wheel NISSAN NAVARA 2005 Repair Workshop Manual

[x] Cancel search | Manufacturer: NISSAN, Model Year: 2005, Model line: NAVARA, Model: NISSAN NAVARA 2005Pages: 3171, PDF Size: 49.59 MB

Page 2985 of 3171

TF-18

4WD SYSTEM

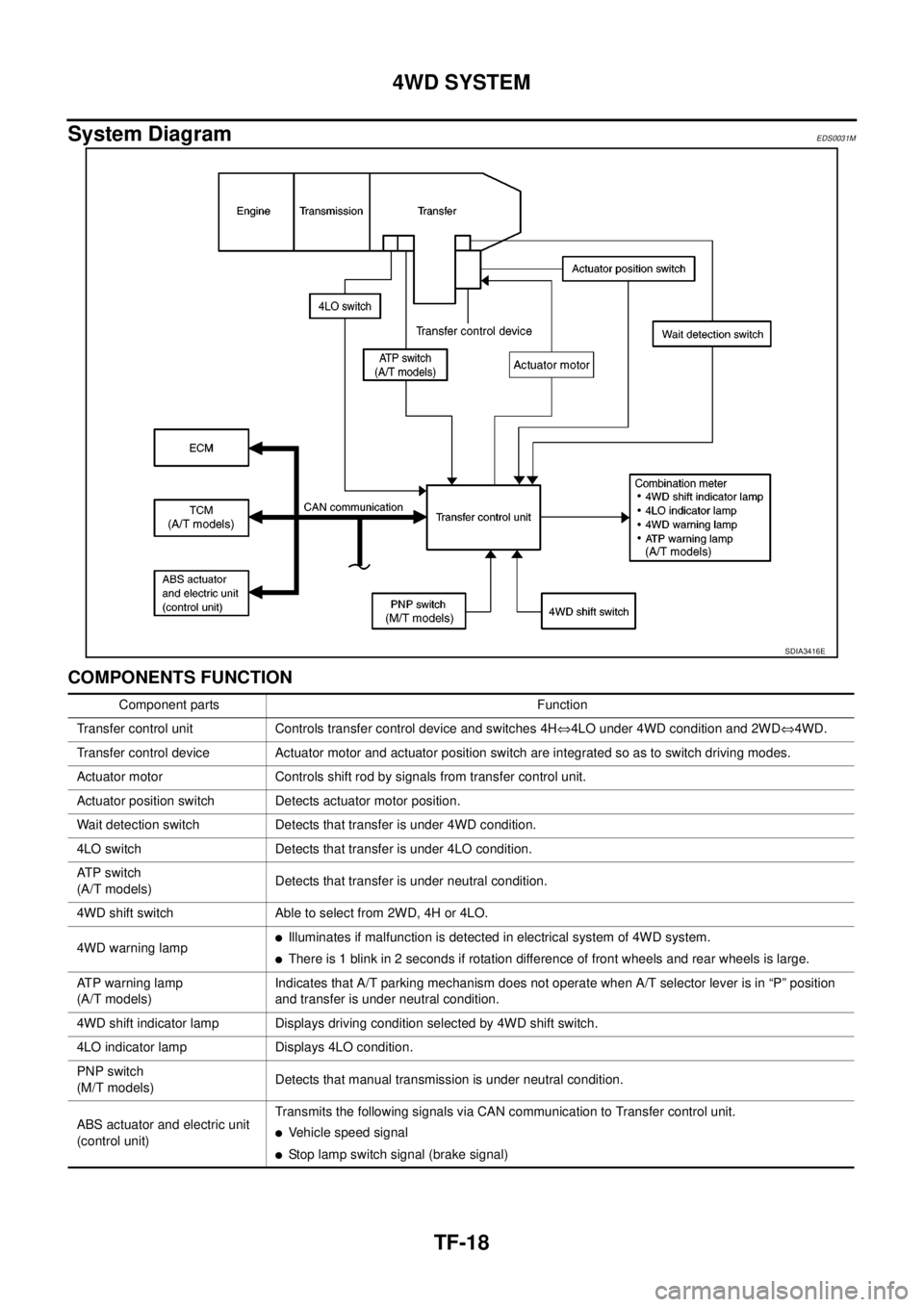

System Diagram

EDS0031M

COMPONENTS FUNCTION

SDIA3416E

Component parts Function

Transfer control unit Controls transfer control device and switches 4HÛ4LO under 4WD condition and 2WDÛ4WD.

Transfer control device Actuator motor and actuator position switch are integrated so as to switch driving modes.

Actuator motor Controls shift rod by signals from transfer control unit.

Actuator position switch Detects actuator motor position.

Wait detection switch Detects that transfer is under 4WD condition.

4LO switch Detects that transfer is under 4LO condition.

AT P s w i t c h

(A/T models)Detects that transfer is under neutral condition.

4WD shift switch Able to select from 2WD, 4H or 4LO.

4WD warning lamp

lIlluminates if malfunction is detected in electrical system of 4WD system.

lThere is 1 blink in 2 seconds if rotation difference of front wheels and rear wheels is large.

ATP warning lamp

(A/T models)Indicates that A/T parking mechanism does not operate when A/T selector lever is in “P” position

and transfer is under neutral condition.

4WD shift indicator lamp Displays driving condition selected by 4WD shift switch.

4LO indicator lamp Displays 4LO condition.

PNP switch

(M/T models)Detects that manual transmission is under neutral condition.

ABS actuator and electric unit

(control unit)Transmits the following signals via CAN communication to Transfer control unit.

lVehicle speed signal

lStop lamp switch signal (brake signal)

