fuse NISSAN NAVARA 2005 Repair Workshop Manual

[x] Cancel search | Manufacturer: NISSAN, Model Year: 2005, Model line: NAVARA, Model: NISSAN NAVARA 2005Pages: 3171, PDF Size: 49.59 MB

Page 2693 of 3171

RF-16

SUNROOF

Work Flow

EIS00D52

1. Check the symptom and customer's requests.

2. Understand the outline of system. Refer toRF-11, "

System Description".

3. According to the trouble diagnosis chart, repair or replace the cause of the malfunction. Refer toRF-16,

"Trouble Diagnosis Symptom Chart".

4. Does sunroof system operate normally? If Yes, GO TO 5. If No, GO TO 3.

5. INSPECTION END.

Trouble Diagnosis Symptom ChartEIS00D53

BCM Power Supply and Ground Circuit CheckEIS00D54

1.FUSE INSPECTION

Check the following.

l50A fusible link (letterG, located in the fuse and fusible link box)

l10A fuse [No. 1, located in the fuse block (J/B)]

l10A fuse [No.21 located in the fuse block (J/B)]

NOTE:

Refer toRF-10, "

Component Parts and Harness Connector Location".

OK or NG

OK >> GO TO 2.

NG >> If fuse is blown, be sure to eliminate cause of malfunction before installing new fuse, refer toPG-

4, "POWER SUPPLY ROUTING CIRCUIT".

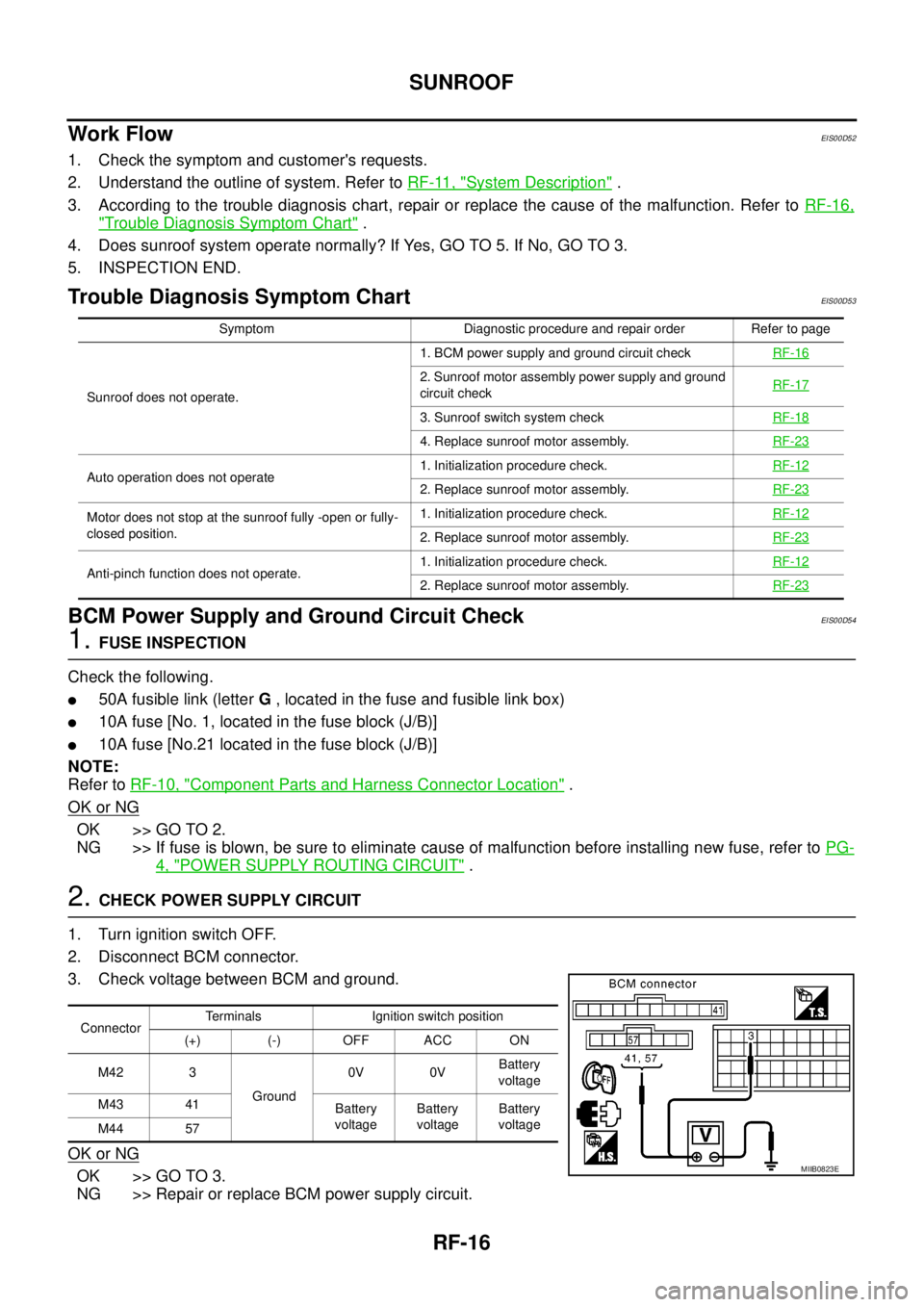

2.CHECK POWER SUPPLY CIRCUIT

1. Turn ignition switch OFF.

2. Disconnect BCM connector.

3. Check voltage between BCM and ground.

OK or NG

OK >> GO TO 3.

