMS

TF-93

C

E

F

G

H

I

J

K

L

MA

B

TF

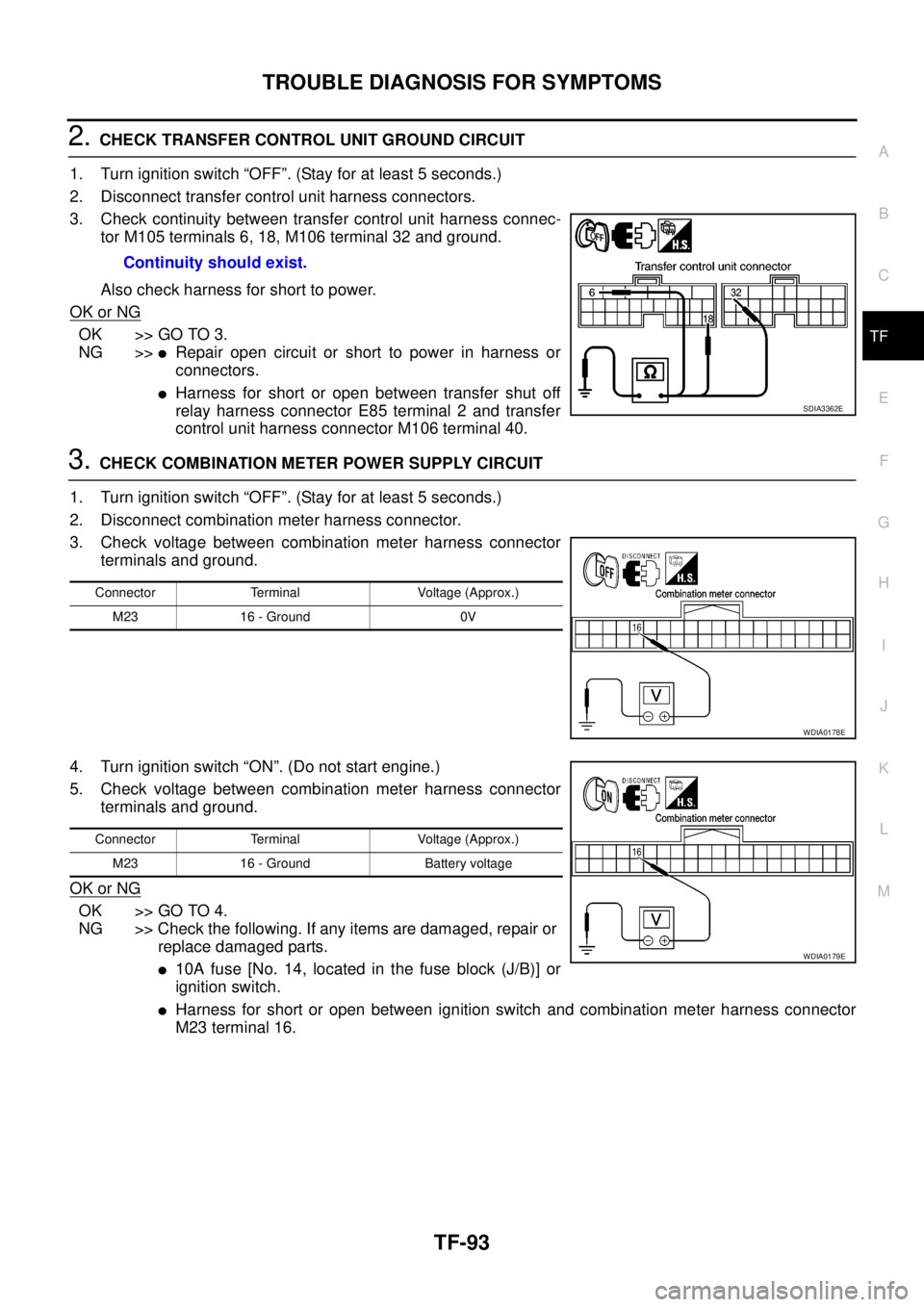

2.CHECK TRANSFER CONTROL UNIT GROUND CIRCUIT

1. Turn ignition switch “OFF”. (Stay for at least 5 seconds.)

2. Disconnect transfer control unit harness connectors.

3. Check continuity between transfer control unit harness connec-

tor M105 terminals 6, 18, M106 terminal 32 and ground.