Page 3005 of 3171

TF-38

TROUBLE DIAGNOSIS

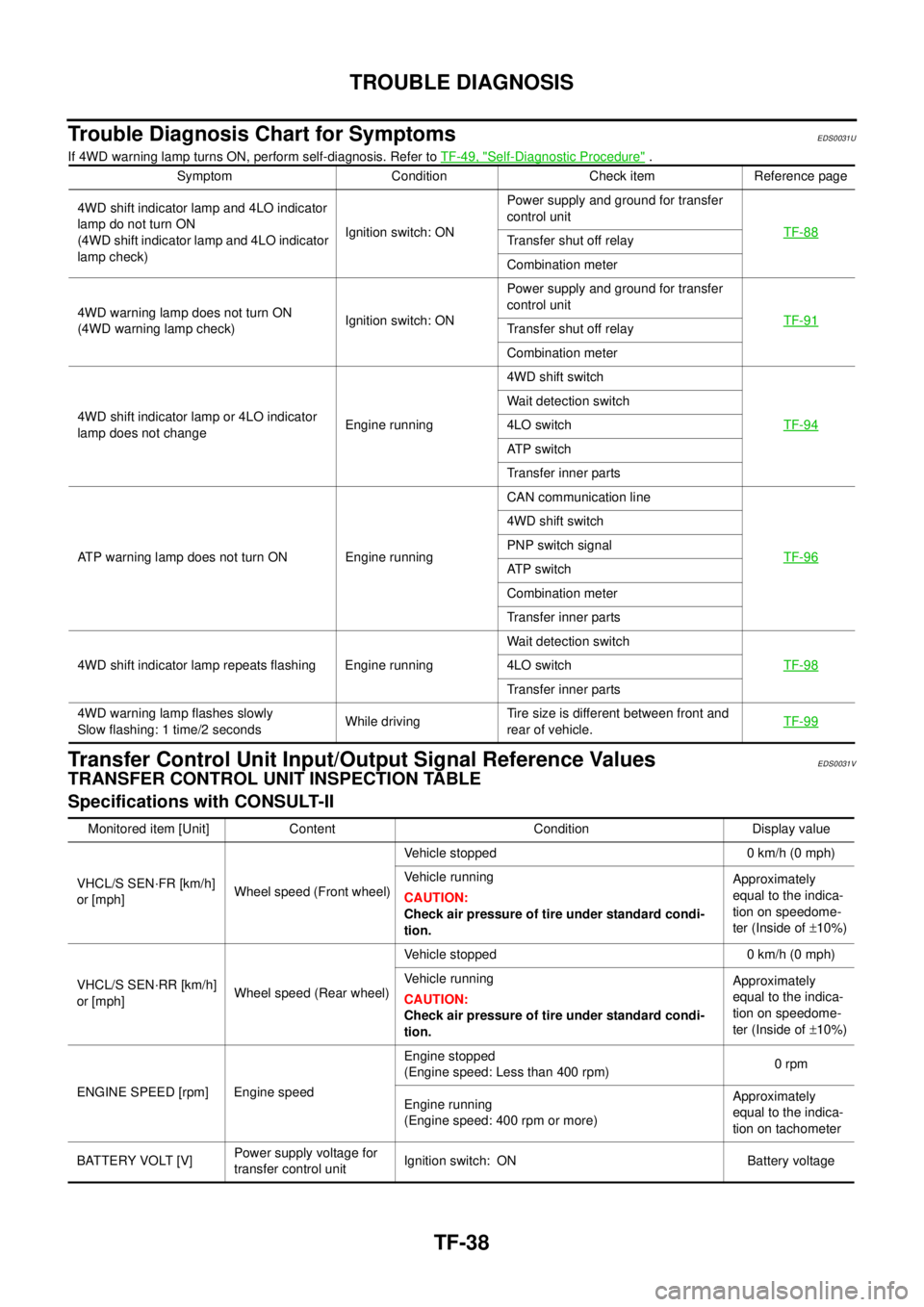

Trouble Diagnosis Chart for Symptoms

EDS0031U

If 4WD warning lamp turns ON, perform self-diagnosis. Refer toTF-49, "Self-Diagnostic Procedure".

Transfer Control Unit Input/Output Signal Reference ValuesEDS0031V

TRANSFER CONTROL UNIT INSPECTION TABLE

Specifications with CONSULT-II

Symptom Condition Check item Reference page

4WD shift indicator lamp and 4LO indicator

lamp do not turn ON

(4WD shift indicator lamp and 4LO indicator

lamp check)Ignition switch: ONPower supply and ground for transfer

control unit

TF-88

Transfer shut off relay

Combination meter

4WD warning lamp does not turn ON

(4WD warning lamp check)Ignition switch: ONPower supply and ground for transfer

control unit

TF-91

Transfer shut off relay

Combination meter

4WD shift indicator lamp or 4LO indicator

lamp does not changeEngine running4WD shift switch

TF-94

Wait detection switch

4LO switch

AT P s w i t c h

Transfer inner parts

ATP warning lamp does not turn ON Engine runningCAN communication line

TF-96

4WD shift switch

PNP switch signal

AT P s w i t c h

Combination meter

Transfer inner parts

4WD shift indicator lamp repeats flashing Engine runningWait detection switch

TF-98

4LO switch

Transfer inner parts

4WD warning lamp flashes slowly

Slow flashing: 1 time/2 secondsWhile drivingTire size is different between front and

rear of vehicle.TF-99

Monitored item [Unit] Content Condition Display value

VHCL/S SEN·FR [km/h]

or [mph]Wheel speed (Front wheel)Vehicle stopped 0 km/h (0 mph)

Vehicle running

CAUTION:

Check air pressure of tire under standard condi-

tion.Approximately

equal to the indica-

tion on speedome-

ter (Inside of±10%)

VHCL/S SEN·RR [km/h]

or [mph]Wheel speed (Rear wheel)Vehicle stopped 0 km/h (0 mph)

Vehicle running

CAUTION:

Check air pressure of tire under standard condi-

tion.Approximately

equal to the indica-

tion on speedome-

ter (Inside of±10%)