NG >> Repair or replace BCM power supply circuit.

Symptom Diagnostic procedure and repair order Refer to page

Sunroof does not operate.1. BCM power supply and ground circuit checkRF-16

2. Sunroof motor assembly power supply and ground

circuit checkRF-17

3. Sunroof switch system checkRF-18

4. Replace sunroof motor assembly.RF-23

Auto operation does not operate1. Initialization procedure check.RF-122. Replace sunroof motor assembly.RF-23

Motor does not stop at the sunroof fully -open or fully-

closed position.1. Initialization procedure check.RF-12

2. Replace sunroof motor assembly.RF-23

Anti-pinch function does not operate.1. Initialization procedure check.RF-122. Replace sunroof motor assembly.RF-23

ConnectorTerminals Ignition switch position

(+) (-) OFF ACC ON

M42 3

Ground0V 0VBattery

voltage

M43 41

Battery

voltageBattery

voltageBattery

voltage

M44 57

MIIB0823E

Page 2758 of 3171

![NISSAN NAVARA 2005 Repair Workshop Manual TROUBLE DIAGNOSIS FOR SYSTEM

RFD-55

[WITH ELECTRONIC LOCKING DIFFERENTIAL]

C

E

F

G

H

I

J

K

L

MA

B

RFD

DIAGNOSTIC PROCEDURE

1.CHECK POWER SUPPLY

1. Turn ignition switch “OFF”.

2. Disconnect differe NISSAN NAVARA 2005 Repair Workshop Manual TROUBLE DIAGNOSIS FOR SYSTEM

RFD-55

[WITH ELECTRONIC LOCKING DIFFERENTIAL]

C

E

F

G

H

I

J

K

L

MA

B

RFD

DIAGNOSTIC PROCEDURE

1.CHECK POWER SUPPLY

1. Turn ignition switch “OFF”.

2. Disconnect differe](/img/5/57362/w960_57362-2757.png)

TROUBLE DIAGNOSIS FOR SYSTEM

RFD-55

[WITH ELECTRONIC LOCKING DIFFERENTIAL]

C

E

F

G

H

I

J

K

L

MA

B

RFD

DIAGNOSTIC PROCEDURE

1.CHECK POWER SUPPLY

1. Turn ignition switch “OFF”.

2. Disconnect differential lock control unit harness connector.

3. Check voltage between differential lock control unit harness

connector terminals and ground.

4. Turn ignition switch “ON”. (Do not start engine.)

5. Check voltage between differential lock control unit harness

connector terminals and ground.

OK or NG

OK >> GO TO 2.

NG >> Check the following. If any items are damaged, repair or

replace damaged parts.

l10A fuse [No. 3 or 19, located in fuse block (J/B)]

lHarness for short or open between battery and differential lock control unit harness connector

terminal 15

lHarness for short or open between ignition switch and differential lock control unit harness con-

nector terminals 1 and 2

lBattery and ignition switch. Refer toPG-4, "POWER SUPPLY ROUTING CIRCUIT".

2.CHECK GROUND CIRCUIT

1. Turn ignition switch “OFF”.

2. Disconnect differential lock control unit harness connector.

3. Check continuity between differential lock control unit harness

connector M107 terminals 3, 10 and ground.

Also check harness for short to ground and short to power.

OK or NG

OK >> GO TO 3.

NG >> Repair open circuit or short to ground or short to power

in harness or connectors.

Connector Terminal Voltage (Approx.)

M1071 - Ground 0V

2 - Ground 0V

15 - Ground Battery voltage

SDIA2562E

Connector Terminal Voltage (Approx.)

M1071 - Ground

Battery voltage 2 - Ground

15 - Ground

SDIA2563E

Continuity should exist.

SDIA2564E

Page 2761 of 3171

![NISSAN NAVARA 2005 Repair Workshop Manual RFD-58

[WITH ELECTRONIC LOCKING DIFFERENTIAL]

TROUBLE DIAGNOSIS FOR SYSTEM

2.CHECK DIFFERENTIAL LOCK MODE SWITCH SUPPLY CIRCUIT

1. Turn ignition switch “ON”.

2. Disconnect differential lock mode s NISSAN NAVARA 2005 Repair Workshop Manual RFD-58

[WITH ELECTRONIC LOCKING DIFFERENTIAL]

TROUBLE DIAGNOSIS FOR SYSTEM

2.CHECK DIFFERENTIAL LOCK MODE SWITCH SUPPLY CIRCUIT

1. Turn ignition switch “ON”.

2. Disconnect differential lock mode s](/img/5/57362/w960_57362-2760.png)

RFD-58

[WITH ELECTRONIC LOCKING DIFFERENTIAL]

TROUBLE DIAGNOSIS FOR SYSTEM

2.CHECK DIFFERENTIAL LOCK MODE SWITCH SUPPLY CIRCUIT

1. Turn ignition switch “ON”.

2. Disconnect differential lock mode switch harness connector.

3. Check voltage between differential lock mode switch harness

connector terminal 3 and ground.

4. Turn ignition switch “OFF”.

5. Check voltage between differential lock mode switch harness

connector terminal 3 and ground.