Also check harness for short to power.

OK or NG

OK >> GO TO 3.

NG >>

lRepair open circuit or short to power in harness or

connectors.

lHarness for short or open between transfer shut off

relay harness connector E85 terminal 2 and transfer

control unit harness connector M106 terminal 40.

3.CHECK COMBINATION METER POWER SUPPLY CIRCUIT

1. Turn ignition switch “OFF”. (Stay for at least 5 seconds.)

2. Disconnect combination meter harness connector.

3. Check voltage between combination meter harness connector

terminals and ground.

4. Turn ignition switch “ON”. (Do not start engine.)

5. Check voltage between combination meter harness connector

terminals and ground.

OK or NG

OK >> GO TO 4.

NG >> Check the following. If any items are damaged, repair or

replace damaged parts.

l10A fuse [No. 14, located in the fuse block (J/B)] or

ignition switch.

lHarness for short or open between ignition switch and combination meter harness connector

M23 terminal 16. Continuity should exist.

SDIA3362E

Connector Terminal Voltage (Approx.)

M23 16 - Ground 0V

WDIA0178E

Connector Terminal Voltage (Approx.)

M23 16 - Ground Battery voltage

WDIA0179E

Page 3115 of 3171

WW-4

FRONT WIPER AND WASHER SYSTEM

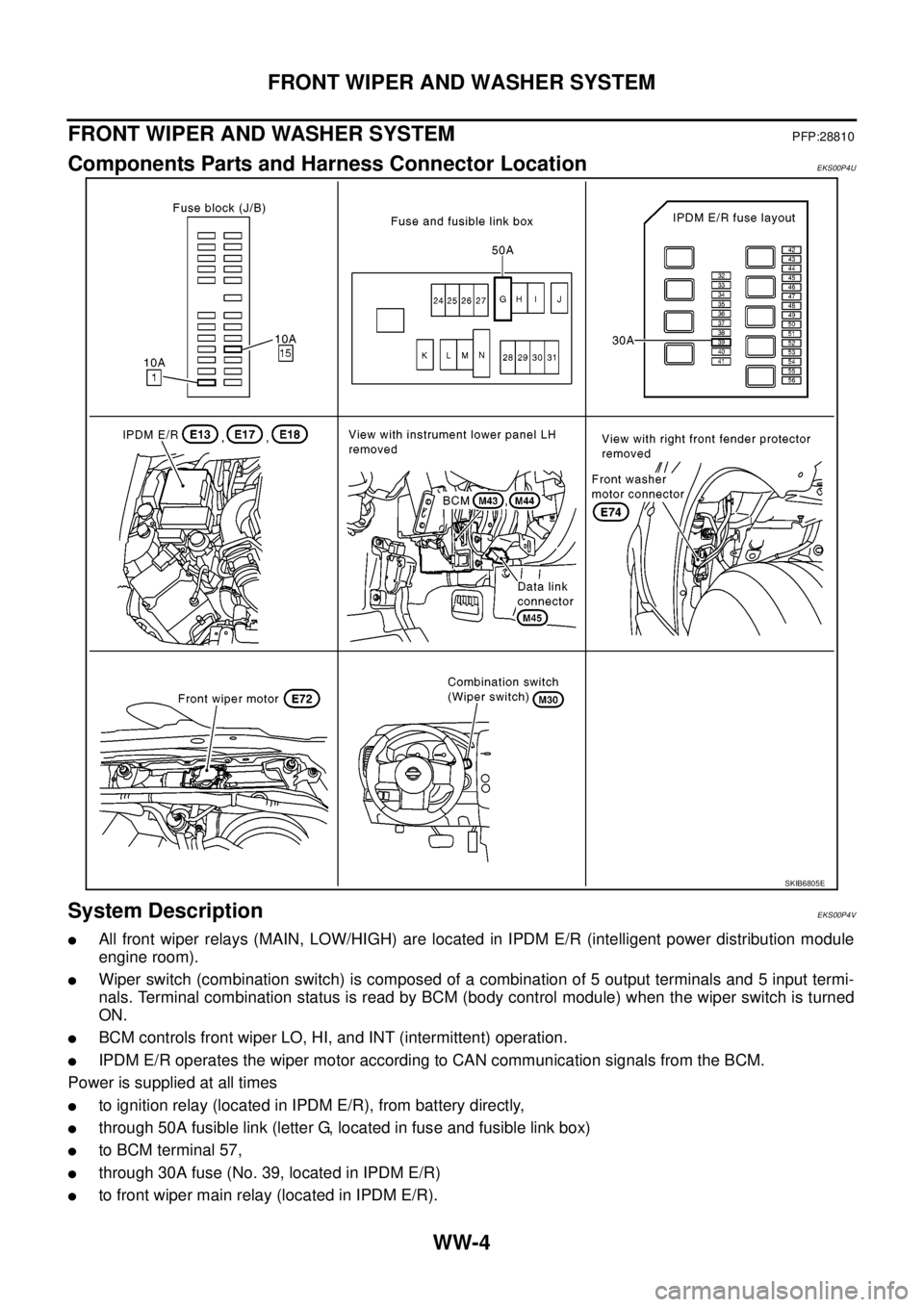

FRONT WIPER AND WASHER SYSTEM

PFP:28810

Components Parts and Harness Connector LocationEKS00P4U

System DescriptionEKS00P4V

lAll front wiper relays (MAIN, LOW/HIGH) are located in IPDM E/R (intelligent power distribution module

engine room).

lWiper switch (combination switch) is composed of a combination of 5 output terminals and 5 input termi-

nals. Terminal combination status is read by BCM (body control module) when the wiper switch is turned

ON.

lBCM controls front wiper LO, HI, and INT (intermittent) operation.

lIPDM E/R operates the wiper motor according to CAN communication signals from the BCM.

Power is supplied at all times

lto ignition relay (located in IPDM E/R), from battery directly,

lthrough 50A fusible link (letter G, located in fuse and fusible link box)