ENGINE SPEED [rpm] Engine speedEngine stopped

(Engine speed: Less than 400 rpm)0rpm

Engine running

(Engine speed: 400 rpm or more)Approximately

equal to the indica-

tion on tachometer

BATTERY VOLT [V]Power supply voltage for

transfer control unitIgnition switch: ON Battery voltage

Page 3014 of 3171

TROUBLE DIAGNOSIS

TF-47

C

E

F

G

H

I

J

K

L

MA

B

TF

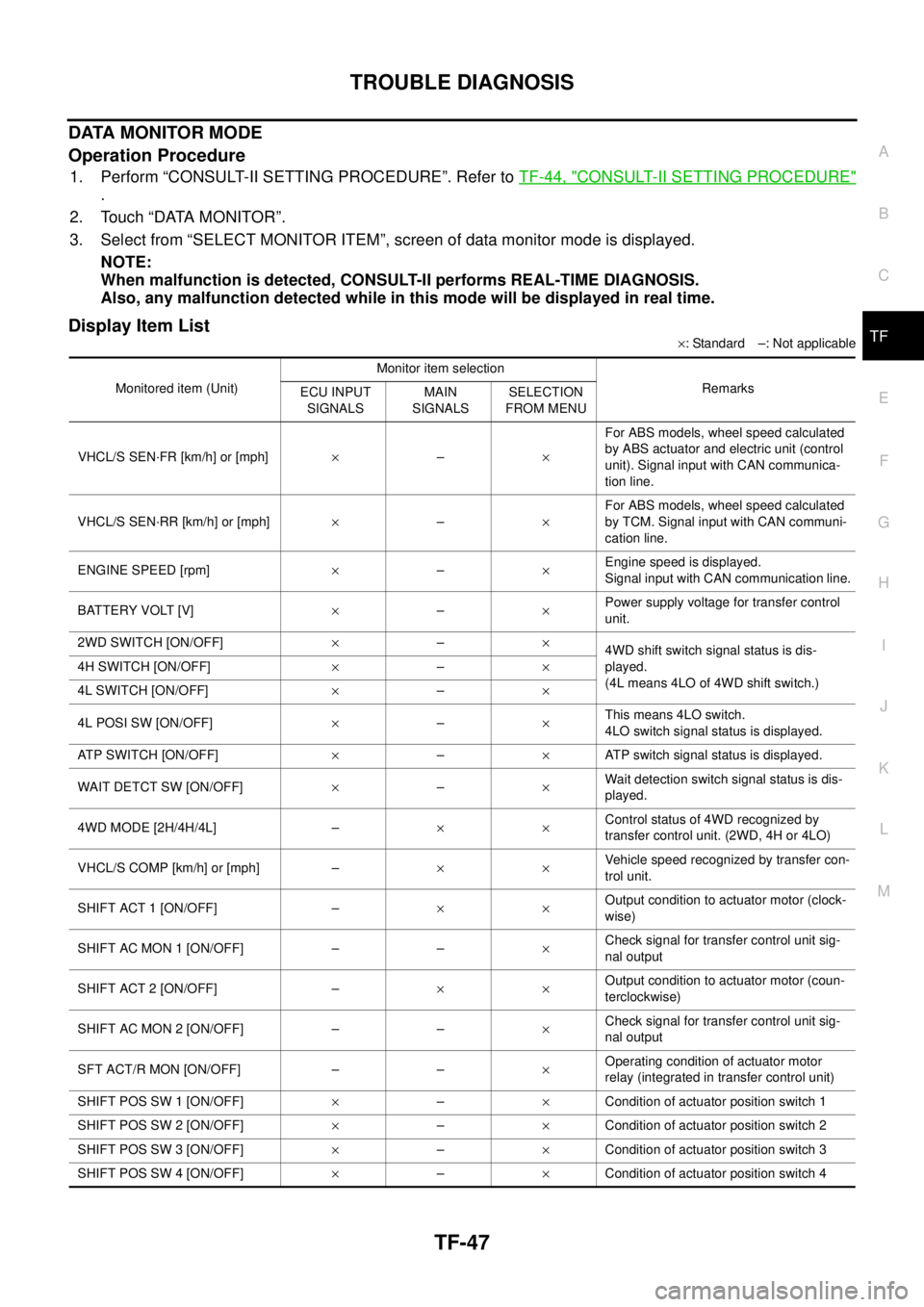

DATA MONITOR MODE

Operation Procedure

1. Perform “CONSULT-II SETTING PROCEDURE”. Refer toTF-44, "CONSULT-II SETTING PROCEDURE"

.

2. Touch “DATA MONITOR”.

3. Select from “SELECT MONITOR ITEM”, screen of data monitor mode is displayed.

NOTE:

When malfunction is detected, CONSULT-II performs REAL-TIME DIAGNOSIS.

Also, any malfunction detected while in this mode will be displayed in real time.

Display Item List

´: Standard –: Not applicable

Monitored item (Unit)Monitor item selection

Remarks

ECU INPUT

SIGNALSMAIN

SIGNALSSELECTION

FROM MENU

VHCL/S SEN·FR [km/h] or [mph]´–´For ABS models, wheel speed calculated

by ABS actuator and electric unit (control

unit). Signal input with CAN communica-

tion line.

VHCL/S SEN·RR [km/h] or [mph]´–´For ABS models, wheel speed calculated

by TCM. Signal input with CAN communi-

cation line.

ENGINE SPEED [rpm]´–´Engine speed is displayed.

Signal input with CAN communication line.

BATTERY VOLT [V]´–´Power supply voltage for transfer control

unit.

2WD SWITCH [ON/OFF]´–´

4WD shift switch signal status is dis-

played.

(4L means 4LO of 4WD shift switch.) 4H SWITCH [ON/OFF]´–´

4L SWITCH [ON/OFF]´–´

4L POSI SW [ON/OFF]´–´This means 4LO switch.

4LO switch signal status is displayed.

ATP SWITCH [ON/OFF]´–´ATP switch signal status is displayed.

WAIT DETCT SW [ON/OFF]´–´Wait detection switch signal status is dis-

played.

4WD MODE [2H/4H/4L] –´´Control status of 4WD recognized by

transfer control unit. (2WD, 4H or 4LO)

VHCL/S COMP [km/h] or [mph] –´´Vehicle speed recognized by transfer con-

trol unit.

SHIFT ACT 1 [ON/OFF] –´´Output condition to actuator motor (clock-

wise)

SHIFT AC MON 1 [ON/OFF] – –´Check signal for transfer control unit sig-

nal output

SHIFT ACT 2 [ON/OFF] –´´Output condition to actuator motor (coun-

terclockwise)

SHIFT AC MON 2 [ON/OFF] – –´Check signal for transfer control unit sig-

nal output

SFT ACT/R MON [ON/OFF] – –´Operating condition of actuator motor

relay (integrated in transfer control unit)