OK or NG

OK >> GO TO 3.

NG >> Check the following. If any items are damaged, repair or

replace damaged parts.

l10A fuse [No. 3, located in fuse block (J/B)]

lHarness for short or open between ignition switch and differential lock mode switch harness

connector terminal 3

lIgnition switch. Refer toPG-4, "POWER SUPPLY ROUTING CIRCUIT".

3.CHECK DIFFERENTIAL LOCK MODE SWITCH

1. Turn ignition switch “OFF”.

2. Disconnect differential lock mode switch harness connector.

3. Operate differential lock mode switch and check continuity

between differential lock mode switch terminals.

OK or NG

OK >> GO TO 4.

NG >> Replace differential lock mode switch.

Connector Terminal Voltage (Approx.)

M108 3 - Ground Battery voltage

SDIA2534E

Connector Terminal Voltage (Approx.)

M108 3 - Ground 0V

SDIA2643E

Terminal Condition Continuity

1-3Differential lock mode switch: ON No

Differential lock mode switch: OFF Yes

2-3Differential lock mode switch: ON Yes

Differential lock mode switch: OFF No

SDIA2535E

Page 2773 of 3171

![NISSAN NAVARA 2005 Repair Workshop Manual RFD-70

[WITH ELECTRONIC LOCKING DIFFERENTIAL]

TROUBLE DIAGNOSIS FOR SYMPTOMS

TROUBLE DIAGNOSIS FOR SYMPTOMS

PFP:00007

DIFF LOCK Indicator Lamp Does Not Turn ONEDS003B9

SYMPTOM:

DIFF LOCK indicator lam NISSAN NAVARA 2005 Repair Workshop Manual RFD-70

[WITH ELECTRONIC LOCKING DIFFERENTIAL]

TROUBLE DIAGNOSIS FOR SYMPTOMS

TROUBLE DIAGNOSIS FOR SYMPTOMS

PFP:00007

DIFF LOCK Indicator Lamp Does Not Turn ONEDS003B9

SYMPTOM:

DIFF LOCK indicator lam](/img/5/57362/w960_57362-2772.png)

RFD-70

[WITH ELECTRONIC LOCKING DIFFERENTIAL]

TROUBLE DIAGNOSIS FOR SYMPTOMS

TROUBLE DIAGNOSIS FOR SYMPTOMS

PFP:00007

DIFF LOCK Indicator Lamp Does Not Turn ONEDS003B9

SYMPTOM:

DIFF LOCK indicator lamp does not turn ON for approx. 1 second when turning ignition switch to

“ON”.

DIAGNOSTIC PROCEDURE

1.CHECK SYSTEM FOR CAN COMMUNICATION LINE

Perform self-diagnosis. Refer toRFD-51, "

SELF-DIAG RESULTS MODE".

Is

“CAN COMM CIRCUIT”displayed?

YES >> Perform trouble diagnosis for CAN communication line. Refer toRFD-69, "CAN Communication

Line".

NO >> GO TO 2.

2.CHECK DIFFERENTIAL LOCK CONTROL UNIT POWER SUPPLY

1. Turn ignition switch “OFF”.

2. Disconnect differential lock control unit harness connector.

3. Check voltage between differential lock control unit harness

connector terminals and ground.

4. Turn ignition switch “ON”. (Do not start engine.)

5. Check voltage between differential lock control unit harness

connector terminals and ground.

OK or NG

OK >> GO TO 3.

NG >> Check the following. If any items are damaged, repair or

replace damaged parts.

l10A fuse [No. 3 or 19, located in fuse block (J/B)]

lHarness for short or open between battery and differential lock control unit harness connector

terminal 15

lHarness for short or open between ignition switch and differential lock control unit harness con-

nector terminals 1 and 2

lBattery and ignition switch. Refer toPG-4, "POWER SUPPLY ROUTING CIRCUIT".

Connector Terminal Voltage (Approx.)

M1071 - Ground 0V

2 - Ground 0V

15 - Ground Battery voltage

SDIA2562E

Connector Terminal Voltage (Approx.)

M1071 - Ground

Battery voltage 2 - Ground

15 - Ground

SDIA2563E

Page 2774 of 3171

![NISSAN NAVARA 2005 Repair Workshop Manual TROUBLE DIAGNOSIS FOR SYMPTOMS

RFD-71

[WITH ELECTRONIC LOCKING DIFFERENTIAL]

C

E

F

G

H

I

J

K

L

MA

B

RFD

3.CHECK DIFFERENTIAL LOCK CONTROL UNIT GROUND CIRCUIT

1. Turn ignition switch “OFF”.

2. Disc NISSAN NAVARA 2005 Repair Workshop Manual TROUBLE DIAGNOSIS FOR SYMPTOMS

RFD-71

[WITH ELECTRONIC LOCKING DIFFERENTIAL]

C

E

F

G

H

I

J

K

L

MA

B

RFD

3.CHECK DIFFERENTIAL LOCK CONTROL UNIT GROUND CIRCUIT

1. Turn ignition switch “OFF”.

2. Disc](/img/5/57362/w960_57362-2773.png)

TROUBLE DIAGNOSIS FOR SYMPTOMS

RFD-71

[WITH ELECTRONIC LOCKING DIFFERENTIAL]

C

E

F

G

H

I

J

K

L

MA

B

RFD

3.CHECK DIFFERENTIAL LOCK CONTROL UNIT GROUND CIRCUIT

1. Turn ignition switch “OFF”.

2. Disconnect differential lock control unit harness connector.

3. Check continuity between differential lock control unit harness

connector M107 terminals 3, 10 and ground.