lto BCM terminal 57,

lthrough 30A fuse (No. 39, located in IPDM E/R)

lto front wiper main relay (located in IPDM E/R).

SKIB6805E

Page 3116 of 3171

![NISSAN NAVARA 2005 Repair Workshop Manual FRONT WIPER AND WASHER SYSTEM

WW-5

C

D

E

F

G

H

I

J

L

MA

B

WW

With the ignition switch in ON or START position, power is supplied

lthrough 10A fuse [No. 15, located in fuse block (J/B)]

lto combination NISSAN NAVARA 2005 Repair Workshop Manual FRONT WIPER AND WASHER SYSTEM

WW-5

C

D

E

F

G

H

I

J

L

MA

B

WW

With the ignition switch in ON or START position, power is supplied

lthrough 10A fuse [No. 15, located in fuse block (J/B)]

lto combination](/img/5/57362/w960_57362-3115.png)

FRONT WIPER AND WASHER SYSTEM

WW-5

C

D

E

F

G

H

I

J

L

MA

B

WW

With the ignition switch in ON or START position, power is supplied

lthrough 10A fuse [No. 15, located in fuse block (J/B)]

lto combination switch terminal 2,

lthrough 10A fuse [No. 1, located in fuse block (J/B)]

lto BCM terminal 3.

Ground is supplied

lto BCM terminal 55 and

lto combination switch terminal 9

lthrough grounds M21, M80 and M83,

lto IPDM E/R terminals 38 and 59 and

lto front wiper motor terminal 2

lthrough grounds E21, E41 and E61.

LOW SPEED WIPER OPERATION

When the ignition switch is in the ON or START position, and the front wiper switch is turned to the low posi-

tion, the BCM detects a low speed wiper ON request through the combination switch (wiper switch) reading

function.

The BCM then sends a front wiper (low) request signal with CAN communication.

lfrom BCM terminals 21 and 22

lto IPDM E/R terminals 39 and 40.

When IPDM E/R receives front wiper (low) request signal, it supplies ground to energize the front wiper main

relay.

With the front wiper LOW/ HIGH relay energized, power is supplied

lthrough front wiper main relay

lthrough front wiper LOW/HIGH relay

lthrough IPDM E/R terminal 32

lto front wiper motor terminal 1.

Ground is supplied

lto front wiper motor terminal 2

lthrough grounds E21, E41 and E61.