SHIFT POS SW 1 [ON/OFF]´–´Condition of actuator position switch 1

SHIFT POS SW 2 [ON/OFF]´–´Condition of actuator position switch 2

SHIFT POS SW 3 [ON/OFF]´–´Condition of actuator position switch 3

SHIFT POS SW 4 [ON/OFF]´–´Condition of actuator position switch 4

Page 3106 of 3171

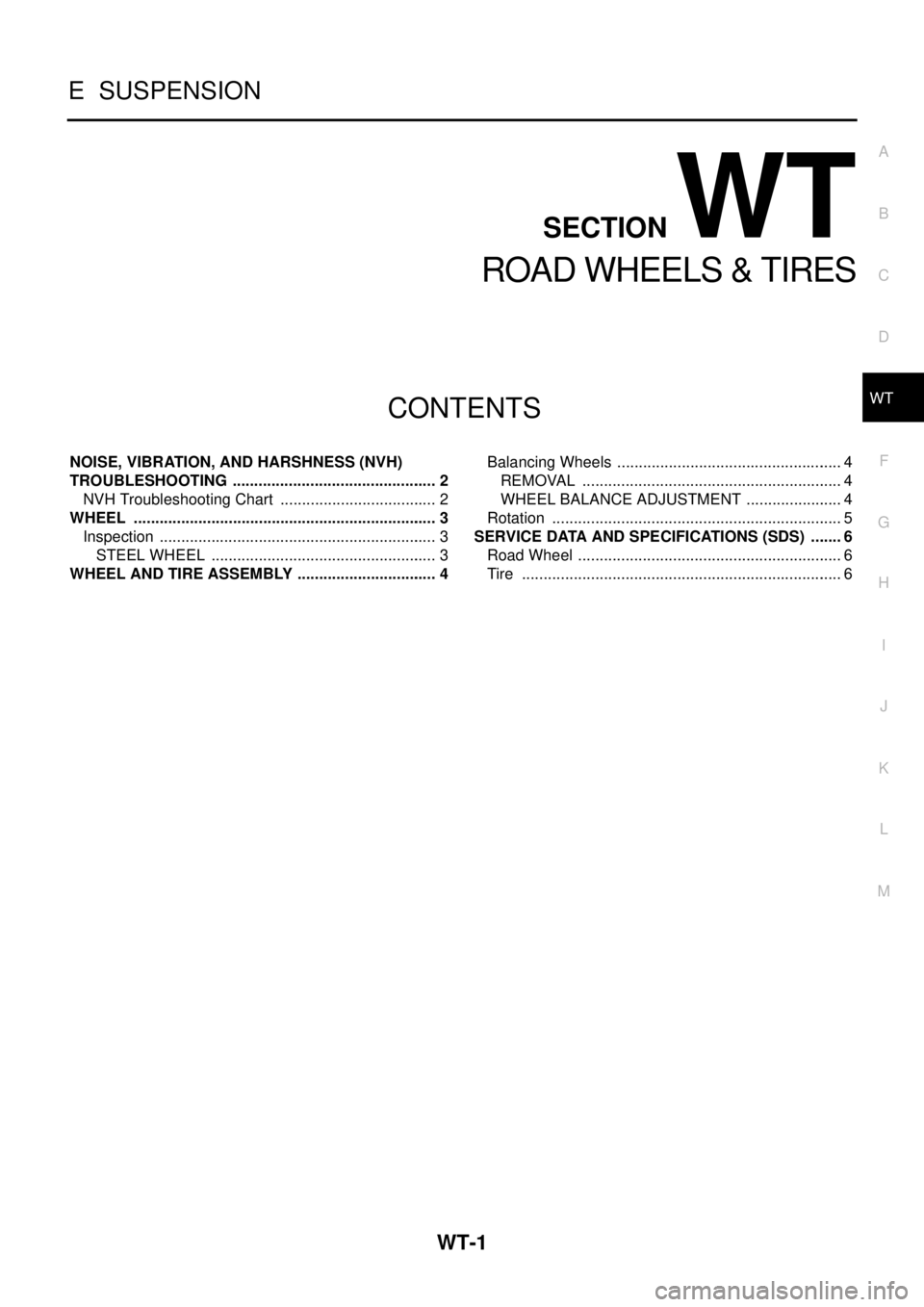

WT-1

ROAD WHEELS & TIRES

E SUSPENSION

CONTENTS

C

D

F

G

H

I

J

K

L

M

SECTIONWT

A

B

WT

ROAD WHEELS & TIRES

NOISE, VIBRATION, AND HARSHNESS (NVH)

TROUBLESHOOTING ................................................ 2

NVH Troubleshooting Chart ..................................... 2

WHEEL ....................................................................... 3

Inspection ................................................................. 3

STEEL WHEEL ..................................................... 3

WHEEL AND TIRE ASSEMBLY ................................. 4Balancing Wheels ..................................................... 4

REMOVAL ............................................................. 4

WHEEL BALANCE ADJUSTMENT ....................... 4

Rotation .................................................................... 5

SERVICE DATA AND SPECIFICATIONS (SDS) ........ 6

Road Wheel .............................................................. 6

Tire ........................................................................... 6