Also check harness for short to ground and short to power.

OK or NG

OK >> GO TO 4.

NG >> Repair open circuit or short to ground or short to power

in harness or connectors.

4.CHECK COMBINATION METER POWER SUPPLY CIRCUIT

1. Turn ignition switch “OFF”.

2. Disconnect combination meter harness connector.

3. Check voltage between combination meter harness connector

terminal and ground.

4. Turn ignition switch “ON”. (Do not start engine.)

5. Check voltage between combination meter harness connector

terminal and ground.

OK or NG

OK >> GO TO 5.

NG >> Check the following. If any items are damaged, repair or

replace damaged parts.

l10A fuse [No.14, located in the fuse block (J/B)]

lHarness for short or open between ignition switch and combination meter harness connector

terminal 16.

lIgnition switch. Refer toPG-4, "POWER SUPPLY ROUTING CIRCUIT". Continuity should exist.

SDIA2564E

Connector Terminal Voltage (Approx.)

M23 16 - Ground 0V

WDIA0250E

Connector Terminal Voltage (Approx.)

M23 16 - Ground 0V

WDIA0251E

Page 2847 of 3171

SC-14

CHARGING SYSTEM

CHARGING SYSTEM

PFP:00011

System DescriptionEKS00MZA

The alternator provides DC voltage to operate the vehicle's electrical system and to keep the battery charged.

The voltage output is controlled by the IC regulator.

Power is supplied at all times to alternator terminal 4 through:

l15A fuse (No. 30, located in the fuse and fusible link box).

Terminal 1 supplies power to charge the battery and operate the vehicle's electrical system. Output voltage is

controlled by the IC regulator at terminal 4 detecting the input voltage. The charging circuit is protected by the

140A fusible link (letter "A", located in the fuse and fusible link box) .

The alternator is grounded to the engine block.

With the ignition switch in the ON or START position, power is supplied

l10A fuse [No. 14, located in the fuse block (J/B)]

lto combination meter terminal 16 for the charge warning lamp.

Ground is supplied With power and ground supplied

lto terminal 2 of the combination meter

lthrough terminal 3 of the alternator.

If the charge warning lamp illuminates with the engine running, a fault is indicated.

The charge warning lamp will illuminate. When the alternator is providing sufficient voltage with the engine

running, the ground is opened and the charge warning lamp will go off.

Page 2852 of 3171

CHARGING SYSTEM

SC-19

C

D

E

F

G

H

I

J

L

MA

B

SC

3.CONNECTOR INSPECTION

1. Turn ignition switch OFF.

2. Check alternator connector and terminal 4 (alternator side, and harness side) for damage, deformation or

improper connection.

OK or NG

OK >> GO TO 4.

NG >> Repair terminals and connectors.

4.CHECK FUSE

Check if any of the following fuses in the alternator are blown.

lCheck 15A fuse

OK or NG

OK >> GO TO 5.

NG >> If fuse is blownout, be sure to eliminate cause of malfunction befer installing new fuse.

5.CONTINUITY INSPECTION

1. Turn ignition switch OFF.

2. Disconnect combination meter connector.

3. Check continuity between combination meter connector terminal 2 and ground, and combination meter

connector terminal 2 and alternator terminal 3.

OK or NG

OK >> Replace combination meter. (Do not replace alternator, since it is normal.)

NG >> Repair the harnesses or connectors. (Do not replace alternator, since it is normal.)2 - Ground : Continuity should not exist.

2 - 3 : Continuity should exist.