With power and ground supplied, the front wiper motor operates at low speed.

HI SPEED WIPER OPERATION

When the ignition switch is in the ON or START position, and the front wiper switch is turned to the high posi-

tion, the BCM detects a high speed wiper ON request through the combination switch (wiper switch) reading

function.

The BCM then sends a front wiper (high) request signal with CAN communication.

lfrom BCM terminals 21 and 22

lto IPDM E/R terminals 39 and 40.

When IPDM E/R receives front wiper (high) request signal, it supplies ground to energize the front wiper main

relays.

With the front wiper LOW/HIGH relays energized, power is supplied

lthrough front wiper main relay

lthrough front wiper LOW/HIGH relay

lthrough IPDM E/R terminal 35

lto front wiper motor terminal 4.

Ground is supplied

lto front wiper motor terminal 2

lthrough grounds E21, E41 and E61.

With power and ground supplied, the front wiper motor operates at high speed.

Page 3117 of 3171

WW-6

FRONT WIPER AND WASHER SYSTEM

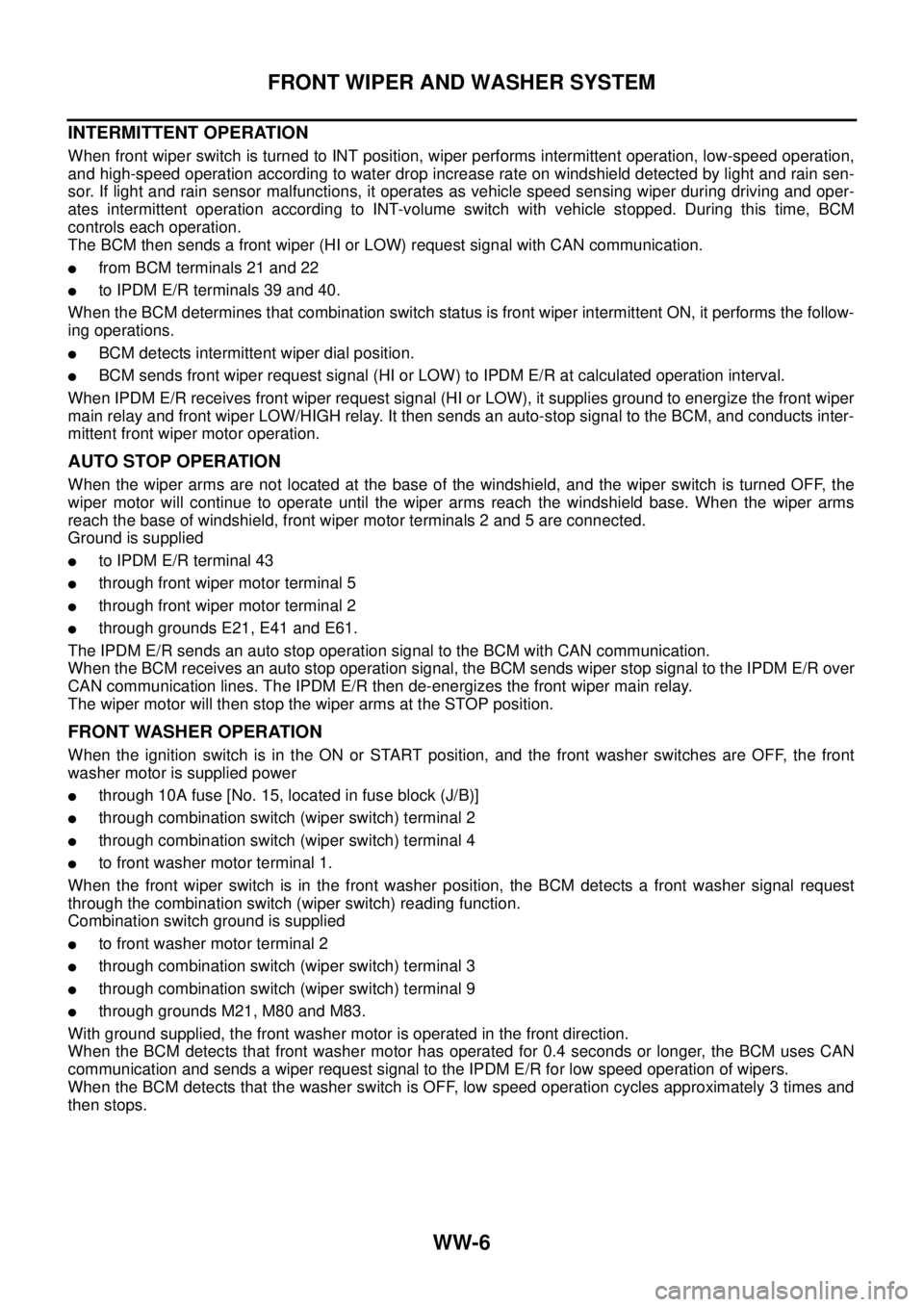

INTERMITTENT OPERATION

When front wiper switch is turned to INT position, wiper performs intermittent operation, low-speed operation,

and high-speed operation according to water drop increase rate on windshield detected by light and rain sen-

sor. If light and rain sensor malfunctions, it operates as vehicle speed sensing wiper during driving and oper-

ates intermittent operation according to INT-volume switch with vehicle stopped. During this time, BCM

controls each operation.

The BCM then sends a front wiper (HI or LOW) request signal with CAN communication.

lfrom BCM terminals 21 and 22

lto IPDM E/R terminals 39 and 40.

When the BCM determines that combination switch status is front wiper intermittent ON, it performs the follow-

ing operations.

lBCM detects intermittent wiper dial position.

lBCM sends front wiper request signal (HI or LOW) to IPDM E/R at calculated operation interval.

When IPDM E/R receives front wiper request signal (HI or LOW), it supplies ground to energize the front wiper