Page 3107 of 3171

WT-2

NOISE, VIBRATION, AND HARSHNESS (NVH) TROUBLESHOOTING

NOISE, VIBRATION, AND HARSHNESS (NVH) TROUBLESHOOTING

PFP:00003

NVH Troubleshooting ChartEES002L1

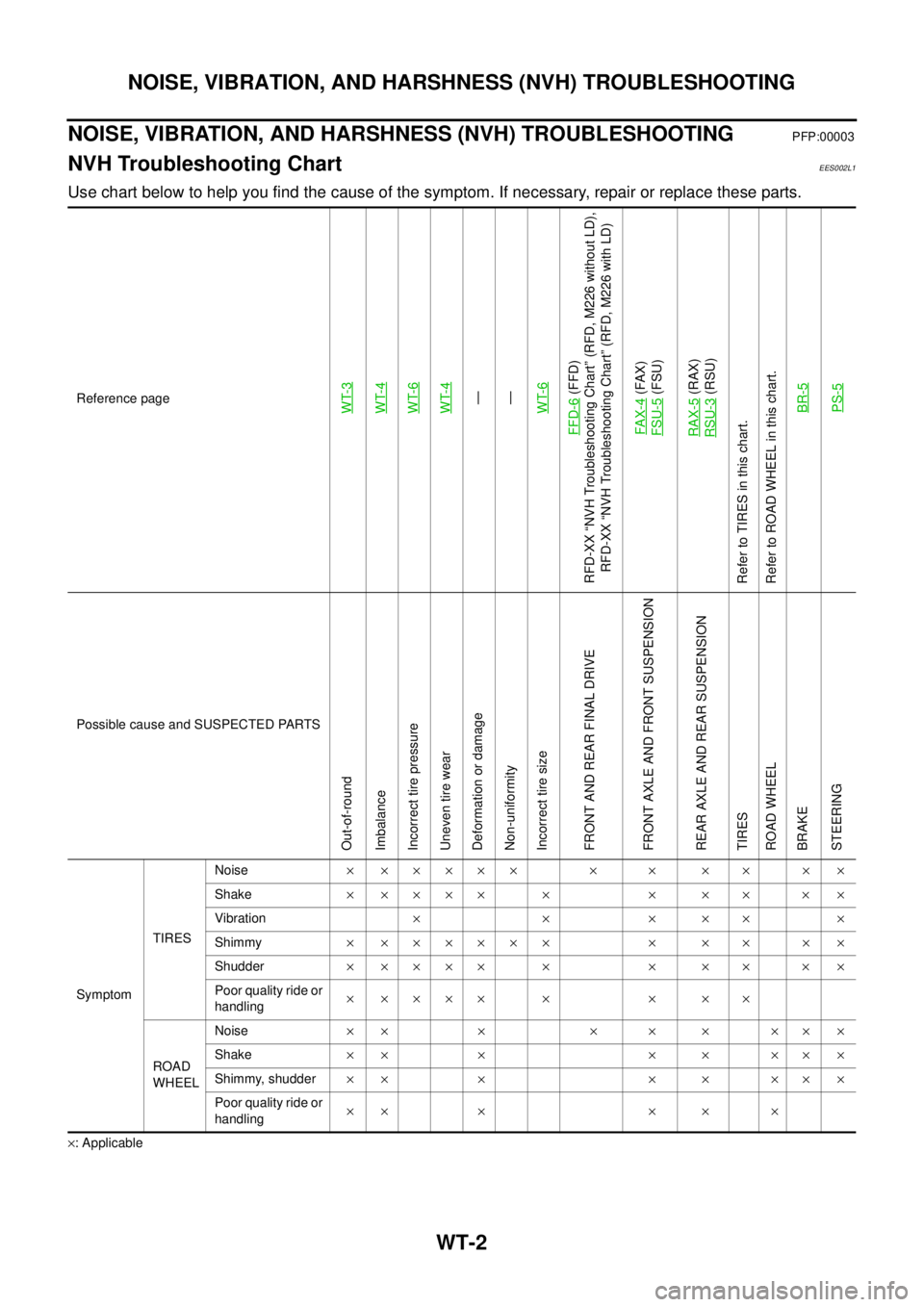

Use chart below to help you find the cause of the symptom. If necessary, repair or replace these parts.

´: ApplicableReference page

WT-3WT-4WT-6WT-4—

—

WT-6

FFD-6

(FFD)

RFD-XX “NVH Troubleshooting Chart” (RFD, M226 without LD),

RFD-XX “NVH Troubleshooting Chart” (RFD, M226 with LD)

FAX-4(FAX)

FSU-5(FSU)

RAX-5(RAX)

RSU-3(RSU)

Refer to TIRES in this chart.

Refer to ROAD WHEEL in this chart.