Page 2854 of 3171

CHARGING SYSTEM

SC-21

C

D

E

F

G

H

I

J

L

MA

B

SC

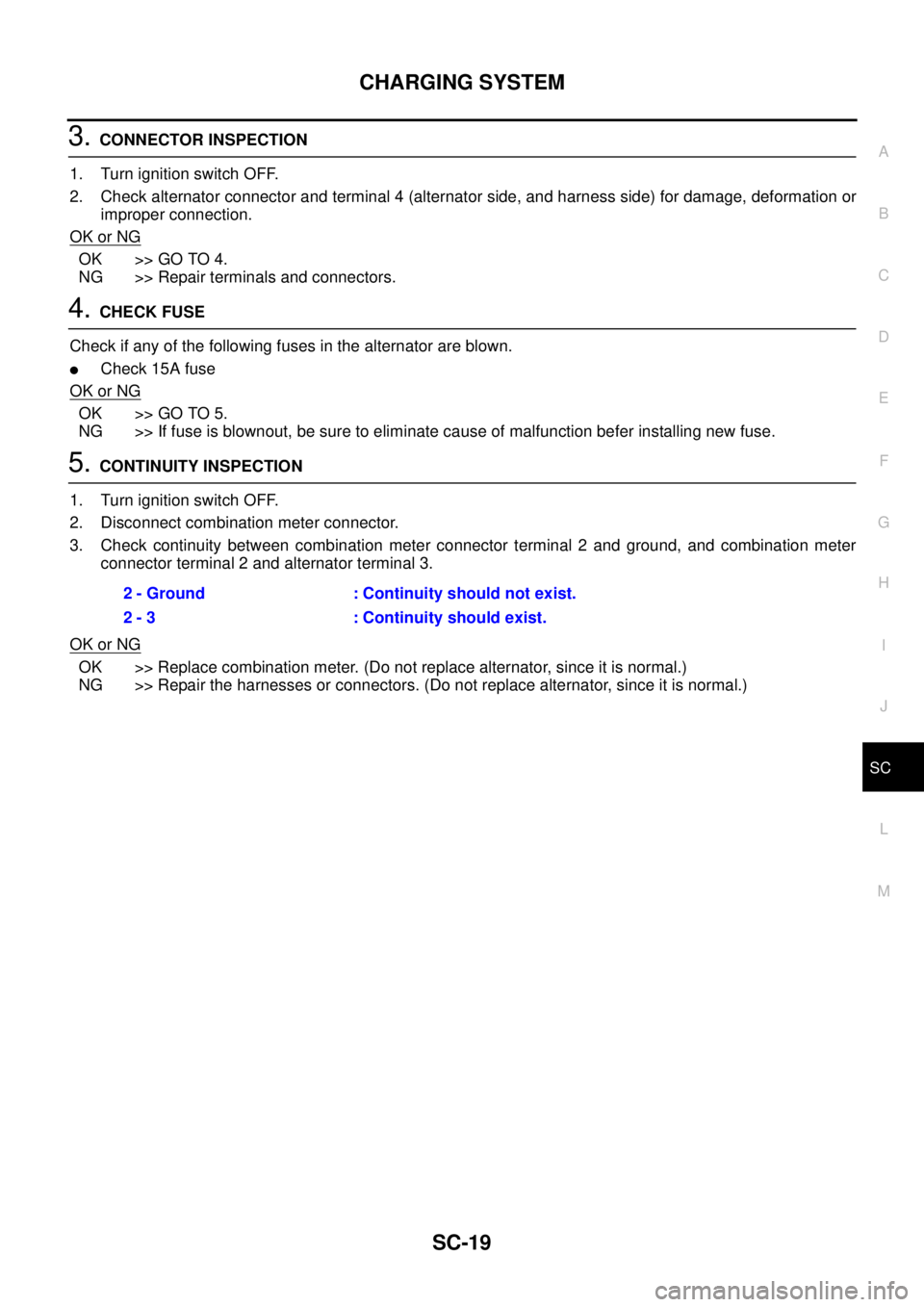

2.BATTERY VOLTAGE INSPECTION

1. Turn ignition switch OFF.

2. Disconnect alternator connector.

3. Turn ignition switch ON.

4. Check voltage between alternator connector terminal 4 and

ground.

Is the inspection result 12V or more?

YES >> Replace alternator. (Alternator power generation error)

NO >> GO TO 3.

3.CHECK FUSE

Check if any of the following fuses in the alternator are blown.

lCheck 15A fuse

OK or NG

OK >> Repair the harnesses.

NG >> If fuse is blownout, be sure to eliminate cause of malfunction befer installing new fuse.