main relay and front wiper LOW/HIGH relay. It then sends an auto-stop signal to the BCM, and conducts inter-

mittent front wiper motor operation.

AUTO STOP OPERATION

When the wiper arms are not located at the base of the windshield, and the wiper switch is turned OFF, the

wiper motor will continue to operate until the wiper arms reach the windshield base. When the wiper arms

reach the base of windshield, front wiper motor terminals 2 and 5 are connected.

Ground is supplied

lto IPDM E/R terminal 43

lthrough front wiper motor terminal 5

lthrough front wiper motor terminal 2

lthrough grounds E21, E41 and E61.

The IPDM E/R sends an auto stop operation signal to the BCM with CAN communication.

When the BCM receives an auto stop operation signal, the BCM sends wiper stop signal to the IPDM E/R over

CAN communication lines. The IPDM E/R then de-energizes the front wiper main relay.

The wiper motor will then stop the wiper arms at the STOP position.

FRONT WASHER OPERATION

When the ignition switch is in the ON or START position, and the front washer switches are OFF, the front

washer motor is supplied power

lthrough 10A fuse [No. 15, located in fuse block (J/B)]

lthrough combination switch (wiper switch) terminal 2

lthrough combination switch (wiper switch) terminal 4

lto front washer motor terminal 1.

When the front wiper switch is in the front washer position, the BCM detects a front washer signal request

through the combination switch (wiper switch) reading function.

Combination switch ground is supplied

lto front washer motor terminal 2

lthrough combination switch (wiper switch) terminal 3

lthrough combination switch (wiper switch) terminal 9

lthrough grounds M21, M80 and M83.

With ground supplied, the front washer motor is operated in the front direction.

When the BCM detects that front washer motor has operated for 0.4 seconds or longer, the BCM uses CAN

communication and sends a wiper request signal to the IPDM E/R for low speed operation of wipers.

When the BCM detects that the washer switch is OFF, low speed operation cycles approximately 3 times and

then stops.