BR-5

PS-5

Possible cause and SUSPECTED PARTS

Out-of-round

Imbalance

Incorrect tire pressure

Uneven tire wear

Deformation or damage

Non-uniformity

Incorrect tire size

FRONT AND REAR FINAL DRIVE

FRONT AXLE AND FRONT SUSPENSION

REAR AXLE AND REAR SUSPENSION

TIRES

ROAD WHEEL

BRAKE

STEERING

SymptomTIRESNoise´ ´´´´´ ´ ´ ´ ´ ´ ´

Shake´´´´´ ´ ´ ´ ´ ´´

Vibration´´´´´´

Shimmy´ ´´´´´´ ´ ´ ´ ´ ´

Shudder´´´´´ ´ ´ ´ ´ ´´

Poor quality ride or

handling´´´´´ ´ ´ ´ ´

ROAD

WHEELNoise´´ ´ ´ ´ ´ ´´´

Shake´´ ´ ´ ´ ´´´

Shimmy, shudder´´ ´ ´ ´ ´´´

Poor quality ride or

handling´´ ´ ´ ´ ´

Page 3108 of 3171

WHEEL

WT-3

C

D

F

G

H

I

J

K

L

MA

B

WT

WHEELPFP:40300

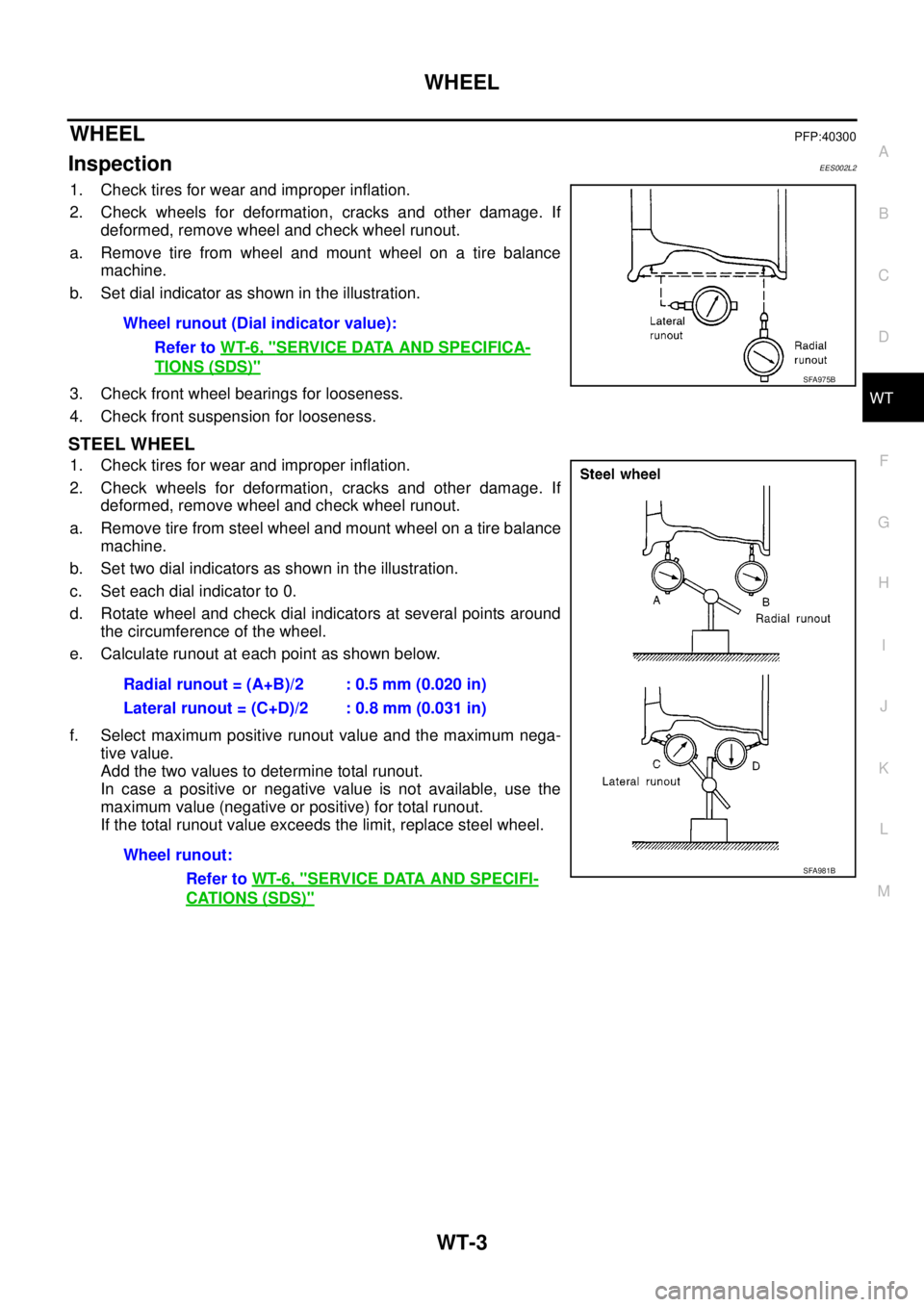

InspectionEES002L2

1. Check tires for wear and improper inflation.

2. Check wheels for deformation, cracks and other damage. If

deformed, remove wheel and check wheel runout.

a. Remove tire from wheel and mount wheel on a tire balance

machine.

b. Set dial indicator as shown in the illustration.

3. Check front wheel bearings for looseness.

4. Check front suspension for looseness.

STEEL WHEEL

1. Check tires for wear and improper inflation.

2. Check wheels for deformation, cracks and other damage. If

deformed, remove wheel and check wheel runout.

a. Remove tire from steel wheel and mount wheel on a tire balance

machine.

b. Set two dial indicators as shown in the illustration.

c. Set each dial indicator to 0.

d. Rotate wheel and check dial indicators at several points around

the circumference of the wheel.

e. Calculate runout at each point as shown below.

f. Select maximum positive runout value and the maximum nega-

tive value.

Add the two values to determine total runout.

In case a positive or negative value is not available, use the

maximum value (negative or positive) for total runout.

If the total runout value exceeds the limit, replace steel wheel.Wheel runout (Dial indicator value):

Refer toWT-6, "

SERVICE DATA AND SPECIFICA-

TIONS (SDS)"SFA975B

Radial runout = (A+B)/2 : 0.5 mm (0.020 in)

Lateral runout = (C+D)/2 : 0.8 mm (0.031 in)

Wheel runout:

Refer toWT-6, "

SERVICE DATA AND SPECIFI-

CATIONS (SDS)"

SFA981B

Page 3109 of 3171

WT-4

WHEEL AND TIRE ASSEMBLY

WHEEL AND TIRE ASSEMBLY

PFP:40300

Balancing WheelsEES002L3

REMOVAL

1. Using releasing agent, remove double-faced adhesive tape from the wheel.

CAUTION:

lBe careful not to scratch the wheel during removal.

lAfter removing double-faced adhesive tape, wipe clean traces of releasing agent from the

wheel.