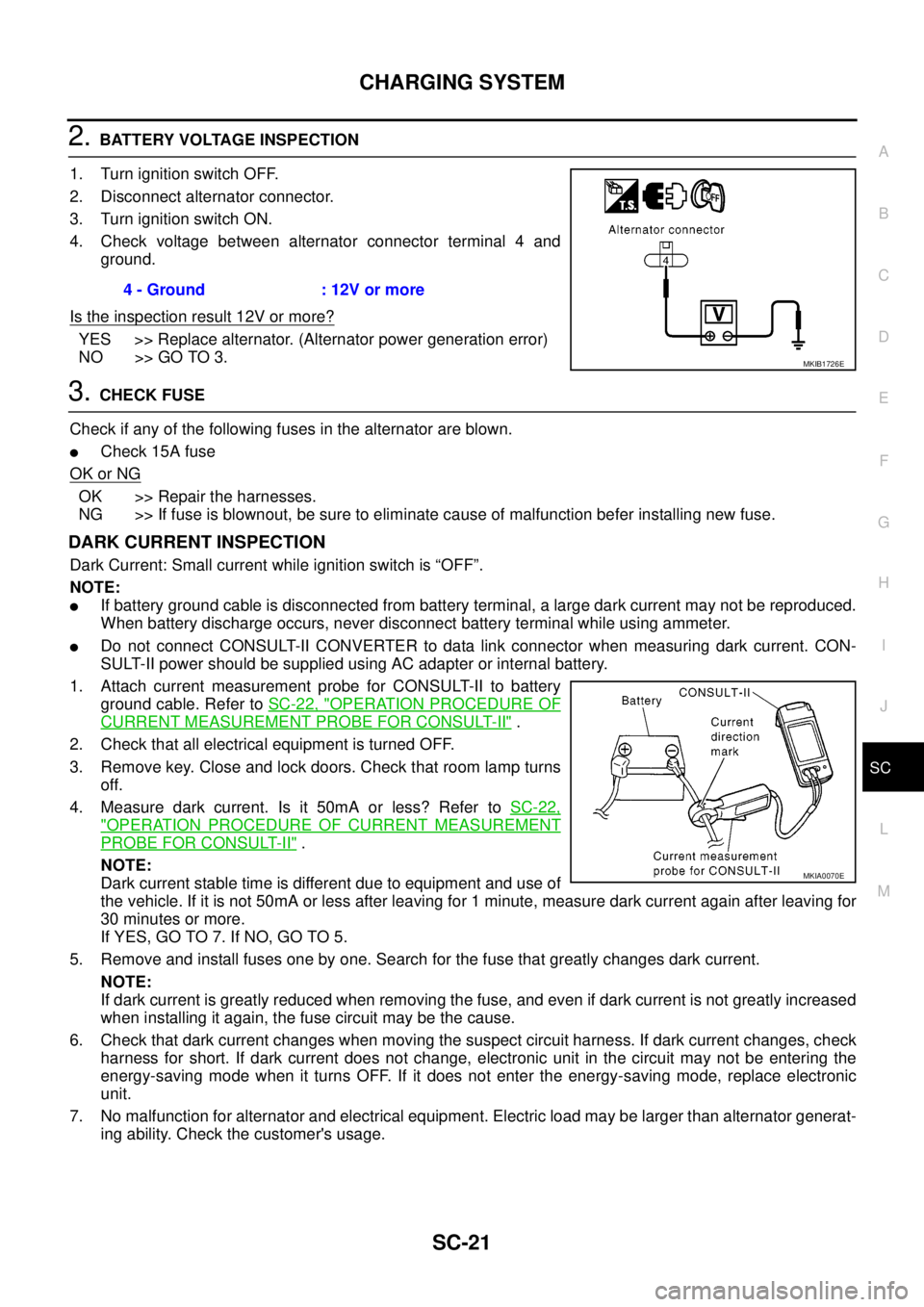

DARK CURRENT INSPECTION

Dark Current: Small current while ignition switch is “OFF”.

NOTE:

lIf battery ground cable is disconnected from battery terminal, a large dark current may not be reproduced.

When battery discharge occurs, never disconnect battery terminal while using ammeter.

lDo not connect CONSULT-II CONVERTER to data link connector when measuring dark current. CON-

SULT-II power should be supplied using AC adapter or internal battery.

1. Attach current measurement probe for CONSULT-II to battery

ground cable. Refer toSC-22, "

OPERATION PROCEDURE OF

CURRENT MEASUREMENT PROBE FOR CONSULT-II".

2. Check that all electrical equipment is turned OFF.

3. Remove key. Close and lock doors. Check that room lamp turns

off.

4. Measure dark current. Is it 50mA or less? Refer toSC-22,

"OPERATION PROCEDURE OF CURRENT MEASUREMENT

PROBE FOR CONSULT-II".

NOTE:

Dark current stable time is different due to equipment and use of

the vehicle. If it is not 50mA or less after leaving for 1 minute, measure dark current again after leaving for

30 minutes or more.

If YES, GO TO 7. If NO, GO TO 5.

5. Remove and install fuses one by one. Search for the fuse that greatly changes dark current.

NOTE:

If dark current is greatly reduced when removing the fuse, and even if dark current is not greatly increased

when installing it again, the fuse circuit may be the cause.

6. Check that dark current changes when moving the suspect circuit harness. If dark current changes, check

harness for short. If dark current does not change, electronic unit in the circuit may not be entering the

energy-saving mode when it turns OFF. If it does not enter the energy-saving mode, replace electronic

unit.

7. No malfunction for alternator and electrical equipment. Electric load may be larger than alternator generat-

ing ability. Check the customer's usage.4 - Ground : 12V or more

MKIB1726E

MKIA0070E

Page 2860 of 3171

STARTING SYSTEM

SC-27

C

D

E

F

G

H

I

J

L

MA

B

SC

STARTING SYSTEMPFP:00011

System DescriptionEKS00MZJ

A/T MODELS

Power is supplied at all times:

lto starter motor terminal 1 and

lthrough 40A fusible link (letterJ, located in the fuse and fusible link box)

lto ignition switch terminal 1.

with the ignition switch in the START position, power is supplied:

lfrom ignition switch terminal 5

lto IPDM E/R terminal 21.

With the ignition switch in the ON or START position, power is supplied to IPDM E/R CPU, and

the selector lever in the P or N position, power is supplied:

lthrough A/T assembly terminal 9

lto IPDM E/R terminal 48.

Ground is supplied at all times:

lto IPDM E/R terminals 38 and 59

lfrom body grounds E21, E41 and E61.

Then the starter relay is turned ON.

The IPDM E/R starter relay is energized and power is supplied:

lfrom terminal 19 of IPDM E/R

lto terminal 2 of the starter motor.

The starter motor plunger closes and provides a closed circuit between the battery and the starter motor. The

starter motor is grounded to the cylinder block. With power and ground supplied, the starter motor operates.

M/T MODELS

Power is supplied at all times:

lto starter motor terminal 1 and

lthrough 40A fusible link (letterJ, located in the fuse and fusible link box)

lto ignition switch terminal 1.

with the ignition switch in the START position, power is supplied:

lfrom ignition switch terminal 5

lto IPDM E/R terminal 21.

With the start signal is input to IPDM E/R CPU, power is supplied:

lthrough IPDM E/R terminal 14

lto IPDM E/R terminal 48.