Page 3127 of 3171

WW-16

FRONT WIPER AND WASHER SYSTEM

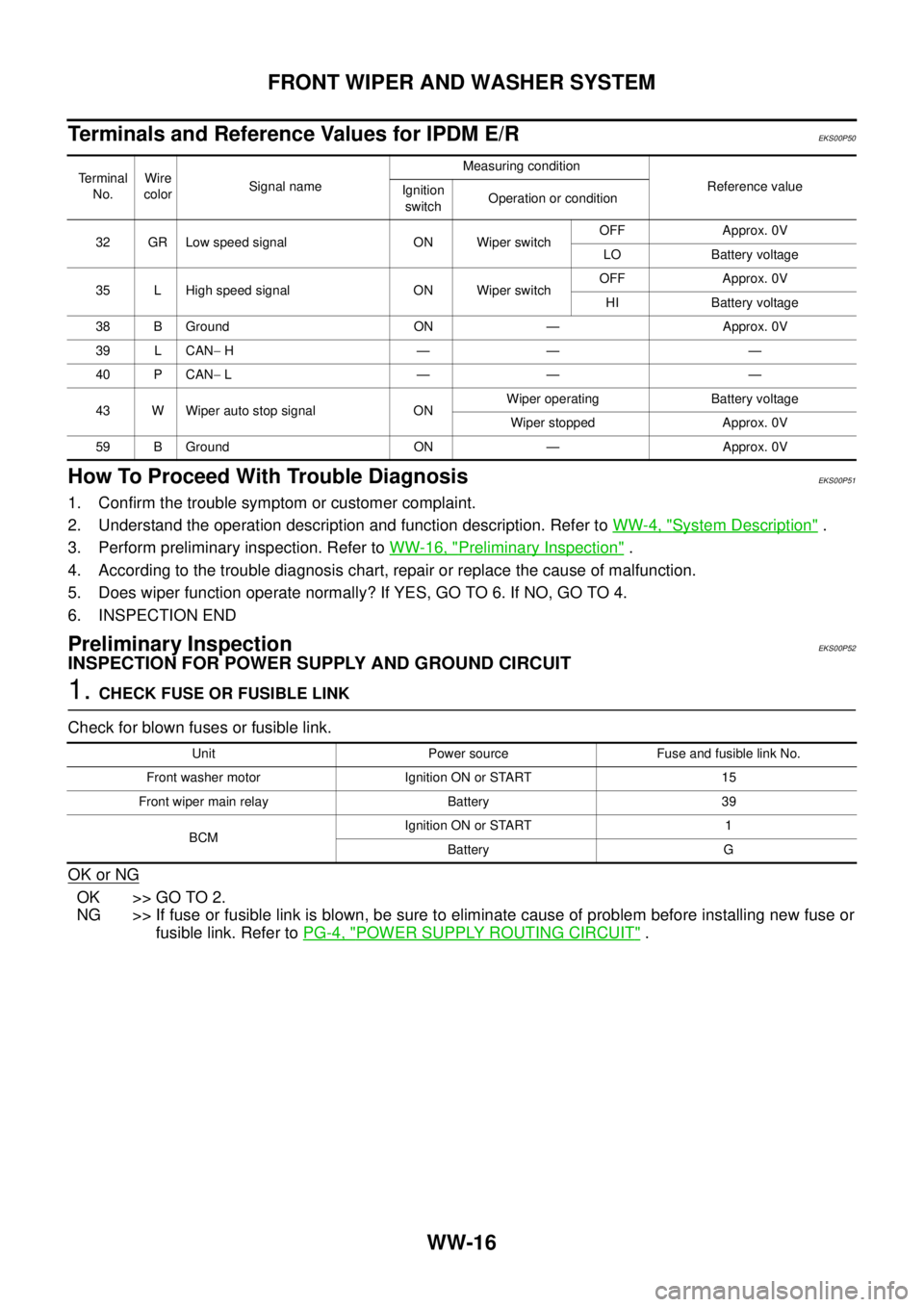

Terminals and Reference Values for IPDM E/R

EKS00P50

How To Proceed With Trouble DiagnosisEKS00P51

1. Confirm the trouble symptom or customer complaint.

2. Understand the operation description and function description. Refer toWW-4, "

System Description".

3. Perform preliminary inspection. Refer toWW-16, "

Preliminary Inspection".

4. According to the trouble diagnosis chart, repair or replace the cause of malfunction.

5. Does wiper function operate normally? If YES, GO TO 6. If NO, GO TO 4.

6. INSPECTION END

Preliminary InspectionEKS00P52

INSPECTION FOR POWER SUPPLY AND GROUND CIRCUIT

1.CHECK FUSE OR FUSIBLE LINK

Check for blown fuses or fusible link.

OK or NG

OK >> GO TO 2.