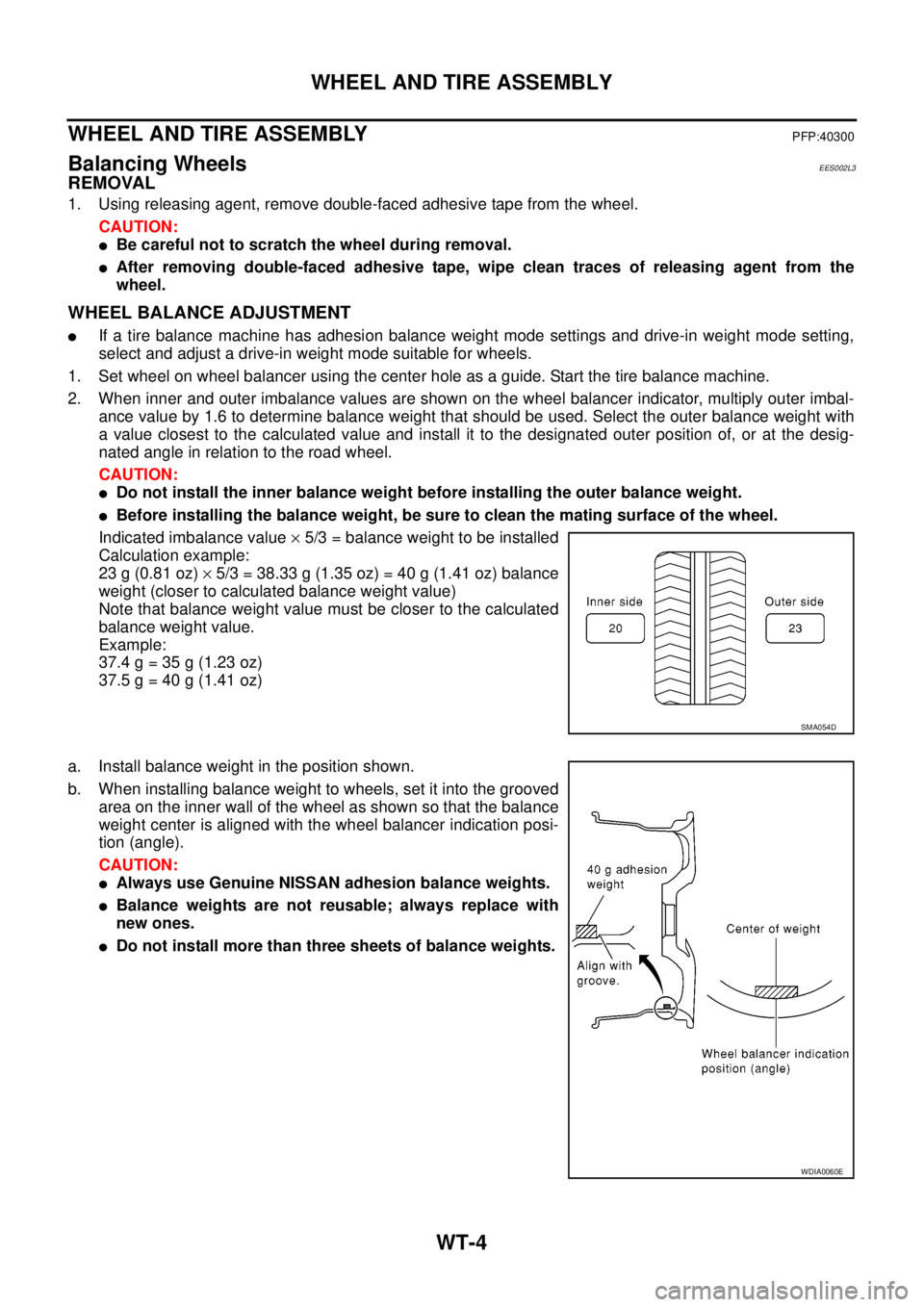

WHEEL BALANCE ADJUSTMENT

lIf a tire balance machine has adhesion balance weight mode settings and drive-in weight mode setting,

select and adjust a drive-in weight mode suitable for wheels.

1. Set wheel on wheel balancer using the center hole as a guide. Start the tire balance machine.

2. When inner and outer imbalance values are shown on the wheel balancer indicator, multiply outer imbal-

ance value by 1.6 to determine balance weight that should be used. Select the outer balance weight with

a value closest to the calculated value and install it to the designated outer position of, or at the desig-

nated angle in relation to the road wheel.

CAUTION:

lDo not install the inner balance weight before installing the outer balance weight.

lBefore installing the balance weight, be sure to clean the mating surface of the wheel.

Indicated imbalance value´5/3 = balance weight to be installed

Calculation example:

23 g (0.81 oz)´5/3 = 38.33 g (1.35 oz) = 40 g (1.41 oz) balance

weight (closer to calculated balance weight value)

Note that balance weight value must be closer to the calculated

balance weight value.

Example:

37.4 g = 35 g (1.23 oz)

37.5 g = 40 g (1.41 oz)

a. Install balance weight in the position shown.

b. When installing balance weight to wheels, set it into the grooved

area on the inner wall of the wheel as shown so that the balance

weight center is aligned with the wheel balancer indication posi-

tion (angle).

CAUTION:

lAlways use Genuine NISSAN adhesion balance weights.

lBalance weights are not reusable; always replace with

new ones.

lDo not install more than three sheets of balance weights.

SMA054D

WDIA0060E

Page 3110 of 3171

WHEEL AND TIRE ASSEMBLY

WT-5

C

D

F

G

H

I

J

K

L

MA

B

WT

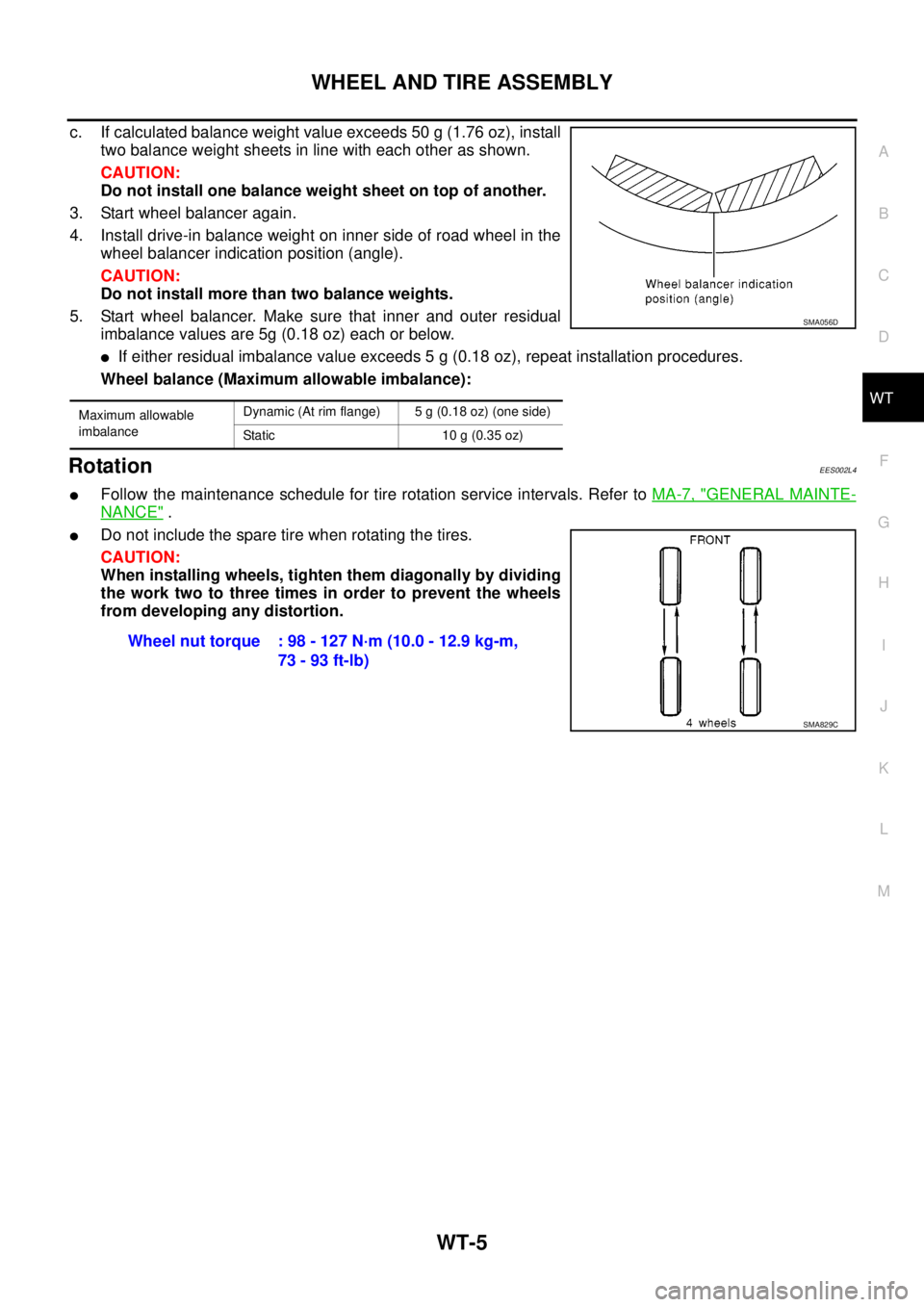

c. If calculated balance weight value exceeds 50 g (1.76 oz), install

two balance weight sheets in line with each other as shown.