Ground is supplied at all times:

lto IPDM E/R terminals 38 and 59

lfrom body grounds E21, E41 and E61.

Then the starter relay is turned ON.

The IPDM E/R starter relay is energized and power is supplied:

lfrom terminal 19 of IPDM E/R

lto terminal 2 of the starter motor.

The starter motor plunger closes and provides a closed circuit between the battery and the starter motor. The

starter motor is grounded to the cylinder block. With power and ground supplied, the starter motor operates.

Page 2894 of 3171

FRONT SEAT

SE-23

C

D

E

F

G

H

J

K

L

MA

B

SE

Removal and InstallationEIS00C62

REMOVAL

When removing or installing the seat trim, handle it carefully to keep dirt out and avoid damage.

CAUTION:

lBefore removing the front seat, turn the ignition switch off, disconnect both battery cables and

wait at least 3 minutes.

lWhen checking the power seat circuit for continuity using a circuit tester, do not confuse its con-

nector with the side air bag module connector. Such an error may cause the air bag to deploy.

lDo not drop, tilt, or bump the side air bag module while installing the seat. Always handle it with

care.

lAfter front side air bag module inflates, front seatback assembly must be replaced.

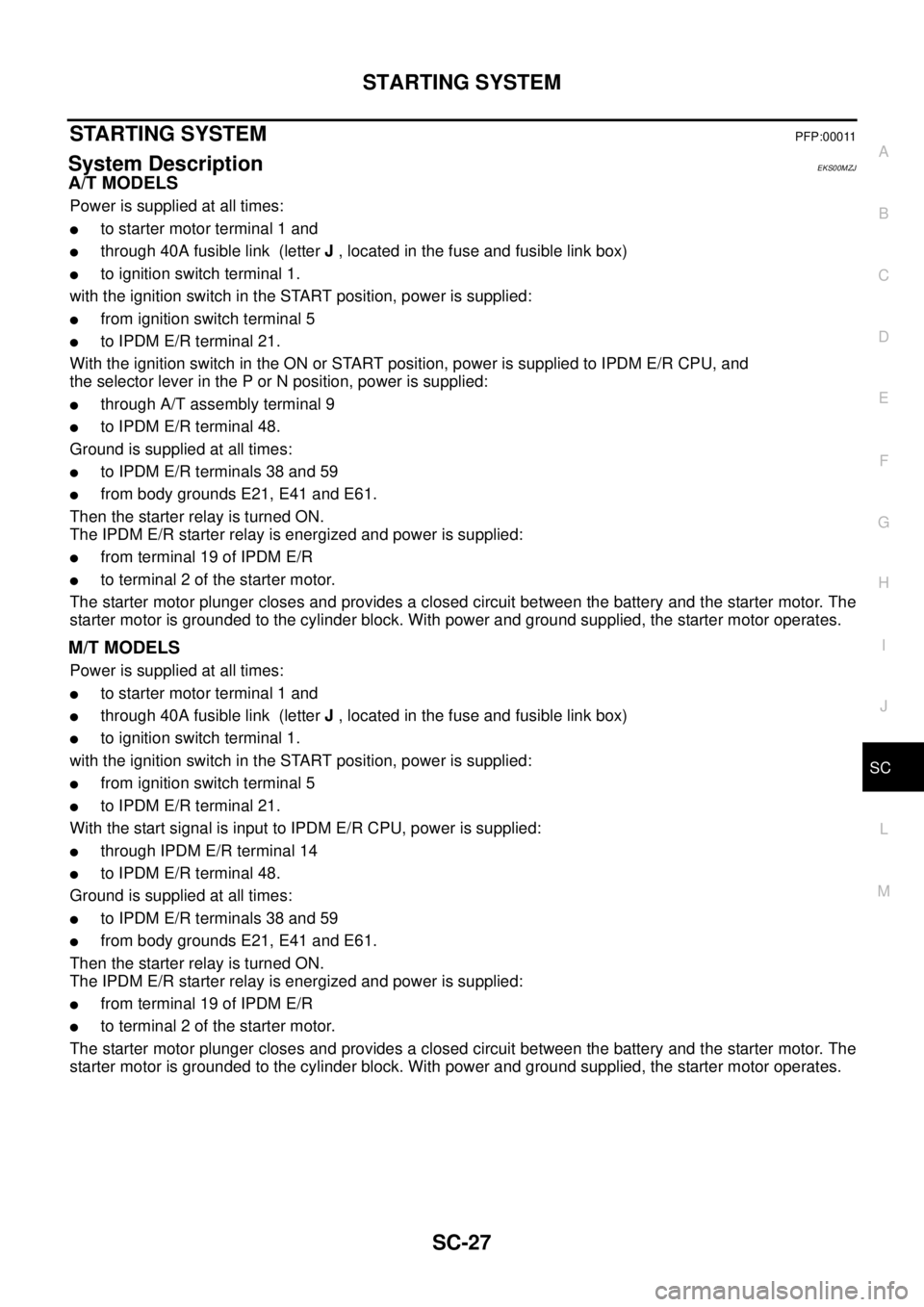

1. Slide the seat backward, and then remove the seat slide cover

cap(1) and rear leg cover(2), and then remove the seat mount-

ing bolts.