NG >> If fuse or fusible link is blown, be sure to eliminate cause of problem before installing new fuse or

fusible link. Refer toPG-4, "

POWER SUPPLY ROUTING CIRCUIT".

Te r m i n a l

No.Wire

colorSignal nameMeasuring condition

Reference value

Ignition

switchOperation or condition

32 GR Low speed signal ON Wiper switchOFF Approx. 0V

LO Battery voltage

35 L High speed signal ON Wiper switchOFF Approx. 0V

HI Battery voltage

38 B Ground ON — Approx. 0V

39 L CAN-H—— —

40 P CAN-L—— —

43 W Wiper auto stop signal ONWiper operating Battery voltage

Wiper stopped Approx. 0V

59 B Ground ON — Approx. 0V

Unit Power source Fuse and fusible link No.

Front washer motor Ignition ON or START 15

Front wiper main relay Battery 39

BCMIgnition ON or START 1

Battery G

Page 3151 of 3171

WW-40

HEADLAMP WASHER

OUTLINE

Power is supplied at all times

lto ignition relay (located in IPDM E/R), from battery directly,

lthrough 50A fusible link (letter G, located in fuse and fusible link box),

lto BCM terminal 57,

lthrough 20A fuse (No. 53, located in IPDM E/R)

lto CPU (central processing unit) (located in IPDM E/R).

With the ignition switch in the ON or START position, power is supplied

lto ignition relay (located in IPDM E/R),

lthrough 10A fuse [No. 1, located in fuse block (J/B)]

lto BCM terminal 3,

lthrough 10A fuse [No. 15, located in fuse block (J/B)]

lto combination switch terminal 2.

Ground is supplied

lto BCM terminal 55 and

lto combination switch terminal 9

lthrough grounds M21, M80 and M83,

lto IPDM E/R terminals 38 and 59

lthrough grounds E21, E41 and E61.

When the headlamp washer switch is ON, ground is supplied

lto BCM terminal 35

lthrough headlamp washer switch terminal 1

lthrough headlamp washer switch terminal 2

lthrough ground M21, M80 and M83.

HEADLAMP WASHER OPERATION

With the headlamp washer switch in the ON position, the BCM receives input signal requesting. This input sig-

nal is communicated to the IPDM E/R via the CAN communication. The CPU located in the IPDM E/R controls

the headlamp washer relay coil, which when energized, power is supplied

lthrough 10A fuse (No. 38, located in IPDM E/R)

lthrough IPDM E/R terminal 27

lto headlamp washer relay terminals 2 and 5,

lthrough headlamp washer relay terminal 1

lto IPDM E/R terminal 5,

lthrough headlamp washer relay terminal 3

lto headlamp washer motor terminal 1.

Ground is supplied

lto headlamp washer motor terminal 2

lthrough grounds E21, E41 and E61.

With power and ground supplied, headlamp washer operates.

Page 3155 of 3171

WW-44

HEADLAMP WASHER

How to Proceed with Trouble Diagnosis

EKS00P6C

1. Confirm the symptoms and customer complaint.

2. Understand operation description and function description. Refer toWW-39, "

System Description".

3. Perform the Preliminary Check. Refer toWW-44, "

Preliminary Check".

4. Check symptom and repair or replace the cause of malfunction.

5. Does headlamp washer operate normally? If YES, GO TO 6. If NO, GO TO 4.

6. INSPECTION END

Preliminary CheckEKS00P6D

CHECK POWER SUPPLY AND GROUND CIRCUIT

1.CHECK FUSES OR FUSIBLE LINK

Check for blown fuses or fusible link.

Refer toWW-41, "Wiring Diagram—HLC—".

OK or NG

OK >> GO TO 2

NG >> If fuse or fusible link is blown, be sure to eliminate cause of malfunction before installing new fuse

or fusible link, Refer toPG-4, "

POWER SUPPLY ROUTING CIRCUIT".