CAUTION:

Do not install one balance weight sheet on top of another.

3. Start wheel balancer again.

4. Install drive-in balance weight on inner side of road wheel in the

wheel balancer indication position (angle).

CAUTION:

Do not install more than two balance weights.

5. Start wheel balancer. Make sure that inner and outer residual

imbalance values are 5g (0.18 oz) each or below.

lIf either residual imbalance value exceeds 5 g (0.18 oz), repeat installation procedures.

Wheel balance (Maximum allowable imbalance):

RotationEES002L4

lFollow the maintenance schedule for tire rotation service intervals. Refer toMA-7, "GENERAL MAINTE-

NANCE".

lDo not include the spare tire when rotating the tires.

CAUTION:

When installing wheels, tighten them diagonally by dividing

the work two to three times in order to prevent the wheels

from developing any distortion.

Maximum allowable

imbalanceDynamic (At rim flange) 5 g (0.18 oz) (one side)

Static 10 g (0.35 oz)

SMA056D

Wheel nut torque : 98 - 127 N·m (10.0 - 12.9 kg-m,

73 - 93 ft-lb)

SMA829C

Page 3111 of 3171

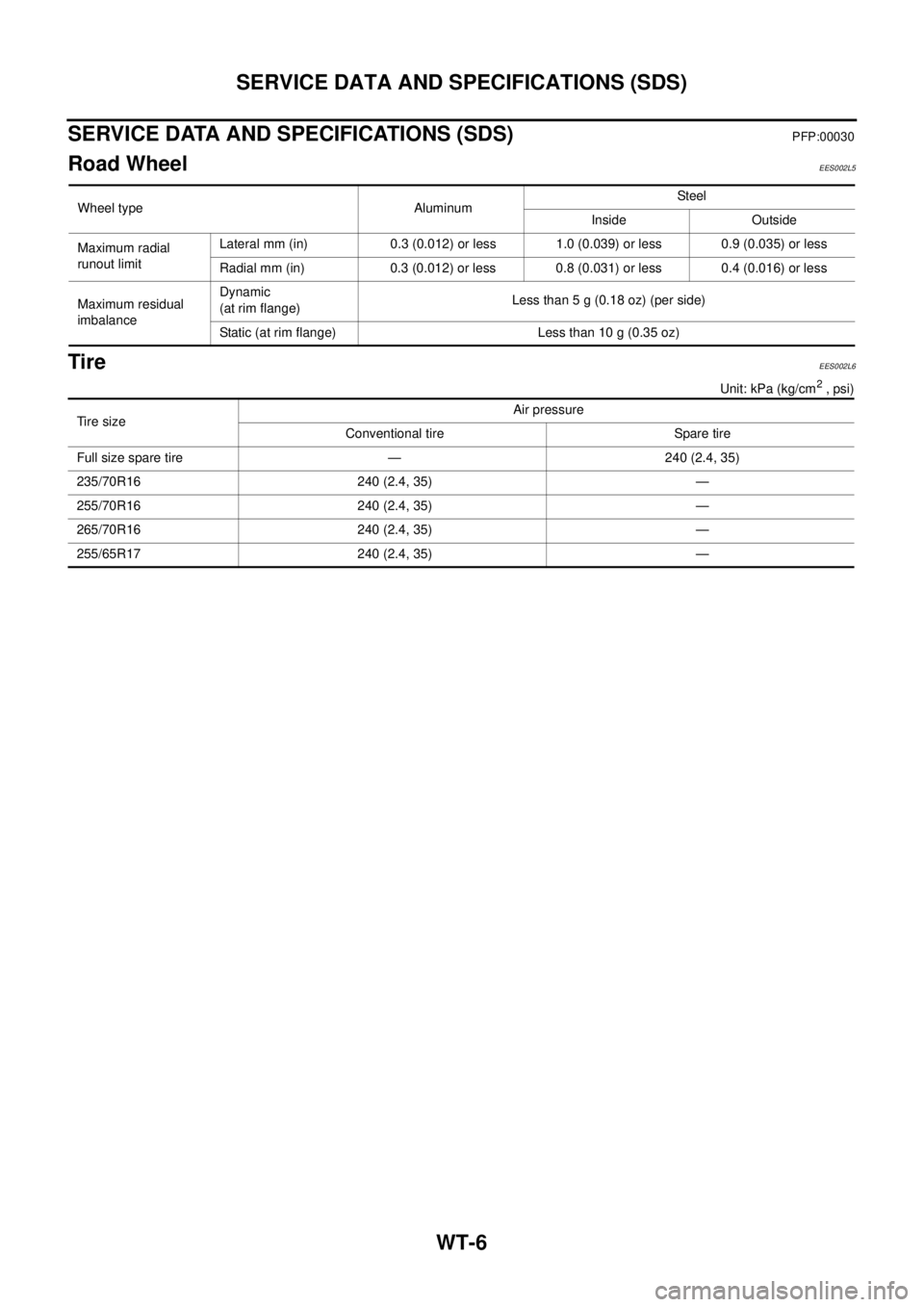

WT-6

SERVICE DATA AND SPECIFICATIONS (SDS)

SERVICE DATA AND SPECIFICATIONS (SDS)

PFP:00030

Road WheelEES002L5

TireEES002L6

Unit: kPa (kg/cm2, psi) Wheel type AluminumSteel

Inside Outside

Maximum radial

runout limitLateral mm (in) 0.3 (0.012) or less 1.0 (0.039) or less 0.9 (0.035) or less

Radial mm (in) 0.3 (0.012) or less 0.8 (0.031) or less 0.4 (0.016) or less

Maximum residual

imbalanceDynamic

(at rim flange)Less than 5 g (0.18 oz) (per side)

Static (at rim flange) Less than 10 g (0.35 oz)

Tire sizeAir pressure

Conventional tire Spare tire

Full size spare tire — 240 (2.4, 35)

235/70R16 240 (2.4, 35) —

255/70R16 240 (2.4, 35) —

265/70R16 240 (2.4, 35) —

255/65R17 240 (2.4, 35) —