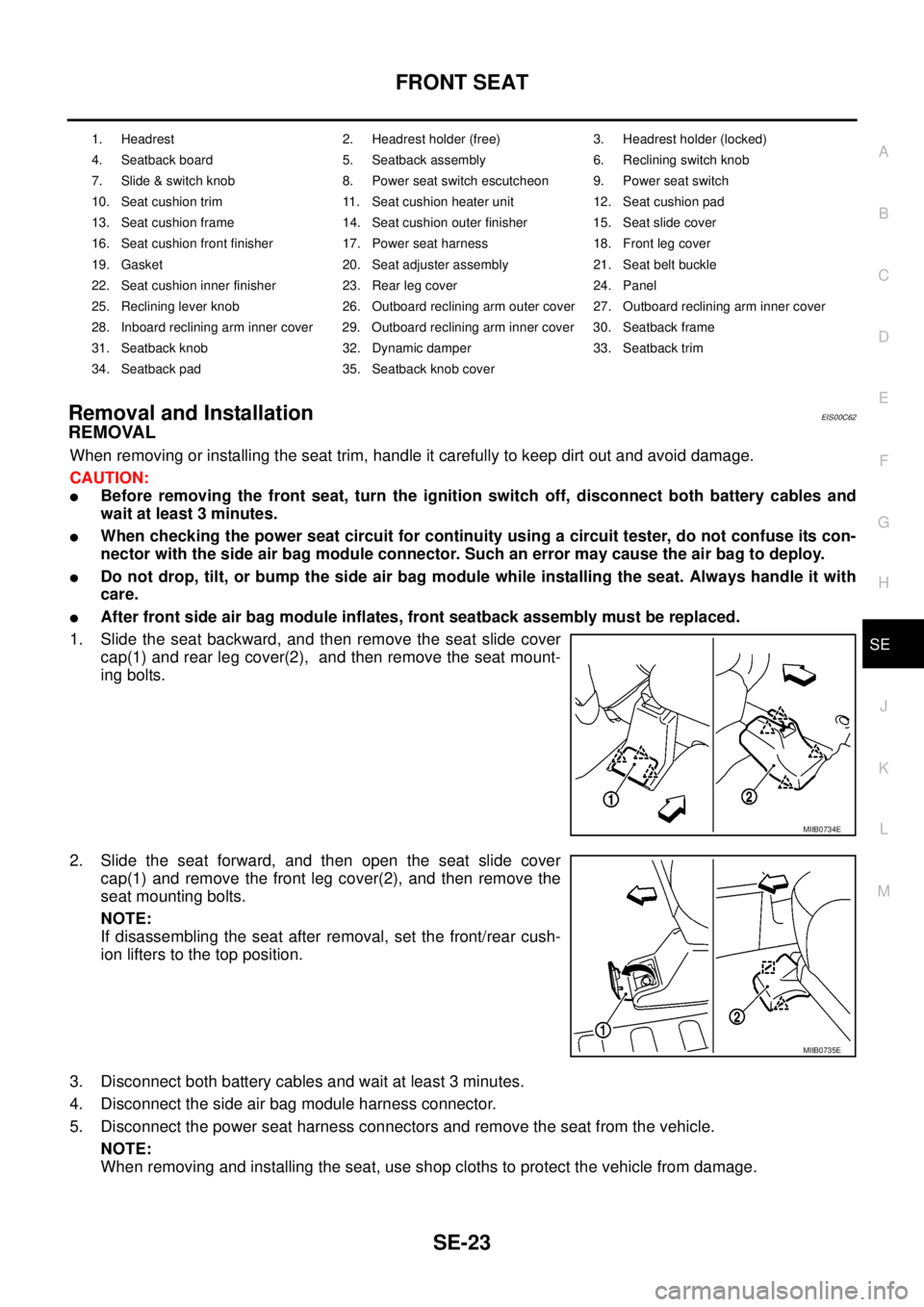

2. Slide the seat forward, and then open the seat slide cover

cap(1) and remove the front leg cover(2), and then remove the

seat mounting bolts.

NOTE:

If disassembling the seat after removal, set the front/rear cush-

ion lifters to the top position.

3. Disconnect both battery cables and wait at least 3 minutes.

4. Disconnect the side air bag module harness connector.

5. Disconnect the power seat harness connectors and remove the seat from the vehicle.

NOTE:

When removing and installing the seat, use shop cloths to protect the vehicle from damage.

1. Headrest 2. Headrest holder (free) 3. Headrest holder (locked)

4. Seatback board 5. Seatback assembly 6. Reclining switch knob

7. Slide & switch knob 8. Power seat switch escutcheon 9. Power seat switch

10. Seat cushion trim 11. Seat cushion heater unit 12. Seat cushion pad

13. Seat cushion frame 14. Seat cushion outer finisher 15. Seat slide cover

16. Seat cushion front finisher 17. Power seat harness 18. Front leg cover

19. Gasket 20. Seat adjuster assembly 21. Seat belt buckle

22. Seat cushion inner finisher 23. Rear leg cover 24. Panel

25. Reclining lever knob 26. Outboard reclining arm outer cover 27. Outboard reclining arm inner cover

28. Inboard reclining arm inner cover 29. Outboard reclining arm inner cover 30. Seatback frame

31. Seatback knob 32. Dynamic damper 33. Seatback trim

34. Seatback pad 35. Seatback knob cover

MIIB0734E

MIIB0735E