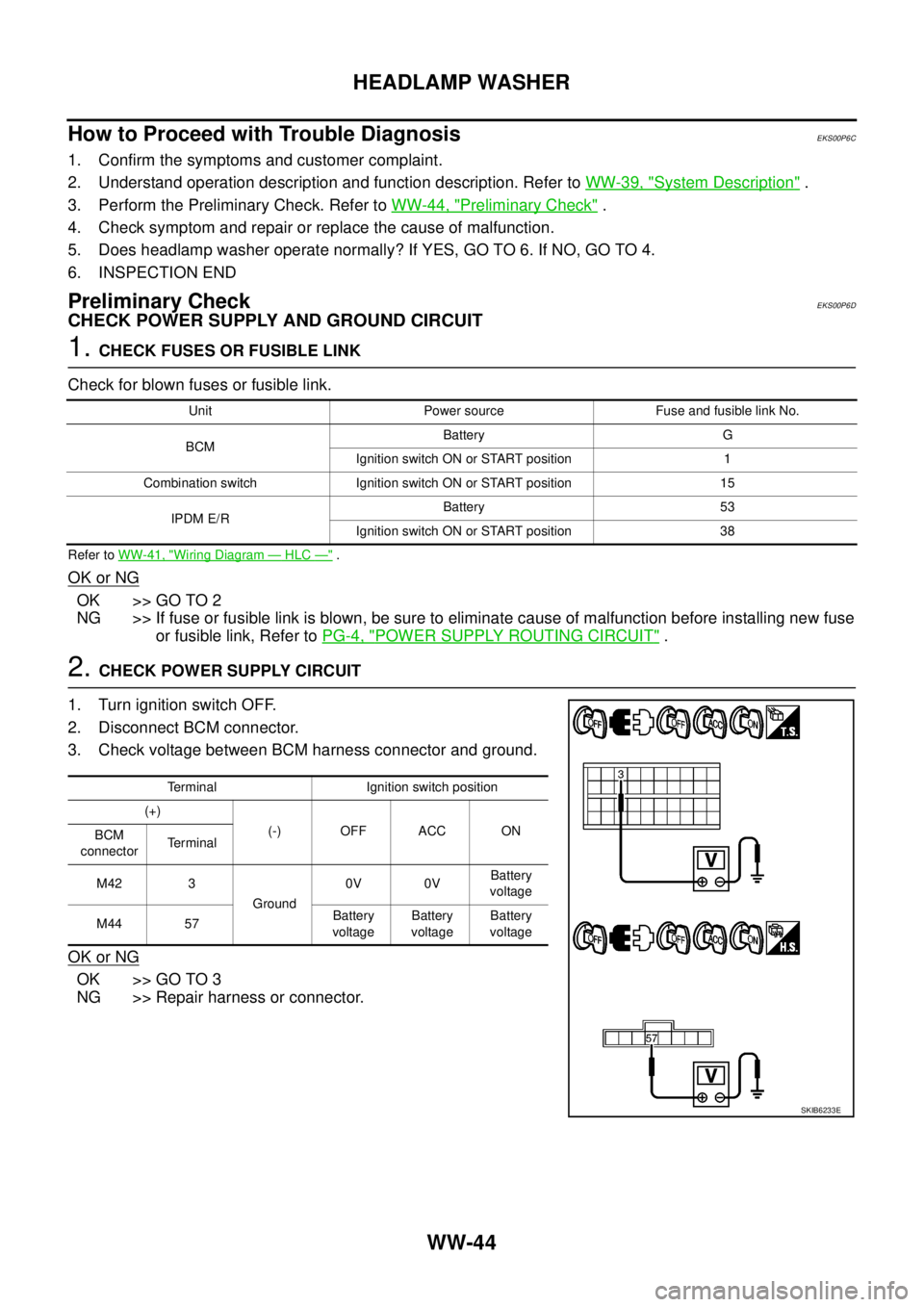

2.CHECK POWER SUPPLY CIRCUIT

1. Turn ignition switch OFF.

2. Disconnect BCM connector.

3. Check voltage between BCM harness connector and ground.

OK or NG

OK >> GO TO 3

NG >> Repair harness or connector.

Unit Power source Fuse and fusible link No.

BCMBattery G

Ignition switch ON or START position 1

Combination switch Ignition switch ON or START position 15

IPDM E/RBattery 53

Ignition switch ON or START position 38

Terminal Ignition switch position

(+)

(-) OFF ACC ON

BCM

connectorTerminal

M42 3

Ground0V 0VBattery

voltage

M44 57Battery

voltageBattery

voltageBattery

voltage

SKIB6233E